Page 1

SFG-20X

5 &10 MHz Arbitrary/ Function

Waveform Generators

User

Manual

Page 2

Safety Summary

The following safety precautions apply to both operating and maintenance personnel

and must be observed during all phases of operation, service, and repair of this

instrument. Before applying power, follow the installation instructions and become

familiar with the operating instructions for this instrument.

If this device is damaged or something is missing, contact the place of purchase

immediately.

This manual contains information and warnings that must be followed to ensure safe

operation as well as maintain the meter in a safe condition.

GROUND THE INSTRUMENT

To minimize shock hazard, the instrument chassis and cabinet must be connected

to an electrical ground. This instrument is grounded through the ground conductor of

the supplied, three-conductor ac power cable. The power cable must be plugged into

an approved three-conductor electrical outlet. Do not alter the ground connection.

Without the protective ground connection, all accessible conductive parts (including

control knobs) can render an electric shock. The power jack and mating plug of the

power cable must meet IEC safety standards.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of ammable gases or fumes.

Operation of any electrical instrument in such an environment constitutes a denite

safety hazard.

KEEP AWAY FROM LIVE CIRCUITS

Instrument covers must not be removed by operating personnel. Component

replacement and internal adjustments must be made by qualied maintenance

personnel. Disconnect the power cord before removing the instrument covers and

replacing components. Under certain conditions, even with the power cable removed,

dangerous voltages may exist. To avoid injuries, always disconnect power and

discharge circuits before touching them.

DO NOT SERVICE OR ADJUST ALONE

Do not attempt any internal service or adjustment unless another person, capable of

rendering rst aid and resuscitation, is present.

DO NOT SUBSTITUTE PARTS OR MODIFY THE INSTRUMENT

Do not install substitute parts or perform any unauthorized modications to this

instrument. Return the instrument to B&K Precision for service and repair to ensure

that safety features are maintained.

WARNINGS AND CAUTIONS

WARNING and CAUTION statements, such as the following examples, denote a

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

1

Page 3

hazard and appear throughout this manual. Follow all instructions contained in these

statements.

WARNING statement calls attention to an operating procedure, practice, or

A

condition, which, if not followed correctly, could result in injury or death to personnel.

CAUTION statement calls attention to an operating procedure, practice, or condition,

A

which, if not followed correctly, could result in damage to or destruction of part or all of

the product.

WARNING:

Do not alter the ground connection. Without the protective ground connection, all

accessible conductive parts (including control knobs) can render an electric shock.

The power jack and mating plug of the power cable meet IEC safety standards.

WARNING:

To avoid electrical shock hazard, disconnect power cord before removing covers.

Refer servicing to qualied personnel.

CAUTION:

Before connecting the line cord to the AC mains, check the rear panel AC line voltage

indicator. Applying a line voltage other than the indicated voltage can destroy the AC

line fuses. For continued re protection, replace fuses only with those of the specied

voltage and current ratings.

CAUTION:

This product uses components which can be damaged by electro-static discharge

(ESD). To avoid damage, be sure to follow proper procedures for handling, storing

and transporting parts and subassemblies which contain ESD-sensitive components.

Compliance Statements

Disposal of Old Electrical & Electronic Equipment

(Applicable in the European Union and other European

countries with separate collection systems). This product

is subject to Directive 2002/96/EC of the European

Parliament and the Council of the European Union on

waste electrical and electronic equipment (WEEE) ,

and in jurisdictions adopting that Directive, is marked

as being put on the market after August 13, 2005, and

should not be disposed of as unsorted municipal waste.

Please utilize your local WEEE collection facilities in

the disposition of this product and otherwise observe all

applicable requirements.

2

Page 4

CE Declaration of Conformity

The power supply meets the requirements of 2006/95/EC Low Voltage Directive and

2004/108/EC Electromagnetic Compatibility Directive with the following standards.

Low Voltage Directive

z EN61010-1: 2001

z EN61010-031: 2002+A1: 2008

EMC Directive

z EN 61326-1:2006

z EN 61000-3-2: 2006+A2: 2009

z EN 61000-3-3: 2008

Safety Symbols

Refer to the user manual for warning information to avoid hazard or

personal injury and prevent damage to instrument.

CAUTION

WARNING

Chassis (earth ground) symbol.

On (Power). This is the In position of the power switch when

instrument is ON.

Off (Power). This is the Out position of the power switch when

instrument is OFF.

Off (Supply). This is the AC mains connect/disconnect switch on the

back of the instrument.

CAUTION indicates a hazardous situation which, if not avoided, will

result in minor or moderate injury

WARNING indicates a hazardous situation which, if not avoided,

could result in death or serious injury

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

3

Page 5

Introduction of SFG-20X Series

The manual covers the following two types of SFG-20X Series Function/Arbitrary

Waveform Generators: SFG-210 and SFG-205.

SFG-20X Series Function/Arbitrary Waveform Generators adopt the direct

digital synthesis (DDS) technology, which can provide stable, high-precision,

pure and low distortion signals. Its combination of excellent system features,

easiness in usage and versatile functions makes this generator a perfect solution

for your job now and in the future.

SFG-20X Series Function/Arbitrary Waveform Generator has a clear and simple

front-panel. The user-friendly panel layout and instructions, versatile terminals,

direct graph interface, built-in instructions and help system have greatly

simplified the operation process, with the help of which, users do not have to

spend a great deal of time learning and familiarizing the operation of the

generator before they can use it proficiently. The built-in AM, DSB-AM,FM, PM,

ASK, FSK and PWM modulation functions generate modulated waveforms at

ease, without the help of a separate modulating source. USB I/O is a standard

accessory, while GPIB is optional. Remote instructions meet the SCPI

specification requirements.

From the characteristics and specifications given below, you will understand how

SFG-20X can satisfy your requirements.

Page 6

DDS technology provides precise, stable and low distortional output!

signal.

3.5’TFT color LCD display.!

125MSa/s sampling rate, 14-bit resolution.!

Frequency characteristics:!

Sine: 1µHz to 30MHz

Square: 1µHz to 10 MHz

Ramp: 1µHz to 300kHz

Pulse: 500µHz to 5MHz

White Noise: 10MHz bandwidth (-3dB)

Arbitrary: 1µHz to 5MHz

5 standard waveforms: Sine, Square, Ramp, Pulse, Noise!

Self-defined arbitrary waveform!

Multiple modulation function: AM, FM, PM, ASK, FSK, PWM, DSB-AM,!

Sweep and Burst.

Multiple interfaces: USB host & USB device(USBTMC)!

Support USB storage device. Software updating could also be!

performed using USB devices.

Up to 16k sample points of internal waveform depth, which can rebuild!

or simulate any complex waveform.

Built-in help system.!

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 7

Catalogue!

General Safety Summary ................................................................................. II

Introduction of SFG-20X Series ...................................................................... VI

1. Getting Started ........................................................................................... 1

1.1. General Inspection ........................................................................... 2

1.2. Handle Adjustment ........................................................................... 2

1.3. The Front/Rear Panel ....................................................................... 3

1.4. To Set a Waveform ........................................................................... 7

1.5. To Set Modulate/Sweep/Burst ........................................................ 12

1.6. To Set Output ................................................................................. 14

1.7. To Use Digital Input ........................................................................ 15

1.8. To Use Store/Utility/Help Function ................................................. 16

2. Operating Your Generator ....................................................................... 17

2.1. To Set Sine Signals ........................................................................ 18

2.2. To Set Square Signals .................................................................... 23

2.3. To Set Ramp Signals ...................................................................... 26

2.4. To Set Pulse Signals ...................................................................... 29

2.5. To Set Noise Signals ...................................................................... 33

2.6. To Set Arbitrary Signals .................................................................. 35

2.7. To Generate the Modulated Waveform .......................................... 42

2.8. To Generate Sweep ....................................................................... 52

2.9. To Generate Burst .......................................................................... 54

2.10. To Store and Recall ..................................................................... 58

2.11. To Set the Utility Function ........................................................... 64

2.12. Test/Cal ....................................................................................... 75

2.13. Edition Information ...................................................................... 80

2.14. Updating Firmware ...................................................................... 82

Page 8

2.15. How to Use the Built-in Help System .......................................... 83

3. Application and Examples ........................................................................ 84

3.1. Example 1:Generate a Sine Wave ................................................. 85

3.2. Example 2:Generate a Square Wave ............................................. 87

3.3. Example 3:Generate a Ramp Wave ............................................... 89

3.4. Example 4:Generate a Pulse Wave ............................................... 91

3.5. Example 5:Generate a Noise Wave ............................................... 93

3.6. Example 6:Generate an Arbitrary Wave ......................................... 94

3.7. Example 7:Generate a Sweep Linear Wave .................................. 96

3.8. Example 8:Generate a Burst Wave ................................................ 98

3.9. Example 9:Generate an AM Wave ............................................... 100

3.10. Example 10:Generate a FM Wave ............................................ 102

3.11. Example 11:Generate a PM Wave ............................................ 104

3.12. Example 12:Generate a FSK Wave .......................................... 106

3.13. Example 13:Generate an ASK Wave ........................................ 108

3.14. Example 14: Generate a PWM Wave ....................................... 110

3.15. Example 15: Generate a DSB-AM Wave .................................. 112

4. Troubleshooting ..................................................................................... 114

General Inspecting .................................................................................... 114

Troubleshooting ........................................................................................ 115

5. Service and Support .............................................................................. 116

Maintain summary .................................................................................... 116

Contact GLOBAL SPECIALTIES .............................................................. 117

6. Appendix ................................................................................................ 117

Appendix A: Accessories .......................................................................... 117

Appendix B: Daily Maintain and Cleaning ................................................. 118

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 9

1. Getting Started

This chapter covers the following topics:

! General Inspection

! Handle Adjustment

! The Front/Rear Panel

! To Set a Waveform

! To Set Modulate/Sweep/Burst

! To Set Output

! To Use Digital Input

! To Use Store/Utility/Help Function

Page 10

1.1. General Inspection

When you get a new SFG-20X Series Function/Arbitrary Waveform Generator,

you are suggested to take the following steps to inspect the instrument.

