Page 1

1

2HP/1600W

32LT

DUAL TANK

COMPRESSOR

WITH REMOVABLE TANK

DTC32L

INSTRUCTION MANUAL

Black

Cyan

Magenta

Yellow

Code: DTC32L IM

Date: 070705 Edition: 05 Op: GM

When filter becomes

dirty or oily, clean or

replace filter. Refer to

instruction manual.

Do not switch on

for the first time

without first

filling with oil.

To prevent build-up of

condensation, open

drain cock daily

Read instruction manual

prior to starting unit.

This equipment

operates from

AC mains only.

Unit starts

automatically.

Switch off power supply,

remove plug & relieve

air pressure prior to

commencing service

tasks.

DTC32L Air Compressor

Tank capacity:

32 litres

Pump displacement:

206 l/m

Free air delivery:

114 l/m

Max. working pressure:

0.8 MPa

Check the oil level before starting the

compressor every time.

Make sure the compressor is on a level

surface prior to checking the oil level.

The oil level is required to be at the

red dot on the oil level sight glass

prior to use.

Use only oil grade specified in the

instruction manual.

Page 2

2

Contents

Warranty Power Tools

Whilst every effort is made to ensure your complete

satisfaction with this tool, occasionally, due to the mass

manufacturing techniques, a tool may not live up to our

required level of performance and you may need the

assistance of our service department.

This product is warranted for a 2-year period for home

domestic use from the date of the original purchase.

If found to be defective in materials or workmanship,

the tool or the offending faulty component will be repaired

or replaced free of charge with another of the same item.

A

small freight charge may apply. Proof of purchase is

essential. We reserve the right to reject any claim where

the purchase cannot be verified.

This warranty does not include damage or defects to the

tool caused by or resulting from abuse, accidents,

alterations or commercial or business use. It also does not

cover any bonus items or included accessories. Only the

power tool is covered under this warranty.

With continuing product development, changes may have

occurred which render the product received slightly

different to that shown in this instruction manual.

Please ensure that you store your receipt in a safe place.

Conditions apply to the above warranty. For full details of

the warranty terms and conditions please refer to our

website – www.gmcompany.com

For prompt service we suggest you log your service

request online - www.gmcservice.com.au, should you

not have access to the internet, please contact our

service department on 1300 880 001 (Australia)

or 0800 445 721 (New Zealand).

