Page 1

Standing Combination Eye Wash Shower & Station Model no. 708383

The Global Industrial Combo Eye Wash Station is essential for industrial spaces where

accidents can occur with chemicals or hazardous substances. These units provide immediate,

reliable and effective treatment as needed. High quality and durable components ensure these

stations comply and meet ANSI Standard Z358.1.

Table of Contents Page

PRODUCT INFO

Pipe & Fittings - Schedule 40 galvanized steel includes

safety yellow polyethylene covers for corrosion resistance

and easy visibility.

Shower Head – ABS plastic, 10” Dia.

Spray Head – Includes “ip top” covers to protect from

dust particles.

Eye Wash Bowl – 11.5” ABS Plastic.

General Information 2

Parts List 3

Product Dimensions 4

Assembly instructions 5

Assembly Checklist 11

Warranty Info 12

Supply & Waste – Inlet and Outlet Tees allow inow for

water supply and separate outow for waste disposal.

Quality Assurance – Valves and Spray heads are tested at

factory to assure efciency.

Please read this manual completely and save these

instructions for reference. Upon receiving, inspect the

unit for any damage. If damage is evident, notify the

carrier immediately to le a claim. These products must

be handled with caution.

1

Page 2

GENERAL INFORMATION & GUIDELINES

Emergency eye wash stations are designed to deliver water to rinse chemical substances from a

person’s eyes, face or body.

WARNING: Eye wash stations are NOT to be used as substitutes for primary protective

equipment (such as gloves, masks, eye protection, and protective clothing) when handling

dangerous substances. Simply installing these stations is not sufcient to assure worker

safety. Staff must be trained in the use, maintenance, and knowledge of the eye wash

station. A response plan and action should be in place in the event that an accident does

occur and employees have guidelines to follow for injured personnel.

Below are guidelines that should be followed in accordance with the eye wash station when

applicable. Note OSHA regulations, accessibility & surroundings, and water connections

before assembling and installing the eye wash combo station. There are certain

circumstances where these guidelines may not be adequate.

LOCATION OF EMERGENCY EQUIPMENT

• Per ANSI Specications, emergency equipment must be installed on the same level as the

possible incident (e.g. stairs/ramps must not be required to use the unit).

• It is advised that emergency equipment be installed within 10 seconds (approx. 55 feet) of

walking time/distance from the location of the possible incident.

WATER TEMPERATURE

• Water temperature should be between 60°F(15.5°C) – 100°F(37.8°C). This can vary depending on the chemical substance and should be consulted with a safety counselor.

SHUT OFF VALVES

• These stationary eye wash units are designed to be connected to a clean and viable water

supply line.

• A shut off valve on the water line is advised to easily maintain/repair the station.

• If a shut off valve is installed, make sure necessary procedures are established to prevent

misuse of the valve. Only authorized personal should be installing/maintaining the shut off

valve.

CORROSION & RUST RESISTANCE

• All parts of the system must be constructed of materials that will not corrode.

FREEZING CONDITIONS

• Emergency equipment that must be installed in potential freezing conditions should

be installed with the proper equipment to protect against freezing per ANSI Z358.1

Section 4.5.5, 5.4.5.

• Freeze resistant equipment includes but is not limited to:

1. Temperature actuated bleed valve that permits water to ow through the unit when the

temperature drops below freezing.

2. Remote-activated valves or electrically heated units/heated

enclosures.

2

Page 3

DISPOSAL OF WATER

• Waste water must be treated with care to avoid creating any hazards. It is highly

recommended that emergency shower stations should be connected to drain piping or

ood drains. Depending on the chemical substances, drainage into an acid waste

disposal system may be recommended.

NOTE: Prior to rst use after installation, use ANSI checklist on page 11 to make sure unit

is compliant and assembled/installed correctly.

