Global Manufacturing Quiet Thunder QT2-40X, Quiet Thunder QT2-80X, Quiet Thunder QT2-130X, Quiet Thunder QT2-100X Operating Instructions Manual

Global Manufacturing, Inc

®

1801 East 22nd St

Little Rock, AR 72206

501.374.7416 TEL

501.376.7147 FAX

800.551.3569 FREE USA & CANADA

GlobalManufacturing.com

®

QT2-80-130X_01/04/18

Copyright © 2018 Global Manufacturing, Inc.

Operating

Instructions

Models

Single Phase

115 Volt - 60 Hertz

QT2-40X

QT2-80X

QT2-100X

QT2-130X

VIBRATORS

Global Manufacturing, Inc ® 800.551.3569

Toll Free USA & Canada

1801 East 22nd St 501.374.7416

Tel

501.376.7147

Fax

Little Rock, AR 72206 USA www.GlobalManufacturing.com

2

• Follow wiring and installation wiring instructions.

• A licensed electrician should adhere to all electrical codes when wiring three phase

and direct wired single phase vibrators.

• Take amperage and voltage readings upon completion of installation. See page 9 for

run and start amp draws for each vibrator and page 21 for more information on

voltage drops.

• High amperage reading means something is wrong and the vibrator may be damaged

or not mounted properly. Do not operate a vibrator that pulls high amps.

• For single-phase, use properly grounded 3-prong receptacle and do not use an

extension cord without knowing the voltage drop in order to use the correct gauge

size. See page 21 for instructions on how to calculate what size of extension cord

you should use.

• Make sure all electrical connections are secure and will not vibrate loose.

• Follow all mounting instructions.

• Boltvibratortoaatsurface,acrossalongverticallyorientedchannelironushto

the outside of the hopper wall.

• Contact factory if you are unable to closely follow all installation instructions or if

amperage readings are high.

• Attach a safety cable or chain from vibrator to an independent stronghold.

• Prior to use, check vibrator for damage (twisted unit, cracked junction box, loose

wires, missing end covers, etc.) Do not operate a damaged vibrator.

• Maximumambientoperatingtemperatureis104˚F(40˚C).

• Do not mount electrical control boxes onto structure (bin/hopper) wall to be vibrated.

• Do not operate vibrators when structure is empty.

• Do not operate vibrators when gate is closed or conveyor is stopped unless

consolidation of material is desired.

• Wear ear protection for 90+ decibel levels.

• Do not operate vibrators without side covers.

• Always disconnect electricity before maintenance.

• Follow OSHA regulation Section 1910.145 for lockout program.

SAFETY PRECAUTIONS

Global Manufacturing, Inc ® 800.551.3569

Toll Free USA & Canada

1801 East 22nd St 501.374.7416

Tel

501.376.7147

Fax

Little Rock, AR 72206 USA www.GlobalManufacturing.com

3

OPERATION

These electric vibrators are built for

continuous duty, however the vibrators

may be cycled on and off for intermittent

duty. The minimum time between

consecutive starts is two (2) minutes.

Each time the vibrator starts it draws high

amperage, therefore allow vibrator to cool

or run for two minutes before starting

again.

Do not operate the vibrator on an empty

hopper. The vibration will vibrate the

hopper and the vibrator causing damage

if no bulk material is present. When the

vibrator is mounted rigidly the vibration will

pass through the structure and resonate

the material inside the hopper.

Operate vibrators when discharge gates

are open unless compaction of material

is d esired . The vibrator should appear

motionless.

