Page 1

globalindustrial.ca

User's manual Manual del usuario Manuel de l'utilisateur

Customer Service

US: 1-800-645-2986

Servicio de atención al Cliente

US: 1-800-645-2986

Service à la clientèle

Canada: 888-645-2986

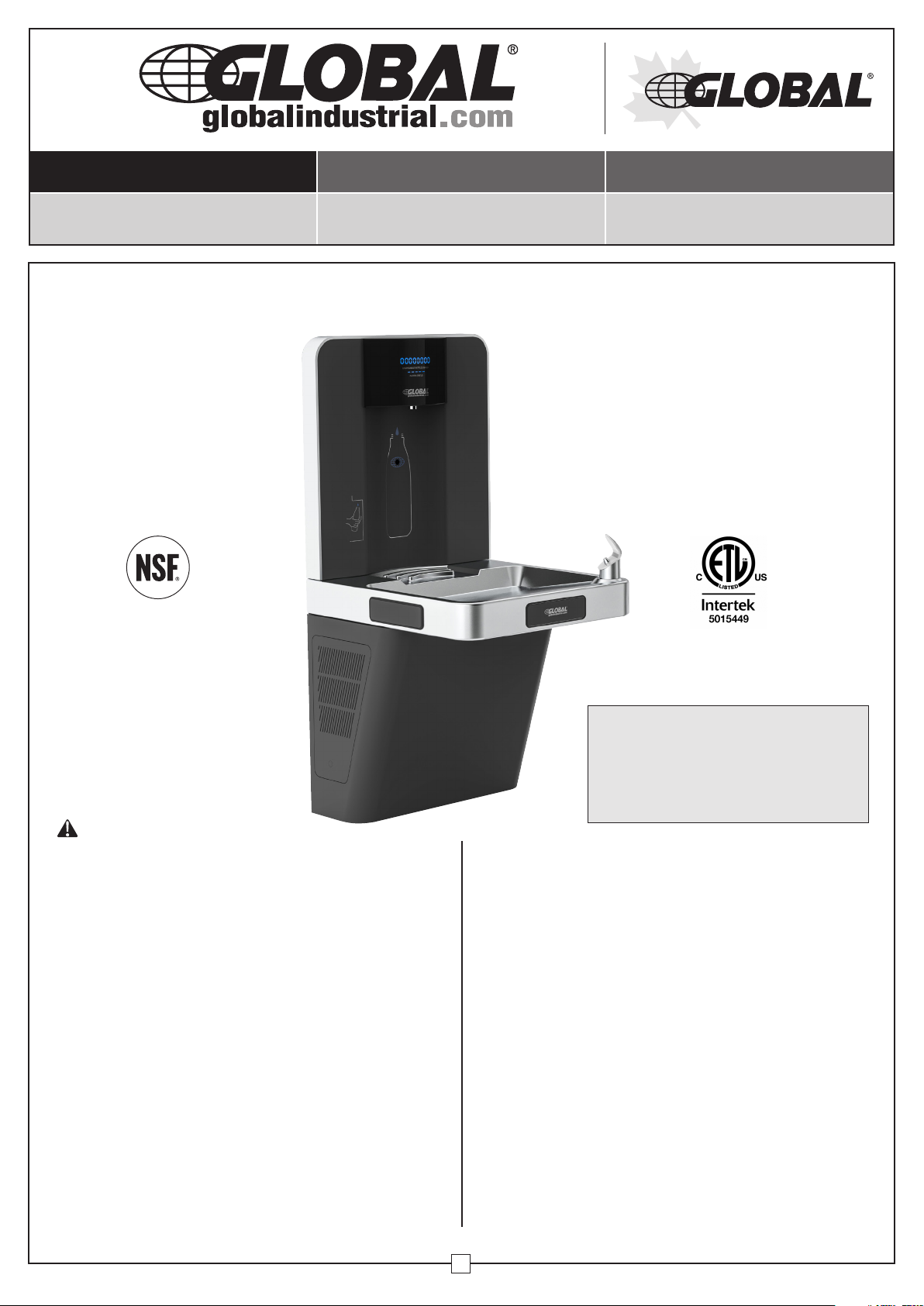

Wall Mounted Water Bottle Refilling Station

Model 761218

WARNING

• Keep compressor in upright position for 24 hours

before water connections and initial power-on. Failure

to do so will void warranty.

• For indoor commercial use only.

