Page 1

globalindustrial.ca

Assembly Instructions Instrucciones de Ensamblaje Directives d’assemblage

Customer Service

US: 1-800-645-2986

Servicio de atención al Cliente

US: 1-800-645-2986

Service à la clientèle

Canada: 888-645-2986

Aluminum Door Closer Model 713153

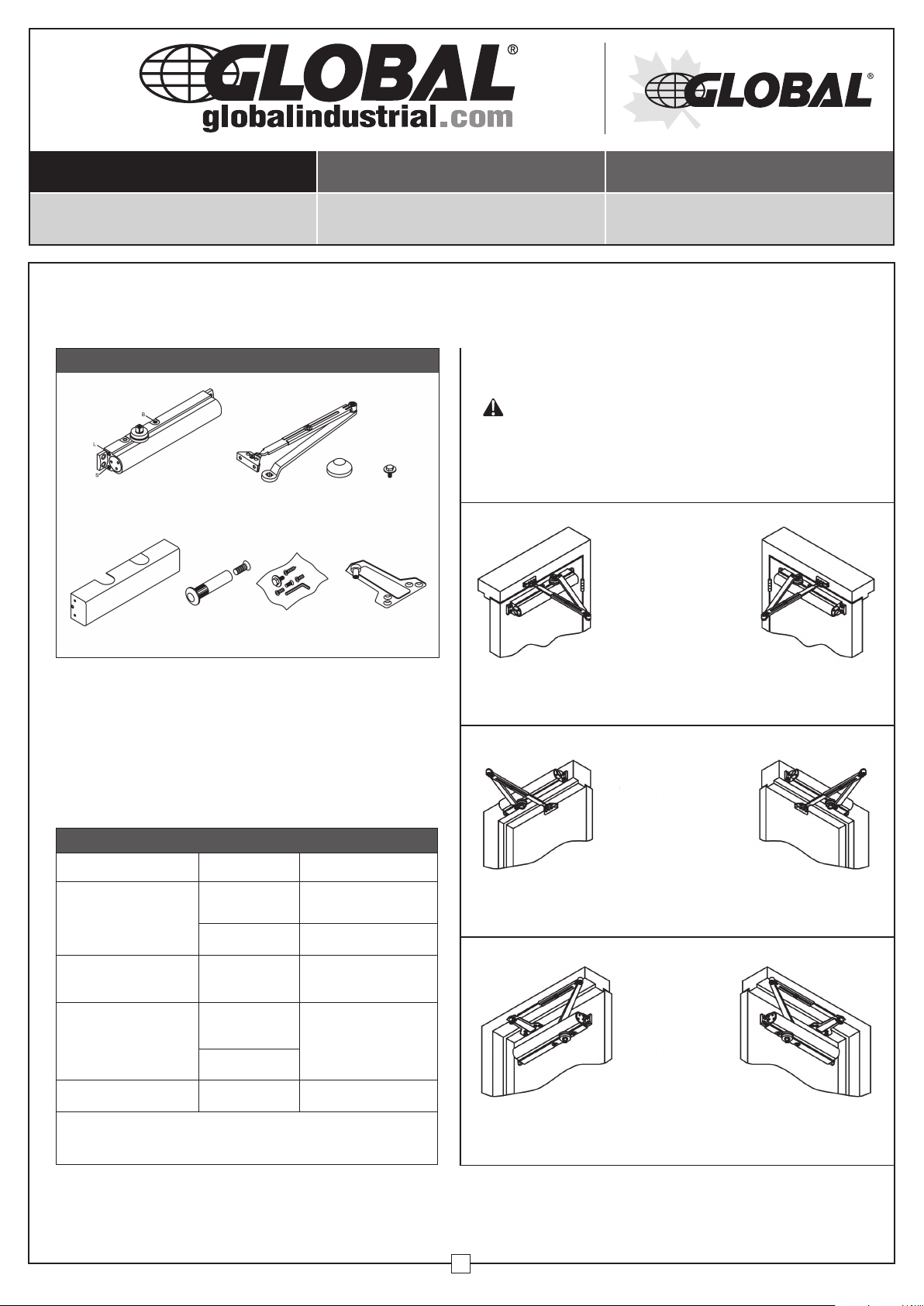

COMPONENTS

Standard Closer Closer Arm

Plastic

Cover

Through Bolt

& Screw

Screws

Package

Pinion

Cap

Main Arm

Screw

Parallel Arm

Plate

Multi-Size 1-6

Non Hold Open Door Closers

CAUTION

An incorrectly installed or improperly adjusted door closer

can cause property damage or personal injury. These

instructions should be followed to avoid the possibility of

misapplication or improper adjustment.

Regular Arm

Installation

Closer mounts on hinge

(pull) side of door

See page 2.

(Closer cover not shown)

• It is recommended that the door be hung on ball

bearing type hinges so door swings freely.

• A separate door stop is recommended to prevent

damage to the door closer, door frame or

adjacent walls.

• Door and frame must be properly reinforced or

through bolts used to prevent the mounting screws

from pulling out.

PREPARATION FOR FASTENERS

Fasteners Door or Frame Drill Sizes

Hollow metal

Self drilling/tapping

machine screw

or aluminum

Wood (see note) 3/16" pilot hole

1/4"-20 Machine screw Hollow Metal

No drill required

Drill #7 (0.201" dia.)

& Tap 1/4"-20

Hollow metal

1/4"-20 Machine screw

used with through bolt

or aluminum

9/32" drill closer side &

3/8" drill opposite side

Wood

Wood Screw Wood 3/16" pilot hole

Note: Wood doors/frames must have a pilot hole drilled when

using Self Drilling/Tapping screws.

Left hand door-LH

Right hand reverse-RHR

Left hand door-LH

Right hand reverse-RHR

Left hand door-LH

Right hand reverse-RHR

Right hand door-RH

Left hand reverse-LHR

Top Jamb Installation

Closer mounts on frame

face on opposite hinge

(push) side of door

See page 3.

(Closer cover not shown)

Right hand door-RH

Left hand reverse-LHR

Parallel Arm

Installation

Closer mounts on

opposite to hinge

(push) side of door

See page 4.

