GLOBALIS impact 1170 Service Manual

Serial Dot Matrix Printer

Service Manual

Service Manual

Introduction

This manual is designed for impact 1170 as a reference for maintenance

procedures. It introduces basic operations briefly and describes the disassembly

and reassembly of the main parts. It also provides the testing methods and

standards for the printer after maintenance. Some necessary measures are

recommended for daily maintenance.

Warning

1. Only qualified service personnel are allowed to maintain the printer.

2. All the marks used in this manual are explained as below:

Warnings must be followed to avoid body injury.

Cautions must be observed to avoid damage to the equipment or personnel.

Notes contain important information and useful tips in the box.

i

Service Manual

Contents

1. Product introduction.........................................................................................1

1.1 External Appearance and Composition .......................................................1

1.2 Operation.....................................................................................................2

1.2.1 Operator Panel......................................................................................2

1.2.2 Installing the Ribbon Cartridge ............................................................6

1.2.3 Using EDS Setting Mode .....................................................................8

2. F/W Upgrade and Parts Replacement ...........................................................15

2.1 F/W upgrade..............................................................................................15

2.1.1 How to Upgrade the F/W ...................................................................15

2.1.2 Download Specifications....................................................................16

2.2 Parts disassembly and reassembly.............................................................16

2.2.1 Upper Case .........................................................................................17

2.2.2 Operator Panel....................................................................................18

2.2.3 Printer Mechanism .............................................................................19

2.2.4Controller (Main Logic Board) ...........................................................20

