Page 1

INSTRUCTION MANUAL

Finishing Nail Gun Kit

• Taipei • New York • Verona • London • Paris

031 21 6 PR ED 08

Fires up to 50mm x 16 Gauge

Page 2

Contents

Full 2 Years Home Use Warranty

Whilst every effort is made to ensure your complete

satisfaction with this tool, occasionally, due to the mass

manufacturing techniques, a tool may not live up to our

required level of performance and you may need the

assistance of our service department.

This product is warranted for a 2-year period for home

domestic use from the date of the original purchase. If

found to be defective in materials or workmanship, the

tool or the offending faulty component will be replaced

free of charge with another of the same item. A small

freight charge may apply.

The warranty replacement unit is only made available by

returning the tool to the place of purchase with a

confirmed register receipt. Proof of purchase is essential.

We reserve the right to reject any claim where the

purchase cannot be verified.

This warranty does not include damage or defects to the

tool caused by or resulting from abuse, accidents,

alterations or commercial or business use.

It also does not cover any bonus accessories unless the

tool is a GMC Platinum Professional model.

Please ensure that you store your receipt in a safe place

.

Conditions apply to the above warranty.

If you need direction of what constitutes a free of

charge warranty claim, please review the guide given on

the rear of the Receipt Holder. An indication is given as

to the types of claim that are permissible, and those

that are not.

Warranty 2

Introduction 3

Environmental protection 3

Description of symbols 3

Specifications 3

General safety instructions for air tools 3

Risk of eye or head injury 5

Risk of fire or explosion 5

Risk of loss of hearing 6

Risk to injury 6

Risk of electric shock 8

Risk of entanglement 9

Risk of cut or burns 9

Know your product 10

Preparing the tool 11

Operation 11

Firing mechanism 12

Where to use finishing nailers 12

Checking the safety strike element 12

Loading & unloading the fasteners 12

Adjusting the exhaust direction 13

Adjusting the fastening depth 13

Clearing a jam 13

Power source 13

Troubleshooting 14

Page 3

Dear Customer

If you require any help with your product, whether it

is a Warranty claim, spare part or user information,

please phone our Help Line for an immediate response. Phone

1300 880 001 in Australia or 0800 445 721 in New Zealand.

Introduction

Your new GMC tool will more than satisfy your expectations.

It has been manufactured under stringent GMC Quality

Standards to meet superior performance criteria.

You will find your new tool easy and safe to operate,

and, with proper care, it will give you many years of

dependable service.

Caution. Carefully read through this entire Instruction

Manual before using your new GMC Tool. Take special care

to heed the Cautions and Warnings.

Your GMC tool has many features that will make your job

faster and easier. Safety, performance, and dependability

have been given top priority in the development of this

tool, making it easy to maintain and operate.

Environmental protection

Recycle unwanted materials instead of

disposing of them as waste. All tools, hoses

and packaging should be sorted, taken to

the local recycling centre and disposed of

in an environmentally safe way.

Description of symbols

The rating plate on your tool may show symbols. These

represent important information about the product or

instructions on its use.

Wear hearing protection.

Wear eye protection.

Wear breathing protection.

Specifications

Operating Pressure: 75 – 120 PSI

Air Consumption: 4 – 8CFM

Magazine Capacity: 100 Nails

Nail size: 16 Gauge C-Brads

Nail lengths: 18, 25, 32, 36, 45 or 50mm

Weight: 1.7kg

Air Inlet: ” PT

Tool Dimensions: 304 x 77 x 254mm

General safety instructions for air tools

To use this tool properly, you must observe the safety

regulations, the assembly instructions and the operating

instructions to be found in this Manual. All persons who

use and service the machine have to be acquainted with

this Manual and must be informed about its potential hazards.

Children and infirm people must not use this tool. Children

should be supervised at all times if they are in the area in which

the tool is being used. It is also imperative that you observe the

accident prevention regulations in force in your area. The same

applies for general rules of occupational health and safety.

Warning. When using air tools, basic safety precautions

should always be taken to reduce the risk of fire, electric

shock and personal injury. Also, please read and heed

the advice given in the additional important safety

instructions.