• All installation work must be performed by authorized

service personnel.

• Two or more people are recommended to lift and install

the unit.

• To avoid the risk of property damage and/or personal

injury, mount the unit to a flat finished wall surface with

adequate support.

• Check local codes for plumbing requirements prior

to installation.

• Prior to initial installation, install a shut-off valve (not

included) from the water supply.

• Thoroughly flush all water lines and fittings of all foreign

matter before connecting to the cooler. Failure to do so

will void warranty.

• Check for any leaks before initial operation.

• DO NOT attempt to repair or replace any part of your

appliance unless it is specifically recommended in

this manual. All other services should be referred to a

qualified technician.

Read this manual thoroughly prior to

installation, operation or maintenance.

Keep these instructions in a safe location

for future reference. For questions, visit

globalindustrial.com or contact Customer

Service at 1-800-645-2982.

• For use with clean, clear potable drinking water only.

• Shut-off water supply during installation to reduce risk

of water damage.

• Ensure proper ventilation by allowing appropriate

clearance of housing louvers to the wall on each side

of the cooler, as specified in rough-in guide.

•

NEVER wire the compressor directly to an electrical supply.

• DO NOT allow children to play with the appliance.

• Interior of unit may contain sharp edges. Wear gloves

when handling or servicing unit.

•

Failure to follow installation instructions will void warranty.

Note: These fixtures are intended for indoor commercial

use only. Do not expose to freezing temperatures.

The grounding of electrical equipment to water lines is

a common procedure. This grounding may be in the

building or occur away from the building. This grounding

can cause electric feedback into the water cooler

creating an electrolysis which creates a metallic taste or

causes the water metal content to increase. Connect to

water supply using non-conductive materials.

1

052120

Page 2

Wall Mounted Water Bottle

Refilling Station

User's Manual

Risk of Electrical Shock

• Disconnect power before servicing unit.

• Electric supply must be identical in voltage, cycle and

phase to those specified in the specifications below.

Unit must be plugged into a GFCI outlet.

• Always pull the plug – not the cord – when disconnecting

from the outlet

• DO NOT use if the power cord is worn or damaged.

Power cords should only be replaced by qualified

service technicians using genuine replacement parts.

• Check local codes for electrical requirements.

• DO NOT disassemble or modify unit.

• Use Global Industrial filters only – Model 670336

Voltage/Hertz 115V/60Hz

*Chilling Capacity 8.0 GPH

Full-Load Amps 1.9 Amps

Rated Watts 185 W

Filter Capacity 4750 or 3000 Gallons

Quick-Fill Rate 1.0 GPM

Water Flow Laminar

Overall Dimensions 18

1

/

"W x 16"D x 37

8

13

/

"H

16

UL399 and CAN/CSA 22.2 No. 120

Certification

ADA Compliant

ANSI/NSF 372

ANSI/NSF 42 and 53 (Filter)

* At 46° - 54° (F) against ambient air temperature of 77° (F)

