Page 1

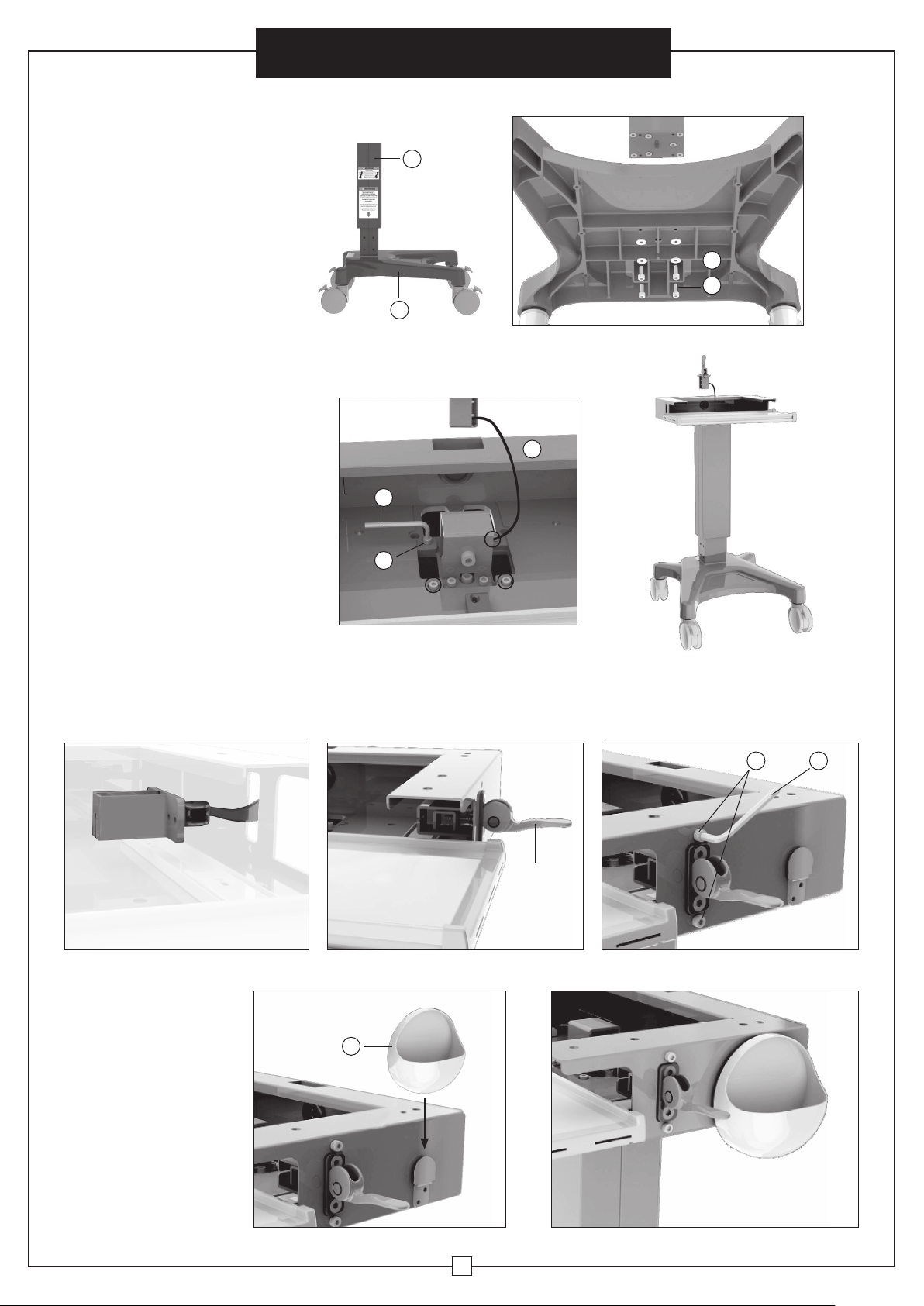

Chariot informatique mobile

à station assise ou debout

CARACTÉRISTIQUES

ET COMPOSANTS

Support d’écran VESA

avec ajustement par pivot

et inclinaison

Surface de travail avec poignées

Directives d’assemblage

Colonne

ACL avec

rangement

de câble

Plateau de clavier

dissimulé

Support

d’unité

centrale

Base

métallique

Support

de souris

Levier d’ajustement

vertical (Soulever le

levier pour ajuster)

Poteau de

soulèvement

Roulettes bloquantes

à pédale

24

Page 2

Distribucion Industrial Globales S DE RL DE CF

Assembly Instructions Instrucciones de Ensamblaje Directives d’assemblage

Customer Service

US: 1-800-645-2986

Mobile Sit and Stand Workstation

WARNING

IMPACT HAZARD!

Moving parts can crush and cut. Raise work surface before

removing the monitor. Failure to heed this warning may result

in serious personal injury or property damage!

Servicio de atención al Cliente

México: 01.800.681.6940

Model 695436

Service à la clientèle

Canada: 888-645-2986

WARNING

TIPPING HAZARD!

