Page 1

1

25.4CC

COMPACT CHAINSAW

PCH25

INSTRUCTION MANUAL

Black

Cyan

Magenta

Yellow

Code: PCH25

Date: 080318 Edition: 11 Op: DJ

Page 2

2

Contents

Warranty Power Tools

Whilst every effort is made to ensure your complete

satisfaction with this tool, occasionally, due to the mass

manufacturing techniques, a tool may not live up to our

required level of performance and you may need the

assistance of our service department.

This product is warranted for a 2-year period for home

domestic use from the date of the original purchase.

If found to be defective in materials or workmanship,

the tool or the offending faulty component will be repaired

or replaced free of charge with another of the same item.

A

small freight charge may apply. Proof of purchase is

essential. We reserve the right to reject any claim where

the purchase cannot be verified.

This warranty does not include damage or defects to the

tool caused by or resulting from abuse, accidents,

alterations or commercial or business use. It also does not

cover any bonus items or included accessories. Only the

power tool is covered under this warranty.

With continuing product development, changes may have

occurred which render the product received slightly

different to that shown in this instruction manual.

Please ensure that you store your receipt in a safe place.

Conditions apply to the above warranty. For full details of

the warranty terms and conditions please refer to our

website – www.gmcompany.com

For prompt service we suggest you log your service

request online - www.gmcservice.com.au, should you

not have access to the internet, please contact our

service department on 1300 880 001 (Australia)

or 0800 445 721 (New Zealand).