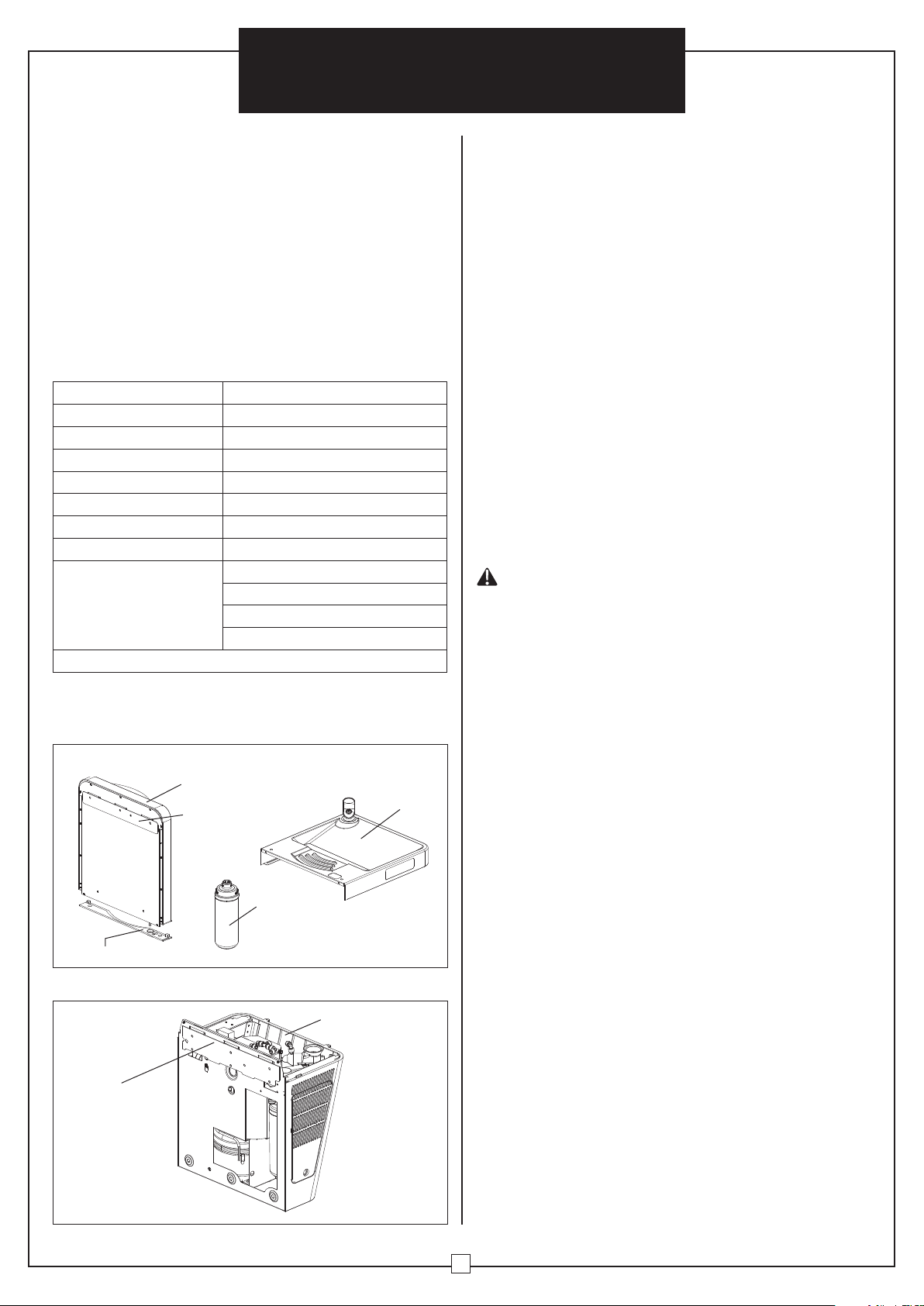

Package Contents:

Box 1 - 761213 Top Assembly for Bottle Filler

Bottle Filler

Top Assembly

Mounting Bracket

(attached to rear)

Stainless

Steel Pan

Note:

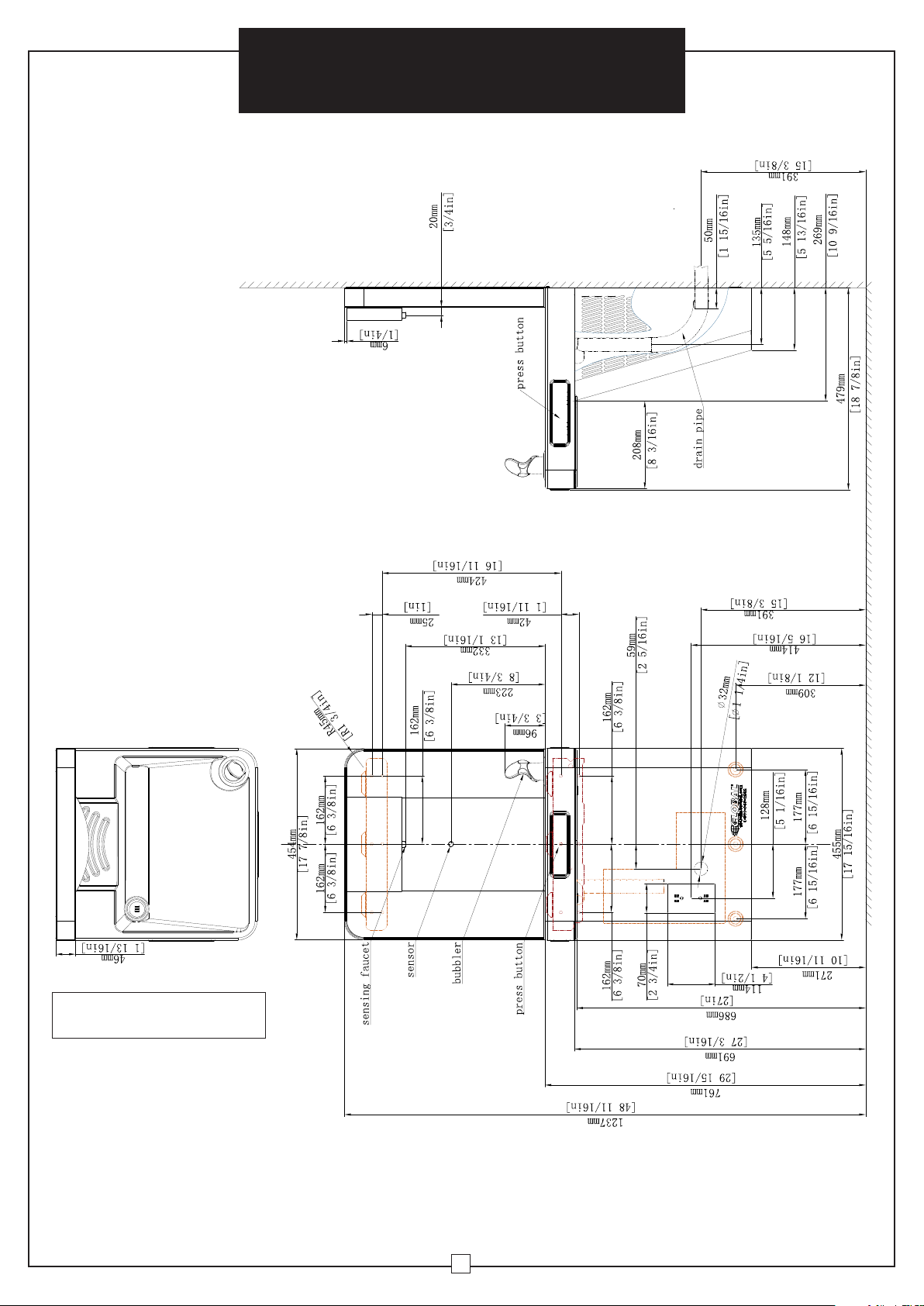

• Prior to installation, consult with local, state, and federal

codes for proper mounting height.

• All installation and service should only be performed by

authorized personnel.

• Dimensions shown below comply with ADA requirements

at time of printing.

• Allow 4" minimum clearance on both sides to allow for

proper ventilation through cabinet louvers.

• Thoroughly flush all water lines and fittings of all foreign

matter before connecting to the Cooling System.

Failure to do so will void warranty.

Required Tools:

1. Safety Glasses

2. Safety Gloves

3. Electric Drill

4. Phillips Head Screwdriver

5. Flathead Screwdriver

6. Tape Measure

7. Pencil

8. Level Device

9. (11) 75-lb. Capacity Flat Head Wall Anchors

(appropriate for your wall type)

10. (11) Flat Head Anchor Screws

WARNING

• Review manual thoroughly and verify rough-ins before

installation. Keep these instructions in a safe location

for future reference.

• Keep compressor in upright position for 24 hours

before water connections and initial power-on. Failure

to do so will void warranty.

• It is recommended to assemble this product on a

tabletop or bench.

• Fixture must be mounted to a flat finished industry

standard wall surface. The wall surface must have

adequate support to secure the fixture, with the

addition of wall anchors (not included) if required.

• All receptacles must be wired to a GFCI protected

circuit. Fixture must be earth grounded per National

Electric Code (NEC).

• Inspect fixture and all parts for damage.

Water

Filter

Rubber Gasket

Not Pictured:

Hardware Bag

Mounting Stencil

Box 2 - 761212 Cooling System for Water Fountain

Cooling System

Mounting Bracket

(attached to rear)

2

Page 3

Wall Mounted Water Bottle

Refilling Station

User's Manual

Check local codes for plumbing

requirements prior to installation.