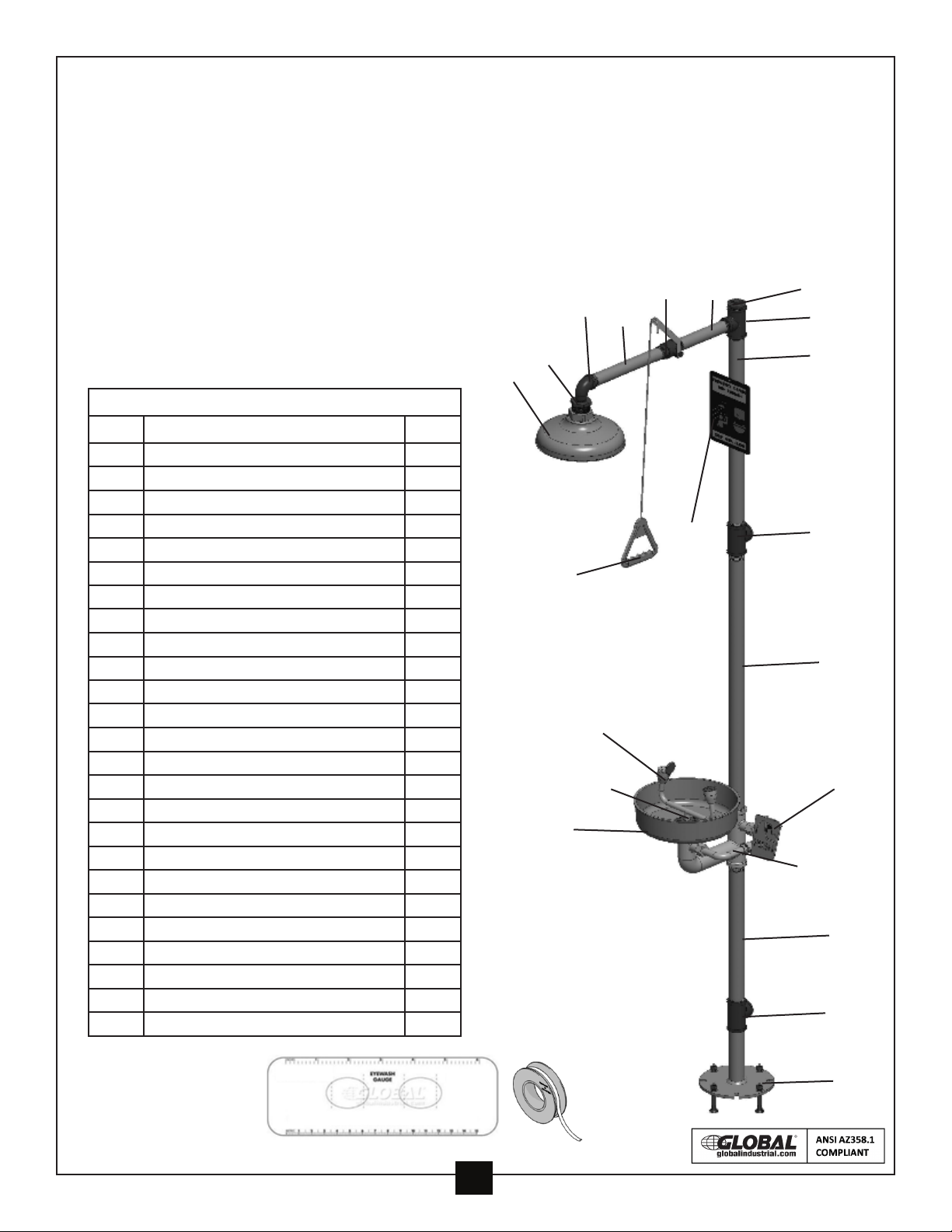

MODEL NO. 708383 PARTS LIST

WARNING:Use Caution when tightening

connections with a pipe wrench to avoid

damaging/scratching protective coating.

