Global Manufacturing Ball Vibrators, BS-13, BS-16, BS-19, BS-10 Operating Instructions Manual

...

AIR BLASTERSVIBRATORSVIBRATORS

Ball Vibrators

Models

Operating Instructions

Pneumatic Ball Vibrators

BS-10 US-13

BS-13 US-19

BS-16 US-25

BS-19 US-38

BS-25

CS-19 DS-41

CS-25 DS-51

CS-35

CS

GlobalManufacturing.com

BV_07/14/14 - rev 2 - email version Copyright © 2014 by Global Manufacturing, Inc

DS

BS

Global Manufacturing Inc.

1801 East 22nd St

Little Rock, Arkansas 72206

501.374.7416 TEL

800.551.3569 TOLL FREE USA & CANADA

501.376.7147 FAX

®

US

Global Manufacturing, Inc ® 800.551.3569 TOLL FREE USA & CANADA

1801 East 22nd Street 501.374.7416 TEL 501.376.7147 FAX

Little Rock, AR 72206 USA www.GlobalManufacturing.com

A I R B L A STER SVIBRA T O R SVIBRA T O R S

Table of Contents Page

I. Introduction 2

II. Operation - Air Requirements 2

III. Installation Procedures 3 - 4

I V. Channel Irons - Size and Mounting 3

V. Mounting Locations 3 - 4

VI. Performance Data and Troubleshooting 5

VII. Dimensions 6

I. Introduction

For optimum performance, cycle the vibrator on and off. The vibrator acts as a friction reducer and once the bulk

solid is set into motion, gravity should do the rest. Do not operate the vibrator on an empty hopper as this may cause

structural damage to the hopper.

Vibrators should be operated only when discharge gates are open. Operating the vibrator with the discharge gate

closed will cause the material inside the structure to compact.

Vibration has two important elements – Frequency and Amplitude. Frequency is the speed (RPM) or the number of

vibrations per minute. It is controlled by the oil ow to a hydraulic vibrator or the air ow to a pneumatic vibrator.

Amplitude is the unbalance or amount of force produced by the eccentric weight. The faster the eccentric weights

turn the more force output generated. Force and frequency work together. It is not necessary to use a lot of force

when you adequate frequency.

SAFETY PRECAUTIONS

• Follow all installation instructions.

• Always use a safety cable or chain for support.

• Do not operate vibrators when structure is empty.

• Wear ear protection for 90+ decibel levels.

• Do not operate vibrator if there is a restriction to the exhaust port.

• Do not operate the pneumatic vibrators above 100 psi.

• Always operate pneumatic vibrator with a lter - regulator.

• Always disconnect air line before maintenance.

II. Operation - Air Requirements

Operate on ltered, regulated air between 20 and 80 PSI (1.36 to 5.44 Bar). An air regulator may be used to control

the vibrator speed. Adjust airow until material ow occurs. More air is not always better. Operating the vibrator at

higher pressures will reduce vibrator life.

Cycle the vibrator on and off. Ball vibrators can run continuously, but it is usually not necessary. Once the material

is set into motion, gravity should do the rest. Do not operate the vibrator on an empty hopper.

The vibrator should appear motionless. Vibrators should NOT shake the hopper wall or make an abundance of noise.

Vibrations pass through the structure and into the material.

Do NOT lubricate the ball vibrator. Lubrication is NOT required. Lubrication will collect dirt, impairing proper vibrator

operation.