(Closer cover not shown)

Right hand door-RH

Left hand reverse-LHR

1

092418

Page 2

Aluminum Door Closer

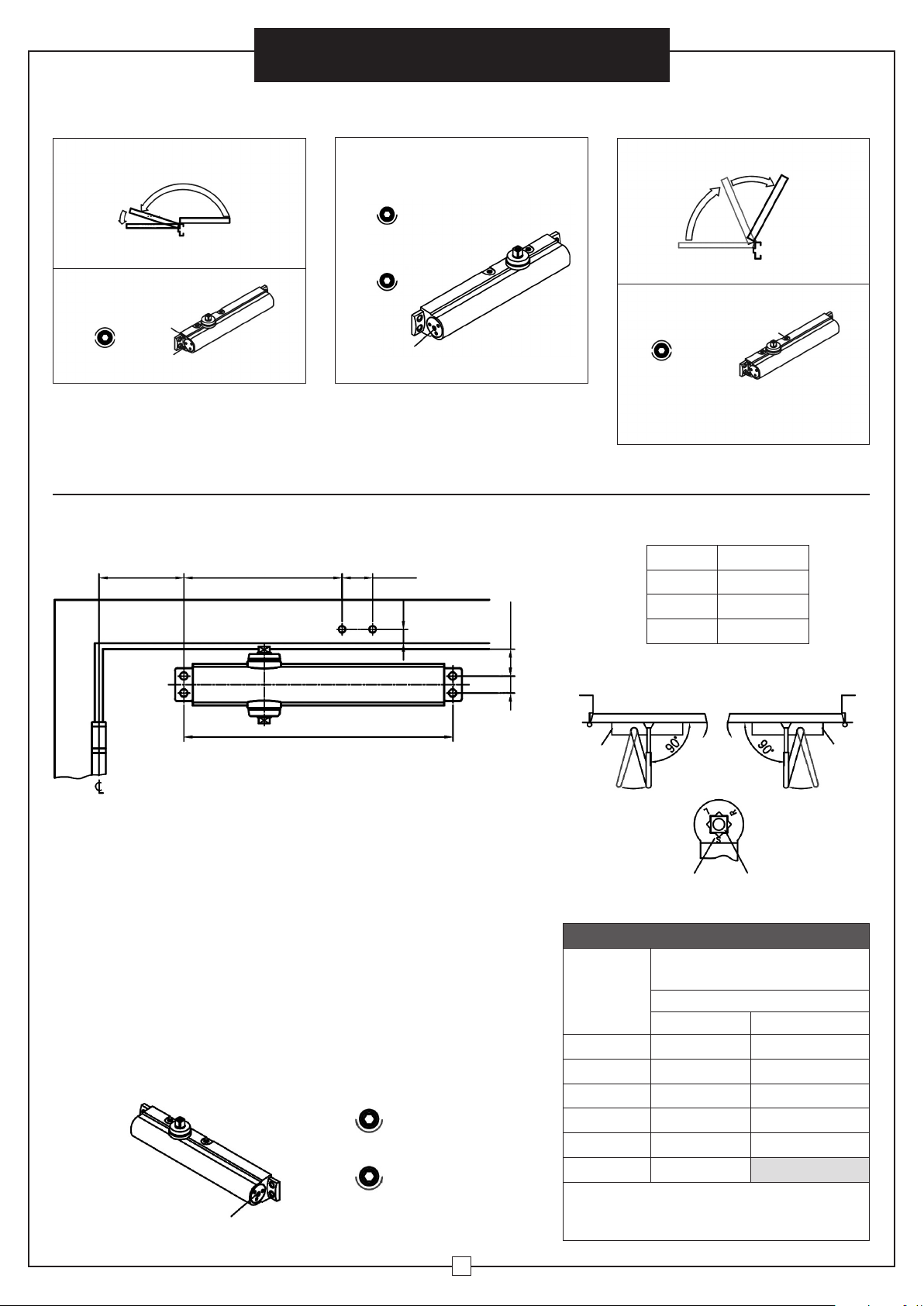

Unit Adjustment

Closing speed controls (Fig. 1 & 2) • Valve "S" controls sweep range • Valve "L" controls latch range

Assembly Instructions

Closing Speed Controls

Sweep range

Latch

Closed

Fig. 1

Fig. 2

Standard closing cycle

Sweep &

Latch

Slow

Fast

"S"

(sweep)

"L" (latch)

Standard

closer

Closing Power Controls

Adjust as required (See charts for your mount type)

T

o increase power, turn

clockwise 13 turns maximum

To decrease power, turn

counterclockwise

Fig. 3

Power adjustment nut

Opening Door Control (Fig. 4)

• Backcheck ("B") Valve controls the hydraulic resistance to door opening. NEVER

close this valve completely-It will not stop.

• Backcheck position ("P") valve controls the door angle where backcheck cushioning

starts. Valve normally closed.

Regular Arm Template

Do not scale drawing.

A 5

1

/2"

3

1

/4"

1"

Right hand door shown.

Dimensions are in inches.

3

1

/16"

Opening Door Controls

Backcheck

Opening

Fig. 4

Backcheck

Cushion

Increase

Decrease

Opening for backcheck later in door-opening cycle

(Never close backcheck valve completely)

Fig. 5

Opening cycle

Backcheck

"B" (backcheck)

Opening Dimension A

To 100° 7

1

/2"

To 130° 6"

To 180° 4

1

/2"

3

/4"

12"

Hinge or pivot

• Select degree of opening and use dimensions shown to locate 4 holes on

door for closer body and 2 holes on frame face for arm shoe.

• Prepare door and frame for fasteners. See "Preparation for Fasteners",

Page 1.

• Before installing closer body, set spring power for closer

using power

adjustment chart.

• Install closer on door with speed regulating valves toward the hinge.

• Remove forearm screw from adjusting rod and disassemble arm. See

Figure 1, Fasten arm shoe (with rod) to frame face.

• Mount main arm onto closer pinion shaft, aligning arm mark "S" with

pinion flat. Secure with main arm screw.

• Reassemble arm. Adjust forearm length so that it will be perpendicular

(at a 90" angle) to the door face. Secure with forearm screw.

• Adjust closer (see above) and install cover.