Warranty 2

Warning labels explained 3

Introduction 4

Environmental protection 4

Description of symbols 4

Specifications 4

General safety instructions 5

Additional safety rules for air compressors 6

Contents of carton 8

Know your product 8

Unpacking 10

Assembly 10

Pre-start routine 10

To start & stop the compressor 11

Operation 11

Tank removal/installation 12

Troubleshooting 14

Maintenance 16

General inspection 16

Cleaning 16

Power cord maintenance 16

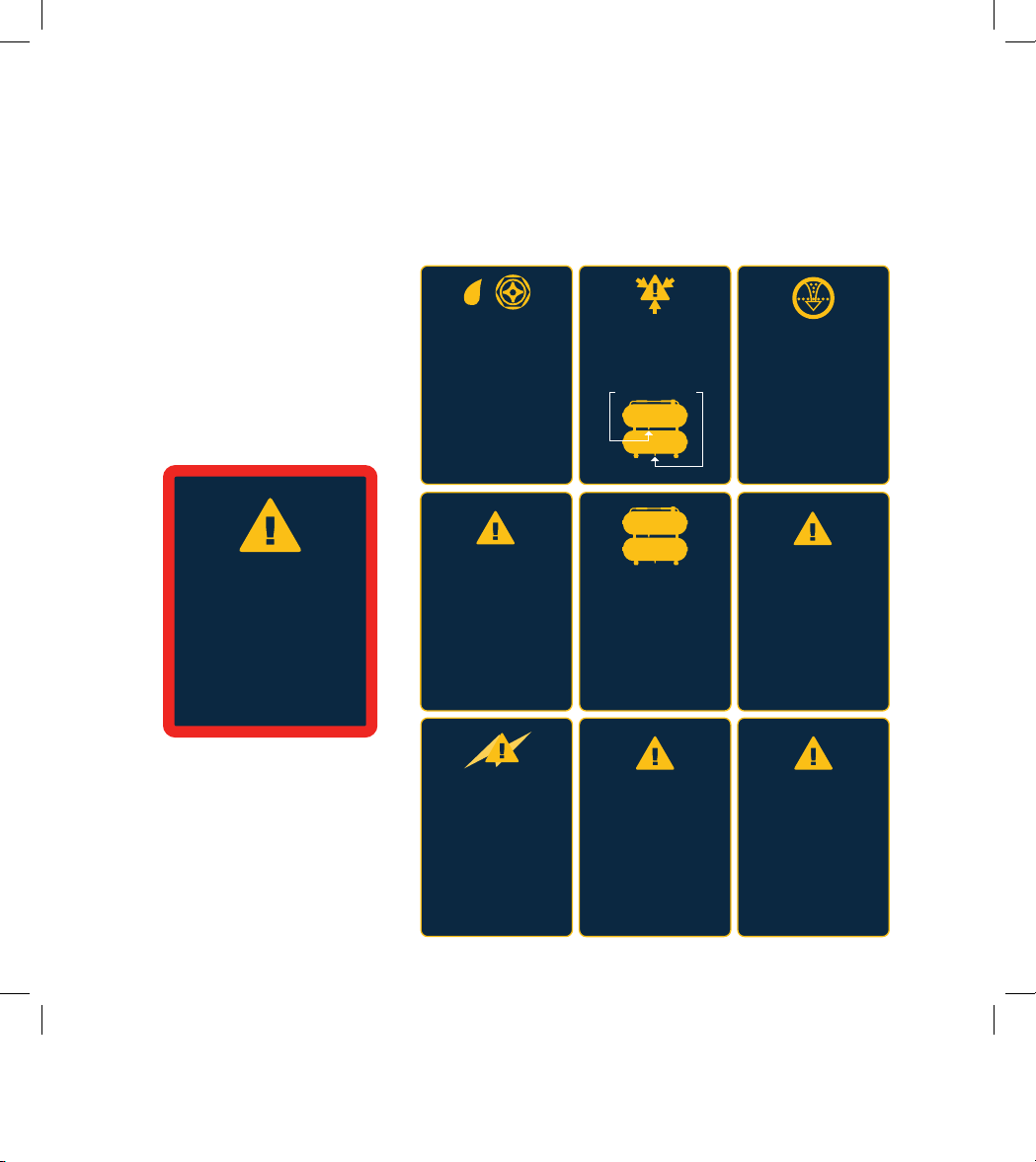

Page 3

3

Warning labels explained

On the tank of your air compressor you will notice various

warnings about the operation of the compressor. These

warnings and the procedures associated with them are

explained fully in this manual on the following pages.

Please take note of these. They are important for your

safety and that of others in the vicinity.

Air discharged from

this unit is not

suitable for human

consumption.

Test the safety relief

valves daily.

Refer the instruction

manual.

When filter becomes

dirty or oily, clean or

replace filter. Refer to

instruction manual.

Do not switch on

for the first time

without first

filling with oil.

To prevent build-up of

condensation, open

drain cock daily

Read instruction manual

prior to starting unit.

This equipment

operates from

AC mains only.

High voltage used on

this equipment. Prior to

servicing or removing the

cover, switch off the

power supply & remove

plug from mains. Ensure

mains outlet is adequately

rated for this unit.

Unit starts

automatically.

Switch off power supply,

remove plug & relieve

air pressure prior to

commencing service

tasks.

DTC32L Air Compressor

Tank capacity:

32 litres

Pump displacement:

206 l/m

Free air delivery:

114 l/m

Max. working pressure:

0.8 MPa

Check the oil level before starting the

compressor every time.

Make sure the compressor is on a level

surface prior to checking the oil level.

The oil level is required to be at the

red dot on the oil level sight glass

prior to use.

Use only oil grade specified in the

instruction manual.

Page 4

4

Description of symbols

The rating plate on your tool may show symbols.

These represent important information about the

product or instructions on its use.

Wear hearing protection.

Wear eye protection.

Wear breathing protection.

Conforms to relevant standards

for electromagnetic compatibility.

Specifications

Power: 2HP/1600W

Voltage: 230–240V ~ 50Hz

No load speed: 2850 min

-1

Discharge pressure: 0.8 MPa(115 psi)

Tank capacity: 32/16 litres

Air outlets X4:

- 2X regulated fitted with Nitto style quick

release couplings

- 1X fitted Nitto style quick release coupler

- 1X fitted tyre inflation hose & gauge

providing easy tyre inflation applications.