3

Page 4

1. Keep the work area clean and tidy. Cluttered work

areas and benches invite accidents and injury.

2. Consider the environment in which you are working.

Do not use air tools in damp or wet locations. Keep

the work area well lit. Do not expose air tools to rain.

Do not use air tools in the presence of flammable

liquids or gases.

3. Keep visitors away from the work area. All visitors

and onlookers, especially children and infirm persons,

should be kept well away from where you are working.

Do not let others in the vicinity make contact with the

tool or air hose.

4. Store tools safely. When not in use, tools should be

locked up out of reach.

5. Do not force the tool. The tool will do the job better

and safer working at the rate for which it was designed.

6. Use the correct tool for the job. Do not force small

tools or attachments to do the job best handled by a

heavier duty tool. Never use a tool for a purpose for

which it was not intended.

7. Dress correctly. Do not wear loose clothing or

jewellery. They can be caught in moving parts. Rubber

gloves and non- slip footwear are recommended

when working outdoors. If you have long hair, wear a

protective hair covering.

8. Use safety accessories. Safety glasses and earmuffs

should always be worn. A face or dust mask is also

required if the sanding operation creates dust.

9. Do not abuse the air hose. Never carry the air tool

by the air hose. Keep the air hose away from heat, oil

and sharp edges.

10. Secure the work piece. Use clamps or a vice to hold

the work piece. It is safer than using your hand and

frees both hands to operate the tool.

11. Do not overreach. Keep your footing secure and

balanced at all times.

12. Look after your tools. Keep tools sharp and clean

for better and safer performance. Follow the instructions

regarding lubrication and accessory changes. Inspect air

hose periodically and, if damaged, have it replaced. Keep

tool handles dry, clean and free from oil and grease.

13. Disconnect idle tools. Disconnect air tools from the

air hose before servicing, when changing accessories

and when the tool is not in use.

14. Remove adjusting keys and wrenches. Check to see

that keys and adjusting wrenches are removed from

the tool before switching on.

15. Avoid unintentional starting. Do not carry a

connected air tool with your finger on the trigger.

16. Stay alert. Watch what you are doing. Use common

sense. Do not operate an air tool when you are tired.

17. Check for damaged parts. Before using a tool, check

that there are no damaged parts. If a part is slightly

damaged, carefully determine if it will operate

properly and perform its intended function. Check for

alignment of moving parts, binding of moving parts,

breakage of parts, proper mounting and any other

conditions that may affect the operation of the tool.

A part that is damaged should be properly repaired

or replaced by an authorised service facility, unless

otherwise indicated in this Instruction Manual.

18. Guard against electric shock. Prevent body contact

with grounded objects such as water pipes, radiators,

cookers and refrigerator enclosures.

19. Use only approved parts. When servicing, use only

identical replacement parts. Use an authorised service

facility to fit replacement parts.

20. Disconnect tool from air supply hose. Before

doing tool maintenance, clearing a jammed fastener,

leaving work area, moving tool to another location,

or handing the tool to another person.

21. Never use a tool that is leaking air, has missing

or damaged parts, or requires repair. Make sure all

screws and caps are securely tightened.

22. Operator and others in work area MUST wear

safety glasses with side shields.

4

Page 5

Important safety instructions

Risk of eye or head injury

What could happen How to prevent it

• Air powered equipment are capable of propelling

materials such as fasteners, metal chips, saw dust, and

other debris at high speed, which could result in serious

eye injury.

• Tool attachments can become loose or break and fly

apart propelling particles at the operator and others in

the work area.

• Compressed air can be hazardous. The air stream can cause

injury to soft tissue areas such as eyes, ears, etc. Particles

or objects propelled by the stream can cause injury.

• Always wear safety glasses with side shields.

• Never leave operating tool unattended. Disconnect air

hose when tool is not in use.

• Wearing hearing protection and helmet during

operation is also strongly recommended.

• For additional protection use an approved face shield in

addition to safety glasses.

• Make sure all connections are secure and check air

hoses for weak or worn condition before each use.

Risk of fire or explosion

What could happen How to prevent it

• Air nailers are capable of generating sparks which could

result in ignition of flammable materials.

