Page 1

INSTRUCTION MANUAL

• Melbourne • Perth • Auckland • Hong Kong • Shanghai

• Taipei • New York • Verona • London • Paris

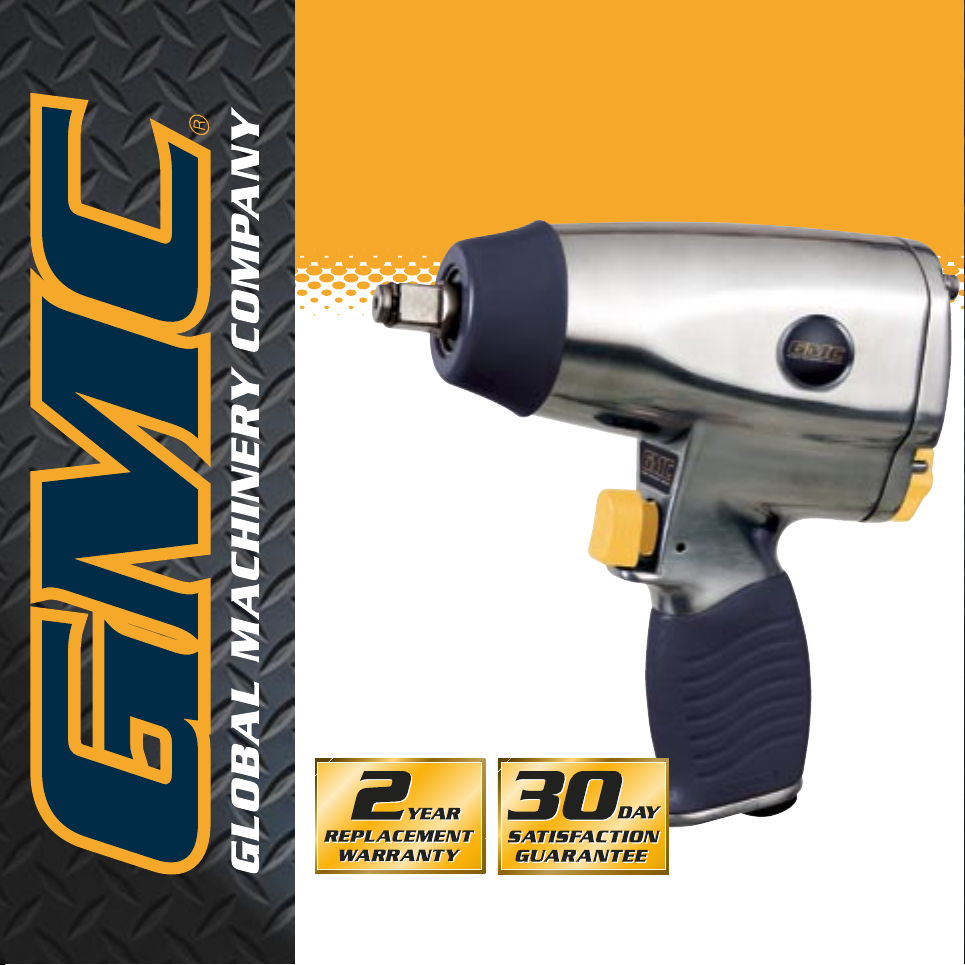

Air Impact

Wrench Kit

1/2” Square Drive

ATIW1/2K

031 117 PR ED 04

Page 2

Contents

Full 2 Years Home Use Warranty

Whilst every effort is made to ensure your complete

satisfaction with this tool, occasionally, due to the mass

manufacturing techniques, a tool may not live up to our

required level of performance and you may need the

assistance of our service department.

This product is warranted for a 2-year period for home

domestic use from the date of the original purchase. If

found to be defective in materials or workmanship, the

tool or the offending faulty component will be replaced

free of charge with another of the same item. A small

freight charge may apply.

The warranty replacement unit is only made available by

returning the tool to the place of purchase with a

confirmed register receipt. Proof of purchase is essential.

We reserve the right to reject any claim where the

purchase cannot be verified.

