Global Machinery Company 2500HD User Manual

2007 TRAILERING WITH GMC TRUCKS

YOU NEED THE RIGHT RIG TO GET THE JOB DONE RIGHT.

It takes the right truck to give you the specific trailering capabilities you need.

A number of factors must be taken into account — everything from the weight of

the load to driving conditions. This document will assist you in selecting the vehicle, powertrain and other equipment that best suit your particular application.

You should look for the same qualities in a tow vehicle that you do in any truck —

you need it to be strong and powerful, as well as comfortable and accommodating.

That’s what makes GMC trucks such a smart choice for trailering. GMC trucks

have what it takes for serious towing. Every truck shown in this document was

engineered and manufactured with trailering in mind. And with the extensive

lineup of GMC trucks, you can be sure there is one that is built to meet your

trailering specifications.

SAFE TRAILERING

Safe trailering isn’t just a matter of hitching up and driving off — it places demands

on all the major systems of your truck, including powertrain, steering, suspension

and brake systems. Safe trailering also places the onus on you to meet legal

requirements, follow break in and maintenance schedules, use proper vehicle and

trailer loading guidelines and employ safe driving techniques. See your Owner’s

Manual for more information. Above all, safe and easy trailering requires a properly

equipped vehicle. It is important to ensure that a vehicle is built to handle your

specific trailering requirements. This will help you choose the right truck for the job.

CAUTION

If you don’t use the correct equipment and drive properly, you can lose control of

your vehicle when you pull a trailer. For example, if the trailer is too heavy, your

vehicle’s brakes may not work well — if at all. Your vehicle passengers and you

could also be seriously injured. Pull a trailer only after you have taken the following

precautions. Trailer Brakes — If your trailer weighs more than 454 kg (1000 lb.)*

loaded, then it must have its own adequate brakes. Be sure to read and follow the

instructions for the trailer brake controller so that it is installed, adjusted and

maintained properly. Hitches — It’s important to have the correct hitch equipment.

Crosswinds, large trucks going by and rough roads are just a few of the reasons

why you’ll need the right hitch. Be sure to use a frame-mounted, weight-distributing

hitch and sway control of the proper size if the loaded trailer will weigh more

than the limit shown for a weight-carrying hitch in the specific vehicle notes.

This equipment is very important for proper vehicle weight distribution and

good handling.

Note: These safety steps are by no means the only precautions to be taken when

trailering. See your vehicle Owner’s Manual for additional information.

*Sierras, Yukons and Yukon XLs can handle loaded trailer weights up to 907 kg (2000 lb.) where local

regulations permit.

THE SELECTION PROCESS

WHEN IT COMES TO TRAILER TOWING, ALL VEHICLES ARE

NOT CREATED EQUAL. IT’S IMPORTANT TO SELECT THE RIGHT

VEHICLE WITH THE PROPER EQUIPMENT FOR THE JOB.

Before you can select the right tow vehicle, you need to define your trailering

requirements, including the trailer type, its loaded weight and the way it will be

used. Pick your trailer first.

Even if you plan to tow a trailer for only one or two trips a year, your tow vehicle

must be strong and stable enough to be safe under the most extreme towing situations

it is likely to face. Will towing include trips in mountainous areas with long, steep

grades and high altitudes? Will you be driving it in extreme temperatures? Will

road conditions, winter operation or slippery boat ramps dictate the need for

four-wheel drive? Each of these factors has an impact on your choice of a towing

vehicle. If you plan to use a vehicle primarily for towing, you should optimize its

trailering equipment. If instead you are going to use a vehicle primarily for

personal transportation with only occasional towing, your need for specialized

equipment may be less. But the vehicle still needs to be capable of towing the

trailer you have selected — even the most basic trailering requires some special

equipment. Obviously, trailer weight is critical in vehicle selection. In making this

calculation, don’t forget to include your estimate of the weight of passengers,

cargo and other equipment in the tow vehicle. Once you have established your

trailering requirements, you are ready to determine specifications for the tow

vehicle. Properly selected vehicle components provide the added durability needed

to support, move and stop the extra weight of a trailer.