• Exceeding the maximum pressure rating of tools or

accessories could cause an explosion resulting in serious

injury.

• Never operate tools near flammable substances as

gasoline, cleaning solvents, etc.

• Work in a clean, well ventilated area.

• Never use oxygen, carbon dioxide or other gases as a

power source for air tools.

• Use compressed air regulated to a maximum pressure at

or below the rated pressure of any attachments.

• Connect tool to air supply hose with a coupling that

automatically removes all pressure from the tool when

the coupling is disconnected.

• Do not exceed maximum operating pressure of this tool

of 120 PSI.

• Only use air hose that is rated for a maximum working

pressure of at least 120 PSI or 150% of the maximum

system pressure, which ever is greater.

• Always verify prior to using the tool that the air source

has been adjusted to the rated air pressure range.

5

Page 6

Risk of loss of hearing

What could happen How to prevent it

• Long term exposure to noise produced from the operation

of air tools can lead to permanent hearing loss.

• Always wear hearing protection.

Risk to injury

What could happen How to prevent it

• Tools left unattended with the air hose attached, can

be activated by unauthorized persons leading to their

injury or injury to others.

• Air tools can propel fasteners or other materials

throughout the work area.

• A wrench or a key that is left attached to a rotating

part of the tool increases the risk of personal injury.

• Remove air hose when tool is not in use and store tool

in secure location away from reach of children and or

untrained users.

• Always keep hands and body away from the fastener

discharge area when air supply is connected to air nailer.

• Use only parts, fasteners, and accessories recommended

by the manufacturer.

• Always assume the finish nailer contains nails. Never

use the nailer as a toy.

• Keep work area clean and free of clutter.

• Keep children and others away from work area during

operation of the tool.

• Grip tool firmly to maintain control while allowing tool

to recoil away from work surface as fastener is driven. If

safety element is allowed to recontact work surface before

trigger is released an unwanted fastener will be fired.

• Keep work area well lit.

• Remove adjusting keys and wrenches before turning the

tool on.

6

Page 7

Risk to injury (cont.)

• Air tools can become activated by accident during

maintenance or tool changes.

• Air tools can cause the workpiece to move upon

contact leading to injury.

• Loss of control of the tool can lead to injury to self or

others.

• Poor quality, improper, or damaged nailers can fly apart

during operation, propelling particles throughout the

work area causing serious injury.

• Disconnect the brad nailer from air compressor before

changing tools, loading/unloading fasteners or accessories,

clearing jams and during non-operation.

• Do not depress trigger when connecting the air hose.

• Never carry the tool by the hose.

• Avoid unintentional starting. Don’t carry an air tool which

is connected to an air hose, with your finger on the trigger.

• Repair servicing should be done only by an authorized

service representative.

• Use clamps or other devices to prevent movement.

• Never operate tool while under the influence of drugs

or alcohol.

• Don’t overreach. Keep proper footing and balance at all

times.

• Always place yourself in a firmly balanced position when

using or carrying the brad nailer.

• Keep handles dry, clean, and free from oil and grease.

• Stay alert. Watch what you are doing. Use common

sense. Do not operate tool when you are tired.

• Always use tool attachments rated for the speed of the

air tool.

• Never use air tools which have been dropped, impacted

or damaged by use.

• Never use tool if safety, trigger or springs are

inoperable, missing or damaged. Do not alter or remove

safety, trigger, or springs. Make daily inspections for free

movement of trigger and safety mechanism.

• Do not apply excessive force to the tool, let the tool

perform the work.

7

Page 8

Risk to injury (cont.)

• Fasteners could ricochet or be propelled causing serious

injury or property damage.

• Improperly maintained tools and accessories can cause

serious injury.

• There is a risk of bursting if the tool is damaged. • Check for misalignment or binding of moving parts,

• Use only accessories identified by the manufacturer to

be used with specific tools.

• Never point discharge of tool at self or others.

• Do not pull trigger unless tool contact safety device is

against work surface.

• Never attempt to drive fasteners into hard surfaces such

as steel, concrete, or tile.

• Take care to avoid driving a fastener on top of another

fastener.