PARTS LIST

Item Description QTY

A Base WITH 1-1/4” tube 1

B 1-1/4” NPT Tee 2

C 1-1/4” IPS x 16-1/2” Pipe 1

D Valve Assembly 1

E 1-1/4” IPS x 30-1/2” Pipe 1

F 1-1/4” IPS x 22-7/8” Pipe 1

G 1-1/4” x 1” NPT Reducing Tee 1

H 1-1/4” NPT Plug 1

I 1” IPS x 11” Lg. Pipe 1

J 1” IPS Shut-off Valve 1

K 1” IPS x 8” Pipe 1

L 90 Deg. Elbow Reducer 1

M NPT Pipe Reducer Bushing 1

N Shower Head 1

O Pull Handle 1

P Eye Wash Container Bowl 1

Q Drain Filter 1

R Spray Head Assembly 1

S Push Handle 1

T Universal Sign 1

H1 5/16-18 Hex Nut (Not shown) 4

H2 Lock Washer (Not shown) 4

H3 Plain Washer (Not shown) 4

H4 Sleeve (Not shown) 4

H5 Concrete anchor (not shown) 4

N

M

O

J

I

KL

H

G

F

T

B

E

R

Q

S

P

D

C

B

NOTE: The Eye

Wash Gauge and

Plumber’s Tape is

included

A

3

Page 4

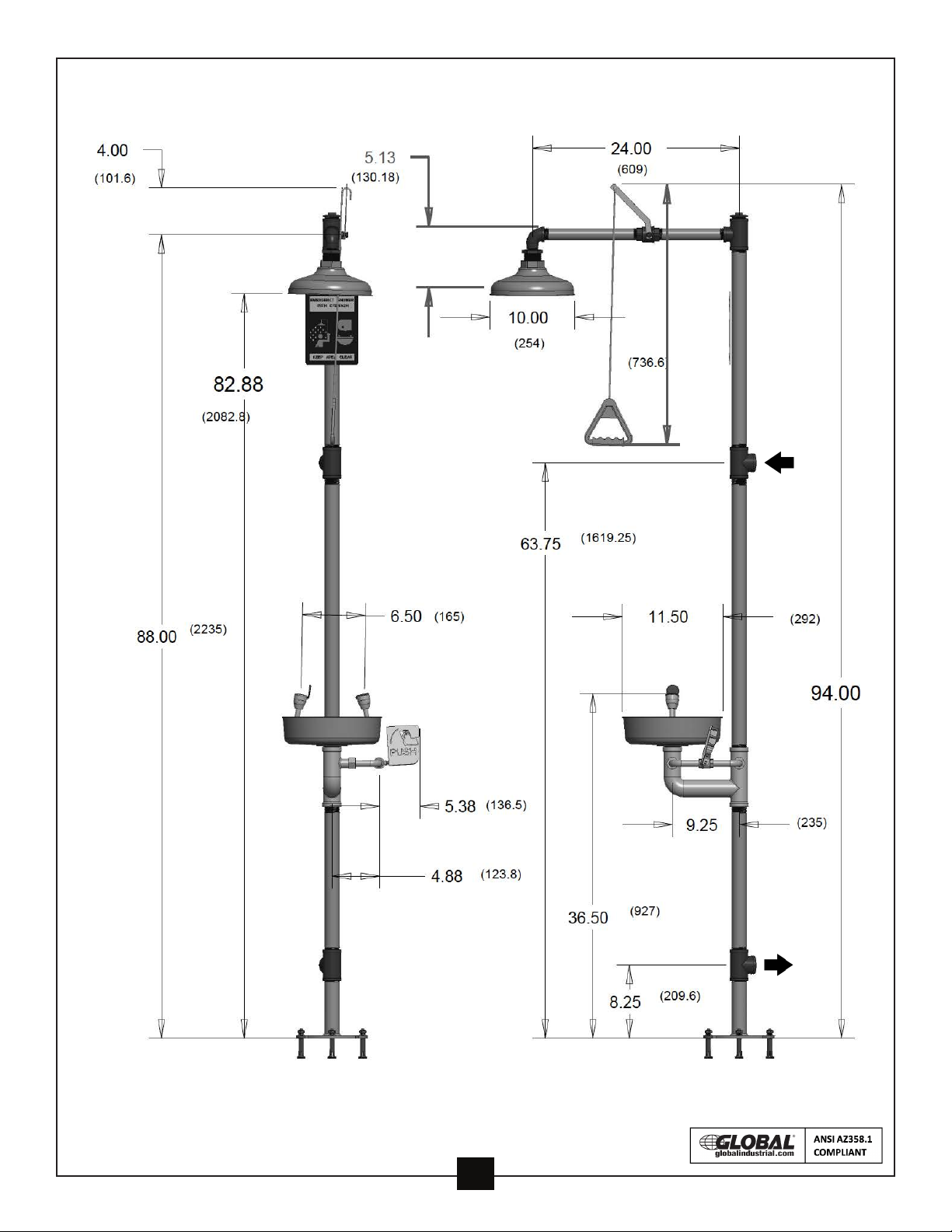

PRODUCT DIMENSIONS

Water

Supply

Drain

4

Page 5

ASSEMBLY INSTRUCTIONS

5

Page 6

678910

Page 7

Page 8

Page 9

Page 10

Page 11

CHECKLIST PER ANSI Z358.1

After assembly and installation of the unit, below summary of checkpoints should be used to

ensure compliance with ANSI 358.1.

Water supply delivers required ow when shower and eye or eye/face are

operated simultaneously. (Section 4.5.5, 7.4.4)

Hands-free stay-open valve activities in one second or less. (Section 4.2)

Height of water column is between 82” (209.3 cm) and 96” (243.8 cm) above the

oor. (Section 4.1.3, 4.5.4)

Shower delivers 20 gallons (75.7 liters) of water per minute for 15 minutes in the

required pattern. (Section 4.1.2, 4.5.5)

Easily located, accessible actuator is no more than 69” (173.3 cm) above oor.

(Section 4.2)

Center of the water pattern is at least 16” (40.6 cm) from any obstruction.

(Section 4.1.4, 4.5.4)

At 60” (152.4 cm) above the oor, the water pattern is at least 20” (50.8 cm) in

diameter. (Section 4.1.4)

Spray heads are protected from airborne contaminants. Cover are removed by

water ow. (Section 5.1.3, 6.1.3)

Unit delivers at least 3.0 GPM (11.4 liters) (for eye/face wash) or 0.4 GPM (1.5

liters) (for eyewash) for 15 minutes. (Section 5.1.6, 6.1.6, 6.4.5)

Hands-free stay-open valve activates in one second or less.

(Section 5.2, 6.1.4, 6.2)

Valve actuator is easy to locate and readily accessible to user.

(Section 5.2, 6.2)

Water ow pattern is positioned between 33” (83.8 cm) and 53” (132.6 cm)

from the oor and at least 6” (15.3 cm) from the wall or nearest obstruction.

(Section 5.4.4, 6.4.4)

Identication: Identify safety station location with highly visible sign. Area around safety station shall be well-lit. (Section 7.4.3)

Water Temperature: Water delivered by safety station shall be tepid (60-100F). (Section 7.4.5; B6)

Training: Instruct all employees in the location and proper use safety station. (Section 7.5.4)

Maintenance/Inspection: Activate safety station at least weekly. (Section 7.5.2) Inspect all safety stations annually for compliance

with standard. (Section 7.5.5)

Eyewash Gauge Instructions:

Place the gauge on top of the stream of the eyewash;

the ushing uid should cover the areas between the lines

3.18 cm (1-1/4 inches) apart and the lines 8.26 cm (3-1/4 inches)

apart when the gauge is not more than 20.2 cm (8 inches) above

the eyewash nozzles.

11

Page 12

Over 1,000,000 products. Industrial strength service.

We can supply that.

REGISTER ONLINE AT

http://www.globalindustrial.com/wr or http://www.globalindustrial.ca/wr

Global Limited 1 Year Warranty

1. LIMITED WARRANTY

Global Equipment Company Inc. (DBA Global Industrial) (“Global”) hereby

warrants to you, the original purchaser and end user (“you” or “your”), that

the products that you purchased which accompany this Limited Warranty

(“Products”) shall be free from defects in materials and workmanship under

normal use consistent with the accompanying documentation for 1 year

commencing upon the date of purchase (the “Warranty Period”).