3

Page 4

Assembly Instructions

Wall Mounted Water Bottle Refilling Station

Model 761218

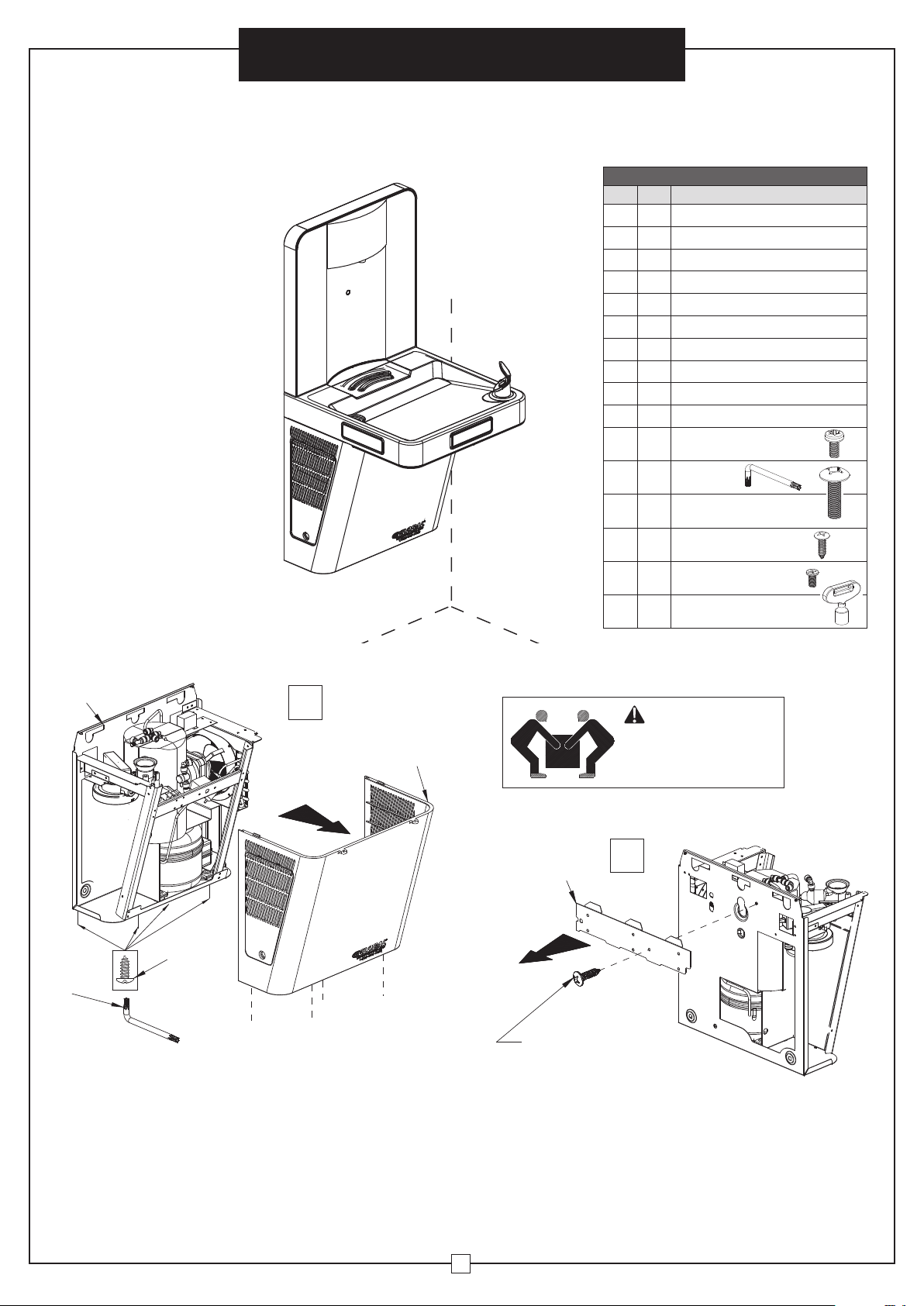

CONTENTS

Ref. Qty. Description

1 1

2 1

3 1

4 1

5 1 Back Plate

6 1 Top Mounting Bracket

7 1 Gasket

8 1 Stainless Steel Pan

9 1 Water Filter

10 1 Filter Access Door

H1

H2

H3

H4

H5

Cooling System

Lower Cover

Bottom Mounting Bracket

Bottle Filler Top Assembly

M4 x 8mm Lg. Torx

4

Pan Head Anti-Theft Screw

1 Torx Key

M6 x 20mm Lg. Phillips

2

Truss Head Screw

#4 x 1/2 Lg. Phillips

4

Pan Head Screw

M4 x .7x 8mm Lg.

6

Phillips Flat Head Screw

H2

H6

1 Filler Access Door Key

1

1

WARNING

Assembly and installation

2

of equipment should be

performed by 2 people.