2.2.5 Power Supply Board...........................................................................21

2.2.6 Print Head...........................................................................................21

2.2.7 Ribbon Septa ......................................................................................22

2.2.8 Carriage Motor Unit ...........................................................................23

2.2.9 LF Motor ............................................................................................25

3. Adjustments and T est s.....................................................................................26

3.1 Adjustments...............................................................................................26

3.1.1 Adjustment of Gap..............................................................................26

3.1.2 BID Adjustment..................................................................................27

3.2 Testing Tools..............................................................................................28

3.2.1 Collective Tests ..................................................................................28

3.2.2 Maintenance .......................................................................................30

3.2.3 Mistake indication on the panel..........................................................32

4. Spare Parts List...............................................................................................33

ii

Service Manual

1. Product introduction

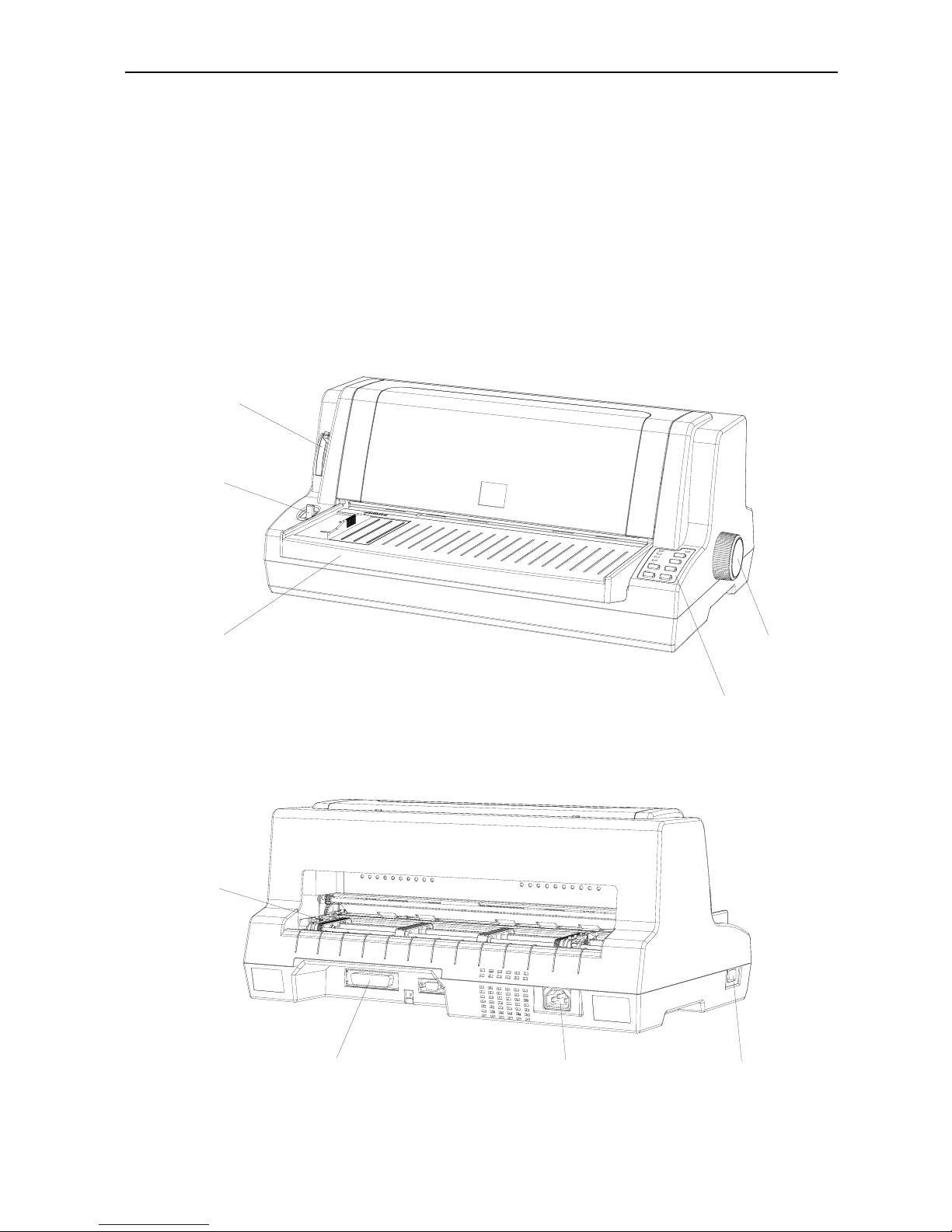

1.1 External Appearance and Composition

Knob

Sheet Holder

Operator Panel

Path Selection Lever

Gap Lever

Tractor

Parallel Interface

Power Switch

AC Power Socket

1

Service Manual

1.2 Operation

1.2.1 Operator Panel

Buttons

Ready

When the READY indicator is lit, pressing this button causes the temporary stop

of the printing job at the end of the current line, the READY indicator is turned

off.

When the printing is paused pressing this button will enable the printing and the

READY indicator is turned on

.

Shift

By holding down this button while pressing another button at the same time, the

printer can accomplish the following functions:

Clear buffer (Shift + Ready button)

Clears up data in buffer, and initializes the printer.

Micro adjustment function:

Shift + LOAD/EJECT button

Feed paper forward in 1/180 inch increment.

Shift + LF/FF button

Feed paper forward in 1/180 inch increment.

2

Service Manual

Note: the functions above must be performed in off-line condition and there’s no data in

the buffer.

Font control

It’s just under the LQ indicator. Press this button to control the printing font. You

can also use the command to control the printing font.

Tear off

When the continuous paper is selected, press this button to feed continuous paper

forward to the tear-off position from the loading position. Press it again will

cause the printer to feed the paper backward the top-of-form position.

LF/FF

Feed paper line by line when pressed shortly.

Eject a single sheet or advance continuous paper to the next top of form position

when held down.

Load/Eject

Press this button to load paper. If paper has already been loaded, pressing this

button will eject the paper. If the cut sheet is selected using path selection lever,

the printer ejects the paper according to its ejection direction, otherwise if the

continuous paper is selected, the printer ejects the paper backward to the standby

position.

Advanced Functions:

To execute the following functions, hold down relevant button while turning the

printer ON. Don’t release the button until the print head starts to move.