Global will repair or replace any Product determined to be defective and which

has been returned, as set forth in section 3 herein, to Global. A Product may

be replaced with a new or used product and/or current or prior revision. Where

Global determines in its sole judgment that repair or replacement of such

Product is not reasonable, Global will keep the non-conforming Product and

refund to you the amount you paid for such Product. Returned Products shall

be subject to the balance of the Warranty Period otherwise applicable. Any

reconditioned parts used by Global shall be subject to all the same provisions

as otherwise applicable to new parts.

THE FOREGOING DESCRIBES THE SOLE LIABILITY OF GLOBAL, AND YOUR SOLE

REMEDY, FOR ANY BREACH OF WARRANTY. IF YOU DO NOT AGREE WITH THE

TERMS OF THIS LIMITED WARRANTY, YOU MUST RETURN THE PRODUCTS

UNUSED AND IN THEIR ORIGINAL PACKAGING WITHIN THREE (3) DAYS AND

YOUR PURCHASE PRICE WILL BE REFUNDED.

2. WARRANTY EXCLUSIONS AND LIMITATION OF LIABILITY

This Limited Warranty does not cover: (i) defects or damages resulting from

acts of God, casualty, accident, misuse or abuse, overloading, exceeding the

recommended weight capacity, neglect, alterations, modification, service or

repair by other than Global or its independent third party service providers,

including without limitation by you; (ii) improper assembly or installation or deinstallation, operation or maintenance, improper connections with peripherals

or other causes not arising out of defects in the materials or workmanship of

Products; (iii) any Product for which the warranty sticker has been removed,

modified or defaced; (iv) shipping containers, batteries, cabinets, media,

software or accessories; (v) normal wear and tear; (vi) damage to or loss of

repaired or replaced Products during shipping by Global except when such

damage or loss is caused by poor or inadequate packaging by Global; or (vii)

Products purchased outside the United States or Canada.

UNDER NO CIRCUMSTANCES WILL GLOBAL BE LIABLE FOR ANY LOSS OF

USE, INTERRUPTION OF BUSINESS OR ANY INDIRECT, SPECIAL, INCIDENTAL,

PUNITIVE OR CONSEQUENTIAL DAMAGES OF ANY KIND (INCLUDING LOST

PROFITS) REGARDLESS OF THE FORM OF ACTION WHETHER IN CONTRACT,

TORT (INCLUDING NEGLIGENCE), STRICT PRODUCT LIABILITY OR OTHERWISE,

EVEN IF GLOBAL HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

IN NO EVENT SHALL THE TOTAL LIABILITY OF GLOBAL HEREUNDER EXCEED

THE GREATER OF $50 OR THE AMOUNT YOU ACTUALLY PAID FOR THE PRODUCT

GIVING RISE TO SUCH LIABILITY, REGARDLESS OF THE CAUSE OF ACTION, IN

CONTRACT, TORT, STRICT LIABILITY OR OTHERWISE. NOT ALL JURISDICTIONS

ALLOW SUCH LIMITATIONS OF DAMAGES SO THE FOREGOING LIMITATIONS

MAY NOT APPLY TO YOU.

3. PROCEDURE FOR WARRANTY SERVICE

Prior to returning any Products to Global for warranty service, you must first

contact Global, by telephone at (800) 645-2986 (US) or (888) 645-0878

(Canada) to confirm that such Products are covered by this Limited Warranty. If

such Products are so covered, you shall obtain from Global a return materials

authorization (“RMA”) number and shipping instructions prior to any shipment

of such Products to Global, and you must include such RMA number with any

corresponding Product shipment, along with a true and correct copy of the

original receipt showing the date of Product purchase by you, and a detailed,

written description of any associated Product problems.

Please note that you are responsible for all shipping charges incurred in

returning an item for exchange or repair. Global shall pay for return shipping

of repaired and/or replaced Products to addresses within the United States and

Canada only, and return shipments to all other addresses outside of the United

States or Canada is your responsibility. If Global determines that any Product is

not covered by this Limited Warranty, you must pay all parts, labor charges and

return shipping for such Product.

4. WARRANTY DISCLAIMER AND LIMITATIONS

EXCEPT AND TO THE EXTENT EXPRESSLY SET FORTH ABOVE THERE ARE NO

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO, ANY

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

AND GLOBAL EXPRESSLY DISCLAIMS ALL WARRANTIES NOT STATED HEREIN.

EXCEPT AND TO THE EXTENT EXPRESSLY SET FORTH ABOVE, THE PRODUCTS

ARE PROVIDED ON AN “AS IS” BASIS, AND GLOBAL MAKES NO ADDITIONAL

WARRANTIES, EXPRESS, IMPLIED, ARISING FROM COURSE OF DEALING OR

USAGE OF TRADE, OR STATUTORY, AS TO THE PRODUCTS OR ANY MATTER

WHATSOEVER. THIS IS A LIMITED WARRANTY AND IS THE ONLY WARRANTY

MADE BY GLOBAL. THE AGENTS, EMPLOYEES, DISTRIBUTORS, AND DEALERS

OF GLOBAL ARE NOT AUTHORIZED TO MAKE MODIFICATIONS TO THIS LIMITED

WARRANTY, OR MAKE ADDITIONAL WARRANTIES BINDING ON GLOBAL.