2

Global Manufacturing, Inc ® 800.551.3569 TOLL FREE USA & CANADA

1801 East 22nd Street 501.374.7416 TEL 501.376.7147 FAX

Little Rock, AR 72206 USA www.GlobalManufacturing.com

A I R B L A STER SVIBRA T O R SVIBRA T O R S

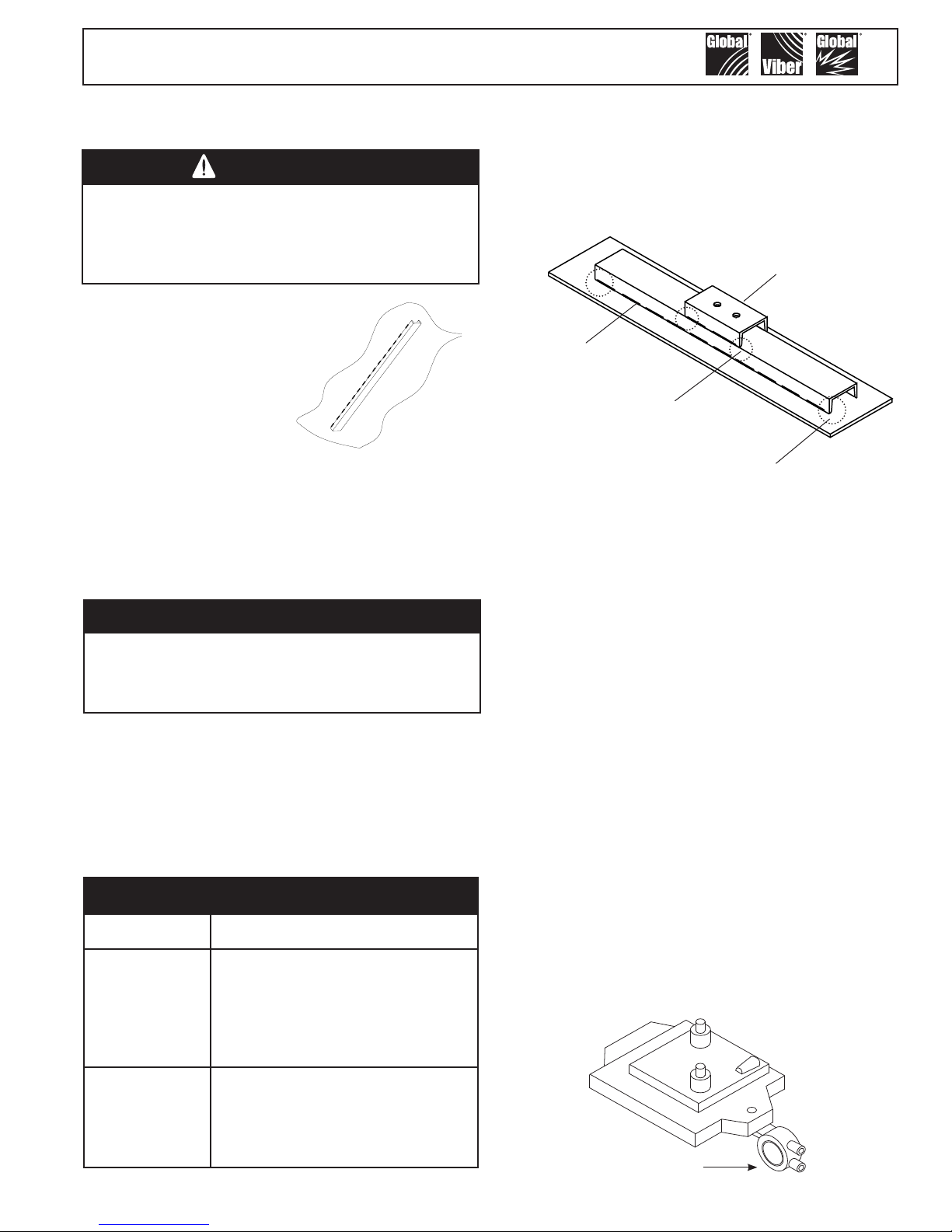

III. Installation Procedures

Caution!

Do not mount the vibrator directly to the

structure wall. Use a channel iron stiffener

for proper mount rigidity and as the

transducer of the vibrational energy.

The key to successful

vibration is a proper mount

because rotary vibration

resonates the material

inside the structure, when

the vibrator is mounted

correctly. The vibrator

should appear motionless. There should not be

a large amount of motion

or noise.

Stitch Weld the

Channel Iron

IV. Channel Irons - Size & Mounting

Important!

The channel iron should be at least 2/3

of the height of the sloped portion of the

hopper but no greater than 6 feet (1.83 m).