LOCKING REAR AXLE

A locking-type differential is available in most GMC trucks and is standard in many.

It permits normal differential action, which helps prevent tire scuffing when turning.

If the differential senses an excessive difference in speed between the rear driving

wheels, it forces power to the wheel with the best traction and is more effective

than the limited slip designs used by most competitors. This advantage is most

evident on slippery surfaces where traction is at a premium, such as on boat ramps

and ice- or snow-covered roads.

TOW/HAUL MODE

Most GMC trucks equipped with a 4-speed automatic transmission feature a Tow/Haul mode,* which helps minimize

wear and tear on the transmission by reducing the frequency of transmission shifting when pulling a heavy trailer. It

also improves performance and control of your vehicle’s speed, for smoother operation. Pressing the Tow/Haul mode

selector switch located on the end of the gearshift lever (on the instrument panel in Savana Vans) produces a more

aggressive transmission shift pattern, which lengthens the shift intervals and produces firmer upshifts.

Take note: this is not the overdrive lock-out used by many competitors. In fact, Tow/Haul mode, combined with Passive

Shift Stabilization, permits towing in overdrive for optimum fuel efficiency in most situations. The Passive Shift

Stabilization feature detects and reduces a condition referred to as “shift busyness.”

*Except GMC Canyon, GMC Envoy, Buick Rainier, Pontiac Montana SV6 and Buick Terraza.

TRAILERING CLASSIFICATIONS

CLASSIFICATIONS TYPICAL EXAMPLES WEIGHT RANGE TYPICAL HITCH TYPE TYPICAL HITCH WEIGHT

(Gross Trailer Weight) (tongue or kingpin)

Light-Duty

Folding camping trailer, Up to 907 kg (2000 lb.) Weight-carrying hitch 10%-15% of loaded trailer weight

Class I

snowmobile and jet-ski trailers 91 kg (200 lb.) maximum

Medium-Duty

Single axle trailer, open utility 908 kg – 1588 kg Weight-carrying hitch 10%-15% of loaded trailer weight

Class ll

trailer and small boat trailers (2001 – 3500 lb.) 159 kg (350 lb.) maximum

Heavy-Duty

Dual axle trailers, larger boats 1589 kg – 2268 kg Weight-carrying or 10%-15% of loaded trailer weight

Class lll

and enclosed utility trailers (3501 – 5000 lb.) Weight-distributing hitch 272 kg (600 lb.) maximum

Extra

Large horse or travel and 2269 kg – 4536 kg Weight-distributing or 10%-15% of loaded trailer weight. 15%-25% of loaded trailer weight.

Heavy-Duty

fifth-wheel recreational trailers (5001 – 10,000 lb.) fifth-wheel hitch 544 kg (1200 lb.) maximum Maximum limited by truck’s

Class IV

for weight-distributing hitch. GVWR.

Maximum

Largest horse, travel and 4537 kg (10,001 lb.) Weight-distributing, 10%-15% of loaded trailer weight. 15%-25% of loaded trailer weight.

Heavy-Duty

fifth-wheel recreational or and over fifth-wheel or 680 kg (1500 lb.) maximum 1588 kg (3500 lb.) maximum

Class V

commercial trailers gooseneck hitch. for weight-distributing hitch. for fifth-wheel hitch.

2

POWERTRAIN SELECTION

ENGINES

The information presented in the charts in this document is intended to help you

identify the right engine for your application. The charts show, by vehicle type

and trailer weight, the minimum engine sizes and available axle ratios needed to

provide good performance at legal highway speeds with no significant reduction

in long-term durability.

Engine performance is measured in horsepower and torque. Horsepower is a

measurement of the work an engine can produce and is a factor of both torque

and engine speed. Torque is a twisting force normally expressed in pounds-feet

(lb.-ft.). You need torque, to put a twisting force on the drive axles and to turn the

wheels when you start a load moving. The engine’s torque can be multiplied using

transmission and drive axle gears. Higher numerical gear ratios increase the

leverage (twisting force) on a rotating shaft. GMC truck engines are designed with

a broad rpm range in which high torque can be produced and sustained.