ACCORDINGLY, ADDITIONAL STATEMENTS SUCH AS DEALER ADVERTISING

OR PRESENTATION, WHETHER ORAL OR WRITTEN, DO NOT CONSTITUTE

WARRANTIES BY GLOBAL AND SHOULD NOT BE RELIED UPON. GLOBAL DOES

NOT WARRANT THAT THE PRODUCTS WILL OPERATE WITHOUT FAILURE, OR

THAT THE PRODUCTS WILL MEET YOUR NEEDS OR EXPECTATIONS. NOT ALL

JURISDICTIONS ALLOW SUCH WARRANTY LIMITATIONS SO THE FOREGOING

LIMITATIONS MAY NOT APPLY TO YOU.

5. CHOICE OF LAW AND JURISDICTION

FOR PURCHASES WITHIN THE US - This Limited Warranty shall be subject solely

to the laws of the State of New York as applied to contracts entered into in the

State of New York between New York residents. Any dispute arising hereunder

shall be subject to the sole jurisdiction of the State and Federal Courts located

in Nassau County, New York. The parties hereby consent to the personal

jurisdiction of such courts.

FOR PURCHASES WITHIN CANADA - This Limited Warranty shall be subject

solely to the laws of the Province of Ontario. Any dispute arising hereunder

shall be subject to the sole jurisdiction of Ontario, Canada. The parties hereby

consent to the personal jurisdiction of such courts.

Page 13

REGISTRARSE EN LÍNEA EN

http://www.globalindustrial.com/wr or http://www.globalindustrial.ca/wr

Garantía global limitada de 1 año

1. GARANTÍA LIMITADA

Global Equipment Company Inc. (DBA Global Industrial) (“Global”) por la presente garantiza al comprador original y

usuario final (“usted” o “su”), que los productos adquiridos por usted que incluyen esta Garantía limitada (“Productos “) se

considerarán libres de defectos respecto de sus materiales y mano de obra en condiciones normales de uso de conformidad

con la documentación adjunta durante 1 año a partir de la fecha de compra (el” Plazo de duración de la garantía “).

Global reparará o reemplazará todo producto calificado como defectuoso y que hubiere sido devuelto a Global,

según lo establecido en la sección 3 de la presente garantía. Un Producto puede ser reemplazado por un

producto nuevo o usado y/o quedar sujeto a una revisión actual o previa. En los casos que Global establezca,

a su exclusivo criterio, la inviabilidad de la reparación o el reemplazo de dicho Producto, Global conservará

el Producto no conforme y le reembolsará a usted el monto abonado por dicho Producto. De ser aplicable,

los Productos devueltos estarán sujetos al tiempo restante del “Plazo de Duración de la Garantía. Todas las

piezas reacondicionadas utilizadas por Global estarán también sujetas a dichas disposiciones mencionadas

anteriormente, aplicables de igual modo a las piezas nuevas, si correspondiere

LA CLÁUSULA MENCIONADA ANTERIORMENTE DESCRIBE LA RESPONSABILIDAD EXCLUSIVA DE GLOBAL,

Y SU ÚNICO RECURSO, POR CUALQUIER INCUMPLIMIENTO DE LA PRESENTE GARANTÍA. SI USTED NO ESTÁ

DE ACUERDO CON LOS TÉRMINOS Y CONDICIONES DE LA PRESENTE GARANTÍA LIMITADA, USTED DEBERÁ

DEVOLVER LOS PRODUCTOS SIN HABERLOS UTILIZADO Y EN SU EMBALAJE ORIGINAL EN EL PLAZO DE TRES

(3) DÍAS Y USTED RECIBIRÁ EL REEMBOLSO DEL DINERO DE SU COMPRA.

2. EXCLUSIONES DE LA PRESENTE GARANTÍA Y LIMITACIÓN DE RESPONSABILIDAD

La presente Garantía limitada no cubre los siguientes supuestos: (i) defectos o daños causados por fuerza mayor,

accidentes, uso inapropiado o excesivo, sobrecarga que supere la capacidad del peso recomendado, negligencia,

alteraciones, modificación, reparación o mantenimiento realizados por proveedores técnicos independientes

o ajenos a Global, entre los que se incluyen las siguientes acciones realizadas por usted ; (ii) ensamblaje o

instalación o desinstalación inadecuados, operación o mantenimiento, conexiones periféricas, funcionamiento o

mantenimiento incorrectos, o cualquier otra causa que no surja de un defecto en los materiales o en la mano de obra

del Producto; (iii) todo Producto que no contenga el sticker de garantía o cuando dicho sticker haya sido retirado,

modificado o esté dañado; (iv) contenedores de envío, baterías, gabinetes, medios, software o accesorios; (v)

desgaste normal por el paso del tiempo; (vi) daño o pérdida de los Productos reparados o reemplazados durante el

envío por parte de Global en los casos en que dicho daño o pérdida se hubieren producido por un mal o inadecuado

embalaje por parte de Global; o (vii) Productos adquiridos fuera de los Estados Unidos o Canadá.

EN NINGÚN CASO GLOBAL SERÁ RESPONSABLE POR LA PÉRDIDA DE USO, INTERRUPCIÓN DE NEGOCIOS O

CUALQUIER TIPO DE DAÑO INDIRECTO, ESPECIAL, INCIDENTAL, PUNITIVO O CONSECUENTE (INCLUIDA LA PÉRDIDA

DE GANANCIAS), INDEPENDIENTEMENTE DEL TIPO DE ACCIÓN LEGAL, YA SEA EMANADOS DE UN CONTRATO, DE UN

ACTO ILÍCITO (INCLUIDA LA CULPA), RESPONSABILIDAD OBJETIVA SOBRE EL PRODUCTO U OTROS. LO ANTERIOR SE

APLICARÁ AÚN EN LOS CASOS EN QUE GLOBAL HAYA SIDO ADVERTIDA SOBRE LA POSIBILIDAD DE DICHOS DAÑOS.