Net weight: 38.5kgs

Cut-in pressure (factory set): 0.6MPa (85psi)

Cut-out pressure (factory set): 0.8MPa (115psi)

Maximum output pressure: 0.8MPa (115psi)

Free air delivery: 114 l/min

(4 CFM)

Pump displacement: 206 l/min

(7.3 CFM)

Introduction

Your new GMC power tool will more than satisfy

your expectations. It has been manufactured under

stringent GMC Quality Standards to meet superior

performance criteria.

You will find your new tool easy and safe to operate,

and, with proper care, it will give you many years

of dependable service.

CAUTION. Carefully read through this entire Instruction

Manual before using your new GMC Power Tool. Take

special care to heed the Cautions and Warnings.

Your GMC power tool has many features that will make

your job faster and easier. Safety, performance, and

dependability have been given top priority in the

development of this tool, making it easy to maintain

and operate.

Environmental protection

Recycle unwanted materials instead

of disposing of them as waste. All tools,

hoses and packaging should be sorted,

taken to the local recycling centre and

disposed of in an environmentally safe way

.

Page 5

5

General safety instructions

To use this tool properly, you must observe the safety

regulations, the assembly instructions and the operating

instructions to be found in this Manual. All persons who use

and service the machine have to be acquainted with this

Manual and must be informed about its potential hazards.

Children and infirm people must not use this tool. Children

should be supervised at all times if they are in the area in

which the tool is being used. It is also imperative that you

observe the accident prevention regulations in force in your

area. The same applies for general rules of occupational

health and safety.

WARNING. When using power tools, basic safety precautions

should always be taken to reduce the risk of fire, electric

shock and personal injury. Also, please read and heed the

advice given in the additional important safety instructions.

1. Keep the work area clean and tidy. Cluttered work areas

and benches invite accidents and injury.

2. Consider the environment in which you are working.

Do not use power tools in damp or wet locations. Keep

the work area well lit. Do not expose power tools to rain.

Do not use power tools in the presence of flammable

liquids or gases.

3. Keep visitors away from the work area. All visitors and

onlookers, especially children and infirm persons, should

be kept well away from where you are working. Do not

let others in the vicinity make contact with the tool or

extension cord.

4. Store tools safely. When not in use, tools should be

locked up out of reach.

5. Do not force the tool. The tool will do the job better and

safer working at the rate for which it was designed.

6. Use the correct tool for the job. Do not force small tools

or attachments to do the job best handled by a heavier

duty tool. Never use a tool for a purpose for which it was

not intended.

7. Dress correctly. Do not wear loose clothing or

jewellery. They can be caught in moving parts. Rubber

gloves and non-slip footwear are recommended when

working outdoors. If you have long hair, wear a protective

hair covering.

8. Use safety accessories. Safety glasses and earmuffs

should always be worn. A face or dust mask is also

required if the sanding operation creates dust.

9. Do not abuse the power cord. Never pull the cord to

disconnect the tool from the power point. Keep the cord

away from heat, oil and sharp edges.

10. Secure the work piece. Use clamps or a vice to hold the

work piece. It is safer than using your hand and frees

both hands to operate the tool.

11. Do not overreach. Keep your footing secure and

balanced at all times.

12. Look after your tools. Keep tools sharp and clean for

better and safer performance. Follow the instructions

regarding lubrication and accessory changes. Inspect

tool cords periodically and, if damaged, have them

repaired by an authorised service facility. Inspect

extension cords periodically and replace them if

damaged. Keep tool handles dry, clean and free from oil

and grease.

13. Disconnect idle tools. Switch off the power and

disconnect the plug from the power point before

servicing, when changing accessories and when the tool

is not in use.

14. Remove adjusting keys and wrenches. Check to see

that keys and adjusting wrenches are removed from the

tool before switching on.

15. Avoid unintentional starting. Always check that the

switch is in the OFF position before plugging in the tool

to the power supply. Do not carry a plugged in tool with

your finger on the switch.

16. Use outdoor rated extension cords. When a tool is used

outdoors, use only extension cords that are intended for

outdoor use and are so marked.

17. Stay alert. Watch what you are doing. Use common

sense. Do not operate a power tool when you are tired.

Page 6

6

18. Check for damaged parts. Before using a tool, check

that there are no damaged parts. If a part is slightly

damaged, carefully determine if it will operate properly

and perform its intended function. Check for alignment of

moving parts, binding of moving parts, breakage of parts,

proper mounting and any other conditions that may

affect the operation of the tool. A part that is damaged

should be properly repaired or replaced by an authorised

service facility, unless otherwise indicated in this

Instruction Manual. Defective switches must be replaced

by an authorised service facility. Do not use a tool if the

switch does not turn the tool on and off correctly.