3

2

H1

Discard after removal

Remove Lower Cover

Using the Anti-Theft Screw Star Key, remove the (4)

screws at the bottom of the Lower Cover. Set Lower

Cover aside and save screws for reinstallation.

Remove mounting bracket

Using a Phillips head screwdriver, remove the

Mount Bracket from the rear of the Cooling

System by removing (1) screw. Discard screw

and set bracket aside.

4

Page 5

Wall Mounted Water Bottle

Refilling Station

3 4

Assembly Instructions

6

4

Discard after

removal

Remove top mounting bracket

Using a Phillips head screwdriver, remove the

Top Wall Mount Bracket fastened to the rear of

the Bottle Filler Top Assembly by removing (1)

screw. Discard screw and set bracket aside.

5

5

4

7X

Remove back plate

Using a Phillips head screwdriver, remove Back Plate

from the rear of the Bottle Filler Top Assembly by

removing (3) screws. Set Back Plate aside and save

screws for reinstallation.

5

7

Attach gasket

Attach Gasket to the bottom of the Bottle Filler

Top Assembly as shown.

Note: Ensure gasket is seated properly and

lies flat so there are no gaps.

6

H3

Stainless

Steel Pan

Attach bottle filler

Flip Bottle Filler Top Assembly right-side-up and carefully

feed connections though the Stainless Steel Pan hole.

Ensure gasket is seated properly and lies flat. Attach

Bottle Filler Top Assembly to the Stainless Steel Pan

using (2) H3 screws.

4

8

5

Page 6

7A

#2

Wall Mounted Water Bottle

Refilling Station

Connect Water Lines

• Connect water line (#1) from the Stainless

Steel Pan to the Water Control Valve (#1) in the

Cooling System.

• Push line until locked into place.

• Connect the water line (#2) in the Bottle Filler

Top Assembly to the Water Control Valve (#2)

in the Cooling System.

• Push line until locked into place.

#1

Connect Wire Connectors

•

Connect white Activation Connector (C) to

Power Supply (C) in the Cooling System.

• Connect white Activation Connector (A)

7B

to Power Supply (A).

• Connect the 2 Activation Connectors (B)

to the Solenoid Valve (B).

Assembly Instructions

7C

B

Reset Button

Connection

A

C

Solenoid

valve

B

Reset Button

Connection

H4

Attach stainless steel pan

• Feed the Reset Button Connection through

the Cooling System's frame and carefully

lower the Stainless Steel Pan on top of the

Cooling System.

• Attach the Stainless Steel Pan to the

Cooling System using (2) H4 screws.

6

CAUTION

Avoid crossing wires

against sharp edges

Page 7

8

Wall Mounted Water Bottle

Refilling Station

Attach back plate

9X

H5

Reattach the Back Plate onto the

rear of the Bottle Filler Top Assembly

using the (3) screws previously

removed, plus (6) (H5) screws.

Unit is now ready for mounting.

Assembly Instructions

See wall

mounting

template

9

10

Level

Note: To comply with ADA requirements, the base of stencil must

be installed 11" to 143/4" from the floor. See Rough-in Guide for

additional ADA requirements.

Note: Before installing brackets to the wall, assure power source,

water line and drain aligns to opening on unit

Attach mounting brackets to wall

• Affix stencil with tape to appropriate wall. It is recommended to use a

level to ensure the stencil is hung straight horizontally.

• Drill (9) holes appropriate for the wall anchors (75 lb. minimum each)

as indicated on the top and bottom mounting brackets on the stencil.

Use appropriate anchors for your wall type.

• Drill 2 holes appropriate for the wall anchors (75 lb. minimum each) as

indicated on the bottom support holes on the stencil. Use appropriate

anchors for your wall type.

• Remove stencil from the wall and install top and bottom brackets onto

the wall using appropriate anchors.

Hanging assembled unit to wall

• Carefully hang assembled bottle filler onto

the wall by lowering onto both top and

bottom wall mount brackets.

CAUTION

Once assembled, do not lift unit by Bottle Filler

Lift

Points

7

Top Assembly. Use two people when lifting.

Always wear work gloves when lifting

Page 8

11

Assembly Instructions

Wall Mounted Water Bottle

Refilling Station

Valve Control

• Ensure both water control valves are turned to the

closed position.

• Attach 2 screws (not included) through the frame

of the Cooling System and into the bottom support

holes previously drilled into the wall.