1. Inspect the shipping container for damage.

If there are damages in the packing or foam, keep them until the whole

machine and the accessories pass the electric and mechanical testing.

2. Check the accessories.

Accessories supplied with the instrument are listed in chapter 6 ‘Appendix

A: Accessories’.

If the contents are incomplete or damaged, please notify your sales

representative.

3. Inspect the instrument.

In case any mechanical damage or defect, or if the instrument does not

operate properly or pass performance tests, notify your sales

representative. If the shipping container is damaged, or the cushioning

materials show signs of stress, notify the carrier as well as your sales office.

Keep the shipping materials for the carrier’s inspection. Offices will arrange

for repair or replacement at their option without waiting for claim settlement.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 11

To adjust the handle position of SFG-20X Function/Arbitrary Waveform

Generator, please grip the handle by the sides and pull it outward. Then, make

the handle rotate to the desired position.

Figure 1- 1 Viewing Position and Carrying Position

1.2. Handle Adjustment

Page 12

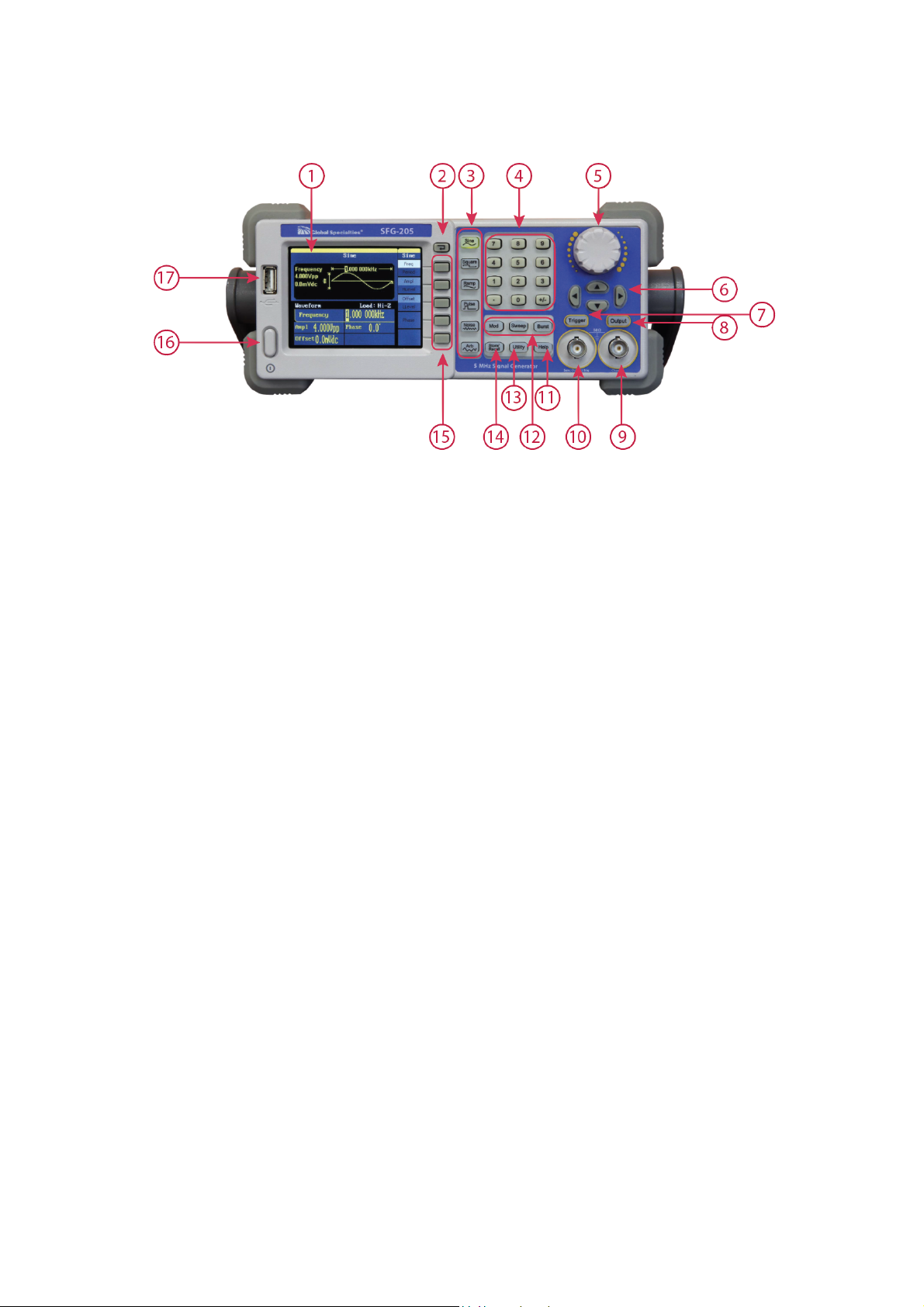

When you get a new SFG-20X Series Function/Arbitrary Waveform Generator,

first you need to understand how to operate the front/rear panel correctly. This

chapter will make a brief introduction and description for the operation and

functions of the front/rear panel.

The SFG-20X Series Function/Arbitrary Waveform Generator has a clear and

simple front panel. See Figure 1- 2 and Figure 1- 3. The front panel has a knob

and functional keys. The 5 blue grey buttons on the right side of the screen are

menu buttons (named F1 to F5 from up to down) with the help of which, you can

enter different functions menu or have direct specific applications. The signal

input and output interfaces are set at the front and rear panels which can help

generating multiple arbitrary waveforms. The various interfaces can meet the

need of the multiple interface communications.

Figure 1- 2 SFG-20X Series

1.3. The Front/Rear Panel

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 13

Figure 1- 3 Front Panel of SFG-20X Series

1. Display

2. Return Key

3. Waveform Selection Keys

4. Number Keypad

5. Knob

6. Cursor Keys

7. Manual Trigger Key (Sweep and Burst only)

8. Output Enable Key

9. Output BNC Connector

10. Sync BNC Connector

11. Help Menu Key

12. Modulation/Sweep/Burst Keys

13. Utility Menu Key

14. State Storage Menu Key

15. Menu Operation Softkeys

16. On/Off Switch

Page 14

17. USB Connector

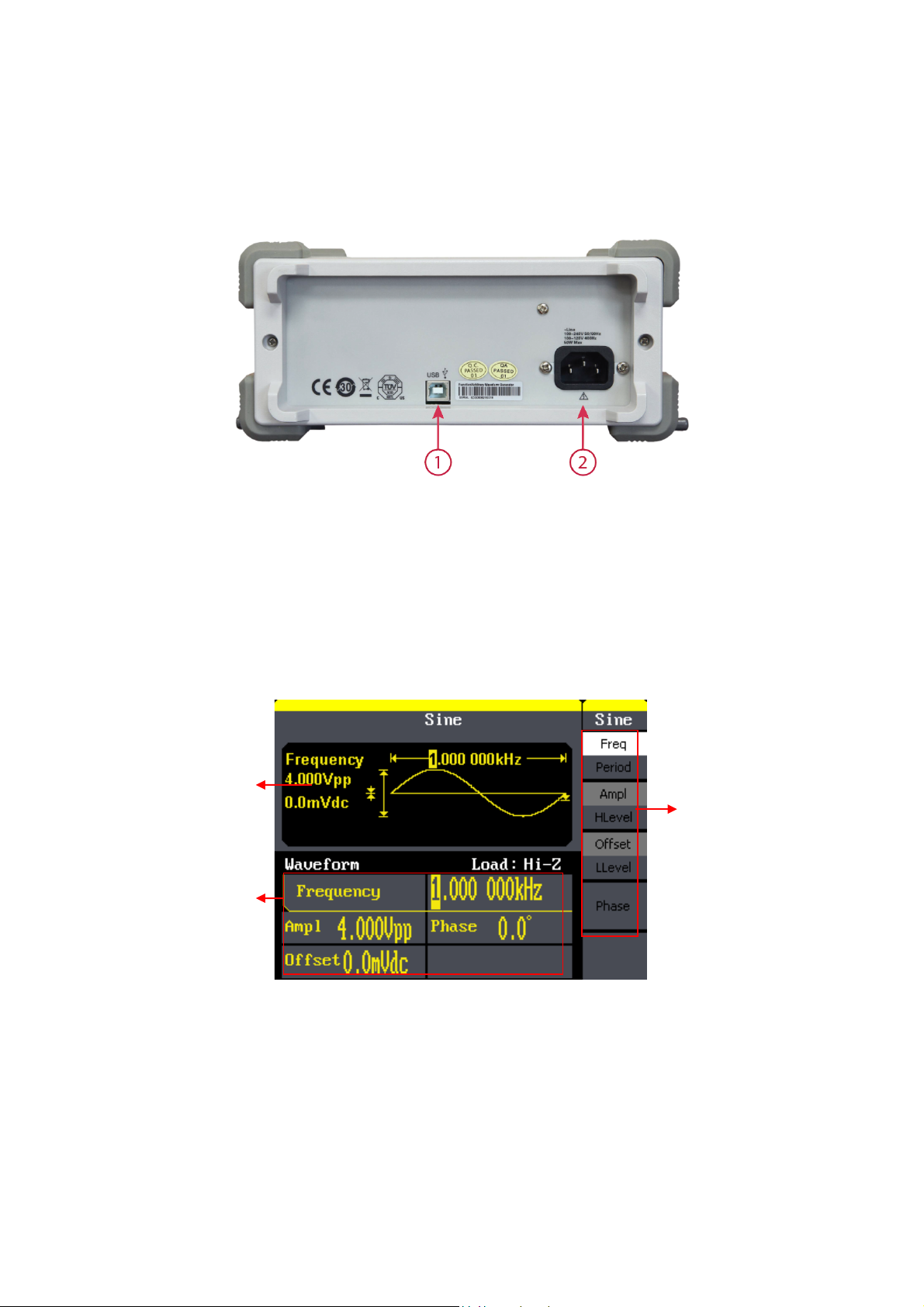

Figure 1- 4 Rear Panel of SFG-20X Series

1. USB Interface

2. AC Input Receptacle

Figure 1- 5 Display Interface (Sine Wave is the default display signal)