This warranty does not include damage or defects to the

tool caused by or resulting from abuse, accidents,

alterations or commercial or business use.

It also does not cover any bonus accessories unless the

tool is a GMC Platinum Professional model.

Please ensure that you store your receipt in a safe place

.

Conditions apply to the above warranty.

If you need direction of what constitutes a free of

charge warranty claim, please review the guide given on

the rear of the Receipt Holder. An indication is given as

to the types of claim that are permissible, and those

that are not.

Warranty 2

Introduction 3

Environmental protection 3

Scope of product 3

Description of symbols 3

Specifications 3

General safety instructions 3

Risk of eye or head injury 5

Risk of fire or explosion 5

Risk of loss of hearing 5

Risk to breathing inhalation hazard 6

Risk to injury 6

Risk of electric shock 8

Risk of entanglement 8

Risk of cut or burns 8

Additional safety instructions

for impact wrenches 9

Operation 9

Maintenance 9

Air Motor Lubrication 9

Impact Mechanism Lubrication 9

Air Supply 10

Air Hose 10

Storage 10

Adjustable Speed Control 10

General inspection 10

Cleaning 10

Repairs 10

Troubleshooting 11

Page 3

Dear Customer

If you require any help with your product, whether it

is a Warranty claim, spare part or user information,

please phone our Help Line for an immediate response. Phone

1300 880 001 in Australia or 0800 445 721 in New Zealand.

Introduction

Your new GMC tool will more than satisfy your expectations.

It has been manufactured under stringent GMC Quality

Standards to meet superior performance criteria.

You will find your new tool easy and safe to operate,

and, with proper care, it will give you many years of

dependable service.

Caution. Carefully read through this entire Instruction

Manual before using your new GMC Tool. Take special care

to heed the Cautions and Warnings.

Your GMC tool has many features that will make your job

faster and easier. Safety, performance, and dependability

have been given top priority in the development of this

tool, making it easy to maintain and operate.

Environmental protection

Recycle unwanted materials instead of

disposing of them as waste. All tools, hoses

and packaging should be sorted, taken to

the local recycling centre and disposed of

in an environmentally safe way.

Scope of product

This product is suited for home and camping applications.

It will allow you to power outdoor lights, sound system,

small television and recharges your car battery.

Description of symbols

The rating plate on your tool may show symbols. These

represent important information about the product or

instructions on its use.

Wear hearing protection.

Wear eye protection.

Wear breathing protection.

Specifications

Square Drive: 1/2”

Free Speed: 7,000RPM

Max Torque: 260FT/LB Reverse

230FT/LB Forward

Air Cons: 4CFM@90PSI

Air Inlet: 1/4”PT

Net Weight: 2.04Kg

Impact Mechanism: Rocking Dog

General safety instructions

To use these air tools properly, you must observe the safety

regulations, the assembly instructions and the operating

instructions to be found in this Manual. All persons who

use and service the machine have to be acquainted with

this Manual and must be informed about its potential

hazards. Children and infirm people must not use these

tools. Children should be supervised at all times if they

are in the area in which the tools are being used. It is

also imperative that you observe the accident prevention

regulations in force in your area. The same applies for

general rules of occupational health and safety.

Warning. When using air operated tools, basic safety

precautions should always be taken to reduce the risk of

fire, electric shock and personal injury. Also, please read

and heed the advice given in the additional important

safety instructions.

3

Page 4

1. Keep the work area clean and tidy. Cluttered work

areas and benches invite accidents and injury.

2. Consider the environment in which you are working.

Do not use air tools in damp or wet locations. Keep the

work area well lit. Do not expose air tools to rain. Do

not use air tools in the presence of flammable liquids

or gases.

3. Keep visitors away from the work area. All visitors

and onlookers, especially children and infirm persons,

should be kept well away from where you are working.

Do not let others in the vicinity make contact with the

tool or air hose.

4. Store tools safely. When not in use, tools should be

locked up out of reach.

5. Do not force the tool. The tool will do the job

better and safer working at the rate for which it was

designed.