Warranty 2

Description of symbols 3

Symbols on the machine 4

Specifications 4

General safety instructions 5

Additional safety rules for petrol chainsaws 6

Unpacking 7

Contents of carton 7

Know your product 8

Installing the guide bar and chain 9

Filling up with fuel and oil 10

Starting the chainsaw 11

Stopping the chainsaw 12

Checking the oil supply 12

Adjusting the carburettor 12

Chain brake 12

Bucking spikes 12

Operation 13

Helpful hints 13

Guard against kickback 13

Felling a tree 13

Limbing 14

Bucking 14

Pruning 14

Maintenance 14

Page 3

3

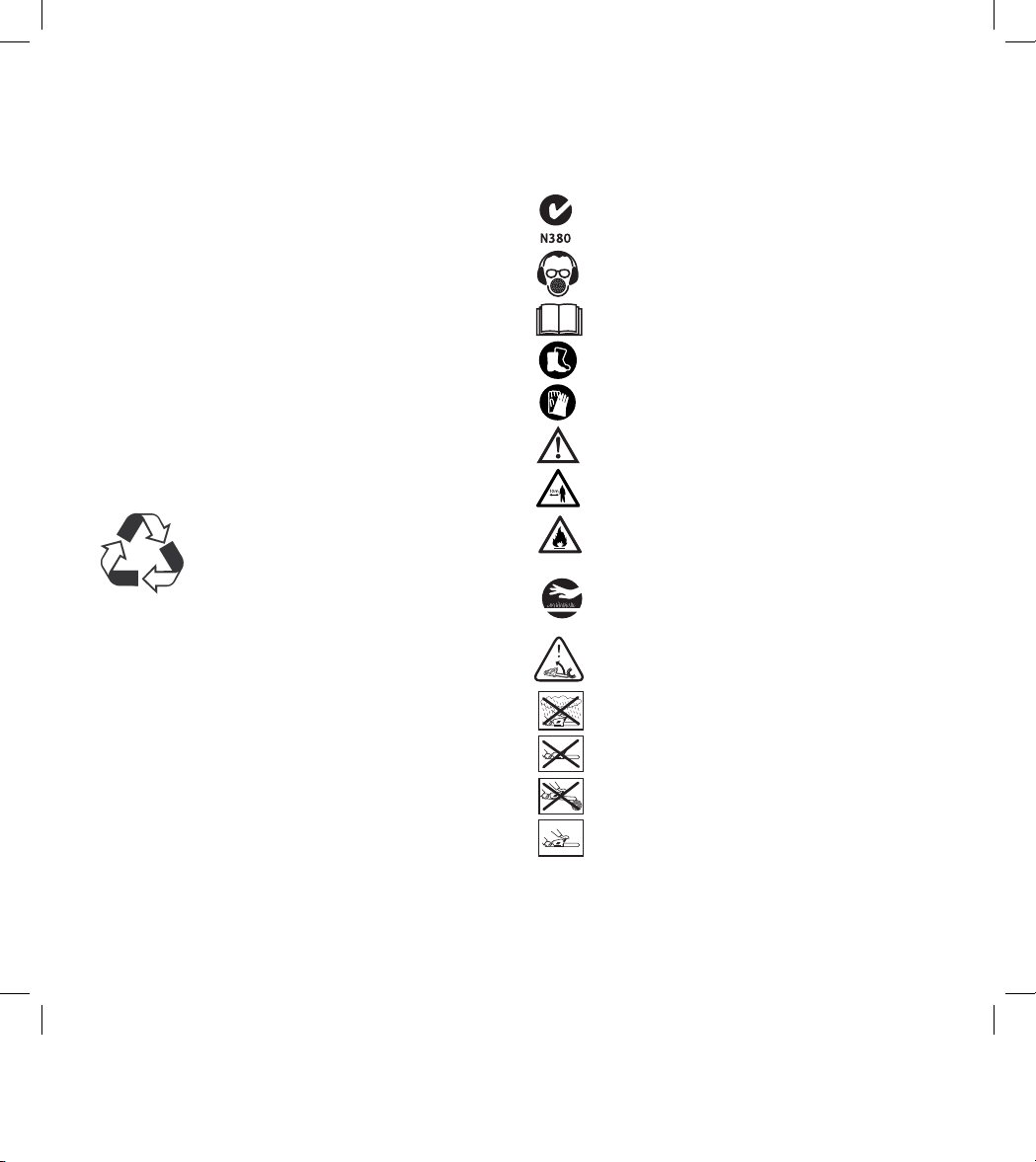

Description of symbols

The rating plate on your tool may show symbols.

These represent important information about the

product or instructions on its use.

Conforms to relevant safety standards.

Wear hearing protection.

Wear eye protection.

Wear head protection.

Read these instructions for use carefully.

Wear safety footwear.

Wear safety gloves.

Warning.

Use at a distance of at least 10m

from other people.

Explosive material.

Extremely hot surface. Do not touch a hot muffler,

gear box or cylinder, you may get burned. These

parts get extremely hot from operation and remain

hot for a short time after the unit is turned off.

WARNING! Danger of kickback.

Do not operate unit in the rain.

Do not attempt to hold saw with one hand.

Do not use the point of the bar.

Hold saw properly with both hands.

Introduction

Your new GMC power tool will more than satisfy

your expectations. It has been manufactured under

stringent GMC Quality Standards to meet superior

performance criteria.

You will find your new tool easy and safe to operate,

and, with proper care, it will give you many years

of dependable service.

CAUTION. Carefully read through this entire Instruction

Manual before using your new GMC Power Tool. Take

special care to heed the Cautions and Warnings.

Your GMC power tool has many features that will make

your job faster and easier. Safety, performance, and

dependability have been given top priority in the

development of this tool, making it easy to maintain

and operate.

Environmental protection

Recycle unwanted materials instead

of disposing of them as waste. All tools,

hoses and packaging should be sorted,

taken to the local recycling centre and

disposed of in an environmentally safe way

.