A larger engine with greater torque and horsepower will provide a performance

improvement while operating with less strain. For example, higher horsepower

allows the engine to maintain highway speeds when pulling a heavy trailer uphill.

Under the following higher performance demands, it is advisable to choose

an engine larger than the minimum recommendation, if one is available:

• if much of the towing will be at high altitudes, since a gasoline engine loses

approximately 10% of its power for every 1000 metres of altitude

• if mountainous terrain involving long,

steep grades will be

encountered frequently

• if the trailer has a very

large frontal area,

which adds to air drag

and therefore to

pulling requirements

TRANSMISSIONS

Transmissions provide various gear ratios that allow for higher engine rpm

relative to road speed. They also multiply the engine’s torque to provide the

pulling power needed to reach cruising speeds. All GMC truck transmissions*

feature an overdrive top gear that reduces engine speed when cruising, for

improved fuel efficiency.

Some GMC trucks offer a choice of manual or automatic transmission. General

Motors recommends automatic transmissions for trailering. Automatic transmissions

utilize a torque converter (a type of fluid coupling) between the engine and

transmission gears. The torque converter is capable of more than doubling the

engine’s torque when starting to move a heavy trailer, in addition to acting as

a cushion to reduce shock loading of powertrain components. The increased

twisting force from the

torque converter is

further multiplied by

the transmission gears

to provide outstanding

load-starting capability —

and there is no

conventional clutch

to slip and burn out.

Caution: The torque

converter’s operation

causes heat to build

up in the automatic

transmission’s oil,

so all GMC automatic

transmissions have an

oil cooler. For heavy-duty applications such as trailering, your vehicle should be

equipped with additional transmission oil cooling if not standard equipment.

*Except Torrent which uses a 5-speed automatic transmission with a 2.65:1 final drive ratio.

REAR AXLE RATIOS

Another important consideration when determining an ideal trailering vehicle is

the rear axle ratio. Higher axle ratios (4.10:1, for example) increase engine speed

relative to road speed, resulting in increased horsepower development and

torque multiplication. This produces greater towing power, but with a possible

reduction in fuel efficiency when lightly loaded. Overdrive transmissions help to

reduce this negative.

Lower ratios (3.42:1, for example) translate into lower engine rpms, reducing the

torque at the drive wheels. Some gains may be expected in fuel efficiency when

lightly loaded and not towing.

The greater your towing requirements, the greater the demand you place on your vehicle’s powertrain. That’s why

it is so important to carefully select all your powertrain components in response to your trailering needs. Below

are some key guidelines.

SELECT THE CORRECT AXLE RATIO FOR YOUR REQUIREMENTS

Charts on pages 6 through 15 show the axle ratios required, with available engines, to provide the torque development for good performance with various loads.

Lower Numerical Ratio REAR AXLE RATIO Higher Numerical Ratio

(such as 3.42:1) (such as 4.10:1)

Lower ENGINE SPEED (RPM) Higher

Slower ACCELERATION Faster

Less FUEL CONSUMPTION More

Less

PERFORMANCE

Greater

(Trailering or mountainous terrain)

3

KNOW YOUR WEIGHTS AND HITCHES

DRY TRAILER WEIGHT

The weight of the empty trailer as manufactured. This weight, usually shown on

a vehicle identification plate, is not usually used as a measure for the selection

of a tow vehicle.

LOADED TRAILER WEIGHT

The weight of the trailer (Dry Weight) plus all equipment, fluids and cargo.

Loaded Trailer Weight can be determined by putting the fully loaded vehicle on

a commercial vehicle scale. If this is not practical, the trailer’s Gross Vehicle

Weight Rating (GVWR), as found in the trailer manufacturer’s literature or

brochures for the model selected, can be used when selecting a tow vehicle.

MAXIMUM TRAILER WEIGHT RATING

Often referred to as the Gross Trailer Weight Rating, it is the most weight that a

given vehicle can safely and reliably haul, as determined by the manufacturer.

This rating usually requires optional equipment such as a specific axle ratio,

suspension components, engine and/or transmission coolers and type of hitch.