Waveform

Display area

Parameter area

Menu Options

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 15

Character definitions in this User Manual:

The signs for buttons in this manual are the same as the panel buttons. Please

note that, the signs for the functional buttons on the operation panel are

represented by squared words, such as Sine , which represents the

transparent functional key with Sine on it on the front panel, while the menu

buttons are represented by brighten words such as Freq, which means the

frequency option in the Sine menu.

1.4. To Set a Waveform

On the operation panel, there is a set of buttons with waveform icon. See Figure

1- 6. The exercise below will help you familiarize with the waveform selection

settings.

Figure 1- 6 Waveform Selection Buttons

1. Press Sine button and the waveform window will display sine waveform.

SFG-20X Series Generator can generate sine signal with a frequency from

1µHz to 30MHz. By setting frequency/period, amplitude/high level,

offset/low level, sine signal with different parameters can be generated.

Page 16

Figure 1- 7 Sine Signal Display Interface

As is shown in Figure 1- 7, the default signal parameters are: 1 kHz frequency,

4.0 Vpp amplitude and 0 Vdc offset.

2. Press Square button, and the waveform window displays square waveform.

SFG-20X Series Generator can generate square signal with a frequency

from 1µHz to 10MHz and variable duty cycle.

Figure 1- 8 Square Signal Display Interface

As is shown in Figure 1- 8, the default signal parameters are: 1kHz frequency,

Page 17

4.0Vpp amplitude, 0Vdc offset and 50% duty cycle.

3. Press Ramp button, and the waveform window displays ramp waveform.

SFG-20X Series Generator can generate ramp signal with a frequency of

from 1µHz to 300kHz and variable symmetry.

Figure 1- 9 Ramp Signal Display Interface

As is shown in Figure 1- 9, the default signal parameters are: 1kHz frequency,

4.0Vpp amplitude, 0Vdc offset and 50% symmetry.

4. Press Pulse button, and the waveform window displays pulse waveform.

SFG-20X Series Generator can generate pulse signal with a frequency

from 500µHz to 5 MHz and variable pulse width and delay.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 18

Figure 1- 10 Pulse Signal Display Interface

As is shown in Figure 1- 10, the default signal parameters are: 1kHz frequency,

4.0Vpp amplitude, 0Vdc offset, 200µs pulse width.

5. Press Noise button, and the waveform window displays noise waveform.

SFG-20X Series Generator can generate noise signal with a band width up

to 10MHz.

Figure 1- 11 Noise Signal Display Interface

As is shown in Figure 1- 11, the default signal parameters are: 128mV Stdev and

0mV Mean.

Page 19

6. Press Arb button, and the waveform window displays arbitrary waveform.

SFG-20X Series Generator can generate repeatable arbitrary waveform

signals with at most 16 kpts and 5 MHz frequency.

Figure 1- 12 Arbitrary Waveform Signal Display Interface

As is shown in Figure 1- 12, the default signal parameters are: 1 kHz frequency,

4.0 Vpp amplitude and 0 mVDC offset.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 20

1.5. To Set Modulate/Sweep/Burst

As shown in Figure 1- 13, there are three buttons on the front panel, which are

used for modulation, sweep and burst settings. The instructions below will help

you familiarize with the setting of these functions.

Figure 1- 13 Modulate/Sweep/Burst Button

1. Press Mod button, the modulated waveforms will be generated. The

modulated waveform can be changed by modifying the parameters such as

type, internal/external modulation, depth, frequency, waveform, etc.

SFG-20X Series can modulate waveform using AM, FM, PM, ASK, FSK,

PWM and DSB-AM. Sine, square, ramp and arbitrary waveforms can be

modulated (pulse, noise and DC cannot be modulated).

Figure 1- 14 Modulated Waveform Display Interface

Page 21

2. Press Sweep button, sine, square, ramp or arbitrary waveform can be swept

(pulse, noise and DC can not be swept).

In the sweep mode, SFG-20X Series generate signal with variable

frequencies.

Figure 1- 15 Sweep Waveform Display Interface

3. Press Burst button, burst for sine, square, ramp, pulse or arbitrary waveform

can be generated.

Figure 1- 16 Burst Waveform Display Interface

Page 22

1.6. To Set Output

As is shown in Figure 1- 17, there are two buttons on the right side of the

operation panel, which are used to output/trigger control. The instruction below

will help you familiarize with these functions.

Figure 1- 17 Output Buttons

Press Output button, activate or deactivate the output signal.

Term Explanation

Burst: Output waveforms with set cycle times.

Burst can last for certain times of waveform cycle (N-Cycle Burst) or be

controlled by external gated signals (Gated Burst). Burst applies to all kinds

of waveforms, but noise can only be used in gated burst. Generally it is called

burst function within every signal generator.

Test Equipment Depot - 800.517.8431

TestEquipmentDepot.com

- 99 Washington Street Melrose, MA 02176

Page 23

1.7. To Use Digital Input

As is shown in Figure 1- 18, there are three sets of buttons on the operation

panel, which are direction button, the knob and the keypad. The instruction

below will help you familiarize with the digital input function.

Figure 1- 18 Front Panel Digital Input

1. The up and down keys are used to shift parameters and the left and right keys

are used to shift digits.

2. Keypad is used to directly set the parameters value.

3. Knob is used to change a signal digit value whose range is 0~9.

Page 24

1.8. To Use Store/Utility/Help Function

As is shown in Figure 1- 19, there are three buttons on the operation panel,

which are used to call the store/recall, utility and help function. The instruction

below will help you familiarize with these functions.

Figure 1- 19 Store/Recall Utility and Help Button

1. The Store/Recall button is used to store waveform data and configure

information.

2. The Utility button is used to set the auxiliary system function, change the

output configure parameters, interface setting, system setting information

or perform the instrument self-test and read the calibration information, etc.

3. The Help button is used to read the help information.

Page 25

2. Operating Your Generator

Up to now you have got a brief understanding about SFG-20X series with the

front/rear panel, every function control area and keys. You should also know

how to set your Function/Arbitrary Waveform Generator for your usage. If you

are not familiar with these operations, you are suggested to read chapter one

‘Getting Started’ again.

This chapter covers the following topics:

! Setting Sine Signal

! Setting Square Signal

! Setting Ramp Signal

! Setting Pulse Signal

! Setting Noise Signal

! Setting Arb Signal

! Output Modulated Signal

! Output Sweep Signal

! Output Burst Signal

! Store/Recall

! Utility Setting

! Help System

You are suggested to read this chapter carefully so as to understand

SFG-20X Series Generator’s versatile waveform setting functions and

more operation methods.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 26

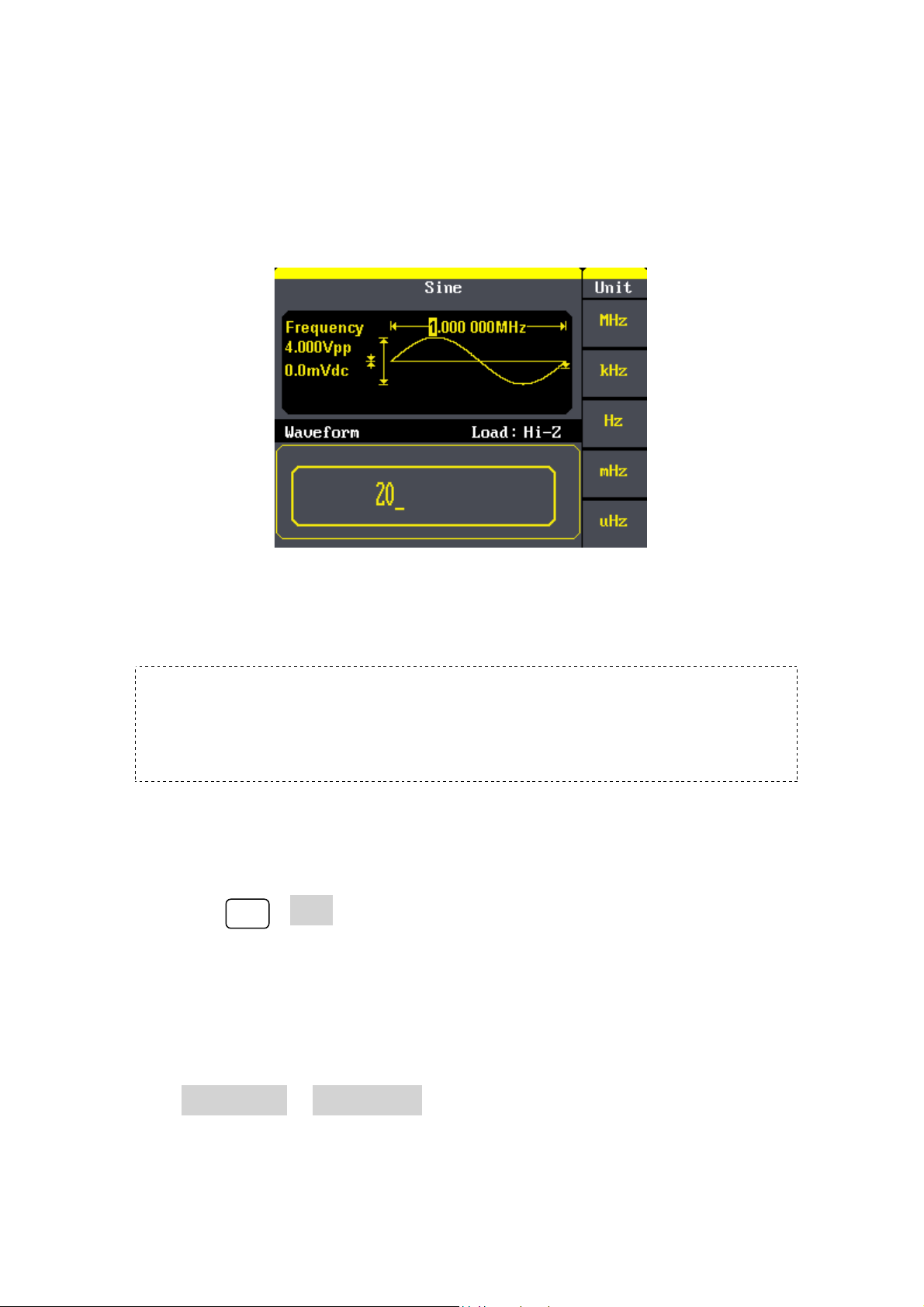

2.1. To Set Sine Signals

Press Sine button to call the sine operation. The sine waveform parameters are

set by using the sine operation menu.

The parameters of sine waveforms are: frequency/period, amplitude/high level,

offset/low level and phase. Different sine signals are generated by setting these

parameters. As is shown in Figure 2- 1, in the soft key menu, select Freq. Cursor

is located in the frequency parameter area in the parameter display window, and

users can set the frequency value here.

Figure 2- 1 Sine Parameter Display Interface

Page 27

Figure 2- 2 Table2- 1 Menu Explanations of Sine Waveform

To Set the Output Frequency/Period

1. Press Sine →Freq, to set the frequency parameter.

The frequency shown on the screen when the instrument is powered is the

default value or the set value beforehand. When setting the function, if the

current value is valid for the new waveform, it will be used sequentially. If

you want to set the period for the waveform, press Freq/Period button again,

to switch to the period parameter (the current operation is displayed in

inverse color).

2. Input the desired frequency.

Use the keypad to input the parameter value directly, and press the

corresponding button to select the parameter unit. Or you can use the

direction button to select the digit you want to edit, and then use the knob

Function

menu

Explanations

Freq/

Period

Set the signal frequency or period;

The current parameter will be switched at a

second press.

Ampl/

HLevel

Set the signal amplitude or high level;

The current parameter will be switched at a

second press.

Offset/

LLevel

Set the signal offset or low level;

The current parameter will be switched at a

second press.

Phase

Set the phase of the signal;

Page 28

to change its value.

Figure 2- 3 Setting the Frequency

To Set the Output Amplitude

1. Press Sine →Ampl, to set the amplitude.

The amplitude shown on the screen when the instrument is powered is the

default value or the set value beforehand. When changing the function, if

the current value is valid for the new waveform, it will be used sequentially.

If you want to set the waveform by high level or low level, press the

Ampl/HLevel or Offset/LLevel button again, to switch into the high level or

low level parameter (the current operation is displayed in inverse color).

Instruction:

When using the keypad to enter the digit, you can use the left direction button to

move the cursor backward and delete or change the value of the previous digit.

Test Equipment Depot - 800.517.8431

TestEquipmentDepot.com

- 99 Washington Street Melrose, MA 02176

Page 29

2. Input the desired Amplitude

Use the keypad or the knob to input the desired value, choose the unit, and

press the corresponding button.

Figure 2- 4 Setting the Amplitude

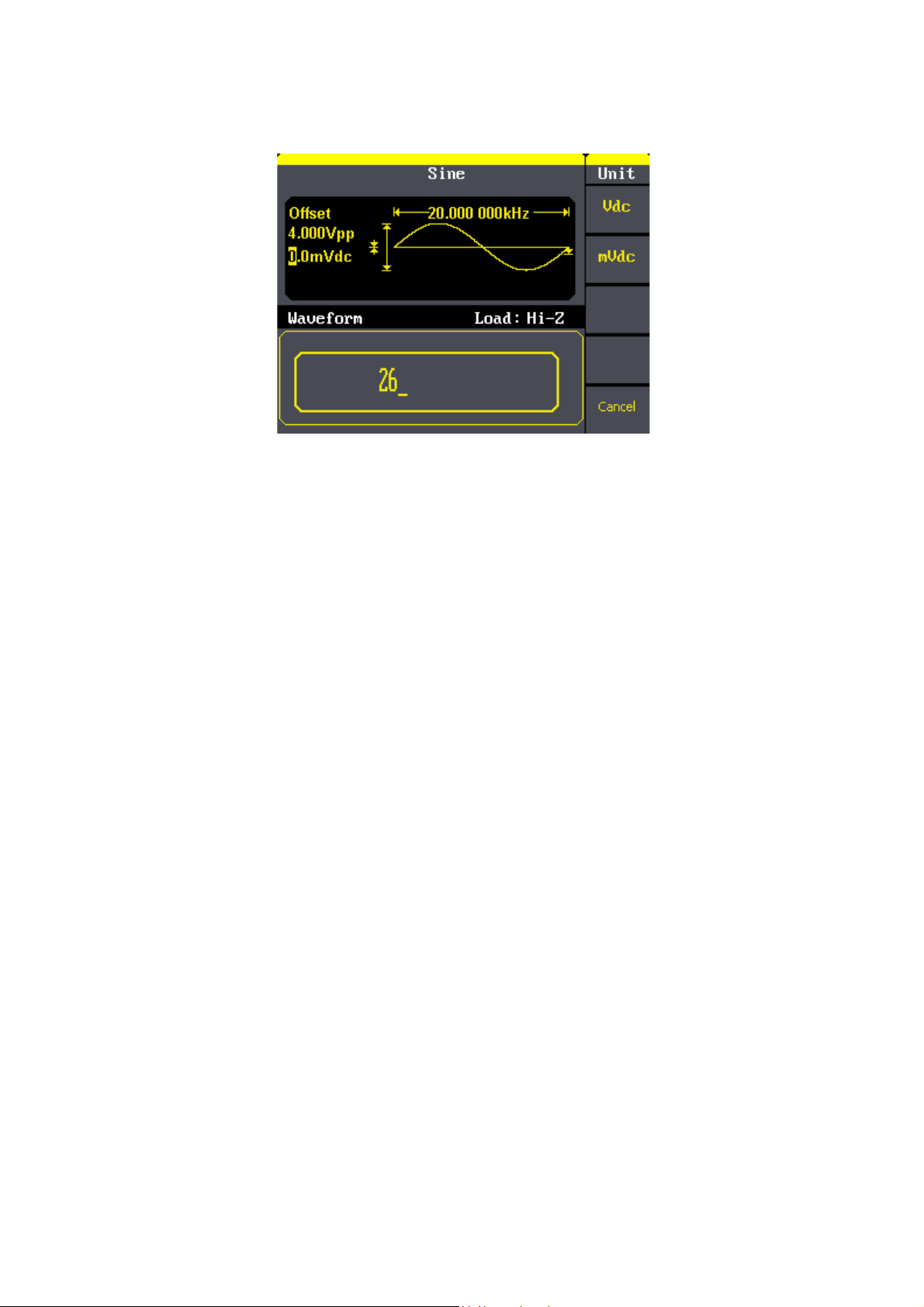

To Set the Output Offset

1. Press Sine →Offset, to set the offset.

The offset shown on the screen when the instrument is powered is the

default value or the set value beforehand. When changing the function, if

the current value is valid for the new waveform, it will be used sequentially.

2. Input the desired Offset

Use the keypad or the knob to input the desired value, choose the unit, and

press the corresponding button.

Page 30

Figure 2- 5 Setting the Offset

Page 31

2.2. To Set Square Signals

Press Square button to call the Square operation. The square waveform

parameters are set by using the Square operation menu.

The parameters of Square waveforms are: frequency/period, amplitude/high

level, offset/low level, phase and duty. As is shown in Figure 2- 6, select Duty.

Cursor is located in the duty parameter area in the parameter display window,

and users can set the duty value here.

Figure 2- 6 Square Parameter Display Interface

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 32

Figure 2- 7 Table2- 2 Menu Explanations of Square Waveform

Term Explanation:

Duty Cycle: The percentage that the high level takes up the whole period.

Please Note : for the frequency Duty Cycle Value

below 10MHz: 20% to 80%

To Set the Duty Cycle

1. Press Square →Duty, to set the duty cycle.

The duty cycle shown on the screen when the instrument is powered is the

default value or the set value beforehand. When changing the function, if

the current value is valid for the new waveform, it will be used sequentially.