To increase power, turn

clockwise 13 turns maximum

To decrease power, turn

Power adjustment nut

counterclockwise

Right hand door

Valves Valves

Arm Preload Arm Preload

Arm Mark Pinion Flat

Swing

Left hand door

Door

POWER ADJUSTMENT CHART

Full clockwise turns of closer power

Door Size

inches

adjustment nut (from "0" turns)

316 series only

Interior Door Exterior Door

24" - 30" -7 -5

30" - 34" -3 0

34" - 38" 0 4

38" - 48" 4 8

48" - 54" 8 13

54" - 60" 13

NOTE: Maximum of 20 turns (360°) of power

adjustment Nut. Closer is shipped set at 7 turns

from the factory.

2

Page 3

Aluminum Door Closer

Assembly Instructions

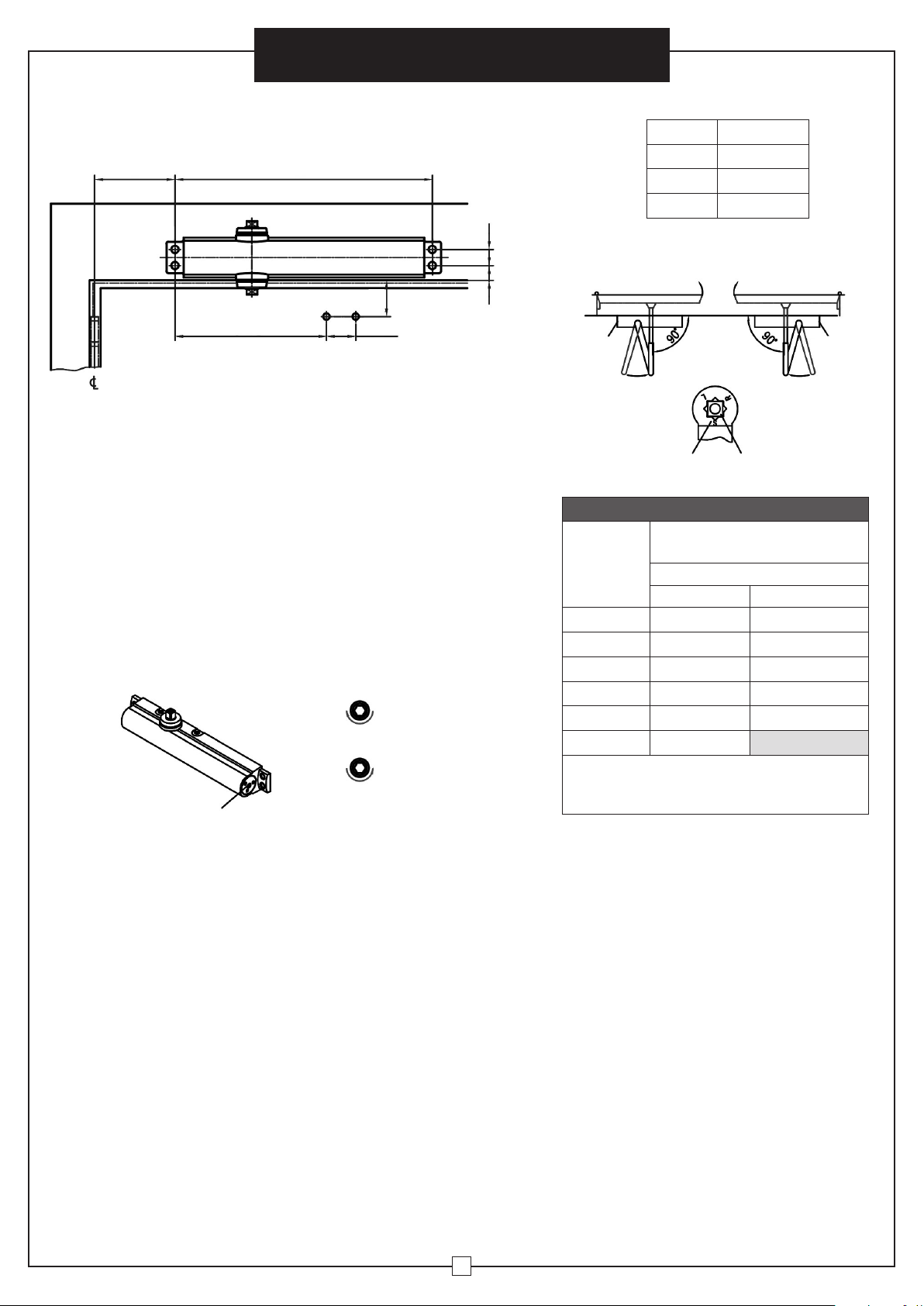

Top Jamb Template

Do not scale drawing.

Right hand door shown.

A 12"

Hinge or pivot

3

1

/4"51/2"

Dimensions are in inches.

3

/4"

1

/2"

• Select degree of opening and use dimensions shown to locate 4 holes on

frame face for closer body and 2 holes on door for arm shoe.

• Prepare door and frame for fasteners. See "Preparation for Fasteners",

Figure 2, Page 2.

• Before installing closer body, set spring power for closer

using power

adjustment chart.

• Install closer on door with speed regulating valves toward the hinge.

• Remove forearm screw from adjusting rod and disassemble arm. See

Figure 1, Fasten arm shoe (with rod) to frame face.

• Mount main arm onto closer pinion shaft, aligning arm mark "S" with

pinion flat. Secure with main arm screw.

• Reassemble arm. Adjust forearm length so that it will be perpendicular

(at a 90" angle) to the door face. Secure with forearm screw.

• Adjust closer (see page 2) and install cover.

To increase power, turn

clockwise 12 turns maximum

To decrease power, turn

Power adjustment nut

counterclockwise

Opening Dimension A

To 100° 7

1

/2"

To 130° 6"

To 180° 4

Door

Swing

Right hand door Left hand door

Valves Valves

Arm Preload Arm Preload

Arm Mark Pinion Flat

1

/2"

POWER ADJUSTMENT CHART

Full clockwise turns of closer power

Door Size

inches

adjustment nut (from "0" turns)

316 series only

Interior Door Exterior Door

24" - 30" -7 -5

30" - 34" -3 0

34" - 38" 0 4

38" - 48" 4 8

48" - 54" 8 13

54" - 60" 13

NOTE: Maximum of 20 turns (360°) of power

adjustment Nut. Closer is shipped set at 7 turns

from the factory.