• Connect the building's water supply to the Filter

Head Connection. This connection must be made

through the back of the Cooling System.

• Connect the internal drain line to the building's

external drain. This connection must be made

through the back of the Cooling System.

Water Control Valves

Closed

Connect filter

head to water

supply

Wall mounting

hardware not

provided

Closed

12

Install water filter

• Remove the receiver protective cover from the

water filter.

• Insert filter into the filter head by turning clockwise

until locked into place.

• Turn both water control valves to the open position.

• Check all connections for leaks. If leaks are

detected ensure all connections are tight and are

fully inserted.

• Turn on buildings water supply and

13

Check local codes for plumbing requirements prior

to installation.

check all connections for leaks.

• Fix any leaks before continuing.

• Plug power cord into outlet.

Water Filter

9

Counter clockwise to remove

Clockwise to install

Open

Turn on both

water control valves

(CHECK FOR LEAKS)

Note: If cooling system is on its side or back for more

than 10 minutes, allow it to stand in the upright

position for 24 hours before water connections and

initial power-on.

Open

8

Page 9

Wall Mounted Water Bottle

Refilling Station

14

10

H6

• Remove the filter access door using

the provided key.

WARNING

Risk Of Electrical Shock

• Turn off power prior to performing any maintenance.

• Verify supply voltage accuracy.

• Ensure all electrical and grounded connections are in

accordance with the National Electrical Code and any

other applicable local code requirements.

• All wiring connections should be capped with approved

wire connectors.

The warnings, precautions, and instructions discussed

cannot cover all possible conditions and situations that may

occur. Failure to heed these warnings may result in property

damage and personal injury.

General Safety Information

• To reduce the risk of property damage, personal injury,

electric shock, falling equipment, and other hazards

please read all instructions and warnings.

• Installation, service, and maintenance should be

• All parties must follow proper safety procedures and

precautions at all times.

• Do Not Install Damaged Products!

15

2

H1

H1

Reattach lower cover

• Reattach the Lower Cover to the Cooling System

using (4) H1 anti-theft screws.

• Fasten the Lower Cover to the bottom of the

Stainless Steel Pan using (2) H1 anti-theft screws.

CAUTION

Make sure all wires are

tucked in before attaching

cover plate to lower cover.

16

Connect reset cable to activation button

• Connect the Reset Button connection cable to

the Activation Buttons located at the top of the

filter access door frame.

•

Reinstall the filter access door using the provided key.

• Unit is now ready for use.

Reset button connection

9

Page 10

Wall Mounted Water Bottle

Refilling Station

User's Manual

Operation

Note: Initial water flow may have sputter due to air in the

water lines; this will be eliminated once air is purged from

all water lines.

To operate bottle filler, verify proper dispensing by

placing bottle, hand or any opaque object in front of the

sensor area.

Adjusting Settings

Water Flow Pressure: Adjust the water flow pressure as

needed by turning the water control valve. Turn clockwise

to decrease the water pressure, or counterclockwise to

increase the water pressure.

Note: When adjusting, aim water flow to the center of the

stainless steel pan.

Note: Initial dispenses may have air in line which may

cause a sputter. Allow a few seconds for air to be purged

from the water line.

Water Temperature: Machine comes with a preset water

temperature of around 45°F. If a different temperature is

required, remove Lower Cover and access the thermostat

on the front housing frame. Using a flathead screwdriver, turn

thermostat screw clockwise to lower temperature setting.

Note: Please allow 5-10 minutes for water temperature

to change.

To operate drinking fountain, push front or side activation

buttons on the stainless steel pan to dispense cooledfiltered water from the bubbler.

When unit is plugged in for the first time, the LCD will

display: 00000000. If not, the filter monitor needs to be

reset – refer to Resetting Filter Monitor section below.

Installing/Replacing Filter

1. Remove filter access door on the lower cover using the

provided key (H6).

2. Grasp old filter and turn counterclockwise to remove

from the filter head.

H6

3. Press and hold ENTER button for 5 seconds to reset

this bottle counter number to zero 00000000.

4. Tap SET button 1 time or wait 5 seconds to return to

standard bottle counter view.

Replacement Filters: Model 670336

For more information visit: globalindustrial.com or

call 1-800-645-2982.