Page 4

4

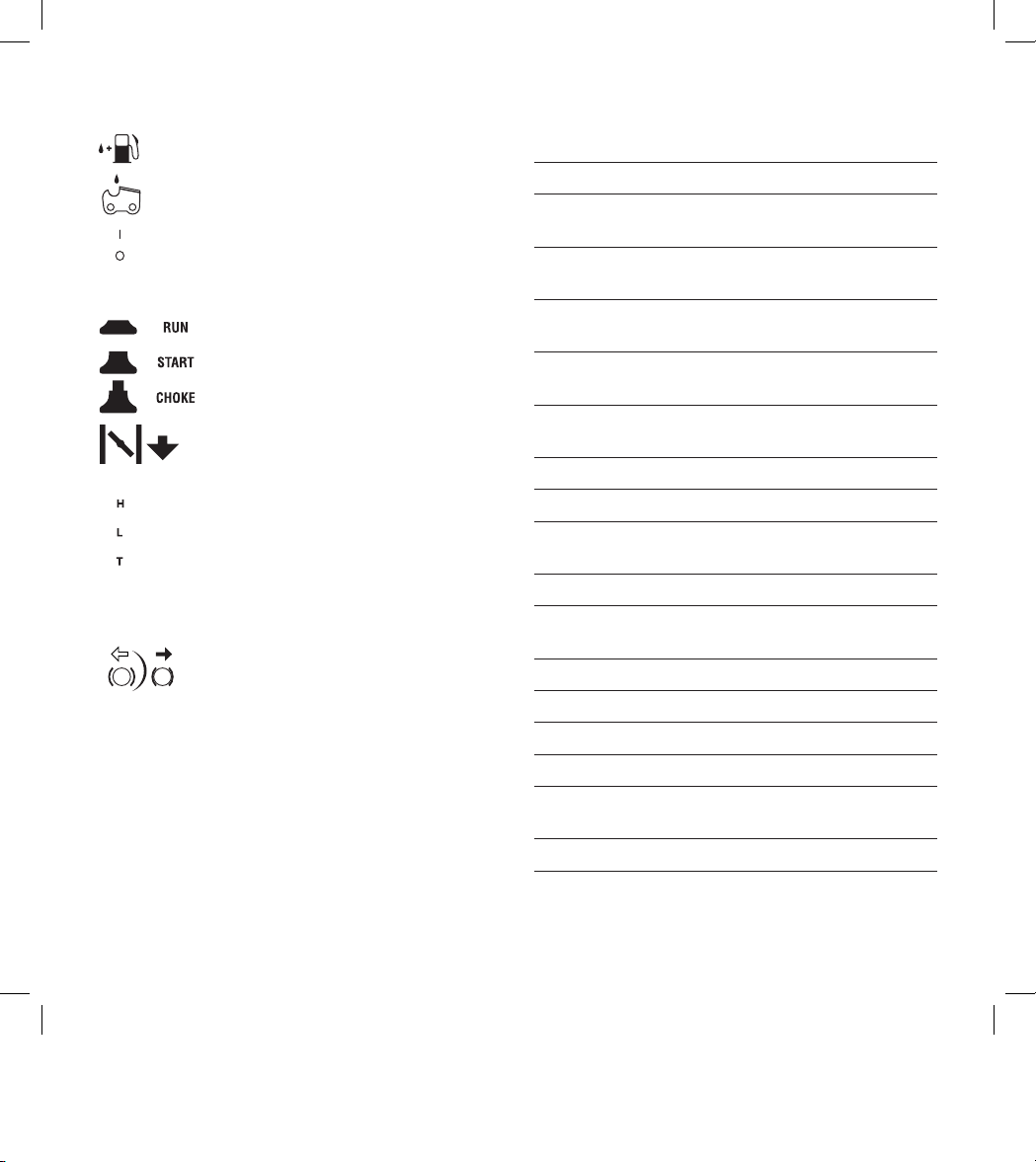

Symbols on the machine

Fuel inlet.

(Position: under the fuel tank cap.)

Chain oil inlet.

(Position: next to the oil tank cap.)

On/Off.

(Position: on the on/off switch.)

Setting the on/off switch to Off, stops the engine

immediately.

Run position.

Start position (when engine is warm.)

Start position (when engine is cold.)

Choke control

(Position: next to knob on the filter cover)

High run adjustment screw.

Low run adjustment screw.

Idle adjustment screw.

(Position: left side of machine close to

pull start handle.)

Chain brake released (hollow arrow) and

activated (solid arrow.) (Position: right side

of machine, on chain drive cover.)

Specifications

Engine displacement: 25.4cc

Maximum engine power: 900W

Engine type: Air cooled, single

cylinder, two-stroke cycle

Recommended maximum

engine speed at idling: 3200min

-1

Maximum engine speed

with cutting attachment: 11000min

-1

Fuel type: Unleaded petrol/

2-stroke oil (35:1)

1 Litre of unleaded petrol: 28.5ml of oil

5 Litre of unleaded petrol: 145ml of oil

Fuel tank capacity: 230ml

Oil tank capacity: 160ml

Spark plug: LD L8RTF NGK BM6A

Champion CJ8

Oil feeding system: Automatic pump

Sprocket wheel: 6–teeth x 9.53mm

(3/8”) pitch

Guide bar type: Sprocket nose

Chain bar length: 305mm (12”)

Chain type: Chinese Chain

Chain pitch: 9.53mm (3/8”)

Weight (including

guide bar and chain): 3.85kg

Sound pressure level: 110 dB(A)

Page 5

5

General safety instructions

WARNING. Read and understand all instructions.

Failure to follow all instructions listed below may result

in fire and/or serious injury.

Save these instructions

1) Work area

a) Keep work area clean and well lit. Cluttered and dark

areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases, or dust. Power tools create sparks which

may ignite the dust or fumes.

c) Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

2) Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under the

influence of drugs, alcohol, or medication. A moment

of inattention while operating power tools may result in

serious personal injury.

b) Use safety equipment. Always wear eye protection.