19. Guard against electric shock. Prevent body contact

with grounded objects such as water pipes, radiators,

cookers and refrigerator enclosures.

20. Use only approved parts. When servicing, use only

identical replacement parts. Use an authorised service

facility to fit replacement parts.

Additional safety rules for air compressors

WARNING. Before connecting a tool to a power source

(mains switch power point receptacle, outlet, etc.) be sure

that the voltage supply is the same as that specified on the

nameplate of the tool. A power source with a voltage greater

than that specified for the tool can result in serious injury to

the user, as well as damage to the tool. If in doubt, do not

plug in the tool. Using a power source with a voltage less

than the nameplate rating is harmful to the motor.

Always remove the plug from the mains socket before

making any adjustments or maintenance, including

renewing the lubricating oil.

• To reduce the risk of fire or explosion, never spray

flammable liquids in a confined area. It is normal for

the compressor motor and pressure switch to produce

sparks during use. If sparks come into contact with petrol

vapours or solvents, they may ignite the vapours and

cause a fire or explosion.

• Always operate the compressor in a well ventilated area.

Do not smoke while spraying. Do not spray where sparks

or flames are present. Keep the compressor as far away

from the spray area as possible.

• The solvents trichloroethane and methylene chloride can

chemically react with the aluminium used in some paint

spray guns and form an explosion. If these solvents are

used, ensure that only stainless steel spray equipment is

connected. The compressor is not affected by the use of

these solvents.

• Never directly inhale the compressed air produced by a

compressor and do not use it for charging breathing tanks.

• Do not use welding equipment in close proximity to the

compressor. Do not weld anything to the air tanks of the

compressor: this could dangerously weaken the tanks

and will void the warranty.

• Do not use the compressor outdoors when it is raining

or on a wet surface; either situation could cause an

electric shock.

• Always shut off the compressor after use and before

servicing. Set the on/off switch to the off position, wait

for the pressurised air to bleed from both tanks via the

release valves located on each tank. Then remove the

electrical plug from the power supply.

• Check the maximum pressure rating of any tools or

accessories that you intend using with the compressor.

The output pressure of the air from the compressor must

be regulated so that it never exceeds the rated pressure

of the tool or accessory.

• To avoid the risk of burns and injury from moving

parts, do not operate the compressor with the safety

cover removed. Allow hot parts to cool before handling

or servicing.

• Be certain to read all the labels on the containers of paint

or other materials to be sprayed. Closely follow all safety

instructions. Use a respirator mask if there is a chance

that you might otherwise inhale the spray material.

Carefully check the effectiveness of any respirator mask

you intend using.

• Always wear safety goggles or glasses when using the

air compressor. Never point the nozzle of an accessory

towards any part of your body or towards another person.

• Do not attempt to adjust the pressure switch or the

release valve.

Page 7

7

• Drain the moisture from the tanks daily. It will help

prevent corrosion.

• Pull the ring on the safety valves daily to ensure that it

operating properly and to clear any possible instructions.

Note. This unit has two safety release valves (one on each

tank). Ensure both are checked daily.

• Keep the compressor at least 300mm from the nearest

wall to ensure adequate ventilation for cooling purposes.

• Prior to transporting the compressor make sure that the

pressurised air is bled from both tanks. Ensure that the

removable tank is correctly connected. Also check that

the compressor is firmly secured.

Note. Never transport pressurised tanks. Even when

transporting the removable air supply it must be empty

of all air.

• Protect the air hoses and cordset from damage. Inspect

for weak or worn spots regularly and replace if necessary.

• Prior to using the removable tank as a temporary air

supply make sure that you place it down on a level

surface and have a firm grip on the air hose prior to use.

• Do not use an extension cord with this product. Use

additional air hose instead of an extension cord to

prevent power loss and possible damage to the motor.

Use of an extension cord voids the warranty.

• After long working periods external metal parts could

be hot.

• Always shut off the compressor at the on/off switch by

lifting the lever to the off position before switching off the

power or removing the power plug.

• Check the oil level before starting the compressor

every time.

• Make sure the compressor is on a level surface prior to

checking the oil level.

• The oil level is required to be at the red dot on the oil

level sight glass prior to use.

• Use only oil grade specified in this instruction manual.

Note. The compressor is supplied empty of oil. It must be

filled with oil before first use.