2. Input the desired Duty Cycle

Function

Menu

Settings

Explanation

Freq/

Period

Set the signal frequency or period;

The current parameter will be switched at a

second press.

Ampl/

HLevel

Set the signal amplitude or high level;

The current parameter will be switched at a

second press.

Offset/

LLevel

Set the signal offset or low level;

The current parameter will be switched at a

second press.

Phase

Set the phase of the signal;

Duty

Set the duty cycle for square waveform.

Page 33

Use the keypad or the knob to input the desired value, choose the unit, and

press the corresponding button. The generator will change the waveform

immediately.

Figure 2- 8 Setting the Duty Cycle

Page 34

2.3. To Set Ramp Signals

Press Ramp button to call the ramp operation. The ramp waveform parameters

are set by using the ramp operation menu.

The parameters for ramp waveforms are: frequency/ period, amplitude/ high

level offset/ low level, phase and symmetry. As is shown in Figure 2- 9, in the

soft key menu, select Symmetry. Cursor is located in the symmetry parameter

area in the parameter display window, and users can set the symmetry value

here.

Figure 2- 9 Ramp Parameter Display Interface

Test Equipment Depot - 800.517.8431

TestEquipmentDepot.com

- 99 Washington Street Melrose, MA 02176

Page 35

Figure 2- 10 Table2- 3 Menu Explanations of Ramp Waveform

To Set the Symmetry

1. Press Ramp →Symmetry, to set the symmetry.

The symmetry shown on the screen when the instrument is powered is the

default value or the set value beforehand. When changing the function, if

the current value is valid for the new waveform, it will be used sequentially.

Function

Menu

Settings

Explanation

Freq/

Period

Set the signal frequency or period;

The current parameter will be switched at a

second press.

Ampl/

HLevel

Set the signal amplitude or high level;

The current parameter will be switched at a

second press.

Offset/

LLevel

Set the signal offset or low level;

The current parameter will be switched at a

second press.

Phase

Set the phase of the signal;

Symmetry

Set the symmetry for ramp waveform.

Term Explanation:

Symmetry: The percentage that the rising period takes up the whole Period.

Input Range: 0~100%.

Page 36

2. Input the desired Symmetry

Use the keypad or the knob to input the desired value, choose the unit, and

press the corresponding button. The generator will change the waveform

immediately.

Figure 2- 11 Setting the Symmetry

Page 37

2.4. To Set Pulse Signals

Press Pulse button to call the pulse operation. The pulse waveform parameters

are set by using the pulse operation menu.

The parameters for pulse waveforms are: frequency/period, amplitude/high

level, offset/low level, pulse width/Duty and Rise/Fall. As is shown in Figure 2-

12, in the soft key menu, select PulWidth. Cursor is located in the pulse width

parameter area in the parameter display window, and users can set the pulse

width value here.

Figure 2- 12 Pulse Parameter Display Interface

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 38

Figure 2- 13 Table 2- 4 Menu Explanations of Pulse Waveform

To Set the Pulse Width

1. Press Pulse →PulWidth, to set the pulse width.

The pulse width shown on the screen when the instrument is powered is the

default value or the set value beforehand. When changing the function, if

the current value is valid for the new waveform, it will be used sequentially.

Function

Menu

Explanation

Freq/

Period

Set the signal frequency or period;

The current parameter will be switched at a

second press.

Ampl/

HLevel

Set the signal amplitude or high level;

The current parameter will be switched at a

second press.

Offset/

LLevel

Set the signal offset or low level;

The current parameter will be switched at a

second press.

PulWidth

/Duty

Set the signal pulse width or duty;

The current parameter will be switched at a

second press.

Rise /

Fall

Setting the rising edge for pulse waveform.

Setting the falling edge for pulse waveform

Term Explanation:

Pulse Width:

Positive Pulse Width: the time span between thresholds of 50% of the rising edge

amplitude to the next 50% of the falling edge amplitude;

Negative Pulse Width: the time span between thresholds of 50% of the falling

edge amplitude to the next 50% of the rising edge amplitude.

Page 39

2. Input the desired Pulse Width

Use the keypad or the knob to input the desired value, choose the unit, and

press the corresponding button. The Generator will change the waveform

immediately.

Figure 2- 14 Setting the Pulse Width

To Set the Rising Edge

1. Press Pulse →Rise, to set the Rise edge.

The rising edge shown on the screen when the instrument is powered is the

default value or the set value beforehand. When changing the function, if

the current value is valid for the new waveform, it will be used sequentially.

2. Input the desired rising edge

Use the keypad or the knob to input the desired value, choose the unit, and

press the corresponding button. The generator will change the waveform

immediately.

Page 40

Figure 2- 15 Setting the Rise edge

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 41

2.5. To Set Noise Signals

Press Noise button to call the Gaussian White noise operation. The noise

waveform parameters are set by using the noise operation menu.

The parameters for noise waveforms are: Stdev and mean. As is shown in

Figure 2- 16, in the soft key menu, select Stdev, Cursor is located in the Stdev

parameter area in the parameter display window, and users can set the Stdev

value here. Noise is non-regulated signal which has no frequency or period.

Figure 2- 16 Noise Parameter Display Interface

Page 42

Figure 2- 17 Table 2- 5 Menu Explanations of Noise Waveform

Function

Menu

Settings

Explanation

Stdev

Set the signal standard deviation

Mean

Set the signal mean

Page 43

2.6. To Set Arbitrary Signals

Press Arb button to call the Arb operation. The Arb waveform parameters are

set by using the Arb operation menu.

The Arb signal consists of two types: the system built-in waveform and the

user-definable waveform. The parameters for Arb waveforms are:

frequency/period, amplitude/high level, offset/ low level and phase.

Figure 2- 18 Arb Parameter Display Interface

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 44

Figure 2- 19 Table 2- 6 Menu Explanations of Arb Waveform (Page 1/2)

Figure 2- 20 Table 2- 7 Menu Explanations of Arb Waveform (Page 2/2)

Function

Menu

Settings

Explanation

Freq/

Period

Set the signal frequency or period;

The current parameter will be switched at

a second press.

Ampl/

HLevel

Set the signal amplitude or high level;

The current parameter will be switched at

a second press.

Offset/

LLevel

Set the signal offset or low level;

The current parameter will be switched at

a second press.

Phase

Set the phase of the signal;

Function

Menu

Settings

Explanation

Load Wform

Select the built-in arbitrary signal as

output.

Page 45

To select the built-in Arbitrary Waveform

There are forty-eight built-in Arbitrary Waveforms and user-definable Arbitrary

Waveforms inside the Generator. To select one of them, follow the instructions

below:

Press Arb →Load Wform, to enter the interface below.

Figure 2- 21 Table 2- 8 Menu Explanations of Built-in Arbitrary Waveform

1. To Select the Built-in Waveform

Press Arb →Load Wform->Built-In, and enter the following interface.

As is shown in Figure 2- 22, there are five kinds of arbitrary waveform.

Function

Menu

Settings

Explanation

Built-In

Select one of the 46 types built-in arbitrary

waveforms.

Stored

Wforms

Select one of arbitrary waveforms stored in

the non-volatile memory.

Cancel

Cancel the current operation, and return to

the upper menu (the followings are the same

and will not be explained).

Page 46

Figure 2- 22 Table 2- 9 Menu Explanations of Built-In Arbitrary Waveform

Figure 2- 23 Common Built-In Arbitrary Waveform interface

Table 2- 10 Menu Explanations of Common Built-In Arbitrary Waveform

Function

Menu

Settings

Explanation

Common

Select common waveform.

Math

Select math waveform.

Project

Select project waveform.

Winfun/

Triangle

Select windows function

/triangle waveform.

Select

Validate the built-in waveform.

Function

Menu

Settings

Explanation

StairUp

Select the built-in stair up waveform.

StairDn

Select the built-in stair down waveform.

StairUD

Select the built-in stair up and down waveform.

PPulse

Select the built-in positive pulse waveform.

NPulse

Select the built-in negative pulse waveform.

Trapezia

Select the built-in trapezoid waveform

UpRamp

Select the built-in up ramp waveform.

DnRamp

Select the built-in down ramp waveform.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 47

Figure 2- 24 Math Built-In Arbitrary Waveform Interface

Table 2- 11 Menu Explanations of Math Built-in Arbitrary Waveform

Figure 2- 25 Project Built-In Arbitrary Waveform interface

Function

Menu

Settings

Explanation

ExpFall

Select the built-in exponential fall waveform.

ExpRise

Select he built-in exponential rise waveform.

LogFall

Select the built-in logarithmic fall waveform.

LogRise

Select the built-in logarithmic rise waveform.

Sqrt

Select the built-in square root waveform.

Root3

Select the built-in Root3 waveform.

X^2

Select the built-in X^2 waveform.

X^3

Select the built-in X^3 waveform.

Sinc

Select the built-in sinc waveform; Sincsin(x)/x.

Gaussian

Select the built-in gaussian waveform.

Dlorentz

Select the built-in D-lorentz waveform.

Haversin

Select the built-in haversine waveform.

Lorentz

Select the built-in lorentz Waveform.

Gauspuls

Select the built-in gaussian-modulated sinusoidal

pulse waveform.

Gmonpuls

Select the built-in Gaussian monopulse waveform.

Tripuls

Select the built-in triangle pulse waveform.