Safety equipment such as a dust mask, non-skid

safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Remove any adjusting key or wrench before turning

the tool on. A wrench or a key that is left attached to

a rotating part of the power tool may result in personal

injury.

d) Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power tool

in unexpected situations.

e) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away from

moving parts. Loose clothes, jewellery or long hair can be

caught in moving parts.

f) If devices are provided for the connection of dust

extraction and collection facilities ensure that these

are connected and properly used. Use of these

devices can reduce dust-related hazards.

3) Power tool use and care

a) Do not force the power tool. Use the correct power

tool for your application. The correct power tool will

do the job better and safer at the rate for which it was

designed.

b) Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

c) Turn tool off completely before making any

adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the risk

of starting the power tool accidentally.

d) Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained

users.

e) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc.,

In accordance with these instructions and in the

manner intended for the particular type of power

tool, taking into account the working conditions

and the work to be performed. Use of the power tool

for operations different from intended could result in a

hazardous situation.

Page 6

6

4) Service

a) Have your power tool serviced by a qualified repair

personnel using only identical replacement parts.

This will ensure that the safety of the power tool is

maintained.

Additional safety rules for petrol chainsaws

Note. For safety reasons the chainsaw is shipped with the

chain brake fully engaged. This brake must be released

before the saw becomes operational.

• Never cut into the ground.

• Never cut into wire fences.

• Never cut into samplings.

• Never cut into prepared wood.

• Use the chainsaw to cut only wood.

• It is advisable to provide a support for the chainsaw

when cutting branches. Do not cut using the bar point

and beware of branches under tension.

• Children under 18 must not use chainsaws.

• Keep people away from the chainsaw when in use.

• Check the following conditions before beginning work:

– There should be no people in the felling area.

– Make sure there is a second person within

calling distance.

– The working area should be free from obstacles.

• Wear suitable clothes which do not hinder movement.

• Use specific protection during operations involving head,

hands, feet, eyes and ears.

• It is recommended the use of a helmet with a visor during

felling, branch cutting and chopping operations.

• Wear gloves with an external protection when using the

chainsaw.

• Use ear protection to prevent hearing injuries.

• Wear safety boots when using the chainsaw.

• During transport the brake must be applied to avoid

accidental start-up.

• Do not use the chainsaw in rainy or windy conditions or in

poor light.

• Find a suitable position before beginning work.

• When working on slopes, the saw operator must stand

beside or above the wood to cut, i.e. felled trees.

• Use the chainsaw holding it firmly with both hands.

• Make a wedge-shaped cut before felling the tree, then

the felling cut leaving a hinge for the felling direction.

• Beware of any falling branches after felling operations.

• Beware of wood splinters when cutting chopped wood.

• Ensure your chainsaw is suitable for the job.

• Never work above shoulder level or reach out to cut a

branch: ensure you have stable footing at all times.

• Do not operate in a hazardous location. Such areas

include where there is a risk of explosion of petrol fumes,

leaking gas or explosive dust.

• Do not operate in a confined area. Exhaust gases, smoke

or fumes could reach dangerous concentrations.

• Protect your tool. This chainsaw is NOT WEATHERPROOF

and should not be exposed to direct sunlight, high

ambient temperature and damp, wet or high humidity

conditions.

• Take care not to spill fuel. When refuelling the chainsaw

ensure that the motor has been switched off. Prevent the

spilling of fuel as this may also ignite with the hot motor.

Never refuel whilst the engine running.

• Be careful where you store the chainsaw. Store the tool in

a dry area away from flammable liquids.

• Keep your distance. The chainsaw emits exhaust fumes.

Ensure bystanders keep a safe distance.

• Operating instructions and instructions for common

cutting tasks, including the use of personal protection

equipment, the need for adequate training and the risks

involved when operating the unit while tired, ill or under

the influence of alcohol or other drugs.

Page 7

7

• Ensure you use oil-mix fuel. Ensure that you mix 35 parts

unleaded fuel to 1 part 2-stroke oil. If not, the engine will

overheat and cause damage to your chainsaw.

• Never fill fuel tank indoors. Never fill fuel tank when

engine is running or hot. Do not smoke when filling

fuel tank.

Kickback safety precautions

• Kickback may occur when the tip of the guide bar

touches an object, or when the wood closes in and

pinches the saw chain.

• If the bar tip or point contacts, it can produce a rapid

reverse reaction, kicking the guide bar up and back

towards the operator. This is known as rotational

kickback.