Power-on self-test

Hold down LF/FF button while turning on the printer, the printer executes

self-test. This function can help you check if the printer operates correctly. Refer

3

Service Manual

to the “Self-test of the printer” for the details.

Bi-directional adjustment

While holding down Shift button, LF/FF button and LOAD/EJECT button

simultaneously, turn on the printer. The printer will enter into bi-directional

adjustment mode. This function helps to correct printout alignment problems.

Refer to chapter 6 “Using the bi-directional adjustment mode”.

Hex dump

To enter into hex dump mode, hold down both LF/FF and Load/Eject buttons

while you turn on the printer. This function can help the experienced customer to

solve some problems. Refer to chapter 6 “Using the Hex dump mode”.

Resume factory default settings

Hold down Shift button, Speed button and Tear off button simultaneously, and

turn on the printer. After a long beep, the printer resumes factory default settings.

EDS (Electronic Dip Switches) setting

While holding down Shift button and Font button (or Shift+Tear off button,or

Shift+Ready button) simultaneously, turn on the printer. The printer enters into

EDS setting mode. Refer to the “Using EDS setting mode” below, and change

the parameter settings of the printer.

Indicators

Power (green)

Lights up when the printer is powered on.

4

Service Manual

Ready (green)

Lit when printer is ready or press the Ready button.

Blinks when print head is overheated.

Paper Empty (red)

Lights up when there is no paper in the selected paper path.

Thick Paper (green)

Lights up when paper gap is set at level 2 or at higher level. And the impact

force of the pins will be increased.

Draft (green)

It works with LQ indicator to indicate the speed. Refer to the table below:

Indicator

printing quality

Draft LQ

Draft On Off

LQ Off On

NLQ On On

HSD Off Off

LQ (green)

It works with Draft indicator to indicate the speed. Refer to the table above.

Tear (green)

Press the Tear off button, and after the printer has fed continuous paper to the

tear-off position, it’s on. Tear off the paper and press the Tear off button again to

feed the paper backward the top-of-form position. It blinks while

5

Service Manual

micro-adjusting the position of the top-of-form or the tear off position.