• Position tool carefully so that fasteners will be delivered

to the proper location.

• Do not drive fasteners close to the edge of the

workpiece. The workpiece is likely to split allowing the

fastener to fly free or ricochet causing personal injury.

• Maintain the tool with care.

• Always check that the striking element is operating

properly. Do not modify or disable the strike element, or

any tool parts.

breakage of parts, and any other condition that affects

the tool’s operation. If damaged, have the tool serviced

before using.

• Use of an accessory not intended for use with the

specific tools, increases the risk of injury to persons.

Risk of electric shock

What could happen How to prevent it

• Using air tools to attach electrical wiring may result in

electrocution or death.

• Contact with a “live” wire will also make exposed metal

parts of the tool “live” and may result in electrocution

or death.

• Fasteners coming in contact with hidden electrical

wiring may cause electrocution or death.

• Never use a nailer to attach electrical wiring while

energized.

• Avoid body contact with grounded surfaces such as

pipes, radiators, ranges, and refrigerators. There is an

increased risk of electric shock if your body is grounded.

• Thoroughly investigate the workpiece for possible

hidden wiring before performing work.

8

Page 9

Risk of entanglement

What could happen How to prevent it

• Tools which contain moving elements, or drive other

moving tools, can become entangled in hair, clothing,

jewellery and other loose objects, resulting in severe

injury.

• Never wear loose fitting clothes, or apparel which

contains loose straps or ties, etc. which could become

entangled in moving parts of the tool.

• Remove any jewellery, watches, identifications,

bracelets, necklaces, etc. which might become caught

by the tool.

• Keep hands away from moving parts. Tie up or cover

long hair.

• Always wear proper fitting clothing and other safety

equipment when using this tool.

Risk of cut or burns

What could happen How to prevent it

• Tools which cut, shear, drill, staple, punch, chisel, etc.

are capable of causing serious injury

• Keep the working part of the tool away from hands and

body.

9

Page 10

10

Know your product

1. Exhaust deflector

2. Trigger

3. Air inlet

4. Latch

5. Nail magazine

6. Safety strike element

(Non marking tip)

8. Drive safety cover

9. Quick release latch

10. Depth adjustment

thumb wheel

5

1

8

7 4

3

2

9

10

10

6

Page 11

11

Preparing the tool

Tool lubrication

This finish nailer requires lubrication BEFORE initial use and

BEFORE and AFTER each additional use throughout its life.

1. Disconnect the air hose, turn the finish nailer so the air

inlet (3) is facing up. Place 3-4 drops of non detergent

oil into the air inlet. Do not use air tool oil as it

contains solvents which will damage the nailer’s internal

parts.

2. Lubricate the drive safety cover & slide guide (8),

trigger (2) and magazine slide mechanism periodically.

3. After lubrication, run brad nailer briefly. Wipe off any

excess oil from the adjustable deflector exhaust (1).

The work surface can become damaged by excessive

lubrication.

4. Finish nailer repairs must be done by a qualified and

experienced service dealer.

Apply a thin coat of

lightweight grease to

safety slide guides.

Apply a few drops of oil

to sliding mechanism of

the magazine.

Apply a few drops

of oil to the trigger

mechanism.

Place a few drops of

non-detergent oil into

air inlet before each use.

Page 12

Operation

Operating the tool:

Firing mechanism:

This tool operates on a single (full sequential actuation)

firing system.

Single (full sequential actuation) firing.

To fire, grip tool firmly to maintain control, position nose

of tool onto work surface, depress safety, and squeeze

trigger to fire a fastener. Allow tool to recoil away from

work surface as fastener is driven. This “full sequential

actuation” method provides the most accurate fastener

placement.

Where to use finishing nailer.

Finishing nailers are used mainly in medium to light duty

applications. The use of C Brad nails enables the nail heads

to be countersunk under the surface of you work surface.

This is important where the ‘finish’ or appearance of the

workpiece is a priority.

Some additional important safety applications are as

follows:

1. Fire fasteners into work surface only, never into

materials too hard to penetrate such as concrete and

steel.