• Pinching the saw chain along the top of the guide

bar may push the guide bar rapidly back towards the

operator. This is known as pinch kickback.

• Either of these reactions can cause loss of control of the

saw, resulting in serious personal injury.

• Do not rely exclusively on the safety devices built into

your saw. Take the following steps to help avoid accident

or injury:

• Reduce the element of surprise by understanding what

causes kickback.

• Keep a firm grip on the chainsaw using both hands, the

right hand on the rear handle and the left hand on the

front handle when the motor is running. A firm grip will help

maintain control. Do not let go whilst the motor is running.

• Make sure that the area of operation is free of

obstructions. Do not let the point of the guide bar contact

a log, branch or any other object.

• Use high speeds when cutting.

• Do not overreach or cut above shoulder height.

• Carefully follow the sharpening and maintenance

instructions given in this manual.

• Use only replacement bars and chains specified by the

manufacturer.

DANGER!

BEWARE OF KICKBACK!

WARNING! Kickback can lead to dangerous loss of control

of the chainsaw and result in serious or fatal injury to the

saw operator or to anyone standing close by. Always be

alert. Rotational kickback and pinch kickback are major

chainsaw operational dangers and the leading cause of

most accidents.

Unpacking

Due to modern mass production techniques, it is unlikely

that your GMC Power Tool is faulty or that a part is missing.

If you find anything wrong, do not operate the tool until the

parts have been replaced or the fault has been rectified.

Failure to do so could result in serious personal injury.

Contents of carton

The GMC Petrol Chainsaw is supplied with the following

accessories as standard.

• Chain

• Guide bar

• Double ended wrench

• Screwdriver

Page 8

8

Know your product

1. Guide bar

2. Chain

3. Chain tensioning screw

4. Chain drive cover

5. Chain drive cover nut

6. Bucking spikes

7. Air filter

8. Front guard (chain brake)

9. Top handle

10. Filter cover

11. Filter cover knob

12. Rear handle

13. Recoil starter

14. Idling adjustment screw

15. HIGH (Fast) run adjustment screw

16. LOW (Slow) run adjustment screw

17. Choke control

18. On/Off switch

19. Trigger switch

20. Lock off switch

21. Chain catcher

22. Oil tank cap

23. Fuel tank cap

24. Drive sprocket wheel

25. Spacer (for shipping

purposes only,

please dispose of)

26. Chain tensioner pin

27. Double ended wrench

28. Screwdriver

29. Priming bulb

9 8

4 5

21

1 2

7

16

15

14

27

28

22 23

1920

3

12

6

2524

26

18

17

10

11

13

29

Page 9

9

Installing the guide bar and chain

WARNING. The chain has sharp

edges. Use work gloves for safety.

IMPORTANT. Front guard (chain

brake) must be disengaged when

installing the guide bar and chain.

1. Pull the front guard (8) towards

the rear of the saw until there

is a “click” to make sure that

the chain brake is released.

2. Remove the chain drive cover nut (5) with the double

ended wrench (27) and remove the chain drive cover (4).

3. Once the chain drive cover (4) has been removed, the

transport- protecting spacer (25) must be removed and

disposed of so that the chain bar can be positively located.

4. Fully loosen the chain tensioning screw (3).

5. Place the guide bar (1) in position over the threaded

stud with the chain tensioning pin (26), in the hole in the

guide bar.

6. Place the chain (2) around the

drive sprocket wheel (24) with

the chain links in the direction

shown on the bar and fit the

chain around the guide bar.

7. Fit the chain drive cover and

fasten the nut (5), finger tight.

8. Tighten the chain tensioner

screw (3) until the links of the

chain just touch the bottom

edge of the guide bar.

9. Tighten drive nut.

Page 10

10

10.

Check that the chain can be

smoothly pulled around the

guide bar by hand and that

it maintains contact with the

guide bar, top and bottom.

To check tension, rotate the

chain to its tightest condition

then suspend a 0.9kg weight from the chain at the mid

point of the underside of the bar. The maximum distance

between the driving links and the bar should be 6.5mm.

Note. Ensure the engine is switched off when making any

adjustments to the chain and bar.

CAUTION. A new chain will stretch after just a few minutes

of use. Check and, if necessary, re-adjust the chain tension.

A loose chain causes rapid wear to both the chain and the

guide bar and could derail causing a major safety hazard.

Filling up with fuel and oil

WARNINGS. Petrol is very flammable. Avoid smoking or

causing any sparks or flames near fuel. Make sure that

you stop the motor and allow it to cool before refuelling the

machine. Select outdoor bare ground for fuelling and move at

least 3m away from the fuelling point before starting the motor.

