GLOBAL RECORDINGS MESSENGER-II Service Manual

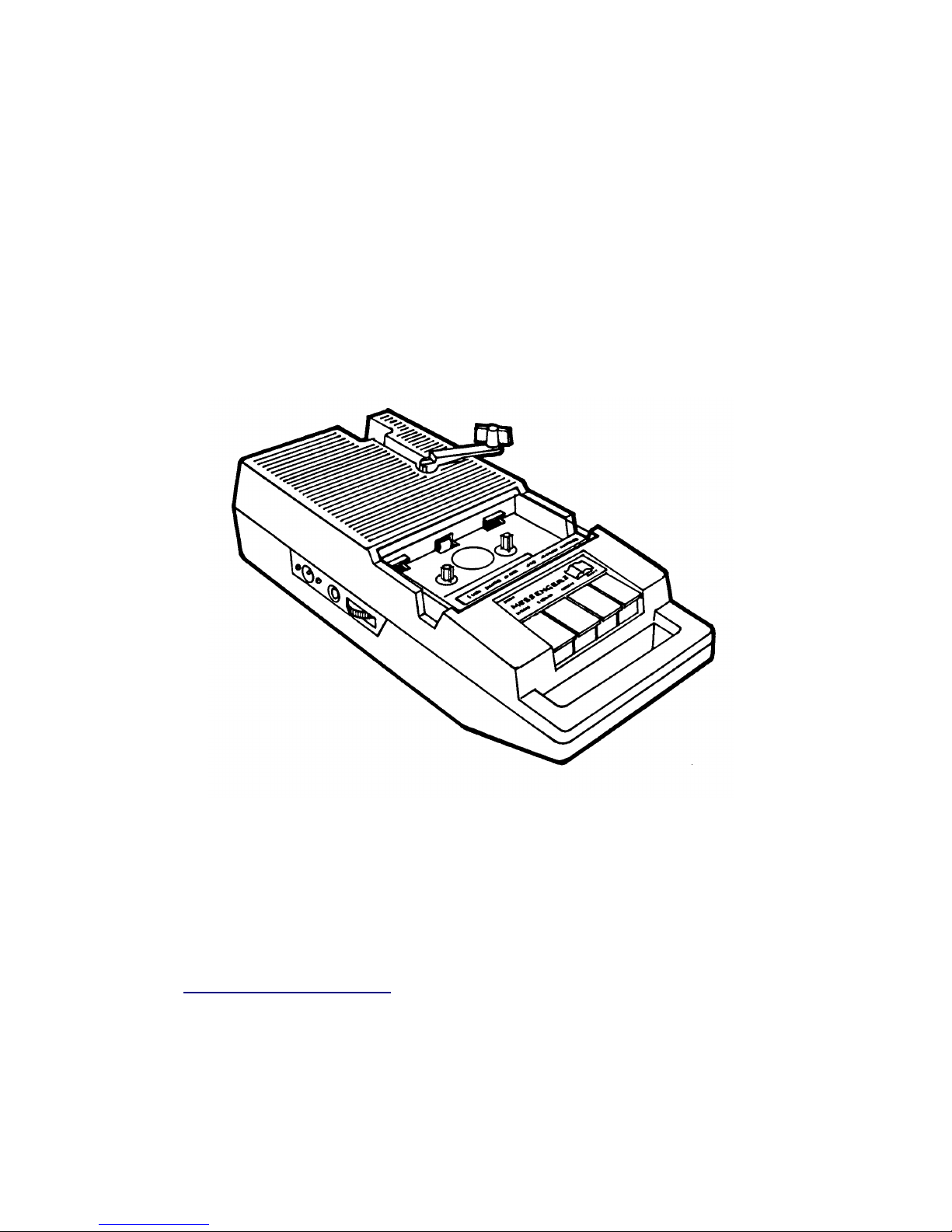

MESSENGER-II

HAND-WIND CASSETTE PLAYER

SERVICE MANUAL

GLOBAL RECORDINGS NETWORK AUSTRALIA

Locked Bag 9019

Castle Hill NSW 1765

AUSTRALIA

Email: au@globalrecordings.net

Phone: +61 2 9899 2211

Fax: +61 2 9899 2602

(A.C.N 000 260 033) Revised June 2004

MESSENGER-II HAND-WIND CASSETTE PLAYER SERVICE MANUAL

INTRODUCTION

Language Recordings has produced the Messenger-II player because of the worldwide demand from

missions and churches for a compact, reliable cassette player that is not dependent on batteries or other

costly power sources.