• After using the compressor, switch off the on/off switch,

disconnect the power supply and open the outlet valves

on both tanks to release the pressure.

• Ensure that the lubricating oil is clean and that the oil

level is maintained at the correct level. Replace the oil

as indicated in the Maintenance section of this Manual.

• Use safety equipment including safety goggles or

shield, ear protection, breathing or respirator mask

and protective clothing.

Wear goggles

Wear earmuffs

Wear a breathing mask

Never apply air from any of the air outlets from this

compressor directly on to any part of a person’s body.

Do not attempt to block any of the air outlets with your

finger or any part of your body.

The tool must be used only for its prescribed purpose.

Any use other than those mentioned in this Manual will

be considered a case of misuse. The user and not the

manufacturer shall be liable for any damage or injury

resulting from such cases of misuse.

The manufacturer shall not be liable for any changes made

to the tool nor for any damage resulting from such changes.

Even when the tool is used as prescribed it is not possible to

eliminate all residual risk factors. The following hazards may

arise in connection with the tool’s construction and design:

• Damage to the lungs if an effective breathing mask is

not worn.

• Damage to hearing if effective earmuffs are not worn.

• Damage to the eyes if effective safety goggles or shield

are not worn.

Page 8

8

WARNING. In the event that an air line is cut or broken,

the air line needs to be immediately disconnected from

the compressor at the quick release fitting. This will

automatically stop the air from free flowing. A broken air

line which is not supported is extremely dangerous and can

whip around very quickly, both with the capability of striking

people, and blowing foreign particles into the air.

Do not attempt to catch the air line but immediately keep

bystanders well clear. Disconnecting the remaining hose

from the quick release fitting on the unit will automatically

shut off the air supply. Turn off the compressor at the

On / Off switch.

Contents of carton

• 400ml of oil in a sealed container

• Instruction manual

Page 9

9

Know your product

1. Handle

2. On/off switch

3. Tank pressure gauge x 2

4. Regulated Nitto style

quick release air outlets x 2

5. Regulating knob

6. Regulated outlet pressure gauge

7. Safety valve x 2

8. Combination valve

(Non return, outlet and

safety release in one valve)

9. Drain cock x 2

10. Air tank 1 (Removable tank)

11. Air tank 2

12. Wheels (x 2)

13. Safety cover

14. Oil filling plug

15. Air filter

16. Oil sight glass/Oil drain plug

17. Power Cord

18. Tank 1 air isolation valve

19. Console/Tray

20. Tank 1 (removable tank) handle

21. Vibration dampening feet

22. Tank 1 rubber support straps

23. Tank 1 support brackets

24. Tank 1 feet (located at each end of the tank)

25. Tank 1 air inlet hose

26. Tank 1 Nitto style quick

release air inlet valve

27. Tank 1 inflator hose

19

2

6

11

4

5

3

8

10

12

13

14

15

1617 18

1

20

23

25

26

27

22

24

7

9

21

16

3

7

Page 10

10

Unpacking

Due to modern mass production techniques, it is unlikely

that your GMC Power Tool is faulty or that a part is missing.

If you find anything wrong, do not operate the tool until the

parts have been replaced or the fault has been rectified.

Failure to do so could result in serious personal injury.

Assembly

Oil

WARNING. The air compressor must be filled with oil

before first use.

To prevent possible spillage of oil during transport, the

compressor oil is supplied in a separate container. It must

be added to the compressor before turning the compressor

on. Failure to add the oil will cause non-repairable damage

to the compressor and will void the warranty.

1. Remove the plastic oil filling plug (14) located on the top

of the crank case of the compressor housing.

2. Use the oil supplied to fill the crank case until the oil level

as seen in the oil sight glass (16) is up to the mid point of

the red circle.

3. Replace the oil filling plug (14). Ensure the plug is fully

fitted and firmly in position.

Pre-start routine

1. Ensure that the location for the compressor is clean,

dry and well ventilated.

2. Ensure the crank case has been filled with oil and is

at the correct level.

3. Start the compressor by

following the procedure in the

section “To start and stop

the compressor”. Prior to

the first time operation of the

compressor open the drain

cocks in both of the tanks (9),

run the compressor for

20 - 30 minutes in this condition

with no load and to ensure all

parts are well lubricated.

4. Turn the air compressor off at

the on/off switch (2) on the air

compressor. Close the drain

cocks (9) in both tanks.

Your compressor is now ready

for use.