• Only use oil that is expressly labelled for use with air-

cooled 2-stroke engines. DO NOT use BIA or TCW

(2-stroke water-cooling type) mixed oil.

The recommended mixing ratio is PETROL 35: OIL 1

• Use unleaded petrol with a minimum Octane number of

89. If you use petrol with an Octane number lower than 89,

there is a danger that the engine might overheat and the

piston seize.

• Poor quality petrol or oil may damage sealing rings, fuel

lines or the fuel tank. Do not use wasted or regenerated

oil, it can damage the oil pump.

CAUTION. To maximise the lifetime of the engine, avoid the

following:

• Do not use raw petrol, it will severely damage the engine

very quickly.

• Do not run the tank dry, as this will cause damage to

the engine.

• Do not use oil meant for 4-stroke engines, it will cause spark

plug fouling, exhaust blocking and piston ring sticking.

• Do not use fuel mixtures that have been left standing for one

month or more, they can cause clogging of the carburettor.

Before storing the chainsaw for an extended period,

empty the fuel tank, clean it then run the motor to empty

the carburettor.

Note. Do not discard an unwanted fuel container with

household waste. It must be taken to an authorised

repository site.

Mixing fuel (35:1 mixing ratio)

1. Measure out the quantities of petrol and oil to be mixed.

2. Put some of the petrol into a clean, approved fuel container.

3. Pour in all of the oil and mix well.

4. Pour in the rest of the petrol and again mix well (at least

one minute).

5. It is very important to mix the two ingredients properly to

prevent unnecessary engine wear.

6. Make sure that the container

is clearly labelled that it is

2-stroke mixture.

Fuelling the chainsaw

1. The engine must be stopped

and cool. Place the chainsaw

on its side with the fuel tank

cap facing upwards.

2. Make sure that the fuel

mixture is well mixed.

3. Remove the fuel tank cap (23).

4. Fill the fuel tank to about 80%

of its capacity.

5. Fasten the fuel cap securely

and wipe up any fuel spillage

around the machine.

Page 11

11

Note: 1 Litre of unleaded fuel: 28.5ml of oil.

5 Litre of unleaded fuel: 145ml of oil

Adding chain oil

WARNING. Never start work

unless the chain and bar are

lubricated.

1. Place the chainsaw on its

side with the oil cap facing up.

Untwist and remove the oil

tank cap (22).

2. Fill the tank to 80% capacity

with chain oil.

3. Fasten the cap and wipe up

any oil spillage.

Starting the chainsaw

WARNING. Do not start the motor whilst the saw hangs

from one hand. This is very dangerous as the chain may

come in contact with your body.

1. Fill the fuel and oil tanks

respectively and tighten the

caps securely.

2. Set the on/off switch (18) to

On (the I position). Make sure

the brake is ON when starting

for safety, by pushing the front

guard forward.

3. When the machine is cold first

pull out the choke control (18)

to the CHOKE position. (Fully

withdrawn).

Note. Once the choke control

has been pulled out, it cannot be

pushed back to the run position.

4. Depress the priming bulb (29)

6 times or when the bulb is full

of fuel.

Note. This is not required if

engine is warm or is being

restarted.

It returns automatically when the

trigger switch is operated.

5. Hold the chainsaw securely on

the ground and pull vigorously

on the recoil starter (13).

Repeat (at least 15 times) until

the engine “kicks” (attempts

to start).

6.

With the lock off switch (20)

held depressed slightly pull on

the trigger switch (19) and then

release it. The choke control will

click back one position.

7. Pull the recoil starter (13)

again and restart the engine.

Allow the engine to warm up.

8. When the engine is warm first

depress the lock off switch

then pull fully on the trigger

switch for a short burst. The choke control will fully retract

to the RUN position, your chainsaw is now ready for use.

9. When restarting the engine when it is still warm, set the

choke control to the START

position. Hold the chainsaw

securely on the ground and

pull vigorously on the recoil starter (13). Allow the

engine to run for a few moments with the trigger switch

pulled slightly.

10. When the engine is fully

warm, pull on the trigger

switch. The choke control will

fully retract to the RUN position.

Page 12

12

11. When ready to start cutting, release the brake, by

pulling the front guard back.

Stopping the chainsaw

1. Release the trigger switch.

2. Set the on/off switch (18) to

Off (the O position).

Checking the oil supply

Run the engine at medium

speed and check that the chain

splatters a thin line of oil which

can be seen on the ground when

the bar is pointed downwards.