The purpose of this service manual is to provide the necessary technical information, parts lists and

drawings for those who will be doing in-service repairs and maintenance to these players.

The technical descriptions have been kept as simple as possible and have been prepared with the nontechnical person in mind. As well as providing this Service Manual and any necessary spare parts, we

believe in the concept that “prevention is better than cure”, and we strongly recommend that where any

“Messenger-II” players are put into use that those using them should be given careful instructions in the

basic care and maintenance of those players.

(See ‘Care of Cassette Players’ on operating instructions leaflet).

The Messenger-II Player is produced in two different ‘formats’:

a. Player Designation: LRI-03M = Plain Mabuchi i.e. Mabuchi Generator.

b. “ “ LRI-03MP = Mabuchi with Power i.e. Mabuchi Generator plus Mains Power Transformer.

TABLE OF CONTENTS

Introduction.................................................................................. 1

Equipment & Specifications for Testing...................................... 2

Trouble Shooting Procedure........................................................ 3-5

How to Order Parts...................................................................... 6

Messenger-II Disassembly and Servicing.................................... 7-8

Messenger-II Player Assemblies - Drawing M-02....................... 9

Case Assembly - Parts List and Drawing M-03........................... 10-11

Generator Assembly - Parts List and Drawing M-04................... 12-13

Mechanism Assembly - Parts List and Drawing M-05................ 14-15

A.C. Power Supply Assembly - Parts List and Drawing M-06.... 16

Circuit Board Assembly - Parts List and Drawing M-07............. 17

Circuit Board Overlay and Schematic Diagram M-10................. 18

Circuit Diagram M-09.................................................................. 19

Generator and Power Wiring Diagram......................................... 20-21

Replacing Generator leads, helpful tips........................................ 22-23

Trouble-Shooting Guide............................................................... 24

EQUIPMENT & SPECIFICATIONS FOR TESTING

NECESSARY EQUIPMENT

1.Basic

a. Multimeter - With approx. 2-3v A.C. range, full deflection. e.g. A meter with a sensitivity of at least

100k/volt

b. Dummy Load - 7.5 ohms resistance and lead; or external speaker(8ohms).

c. D.C. Power Test Lead - To allow measurement of voltage & current. (Ref. Figure 1&3)

d. Test Tapes - 6.3 KHz at 15dB for Head Azimuth.

- 1 KHz at OdB for current consumption & output level.

e. 6v regulated power supply or 6v battery pack, (Fig. 1&3)

Note: Language Recordings is prepared to supply any of the above equipment to those who do not have

ready access to such.

2. Optional

a. Oscilloscope )

b. Frequency counter ) desirable for major servicing

c. Cassette Torque Meter ) centres.

d. Signal Generator - helpful for trouble shooting of circuit board.

MEASUREMENTS & ALIGNMENT

1. Supply voltage for testing: 6v +/- 0.2v Measure the voltage across supply used for testing, with 1Khz

tape playing at full volume into dummy load (fitted to external speaker socket). If the voltage is outside

of tolerance, incorrect readings may be obtained for other tests.

2. Generator Output Voltage: Must be over 4.5v

Measure voltage across the Generator Leads at the Circuit Board while playing 1 KHz tape at full volume

into dummy load, and cranking at normal speed.

3. Playback Head Azimuth Adjustment:

(NOTE. A dot on the Name Plate Label, C120 indicates the location of a hole in the Front Case provided for

the insertion of a small screwdriver to adjust the head alignment screw).

After cleaning and demagnetising playback head, adjust the volume control to maximum and use 6.3KHz

-15dB test tape to adjust the head azimuth. Adjust output to maximum reading and when satisfied place

some contact cement on srew heads to prevent vibration moving them.

(Beware of false harmonic readings) For this reading the oscilloscope is adjusted to the following settings –

Sweep range 100-1K; Vertical gain 1/100. If an oscilloscope is unavailable a multimeter may be used.