For carts without an internal

power system, a CPU should

be mounted to the cart before

displays are mounted. DO NOT

remove CPU while displays are

mounted because personal injury

or equipment damage may occur.

WARNING

TO MOVE CART:

1. Lower the display to the

lowest position.

2. Disconnect any power cords.

3. Stow cords to keep out of the way.

4. Unlock casters and pivot to the

direction of travel.

5. Push the cart from the sides

using the hand holds.

WARNING

This component is under high tension, and can cause injury

or damage if release bolt Is removed before assembly. This

release bolt should only be removed after assembly is

complete. Please refer to manual.

EXCLUSIVE DISTRIBUTORS

globalindustrial.ca

1

012016

Page 3

Mobile Sit and Stand Workstation

Assembly Instructions

WARNING

This warning alerts you to the possibilities of serious injury

or death if you do not follow the following instructions. It is

the installer's responsibility to make sure all components

are properly assembled and installed using the instructions

provided. Severe personal injury and property damage can

result from improper installation or assembly.

WARNING

It is the installer's responsibility to make sure the combined

weight of all components does not exceed weight capacity

of 50Kg (110 lbs). Exceeding weight capacities can result in

severe personal injury or damage to equipment.

WARNING

WARNING

Attachment holes may be damaged if a powered screwdriver

is used to insert button head cap screws. Screws should first

be inserted and turned by hand with hexagon key or with

screwdriver before using a powered screwdriver to complete

the attachment.

Read the following warning before installing:

• Verify all parts are included. Do not install if the products or hardware are damaged.

• This product contains moving parts. Assemble with caution.

• This product contains small items. Keep these items away from children.

• Do not exceed the maximum weight capacity for this product. Exceeding the weight capacity

can result in serious personal injury or damage to equipment. Maximum weight capacity is

9kg (19.8 lbs.) for the monitor bracket, and 50kg (110 lbs.) for the work surface platform.

CONTENTS

1 2 3

Do not load mobile workstation above maximum weight

capacities.

Do not mount a display above recommended monitor sizes.

Do not allow children to climb on top of mobile

workstation.

Do not move mobile computer cart on sloping surface.

LCD Column

Qty. (1)

4

Keyboard Tray Slot Qty. (1)

7

VESA Bracket Qty. (1)

10 12 13

Round Head Hex Screw

M6 x 15mm Qty. (12)

14 16 17

Flat Head Hex Screw

M6 x 15mm Qty. (3)

11

Washer Qty. (4)

15

Phillips Screw M4 x 12mm Qty. (4)

Lift Pole

Qty. (1)

5

Work Surface Qty. (1)

8 9

Fixed Plate Qty. (1)

Round Head Hex Screw

M5 x 10mm Qty. (2) Phillips Screw M6 x 12mm Qty. (4)

Phillips Screw M4 x 25mm Qty. (4) Oval Spacers Qty. (4)

Base Qty. (1)

6

Mouse Holder Qty. (1)

CPU Holder and Screws Qty. (1)

22

18

19

Hex Allen Wrench 4mm Qty. (1) Hex Allen Wrench 5mm Qty. (1)Hex Allen Wrench 3mm Qty. (1)

20 21

Hex Allen Wrench 6mm Qty. (1)

2

Magnetic Screwdriver

Page 4

Directives d’assemblage

Chariot informatique mobile

à station assise ou debout

Spécifications

• Modèle: 695436

• Plage d’ajustement de la hauteur de l’ACL et de la surface de travail: 400 mm (16 po)

• Hauteur de la surface de travail: 892 à 1292 mm (35 à 51 po)

• Dimensions de la surface de travail: 560 (long) x 430 mm (lar) (22 x 17 po)

• Dimensions du plateau du clavier: 450 (long) x 200 mm (lar) (18 x 8 po)

• Le support ACL peut s’ajuster par inclinaison: ±90°, pivotement: ±15°

• Capacité de poids : jusqu’à: 9 kg (19,8 lb.); Appliqué à un écran ACL de ≤24 pouces

• Roulettes bloquantes à pédale: 101 mm (4 po) de diamètre

23

Page 5

Chariot informatique mobile

à station assise ou debout

Directives d’assemblage

Ajustement de

la résistance

13.

L’écran peut pivoter

horizontalement d’un côté à

l’autre, jusqu’à 15 degrés, comme

il est montré. Pour ajuster,

desserrez la vis bouton située

sur le joint du support VESA en

utilisant la clé hexagonale 4 mm

(19) fournie, puis resserrez à la

position désirée.

14. On peut également ajuster

l’inclinaison verticale de l’écran.

Pour ajuster, desserrez la vis

bouton située sur le joint du

support VESA en utilisant la clé

hexagonale 4 mm (21) fournie,

puis resserrez en position.

+15°

19

Réglage

du pivot de

l’écran

-15°

Réglage de

l’inclinaison

verticale de

l’écran

21

22

Page 6

Installation

Assembly Instructions

Mobile Sit and Stand Workstation

Attaching the Lift Pole

Note: This step may require

assistance. 1. Do not remove the gas

spring tension screw below the label

before completing the assembly. Put

lift pole (2) on the base (3). Note:

Back label must face back of base.