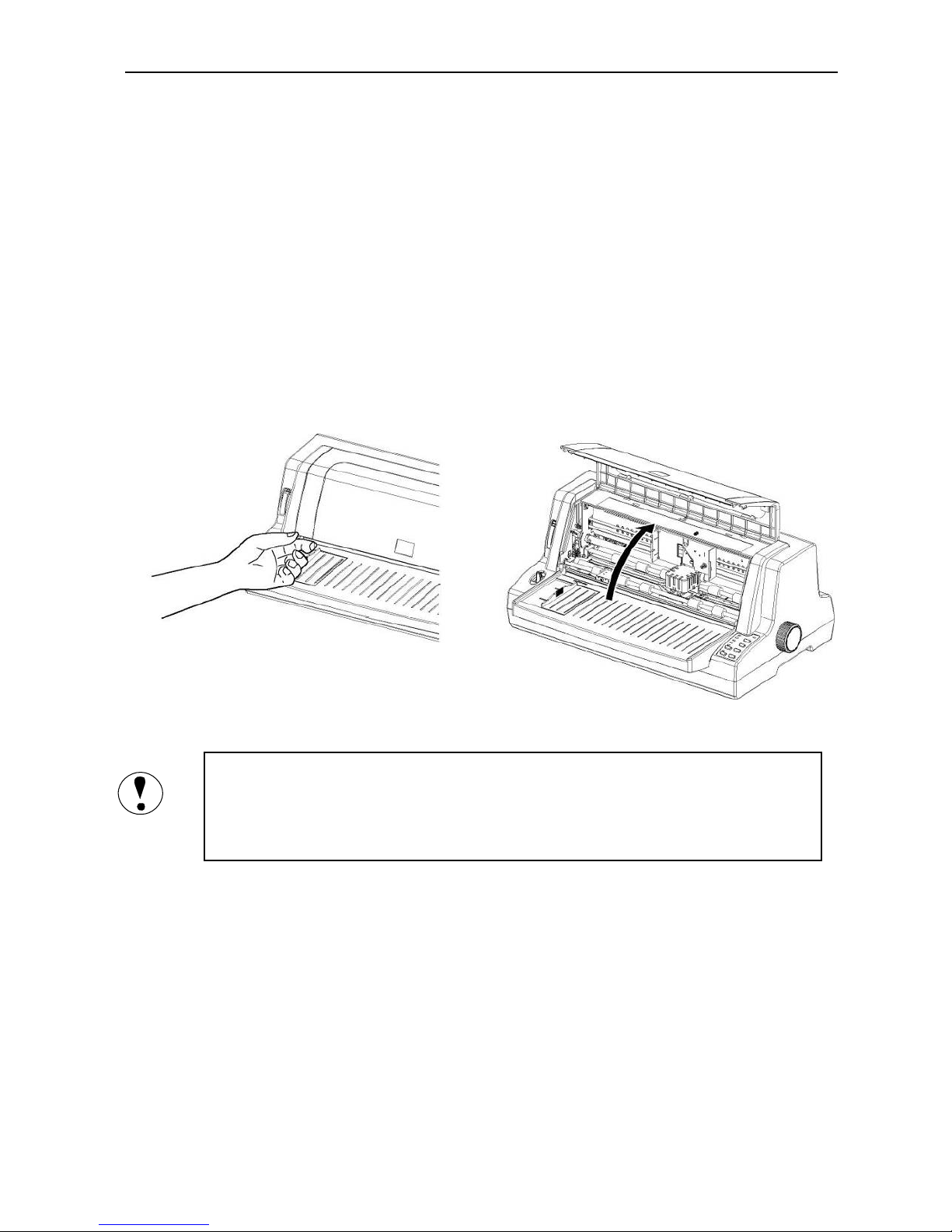

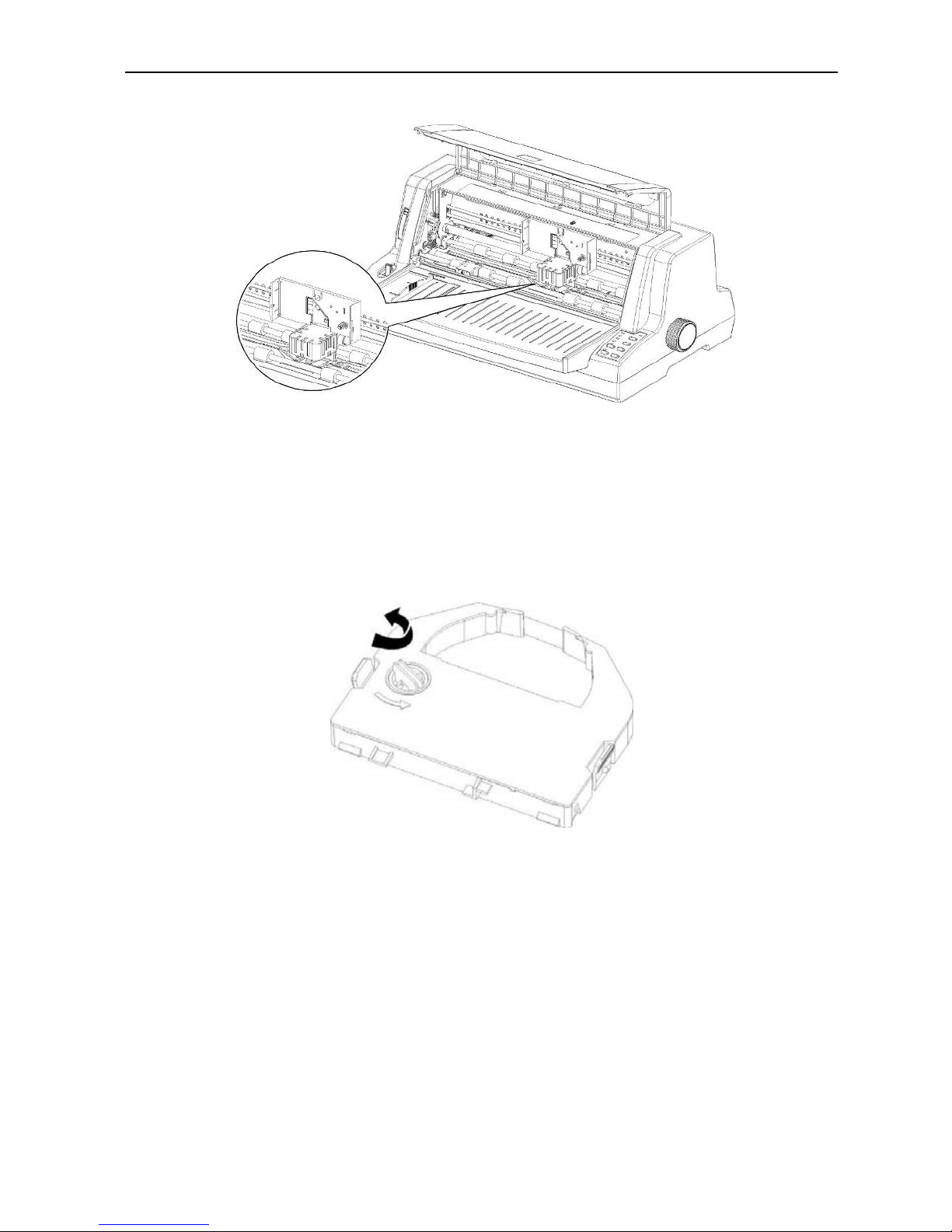

1.2.2 Installing the Ribbon Cartridge

Power off the printer before installing the ribbon cartridge.

Take out the ribbon cartridge from the package, and follow the steps below to

install it:

1. Lift up the transparent cover part and set the gap lever to the highest level.

Don’t move the print head while it is power-on, otherwise it may cause device

damage. The print head may be hot while it just finishes printing. Wait until it

cools down before restartin

g

.

2. Refer to the figure below and move the print head to the middle (indicated

by the gap on the metal board).

6

Service Manual

3. Tighten the ribbon according to the arrowhead so that the cartridge can be

set easily.