The rating assumes the tow vehicle is properly equipped with a driver allowance

of 68 kg (150 lb.) and no cargo. The weight of additional options or equipment,

passengers and cargo must be deducted from the trailer weight rating.

GROSS VEHICLE WEIGHT RATING (GVWR)

The maximum allowable weight, as determined by the manufacturer, for any

vehicle (or trailer) including the weight of the vehicle, fuel and other fluids,

driver and passengers, cargo and equipment. Tongue Weight or Kingpin Weight

(see below) is included when trailering.

CURB WEIGHT

The weight of the empty vehicle as equipped, including a full tank of fuel. It does

not include the driver, passengers or cargo — so it is similar to Dry Trailer Weight.

PAYLOAD WEIGHT

The weight carried by the vehicle, including the driver, passengers and cargo,

plus options or aftermarket equipment such as boxliners, hitches or fifth wheels.

It should not exceed the Gross Vehicle Weight Rating (GVWR) minus the Curb Weight.

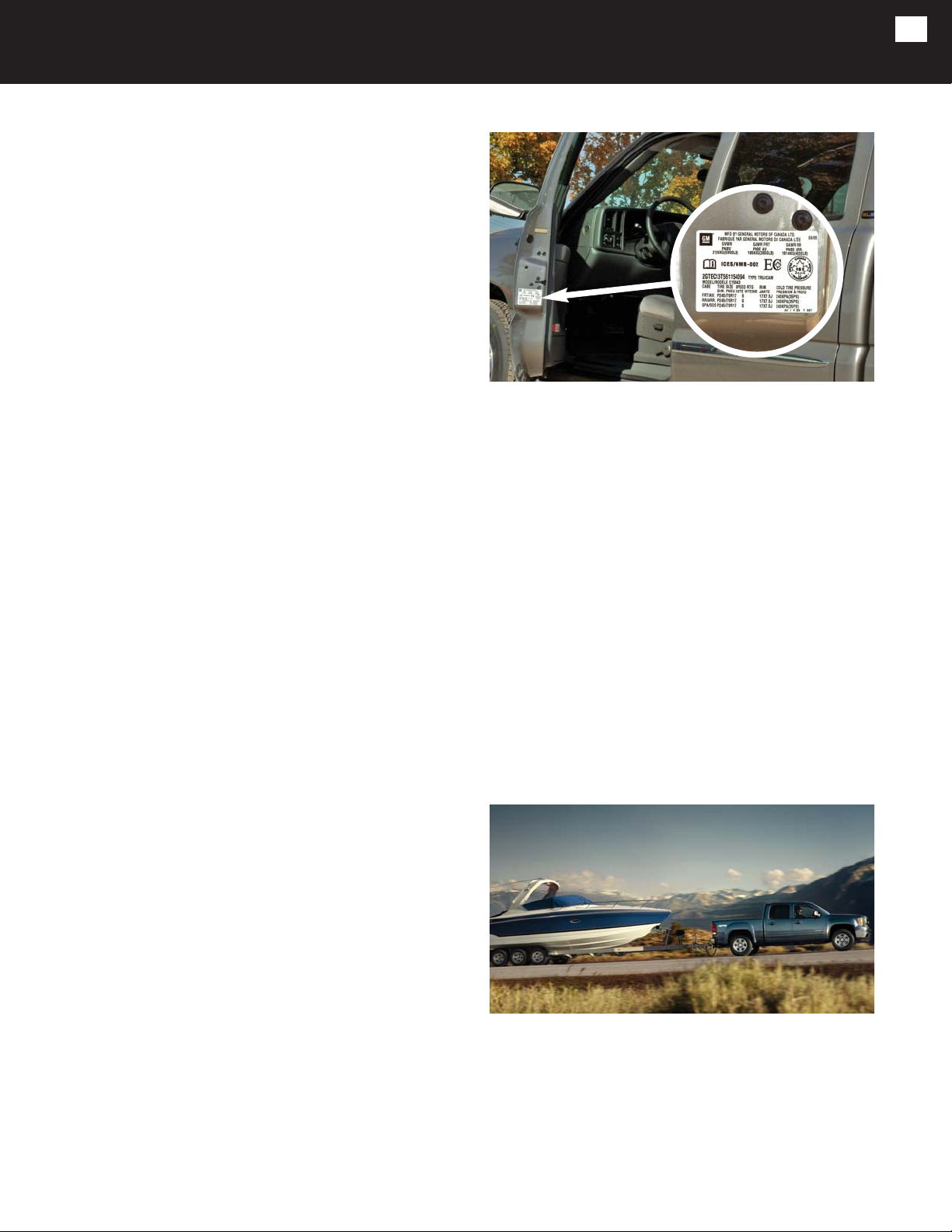

GROSS AXLE WEIGHT RATING (GAWR)

The maximum allowable weight that can be carried on a vehicle’s axle or individual

suspension system, either front or rear. It includes the weight of the vehicle

plus cargo and equipment supported by the axle and includes Tongue Weight

or Kingpin Weight when trailering. These ratings are shown on the vehicle’s