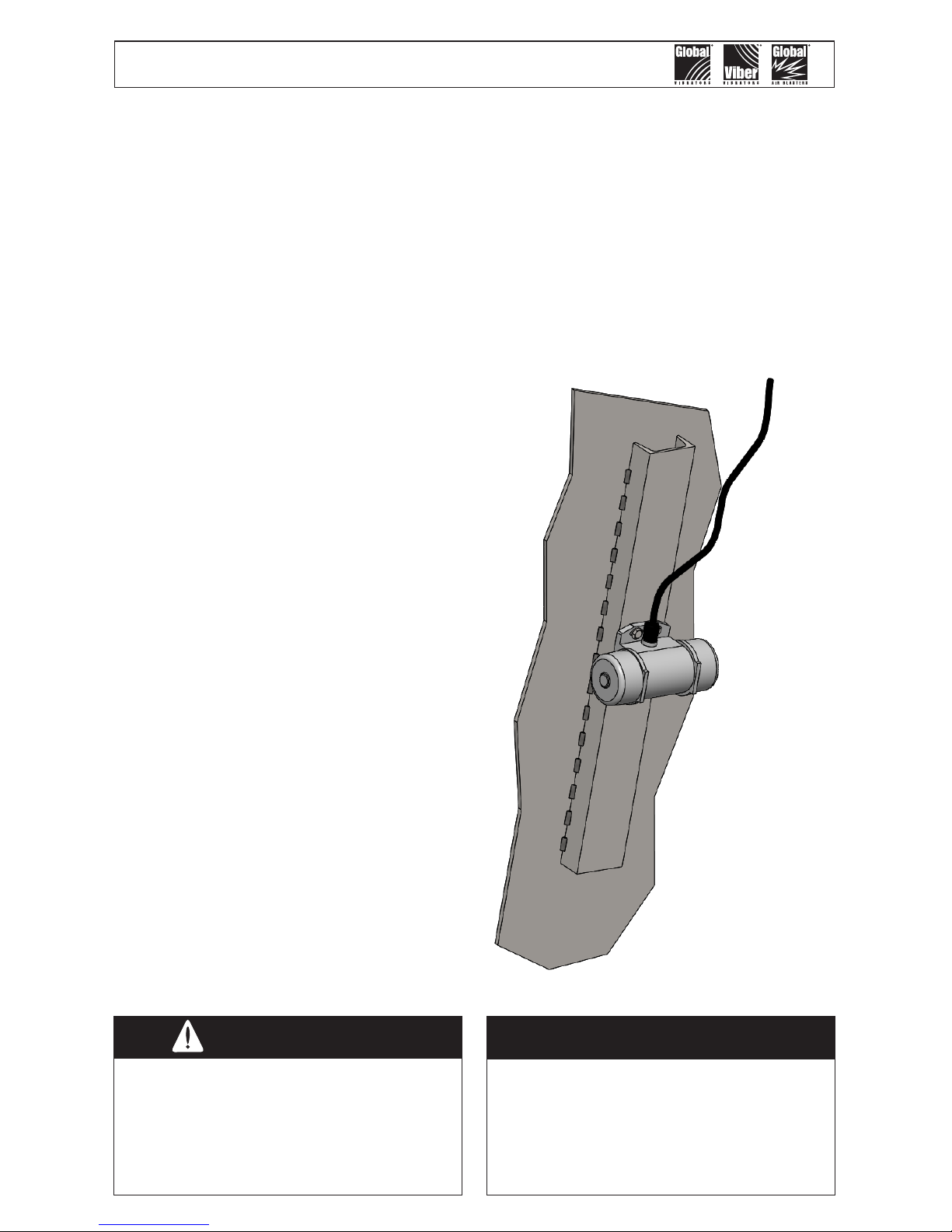

INSTALLATION

The key to successful vibration is the proper

installation of the vibrator.

The axis of rotation of the eccentric

weights, which are found on the end(s) of

the motor shaft, should rotate toward the

desireddirectionofmaterialow.Inhopper

applications, the weights should rotate

towards the bin wall and down. The shaft of

the vibrator should ideally be in a horizontal

position to prolong bearing life.

Guidelines for the mounting industrial

vibrators:

QT2-40X, QT2-80X, QT2-100X, QT2-130X

Single Phase models: Mount vibrator with

the power cord facing upwards.