The channel iron should be at least two-thirds the height

of the sloped portion of the hopper, but not be greater

than 6 feet (1.83 m) in length. The channel iron width

should not be less than the base width of the vibrator.

See chart below for recommended channel sizes. DO

NOT install more than one vibrator on the same channel

iron or use a channel iron shorter than the recommended

length. A short channel may ex the bin wall.

Channel Iron Size Recommendation

Vibrator Channel Iron Size

Attach the vibrator to the channel iron. Stitch weld

nuts to the back of the channel iron or the channel iron

may be drilled and tapped to accept the mounting bolts.

An alternate method is to cut a second channel iron

slightly longer than the footprint of the vibrator. Stitch

weld the second channel iron to the rst. Do not weld

the ends. Mount the vibrator to the second channel iron.

Piggy-back

channel

Stitch weld

channel iron

Do not weld the ends of the channel

iron - this allows the vibrational force

to “escape”. Solid welded ends trap

the force which can cause stress

cracks.

Stitch weld the channel iron vertically to the sloped

portion of the bin wall. Weld 3 inches (7.5 cm), skip

1 inch (2.5 cm), weld 3 inches (7.5 cm), etc... Leave 1

inch (2.5 cm) un-welded on the ends and corners. This

allows the vibration to dissipate out the ends of channel

without causing stress cracks to the hopper or bin. By

doing so, should the weld fail, the entire mount will not

fall off. Do not mount the channel iron horizontally.

Secure the vibrator to the channel iron with SAE

coarse thread grade 8 plated bolts with lock

washers or an adhesive such as Loctite

Tighten bolts in a sequential process. At least two passes

are required in most situations. Give all bolts the same

torque value. Grade 8 bolts can handle more torque than

standard bolts. If Loctite

after the vibrator has operated for a few minutes and

check tightness often. If Loctite

the bolts as this will break the Loctite® bond.

Attach a safety cable to a stronghold (not the channel

iron mount), which is higher than the mounted vibrator

and capable of holding the vibrator’s weight.

®

is not used, retorque the bolt

®

is used do not retorque

®

262.

V. Mounting Guidelines

BS-10

BS-13

BS-16

BS-19

BS-25

CS-25

CS-35

DS-41

DS-51

CS-19

US-13

US-19 2" X 1" X 3/16" X 2.5 lb/ft

US-25

US-38

3" X 1.41" X .170" X 4.1 lb/ft

Installation on Foundry Molds - The BS model

vibrator may be used on foundry matchplate molds. Bolt

the vibrator to the matchplate as shown.

BS-10 Ball Vibrator

3

Global Manufacturing, Inc ® 800.551.3569 TOLL FREE USA & CANADA

H

1/3 of H

2/3 of H

1/3 of H

2/3 of H

H

3/4 of H

1/4 of H

1/2 of H

1801 East 22nd Street 501.374.7416 TEL 501.376.7147 FAX

Little Rock, AR 72206 USA www.GlobalManufacturing.com

A I R B L A STER SVIBRA T O R SVIBRA T O R S

Single Vibrator

Install a channel iron stiffener on the outside of the

sloping wall 1/3 the distance above the discharge

opening.

Multiple Vibrators

Use more than one vibrator when the diameter or width

of any wall is greater than 12 feet (3.66 m). Always

mount the vibrators on different planes.

Two Vibrators on Round or Square Hoppers

Install channel iron stiffeners 180° apart. Install one

vibrator on the outside of the sloping wall 1/3 the

distance above the discharge opening. Install the second

vibrator on the outside of the opposite sloping wall 2/3

the distance above the discharge opening.

Two Vibrators on Rectangular Hoppers

Install channel iron stiffeners on opposite sides of

the long walls. Install one vibrator on the outside of

the sloping wall 1/3 the distance from the discharge

opening. Install the second vibrator on the outside of

the opposite sloping wall 2/3 the distance above the

discharge opening. When only one wall slopes, mount

both stiffeners on it. Equally space the stiffeners on the

wall. Place one vibrator 1/3 above the discharge opening

on one channel iron and the other vibrator 2/3 above the

bin’s discharge opening on the second channel.

