Global Industrial 708382 User Manual

Emergency Eyewash, Pedestal Mounted Model no. 708382

The Global Industrial Eye Wash Station is essential for industrial spaces where accidents can

occur with chemicals or hazardous substances. These units provide immediate, reliable and

effective treatment as needed. High quality and durable components ensure these stations

comply and meet ANSI Standard Z358.1.

PRODUCT INFO

Pipe & Fittings

safety yellow polyethylene covers for corrosion resistance

and easy visibility.

Spray Head – Includes “flip top” covers to protect from

dust particles.

Eye Wash Bowl – 11.5” ABS Plastic.

Supply & Waste – Inlet and Outlet Tee allow inflow for

water supply and separate outflow for waste disposal.

Quality Assurance – Valves and Spray heads are tested

at factory to assure efficiency.

Please read this manual completely and save these

instructions for reference. Upon receiving, inspect the

unit for any damage. If damage is evident, notify the

carrier immediately to file a claim. These products must

be handled with caution.

- Schedule 40 galvanized steel includes

Table of Contents Page

General Information 2

Parts List 3

Product Dimensions 4

Assembly instructions 5

Warranty Info 8

1

GENERAL INFORMATION & GUIDELINES

Emergency eye wash stations are designed to deliver water to rinse chemical substances from a

person’s eyes, face or body.

WARNING: Eye wash stations are NOT to be used as substitutes for primary protective

equipment (such as gloves, masks, eye protection, and protective clothing) when handling

dangerous substances. Simply installing these stations is not sufcient to assure worker

safety. Staff must be trained in the use, maintenance, and knowledge of the eye wash

station. A response plan and action should be in place in the event that an accident does

occur and employees have guidelines to follow for injured personnel.

Below are guidelines that should be followed in accordance with the eye wash station when

applicable. Note OSHA regulations, accessibility & surroundings, and water connections

before assembling and installing the eye wash combo station. There are certain

circumstances where these guidelines may not be adequate.

LOCATION OF EMERGENCY EQUIPMENT

• Per ANSI Specications, emergency equipment must be installed on the same level as the

possible incident (e.g. stairs/ramps must not be required to use the unit).

• It is advised that emergency equipment be installed within 10 seconds (approx. 55 feet) of

walking time/distance from the location of the possible incident.

WATER TEMPERATURE

• Water temperature should be between 60°F(15.5°C) – 100°F(37.8°C). This can vary depending on the chemical substance and should be consulted with a safety counselor.

SHUT OFF VALVES

• These stationary eye wash units are designed to be connected to a clean and viable water

supply line.

• A shut off valve on the water line is advised to easily maintain/repair the station.

• If a shut off valve is installed, make sure necessary procedures are established to prevent

misuse of the valve. Only authorized personal should be installing/maintaining the shut off

valve.

CORROSION & RUST RESISTANCE

• All parts of the system must be constructed of materials that will not corrode.

FREEZING CONDITIONS

• Emergency equipment that must be installed in potential freezing conditions should

be installed with the proper equipment to protect against freezing per ANSI Z358.1

Section 4.5.5, 5.4.5.

• Freeze resistant equipment includes but is not limited to:

1. Temperature actuated bleed valve that permits water to ow through the unit when the

temperature drops below freezing.

2. Remote-activated valves or electrically heated units/heated

enclosures.

2

DISPOSAL OF WATER

• Waste water must be treated with care to avoid creating any hazards. It is highly

recommended that emergency shower stations should be connected to drain piping or

ood drains. Depending on the chemical substances, drainage into an acid waste

disposal system may be recommended.