2. Do not drive fasteners on top of other fasteners, or with

the tool at too steep an angle as the fasteners may

ricochet causing personal injury.

3. Do not drive fasteners close to the edge of the

workpiece. The workpiece is likely to split allowing the

fastener to fly free or ricochet causing personal injury.

Checking the safety strike element:

1. Disconnect the air hose from the brad nailer and remove

all fasteners from the magazine.

2. Make sure the trigger and the strike nose move freely up

and down.

3. Reconnect air hose to the finish nailer.

4. Push the strike element against the work surface without

depressing the trigger. The finish nailer MUST NOT cycle.

5. Remove the finish nailer from the work surface, the

strike element should return to its original position. Pull

the trigger, the brad nailer MUST NOT cycle. If it cycles

DO NOT use it.

Loading & unloading the fasteners:

1. Always disconnect the finish nailer to the air hose before

loading fasteners.

2. Press and pull the latch (4)

back until it catches onto the

back of the nail magazine

cover (5).

3. Insert a row of quality C - brad

fasteners into the magazine.

Make sure the pointed ends

of the fasteners are resting on

the bottom of the magazine.

IMPORTANT: Make sure the fasteners are not rusted,

damaged or dirty.

5. Push the nail magazine cover (5) forward until the latch

meets with the nails.

6. Always disconnect the air hose before unloading

fasteners.

12

Page 13

Adjusting the exhaust direction:

1. The finish nailer is equipped

with an adjustable direction

exhaust deflector (1). Simply

adjust the directional exhaust

deflector so that the exhaust

air blast will be directed away

from the operator. Grasp the

deflector and rotate it to the

desired position for the current

application.

Adjusting the fastening depth:

1. Regulate the air pressure to 120 PSI at the compressor.

2. Connect the air hose to the nailer and test for

penetration by driving fasteners into a sample piece of

wood. If the fasteners do not achieve the desired depth,

rotate the depth adjustment thumb wheel (10) until the

desired depth is achieved.

Clearing a jam:

1. Disconnect the air supply from

the nailer and remove all

fasteners from the magazine.

2. Press the quick release latch

(9) which will disengage the

the driver safety cover (8).

Remove the driver safety cover

(8) so the jammed fastener is

exposed.

3. Remove the jammed fastener,

using screwdriver or long nose

pliers if required.

4. Close back the driver safety

cover tightly.

5. Test the finish nailer.

Power source

This tool is designed to operate on clean, dry, compressed

air at regulated pressures between 75 and 120 PSI.

The preferred system would include a filter, a pressure

regulator, and an automatic oiler located as close to the

tool as possible.

All compressed air contains moisture and other

contaminates that are detrimental to internal components

of the tool. An air line filter will remove most of these

contaminates and significantly prolong the life of the tool.

If an in-line oiler is not available, place 3 - 4 drops of non

detergent oil into the tool’s air inlet at the beginning of

each workday.

DANGER: All air line components (hoses, connectors,

filters, regulators, etc.) must have a minimum working

pressure rating of at least 120 PSI or 150% of maximum

system potential, whichever is greater.