H

2/3 of H

1/3 of H

2/3 of H

2/3 of H

Thr ee Vibrators on Round or Square Hoppers

Install channel iron stiffeners mounted 120° apart.

Install the rst vibrator on the outside of the sloping wall

1/4 the distance above the discharge opening. Install

the second vibrator on a separate channel iron at 1/2

the distance above the discharge opening. Install the

third vibrator on the remaining channel iron at 3/4 the

distance above the discharge opening.

Installation on Chutes and Flow Pipes

Mount channel iron stiffeners vertically or in the direction

of material ow. Center the channel if the chute is less

than 6 feet (1.83 m) in width. If the chute is greater than

6 feet in width, use two vibrators on separate channel

irons. To maximize each vibrator’s radius of inuence;

center each channel iron in each half of the chute. Each

channel iron should be located ¼ of the chute width from

the edge and ½ of the chute width apart. (e.g. – for a

chute 8’ wide, the channel iron locations would be 2’

from each edge and 4’ apart.) When wall thickness is

less than 1/8”, additional reinforcement may be required.

Width is more than 6’

¼ of Width

½ of Width

¼ of Width

4

Global Manufacturing, Inc ® 800.551.3569 TOLL FREE USA & CANADA

1801 East 22nd Street 501.374.7416 TEL 501.376.7147 FAX

Little Rock, AR 72206 USA www.GlobalManufacturing.com

VI. Performance Data and Troubleshooting

Ball Vibrator Performance Data

Vibrator

Model

BS-10

BS-16

BS-19

BS-25

US-13

US-19

US-25

US-38

CS-19

CS-25

CS-35

DS-41

DS-51

Unbalance

lb-in psi psi

kg-mm bar bar lpm N lpm N lpm N lpm N

0.003 5 2

0.392 0.3 0.1

0.020 15 7

2.30 1.0 0.5

0.043 20 10

4.95 1.4 0.7

0.120 30 15

13.8 2.1 1.0

0.009 5 2

1.07 0.3 0.1

0.043 20 10

4.95 1.4 0.7

0.120 30 15

13.8 2.1 1.0

0.520 50 25

59.9 3.4 1.7

0.043 20 10

4.95 1.4 0.7

0.120 30 15

13.8 2.1 1.0

0.240 50 25

27.7 3.4 1.7

0.820 55 25

94.5 3.8 1.7

1.300 60 30

149.8 4.1 2.1

Start Minimum 20 psi (1.4 bar) 40 psi (2.8 bar) 60 psi (4.1 bar) 80 psi (5.5 bar)