6. Use the correct tool for the job. Do not force small

tools or attachments to do the job best handled by a

heavier duty tool. Never use a tool for a purpose for

which it was not intended.

7. Dress correctly. Do not wear loose clothing or

jewellery. They can be caught in moving parts. Rubber

gloves and non- slip footwear are recommended

when working outdoors. If you have long hair, wear a

protective hair covering.

8. Use safety accessories. Safety glasses and earmuffs

should always be worn. A face or dust mask is also

required if the sanding operation creates dust.

9. Do not abuse the air hose. Never carry the air tool

by the air hose. Keep the air hose away from heat, oil

and sharp edges.

10. Secure the work piece. Use clamps or a vice to hold

the work piece. It is safer than using your hand and

frees both hands to operate the tool.

11. Do not overreach. Keep your footing secure and

balanced at all times.

12. Look after your tools. Keep tools sharp and

clean for better and safer performance. Follow the

instructions regarding lubrication and accessory

changes. Inspect air hose periodically and, if

damaged, have it replaced. Keep tool handles dry,

clean and free from oil and grease.

13. Disconnect idle tools. Disconnect air tools from the

air hose before servicing, when changing accessories

and when the tool is not in use.

14. Remove adjusting keys and wrenches. Check to see

that keys and adjusting wrenches are removed from

the tool before switching on.

15. Avoid unintentional starting. Do not carry a

connected air tool with your finger on the trigger.

16. Stay alert. Watch what you are doing. Use common

sense. Do not operate an air tool when you are tired.

17. Check for damaged parts. Before using a tool, check

that there are no damaged parts. If a part is slightly

damaged, carefully determine if it will operate

properly and perform its intended function. Check for

alignment of moving parts, binding of moving parts,

breakage of parts, proper mounting and any other

conditions that may affect the operation of the tool.

A part that is damaged should be properly repaired

or replaced by an authorised service facility, unless

otherwise indicated in this Instruction Manual.

18. Guard against electric shock. Prevent body contact

with grounded objects such as water pipes, radiators,

cookers and refrigerator enclosures.

19. Use only approved parts. When servicing, use only

identical replacement parts. Use an authorised service

facility to fit replacement parts.

4

Page 5

Important safety instructions

Risk of eye or head injury

What could happen How to prevent it

• Air powered equipment are capable of propelling

materials such as fasteners, metal chips, saw dust, and

other debris at high speed, which could result in serious

eye injury.

• Tool attachments can become loose or break and fly

apart propelling particles at the operator and others in

the work area.

• Compressed air can be hazardous. The air stream can cause

injury to soft tissue areas such as eyes, ears, etc. Particles

or objects propelled by the stream can cause injury.

• Always wear safety glasses with side shields.

• Never leave operating tool unattended. Disconnect air

hose when tool is not in use.

• For additional protection use an approved face shield in

addition to safety glasses.

• Make sure that any attachments are securely assembled.

Risk of fire or explosion

What could happen How to prevent it

• Abrasive tools such as sanders and grinders, rotating

tools such as drills, and impact tools such as nailers,

staplers, wrenches, hammers, and reciprocating saws

are capable of generating sparks which could result in

ignition of flammable materials.

• Exceeding the maximum pressure rating of tools or

accessories could cause an explosion resulting in serious

injury.

• Never operate tools near flammable substances as

gasoline, cleaning solvents, etc.

• Work in a clean, well ventilated area.

• Never use oxygen, carbon dioxide or other gases as a

power source for air tools.

• Use compressed air regulated to a maximum pressure at

or below the rated pressure of any attachments.

• Never connect to an air source that is capable of

exceeding 200 psi.

• Always verify prior to using the tool that the air source

has been adjusted to the rated air pressure range.

Risk of loss of hearing

What could happen How to prevent it

• Long term exposure to noise produced from the operation

of air tools can lead to permanent hearing loss.

• Always wear hearing protection.

5

Page 6

Risk to breathing inhalation hazard

What could happen How to prevent it

• Abrasive tools, such as grinders, sanders, and cut-off

tools generate dust and abrasive materials which can

be harmful to human lungs and respiratory system.