4. Motor Speed Adjustment

Use the 1KHz -11dB tape to adjust the speed (1000-1010Hz) on the digital frequency counter, or digital

multimeter with frequency range. The adjustment is made by inserting a small screwdriver through the small

hole in the top of the drive motor and turning the adjusting screw.

5. Output Level Adjustment

Using the 1KHz -11dB tape, check the output level. It should measure about 3.6 volts peak to peak. If

necessary adjust the variable resistor VR2 to achieve the desired output. Too high a level will cause

distortion(clipping of the waveform).

If an oscilloscope is not available use the following procedure.

i.) Using an extension speaker plug and a piece of wire, fit a dummy load of 8.2 ohms across the plug. (See

Fig. 2)

ii.) Attach an AC volt meter with approximately 5-10 volts full scale deflection.

iii.) With a 1KHz -11dB tape at maximum volumethe output should be 1.3 volts RMS. (Equal to 3.6 volts

peak to peak.)

iv.) The same variable resistor adjustment VR2 can be used to obtain the right voltage reading.

6. Current consumption:190-270 mA at 6v.

Using the 1KHz -11dB tape and volume at minimum the current should be approximately 130mA, played

into an 8.2 ohm dummy load plugged into the external speaker socket. With the volume at maximum the

current should be approximately 200mA. If current is excessively high check for free movement of

mechanical parts, especially the capstan flyhweel assembly and the pinch roller.

7.Wow and Flutter: Less than 2% Play 1 KHz tape and listen for clear tone, or observe wave stability on

oscilloscope. Set up the Oscilloscope as for Azimuth Alignment and check stability at the right hand side of

the screen. Variation should not exceed 2% of screen width. Rapid fluctuation usually indicates a bent

capstan, while slower fluctuation (about 1 second duration) would indicate a worn pinch roller or other drive

component.

8.Take up Torque: 35-60 gm/cm Measured with cassette torque meter. Too much torque tends to raise

current consumption of the machine. Low torque can cause tape to wrap around capstan.

TROUBLESHOOTING PROCEDURE

INTRODUCTION

The key to efficient, effective repair is a logical approach to troubleshooting and diagnosing the

fault. The first step in any troubleshooting process is to examine carefully all the symtoms of the

fault. This investigation should guide us to a limited range of possible problem areas in the

machine. At the same time we need to eliminate areas that are functioning correctly. This enables us

to focus attention on a particular part of the machine and should help us to locate and rectify the

fault as quickly as possible.

This first step could be called the “mapping” step since the effect is to map out the problem areas

for further investigation. It is important to do a complete “mapping” of the machine before

proceeding to analyse each of the areas which may have caused the trouble. Premature assessment

of a fault, without logical and thorough investigation, can result in unnecessary removal of parts for

observation, needless replacement of good parts, tampering with adjustments that should be left

alone, and, in general, wasting a lot of valuable time.

The service manual is an essential part of the “troubleshooter’s” equipment. The information

provided in the drawings, circuit diagrams, block diagrams, parts list, etc. will help us to quickly

isolate a fault to a single area of the machine.

The novice or layman in the area of electronic repair should not be overawed by the apparent

complexity of the service manual. The manual has been prepared with the non-expert in mind and

we trust that the instructions given will be clear enough for all to follow. Regular experience in

maintenance and repair of the Messenger-II will soon help the novice to become familiar with the

parts of the machine most likely to give problems. Those who only carry out repairs on odd

occasion s or in emergencies need to take special care and be aware that hasty action or diagnosis of

the problems may lead to a lot more expense and time expended than is really necessary.

TROUBLESHOOTING PROCEDURE

The three major areas of the troubleshooting map that need to be considered when working on a

Messenger-II player are:-

1. The generator assembly

2. The cassette mechanism

3. The amplifier

1. The Generator Assembly

The generator assembly is probably the most straight forward mechanism within the Messenger-II

player, consisting of a drive train of gears and pulleys. However, it is subject to more wear than any

other part of the machine and usually requires a greater amount of maintenance.

