Globaljig Super Rotax User Manual

USERS’ MANUAL

Via Aurelia Ovest, Km. 383 - 54100 Massa (MS) - ITALY

Tel.: +39 0585 8364 - Fax: +39 0585 833880 - www.globaljig.it

USERS’ MANUAL

Year of Manufacture: .......................

INSTRUCTION MANUAL

Issue.

08 / 2004

Pag.

1 - 42

CHAPTERS :

1. INTRODUCTION

2. GENERAL SAFETY RULES

3. CHARACTERISTICS AND TECHNICAL DATA

4. FREIGHT AND UNPACKING

5. INSTALLATION

6. COMMISSIONING

7. CONTROLS AND SET UP

8. OPERATING

9. SAFETY DEVICE

10. WORKING AREA

11. START/ STOP/ EMERGENCY

12. MAINTENANCE

13. REPAIR / COMPONENTS AND SPARE PARTS

14. DIAGRAMS AND OVERALL DIMENSIONS

15. DEMOLITION

APPEDIX: CE CONFORMITY DECLARATION

1. INTRODUCTION

GLOBALJIG INTERNATIONAL. srl, the Manufacturer of the Super Rotax equipment, invite you

to read carefully all the information contained in this Manual until you understand completly all

the instructions.

This Manual explains how to use the Super Rotax, and includes instructions and suggestions for

ensuring safe operations and optimum performance.

The Super Rotax Lifting Bench (here after called “L.B.”) has been designed and manufactured to

have a long working life and simple operation.

Read and observe the Safety message indicated by the following symbols:

DANGER

INSTRUCTION MANUAL

Issue.

08 / 2004

2 - 42

If you do not follow these instructions you may cause injury

Pag.

WARNING

If you do not follow the indicated instruction you may damage the

equipment.

This Manual is an INTEGRAL PART of the equipment

• It must be kept in the provided space on the mobile command unit.

• It must be kept for the whole operating life of the equipment.

• It must be consulted without causing damage.

• It must be kept unabridged and complete as originally supplied.

• If the ownership changes the Manual must accompany the Equipment.

The Manufacturer is not responsible in any way if the operator does not follow the instructions

contained in this Manual, if damage occurs or personal injury results from improper use of the

Equipment or a different use from that intended by the designer (see Chap. 2).

This Manual refers to the MACHINERY DIRECTIVE 98/37/CE.

The Manufacturer has made every effort to provide you with detailed and accurate information.

However, because of the continuos evolution of the product, some data may differ from those

reported in this Manual. If you need more precise data, please contact our Assistance Service.

2. GENERAL SAFETY RULES

Read this Manual carefully before proceeding to the installation and use of the Equipment.

Only authorized and trained staff should be allowed to use this equipment.

The “L.B.” should be used only indoors.

Installation must be carried out by Qualified Staff only and in accordance with the instructions

given in this Manual.

Any modification of the equipment or tamperings with safety devices without permission of the

manufacturer are considered as an infringement of the European Safety Standards.

We recommend the use of original components and spare parts only .

Any intervention to the electric/hydraulic/pneumatic plant requires Qualified Staff only.

INSTRUCTION MANUAL

Issue.

08 / 2004

Pag.

3 - 42

INSTRUCTION MANUAL

3. CHARACTERISTICS AND TECHNICAL DATA

3.1 CHARACTERISTICS

3.1.0 SUPER-ROTAX is the commercial name of the Machine considered as EQUIPMENT

FOR CHECKING AND REALIGNING DAMAGED VEHICLES.

It is composed of two main parts which are mechanically integrated:

• a scissor lift, which lifts up the Bench, together with the damaged vehicle, to a suitable

working height for the User.

• A bench

for checking and realigning the vehicle with the additional function of supporting

– the universal system

– the pulling arms

– the damaged car.

3.1.1 OPERATION AND SAFETY

– The lift is operated by an electro-hydraulic system.

– Low voltage control (24V).

– Antifall devices, always operating:

• One-direction “parachute” valve, mounted directly on the hydraulic cylinder, ensures the

automatic stop of the oil flow caused by the accidental break of the feed pipe, meccanismo

di blocco meccanico "ad arpione" che, ad inserimento per gravità, blocca il movimento di

discesa. Lo sgancio dell'arpionismo avviene solo con comando alla pulsantiera

dell'operatore ed in presenza dell'energia elettrica e pneumatica.

– Upstroke and downstroke are controlled by the operator by the remote control.