3

Page 4

Aluminum Door Closer

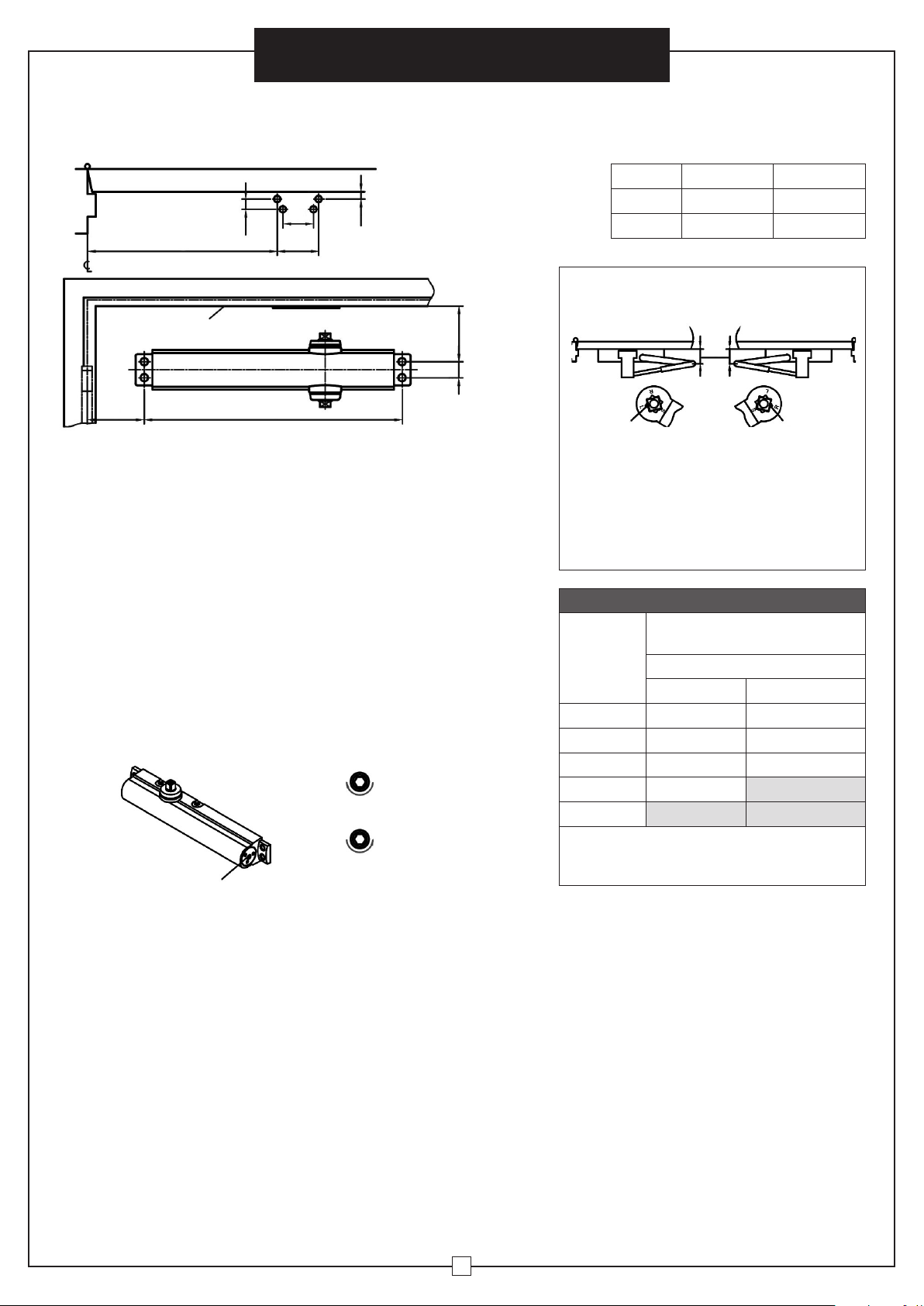

Parallel Arm Template

2"

3

2

/4"

A

Frame

7

/16"

Assembly Instructions

Do not scale drawing.

Right hand door shown.

1

/2"

Dimensions are in inches.

Opening Dimension A Dimension B

To 120° 9

To 180° 7" 1

1

/2" 33/4"

1

/4

Main Arm Installation Instructions

Door

1

3

/2"

3

/4"

Right hand door Left hand door

Swing

1

1

/2"

38mm

B

12"

• Select degree of opening and use dimensions shown to locate 4 holes

on door for closer body and 4 holes on underside of frame for PA plate.

• Prepare door and frame for fasteners. See "Preparation for Fasteners",

Figure 2, Page 2.

• Before installing closer body, set spring power for closer

using power

adjustment chart.

• Install closer on door with speed regulating valves toward the hinge.

• Mount soffit plate to frame. Remove forearm screw from adjusting

rod (See Figure 1) and attach adjusting rod.

• Install main arm on pinion shaft; see main arm installation instructions

•

Reassemble arm. Preload is accomplished by adjusting forearm length

so that it will set arm elbow approximately 1

1

/2"(38mm) from the door

face when connected to the main arm. Secure with forearm screw.

• Adjust closer (see page 2) and install cover.

To increase power, turn

clockwise 12 turns maximum

To decrease power, turn

Power adjustment nut

counterclockwise

Flat Flat

Left hand door Right hand door

Use adjustable wrench to rotate spindle 45°

counter clockwise for right hand door or clockwise

for left hand door. Place main arm on spindle so

that the "R"(Right hand door) or "L"(Left hand

door) lines up with the spindle flat. Secure main

arm and spindle by tightening spindle bolt.

POWER ADJUSTMENT CHART

Full clockwise turns of closer power

Door Size

inches

adjustment nut (from "0" turns)

316 series only

Interior Door Exterior Door

24" - 30" -4 0

30" - 34" 0 5

34" - 38" 6 10

38" - 48" 12

48" - 54"

NOTE: Maximum of 20 turns (360°) of power

adjustment Nut. Closer is shipped set at 7 turns

from the factory.