2. The Cassette Mechanism

The cassette mechanism can be further broken down into smaller areas, e.g. Motor, keyboard, fast

forward mechanism etc. and each of these can be examined as separate entities. Keep in mind that a

machine takes a source of motion and processes it so as to fulfill some useful purpose. For example,

the motor provides the motion necessary to move the tape within the cassette case. It does this via a

belt, pulleys and wheels. As another example, a finger can be the source of movement. It can be

used to depress a key which then directs the motion from the motor to drive the tape forward, into

rewind, play, or if the stop key is depressed, to halt all tape motion.

3. The Amplifier

When considring the amplifie we also need to take into account the playback head, volume control,

extension speaker socket and speaker. The magnetically encoded signal on the tape produces a very

weak signal in the playback head as it passes over it. This is then amplified for the purpose of

driving the speaker.

SAMPLE PROCEDURE - 1

Symptoms of faulty player. The Messenger-II player will not operate at the correct speed when

powered by its own generator.

Preliminary Diagnosis

At first consideration you cannot help but be equally suspicious of the three main areas -

1. The generator belt may have slackened with age or the generator itself may have failed.

2. The cassette mechanism could have a faulty motor, a jammed pinch roller etc.

3. The amplifier could have a fault which causes it to drain an excess amount of current from the

generator.

You need to eliminate as many areas of the “map” as you can and concentrate on the one area at

fault.

Procedure for investigation

1. Plug in an extenal 6v D.C. Source. If the player now works correctly and does not draw excessive

current, then the generator most likely is at fault. Conversely, if the player still does not work

then the generator is probably not at fault and the fault lies in one of the two other areas.

2. Check the motor by disconnecting it from the circuit board and connecting it to a seperate 6v

D.C. Power supply. If motor and mechanism operate, they are probably not at fault. If motor

speed appears to be slow, investigate current consumption of motor or replace motor.

3. Investigate current consumption of circuit board, or replace circuit board.

By following this type of procedure you are successfully reducing the areas in which you need to

look for the fault and by carrying out tests like these on each of the possible areas of failure you will

be able to locate and identify the offending component.

SAMPLE PROCEDURE - 2

Symptoms of Faulty Player: No sound.

Preliminary Diagnosis

The fault is probably in the amplifier but, before proceding to investigate this, do the following

quick checks :-

1. Check the cassette tape. Is it broken, jammed, or simply stopped at its end?

2. Check the cassette mechanism. In play mode is the mechanism working correctly and pulling the

tape across the playback head?

If both of the above checks show that the cassette and mechanism are satisfactory we can then

move on to investigate the amplifier chain. Note that there are 3 main sections of this:-

a) The speaker and extension speaker socket.

b) The amplifier section of circuit board.

c) The playback head.

(refer also to block diagram, fig. 5, p.4)

Procedure for Investigation

1. Plug an extension speaker into the extension speaker socket. This effectively by-passes the player’s own

speaker and introduces a new one. If the extension speaker works, then either the speaker in the player is

faulty, or else there is possibly a fault in the switch which is located within the extension speaker socket

or a broken wire.

2. If Procedure 1 produces no result, move on to the amplifier board. First, check this visually to see if there

are any obvious broken or loose connections. These should be resoldered. If no sound results, place

finger on both connections of the lead from the head where it 3 joins the circuit board and turn volume

up. If no noise is heard the circuit board is possibly at fault and should be replaced.

3. If Procedure 2 produces noise, proceed to check the playback head and its connections. Use a mutimeter

to check the wires from the head to the amplifier board. if the connections are satisfactory the head

should be replaced.

Messenger-II PLAYER PARTS LIST

HOW TO ORDER PARTS

1.INTRODUCTION

a. SERIAL NUMBER: Example of a serial No. 09-89 M DCEC 00022

The serial number, as found both inside and outside the player, is composed of three main parts.

i. Date of manufacture ’09-89' Letter- ‘M’ Designates what generator type is used, and whether

A.C. power supply is included, e.g. M= Mabuchi, MP= Mabuchi with A.C. Power.

ii. Batch Letters - These designate the revision batches of the main assemblies in the machine.