– The crossbeams with base block, which are parts of the Universal Jig GLOBALJIG, are

always on the bench and they have the double function of receiving the jigs or the side runners

and ramps for positioning the vehicle for repair.

– The tilt mechanism provided with the bench allows the movement necessary to get the vehicle

on and off the equipment.

– The damaged vehicle is pulled on or off by an electrical winch, supplied with the equipment.

– Safety ramp (with integrated stop rammer). This device provides the vehicle stop during the

lowering phase, when the vehicle is not anchored to the winch and the bench is inclined.

3.1.2 INTENDED USE

The Super Rotax equipment has been designed and built to be used as a Lifting – Bench (L.B.) for

checking and realigning damaged vehicles.

It must be located inside bodyshops and used only without exceeding the indicated maximum

capacity and loading.

Any other use is considered incorrect and therefore irresponsible.

The manufacturer cannot be considered responsible for damage caused by improper, incorrect or

irresponsible use.

Issue.

08 / 2004

Pag.

4 - 42

INSTRUCTION MANUAL

3.1.3 EQUIPMENT IDENTIFICATION DATA

All identification data are written on an alluminium plate positioned on the internal cross beam on

the front of the bench, and it reports : the name of the manufacturer GLOBALJIG

INTERNATIONAL. srl - Via Aurelia Ovest, Km 383 - 54100 Massa - ITALIA

• The serial number : SR xxx, wheew xxx represents the progressive serial number

• CE mark.

IT IS STRICTLY FORBIDDEN TO REMOVE, CHANGE OR DAMAGE THE ABOVE

MENTIONED PLATE.

Issue.

08 / 2004

Pag.

5 - 42

3.2 TECHNICAL DATA

– Rated Votage: 200 / 415 V-50 / 60 Hz

– Rated power: 2,5 Kw

– Rated capacity: 3500 kg*

– Lifting Height: 1750 mm

– Lifting/lowering time: 60 / 72 sec

– Oil pressure: 200 bar

– L.B. mass values.: see drawing page 6.

The Super Rotax equipment is produced in the following versions:

– with 4 meters bench, with 1 or 2 pulling arms

– with 5 meters bench, with 1 or 2 pulling arms.

If not otherwise specified, the technical data here described refers to both versions.

The noise produced by the equipment always below 85 dB (A).

*The useful lifting capacity is intended

with the bench already equiped

complete with cross beams, jigs and

pulling tower.

For each extra pulling tower the useful

lifting capacity decreases by 350Kg.

INSTRUCTION MANUAL

4. FREIGHT AND UNPACKING

4.1.1 TECHNICAL DATA FOR TRANSPORTATION

GROSS WEIGHT [ kg ]

POS. CODE DESCRIPTION Q.TY 4m 5m

01 E118 Wooden box containing Globaljig System 1 750

02 E119 Wooden box containing Globaljig System 1 670

03 D495 Frame with lift 1 // 2470

04 D496 Frame with lift 1 2250 //

05 D497 Fixed pulling arm 1 370 370

06 D498 Articulated pulling arm 1 410 410

07 E121 Wooden box containing MacPherson 1 90 90

08 E409 Side runners + ramps 1 190 220

09 D475 Axle stands + crossbeam 1 60 60

10 D211 Electrical winch 1 30 30

11 E418 Trolley 1 70 70

12 E680 Control unit 1 120 120

GLOBALJIG INTERNATIONAL. srl grants the quality of the packaging material and the best

procedure concerning the correct location of the goods inside the packages.

All operations of loading and unloading packages, must be carried out using specific procedures

and methods as required by Health and Safety Regulations.

The assigned staff must wear the necessary protective clothing.

GLOBALJIG INTERNATIONAL. srl desclaims all responsibility for damage to people and/or

objects caused when not observing the warnings, the procedures and recommendations during

delivery, loading and handling.

4.1.2 PACKAGE CHECKING

With reference to the standard supply conditions, the transportation of the goods is always at

consignee’s risk, if not otherwise agreed .

Check at sight the delivered goods in the presence of the staff who made the transportation:

• The quantity of the packages.

• That no packge has been damaged or broken

• The presence of condensation or water inside the packages

It is very important to make this first check because the manufacturer will not accept

responsibility for any damage caused during carriage.

Issue.

08 / 2004

Pag.

6 - 42

INSTRUCTION MANUAL

Issue.

08 / 2004

5. INSTALLATION

The installation of the L.B. must be carried out by trained personnel only who must follow the

instructions contained in this manual.

The “Lifting Bench” is packaged as

shown in this picture .