• Some materials such as adhesives and tar, contain

chemicals whose vapors could cause serious injury with

prolonged exposure.

• Always wear a face mask or respirator when using such

tools.

• Always work in a clean, dry, well ventilated area.

Risk to injury

What could happen How to prevent it

• Tools left unattended with the air hose attached, can

be activated by unauthorized persons leading to their

injury or injury to others.

• Air tools can propel fasteners or other materials

throughout the work area.

• A wrench or a key that is left attached to a rotating

part of the tool increases the risk of personal injury.

• Using inflator nozzles for duster applications can cause

serious injury.

• Air tools can become activated by accident during

maintenance or tool changes.

• Air tools can cause the workpiece to move upon

contact leading to injury.

• Remove air hose when tool is not in use and store tool

in secure location away from reach of children and or

untrained users.

• Use only parts, fasteners, and accessories recommended

by the manufacturer.

• Keep work area clean and free of clutter.

• Keep children and others away from work area during

operation of the tool.

• Keep work area well lit.

• Remove adjusting keys and wrenches before turning the

tool on.

• DO NOT use inflator nozzles for duster applications.

• Remove air hose to lubricate or add grinding

attachments, sanding discs, drills, etc. to the tool.

• Never carry the tool by the hose.

• Avoid unintentional starting. Don’t carry an air tool which

is connected to an air hose, with your finger on the trigger.

• Repair servicing should be done only by an authorized

service representative.

• Use clamps or other devices to prevent movement.

6

Page 7

Risk to injury (cont.)

• Loss of control of the tool can lead to injury to self or

others.

• Poor quality, improper, or damaged tools such as

grinding wheels, chisels, sockets, drills, nailers, staplers,

etc., can fly apart during operation, propelling particles

throughout the work area causing serious injury.

• Fasteners could ricochet or be propelled causing serious

injury or property damage.

• Improperly maintained tools and accessories can cause

serious injury.

• There is a risk of bursting if the tool is damaged. • Check for misalignment or binding of moving parts,

• Use only accessories identified by the manufacturer to

be used with specific tools.

• Never operate tool while under the influence of drugs

or alcohol.

• Don’t overreach. Keep proper footing and balance at all

times.

• Keep handles dry, clean, and free from oil and grease.

• Stay alert. Watch what you are doing. Use common

sense. Do not operate tool when you are tired.

• Always use tool attachments rated for the speed of the

air tool.

• Never use air tools which have been dropped, impacted

or damaged by use.

• Use only impact grade sockets on an impact wrench.

• Do not apply excessive force to the tool, let the tool

perform the work.

• Never point discharge of tool at self or others.

• Do not pull trigger unless tool contact safety device is

against work surface.

• Never attempt to drive fasteners into hard surfaces such

as steel, concrete, or tile.

• Take care to avoid driving a fastener on top of another

fastener.

• Position tool carefully so that fasteners will be delivered

to the proper location.

• Maintain the tool with care.

• Keep a cutting tool sharp and clean. A properly

maintained tool, with sharp cutting edges reduces the

risk of binding and is easier to control.

breakage of parts, and any other condition that affects

the tool’s operation. If damaged, have the tool serviced

before using.

• Use of an accessory not intended for use with the

specific tools, increases the risk of injury to persons.

7

Page 8

Risk of electric shock

What could happen How to prevent it

• Using air tools to attach electrical wiring may result in

electrocution or death.

• Contact with a “live” wire will also make exposed metal

parts of the tool “live” and may result in electrocution

or death.

• Fasteners coming in contact with hidden electrical

wiring may cause electrocution or death.

• Never use nailer/staplers to attach electrical wiring

while energized.

• Avoid body contact with grounded surfaces such as

pipes, radiators, ranges, and refrigerators. There is an

increased risk of electric shock if your body is grounded.

• Thoroughly investigate the workpiece for possible

hidden wiring before performing work.