Certification Label, usually located in the driver’s door frame, and should not

be exceeded, nor should the total load exceed the GVWR.

TONGUE WEIGHT/KINGPIN WEIGHT

The weight of the trailer tongue or kingpin that is carried on the hitch ball or

fifth-wheel hitch, respectively. This is a critical measurement as it has an impact

on vehicle handling. Too much Tongue/Kingpin Weight causes overloading of the

rear axle, causing the front suspension to lift and reducing steering response.

Too little Tongue/Kingpin Weight can reduce rear-wheel traction and cause

excessive swaying or jackknifing. Depending on the type of hitch being used,

Tongue Weight is generally 10-15% of the Loaded Trailer Weight. Kingpin Weight

is usualy 15-25% of the trailer weight. Some adjustment to Tongue Weight or

Kingpin Weight can be made by moving the cargo in the trailer.

GROSS COMBINATION WEIGHT RATING (GCWR)

The maximum weight allowable, as established by the manufacturer, for the truck,

the trailer, all equipment, total payload, fuel, fluids and occupants. This is the

total loaded road-ready rig.

HITCHES

Once you have selected your vehicle, the next step is making sure you have

the necessary equipment to help you trailer safely and confidently. The vehicle

owner is responsible for obtaining the hitch ball, a hitch of the proper size,

type and capacity, and other appropriate equipment required to safely tow the

loaded trailer.