Page 48

Table 2- 12 Menu Explanations of Project Built-in Arbitrary Waveform

Figure 2- 26 Winfun/Triangle Built-In Arbitrary Waveform interface

Table 2- 13 Menu Explanations of Winfun/Triangle Built-in Arbitrary Waveform

Function

Menu

Settings

Explanation

Cardiac

Select the built-in electrocardiogram (ECG) signal

waveform.

Quake

Select the built-in loma prieta earthquake waveform.

Chirp

Select the built-in swept-frequency cosine

waveform.

TwoTone

Select the built-in two tone signal waveform.

SNR

Select the built-in sin wave with white noise

waveform.

Function

Menu

Settings

Explanation

Hamming

Select the built-in hamming window waveform.

Hanning

Select the built-in hanning window waveform.

Kaiser

Select the built-in kaiser window waveform.

Blackman

Select the built-in blackman windows

waveform.

Gaussian

Select the built-in gaussian window waveform.

Triangle

Select the built-in triangle window waveform.

Hairs

Select the built-in hairs window waveform.

Bartlett

Select the built-in bartlett window waveform.

Tan

Select the built-in tangent waveform.

Cot

Select the built-in cotangent waveform.

Sec

Select the built-in secant waveform.

Csc

Select the built-in cosecant waveform

Asin

Select the built-in inverse sine waveform.

Acos

Select the built-in inverse cosine waveform.

Atan

Select the built-in tangent waveform.

Page 49

2. To Select the Stored Waveform

Press Arb →Load Wform->Stored Wforms, and enter the following interface.

As is shown in Figure 2- 27, use the direction keys or knob to choose the

corresponding arbitrary waveform and press Select.

Figure 2- 27 Stored Wform Display Interface

Acot

Select the built-in inverse cotangent waveform.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 50

2.7. To Generate the Modulated Waveform

Use the Mod button to generate modulated waveform.SFG-20X Series can

generate AM, FM, ASK, FSK, PM, PWM and DSB-AM modulated waveforms.

Modulating parameters vary with the types of the modulation. In AM, users can

set the depth, modulating frequency, modulating waveform and carrier

waveform; In FM, users can set the modulating frequency, frequency deviation,

modulating waveform and carrier waveform; In ASK, users can set the Key Freq

and carrier waveform; In FSK, users can set the key frequency, Hop Freq and

carrier waveform; In PM, users can set the phase deviation, modulating

frequency, modulating waveform and carrier waveform.

We will cover how to set these parameters in details according to the modulation

types.

Figure 2- 28 Display Interface of Modulated Waveform Parameter

Carrier

Frequency

Modulating

Frequency

Carrier

Amplitude

Page 51

AM

The modulated waveform consists of two parts: the carrier waveform and the

modulating waveform. In AM, the amplitude of the carrier waveform varies with

the instantaneous voltage of the modulating waveform. The parameters for the

AM are in Figure 2- 29

Press Mod →Type→ AM, to enter the following menu.

Figure 2- 29 Table 2- 14 Menu Explanations of the AM Parameters

Term Explanation

Modulation Depth

The amplitude range (also called ‘Percentage Modulation’). Modulation depth

varies from 0% to 120%.

In the 0% modulation, the output amplitude is the half of the set one. !

In the 100 modulation, the output amplitude is the same with the set !

one.

Function

Menu

Settings

Explanation

AM Freq

Set the modulating waveform frequency.

Frequency range: 2mHz~20kHz

(internal source only).

AM Depth

Set the amplitude range.

Type

AM

Amplitude modulation.

Shape

Sine

Square

Triangle

UpRamp

DnRamp

Noise

Arb

Choose the modulating waveform.

To change the carrier waveform

parameter, press Sine, Square, Ramp,

Arb

Page 52

FM

The modulated waveform consists of two parts: the carrier waveform and the

modulating waveform. In FM, the frequency of the carrier waveform varies with

the instantaneous voltage of the modulating waveform. The parameters for the

FM are as shown in Figure 2- 30.

Figure 2- 30 Setting Interface of FM Waveform Parameter

Press Mod →Type→ FM, to enter the following menu.

Figure 2- 31 Table 2- 15 Menu Explanations of the FM Parameters

Function

Menu

Settings

Explanation

FM Freq

Set the modulating waveform frequency.

Frequency range 2mHz~20kHz (internal

source).

FM Dev

Set the maximum frequency deviation

Type

FM

Frequency modulation

Shape

Sine

Square

Triangle

UpRamp

DnRamp

Noise

Arb

Choose the modulating waveform. To

change the carrier waveform parameter,

press Sine, Square, Ramp, Arb

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 53

ASK

ASK is a form of modulation that represents digital data as variations in the

amplitude of a carrier wave. The amplitude of an analog carrier signal varies in

accordance with the bit stream (modulating signal), keeping frequency and

phase constant. The parameters for the ASK are as shown in Figure 2- 32

Figure 2- 32 Setting Interface of ASK Waveform Parameter

Term Explanation

Frequency Deviation

The deviation should be equal to or less than the carrier waveform !

frequency.

The sum of the deviation and the carrier frequency should be equal to !

or less than maximum frequency of the selected function.

Page 54

Press Mod →Type→ ASK, to enter the following menu.

Figure 2- 33 Table 2- 16 Menu Explanations of the ASK Parameters

Function

Menu

Settings

Explanation

Key Freq

Set the frequency at which the output

amplitude shifts between the carrier

amplitude and zero (internal modulation

only): 2mHz~50kHz.

Type

ASK

Amplitude shift keying modulation.

Page 55

FSK

The FSK Modulation is a modulation method, the output frequency of which

switches between two the pre-set frequencies (carrier waveform frequency and

the hop frequency). The frequency at which the output frequency switches is

called the key frequency.

Figure 2- 34 Setting Interface of FSK Waveform Parameter

Press Mod →Type→ FSK, to enter the following interface

Figure 2- 35 Table 2- 17 Menu Explanations of the FSK Parameters

Function

Menu

Settings

Explanation

Key Freq

Set the frequency at which the output

frequency shifts between the carrier

frequency and the hop frequency (internal

modulation only):

2mHz~50kHz.

Type

FSK

Frequency shift keying modulation.

Hop Freq

Set the hop frequency.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 56

PM

The modulated waveform consists of two parts: the carrier waveform and the

modulating waveform. In PM, the phase of the carrier waveform varies with the

instantaneous voltage level of the modulating waveform. The parameters for

the PM are as shown in Figure 2- 36.

Figure 2- 36 Setting Interface of PM Waveform Parameter

Press Mod →Type →PM, enter the following interface.

Figure 2- 37 Table 2- 18 Menu Explanations of the PM Parameters

Function

Menu

Settings

Explanation

PM Freq

Set the modulating waveform frequency.

Page 57

PWM

The modulated waveform consists of two parts: the carrier waveform and the

modulating waveform, the carrier waveform is only pulse. In PWM, the pulse

width of pulse varies with the instantaneous voltage of the modulating waveform.

The parameters for the FM are as shown in Figure 2- 38.

Figure 2- 38 Setting Interface of PWM Waveform Parameter

Press Mod→ Pulse →PWM, to enter the following menu.

Frequency range:

2mHz~20kHz

Phase

Dev

Range from 0° ~ 360°.

Type

PM

Phase modulation

Shape

Sine

Square

Triangle

UpRamp

DnRamp

Noise

Arb

Choose the modulating waveform.

To change the carrier waveform parameter,

press Sine, Square, Ramp, Arb

Page 58

Figure 2- 39 Table 2- 19 Menu Explanations of the PWM Parameters

DSB-AM

Press Mod→ Type →DSB-AM. The parameters for the DSB-AM are as shown

in Figure 2- 40.

Figure 2- 40 Setting Interface of DSB-AM Waveform Parameter

Figure 2- 41 Table 2- 20 Menu Explanations of the DSB-AM Parameters

Function

Menu

Settings

Explanation

PWM Freq

Set the modulating waveform

frequency. 2mHz~20kHz

Width Dev

Duty Dev

Set the width or Duty range.

Type

PWM

Amplitude modulation.

Shape

Sine

Square

Triangle

UpRamp

DnRamp

Noise

Arb

Choose the modulating waveform.

The carrier waveform is pulse.

Function

Menu

Settings

Explanation

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 59

DSB Freq

Set the modulating waveform frequency.

Frequency range: 2mHz~20kHz

Type

DSB-AM

Amplitude modulation.

Shape

Sine

Square

Triangle

UpRamp

DnRamp

Noise

Arb

Choose the modulating waveform.

To change the carrier waveform parameter,

press Sine, Square, Ramp, Arb

Page 60

2.8. To Generate Sweep

In the frequency sweep mode, the function generator ‘steps’ from the start

frequency to the stop frequency at the sweep time you specify. Sweep can be

generated by sine, square, ramp or arbitrary waveforms (pulse, noise and DC

are not allowed).

Figure 2- 42 Setting Interface of Sweep Waveform Parameter

Press Sweep button to enter the following menu. Set the waveform parameters

by using the operation menu.

Page 61

Figure 2- 43 Table 2- 21 Menu Explanations of Waveform Sweep (Page 1/2)

Sweep Frequency Setting

Use start freq and stop freq or center freq and freq span to set the range of the

frequency. Press the button again to switch between each other.

Figure 2- 44 Table 2- 22 Menu Explanations of Waveform Sweep (Page 2/2)

Function

Menu

Settings

Explanation

Swp Time

Set the time span of the sweep in which

the frequency changes from the start

frequency to stop frequency.

Stop Freq

Freq Span

Set the stop frequency of the sweep;

Set the frequency span of the sweep.

Start Freq

Mid Freq

Set the start frequency of the sweep;

Set the center frequency of the sweep.