WARNING. Be aware that pressurised air will be discharged

from the drain cocks (9) and care should be taken that this

discharge is not directed towards you the operator, or other

persons within the area.

To start & stop the compressor

1. Check the rating label on the compressor indicates

230V–240V.

2. Plug in the mains cable of

the compressor to a standard

240V household power point

and turn on.

3. To start the compressor, push

the On/Off lever (2) downward

so that the lever is in the

vertical position.

4. To stop the compressor, lift the

On/Off lever (2) to the horizontal position.

OFF

ON

Page 11

11

Operation

1. The pressure in the tank is controlled by the action of

the pressure switch. When the set maximum pressure

is reached the pressure switch activates and the motor

is switched off. The pressure then decreases as the

air is used by the connected tool until the set minimum

pressure is reached after which the pressure switch

causes the motor to switch on again. The operator of

the compressor should be well aware that during use of

the compressor the motor will start and stop under the

influence of the rising or falling pressure in the tank. The

motor will start without any warning.

2. The maximum and minimum pressures are factory set

and the operator should not try to change them.

3. All accessories are connected to either the Nitto style

quick coupler regulated air

outlets (4) or the removable

tank inflator hose (27).

4. The pressure of the regulated

quick connect outlets is shown

on the regulated outlet pressure

gauge (6). The regulated

pressure can be adjusted by

turning the regulating knob (5).

Note. To obtain the correct output reading on the regulated

output gauge, the air must be flowing through the outlet(s)

(4). The regulating valve should be adjusted and the gauge

read with the outlet valve open and the air being discharged

from the regulated outlet through the accessory being

used. If you are using both of the regulated outlets (4)

simultaneously make sure that the tools being connected

have the same pressure operation requirements. To

increase the air pressure, rotate the regulating valve

clockwise. To decrease the pressure, rotate the regulating

valve anti-clockwise.

Note. If you do not allow the air to discharge while you

are setting the regulator, the pressure as indicated on the

regulated outlet gauge will be incorrect. This gauge ONLY

indicates the correct pressure while air is being discharged

from the outlet.

5. On completion of the task, i.e. when you have finished

using the compressor, or when you are leaving the

compressor unattended, turn off the compressor in the

following way:

• Lift the on/off switch (2) to the off position

• Wait for the pressurised air to bleed from the release valve.

Note. You will hear a short air discharge of approx

½ second however, this discharge only occurs if the

compressor is actually running at the time, and not in idle.

• Switch off the electrical

power supply and remove the

electrical plug.

• Pull the ring on both of the

safety valves (7) to ensure all

the pressurised air is released

from the tank, or open the both

drain cocks (9) to release the

pressure from the tank.

Tank removal/installation

This twin tank air compressor has the added benefit of a

removable tank which provides a mobile source of limited/

short term compressed air. This has many advantages

including inflating flat tyres on site as well as performing

small brad nailing tasks.

Note. It is important that end users understand the

capabilities of the removable tank and work with in it’s

capabilities.

Removing the air tank:

1. Turn the On/Off switch (2) on the compressor to the

off position.

2. Turn the power supply off and disconnect the power cable.

3. Lift the main handle (1) up and away from the portable tank.

Page 12

12

4. Close the tank 1 isolation valve (18).

5. Disconnect the tank 1 inlet hose (25) from the combination

valve (8), by sliding back the sleeve of the quick connect

fitting and removing the inlet hose.

Note. The inlet hose has been fitted with a special one way

valve. On removal of the inlet hose there will be a slight

discharge of air.

6. Place the tank 1 inlet hose

(25) on the provided clip.

7. Disconnect the rubber support

straps (22) by pulling them

over the support brackets (23)

to release the air tank.

WARNING. Be careful when

releasing the straps they do have

a tight fit.

8. The tank has now been

correctly disconnected from the

air compressor unit. You can

now move the tank freely

by using the carry handle (20)

to lift and move the tank. You

can now use the removed tank.

The separated tank has two

outlets that you can choose

from;

a) the attached inflation hose; or

b) the provided quick connect coupler that you can connect

another air hose to. This can be done by sliding back

the sleeve of the quick connect coupler and inserting an

air hose assembly that is fitted with a Nikko style fittings.

Due to the limited supply of air it is recommended that

the removable tank is fully charged with air prior to being

removed.

Note. While the tank has been

removed you can still use the

master unit/compressor with only

one tank. This can be done by

simply reconnecting the master

unit/compressor back to the power

supply, and turning the unit on at

the On/Off switch (2).