EN NINGÚN CASO, EN VIRTUD DE LA PRESENTE GARANTÍA, EL MONTO INDEMNIZATORIO POR RESPONSABILIDAD DE

GLOBAL PODRÁ EXCEDER LOS USD 50.00 O LA SUMA QUE USTED HAYA PAGADO POR EL PRODUCTO OBJETO DE DICHA

RESPONSABILIDAD, INDEPENDIENTEMENTE DE LA CAUSAL DE LA ACCIÓN LEGAL, POR EL CONTRATO, ACTO ILÍCITO,

RESPONSABILIDAD OBJETIVA U OTRAS. DADO QUE NO EN TODAS LAS JURISDICCIONES RIGEN DICHAS LIMITACIONES

EN LAS INDEMNIZACIONES, LAS LIMITACIONES ANTERIORES PUEDEN NO SER APLICABLES EN SU CASO.

3. PROCEDIMIENTO PARA EL SERVICIO DE GARANTÍA

Antes de devolver un Producto a Global para obtener el servicio de garantía, Usted debe contactar a Global, por teléfono al

(800) 645-2986 (Estados Unidos) ó 888) 645-0878 (Canadá) a los fines de confirmar que dicho Producto esté contemplado

en la presente Garantía Limitada. Si dicho Producto estuviera cubierto por la Garantía, usted recibirá un número de

autorización de devolución de materiales de Global (en adelante, “ADM”) y las instrucciones de envío previas al envío del

Producto mencionado a Global. Usted deberá incluir su número de ADM con el envío del Producto correspondiente, junto con

una copia fiel del recibo original que incluya la fecha de la compra del Producto realizada por usted.

Por favor tenga en cuenta que usted será responsable de todos los gastos de envío resultantes de la

devolución de un artículo para su reemplazo o reparación. Global deberá abonar el envío de devolución del

Producto reparado o reemplazado a direcciones dentro de Estados Unidos y Canadá solamente. Los gastos de

envío a todas las demás direcciones fuera de Estados Unidos y Canadá quedan bajo su responsabilidad. En el

caso de que Global estableciera que un Producto no se encuentra contemplado en la presente Garantía Limitada,

usted deberá pagar todos los repuestos, la mano de obra y los gastos de envío por la devolución de dicho Producto

4. EXCLUSIONES Y LIMITACIONES DE LA GARANTÍA

SALVO EN LA MEDIDA EXPRESAMENTE ESTABLECIDA ANTERIORMENTE, NO EXISTEN DENTRO DE LA PRESENTE GARANTÍAS

EXPRESAS O IMPLÍCITAS, INCLUIDAS, AUNQUE SIN LIMITACIÓN, GARANTÍAS IMPLÍCITAS DE COMERCIABILIDAD O IDONEIDAD

PARA UN PROPÓSITO DETERMINADO Y GLOBAL RECHAZA CUALQUIER TIPO DE GARANTÍA NO INCLUIDA EN LA PRESENTE.

SALVO EN LA MEDIDA EXPRESAMENTE ESTABLECIDA ANTERIORMENTE, LOS PRODUCTOS SON ENTREGADOS

EN EL “ESTADO EN QUE SE ENCUENTRAN”. GLOBAL NO OFRECE GARANTÍA ALGUNA, NI EXPRESA NI IMPLÍCITA,

QUE PUDIERA SURGIR DURANTE EL TRANSCURSO DE UNA NEGOCIACIÓN O EL USO O QUE SEAN ESTABLECIDAS

POR LEY, EN LO QUE RESPECTA A LOS PRODUCTOS O A CUALQUIER OTRO ASUNTO. LA PRESENTE CONSTITUYE

UNA GARANTÍA LIMITADA Y ES LA ÚNICA GARANTÍA OTORGADA POR GLOBAL. LOS MANDATARIOS, EMPLEADOS,

DISTRIBUIDORES Y COMERCIANTES DE GLOBAL NO PODRÁN REALIZAR MODIFICACIONES A LA PRESENTE GARANTÍA

LIMITADA NI PRESTAR GARANTÍAS ADICIONALES QUE OBLIGUEN LEGALMENTE A GLOBAL. EN CONSECUENCIA,

TODA DECLARACIÓN ADICIONAL, TALES COMO PUBLICIDADES O PRESENTACIONES DEL COMERCIANTE, YA SEAN

ORALES O ESCRITAS, NO CONSTITUIRÁN GARANTÍAS OTORGADAS POR GLOBAL Y NO DEBERÁN CONSIDERARSE

VÁLIDAS. GLOBAL NO GARANTIZA QUE LOS PRODUCTOS FUNCIONEN SIN FALLAS O QUE SATISFAGAN SUS

NECESIDADES O EXPECTATIVAS. DADO QUE NO EN TODAS LAS JURISDICCIONES RIGEN DICHAS LIMITACIONES EN

LAS INDEMNIZACIONES, LAS LIMITACIONES DE LA CLÁUSULA PUEDEN NO SER DE APLICACIÓN EN SU CASO.