Install four round head hex screws

M6 x15mm (10) each with a washer

(11) through mounting holes in the

base and into lift pole with a 6mm

allen wrench (21) so the lift pole is

firmly attached.

Attaching Keyboard

Tray Slot

2. Put keyboard tray slot (4) on the

lift pole. Install four round head

hex screws M6 x15mm (10) through

mounting holes on the keyboard tray

slot and finally into lift pole with a

6mm allen wrench (21) so that the

keyboard tray slot is firmly attached to

the lift pole. No washers are required

for this portion of the installation.

2

Labels

should

face the

same side

3

21

10

11

10

Bottom of Base

4

Lever Installation

3. CAUTION! Do not remove the gas spring tension retainer

before assembling the lever. Put the lever through the hole on

the side of keyboard tray slot (See Figure A). Turn the lever by

facing up (See Figure B). Once the lever is in position, tighten

A B

Mouse Holder

Installation

4. Insert mouse holder (6) on

the side of keyboard tray slot

from top to bottom.

6

two round head hex screws M5 x10mm (12) with a 4mm allen

wrench (19), so that the lever is firmly secured to the keyboard

tray slot (Figure C).

1912

Lever

C

3

Page 7

Mobile Sit and Stand Workstation

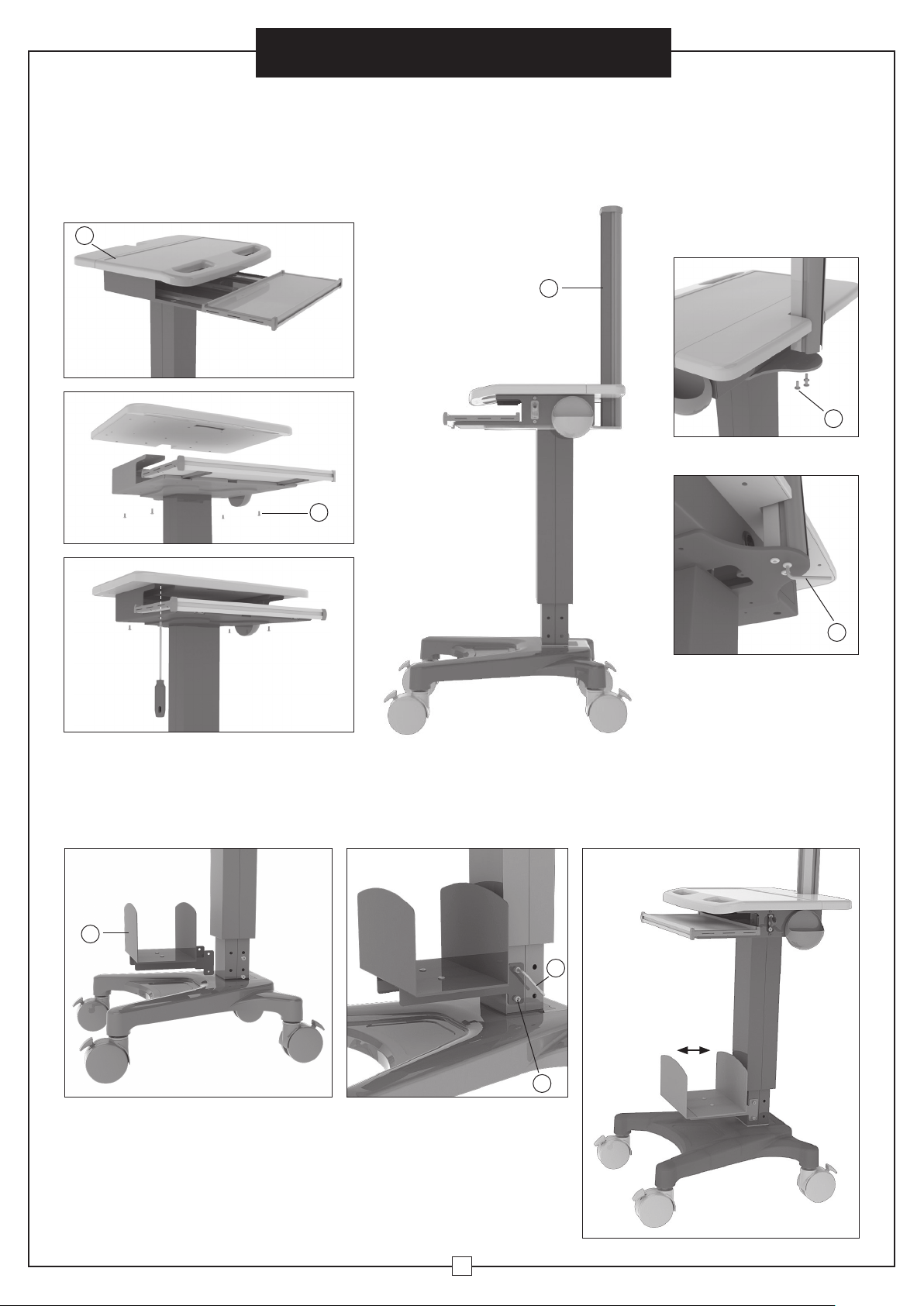

Attaching Work Surface Attaching LCD Column

5. Put the work surface (5) over the keyboard

tray slot. Install four phillips screws M6 x 12mm

(13) through mounting holes on the keyboard tray

slot and finally into work surface using long shaft

phillips magnetic screwdriver (22) until it is firmly

attached to keyboard tray slot.