13

Page 14

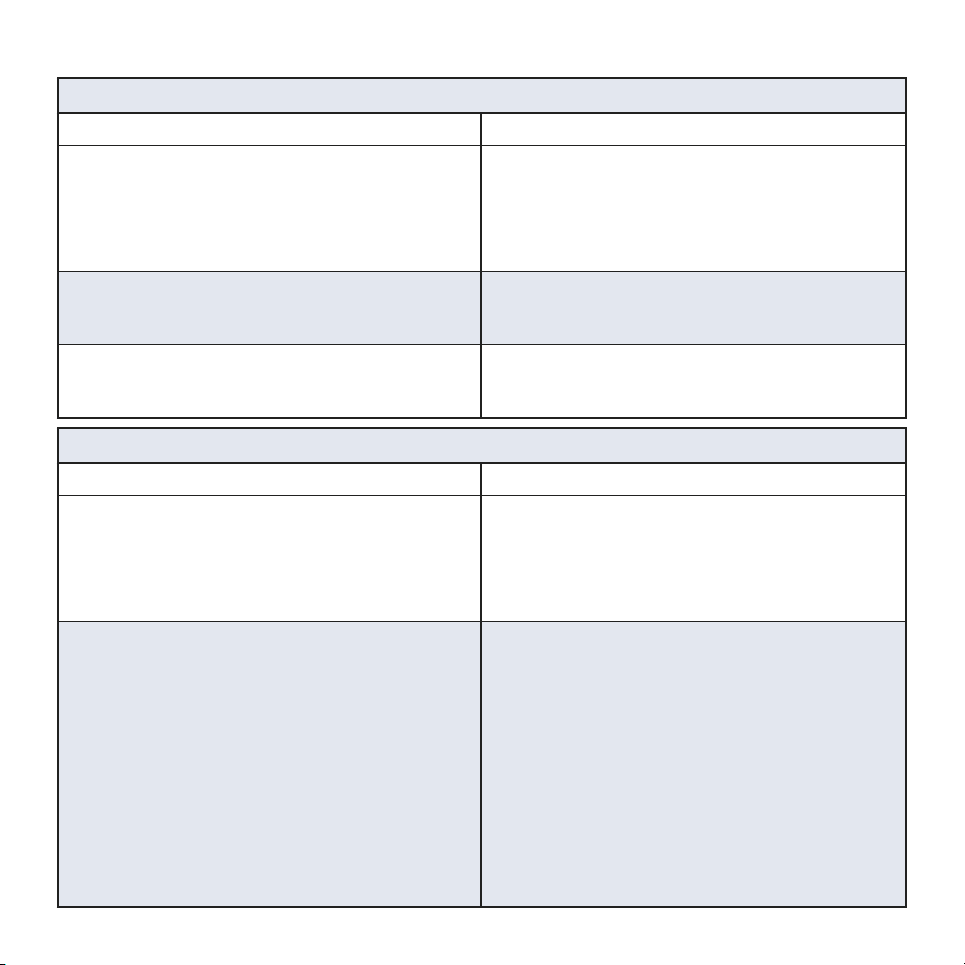

Troubleshooting

Trouble Possible cause Suggested remedy

Nailer skips when driving

brad nails.

Air leaking near the top of

the tool or in trigger area.

Nailer runs slow or has loss

of power.

Air leaking near the

bottom of the tool.

Tool jams frequently.

WARNING: Disconnect tool from air supply before performing any cleaning and maintenance procedures.

Dirt in the nose piece. Drive channel needs to be cleaned.

Dirt or damage prevent nails or pusher

from moving freely in magazine.

Inadequate air flow to nailer. The fittings, hose or air compressors

Loose screws. Tighten screws.

Nailer not lubricated sufficiently. Nailer needs to be lubricated.

Exhaust port in the cap has been

blocked.

Loose screws. Tighten screws.

Incorrect fasteners. Verify approved fasteners of correct size.

Damaged fasteners. Replace with undamaged fasteners.

Magazine is dirty. Clean magazine.

Magazine needs to be cleaned.

needs to be checked.

Damaged internal parts needs to be

replaced by an authorized service centre.

14

Page 15

15

Page 16

Carefully read the entire Instruction Manual

before using this product.

Before returning this product for a

Warranty Claim or any other reason

Please Call 1300 880 001 (Australia)

or 0800 445 721 (New Zealand)

When you make your call, please have

the following information at hand:

• GMC Product Type • GMC Product Code

A GMC Service Engineer will take your call and, in

most cases, will be able to solve your problem over

the phone.

You are welcome to use this phone-in service to

make suggestions or give comments about any

GMC product.

With continuing product development changes may

have occurred which render the product received

slightly different to that shown in this instruction

manual. The manufacturer reserves the right to

change specifications without notice. Note:

Specifications may differ from country to country.

The GMC 777 Helpline operates from 7am to

7pm, 7 days a week (EST). This allows you

to contact GMC directly with any queries and

technical questions you have regarding

our products.

45–55 South Centre Road

Melbourne Airport

Victoria, Australia 3045

Tel: (03) 8346 1100 Fax: (03) 8346 1200

Save this Manual for future reference.

16

Loading...

Loading...