VERT HORZ SPEED FLOW FORCE SPEED FLOW FORCE SPEED FLOW FORCE SPEED FLOW FORCE

rpm

16,000

9,400

8,600

5,700

13,000

8,700

6,300

4,300

9,100

6,300

5,300

3,200

3,100

cfm lb

4.3 25

122 111 198 169 255 200 306

4.1 50

116 222 181 414 232 489 283

5.5 89

156 396 238 667 311 890 388

7.5 110

212 489 340 712 453 1023 561

6.5 45

184 200 311 374 425 489 538

5.5 92

156 409 238 712 340 934 453

7.0 140

198 623 340 1068 453 1246 566

12.0 270

340 1201 538 2091 708 2402 878

5.7 100

161 445 238 756 340 979 445

7.8 130

221 578 368 979 510 1290 631

7.8 190

221 845 368 1379 453 1735 538

13.0 240

368 1068 595 1646 765 2002 954

13.0 350

368 1557 566 2580

rpm

20,000

13,000

11,000

6,900

18,000

11,000

8,400

5,600

12,000

8,100

6,700

4,000

4,000

Air Pressure

cfm lb

7.0 38

6.4 93

8.4 150

12.0 160

11.0 84

8.4 160

12.0 240

19.0 470

8.4 170

13.0 220

13.0 310

21.0 370

20.0 580

rpm

22,000

14,000

13,000

8,200

20,000

13,000

9,100

6,000

14,000

9,200

7,600

4,400

4,300

A I R B L A STER SVIBRA T O R SVIBRA T O R S

cfm lb

9.0 45

8.2 110

11.0 200

16.0 230

15.0 110

12.0 210

16.0 280

25.0 540

12.0 220

18.0 290

16.0 390

27.0 450

27.0 680

765 3025 954

rpm

22,800

14,800

14,800

9,600

22,400

15,000

9,600

6,200

17,000

10,000

8,100

4,700

4,400

cfm lb

10.8

10.0

13.7

19.8

19.0

16.0

20.0

31.0

15.7

22.3

19.0

33.7

33.7

50

223

124

553

267

1190

314

1397

133

589

275

1222

314

1397

568

2525

353

1570

341

1516

447

1989

514

2288

715

3179

Problem Probable Cause Solution

Air line is blocked, restricted, or is connected to

the exhaust port and not to the inlet port.

Vibrator

runs

slowly or

does not

operate

Pipe or hose size is inadequate for distance from

compressor.

Contamination is in the vibrator. Disassemble vibrator and clean.

Faulty control valve.

Inadequate air supply to operate vibrator.

Mounting is not rigid.

Vibrator

makes

excessive

noise

Mufer not used. Use exhaust mufer.

Hopper or bin is empty. Do not run vibrator on an empty hopper or bin.

Ball and/or raceway rings may be worn out. Rebuild vibrator with repair kit.

Troubleshooting

Remove restriction in the air line. Check for kinked air

line. Check hose connections.

The air line should be at least equal to vibrator inlet

port.

Clean, repair, or replace.

Start valve should be within 6’ of vibrator.

Check compressor. Provide more volume of air to

vibrator.

Check mounting bolts, broken welds, or fatigue in

structure.