This is normal. If there is no

line of chain oil, stop the motor

immediately and investigate the

cause. The oil tank could be

empty or the oil supply to the

chain blocked. This may require

removal of the bar and checking

that the upper oil hole in the bar

is clear of any blockages.

Adjusting the carburettor

The carburettor is factory set and

should not require adjustment.

Changes in operating conditions

may require fine tuning of the

carburettor. Proceed as follows.

1. Stop the engine and screw in

both the H and L needles (15)

using screwdriver (28). Do not

force.

2. Turn the H screw (15) back 3/4 of a turn.

3. Turn the L screw (16) back 1-1/2 turns.

4. Start the engine and let it warm up with the trigger switch

half pulled in. When the engine is warm, release the

trigger switch.

5. Turn the L screw (17) slowly clockwise until the idling

speed is at its maximum then turn the screw back

(anticlockwise) 1/4 of a turn.

6. Turn the idling adjusting screw (T) (14) anticlockwise until

the chain does not turn.

7. If the idling speed is too slow, turn screw (T) clockwise.

8. Make a test cut and adjust screw (15) for best cutting

power, not for maximum speed.

Chain brake

The chain brake operates automatically in the event of

kickback. As the guide bar (1) kicks up, the wrist of the

operator’s hand on the top handle knocks against the front

guard (8) causing the front guard to move forward and

activating the chain brake.

1. The chain brake can be

operated manually by moving

the front guard forward.

2. To release the chain brake,

pull the front guard towards

the top handle until a “click”

is heard.

CAUTION. Check that the chain

brake is operating correctly each time the chainsaw is used.

Bucking spikes

The Chainsaw has bucking

spikes (6) to assist with cutting

and reduce the chance of

kickback, use them as follows:

T

L

H

Page 13

13

Operation

WARNINGS.

• Always follow the safety instructions given at the front

of this manual. This chainsaw must only be used for

cutting wood. It must not be used for cutting other types

of material. Do not use the chainsaw as a lever for lifting,

moving or splitting objects.

• Do not attach the chainsaw to a fixed stand.

• Do not attach any devices to the chainsaw other than

those specified by the manufacturer.

Helpful hints

• Do not force the saw into the cut. Apply only light pressure

whilst running the engine at full throttle.

• If the saw chain gets caught in the cut, do not try to

remove it by twisting the guide or pulling forcibly. Use a

lever or wedge to open up the cut so that the saw chain

is freed.

While cutting, always:

• Run the chainsaw motor at full revs. This makes the job

safer, as there is less chance of pull-in or kick-back.

• Position your body to the left of the chainsaw so if it kicks

back uncontrollably, it goes over your right shoulder,

never stand in the cutting line of the saw.

• Keep a firm grip with your left hand on the front handle,

with your thumb securely below the handle.

• The swivel of your wrist in a kick-back situation will

activate the chain brake.

• Make sure the chain is tensioned correctly.

Guard against kickback

Check the operation of the chain brake each time you use

the chainsaw.

Run the saw at full throttle for 1-2 seconds then push the

front guard (8) forwards. The chain should stop immediately.

If the chain is slow to stop or only slows down you must

take the tool to an authorised repair centre to have the

brake band and clutch drum replaced. Disengage the chain

brake by pulling the front guard backwards until you hear

a click. Do not use the chainsaw if the chain brake is not

operating correctly.

• Be constantly aware of the position of the upper quadrant

of the blade tip. This is the part that triggers a kickback

when it hits resistance.

• Never engage the upper quadrant of the guide bar with

whatever you are cutting and avoid contact with any

hidden branches or obstructions. Ensure there is a clear

work area.

• Always clear away brush, vegetation and any obstructing

debris before attempting a cut that might trigger a

kickback.

• Avoid cuts that will cause the chainsaw to jam in a tree

trunk or limb.

• Observe the size of wood shavings, if they become dusty

your chain could need sharpening.

Felling a tree

WARNING. Felling a tree should only be done by

trained operators.

Decide the direction in which

you wish the tree to fall taking

into account the direction

of the wind, the position of

branches, lean of the tree,

ease of subsequent limbing

and bucking and other factors

prevalent at the time.

1. Clear the area around the tree and make sure that you

have a good foothold and clear retreat path.

2. Ensure that others in the area are aware of the felling

and ensure people and animals are well clear.

3. Make a notch cut one-third of the way into the tree on the

felling side.