Source

Internal

Choose internal source.

External

Choose external source.

Manual

Set the start and stop time by hand.

Function

Menu

Settings

Explanation

Linear/

Log

Set the sweep with linear spacing;

Set the sweep with logarithmic spacing.

Direct

Sweep upward;

Sweep downward.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 62

2.9. To Generate Burst

Burst function can generate versatile waveforms in burst, which can last specific

times of waveform cycle (N-Cycle burst), or when external gated signals (gated

burst) is applied, any waveform could be used, but noise can only be used in

Gated Burst.

Press Burst button to enter the following interface. Set the waveform

parameters by using the operation menu.

Figure 2- 45 Setting Interface of Burst Waveform Parameter

Page 63

Set the N-Cycle Burst

Press Burst → N Cycle, to enter the following interface.

Figure 2- 46 Table 2- 23 Menu Explanations of the N-Cycle Parameters(Page 1/2)

Burst Period

Set the time span between an N-Cycle burst and the next. If necessary the

period will increase to allow the specific number of cycles in a burst. Burst

Period>Carrier Period × Burst Number

Start Phase

Define the start point in a waveform. The phase varies from 0° to 360°, and the

default setting is 0°. For an Arbitrary Waveform, 0° is the first waveform point.

Function

Menu

Settings

Explanation

Period

Set the burst Period.

Start

Phase

Set the start phase of the burst.

NCycle

Gated

Use the N-Cycle mode.

Use the Gated mode.

Source

Internal

Choose internal source.

External

Choose external source.

Manual

Choose external source, set the start time by

hand.

Page 64

N-Cycle/Gated

N-Cycle has specific number of waveform cycles, and every burst is activated

by a trigger event. Gated burst use external source to control burst as when to

be activated.

Figure 2- 47 Table 2- 24 Menu Explanations of the N-Cycle Parameters (Page2/2)

Cycles

Set the number of waveform cycle in an N-Cycle (1 to 50,000 or Infinite).

If you choose Infinite, then a continuous waveform will be generated which will

not stop until a trigger event happens.

If needed, Burst Period will increase to cater to the specific number !

of cycles.

For an infinite-cycle burst, external or manual trigger is needed to!

activate burst.

Function

Menu

Settings

Explanation

Cycles/

Infinite

Set the number of the bursts in a N-Cycle.

Set the number of the bursts in a N-Cycle to

be infinite.

Delay

Set the delay time before the burst starts.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 65

Delay

Set the time delay between the trigger input and the start of the N-Cycle burst.

The max delay is 240ns.

Set the Gated Burst

Press Burst →Gated, to enter the following interface.

Figure 2- 48 Table 2- 25 Menu Explanations of the Gated Burst Parameters

Function

Menu

Settings

Explanation

NCycle

Gated

Set the NCycle mode;

Set the gated mode.

Polarity

Positive

Negative

Set the polarity for the gated signal.

Page 66

2.10. To Store and Recall

Press Store/Recall button to enter the following interface. You can save or recall

the state documentation inside the generator. The state file on the U Disk is also

allowed to recall or delete. File names can only be English. User can only recall

or delete the data documentation you save via CSV of the Oscilloscopes.

Figure 2- 49 Save and Read Interface

Figure 2- 50 Table 2- 26 Menu Explanations of Save and Recall (Page 1/2)

Function

Menu

Settings

Explanation

File Type

State

Data

The setting of the generator;

Arbitrary waveform file;

Browser

Directory

File

Shift between the directory and file.

Save

Save the waveform to the appointed

place.

Recall

Recall the waveform or setting

information in the specific position of the

memory.

Delete

Delete the selected file.

Page 67

About the Browser

The directory selection shift is done by the direction keys. In the directory mode,

pressing the right key will open the lower directory while the left key will fold the

directory. Up and down key are used to shift between the directories;

To Save the Instrument State

Users are allowed to store the instrument state in any of the 10 non-volatile

memories. The state storage will ‘memorize’ the selected function (including the

arbitrary waveform, frequency, amplitude, DC offset, duty cycle, symmetry, and

other modulation parameter used.)

To save the instrument state, the procedures are given as followed:

1. Choose the file type to store

Press Store/Recall →Type→ State, and choose state as the storage type.

2. Choose the location of the file.

There are ten positions in the Local(C :), choose anyone of them by rotating

the knob.

3. Name the file and save it

Press Save button, enter the desired name. Press Save to finish.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 68

To Use USB Storage

As is shown in Figure 2- 51, the storage location is divided into: The internal

storage Local(C :) and the U Disk storage USB Device (A :). At the left side of

the front panel, there is a USB interface. When a USB storage is connected, the

storage menu will show ‘USB Device (A:)’. Otherwise, the default location is the

internal location Local(C :).

Figure 2- 51 USB Storage Interface

1. Install the USB Device

Insert the USB Device into the USB interface on the front panel, and the

screen will show ‘USB flash device plug in’, and storage menu will show

‘USB Device (A :)’

2. Choose the USB Device

Press Browser->Directory, move the cursor with the up or down direction

key to select ‘USB Device (A :)’. Press the right key to open the lower

directory, use the up and down direction key to choose the file ‘SFG-20X’.

Use the right key to open the lower directory, and up and down key to select

the file ‘Workspace’. Input the file name and save.

3. Remove the USB Device

Page 69

Remove the USB Device from the interface. The system will inform you

‘USB flash device plug out’, and the ‘USB Device (A :)’ in the storage menu

will disappear.

Note: USB Device can only be used by U Disk; portable hard disk is not

supported.

To Save a File

Press Store/Recall →Store, to enter the following interface. Enter the desired

file name in the ‘File Name’ frame. In the middle of the figure below is the input

keypad, used to edit the file name. Use the up and down direction keys and knob

to select the desired character; use the left and right direction keys to edit the

input file name.

Figure 2- 52 File Storage Interface

Page 70

Figure 2- 53 Table 2- 27 Menu Explanation of File Storage

1. English Input

The alphnumeric input interface is as shown in Figure 2- 54, to save a file named

‘NEWFILE’, follow the steps below:

Figure 2- 54 Alphanumeric Input Interface

(1) Press InType->En, to enter the alphanumeric interface.

(2) Input the file name’ NEWFILE’.

Use the Knob to adjust the cursor’s horizontal position and the up and down

key to adjust the vertical position. Select the Character ‘N’ and press Select.

Function

Menu

Settings

Explanation

Input

Type

En

English input.

Select

Select the current character.

Delete

Delete the current character.

Save

Store the file with the current name

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 71

Repeat this until you have inputted ‘NEWFILE’.

(3) Edit the File Name

When you have entered a wrong character, move the cursor to the wrong

character to be deleted and press Delete to remove it. Reenter the file

name.

(4) Press Save, to finish and save the file.

Page 72

2.11. To Set the Utility Function

With the Utility Function, you can set the parameters of the generator such as:

DC On/Off, Sync On/Off, Output Parameter, Interface Parameter, System

Setting and Testing Parameter. The DC switch offers the options of DC output

or Arbitrary Waveform Output. Sync Switch offers the option to choose the Sync

Signal or not. Output Setting provides the parameter setting for Load/HighZ and

Normal/Inverse. The System Setting provides the setting for Language,

Display, Beep, Screen Guard, Format, Power System Configure and default

setting; Test provides the self-testing and calibration function.

Press Utility button, to enter the Utility Menu. Its functions are listed below in

Figure 2- 55

Figure 2- 55 Table 2- 28 Menu Explanations of Utility System Setting (Page1/2)

Function

Menu

Settings

Explanation

DC

On

Off

Set the output waveform to be DC.

Set the output waveform to be arbitrary.

Output

Setup

Set the output parameter.

Sync

Set the sync output

Page 73

Figure 2- 56 Table 2- 29 Menu Explanations of Utility System Setting (Page2/2)

To Set the DC Output

Press Utility →DC→DC On, to enter the following interface. Please note that

there is a ‘DC On’ sign at the middle left of the screen.

Figure 2- 57 DC Setting Interface

Function

Menu

Settings

Explanation

System

Set the system configuration.

Test/Cal

Test and calibrate the instrument.

EditInfo

Information of the system.

Update

Update function.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 74

DC Offset

Set the DC voltage level.

To Shift into the Arbitrary Waveform Output

1. Press Utility →DC→DC Off, to close DC output and return to arbitrary

waveform output.

2. Press any functional button, and the waveform output setting turns into the

arbitrary waveform output. The DC output is turned off automatically.

To Set IO

Press Utility →IO Setup, to set the IO interface. The equipment stands for RAW

protocol and TMC protocol, user may setup corresponding protocol by IO

Setup.

To Set Output Parameter

Press Utility →Output Setup, to enter the following interface.

Figure 2- 58 Table 2- 30 Menu Explanations of Output Setting (Page 1/2)

Function

Menu

Settings

Explanation

Load

HighZ

Set the load connected to the Output

Connector;

Set the load connected to the Output

Connector to be HighZ.

Normal

Invert

Normal output;

Inverse output.

Page 75

1. To Set the Output Load

For the [Output] connector on the front panel, the generator has a built-in

50Ω series impendence. If the actual load does not match the set one, the

displayed amplitude and offset will be incorrect. This function is used to

match the displayed voltage with the expected one.

Steps for setting the load:

Press Utility →Output Setup→ Load, to enter the following interface.

Please note that the load parameter shown on the right bottom

is the default setting when the power is on or the pre-set load value. If the

current value is valid for the output, then current value will be used.