4

Page 5

globalindustrial.ca

Assembly Instructions Instrucciones de Ensamblaje Directives d’assemblage

Customer Service

US: 1-800-645-2986

Servicio de atención al Cliente

US: 1-800-645-2986

Service à la clientèle

Canada: 888-645-2986

Cierrapuertas de aluminio Modelo 713153

COMPONENTES

Cierrapuertas Estándar Brazo del

Tapa de

plástico

Perno Pasante

y Tornillos

Cierrapuertas

Paquete de

Tornillos

Tapa del

piñón

Tornillo

principal del

Brazo

Placa de Brazo

Paralela

Cierrapuertas Sin Retención

de varios tamaños 1-6

PRECAUCIÓN

Un cierrapuertas incorrectamente instalado o mal ajustado

puede causar daños a la propiedad o lesiones personales.

Estas instrucciones deben seguirse para evitar la posibilidad

de una instalación incorrecta o un ajuste incorrecto

Instalación de

brazo regular

El cierrapuertas se instala

en el lado de la bisagra

(tirador) de la puerta.

Consulte la página 2.

(No se muestra la Cubierta

del cierrapuertas)

.

•

Se recomienda colgar la puerta en bisagras con cojinetes

de bolas para que la puerta se balancee libremente.

• Se recomienda un tope de puerta separado para

evitar daños en el cerradero de la puerta, el marco de

la puerta o las paredes adyacentes.

• La puerta y el marco deben estar debidamente

reforzados o mediante pernos que se utilizan para

evitar que los tornillos de montaje se salgan.

PREPARACIÓN DESUJETADORES

Sujetadores Puerta o marco Tamaños de Taladros

Tornillo de auto

perforado/roscado

Metal hueco o

aluminio

Madera

(vea la nota)

No requiere taladro

Orificio piloto de 3/16"

Taladro Nº 7 (0.201"

1/4" -20 Tornillo Metal hueco

de diámetro) & Tap

1/4" -20

1/4" -20 Tornillo

utilizado con perno

pasante

Metal hueco o

aluminio

Madera

Taladro de 9/32" del

lado del cierrapuertas y

taladro 3/8" del lado

opuesto

Tornillo de Madera Madera 3/16" Orificio Piloto

Nota: Las puertas/marcos de madera deben tener un orificio piloto

taladrado cuando se usan tornillos de auto perforación/roscado.

Puerta Mano Izquierda-LH

Mano Derecha Invertida-RHR

se instala en la cara del

marco en el lado opuesto

(No se muestra la Cubierta

Puerta Mano Izquierda-LH

Mano Derecha Invertida-RHR

Puerta Mano Izquierda-LH

Mano Derecha Invertida-RHR

Puerta Mano Derecha-RH

Mano Izquierda Invertida-LHR

El cierrapuertas Top

Jamb Installation

de la bisagra (empuje).

Vea la página 3.

del cierrapuertas)

Puerta Mano Derecha-RH

Mano Izquierda Invertida-LHR

El Parallel Arm

Installation

se instala opuesto al

lado de la bisagra

(empuje) Vea la página 4

(No se muestra la

Cubierta del

cierrapuertas)

Puerta Mano Derecha-RH

Mano Izquierda Invertida-LHR

1

092418

Page 6

Instrucciones de Ensamblaje

Cierrapuertas de aluminio

Ajuste de la uni

Controles de velocidad de cierre (figuras 1 y 2) • La válvula "S" controla el rango de barrido • La válvula "L" controla el rango de pestillo

Controles de Velocidad de cierre

Rango de barrido

Pestillo

Cerrado

Fig. 1

Fig. 2

Ciclo Estándar de cierre

Barrido y

Pestillo

Lento

Rápido

“S”

(barrido)

“L” (pestillo)

Cierrapuertas

estándar

Controles de Fuerza de Cierre

Ajuste según sea necesario (Vea tablas

para su tipo de montaje)

Para aumentar la fuerza, gire hacia la

derecha 13 vueltas máximo

Para disminuir la fuerza,

gire hacia la izquierda

Tuerca de ajuste de fuerza

Fig. 3

Control de apertura de la puerta (Fig. 4)

• La válvula ("B") controla la resistencia hidráulica a la apertura de la puerta. NUNCA

cierre esta válvula por completo; no se detendrá.

• La válvula de posición de retención ("P") controla el ángulo de la puerta donde

comienza la amortiguación de la retención. Válvula normalmente cerrada.

Plantilla de brazo regular

No escale el dibujo.

Se muestra la Puerta Mano Derecha.

A 5

1

/2"

Las dimensiones están en pulgadas.

3

1

/4"

1"

3

1

/16"

Controles de Apertura de la Puerta

Retención

Apertura

Fig. 4

Cojín de

resistencia

Aumentar

Disminuir

Apertura para retención más adelante en el ciclo de

(Nunca cerrar completamente la válvula de retención)

Fig. 5

Ciclo de apertura

Retención

“B” (Retención)

apertura de la puerta

Apertura Dimensión A

a 100° 7

1

/2"

a 130° 6"

a 180° 4

1

/2"

3

/4"

12"

Bisagra o pivote

• Seleccione el grado de apertura y utilice las dimensiones que se muestran

para ubicar 4 orificios en la puerta para el cuerpo del cierrapuertas y 2

orificios en la cara del marco para la zapata del brazo.

• Prepare la puerta y el marco para los sujetadores. Consulte "Preparación

para sujetadores", página 1.

• Antes de instalar el cuerpo del cierrapuertas, configure la fuerza del resorte

del cierrapuertas usando la tabla de ajuste de fuerza.

• Instale el cierrapuertas en la puerta con las válvulas reguladoras de velocidad

hacia la bisagra.

•

Retire el tornillo del antebrazo de la varilla de ajuste y desarme el brazo. Consulte

la Figura 1, Fije la zapata del brazo (con la varilla) a la cara del marco.

•

Instale el brazo principal sobre el eje del piñón más cercano, alineando la marca

del brazo "S" con el piñón plano. Asegúrelo con el tornillo del brazo principal.

• Vuelva a armar el brazo. Ajuste la longitud del antebrazo para que quede

perpendicular (en un ángulo de 90°) a la cara de la puerta. Asegure con el

tornillo del antebrazo.

• Ajuste el cierrapuertas (vea arriba) e instale la tapa.