Risk of entanglement

What could happen How to prevent it

• Tools which contain moving elements, or drive other

moving tools, such as grinding wheels, sockets, sanding

discs, etc. can become entangled in hair, clothing,

jewellery and other loose objects, resulting in severe

injury.

• Never wear loose fitting clothes, or apparel which

contains loose straps or ties, etc. which could become

entangled in moving parts of the tool.

• Remove any jewellery, watches, identifications,

bracelets, necklaces, etc. which might become caught

by the tool.

• Keep hands away from moving parts. Tie up or cover

long hair.

• Always wear proper fitting clothing and other safety

equipment when using this tool.

Risk of cut or burns

What could happen How to prevent it

• Tools which cut, shear, drill, staple, punch, chisel, etc.

are capable of causing serious injury

• Keep the working part of the tool away from hands and

body.

8

Page 9

Know your product

Before using the impact wrench, familiarise yourself with

all the operating features and safety requirements.

Use the tool only for the applications intended. All other

applications are expressly ruled out.

1.Drive anvil

2. Rubber nose guard

3. Body

4. Adjustable speed control

5. Contoured pistol grip

6. Air inlet

7. Exhaust port

8. Trigger

9. Impact mechanism oil port

1 2 3

4

8

9

5

6

7

9

Page 10

Additional safety instructions

for impact wrenches

This air impact wrench kit is designed for removing and

installing nuts and bolts. With one hammer (Rocking Dog)

impact mechanism and useful accessories, this kit is used

as a general purpose tool kit by DIYers and hobbyists.

1. This impact wrench is a part of a high pressure system.

Do not exceed maximum operating pressure of the air

tool (90PSI). The impact wrench could explore and may

result in death or serious injury.

2. Disconnect the impact wrench from air compressor

before changing tools or accessories, servicing and

during non-operation.

3. Always wear safety glasses and using hearing protection

during operation.

4. Do not wear loose fitting clothing and jewellery which

may become caught in moving parts and result in

serious injury.

5. Do not depress trigger when connecting the air hose.

6. Always use accessories fittings designed for use with air

tools. Use impact-quality sockets only. Do not use handtool sockets, damaged or worn accessories.

7. Never trigger the tool when not applied to a work object.

Accessories must be securely attached.

8. Make sure all connections are secure and check air hoses

for weak or worn condition before each use.

9. Disconnect air supply before installing or any maintenance.

Operation

Before each use:

• Drain water from air compressor tank and condensation

from air lines. Refer to your air compressor instruction

manual.

CAUTION: Disconnect the tool from the air supply before

lubricating or changing sockets.

• Lubricate tool, see “Maintenance” section in this manual.

CAUTION: Impact sockets and accessories must be used

with this tool. Do not use hand sockets and accessories.

• Select the required impact socket. This tool has a

1/2” square drive, use 1/2” deep sockets. Use 1/2”

extensions only when needed.

IMPORTANT: The use of air filters and air line lubricators is

recommended.

Maintenance

This impact wrench requires lubrication before initial use

and before and after each additional use throughout its life.

Air motor lubrication

1. Disconnect the impact wrench from the air supply and

hold the tool upside down.

2. Pull the trigger, put one teaspoon of air tool oil in the

air inlet lubricating the air motor the air inlet (6), and

then adjust the adjustable speed control (4) in both the

forward and reverse directions to help circulate oil in the

motor.

3. Reconnect the impact wrench to the air supply and

cover the exhaust port (7) with a towel and run in both

the forward and reverse directions for 20 seconds. Oil

will discharge from the exhaust port when air pressure

is applied. Any excess oil in the motor is immediately

expelled from the exhaust port. Always direct exhaust

port away from people or objects.

Impact mechanism lubrication

1. Disconnect the air impact wrench from the air supply.

2. Remove the allen head screw from the impact

mechanism oil port (9) hole on the right side of the tool

that has “OIL”.

3. Put three teaspoons of air tool oil in the oil port. Then,

replace the screw.

4. Reconnect the impact wrench with the air supply

and run for 20 seconds. Lubricate the whole impact

mechanism by rotating the tool upside down and

sideways while running the tool.