Do not mount the vibrator directly

to the structure wall. Use a channel

iron stiffener for proper mount

rigidity and as the transducer of

the vibrational energy.

Caution!

The key to successful vibration is a proper

mount because rotary vibration resonates

the material inside the structure. The

vibrator should appear motionless. There

should not be a large amount of motion

or noise. Follow the instructions on how to

mount the vibrator and you will get great

results.

Important!

The channel iron should be at least

two-thirds of the height of the

sloped portion of the hopper but

no greater than 10 feet (3 m).

Models

Single Phase

115 Volt - 60 Hertz

QT2-40X

QT2-80X

QT2-100X

QT2-130X

Global Manufacturing, Inc ® 800.551.3569

Toll Free USA & Canada

1801 East 22nd St 501.374.7416

Tel

501.376.7147

Fax

Little Rock, AR 72206 USA www.GlobalManufacturing.com

4

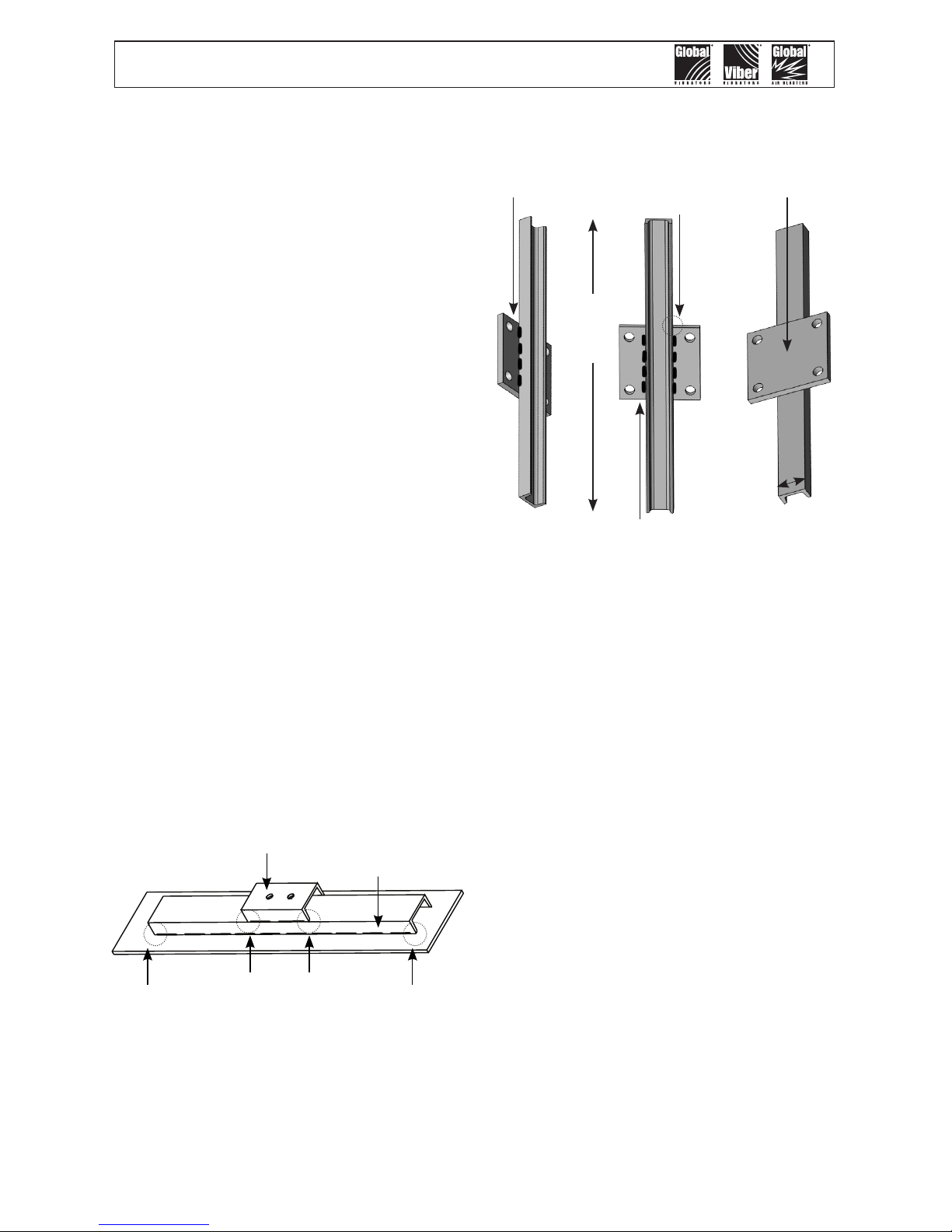

Channel Irons - How to Mount

The channel iron should be at least two-

thirds the height of the sloped portion of

the hopper, but not less than 6' (1.8 m)

or greater than 10' (3 m) in length. The

channel iron width should not be less than

the base width of the vibrator. However,

a mount plate of 3/4" (19.05 mm) thick,

sizedtotthefootpatternofthevibrator,

may be skip welded to the channel. 3/4"

plate thickness prevents warpage when

welding plate to channel. The mount plate

must allow the vibrator to sit FLAT on

the plate with no detectable rocking.

If the vibrator does not sit at, the plate

may be warped. Shim the vibrator prior to

mounting to compensate for any warping.

See Table on page 8 for recommended

channel iron and mount plate sizes.

DO NOT install more than one vibrator on

the same channel iron or use a channel

iron shorter than the recommended length.

Ashortchannelmayexthebinwall.

Attach the vibrator to the channel iron.

Stitch weld nuts to the back of the channel

iron or the channel iron may be drilled and

tapped to accept the mounting bolts. An

alternate method is to cut a second channel

iron slightly longer than the footprint of the