Para aumentar la fuerza, gire hacia

la derecha 13 vueltas máximo

Para disminuir la fuerza,

Tuerca de ajuste de potencia

gire hacia la izquierda

Puerta Mano

Derecha

Válvulas Válvulas

Precarga del Brazo Precarga del Brazo

Marca del Brazo Piñón plano

Barrido

de la

Puerta

Puerta Mano

Izquierda

TABLA DE AJUSTE DE FUERZA

Giros completos en dirección a

Tamaño de

Puerta

(pulgadas)

las agujas del reloj de la tuerca de

ajuste de fuerza (desde '0' vueltas )

Solo para Serie 316

Puerta Interior Puerta Exterior

24" - 30" -7 -5

30" - 34" -3 0

34" - 38" 0 4

38" - 48" 4 8

48" - 54" 8 13

54" - 60" 13

NOTA: Máximo de 20 vueltas (360°) de la Tuerca

de ajuste de fuerza. El Cierrapuertas se envía

configurado a 7 vueltas desde la fábrica.

2

Page 7

Cierrapuertas de aluminio

Instrucciones de Ensamblaje

Plantilla de Top Jamb

No escale el dibujo.

Se muestra la Puerta Mano Derecha.

Las dimensiones están en pulgadas.

A 12"

3

/4"

1

/2"

3

1

/4"51/2"

Hinge or pivot

• Seleccione el grado de apertura y utilice las dimensiones que se

muestran para ubicar 4 orificios en la cara del marco para el cuerpo del

cierrapuertas y 2 orificios en la puerta para la zapata del brazo.

• Prepare la puerta y el marco para los sujetadores. Consulte "Preparación

para los sujetadores", figura 2, página 2.

• Antes de instalar el cuerpo del cierrapuertas, configure la fuerza del

resorte del cierrapuertas usando la tabla de ajuste de fuerza

.

• Instale el cierrapuertas en la puerta con las válvulas reguladoras de

velocidad hacia la bisagra.

• Retire el tornillo del antebrazo de la varilla de ajuste y desarme el

brazo. Consulte la Figura 1, Fije la zapata del brazo (con la varilla) a

la cara del marco.

• Instale el brazo principal sobre el eje del piñón más cercano, alineando

la marca del brazo "S" con el piñón plano. Asegúrelo con el tornillo

del brazo principal.

• Vuelva a armar el brazo. Ajuste la longitud del antebrazo para que

quede perpendicular (en un ángulo de 90°) a la cara de la puerta.

Asegure con el tornillo del antebrazo.

• Ajuste el cierrapuertas (vea la página 2) e instale la tapa.

Para aumentar la fuerza, gire hacia

la derecha 12 vueltas máximo

Para disminuir la fuerza,

Tuerca de ajuste de potencia

gire hacia la izquierda

Apertura Dimensión A

a 100° 7

1

/2"

a 130° 6"

a 180° 4

Barrido

de la

Puerta Mano

Derecha

Válvulas Válvulas

Precarga del Brazo Precarga del Brazo

Marca del Brazo Piñón plano

Puerta

1

/2"

Puerta Mano

Izquierda

TABLA DE AJUSTE DE FUERZA

Giros completos en dirección a

Tamaño de

Puerta

(pulgadas)

las agujas del reloj de la tuerca de

ajuste de fuerza (desde '0' vueltas )

Solo para Serie 316

Puerta Interior Puerta Exterior

24" - 30" -7 -5

30" - 34" -3 0

34" - 38" 0 4

38" - 48" 4 8

48" - 54" 8 13

54" - 60" 13

NOTA: Máximo de 20 vueltas (360°) de la Tuerca

de ajuste de fuerza. El Cierrapuertas se envía

configurado a 7 vueltas desde la fábrica.

3

Page 8

Cierrapuertas de aluminio

Instrucciones de Ensamblaje

Plantilla de Brazo Paralelo

No escale el dibujo.

Se muestra la Puerta Mano Derecha.

Las dimensiones están en pulgadas.

2"

1

/4"

/2"

1

3

/2"

3

/4"

7

/16"

A

Marco

B

12"

3

2

• Seleccione el grado de apertura y use las dimensiones que se muestran

para ubicar 4 orificios en la puerta para el cuerpo del cierrapuertas y 4

orificios en el inferior del marco para la placa del brazo paralelo.

• Prepare la puerta y el marco para los sujetadores. Véase "Preparación

para sujetadores", la figura 2, página 2.

• Antes de instalar el cuerpo del cierrapuertas, configure la fuerza del

resorte del cierrapuertas usando la tabla de ajuste de fuerza

.

• Instale el cierrapuertas en la puerta con las válvulas reguladoras de

velocidad hacia la bisagra.

• Instale la placa del sofito en el marco. Quite el tornillo del antebrazo

de la varilla de ajuste (Vea la Figura 1) y coloque la varilla de ajuste.

• Instale el brazo principal en el eje del piñón. Vea las instrucciones de

instalación del brazo principal.

•

Vuelva a armar el brazo. La precarga se logra ajustando la longitud del

antebrazo para que coloque el codo del brazo aproximadamente a

1

1

/2" (38 mm) de la cara de la puerta cuando esté conectado al brazo

principal. Asegure con el tornillo del antebrazo.

• Ajuste el cierrapuertas (vea la página 2) e instale la tapa.

Para aumentar la fuerza, gire hacia

la derecha 12 vueltas máximo

Para disminuir la fuerza,

Tuerca de ajuste de potencia

gire hacia la izquierda

Apertura Dimensión A Dimensión B

a 120 ° 9

a 180 ° 7" 1

1

/2" 33/4"

1

/4

Instrucciones de instalación del

brazo principal

Barrido

de la

Puerta Mano

Derecha

Plana Plana

Puerta Mano Derecha Puerta Mano Izquierda

Use una llave ajustable para girar el husillo 45° en

sentido anti horario para la Puerta Mano Derecha o

en sentido horario para la Puerta Mano Izquierda.

Coloque el brazo principal en el husillo de manera

que la "R" (Puerta Mano Derecha) o "L" (Puerta

Mano Izquierda) se alinee con el husillo plano.

Asegure el brazo principal y el husillo apretando

el perno del husillo.

TABLA DE AJUSTE DE FUERZA

Tamaño de

Puerta

(pulgadas)

24" - 30" -4 0

30" - 34" 0 5

34" - 38" 6 10

38" - 48" 12

48" - 54"

NOTA: Máximo de 20 vueltas (360°) de la Tuerca

de ajuste de fuerza. El Cierrapuertas se envía

configurado a 7 vueltas desde la fábrica.