Clockwise

To Install

Counterclockwise

To Remove

10

Page 11

Wall Mounted Water Bottle

Refilling Station

Programming Settings

Accessing the Programming Buttons:

To access the programming buttons, open the filter

access door on the lower cover using the provided key

(H6). The two program buttons are located on the top of

the filter access door frame.

Programming

Buttons:

User's Manual

Enter

Set

Resetting Filter Status

1. Press and hold ENTER button for 5 seconds, until

Reset Ft is displayed on the LCD screen.

2. Tap SET button to select.

3. Press and hold SET button for 5 seconds to reset filter

status. The LCD screen will display 0000 and the LCD

filter status bar will reset to the full 5 bars.

Select Filter Size

1. Press and hold ENTER button for 5 seconds until

Reset Ft is displayed on the LCD screen. Tap ENTER

button. The LCD screen will display: Ft Size.

2. Tap SET button to access Filter Size mode.

3. Tap SET to toggle between 1500, 3000, and 3600

gallon filter size options, or No Ft to bypass filter size

if a filter is not being used. Note: For filter capacities

higher than 3600 gallons, select 3600.

4. Tap ENTER button to confirm your filter size.

Resetting Bottle Counter:

1. Press and hold ENTER button for 5 seconds.

2. Tap ENTER button until Reset Ft is displayed on the

LCD screen, then tap SET button.

3. Press and hold SET button for 5 seconds to reset

bottle counter number to zero 00000000.

4. Tap ENTER button 1 time to return to standard bottle

counter view.

Note: If a selection is not made within 2 minutes, system

will automatically return to the standard bottle counter view.

11

Page 12

Wall Mounted Water Bottle

Refilling Station

Filter Status Lights

When filter level is at 100% 5 LED bars will be displayed

When filter level is at 80% 4 LED bars will be displayed

When filter level is at 60% 3 LED bars will be displayed

When filter level is at 40% 2 LED bars will be displayed

When filter level is at 20% 1 LED bar will be displayed

When filter level is at 10%

When filter level is at 0%

Maintenance

WARNING

ALWAYS disconnect power and shut-off main water

supplier prior to maintenance. Observe entire unit for

possible water leakage.

• Inspect Cooling System every 6 months for leakage,

proper operation and performance.

•

When cleaning, do not use harsh chemicals, abrasive or

petroleum based cleaners. Doing so will void warranty.

• Exterior parts can be cleaned using a soft cloth with

mild detergents or soapy water. Do not use steel soap

pads. Rinse and towel dry.

User's Manual

1 LED bar will be displayed and will FLASH

LCD will FLASH between "CHG FLT"

and the bottle count

0 LED bars will be displayed

CD will FLASH between "CHG FLT"

entire time

• Extra caution should be used to clean mirror finished

stainless steel panels, as they can be easily scratched.

• Periodically clean cabinet ventilation louvers and

condenser fins with a vacuum cleaner, or air hose to

avoid excess dirt.

• Periodically remove the Lower Cover of the Cooling

System the and clean out water drain.

Troubleshooting

Issue Possible Cause Suggested Action

Water temperature not

cool

Restricted or no water

flow

Noisy operation

Water not dispensing

properly to bottle

The thermostat is set too high

No power to unit

Water control valve(s) are closed

Blockage in water line

Condenser fan blades not turning freely Clear fan blades free from any restrictions

Hardware rattling Ensure hardware is tightened

Infrared sensor range needs to be adjusted

Lower the water temperature on the thermostat

(see Adjusting Settings, page 10).

• Check power cord

• Check the electrical receptacle for power and

correct voltage; electric supply must be identical

in voltage, cycle and phase to that specified on

nameplate

• Check for loose wires within the Cooling System

• Check to see if GFCI outlet tripped

Access water control valve and turn on. Adjust water

flow pressure as needed (see Adjusting Settings, pg 10)

Check water supply lines and flush out any

blockage

The infrared sensitivity range is factory preset. If

this range requires adjusting, it can be set with a

sensitivity range from 01 (minimum sensitivity) to

10 (maximum sensitivity).

1. Access programming buttons (see

Programming Settings, pg 10).

2. Press and hold SET button for 5 seconds until

Reset FT is displayed on the LCD screen. Then

tap SET button 1 time to toggle to Sens Set 1.

setting on the LCD screen.

3.

Tap ENTER button multiple times to toggle

through desired range and set to user preference.

4. Tap SET button 3 times or wait 5 seconds to

return to standard bottle counter view.

12

Loading...

Loading...