1

2

1

2

1

2

1

2

Page 14

14

4. Make the felling cut on the opposite side to the initial

notch and slightly higher than the notch. As the felling cut

gets close to the notch cut, the tree will begin to fall.

5. Remove the saw from the cut, stop the engine with the

on/off switch (18), put the saw down and leave the area

along the retreat path.

Limbing

Limbing is the process of

removing the branches from

a fallen tree.

Check the direction in which a branch will bend before

cutting it. Always cut on the opposite side to the bending

direction so that the guide bar is not pinched in the cut.

For large limbs that cannot be removed in one cut, make

an initial cut from the bent side and finish by sawing from

the opposite direction. Do not remove limbs that are

supporting the fallen tree on the ground until the tree has

been cut into lengths.

WARNINGS. Always keep a balanced stance. Do not stand

on the log. Be alert to the fact that the log may roll over.

When working on a slope, always stand on the uphill side

of the log.

Bucking

Bucking is cutting a log into

lengths for easier handling.

To saw a log lying on the ground,

first saw halfway, then roll the log

over and cut from the opposite

side. To saw the end of a log

supported off the ground, first

saw up from the bottom one-third through the log then finish

by sawing down from the top. To saw a log in the middle of

two supports holding it off the ground, first saw down from

the top one-third through the log then finish by sawing up

from the bottom.

CAUTION. Avoid cutting into the ground as this will very

quickly dull the saw chain.

Pruning

Pruning is the removal of a limb

or branch from a standing tree.

WARNINGS. Do not use an

unstable foothold or ladder. Do

not overreach. Do not saw above

shoulder height. Always use both

hands to hold the saw.

First cut up from the bottom and finish down from the top.

Maintenance

Note. Before cleaning your chainsaw or carrying out any

maintenance procedure, make sure that the engine is off

and is cool. Disconnect the spark plug to prevent

accidental starting.

Maintenance to be preformed after each use

1. Loosen the filter cover knob (11) and remove the filter

cover (10).

2. Remove the air filter (7).

3. Split the air filter into its two

halves and clean the mesh.

Dry particles can be removed

by tapping on a hard surface.

More stubborn dirt may

require washing out the filter

with petrol or using an air

compressor.

4. Re-assemble the two halves

and replace the airfilter, filter

cover (10) and knob (11).

5. Take off the guide bar (1)

and maintain it as follows,

remove any sawdust from the

groove in the guide bar.

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

Page 15

15

6. Make sure that the oil port is

not clogged. Grease the nose

sprocket at the tip of the

guide bar.

7. Check for fuel and oil leakage

and loose fastenings,

especially those securing the

handles and the guide bar. If

any defects are found, take

the tool to an authorised

repair centre.

8. Clean any dust away from the cooling vents as clogged

vents can cause overheating.

Chain sharpening

Sharpen the chain regularly to maintain optimum

performance of the saw. Signs of a dull chain are:

• The sawdust becomes powder-like

• Extra force is required to execute a cut

• The cut does not track in a straight line

• Increased vibration

• Increased fuel consumption

WARNING. Wear heavy

gloves when handling the chain.

Hold the guide bar (1) securely

in a vice.

Sharpen each cutter using a

chain file. Always use outward

strokes.

After sharpening, the cutters

must all have the same width and length. After every 3-4

times use an authourised repair centre to professionally

sharpen your saw chain. They have the special tools

necessary to ensure the correct cutting angles and depths.

Guide bar wear

Reverse the guide bar every 8 working hours to ensure

uniform wear. Check the bar rails frequently and if

necessary remove burs and square-up the rails using

a flat file.

Page 16

16

GMC customer assist

If your product needs repairing, replacing,

technical service or you simply need help or advice,

please contact us on our Customer Assist Line

1300 880 001 (Australia) or 0800 445 721 (New Zealand).

For prompt service we suggest you log your service request

online at www.gmcservice.com.au. Should you not have

access to the Internet, please contact our service department

on 1300 880 001 (Australia) or 0800 445 721 (New Zealand).

7am –7pm, 7days a week (AEST).

Please note that if repair or replacement is required,

you must provide a valid original purchase receipt.

You will need the following details at hand to log your service request;

Personal details: First & Last name, address, pick up address,

c

ontact phone numbers, email address

Product details: Product number, date of purchase, retailer bought from,

State & postcode, receipt number,

reason for the request,

c

opy of official purchase receipt

Attach your purchase receipt and save with this Manual for future reference

.

Please refer to our website www.gmcompany.com for full GMC warranty Terms and Conditions.

Loading...

Loading...