Puerta

1

1

/2"

38mm

Puerta Mano

Izquierda

Giros completos en dirección a

las agujas del reloj de la tuerca de

ajuste de fuerza (desde '0' vueltas )

Solo para Serie 316

Puerta Interior Puerta Exterior

4

Page 9

globalindustrial.ca

Assembly Instructions Instrucciones de Ensamblaje Directives d’assemblage

Customer Service

US: 1-800-645-2986

Servicio de atención al Cliente

US: 1-800-645-2986

Service à la clientèle

Canada: 888-645-2986

Porte en aluminium du Fermoir Modèle 713153

COMPOSANTS

Fermoir standard Bras du fermoir

Couvercle

en plastique

Boulon et la

vis vide

Paquet de vis Plaque de bras

Embout

de pignon

Vis de bras

principal

parallèle

Fermoirs de portes ouvertes multi-tailles

1-6 sans retenue

ATTENTION

Un fermoir de porte incorrectement installée ou mal

ajustée peut causer des dommages matériels ou

corporels. Ces instructions doivent être suivies pour

éviter la possibilité d'une mauvaise application ou d'un

mauvais réglage.

Installation

régulière du bras

Fixations rapprochées sur

la charnière (tirer) côté

de la porte. Voir page 2.

(couverture du fermoir

non illustrée)

• Il est recommandé que la porte soit accrochée sur les

charnières de type roulement à billes pour que la porte

se balance librement.

• Une butée de porte séparée est recommandée pour

éviter d'endommager le fermoir de la porte, le cadre

de porte ou les parois adjacentes.

• la porte et le cadre doivent être correctement

renforcés ou des boulons a trou sont a être utilisés

pour empêcher les vis de montage de se retirer.

PRÉPARATION DES ATTACHES

Attaches Porte ou cadre Tailles de foret

Vis machine Auto

perçage/taraudage

Vis machine

de 1/4 "-20

1/4 "-20 vis de

machine utilisé avec

boulon à travers

Métal creux ou

aluminium

Bois (voir note) Trou pilote de 3/16"

Métal creux

Métal creux ou

aluminium

Bois

Aucun foret requis

Mèche #7 (0,201 "dia.)

et TAP de 1/4 "-20

Mèche latérale du

fermoir de 9/32" et

De 3/8" pour percer de

l’autre côté

Vis à bois Bois 3/16" trou pilote

Remarque: les portes/cadres en bois doivent avoir un trou pilote

percé lors de l'utilisation de vis auto-taraudeuses.

Porte gauche-main

droite Revers-RHR

Porte gauche-main

droite Revers-RHR

Porte gauche-main

droite Revers-RHR

Montage du montant

supérieur

montages du fermoir

sur la face de l'armature

sur la charnière opposée

(pousser) côté de la porte

Voir page 3

(couverture du fermoir

non illustrée).

Installation du bras

parallèle

du fermoir et de ses

montages rapprochés à

l'opposé de la charnière

(pousser) côté de la

porte voir page 4

(couverture du fermoir

non illustrée).

Porte droite-Revers

main gauche-LHR

Porte droite-Revers

main gauche-LHR

Porte droite-Revers

main gauche-LHR

1

092418

Page 10

Directives d’assemblage

Porte en aluminium du Fermoir

Réglage de l'unité

Réglage de la vitesse de fermeture (Fig. 1 & 2) • Valve "S " contrôle la plage de balayage • Valve "L" contrôle la plage de verrous

Contrôle de vitesse de fermeture

Gamme de la trajectoire

Loquet

Fermé

Fig. 1

Fig. 2

Cycle de fermeture standard

Balayage et

loquet

Lent

Rapide

"S"

(balayage)

"L" (loquet)

Fermoir

standard

Fermeture des commandes

d'alimentation

Ajuster au besoin (voir graphiques pour votre type de montage)

Pour augmenter la puissance,

tournez dans le sens horaire

13 tours maximum

Pour diminuer la puissance,

tourner dans le sens antihoraire

Écrou de réglage de puissance

Fig. 3

Commande de porte ouvrante (Fig. 4)

• Contrôle de retour ("B") la vanne contrôle la résistance hydraulique à l'ouverture de la

porte. Ne fermez jamais complètement cette valve-elle ne s'arrêtera pas.

• Position de retour ("P") la valve contrôle l'angle de la porte où commence le

rembourrage de contrôle. La valve se ferme normalement.

Modèle de bras régulier

A 5

1

/2"

3

1

/4"

1"

Ne pas dimensionner le dessin.

Porte droite illustrée.

Les dimensions sont en pouces.

3

1

/16"

Ouverture des commandes de porte

Contrôle

Ouverture

Fig. 4

Coussin de

contrôle

Augmentation

Diminution

Ouverture pour vérification postérieure dans

(Ne fermez jamais complètement le clapet anti-retour)

Fig. 5

Cycle d'ouverture

Contrôle

"B" (Contrôle)

le cycle d'ouverture de porte.

Ouverture Dimension A

À 100 ° 7

1

/2"

À 130 ° 6"

À 180 ° 4

1

/2"

3

/4"

12"

Charnière ou pivot

• Sélectionner le degré d'ouverture et les dimensions d'utilisation indiquées

pour localiser 4 trous sur la porte pour un corps plus rapproché et 2 trous

sur la face de l'armature pour le sabot de bras.

• Préparer la porte et le cadre pour les attaches. Voir "préparation pour

les attaches ", page 1.

• Avant d'installer le corps plus près, réglez l'alimentation du ressort pour

le rapprocher à l'aide du tableau de réglage

.

• Installer plus près de la porte avec les vannes de régulation de vitesse

vers la charnière.

•

Retirer la vis de l'avant-bras de la tige de réglage et démonter le bras. Voir

Figure 1, attachez la chaussure du bras (avec la tige) à la face du cadre.

• Monter le bras principal sur l'arbre du pignon, en alignant le marqueur

de bras "S" avec le pignon plat. Fixez avec la vis du bras principal.

• Remonter le bras. Réglez la longueur de l'avant-bras de façon à ce

qu'elle soit perpendiculaire (à un angle de 90") à la face de la porte.

Fixez avec la vis d'avant-bras.

• Ajuster plus près (voir ci-dessus) et installer le couvercle.