CAUTION. When using the master unit/compressor with

the top tank removed always check to ensure that the air

isolation vale (18) is in the off position.

Installing the air tank:

1. Turn the On/Off switch (2) on the compressor to the

off position.

2. Turn the power supply off and disconnect the power cable.

3. Lift the main handle (1) up and away from the portable

tank location.

4. Sit the tank down on the

support brackets (23).

5. Reconnect the rubber support

straps (22) to the support

brackets (23).

Note. Grip the rubber straps at

the fixed end and stretch evenly

over the tank until the straps are

connected securely to the support

brackets.

WARNING. When extending the rubber straps be careful. If

released early they can flick back and hurt you. Make sure

that your face is at a safe distance from the rubber straps

while they are being stretched.

Page 13

13

CAUTION. Over stretching the rubber straps may result in

fracturing the straps.

6. Reconnect the tank 1 inlet hose (25) onto the combination

valve (8), by depressing and sliding back the sleeve of

the quick coupler valve while reconnecting the hose.

7. Open the tank 1 isolation

valve (18).

Note. When the isolation

valve is opened and there is is

compressed air in the lower tank

you will hear the air equalise into

the top tank.

The portable air tank has been

properly installed and connected

to the air compressor unit. Your

air compressor is now ready

for use.

WARNINGS.

1. Never attempt to remove any electrical component whilst

the compressor is connected to the power supply. Switch

off the power and remove the electrical plug.

2. Do not adjust the safety valve.

3. Do not use an electrical extension cable.

4. Ensure that the lubricating oil is clean and that the oil

level is maintained at the mid point of the red circle in the

oil sight glass (16).

5. Take care when discharging air from the tank, i.e. from

the safety valves (7), the drain cocks (9) or the air outlets

(4 and 27). Compressed air can be extremely dangerous.

Take care the discharge air does not cause dust, stones

or any other foreign particles to be blown through the air

and that the air is discharged in a safe manner.

Page 14

14

Troubleshooting

Trouble Possible cause Possible remedy

Motor will not run, running too

slow or becoming excessively hot

Power fault or supply voltage too low Check the power supply

Power cord too long or too thin Use authorised service centre

to replace the power cord

Faulty pressure switch Use authorised service centre

to repair or replace the switch

Faulty motor Use authorised service centre

to repair or replace the motor

Main compressor sticking/tight Use authorised service centre

to repair or replace faulty parts

Main compressor sticking/tight

Moving parts damaged by heat

due to insufficient lubrication

Use authorised service centre to

check crankshaft, bearings, con rod,

piston rings, etc and replace

where necessary

Moving parts damaged or blocked

by foreign particle

Vibration or abnormal noise

Loose part Use authorised service centre

to check and repair if necessary

Foreign body in main compressor Use authorised service centre

to check and clean if necessary

Piston connecting with the valve seat Use authorised service centre

to increase size of gasket

Moving parts excessively worn Use authorised service centre

to repair or replace

Page 15

15

Troubleshooting continued

Trouble Possible cause Suggested Remedy

Insufficient pressure

or decreased outlet

capacity

Motor running too slow Use authorised service centre to check and repair if necessary

Dirty air filter cartridge Clean or replace the filter cartridge

Leaking safety valve Use authorised service centre to repair

or replace the switch

Leaking pipe Use authorised service centre to check and repair if necessary

Damaged gasket Use authorised service centre to check and repair if necessary

Damaged or carbon coated

valve seat

Use authorised service centre to check and repair if necessary

Damaged piston ring or cylinder Use authorised service centre to check and repair if necessary

Open drain cock Check both drain cock(s) are closed, if not immediately

switch off the unit as per the shut down instructions and

close the drain cock(s)

Safety valve fully leaking

Check out the condition of the safety valve. If the valve is

leaking immediately shut off the compressor and cease using.

Have the unit serviced/checked by an authorised service centre

and repaired. Don’t continue to use the unit with a leaking

safety valve.

Air line hose leaking

Examine the air hose for any holes and tears.

If you find any holes or tears replace the air hose

Air fittings leaking

Check all air fittings. Make sure that they are tight and

not leaking at the joins. If a quick release fitting is leaking,

disconnect it and reconnect it. If it continues to leak replace the

defective fitting(s). If a male or female fitting is leaking around

the thread tighten using a spanner. If the fitting is already tight

and can’t be tightened, unscrew the connection and remove

the Teflon tape. Examine the condition of the fitting(s). If the a

fitting(s) is damaged replace and reassemble using Teflon tape

on threaded fittings. If the fittings are OK reapply Teflon tape

and reassemble.