Fig. 5-01

5.1. HOW TO MOVE THE PACKAGE

Once you have chosen the suitable area to

locate the equipment, use a fork lift truck

min. Capacity 2,0 tons to move the package

“L.B.”.Fig. 5-02

Please note: when positioning the “L.B.”

you should :

– Consider the vehicle’s side for lifting and lowering, called Front Side. The manufacturer plate

(pag.05) positioned on the first crossbeam of the bench deternines the Front Side.

– please read chapter 10 (Working Area) and chapter 14 (Overall Drawing).

After you have positioned the “L.B.”,

remove the wooden pallet from beneath the

lift. You can do this using standard jacks.

Fig. 5-03

During this lifting operation, you should protect the rack under the

WARNING

bench from any damage for this reason you should insert a wooden

spacer between the jack and the bench.

Proceeding with the utmost care, remove the

wooden pallet from underneath the “L.B.”

Fig. 5-04

Pag.

7 - 42

INSTRUCTION MANUAL

Issue.

08 / 2004

Pag.

8 - 42

5.2 UNPACKING

Cut the plastic straps and remove the four protective wooden angles for crossbeams and

measuring tapes.

Take out the two brackets, which are useful to fix the bench

with the base of the lift only during transportation.

Photo. 5-05

5.3 HOW TO FIX IT TO THE GROUND

– In order to arrange for the installation area you should refer to Overall Dimensions Drawing (Chapter

14)

– Before setting the equipment on the floor you should ensure that the ground is level and has suitable

bearing capability. It is recommended that it should be able to bear a total weight of 9.000 daN, with a

specific pressure of 0.50 daN/cm² and made of the correct consistency necessary to allow a proper

fixing of the anchoring plugs to the floor.

– The plugs supplied with the equipment are 6 (Ø 20x90 mm), with M12 screws.

– The plugs can be set and fixed only after electrical connection, because you must lift up the bench in