5

Extend tray when

mounting work surface.

6. Put the LCD column (1) on the end of keyboard tray slot. Install three flat head hex

screws M6 x 15mm (14) through mounting holes on the keyboard tray slot and tighten

into LCD column with a 4mm allen wrench (19) until the LCD column is firmly attached

to keyboard tray slot.

1

Assembly Instructions

14

13

7. The CPU holder can be installed in front of or behind the fixed

column portion of the lift pole. To install, align the CPU holder

screw holes with the screw insert holes on the side of column,

9

19

then insert four round head hex screws M6 x 15mm (10) and

tighten using a 6mm allen wrench (21). The CPU holder width can

also be adjusted using the phillips screw driver.

21

10

4

Page 8

Chariot informatique mobile

à station assise ou debout

Directives d’assemblage

Installation de l’écran

8.

Choisissez la profondeur des vis Phillips M4 x 12 mm (15) ou M4

x 25 mm (16) relative aux trous de montage à l’arrière de l’écran.

Placez le support VESA (7) à l’arrière de l’écran. Alignez les trous

de montage avec les insertions de vis. Une fois le support VESA en

position, serrez avec soin les quatre vis jusqu’à ce que le support

VESA soit fermement fixé à l’écran. Cessez immédiatement si

- AVERTISSEMENT - une unité centrale devrait être montée au chariot avant l’installation des écrans.

vous rencontrez une résistance, ce qui pourrait endommager le

moniteur. Si vous rencontrez une résistance avant que le montage

soit fermement maintenu, vous pourriez devoir utiliser des vis moins

profondes ou des espaceurs. Veuillez consulter le manuel d’utilisation

de votre moniteur. Remarque: des espaceurs ovales (17) pourraient

être utilisés pour les types d’écrans courbés.

Fixer un support d’écran et d’unité centrale

10. Enlevez le couvercle de la colonne ACL (1), et insérez un écran

avec support VESA à partir du haut de la colonne ACL.

11. Une fois l’assemblage de l’écran en position, serrez les vis à

chacune des extrémités du support VESA avec une clé hexagonale 3

mm (18) en sens horaire, puis remettez le couvercle en place, au haut

de la colonne ACL.

9. Placez une plaque fixe (8)

7

16 15

17

sur le support VESA.

8

Cover

1

Retirez la vis de

réglage de la tension

du ressort à gaz.

Toutes les

étiquettes

doivent être du

même côté de

l’étiquette

de la base.

18

12. Après l’assemblage final, retirez les vis de réglage de la tension du

ressort à gaz, comme il est indiqué à la fig. (A) et (B) ci-dessous. Tirez le

levier vers le haut pour modifier la hauteur de la surface de travail.

Base mobile

Retirez la vis

de réglage de

la tension du

ressort à gaz.

B A

Sous la surface de travail

21

Page 9

Chariot informatique mobile

à station assise ou debout

Fixation à la surface de travail Fixer la colonne ACL

5. Placez la surface de travail (5) par-dessus la fente

du plateau du clavier. Installez quatre vis Phillips M6

x 12 mm (13) dans les trous de montage de la fente

du plateau du clavier et enfin, dans la surface de

travail en utilisant un Phillips tournevis magnétique

(22) jusqu’à ce que ce soit fermement fixé à la fente

du plateau du clavier.

5

Déployez le plateau lors du

montage de la surface de travail.

6. Placez la colonne ACL (1) sur l’extrémité de la fente du plateau du clavier. Installez

trois vis de montage M6 x 15 mm (14) dans les trous de montage de la fente du plateau

du clavier et serrez à travers la colonne ACL grâce à une clé hexagonale 4 mm (19),

jusqu’à ce que la colonne ACL soit fermement fixée à la fente du plateau du clavier.

1

Directives d’assemblage

14

13

7.

L’unité centrale peut être installée à l’avant ou à l’arrière de la

portion fixe de la colonne du poteau de soulèvement. Pour installer,

alignez les trous des vis du support de l’unité centrale au côté de la

9

19

colonne, puis insérez quatre vis bouton M6 x 15 mm (10) et serrez en

utilisant une clé hexagonale 6 mm (21). Le support de l’unité centrale

peut aussi être ajusté en utilisant un tournevis Phillips.

21

20

10

Page 10

Assembly Instructions

Mobile Sit and Stand Workstation

Display Installation - WARNING! A CPU should be mounted to the cart before displays are mounted.