5. ELECCIÓN DE LA LEGISLACIÓN Y JURISDICCIÓN

PARA COMPRAS REALIZADAS DENTRO DE LOS ESTADOS UNIDOS, la presente Garantía Limitada estará sujeta

únicamente a las leyes del Estado de Nueva York, según se aplica a los contratos celebrados en el Estado de Nueva

York entre residentes del Estado de Nueva York. Toda controversia que surja en virtud de la presente Garantía quedará

sujeta a la sola jurisdicción de los Tribunales Estatales y Federales ubicados en el Condado de Nassau, Nueva York.

Por medio de la presente Garantía, las partes acuerdan someterse a la jurisdicción personal de dichos tribunales.

PARA COMPRAS REALIZADAS EN CANADÁ - La presente Garantía Limitada quedará sujeta únicamente a las

leyes de la Provincia de Ontario. Toda controversia que surja en virtud de la presente Garantía quedará sujeta

a la sola jurisdicción de Ontario, Canadá. Por medio de la presente Garantía, las partes acuerdan someterse a la

jurisdicción personal de dichos tribunales.

INSCRIVEZ-VOUS EN LIGNE AU

http://www.globalindustrial.com/wr or http://www.globalindustrial.ca/wr

Garantie globale limitée de 1 an

1. GARANTIE LIMITÉE

Global Equipment Company Inc. (DBA Global Industrial) («Global») vous garantit, l’acheteur initial et à l’utilisateur

(«vous» ou «votre»), que les produits que vous avez achetés et qui accompagnent cette garantie limitée

(«produits») sont exempts de tout défaut de matériaux et fabrication dans des conditions normales d’utilisation

conformément à la documentation suivant pour une période d’un an débutant à la date d’achat (la «période de

garantie»).

Global réparera ou remplacera tout produit jugé défectueux et qui a été retourné, tel que stipulé à la section 3

ci-dessous, à Global. Un produit peut être remplacé par un produit neuf ou usagé et/ou par une révision actuelle

ou antérieure. Lorsque global détermine à son seul jugement que la réparation ou le remplacement de ce produit

n’est pas raisonnable, Global gardera le produit non conforme et vous remboursera le montant que vous avez

payé pour ce produit. Les produits retournés sont soumis au reste de la période de garantie applicable par

ailleurs. Toutes les pièces reconditionnées utilisées par Global sont soumises à toutes les mêmes dispositions

que celles qui s’appliquent autrement aux nouvelles pièces.

CE QUI PRÉCÈDE DÉCRIT LA RESPONSABILITÉ EXCLUSIVE DE GLOBAL, ET VOTRE SEUL RECOURS, POUR TOUT

MANQUEMENT À LA GARANTIE. SI VOUS N’ÊTES PAS D’ACCORD AVEC LES TERMES DE CETTE GARANTIE

LIMITÉE, VOUS DEVEZ RETOURNER LES PRODUITS INUTILISÉS ET DANS LEUR EMBALLAGE D’ORIGINE DANS

LES TROIS (3) JOURS ET VOTRE PRIX D’ACHAT SERA REMBOURSÉ.

2. EXCLUSIONS DE GARANTIE ET LIMITATION DE RESPONSABILITÉ

La présente garantie limitée ne couvre pas: (i) les défauts ou dommages résultant d’actes de Dieu, d’accident, de

mauvais usage ou d’abus, de surcharge, du dépassement de la capacité de poids recommandée, de négligence,

des altérations, modification, service ou réparation par autre que Global ou ses fournisseurs de services tiers

indépendants, y compris sans vos limites; (ii) d’un montage ou d’une installation ou d’une désinstallation, d’un

fonctionnement ou d’un entretien incorrects, des connexions incorrectes avec des périphériques ou d’autres

causes ne résultant pas de défauts dans les matériaux ou la fabrication de produits; (iii) tout produit pour lequel la

vignette de garantie a été enlevée, modifiée ou défigurée; (iv) des conteneurs, piles, armoires, supports, logiciels

ou accessoires d’expédition; (v) d’une usure normale; (VI) des dommages ou la perte de produits réparés ou

remplacés pendant l’expédition par Global, sauf si ces dommages ou pertes sont causés par des emballages

pauvres ou inadéquats par Global; ou (vii) des produits achetés en dehors des États-Unis ou du Canada.

GLOBAL NE POURRA EN AUCUN CAS ÊTRE TENU RESPONSABLE DE TOUTE PERTE D’UTILISATION,

D’INTERRUPTION D’ACTIVITÉ OU DE TOUT DOMMAGE INDIRECT, SPÉCIAL, ACCIDENTEL, PUNITIF OU CONSÉCUTIF

DE QUELQUE NATURE QUE CE SOIT (Y COMPRIS LES PERTES DE PROFITS), QUELLE QUE SOIT LA FORME

D’ACTION CONTRACTUELLE, DÉLICTUELLE ( Y COMPRIS LA NÉGLIGENCE), LA RESPONSABILITÉ STRICTE DU

PRODUIT OU AUTRE, MÊME SI GLOBAL A ÉTÉ AVISÉ DE LA POSSIBILITÉ DE TELS DOMMAGES. EN AUCUN CAS LA

RESPONSABILITÉ ENTIÈRE CI-DESSOUS DE GLOBAL NE DÉPASSERA CE QUI EST PLUS ÉLEVÉ ENTRE $50 OU LE

MONTANT QUE VOUS AVEZ EFFECTIVEMENT PAYÉ POUR LE PRODUIT DONNANT LIEU À CETTE RESPONSABILITÉ,

INDÉPENDAMMENT DE LA CAUSE D’ACTION, DANS LE CONTRAT, LE DÉLIT, LA RESPONSABILITÉ STRICTE OU

AUTREMENT. TOUTES LES JURIDICTIONS N’AUTORISENT PAS CES LIMITATIONS DE DOMMAGES, DE SORTE QUE

LES LIMITATIONS QUI PRÉCÈDENT PEUVENT NE PAS S’APPLIQUER À VOUS.