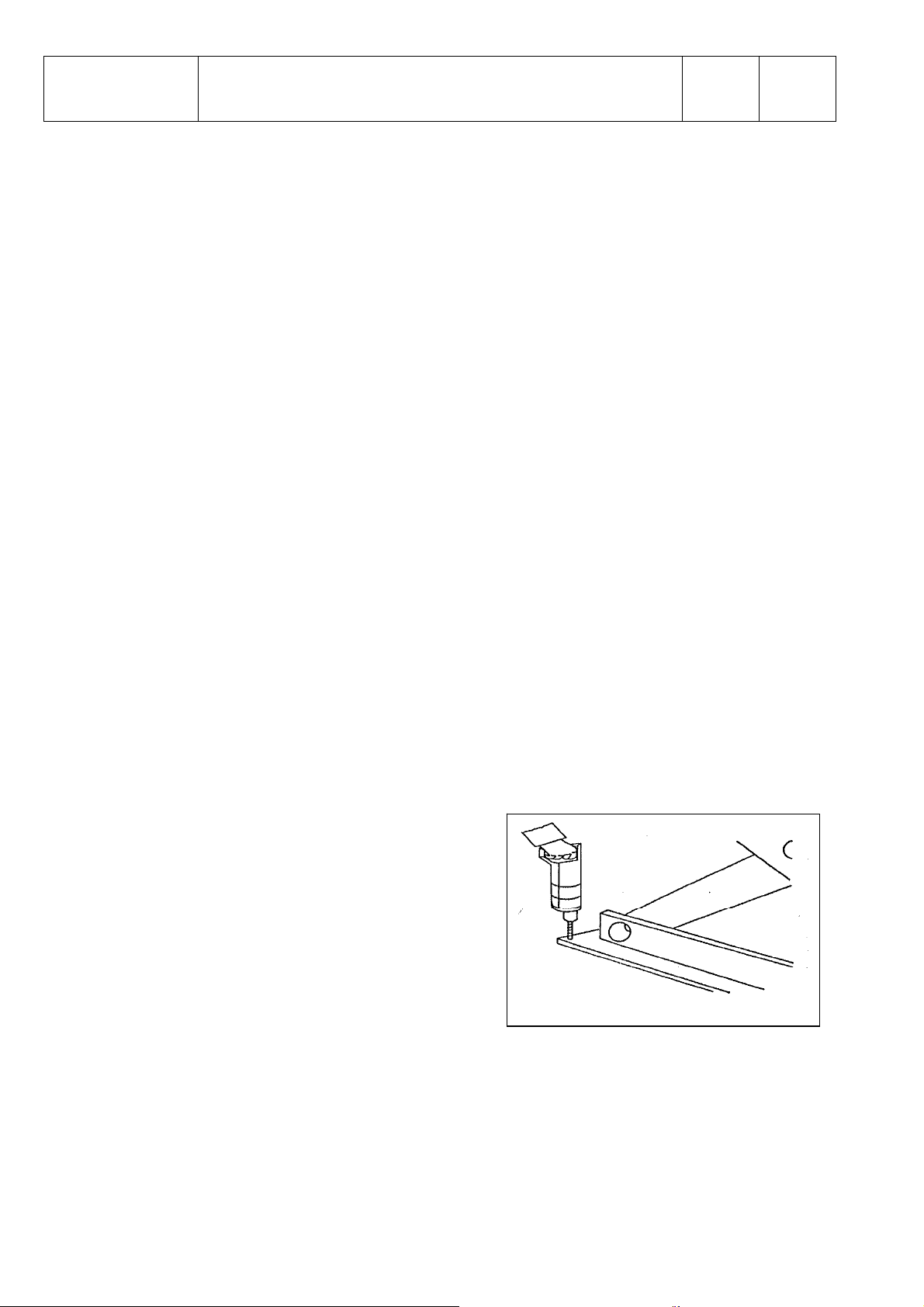

order to reach the floor and work with the drill. Fig. 5-06 Ð

How to proceed to fix the plugs:

– Using the holes of the base of the equipment as

a drilling jig, drill the floor with helicoidal point

Ø 20, to a depth of 95 mm..

– Clean the hole, insert the plugs, tighten the

screws.

6. COMMISSIONING

6.1 POWER UNIT CABINET

6.2 HYDRAULIC PLANT CONNECTION

6.3 PNEUMATIC PLANT CONNECTION

6.4 ELECTRICAL PLANT CONNECTION (low tension 24V)

6.5 ELECTRICAL PLANT CONNECTION (supplied from the network)

6.1 POWER UNIT CABINET

- Once you have positioned the bench, place the cabinet near its final position.

INSTRUCTION MANUAL

Issue.

08 / 2004

Pag.

9 - 42

On the back side of the cabinet you will find : (See picture 6-01 e 6-02)

• Tuboflex A70066, lifting jack supply

• Tuboflex A70067, inclination jack supply

• Feed pipe (blue) A70072, for safety bolt release jack

• Cable and plug for up-stroke end control.

Photo 6-01

Photo 6-

A70072

A70066

A70067

End stroke

cable

INSTRUCTION MANUAL

Issue.

08 / 2004

6.2 HYDRAULIC CONNECTION

6.2.1 To the liftting bench

- The cable and the pipes have a standard lenght of 5000 mm.

- Place in the provided setting-out the cable and the pipes to

the base of the lift (inclination jack’s side of the bench).

Picture 6-03Î

- Provide yourselves of the following keys :

- n° 1 of 18

- n° 1 of 19

- n° 2 of 22

- always working with two keys (as shown in the picture) untighten the caps placed on the

bracket and on the cylinder connection.

Photo Ô

6-04

Pag.

10 - 42

- untighten the caps at the end of the flexible feed pipes

coming out of the cabinet..

- Now connect the pipes to the connection on the bracket and

the connection on the cylinder.

We advise to proceed quickly in order to avoid a leak of oil from the

pipes.

Actually the plant is always supplied with oil because every lift is tested before shipment

- Tighten the connection feed pipes, always using two keys (see pictures below, in the correct

sequence)

Photo 6-05 Photo 6-06

INSTRUCTION MANUAL

6.2.2 To the hydraulic power unit

6.2.2.1 see picture A

Issue.

08 / 2004

Pag.

11 - 42

See detail

(picture

B)

EMERGENCY

VALVES

Electric engine

Pump unit

Tank

A

B

Electro-valves(bench

inclination up/down)

Valves unit

DETAIL

VALVES UNIT

INSTRUCTION MANUAL

Issue.

08 / 2004

Pag.