9. Select the depth of the phillips screws M4 x 12mm (15)

or M4 x 25mm (16) relative to mounting holes in the back of

display. Place the VESA bracket (7) on the back of display.

Align the mounting holes with the screw inserts. Once the

VESA bracket is in position, carefully tighten the four screws

until the VESA bracket is firmly attached to display monitor.

Stop immediately if you encounter any resistance, or you

may damage your monitor. If you encounter resistance

before the mount is firmly attached, you may need to use

a shallower depth screw or spacers. Please consult your

monitor's operation manual. Note: oval spacers (17) may be

used for curved or other type of display monitors.

8. Put fixed plate (8) onto

7

16 15

17

VESA bracket.

8

Attaching Display

10. Take off the cover of LCD column (1), and insert display monitor

with VESA bracket from top down into the LCD column.

Cover

1

Remove gas spring

tension retaining

screw

All labels must

be on the same

side as the label

at the base.

12. After final assembly, remove the gas spring tension

retaining screws as shown in Fig. (A) and (B) below. Pull the

lever up to change the work surface to desired height.

11. Once the display assembly is in position, tighten screws at both

ends of VESA bracket with 3mm allen wrench (18) clockwise and put

the cover back on the top of LCD column.

18

Mobile Base

Remove gas

spring tension

retaining

screw

B A

Under Work Surface

5

Page 11

Mobile Sit and Stand Workstation

Assembly Instructions

Adjusting

Resistance

13. The monitor display can

horizontally swivel from side

to side up to 15 degrees as

shown. To adjust, loosen the

tension hex socket cap screw

located on the VESA bracket

Joint using the supplied 4mm

allen wrench (19) and then

tighten to desired position.

14. The monitor display can also

adjust for vertical tilt. To adjust,

loosen the tension hex socket

cap screw located on the VESA

bracket joint using the supplied

6mm allen wrench (21), and then

tighten to position.

+15°

19

Monitor

Swivel

Adjustment

-15°

Monitor

Vertical

Tilt

Adjustment

21

6

Page 12

Installation

Directives d’assemblage

Chariot informatique mobile

à station assise ou debout

Fixation du poteau

de soulèvement

Remarque: Cette étape pourrait exiger

de l’aide. 1. Ne retirez pas la vis de

réglage de la tension du ressort à gaz sous

l’étiquette avant la fin de l’assemblage.

Placez le poteau de soulèvement (2) sur la

base (3). Remarque: l'étiquette de Retour

doit faire face arrière de la base . Installez

quatre vis bouton M6 x 15 mm (10) avec

une rondelle (11) en plaçant les trous dans

la base et dans le poteau de soulèvement

à l’aide d’une clé hexagonale de 6 mm (21)

afin que le poteau de soulèvement soit

fermement fixé.

Fixer la fente du

plateau du clavier

2. Placez la fente du plateau du clavier

(4) sur le poteau de soulèvement.

Installez quatre vis bouton M6 x 15

mm (10) dans les trous de montage

de la fente du plateau du clavier et

ensuite au poteau de soulèvement à

l’aide d’une clé hexagonale (21) afin

que la fente du plateau du clavier

soit fermement fixée au poteau

de soulèvement. Aucune rondelle

n’est requise pour cette portion de

l’installation.

2

Les étiquettes

devraient être

orientées du

même côté

3

21

10

11

10

Bas de la base

4

Lever Installation

3. ATTENTION! Ne retirez pas la bague d’arrêt de la tension

du ressort à gaz avant l’assemblage du levier. Placez le levier

dans le trou latéral de la fente du plateau du clavier (voir la

figure A). Tournez le levier en le redressant (voir la figure B).

A B

Installation du

support de souris

4. Insérez le support de souris

(6) sur le côté de la fente du

plateau du clavier, du haut

vers le bas.

6

Une fois le levier en position, serrez deux vis bouton M5 x

10 mm (12) avec une clé hexagonale 4 mm (19), afin que le

levier soit maintenu fermement à la fente du plateau du clavier

(figure C).

1912

Lever

C

19

Page 13

Chariot informatique mobile

à station assise ou debout

Directives d’assemblage

AVERTISSEMENT

Ces avertissements vous préviennent de la possibilité de blessures

graves ou de mort si vous ne respectez pas les directives suivantes

Il est de la responsabilité de l’installateur de s’assurer que tous

les composants sont correctement assemblés et installés selon

les directives fournies. Des blessures graves et dommages à la

propriété peuvent survenir d’une installation incorrecte ou d’un

mauvais assemblage.

:

AVERTISSEMENT

Les trous de fixation peuvent être endommagés si un tournevis

électrique est utilisé pour insérer les vis bouton. Les vis devraient

d’abord être insérées et tournées à la main avec une clé hexagonale

ou un tournevis avant d’utiliser un tournevis électrique afin de

compléter la fixation.

Il est de la responsabilité de l’installateur de s’assurer que le poids

combiné de tous les composants n’excède pas la capacité totale de

50 kg (110 lb). Le dépassement de la capacité de poids peut causer de

graves blessures ou endommager l’équipement.