Page 16

16

Troubleshooting continued

Trouble Possible cause Suggested Remedy

Excessive oil

consumption

Oil level too high

Maintain the oil at the correct level

Hole in oil filling plug (14)

blocked

Check and clean

Piston ring and/or cylinder

worn or damaged

Use authorised service centre to check and repair if necessary

Page 17

17

Maintenance

1. After the first 10 hours of working, empty the crank case

of oil and refill with clean oil by removing the crank case

oil plug (left hand side of the crank case at the bottom)

Note. Use good quality compressor lubricating oil.

• SAE30 or L-DAB 100 over 10°C

2. After each subsequent 250 hours of operation, again

drain the oil and refill the crank case with clean oil.

3. After each day of operation unscrew the two drain cocks

(9) under the tanks to drain out any condensation that

is in the tanks. This will protect the tanks from rusting

and prolong the product life. Once the draining has

been completed screw the drain cocks (9)closed and re

assemble the air compressor.

Note. Both tanks have independent drain cocks and both

have to be drained after each day of use.

CAUTION. The top tank must be removed from the

compressor prior to draining every time.

4. Regularly check the air filter insert cartridge inside the

air filter assembly (15) and clean or replace the insert

when necessary.

5. Check daily the operation of the safety valves (7). This

check should be performed when the tank contains close

to max pressure in the tank.

To check the valves, pressurise the tank, and pull the ring

OUTWARDS on the safety valve.

Air should discharge from the valve.

Release the ring of the safety valves. When the ring is

released the air discharge must stop.

WARNINGS.

Safety glasses must be worn when performing this test.

Do not have your face close to the safety valve when

performing this test as air will discharge from the valve at a

high force.

If the safety valve does not operate correctly in any way as

described above, turn off the compressor immediately and

have the compressor and safety valve checked and tested

at an authorised Service centre.

DO NOT CONTINUE TO USE THE COMPRESSOR

IN ANY WAY IF THE SAFETY VALVE DOES NOT

WORK AS ABOVE.

Maintaining the air filter

1. To clean the air filter insert you need to take the air filter

(15) apart first. Remove the cover along by twisting it

anti-clockwise.

2. Pull out the air filter and tap it a few times against a

surface that is dry and clean to loosen up and remove

any dust and build up. Then vacuum it for a minute or so

to draw out the more stubborn particles.

3. Replace the air filter insert cartridge, then re-install the

filter cover back on by firstly lining up the lugs and then

twisting it clockwise, to lock into position.

General inspection

1. Regularly check that all the fixing screws are tight.

2. The supply cord of the tool should be checked frequently

for damage. If damaged, have the cordset replaced by an

authorised service facility to avoid

a hazard.

Cleaning

1. Keep the tool’s air vents unclogged and clean at

all times.

2. Remove dust and dirt regularly. Cleaning is best done

with a soft brush or a rag.

3. Re-lubricate all moving parts at regular intervals.

Page 18

18

4. If the body of the compressor needs cleaning, wipe it

with a soft damp cloth. A mild detergent can be used but

nothing like alcohol, petrol or other cleaning agent.

5. Never use caustic agents to clean plastic parts.

CAUTION. Water must never come into contact

with the tool.

Power cord maintenance

Only an authorised service centre should replace the

cordset or carry out other repairs. If the cordset is damaged

or worn, have it repaired or replaced by an authorised

service centre.

Page 19

19

Page 20

20

Page 21

GMC customer assist

If your product needs repairing, replacing,

technical service or you simply need help or advice,

please contact us on our Customer Assist Line

1300 880 001 (Australia) or 0800 445 721 (New Zealand).

For prompt service we suggest you log your service request

online at www.gmcservice.com.au. Should you not have

access to the Internet, please contact our service department

on 1300 880 001 (Australia) or 0800 445 721 (New Zealand).

7am –7pm, 7days a week (AEST).

Please note that if repair or replacement is required,

you must provide a valid original purchase receipt.

You will need the following details at hand to log your service request;

Personal details: First & Last name, address, pick up address,

contact phone numbers, email address

Product details: Product number, date of purchase, retailer bought from,

State & postcode, receipt number,

reason for the request,

c

opy of official purchase receipt

Attach your purchase receipt and save with this Manual for future reference

.

Please refer to our website www.gmcompany.com for full GMC warranty Terms and Conditions.

Loading...

Loading...