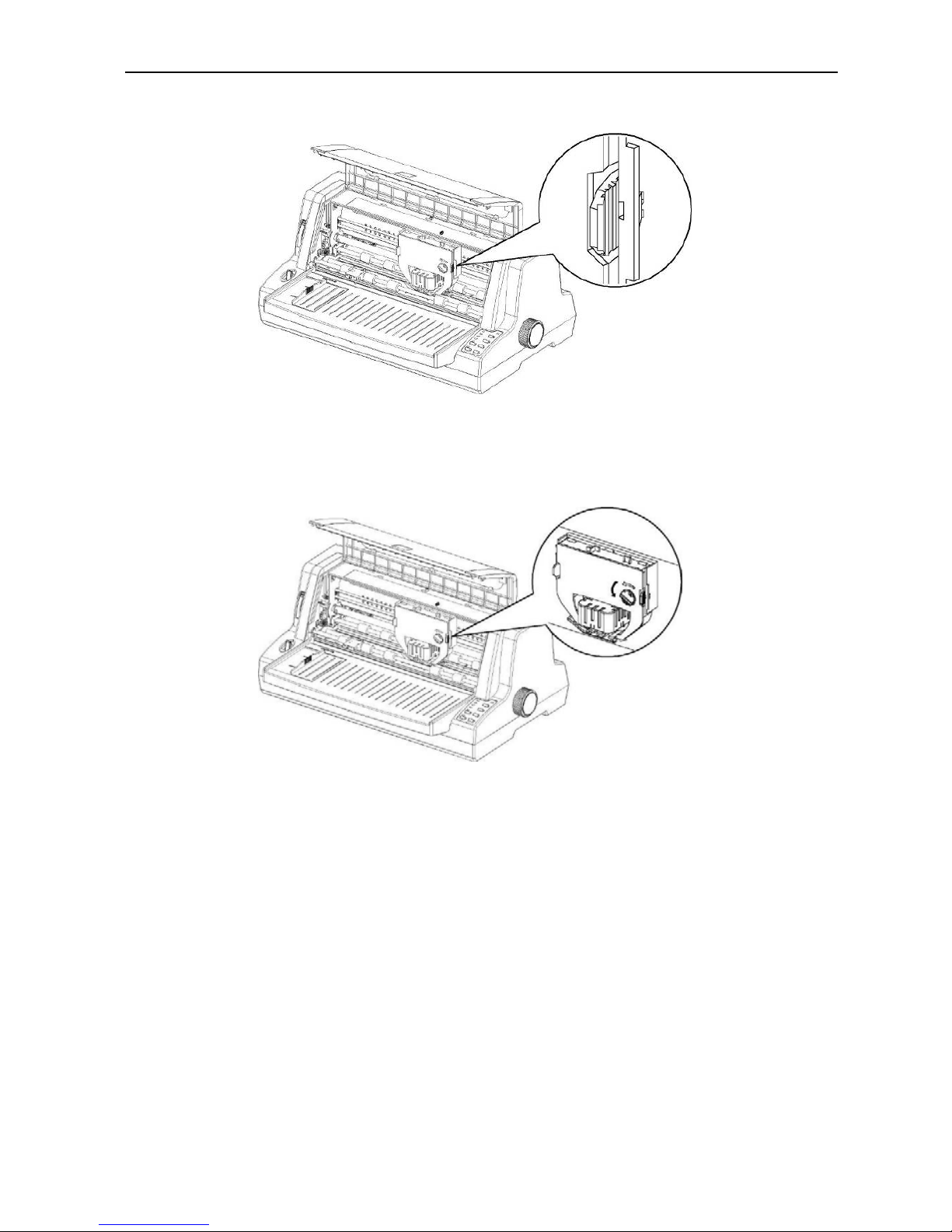

4. According to the Figure below, set the ribbon between the print head and

the platen and press the cartridge to the right position. Please make sure

that it is fixed to the grooves firmly by its clips on both sides.

7

Service Manual

5. Tighten the ribbon again, and make sure that the ribbon is even and not

overturned.

6. Lay down the transparent cover part and set the gap lever to the proper

position.

1.2.3 Using EDS Setting Mode

The EDS setting can execute different functions by changing default power-on

parameters. The EDS setting options can be selected through software, printer

driver, or using the operator panel buttons.

8

Service Manual

The part below shows all the options of EDS in detail. Refer to the “How to

change the EDS settings” for the alteration guidance about the EDS setting.

EDS Settings Options

The following table shows all the function options and relative parameter

settings available in EDS setting mode. The factory default values are shown in

Bold. (Note: There may be small differences among different versions for the

factory default values.)

EDS1

Function option

Parameter settings

Reservation

Emulator

ESC/P, IBM PP

Line width

110, 106, 80

Copy capability

Normal, Mode 1, Mode 2, Mode 3

Reservation

Print direction

Auto, Bi-D, Uni-D

Reservation

Pin Broken/Quiet Mode

Invalid, 1-12pin, 13-24pin, Quiet

Reservation

Single sheet loaded

.5S auto, .8S auto, 1S auto, 2S auto, manual

Tear off

Mnual, 0.5S auto, 1S auto, 1.5S auto

Single sheet ejected

Frward, Bckward

Line Spacing

1/6inch, 1/8inch, 2/15inch

Reservation

Reservation

Char pitch

10, 12, 15, 17, 20, proportion

9

Loading...

Loading...