Ne pas dépasser la capacité de poids du chariot informatique mobile.

Ne pas monter d’écran dépassant les tailles maximales recommandées.

Ne pas laisser les enfants monter sur le chariot informatique mobile.

Ne pas déplacer le chariot informatique mobile sur une surface en pente.

AVERTISSEMENT

AVERTISSEMENT

Lire l’avertissement suivant avant d’installer:

• Vérifiez que toutes les pièces sont incluses. Ne pas installer si les produits ou le matériel sont endommagés.

• Ce produit comporte des pièces mobiles. Assemblez avec précaution.

• Ce produit contient de petits éléments. Gardez hors de la portée des enfants.

• Ne pas dépasser la capacité maximale de poids de ce produit. Excéder la capacité de poids pourrait causer

des blessures corporelles ou endommager l’équipement. La capacité maximale est de 9 kg (19,8 lb) pour le

support du moniteur, et de 50 kg (110 lb) pour la plateforme de la surface de travail.

CONTENU

1 2 3

Poteau de

Colonne ACL

Qté (1)

4

Fente du plateau du clavier Qté (1)

7

Support VESA Qté (1)

10 12 13

Vis bouton M6 x 15 mm

Qté (12)

14 16 17

11

Rondelle

15

soulèvement

Qté (1)

5

Surface de travail Qté (1)

8 9

Plaque fixe Qté (1)

Qté (4)

Vis bouton M6 x 15 mm

Qté (2) Vis Phillips M6 x 12 mm Qté (4)

Base Qté (1)

6

Support de souris Qté (1)

Vis et support de l’unité centrale Qté (1)

22

Vis d’assemblage

M6 x 15mm Qté (3)

18

Vis Phillips M4 x 12mm Qté (4)

19

Clé hexagonale de 4mm Qté (1) Clé hexagonale de 5mm Qté (1)Clé hexagonale de 3mm Qté (1)

Vis Phillips M4 x 25mm Qté (4) Espaceurs ovales Qté (4)

20 21

Clé hexagonale de 6mm Qté (1)

18

Tournevis magnétique

Page 14

Mobile Sit and Stand Workstation

Specifications

• Model: 695436

• Height adjustment range for LCD and work surface: 400mm (16")

• Work surface height: 892mm-1292mm (35"- 51")

• Work surface dimensions: 560mm (L) x 430mm ( W) (22" x 17")

• Keyboard tray dimensions: 450mm (L) x 200mm (W) (18" x 8")

• LCD hanger can tilt adjustment: ±90°,swivel: ±15°

• Weight capacity: up to: 9kg (19.8 lbs.); Applied for ≤24 inch LCD display

• Pedal locking casters: 101mm (4") diameter

Assembly Instructions

7

Page 15

Mobile Sit and Stand Workstation

FEATURES AND

COMPONENTS

VESA monitor mount with

swivel and tilt adjustment

Work surface with handles

Assembly Instructions

LCD column

with cable

management

Hideaway keyboard tray

CPU holder

Metal base

Mouse

holder

Vertical

adjustment lever

(lift lever to adjust)

Lift pole

Pedal locking casters

8

Page 16

Distribucion Industrial Globales S DE RL DE CF

Assembly Instructions Instrucciones de Ensamblaje Directives d’assemblage

Customer Service

US: 1-800-645-2986

Servicio de atención al Cliente

México: 01.800.681.6940

Service à la clientèle

Canada: 888-645-2986

Chariot informatique mobile à station assise ou debout

Modèle 695436

AVERTISSEMENT

DANGER D’IMPACT!

Les pièces mobiles peuvent écraser et couper. Soulevez la

surface de travail avant de retirer le moniteur. Ne pas tenir

compte de cet avertissement pourrait causer de sérieuses

blessures corporelles ou des dommages à la propriété!

AVERTISSEMENT

DANGER DE RENVERSEMENT!

Pour les chariots sans système

d’alimentation interne, une unité

centrale devrait être montée au

chariot avant l’installation des

écrans. NE PAS retirer l’unité

centrale pendant que les écrans

sont montés en raison de

possibles blessures corporelles

ou dommages à l’équipement.

AVERTISSEMENT

POUR DÉPLACER LE CHARIOT:

1. Abaissez l’écran à la position la plus basse.

2. Débranchez tous les cordons d’alimentation.

3. Mettre les cordons en sécurité, hors

du chemin.

4. Débloquez les roulettes et faites pivoter dans

la direction du déplacement.

5. Poussez le chariot par les côtés en utilisant

les poignées.