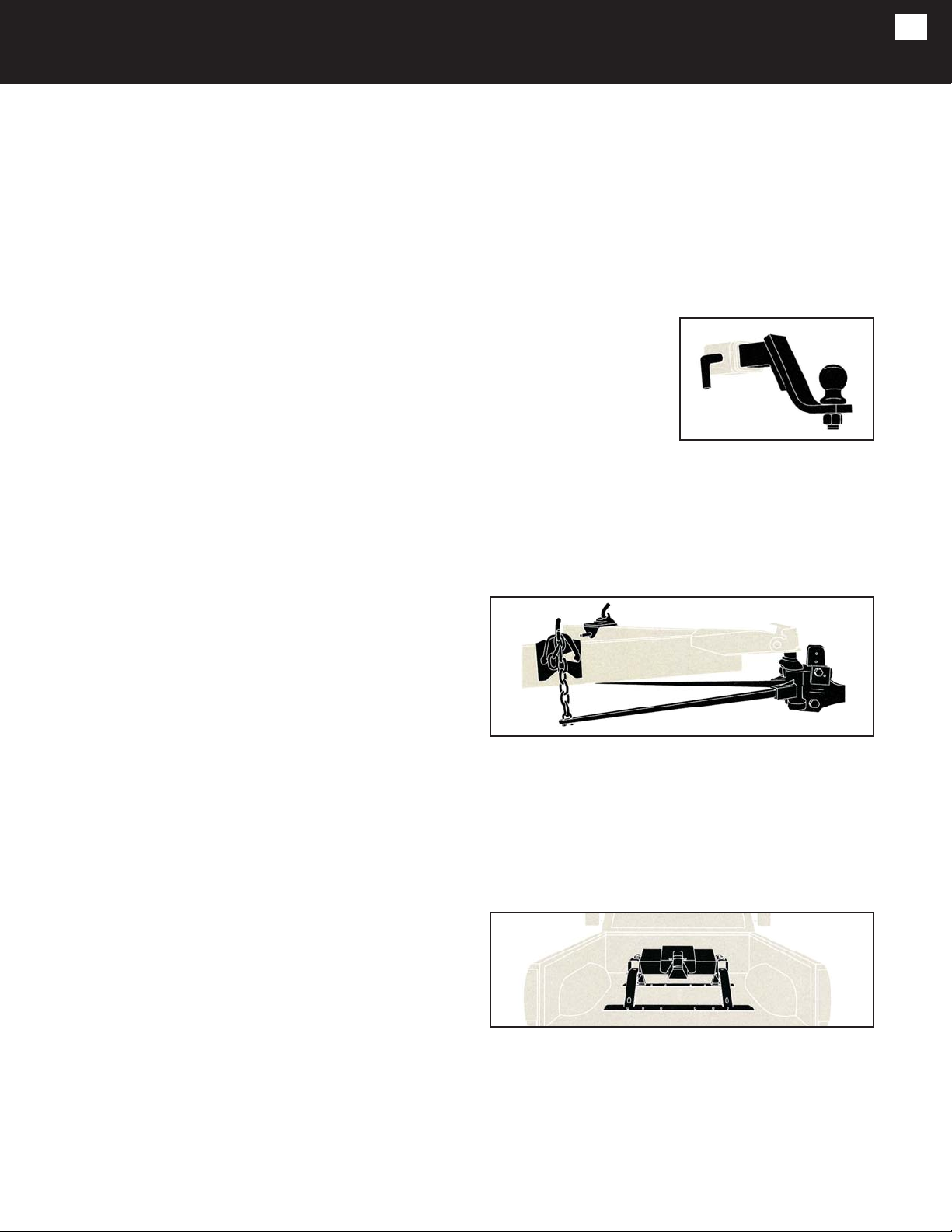

There are three categories of trailer hitches: weight-carrying, weight-distributing

and fifth-wheel. Each is designed for specific types of trailering.

Weight-Carrying Hitch is the most

basic and most common hitch

for light and medium weights.

A weight-carrying hitch uses a

hitch ball mounted to a draw bar

or a step-bumper and supports the

trailer tongue weight just as though

it were cargo located at the ball.

The hitch ball must match the trailer

coupler and meet or exceed the

maximum trailer weight rating.

Weight-Distributing Hitch is used for heavy trailering. This hitch, with its equalizing

bars and snap-up brackets, applies leverage between the tow vehicle and the

trailer to help distribute your trailer’s tongue weight evenly to your vehicle

and trailer instead of “carrying” the load mostly on the rear of the vehicle. The

brackets and spring bars raise the hitch point parallel to the ground, equalizing

the load onto all axles. This results in a more level ride, reduced weight on the

rear suspension and provides improved steering and braking control.

Fifth-Wheel Hitch, or gooseneck hitch, is used for heavy trailering with a full-size

pickup, and it must be attached to the truck’s frame, usually just slightly ahead

of the rear axle centreline. Make sure to follow the manufacturer’s installation

instructions, paying careful attention to the truck’s payload capacity and rear

axle weight ratings. These kingpin loads are generally higher than conventional

trailer tongue loads and for most calculations becomes the payload in the truck

box. The addition of kingpin weight must not cause the vehicle to exceed its

GVWR or GAWRs.

Overloading of tow vehicles and trailers compromises safety and can result in vehicle failure. An understanding of

the following terms will assist in proper vehicle selection and help prevent overloading.

Draw bar type weight-carrying hitch.

Weight-distributing hitch.

Fifth-wheel hitch.

4

NOTES AND CONDITIONS

TRAILER BRAKES

The towing vehicle’s brake system is rated for safe operation at the GVWR and

not the GCWR.

If the loaded trailer will weigh more than 450 kg (1000 lb.), it must have its own

separate brakes when towing with a compact or mid-size truck, or a Savana Van.