Pour augmenter la puissance, tournez

dans le sens horaire 13 tours maximum

Pour diminuer la puissance,

Écrou de réglage de puissance

tourner dans le sens antihoraire

Porte droite

Vannes Vannes

Précharge des bras Précharge des bras

Marque de bras Pignon plat

Oscillation

de porte

Porte gauche

TABLEAU DE RÉGLAGE DE PUISSANCE

Rotation dans le sens des aiguilles

d'une montre de l'écrou de réglage

Taille de porte

Pouces

de puissance (d’aucun tour)

série 316 seulement

Porte intérieure Porte extérieure

24" - 30" -7 -5

30" - 34" -3 0

34" - 38" 0 4

38" - 48" 4 8

48" - 54" 8 13

54" - 60" 13

Remarque : maximum de 20 tours (360°) d'écrou

de réglage de puissance. Le fermoir est livré réglé à

7 tours de l'usine.

2

Page 11

Porte en aluminium du Fermoir

Directives d’assemblage

Gabarit de jambage supérieur

Ne pas dimensionner le dessin.

Porte droite illustrée.

A 12"

Charnière ou pivot

3

1

/4"51/2"

Les dimensions sont en pouces.

3

/4"

1

/2"

• Sélectionner le degré d'ouverture et les dimensions d'utilisation indiquées

pour localiser 4 trous sur la face du cadre pour un corps plus rapproché

et 2 trous sur la porte pour le sabot de bras.

• Préparer la porte et le cadre pour les attaches. Voir "préparation pour les

attaches", figure 2, page 2.

• Avant d'installer le corps du fermoir, réglez l'alimentation du ressort pour

le rapprocher à l'aide du tableau de réglage

.

• Installer plus près de la porte avec les vannes de régulation de vitesse

vers la charnière.

•

Retirer la vis de l'avant-bras de la tige de réglage et démonter le bras. Voir

figure 1, attachez la chaussure du bras (avec la tige) à la face du cadre.

•

Monter le bras principal sur l'arbre du pignon du fermoir, en alignant le

marqueur de bras "S" avec le pignon plat. Fixez avec la vis du bras principal.

• Remonter le bras. Réglez la longueur de l'avant-bras de façon à ce

qu'il soit perpendiculaire (à un angle de 90") à la face de la porte.

Fixez avec la vis d'avant-bras.

• Ajuster plus près (voir page 2) et installer le couvercle.

Pour augmenter la puissance, tournez

dans le sens horaire 12 tours maximum

Pour diminuer la puissance,

Écrou de réglage de puissance

tourner dans le sens antihoraire

Ouverture Dimension A

À 100 ° 7

1

/2"

À 130 ° 6"

À 180 ° 4

Oscillation

de porte

Porte droite Porte gauche

Vannes Vannes

Précharge des bras Précharge des bras

Marque de bras Pignon plat

1

/2"

TABLEAU DE RÉGLAGE DE PUISSANCE

Rotation dans le sens des aiguilles

d'une montre de l'écrou de réglage

Taille de porte

Pouces

de puissance (d’aucun tour)

série 316 seulement

Porte intérieure Porte extérieure

24" - 30" -7 -5

30" - 34" -3 0

34" - 38" 0 4

38" - 48" 4 8

48" - 54" 8 13

54" - 60" 13

Remarque : maximum de 20 tours (360°) d'écrou

de réglage de puissance. Le fermoir est livré réglé à

7 tours de l'usine.

3

Page 12

Porte en aluminium du Fermoir

Modèle de bras parallèle

2"

7

/16"

A

Cadre

B

2

12"

1

3

/4"

/2"

Ne pas dimensionner le dessin.

Porte droite illustrée.

Les dimensions sont en pouces.

1

3

/2"

3

/4"

Directives d’assemblage

Ouverture Dimension A Dimension B

À 120° 9

À 180° 7" 1

1

/2" 33/4"

1

Instructions d'installation

du bras principal

Oscillation

Porte droite Porte gauche

Plat Plat

Porte gauche Porte droite

de porte

1

1

/2"

38mm

/4

• Sélectionner le degré d'ouverture et les dimensions d'utilisation indiquées

pour localiser 4 trous sur la porte pour le corps plus proche et 4 trous sur

le dessous du cadre pour la plaque PA.

• Préparer la porte et le cadre pour les attaches. Voir "préparation pour les

attaches", figure 2, page 2.

• Avant d'installer le corps du fermoir, réglez l'alimentation du ressort pour

le rapprocher à l'aide du tableau de réglage

.

• Installer plus près de la porte avec les vannes de régulation de vitesse

vers la charnière.

• Monter la plaque de soffite sur le cadre. Enlevez la vis de l'avant-bras

de la tige de réglage (voir figure 1) et fixez la tige de réglage.

• Installer le bras principal sur l'arbre du pignon; Voir les instructions

d'installation du bras principal.

•

Remonter le bras. La précontrainte s'effectue en réglant la longueur

de l'avant-bras de façon à ce qu'elle règle le coude du bras d'environ

11/2"(38mm) de la face de la porte lorsqu'il est raccordé au bras principal.

Fixez avec la vis d'avant-bras.

• Ajuster plus près (voir page 2) et installer le couvercle.

Pour augmenter la puissance, tournez

dans le sens horaire 12 tours maximum

Pour diminuer la puissance,

Écrou de réglage de puissance

tourner dans le sens antihoraire

Utiliser une clé à molette pour faire pivoter la

broche 45° dans le sens antihoraire pour la

porte droite ou dans le sens horaire pour la porte

gauche. Placez le bras principal sur la broche de

façon à ce que le "R" (porte de droite) ou "L"

(porte de gauche) s'aligne avec la broche à plat.

Fixez le bras principal et la broche en serrant le

boulon de broche.

POWER ADJUSTMENT CHART

Rotation dans le sens des aiguilles

d'une montre de l'écrou de réglage

Taille de porte

Pouces

de puissance (d’aucun tour)

série 316 seulement

Porte intérieure Porte extérieure

24" - 30" -4 0

30" - 34" 0 5

34" - 38" 6 10

38" - 48" 12

48" - 54"

Remarque : maximum de 20 tours (360°) d'écrou

de réglage de puissance. Le fermoir est livré réglé à

7 tours de l'usine.

4

Loading...

Loading...