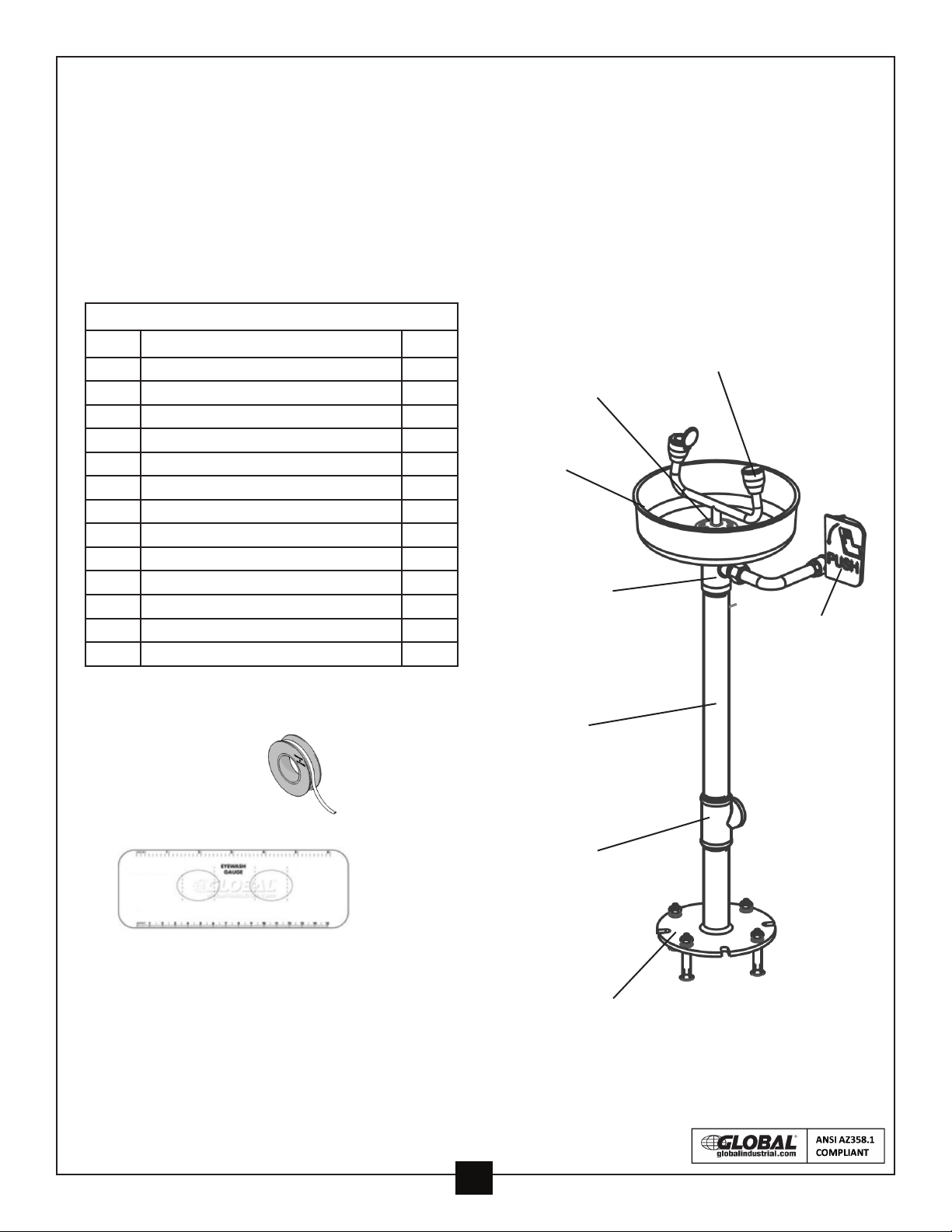

MODEL NO. 708381 PARTS LIST

WARNING:Use Caution when tightening connections with a pipe wrench to avoid

damaging/scratching protective coating.

PARTS LIST

Item Description QTY

A Base with 1-1/4” Tube 1

B 1-1/4” NPT Outlet Tee 1

C 1-1/4” IPS x 16-1/2" Pipe 1

D Valve Assembly 1

E Eye Wash Container Bowl 1

F Drain Filter 1

G Spray Head Assembly 1

H Push Handle 1

H1 5/16-18 Hex Nut (Not shown) 4

H2 Lock Washer (Not shown) 4

H3 Plain Washer (Not shown) 4

H4 Sleeve (Not shown) 4

H5 Threaded Post (not shown) 4

NOTE: The Eye

Wash Gauge and

Plumber’s Tape is

included

G

F

E

D

H

C

B

A

3

Loading...

Loading...