12 - 42

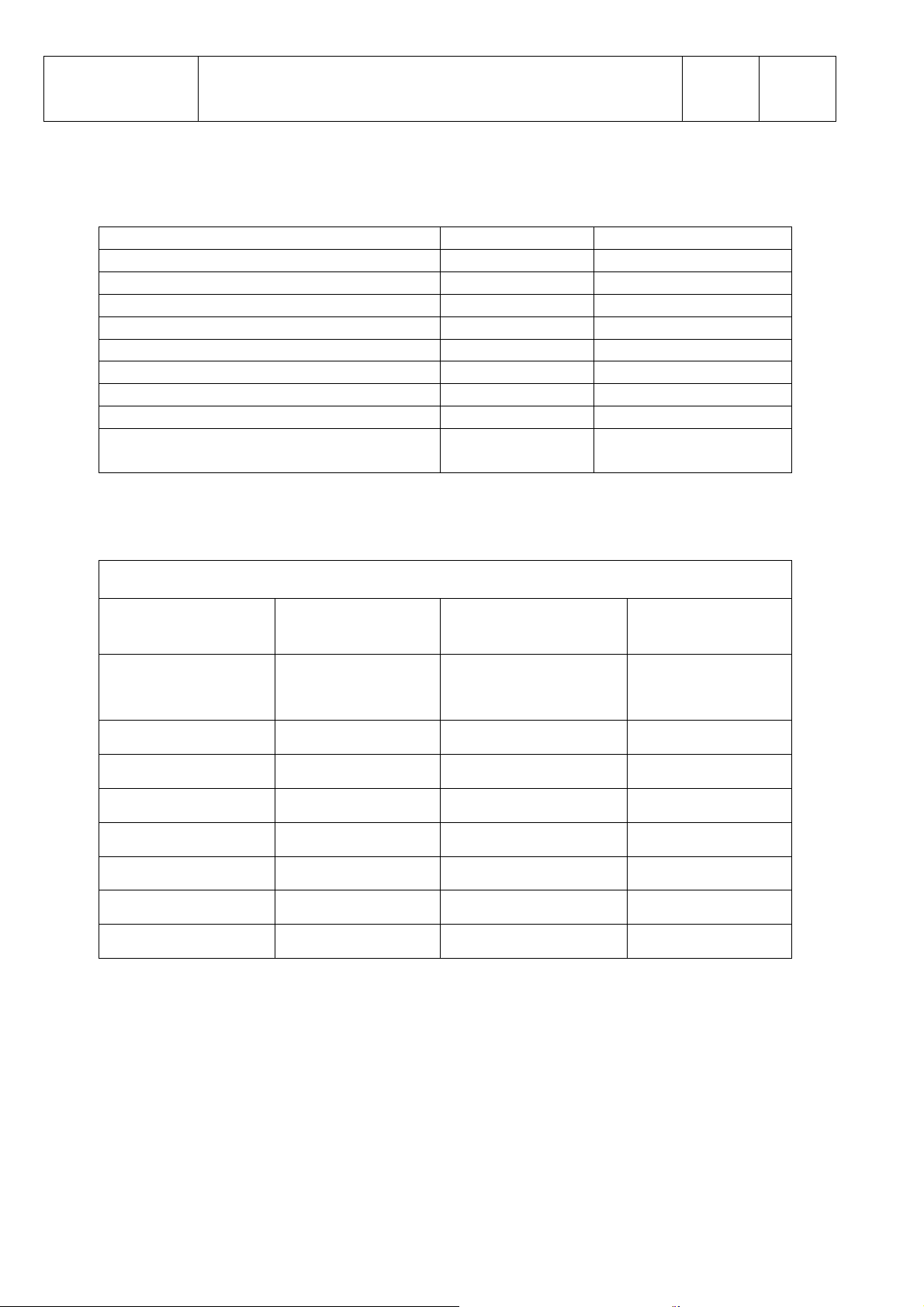

6.2.2.2 Hydraulic Unit Table

Pump engine power kW 2,2

Number of poles of electric engine n° 4

Velocità di rotazione a vuoto g/1' 1500

Hydraulic pump type - Gears

Type of coupling Engine/Pump - Direct

Max hydraulic pressure bar 220

Pressione idraulica di esercizio bar 190

Oil tank capacity lt 12

Advised oil type SHELL TELLUS

SAE 32

or similar (see table below)

Hydraulic oils Table

Intervals of

Temperature

Up to 30°C From 30°C to 45°C Beyond 45°C

Standard viscosity

in Centistokes at

16-20 24-28 31-39

50°C

AGIP OSO 32 OSO 46 OSO 68

CASTROL HYSPIN AWS 32 HYSIN AWS 46 HYSPIN AWS 68

CHEVRON EP HYDR. OIL 32 EP HYDR. OIL 46 EP HYDR. OIL 68

ESSO NUTO H 32 NUTO H 46 NUTO H 68

IP IP HYDR. OIL 32 IP HYDR. OIL 46 IP HYDR. OIL 68

MOBIL D T E 24 D T E 25 D T E 26

TOTAL AZOLLA 32 AZOLLA 46 AZOLLA 68

Loading...

Loading...