3. PROCÉDURE DE SERVICE SOUS GARANTIE

Avant de retourner tous les produits à Global pour le service de garantie, vous devez d’abord contacter Global, par

téléphone au (800) 645-2986 (US) ou (888) 645-0878 (Canada) pour confirmer que ces produits sont couverts

par cette garantie limitée. Si ces produits sont ainsi couverts, vous obtiendrez de Global un numéro d’autorisation

de retour de matériel («ARM») et des instructions d’expédition avant toute expédition de ces produits à global et

vous devez inclure ce numéro ARM avec n’importe quelle expédition correspondante de produit, ainsi qu’une

copie exacte et correcte du reçu original indiquant la date d’achat de l’achat de votre produit, ainsi qu’une

description détaillée et écrite de tout problème de produit associé.

Veuillez noter que vous êtes responsable de tous les frais d’expédition engagés pour retourner un article pour un

échange ou une réparation. Global doit payer pour l’expédition de retour des produits réparés et/ou remplacés

aux adresses aux États-Unis et au Canada seulement ainsi que pour les expéditions de retour à toutes les autres

adresses à l’extérieur des États-Unis ou du Canada en revient de votre responsabilité. Si Global détermine que

n’importe quel produit n’est pas couvert par cette garantie limitée, vous devez payer toutes les pièces, frais de

main-d’œuvre et expédition de retour pour ce produit.

4. DÉNI DE GARANTIE ET LIMITATIONS

SAUF ET DANS LA MESURE EXPRESSÉMENT ÉNONCÉE CI-DESSUS IL N’Y A AUCUNE GARANTIE, EXPRESSE OU

IMPLICITE, Y COMPRIS MAIS SANS S’Y LIMITER À TOUTE GARANTIE DE QUALITÉ MARCHANDE OU D’ADAPTATION

À UN USAGE PARTICULIER ET GLOBAL DÉCLINE EXPRESSÉMENT TOUTES LES GARANTIES NON MENTIONNÉES

DANS LE PRÉSENT DOCUMENT.

SAUF ET DANS LA MESURE EXPRESSÉMENT ÉNONCÉE CI-DESSUS, LES PRODUITS SONT FOURNIS SUR UNE BASE

«TEL QUEL» ET GLOBAL NE FAIT AUCUNE GARANTIE ADDITIONNELLE, EXPRESSE, IMPLICITE, DÉCOULANT DE

COURS DE TRAITEMENT OU D’UTILISATION DU COMMERCE OU STATUTAIRE, QUANT AUX PRODUITS OU QUELQUE

MATIÈRE QUE CE SOIT. IL S’AGIT D’UNE GARANTIE LIMITÉE ET EST LA SEULE GARANTIE FAITE PAR GLOBAL. LES

AGENTS, LES EMPLOYÉS, LES DISTRIBUTEURS ET LES CONCESSIONNAIRES DE GLOBAL NE SONT PAS AUTORISÉS

À APPORTER DES MODIFICATIONS À CETTE GARANTIE LIMITÉE, OU À FAIRE DES GARANTIES SUPPLÉMENTAIRES

CONTRAIGNANTES POUR GLOBAL. PAR CONSÉQUENT, DES DÉCLARATIONS SUPPLÉMENTAIRES TELLES QUE

LA PUBLICITÉ OU LA PRÉSENTATION DES CONCESSIONNAIRES, QU’ELLES SOIENT ORALES OU ÉCRITES, NE

CONSTITUENT PAS DES GARANTIES GLOBALES ET NE DEVRAIENT PAS ÊTRE INVOQUÉES. GLOBAL NE GARANTIT

PAS QUE LES PRODUITS FONCTIONNERONT SANS DÉFAILLANCE, OU QUE LES PRODUITS RÉPONDRONT À VOS

BESOINS OU À VOS ATTENTES. PAS TOUTES LES JURIDICTIONS NE PERMETTENT DE TELLES LIMITATIONS DE

GARANTIE AINSI LES LIMITATIONS CI-DESSUS PEUVENT NE PAS S’APPLIQUER À VOUS.

5. CHOIX DE LA LOI ET DE LA JURIDICTION

POUR LES ACHATS AUX ÉTATS-UNIS : cette garantie limitée est soumise aux seules lois de l’état de New York, telles

qu’appliquées aux contrats conclus dans l’état de New York entre les résidents de New York. Tout litige découlant

des présentes est soumis à la seule compétence de l’État et des tribunaux fédéraux situés dans le comté de

Nassau, New York. Les parties consentent par la présente à la compétence personnelle de ces tribunaux.

POUR LES ACHATS AU CANADA : cette garantie limitée est assujettie uniquement aux lois de la province de

l’Ontario. Tout différend découlant des présentes est assujetti à la seule compétence de la province de l’Ontario,

au Canada. Les parties consentent par la présente à la compétence personnelle de ces tribunaux.

Loading...

Loading...