AVERTISSEMENT

Poussez le chariot par les côtés en utilisant les poignées. Si

le composant est sous haute tension pouvant causer des

blessures ou dommages si le boulon de dégagement est

retiré avant l’assemblage. Ce boulon de dégagement ne

devrait être retiré qu’une fois l’assemblage terminé. Veuillez

vous référer au manuel.

distributeurs exclusifs

globalindustrial.ca

17

Page 17

Estación de trabajo

móvil para computadora

CARACTERÍSTICAS

Y COMPONENTES

Montaje de monitor

VESA con giro y ajuste

de inclinación

Superficie de trabajo con asas

Instrucciones de Ensamblaje

Columna LCD

con gestión

de cables

Bandeja del teclado

que se oculta

Soporte

de la CPU

Base de metal

Soporte

de ratón

Palanca de ajuste

vertical (Levante la

palanca para ajustar)

Barra de la

elevación

Ruedas de bloqueo

del pedal

16

Page 18

Distribucion Industrial Globales S DE RL DE CF

Assembly Instructions Instrucciones de Ensamblaje Directives d’assemblage

Customer Service

US: 1-800-645-2986

Estación de trabajo móvil para computadora

ADVERTENCIA

¡IMPACTO DE PELIGRO!

Las partes móviles pueden aplastar y cortar. Levante

superficie de trabajo antes De retirar el monitor. ¡No prestar

atención a esta advertencia puede resultar en lesiones

personales graves o daños materiales!

ADVERTENCIA

¡PELIGRO DE VUELCO!

Para los carros sin un sistema

de alimentación interna, la CPU

debe montarse en el carro

antes de montar las pantallas.

NO retire la CPU mientras se

montan pantallas porque pueden

producirse lesiones personales o

daños en el equipo.

Servicio de atención al Cliente

México: 01.800.681.6940

Modelo 695436

Service à la clientèle

Canada: 888-645-2986

ADVERTENCIA

PARA MOVER EL CARRO:

1. Baje la pantalla hasta la posición

más baja.

2. Desconecte todos los cables de

alimentación.

3. Recoja los cables para mantenerlos

fuera del camino.

4. Quite el seguro de las ruedas y gire

en la dirección de desplazamiento.

5. Empuje el carro de los lados

utilizando las manijas.

ADVERTENCIA

Este componente está bajo alta tensión, y puede causar

lesiones o daños si el el perno de liberación se retira

antes del montaje. Este perno de liberación sólo debe

ser retirado después de completar el montaje. Por favor,

consulte el manual.

DISTRIBUIDORES EXCLUSIVOS

globalindustrial.ca

9

Page 19

Estación de trabajo

móvil para computadora

Instrucciones de Ensamblaje

ADVERTENCIA

Esta advertencia le alerta sobre la posibilidad de lesiones

graves o la muerte si no se siguen las instrucciones siguientes.

Es responsabilidad del instalador asegurarse de que todos los

componentes estén correctamente montados e instalados

usando las instrucciones proporcionadas. Lesiones y daños

graves a la propiedad personal pueden ser el resultado de la

instalación o montaje incorrecto.

ADVERTENCIA

Es responsabilidad del instalador asegurarse de que el peso

combinado de todos los componentes no exceda la capacidad

de peso de 50Kg (110 lbs). Exceder capacidades de peso

puede resultar en lesiones corporales graves o daños al equipo.

ADVERTENCIA

ADVERTENCIA

Los Orificios de fijación pueden dañarse si se usa

un destornillador eléctrico para insertar los tornillos. Los

tornillos deben ser insertados y apretados n a mano con

llave hexagonal o con un destornillador antes de utilizar un

destornillador eléctrico para finalizar la unión.

Lea la siguiente advertencia antes de instalar:

• Verifique que todas las partes estén incluidas. No instale si los productos o el equipo están dañados.

• Este producto contiene piezas móviles. Ensamble con precaución.

• Este producto contiene piezas pequeñas. Mantenga estos artículos lejos de los niños.

• No exceda la capacidad máxima de peso de este producto. Exceder la capacidad de peso puede resultar

en lesiones personales graves o daños al equipo. La capacidad máxima de peso es 9kg (19,8 lbs.) Para el

soporte del monitor, y 50 kg (110 lbs.) Para la plataforma de la superficie de trabajo.

No cargue el carrito móvil de computadora por encima

de las capacidades máximas de peso.

No monte una pantalla por encima de tamaños de

monitor recomendados.

No permita que los niños se suban en la parte superior

del carro móvil de computadora.

No mueva el carro móvil de computadora en una

superficie inclinada.

CONTENIDO

1 2 3

Barra de

Columna LCD

Cant. (1)

4

Bandeja del teclado Cant. (1)

7

Soporte VESA Cant. (1)

10 12 13

Tornillo Cabeza Redonda

hexagonal M6 x 15mm Cant. (1)

14 16 17

11

Arandela

15

elevación

Cant. (1)

5

Superficie de trabajo Cant. (1)

8 9

Placa fija Cant. (1)

Cant. (1)

Tornillo Cabeza Redonda hexagonal

M5 x 10mm Cant. (1)

Base Cant. (1)

6

Soporte del ratón Cant. (1)

Soporte de CPU y tornillos Cant. (1)

22

Tornillo Phillips M6 x 12mm

Cant. (1)

Tornillo Cabeza plana hexagonal

M6 x 15mm Cant. (1)

18

Llave Allen hexagonal de 3mm

Cant. (1)

Tornillo Phillips M4 x 12mm Cant. (1)

Tornillo Phillips M4 x 25mm Cant. (1)