10

Page 11

5. Remove the screw and hold

the oil port hole over a

container to allow excess oil

to drain.

6. If the oil is dirty, repeat the

procedure above until the oil

comes out clear. Install the

screw and tighten. The residual

oil remaining in the impact

mechanism chamber is all that is needed for proper

lubrication

Air supply

Air supply MUST be greater than air requirement of the

tool. Recommended air compressor is 3/4HP tank for

intermittent use; 1.5HP or larger for heavier duty use

Storage

The impact wrench must be lubricated before storing.

Follow the air motor lubrication instructions. Only run for

3 seconds instead of 20 seconds because more oil needs to

remain in the tool when storing.

Adjustable speed control

This impact wrench is equipped

with a regulator for adjustable

speed control (4). This switch is

located at the rear of the tool.

The impact wrench should NEVER

be used to set torque. Use a

torque wrench to set the torque.

To remove nuts, set the regulator to the maximum setting.

To install nuts, set the regulator to the minimum to

medium setting. Do not over-tighten the nuts.

Forward and reverse directions are controlled by rotating

the speed control knob noted.

General inspection

1. Regularly check that all the fixing screws are tight.

2. The supply cord of the compressor should be checked

frequently for damage. If damaged, have the cordset

replaced by an authorised service facility to avoid a

hazard.

Cleaning

1. Keep the tool’s air vents unclogged and clean at all

times.

2. Remove dust and dirt regularly. Cleaning is best done

with a soft brush or a rag.

3. Re-lubricate all moving parts at regular intervals.

4. If the body of the air tool needs cleaning, wipe it with

a soft damp cloth. A mild detergent can be used but

nothing like alcohol, petrol or other cleaning agent.

5. Never use caustic agents to clean plastic parts.

CAUTION: Water must never come into contact with the tool.

Repairs

1. Only an authorised service centre should carry out

repairs on air tools.