vibrator. Stitch weld the second channel

iron to the rst. Do not weld the ends.

Mount the vibrator to the second channel

iron.

Stitch weld the channel iron vertically

to the slope portion of the bin wall.

Weld 3 inches (7.5 cm), skip 1 inch (2.5

cm), weld 3 inches (7.5 cm), etc... Leave

1 inch (2.5 cm) un-welded on the ends

and corners. This allows the vibration to

dissipate out the ends of channel without

causing stress cracks to the hopper or bin.

By doing so, should the weld fail, the entire

mount will not fall off. Do not mount the

channel iron horizontally.

Secure the vibrator to the channel

iron using the 4 slotted holes with SAE

coarse thread ¼"-20 grade 8 plated

bolts with lock washers or an adhesive

such as Loctite

®

262. If the four round

holes are used for mounting use 10-24

grade 2 plated bolts with lock washers or

an adhesive such as Loctite® 262. A wider

channel iron is also needed with this bolt

pattern or use a mount plate as illustrated

above.Tighten bolts in a sequential process.

At least two passes are required in most

situations. Give all bolts the same torque

value. If Loctite

®

is not used, torque the

bolt after the vibrator has operated for a

few minutes and check tightness often.

If Loctite® is used do not torque the bolts a

second time as this will break the Loctite

®

bond.

Channel Iron with Mount Plate

Channel Iron with Piggy-back Channel

Place vibrator

on top of

mount plate

Skip weld

along back

side of plate

Weld along the length of the

channel on back side of plate.

Do not weld across the width

of channel.

Length

of

Channel

Width of

Channel

Do not weld

the ends

of plate to

channel

Do not weld the ends of the channel iron.

This allows the vibrational force to “escape”.

Solid welded ends trap the force, which

can cause stress cracks.

Piggy-back

channel

Stitch weld

channel iron

Attach a safety cable to a stronghold (not

the channel iron mount), which is higher

than the mounted vibrator and capable of

holding the vibrator’s weight.

Loading...

Loading...