These are essential for supply of correct repalcement parts. They are stamped on each assembly as

indicated on the parts drawings and are listed in the serial number in the following order Case Assembly - Generator Assembly - Mechanism Assembly - Circuit Board Assembly.

iii. Machine No. - Identifies the particular machine.

e.g. Model Letters Batch Letters Machine No.

M D C E C 00022

b.PARTS NUMBERS: Example of a Part No. 5G217

These consist of i. A prefix letter ’5G’ which indicates which assembly the part is from, and thereby on which

drawing it is shown.

ii. A single digit numeral to indicate major part revisions or alternative types. These are listed

underneath each other in the parts list, and must be determined when ordering parts. An ‘x’

indicates alternative types of the part, and that appropriate type no. must be selected from the parts

list when ordering. (The ‘5’ is a computer prefix)

e.g. Gx17 refers to G117 or G217 in parts list.

iii. A two digit numeral to identify the particular part in the assembly.

Assembly Letter Type No. Part No.

e.g. Part No. B104 B 1 04

2. HOW TO ORDER PARTS.

Please identify the part from Parts Drawings, and write both its Part No. (including appropriate

type), and Name plus Quantity.

Also, please include complete Serial Number/s of the player/s for which the parts are required. If the

parts are for spares for a a quantity of players, then the most common Model Letters and Batch

Letters would be sufficient.

Sample Order

QUANTITY PART NO. NAME SERIAL NO.

5 05-G104 Gen. Belt MP-DCEC-01548

If possible, please try to explain what is the fault in worn parts and what may have caused them to

fail. Also describe the symptoms of the fault and the in-service age of the player. This will greatly

help us to develop a better player for the mutual benefit of all users of these players.

MESSENGER-II DISASSEMBLY AND SERVICING

Please refer to Drg. M-02

To Open Case (See also drg. M-03)

a) Unscrew the Crank arm Assembly G150 by raising the handle and turning it anticlockwise (opposite

direction to the arrow). This may require a sharp tap on the winding arm to begin the unwinding.

b) Remove 5 screws (4 Case Screws C114 and one Handle Screw C115) in back of case. Carefully pull the

two halves fo the case apart while keeping them parallel to each other. There may be some resistance at

first, until the Crank Shaft G109 is pulled through the Upper Crank Bearing C106, but pull the halves

apart carefully as the generator wires may be broken. It is now possible to unplug socket connector G141

on Mabuchi player without power, and socket connector p112 on Mabuchi player with power, from the

circuit board and so separate the two halves of the player case. Note: Be careful not to pull on the wires.

Grasp the socket connector between thumb and forefinger from above and gently ease out with the help

of a small screw driver.

2.To Remove Mechanism 05-M200 and Circuit Board Assemblies.

( See also drg. M-03, M-05)

a) Buttons (keys) M102, M103, M104, M105 must be in OFF position.

b) Desolder the two wires from the Speaker C103, and unplug PIN connector.

c) Unscrew the Spacer Post C112, Motor Plate Screw S12 and the Mechanism Screw C116 located near the

Clutch Assembly on the mechanism, then lift the mechanism from the Front Case C101.

3. Circuit Board Assembly B600. (See also Drg. M-97)

a. To Remove and Disassemle

i. Remove Circuit Board Screw M106 and Washer M107. Loosen the Side Plate Screws M108 and then

move the assembly sideways from the mechanism.

ii. If the circuit board is to be replaced, desolder all wires from the circuit board, noting their colour and

position on the board. Remove the two D.C. Socket Screws S02 and the Dress Ring B207 from the

External speaker Socket B206 and them remove the Side Plate B208. Remove the Volume Control Screw

S01 and Wheel B202.

b. To Reassemble and Replace

i. Replace Volume Control Wheel B202 and Screw S01

ii. Attach Side Plate B208 with Screws S02 and Dress Ring B207.

iii. Position the Circuit Board Assembly correctly on the mechanism, by pushing the slots of the Side Plate

firmly against the Side Plate Screws M108 before tightening them. Then replace Circuit Board Screw

M106 and Washer M107.

4. Servicing the Mechanism M100 (See also drg. M-05)

a) With the mechanism removed from the case, all pars of it are easily accessible for adjustment and

replacement of parts.

Loading...

Loading...