Figure 2- 59 Set the Output Load

Instruction

SFG-20X Series has a fixed 50Ω Series Impendence. No matter what value the

set parameter is, if the real load is different from the set one, the displayed voltage

Page 76

will not equal the real voltage.

2. To Set the Invert Waveform

Press Utility →Output Setup→ Invert, to set the Inverse Waveform Output.

When the waveform is inverse, no offset will change.

3. To Set the Sync Output

The generator provides Sync output through the [Sync] connector on the rear

panel. All standard output functions (except DC and Noise) have a

corresponding Sync signal. For some applications, they can be disabled if users

do not want to use it,

In the default setting, the Sync signal should be connected to the !

[Sync] connector (activated). When the Sync Signal is disabled, the

output voltage of the [Sync] connector is level low.

In the Inverse Mode, the Waveform that corresponds to the Sync!

Signal does not inverse.

The Sync Signal is a Pulse Signal with fixed positive pulse width,!

which is more than 50ns.

For non-modulated waveform, the Sync Signal reference is the!

carrier.

For internal modulating AM, FM and PM, the Sync signal reference is!

the modulated signal (not the carrier signal).

For ASK and FSK, the Sync Signal Reference is the keying!

Frequency.

For a Sweep, when the sweep starts, the Sync Signal becomes TTL!

Level High. The Sync frequency equals the specific Sweep time.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 77

For the Burst, when the burst starts, the Sync Signal is Level High. !

For the External Gated Burst, the Sync Signal follows the External !

Gated Signal.

To Set the System

Press Utility → System, to enter the following interface.

Figure 2- 59 Table 2- 31 Menu Explanations of System Setup (Page 1/2)

Figure 2- 60 Table 2- 32 Menu Explanations of System Setup (Page 2/2)

Function

Menu

Settings

Explanation

Number

format

Set the number format.

Language

Set the display language.

Power On

Default

Last

All the settings return to default when

powered;

All the settings return to the last one when

powered.

Set to

Default

Set all the settings to default.

Function

Menu

Settings

Explanation

Beep

On

Off

Open beep;

Close beep.

ScrnSvr

1min

5min

15min

30min

1hour

2hour

5hour

Activate the screen saver program.

Screen saver will be on if no action is

taken within the time that you have

selected. Press any button the resume.

Page 78

Key points:

Power On

Choose the configuration setting when the machine is powered.

Two choices are available: the default setting and the latest. Once selected, the

setting will be used when the instrument is powered.

Beep

Activate or deactivate the sound when an error occurs from the front panel or

the remote interface. Activate or deactivate any sound made by the button or

knob on the front panel. The current setting is stored in the non-volatile memory.

1. Set the Format

Press Utility →System→ Number Format, to enter the following interface.

Off

Deactivate the screen saver program.

Page 79

Figure 2- 61 Set the number Format

Figure 2- 62 Table 2- 33 Menu Explanations of Setting the Number Format

According to the different choices of the point and the separator, the format can

have various forms.

(1) as point, press Separator->On, the example is as followed:

Function

Menu

Settings

Explanation

Point

Using dot to represent point;

Using comma to represent point.

Separator

On

Off

Space

Enable the Separator;

Close the Separator;

Use Space to separate.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 80

Figure 2- 63 Set Format

(2) as point, press ->Separator->On, the example is as followed:

Figure 2- 64 Set Format

(3) as point, press Separator->Off, the example is as followed:

Figure 2- 65 Set Format

(4) as point, press Separator->Off, the example is as followed:

Figure 2- 66 Set Format

(5) as point, press Separator->Space, the example is as followed:

Figure 2- 67 Set Format

(6) as point, press Separator->Space, the example is as followed:

Figure 2- 68 Set Format

Page 81

2. Language Setup

The SFG-20X Series Generator offers two languages (English and Simplified

Chinese) for user to choose.

To Select Language, press Utility and then Language to select the language.

The Procedure is as followed:

Press Utility →System→ Language, to change the language.

3. To Return to Default Setting

Press Utility →System→ Set to Default, to set the system to the default setting.

The default settings of the system are as followed:

Table 2- 34 Factory Default Setting

Output

Default

Function

Sine Wave

Frequency

1kHz

Amplitude/Offset

4Vpp/0Vdc

Phase

0°

Terminals

High Z

Modulation

Default

Carrier

1kHz Sine Wave

Modulating

100Hz Sine Wave

AM Depth

100

FM Deviation

500Hz

Key Freq

100Hz

Key Freq

100Hz

FSK Hop Frequency

1MHz

Phase Deviation

180°

Page 82

Sweep

Default

Start/Stop Frequency

100Hz/1.9kHz

Sweep Time

1S

Trig Out

Off

Mode

Linear

Direction

↑

Burst

Default

Period

10ms

Phase

0°

Count

1Cycle

Trig

Off

Trigger

Default

Source

Internal

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 83

2.12. Test/Cal

Press Utility →Test/Cal, to enter the following menu.

Figure 2- 69 Test/Cal function Menu

Figure 2- 70 Table 2- 35 Menu Explanations of Test Setting

Function

Menu

Settings

Explain

SelfTest

Perform system self-test.

SelfCal

Do self calibration

Page 84

SelfTest

Press Utility →Test/Cal →SelfTest, to enter the following menu.

Figure 2- 71 Table 2- 36 Menu Explanations of Self Test

1. Scr Test

Select Scr Test to enter the screen test interface. The clew words ‘Press ‘7’ Key

to continue, Press ‘8’ Key to exit’ is displayed. You could press the ‘7’ for test.

Figure 2- 72 Screen Test Interface

Function

Menu

Settings

Explain

Scr Test

Run screen test program.

Key Test

Run keyboard test program.

LED Test

Run LED test program.

Page 85

2. Key Test

Select ‘keyboard Test’ to enter the keyboard test interface, the on-screen lathy

rectangle shapes represent the front panel keys. The shapes with two arrows

beside them represent the front panel knobs. Test all keys and knobs and you

should also verify that all the backlit buttons illuminate correctly.

Note:

When you operate, the screen would display the white (color LCD). !

The tested button or knobs corresponding area would display green!

(color LCD).

At the bottom of the screen display ‘Press ‘8’ Key Three Times to exit’!

information prompt to show that press ‘8’ three times for quitting the

test.

Figure 2- 73 Key Test Interface

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 86

3. LED Test

Select ‘LED Test’ to enter the lighten interface, the on-screen lathy rectangle

shapes represent the front panel keys; the shapes with two arrows beside them

represent the front panel knobs. The clew words ‘Press ‘7’ Key to continue,

‘Press ‘8’ Key to exit’ is displayed, You could press the ‘7’ button continuously

for testing, when buttons are lighted ,the corresponding area on the screen

would display green(color LCD).

Figure 2- 74 Led Test Interface

Page 87

SelfCal

Press Utility →1/2→Test/Cal →SelfCal, to enter SelfCal, as is shown in Figure

2- 5

SelfCal: do self calibration, environment you use the generator changes,

system may calibrate data based on change of current environment

Figure 2- 75 SelfCal Interface

Page 88

2.13. Edition Information

Press the EditInfo option button of the Utility Menu to view the generator’s

hardware and software configuration.

Figure 2- 76 Edit Info Interface

Edition Information introduce

Boot-strap No:

The times of boot-strap

Software version:

Software version of current equipment

Hardware version:

02-00-00-21-25 represents ordinally: PCB version, BOM version, Daughter

card version, FPGA version, CPLD version.

Model:

Contains information of brand of product, series, bandwidth.

For example: SFG-210 represents GLOBAL SPECIALTIES’s 200 series

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 89

function/arbitrary waveform generator, the bandwidth is 10 MHz.

Serial No:

Bit 1-6 represent maker and series of the product. Bit 7-10 represent production

date. Bit 11-14 represent serial number of product.

For example: SFG00004130008 represents the eighth generator made by

GLOBAL SPECIALTIES in the fourth quarter of 2013.

Page 90

2.14. Updating Firmware

Using USB flash drive update firmware

The software of the generator can be updated directly via USB flash drive. This

process takes about two minutes. Follow the next steps:

1. Insert USB flash drive with firmware procedure to USB host interface on the

front panel of the generator.

2. Press the Utility button to enter the ‘Utility Menu’.

3. Press ‘1/2’ option button to enter the second page of ‘Utility Menu’.

4. Press the ‘Update’ option button.

5. Press ‘Brower’ option button to select ‘Directory’, then select the ‘USB

Device (A:)’ through direction key.

6. Press ‘Brower’ option button to select ‘File’, then select the ‘XXXX.ADS’ file

by direction key.

7. Press the ‘Recall’ option button to updating.

8. After accomplish update, restart the generator.

Note: Don’t cut off the power during product is being updating.

Page 91

2.15. How to Use the Built-in Help System

You can get a particularly help for every button on the front panel by using the

built-in help system. Or you can get help about the operation of the front panel

buttons with the help list.

Press Help to enter the following interface.

Figure 2- 77 Help Menu

Figure 2- 78 Table 2- 37 Help Menu Explanations

Function

Menu

Settings

Explanation

Cursor upward to select.

Cursor downward to select.

Choice

Select to read the information.

Th

e

im

Th

e

im

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 92

3. Application and Examples

Example 1: Generate a Sine Wave!

Example 2: Generate a Square Wave!

Example 3: Generate a Ramp Wave!

Example 4: Generate a Pulse Wave!

Example 5: Generate a Noise Wave!

Example 6: Generate an Arbitrary Wave!

Example 7: Generate a Sweep Wave!

Example 8: Generate a Burst Wave!

Example 9: Generate an AM Wave!