11

Page 12

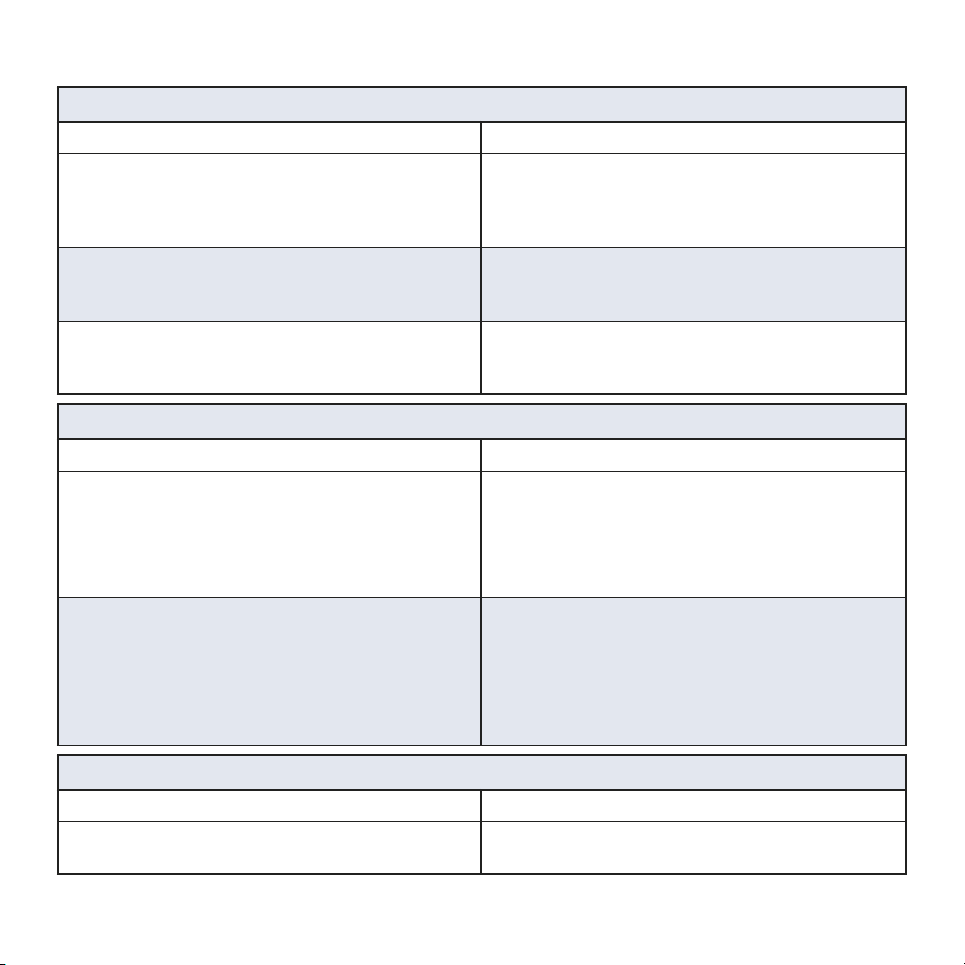

Troubleshooting

Trouble Possible cause(s) Suggested remedy(s)

Tool runs slowly or will not

operate.

1. No oil in tool. 1. Lubricate the tool according to the

lubrication instructions.

2. Grit or gum in tool. 2. Flush the tool with air tool oil, gum

solvent, or an equal mixture of motor

oil and kerosene.

3. Low air pressure. 3. a. Adjust the regulator on the tool to

the maximum setting.

b. Adjust the compressor regulator to tool

maximum the tool is running free.

4. Air hose leaks. 4. Tighten and seal hose fittings if leaks

are found.

5. Pressure drops. 5. a. Be sure the hose is the proper

size. Long hoses or tools using

large volumes of air may require

a hose with an I.D. of 1/2” or

larger depending on the total

length of the hose.

b. Do not use a multiple number of

hoses connected together with

quick connect fittings. This causes

additional pressure drops and

reduces the tool power.

6. Worn rotor blade. 6. Replace rotor blade.

7. Worn ball bearing. 7. Remove and inspect bearing for rust,

dirt and grit. Replace or clean and

regrease bearing with bearing grease.

12

Page 13

Troubleshooting (cont.)

Trouble Possible cause(s) Suggested remedy(s)

Moisture blowing out of

tool.

Impacts slowly or will not

impact.

Impacts rapidly but will

not remove bolts.

Does not impact.

1. Water in tank. 1. Drain tank. Oil tool and run until no

water is evident.

2. Water in air hoses. 2. a. Install a water filter.

b. Install an air dryer.

1. Lack of lubrication. 1. Lubricate the air motor and impact

mechanism.

2. Tool regulator set in wrong position. 2. Adjust the regulator on the tool to

the maximum setting.

3. Inline regulator too low. 3. Adjust regulators in the air system.

1. Worn impact mechanism. 1. a. Replace worn impact

mechanism components.

b. Return impact wrench for repair.

1. Broken impact mechanism. 1. a. Replace broken impact

mechanism components.

b. Return impact wrench for repair.

13

Page 14

141516

Page 15

Page 16

Carefully read the entire Instruction Manual

before using this product.

Before returning this product for a

Warranty Claim or any other reason

Please Call 1300 880 001 (Australia)

or 0800 445 721 (New Zealand)

When you make your call, please have

the following information at hand:

• GMC Product Type • GMC Product Code

A GMC Service Engineer will take your call and, in

most cases, will be able to solve your problem over

the phone.

You are welcome to use this phone-in service to

make suggestions or give comments about any

GMC product.

With continuing product development changes may

have occurred which render the product received

slightly different to that shown in this instruction

manual. The manufacturer reserves the right to

change specifications without notice. Note:

Specifications may differ from country to country.

The GMC 777 Helpline operates from 7am to

7pm, 7 days a week (EST). This allows you

to contact GMC directly with any queries and

technical questions you have regarding

our products.

45–55 South Centre Road

Melbourne Airport

Victoria, Australia 3045

Tel: (03) 8346 1100 Fax: (03) 8346 1299

Save this Manual for future reference.

Loading...

Loading...