The GM full-size pickups, sport-utilities and chassis cabs can haul trailers weighing

up to 907 kg (2000 lb.) without a separate trailer brake system, where local

regulations permit. Trailer brakes come in three main types:

1. Electric actuation brakes typically utilize the tow vehicle’s battery power and

the brake light circuit to trigger their function. They provide both automatic and

manual control of electric trailer brakes. Recent versions have attempted to use

a sensor in the tow vehicle’s hydraulic system in order to vary trailer brake

pressure in concert with the driver’s input. The GM full-size pickups and sportutility vehicles with the available Z82 Trailering Special Equipment Package

provide an under-dash provision for an Electronic Brake Controller (EBC) jumper

harness. This special wiring harness, with 4 blunt cut wires, is included with the

Trailering Package. It allows the EBC to electronically adjust brake pressure

to the trailer brakes.

2. Hydraulic actuation brakes tap into the tow vehicle’s own brake system and

are not recommended. Although brake modulation is very good, this method is

restricted to large tow vehicles with high volume master cylinders and strongly

assisted power brakes. Care must be taken to follow proper installation procedures

or complete loss of braking may result. The trailer’s brake parts must be able

to withstand 3000 pounds per square inch of pressure and not use more than

0.02 cubic inches of fluid from the tow vehicle’s master cylinder.

3. Surge brakes actuate hydraulic trailer brakes via a master cylinder mounted

in the trailer coupler. As the vehicle slows, the trailer presses (or surges) against

the hitch, operating the master cylinder and applying the brakes. Surge brakes

are ideal for marine trailers where the wheels may be submerged. Surge brakes

present problems when backing up, as they will lock on unless some manually

actuated override is provided.

NOTE: Be sure to read and follow the instructions for the trailer brake controller

so that it is installed, adjusted and maintained properly. Many jurisdictions

require a “breakaway” device which activates the trailer brakes automatically in

the event the trailer becomes detached.

TRAILERING AND THE LAW

Trailering laws vary from place to place. A set-up that’s legal in one province may

not be legal in another, or in an American state. In some locations, you may be

required to have a commercial driver’s licence. It pays to check ahead when

planning a trip to ensure your trailering rig meets the local requirements in all

provinces and/or states you will be visiting.

BE SURE AND READ THE TRAILERING INFORMATION FOUND IN YOUR VEHICLE

OWNER’S MANUAL.

Maximum trailer ratings are calculated based on a properly equipped tow vehicle

with a driver as its only occupant. The weight of additional equipment, passengers

or cargo will reduce the trailer rating. In addition to the weight of the trailer,

maximum trailer weight includes the weight of passengers, equipment and

cargo in the tow vehicle, plus any cargo on the trailer. The addition of the

trailer’s tongue weight (or fifth-wheel kingpin weight) must not cause the vehicle

weights to exceed the Rear Gross Axle Weight Rating (RGAWR) or Gross Vehicle

Weight Rating (GVWR). The tongue load of any trailer is an important weight to

measure because it affects the total or gross vehicle weight of your vehicle as well

as the front and rear axle loads.

If a weight-carrying or a weight-distributing hitch is used, the trailer tongue

weight should be 10-15% of the total loaded trailer weight. The kingpin weight of

fifth-wheel trailers is typically 15-25% of the loaded trailer weight. After you’ve

loaded your trailer, weigh the trailer and then the tongue separately on a commercial

scale to see if the weights are accurate. If they are not, some adjustment can be

made by moving some cargo fore or aft in the trailer. Do not exceed the maximum

allowable tongue weight for your vehicle. The weight of additional equipment,

passengers or cargo in the tow vehicle will reduce the allowable tongue weight.

Refer to the Owner’s Manual for additional information. A Certification/Tire label

can be found on the rear edge of the vehicle’s driver-side door. The label shows

the size of the original tires and the inflation pressures needed to obtain the gross

TRAILER LOADING

weight capacity of the vehicle. The GVWR (Gross Vehicle Weight Rating) and both

front and rear GAWRs (Gross Axle Weight Ratings) are also indicated. Never exceed

the GVWR, or the GAWR for either the front or rear axle.

5

Loading...

Loading...