5

Global Manufacturing, Inc ® 800.551.3569 TOLL FREE USA & CANADA

BS Models

CS Models

DS Models

B

US Models

1801 East 22nd Street 501.374.7416 TEL 501.376.7147 FAX

Little Rock, AR 72206 USA www.GlobalManufacturing.com

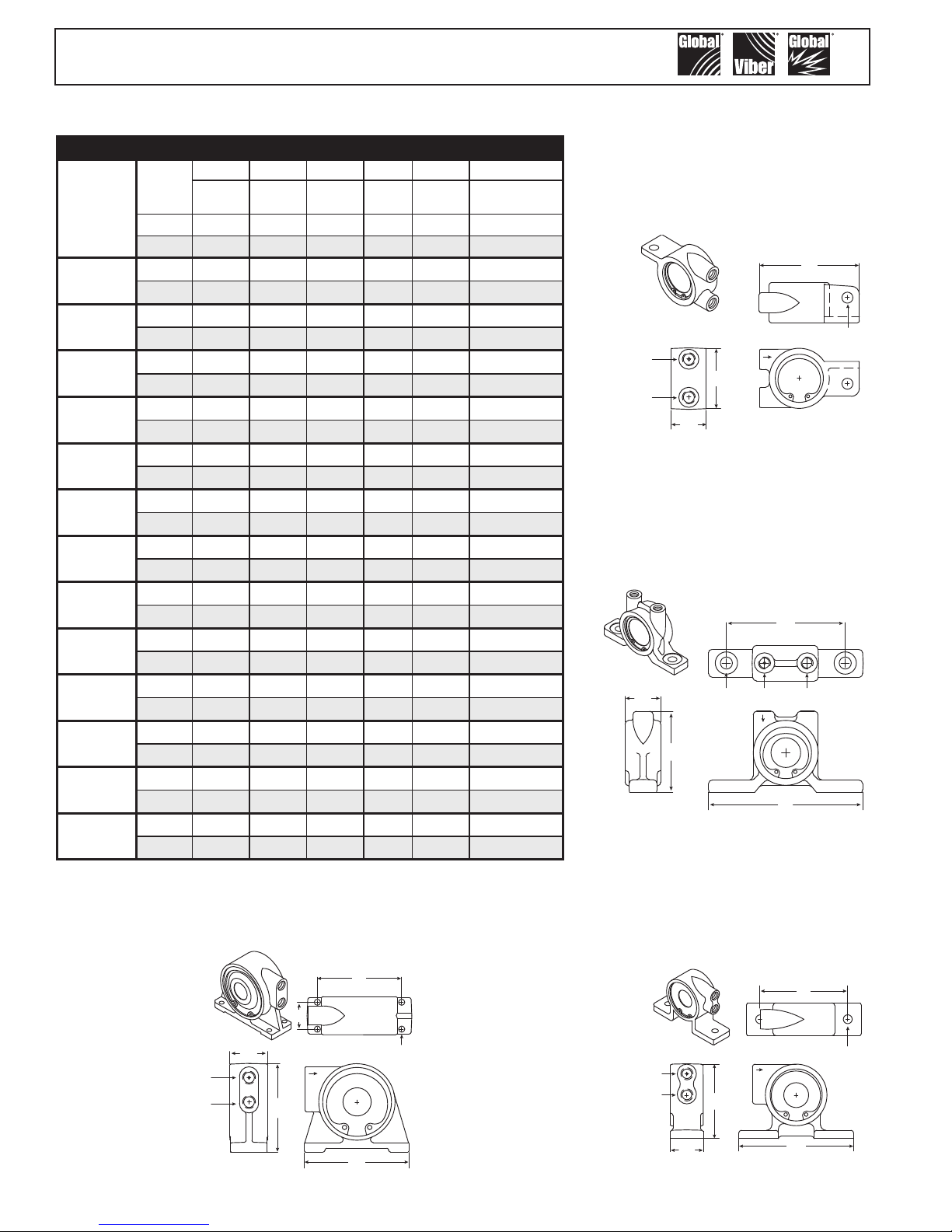

VII. Ball Vibrator Dimensions

Ball Vibrator Dimensions

A B C D E F

VIBRATOR

MODEL

BS-10

BS-16

BS-19

BS-25

US-13

US-19

US-25

US-38

CS-19

CS-25

CS-35

DS-41

DS-51

WEIGHT

0.70 1.90 3.10 1.10 1/8 0.34 Single Bolt

0.32 48 79 28 9

1.40 2.50 4.00 1.30 1/4 0.44 Single Bolt

0.64 64 102 33 11

1.90 2.80 4.50 1.50 1/4 0.44 Single Bolt

0.86 71 114 38 11

3.10 3.20 5.20 1.80 1/4 0.44 Single Bolt

1.41 81 132 46 11

1.20 2.70 5.20 1.20 1/8 0.34 4.00

0.54 69 132 30 9 102

2.20 3.40 5.10 1.50 1/4 0.44 4.00

1.00 86 130 38 11 102

3.50 3.90 6.60 1.80 1/4 0.44 5.00

1.59 99 168 46 11 127

7.60 5.40 7.90 2.30 3/8 0.56 6.00

3.45 137 201 58 14 152

2.40 3.40 5.30 1.50 1/4 0.44 4.00

1.09 86 135 38 11 102

4.30 4.40 5.40 2.10 1/4 0.53 4.00

1.95 112 137 53 13 102

4.60 4.40 5.40 2.10 1/4 0.53 4.00

2.09 112 137 53 13 102

10.40 5.70 6.80 2.50 1/2 0.41 5.50 X 1.80

4.72 145 173 64 10 140 X 45

10.80 5.70 6.80 2.50 1/2 0.41 5.50 X 1.80

4.90 145 173 64 10 140 X 45

HEIGHT LENGTH WIDTH INLET

lb in lb lb in in in

kg mm mm mm NPT mm mm

BOLT

HOLE

BOLT

CENTERS

A I R B L A STER SVIBRA T O R SVIBRA T O R S

BS Series - Have a single

bolt hole mounting base.

B

D

A

exhaust

C

US Series - Air travels in

a “U” pattern.

F

C

E

exhaust

D

A

CS Series - Air travels in a

“C” pattern.

E

DS Series - These models have a four bolt

mounting base.

F

C

D

exhaust

6

A

F

F

E

E

D

exhaust

B

A

C

B

Loading...

Loading...