19

Llave Allen hexagonal de 4mm

Cant. (1)

20 21

Llave Allen hexagonal de 5mm

Cant. (1)

10

Espaciadores Ovales Cant. (1)

Llave Allen hexagonal de 6mm

Cant. (1)

Destornillador magnético

Page 20

Instrucciones de Ensamblaje

Estación de trabajo

móvil para computadora

Especificaciones

• Modelo: 695436

• Rango de ajuste de altura para el LCD y la superficie de trabajo: 400mm (16")

• Altura de la superficie de trabajo: 892mm-1292mm (35 "- 51")

• Dimensiones de la superficie de trabajo: 560mm (L) x 430mm (A) (22" x 17")

• Dimensiones de la bandeja del teclado: 450mm (L) x 200mm (A) (18 " x 8")

• Soporte de LCD se puede inclinar con ajuste: ± 90 °, giro: ± 15 °

• Capacidad de peso: hasta: 9 kg (19.8 lbs.); Aplicado para ≤24 pulgadas monitor LCD

• Ruedas de bloqueo del pedal: 101 mm (4") de diámetro

15

Page 21

Estación de trabajo

móvil para computadora

Instrucciones de Ensamblaje

Ajuste de

Resistencia

13.

La pantalla del monitor

se puede girar sobre un eje

horizontal de lado a lado hasta

15 grados, como se muestra.

Para ajustar, afloje el tornillo de

cabeza hexagonal de tensión que

se encuentra en el soporte VESA

utilizando la llave Allen de 4 mm

suministrada (19) y apriete a la

posición deseada.

14. La pantalla del monitor

también puede ajustar la

inclinación vertical. Para ajustar,

afloje el tornillo de tensión de

cabeza hexagonal situado en la

articulación del soporte VESA con

la llave allen de 6 mm suministrada

(21) y apriete a la posición.

+15°

19

Ajuste

Giratorio del

Monitor

-15°

Ajuste

vertical de la

inclinación

del monitor

21

14

Page 22

Instalación

Instrucciones de Ensamblaje

Estación de trabajo

móvil para computadora

Fijación del soporte

de elevación

Nota: Este paso puede requerir

asistencia. 1. No quite el tornillo de

tensión del resorte debajo de la etiqueta

antes de completar el montaje. Ponga

soporte de la elevación (2) en la base (3).

Nota: contraetiqueta debe enfrentar parte

de atrás de la base. Instale cuatro tornillos

hexagonales de cabeza redonda M6 x

15mm (10) cada uno con una arandela

(11) a través de los agujeros de montaje

en la base y en la barra de elevación con

una llave allen de 6mm (21) de forma que

la barra de elevación esté bien conectada.

Colocación de la

bandeja del teclado

2. Coloque la bandeja del teclado (4)

en la barra de elevación. Instale cuatro

tornillos hexagonales de cabeza

redonda M6x15mm (10) a través de

los agujeros de montaje en la ranura

de la bandeja del teclado y, finalmente,

en la barra de elevación con una llave

allen de 6mm (21) de manera que la

bandeja del teclado está firmemente

conectada a la barra de elevación. No

se requieren arandelas para esta parte

de la instalación.

2

Las etiquetas

de base deben

enfrentar el

mismo lado

3

21

10

11

10

Parte inferior de la base

4

Instalación de palanca

3. ¡CUIDADO! No quite el resorte de tensión antes de montar

la palanca. Ponga la palanca a través del agujero en el lado

de la ranura de la bandeja del teclado (Ver Figura A). Gire la

palanca hacia arriba (Ver Figura B). Una vez que la palanca

A B

Instalación del

soporte de ratón

4. Inserte el soporte de ratón

(6) en el lado de la ranura de la

bandeja del teclado de arriba

a abajo.

6

esté en posición, apriete los dos tornillos hexagonales de

cabeza redonda M5 X 10mm (12) con una llave Allen de 4 mm

(19), de modo que la palanca esté firmemente asegurada a la

ranura de la bandeja del teclado (Figura C).

1912

Palanca

C

11

Page 23

Estación de trabajo

móvil para computadora

Instrucciones de Ensamblaje

Fijación Superficie de trabajo

5. Ponga la superficie de trabajo (5) sobre la ranura de la

bandeja del teclado. Instale cuatro tornillos Phillips M6 x

12mm (13) a través de los agujeros de montaje en la ranura

de la bandeja del teclado y, finalmente, en la superficie

de trabajo utilizando destornillador Phillips destornillador

magnético (22) hasta que esté firmemente conectado a la

ranura de la bandeja del teclado.

5

Extienda la bandeja al

montar la superficie

de trabajo.

13

Fijación de Columna LCD

6. Ponga la columna del LCD (1) en el extremo de ranura de la bandeja de

teclado. Instale tres tornillos hexagonales de cabeza plana M6 x 15mm (14)

a través de los agujeros de montaje en la ranura de la bandeja del teclado

y apriete en la columna LCD con una llave allen de 4mm (19) hasta que la

columna de la LCD se une firmemente a la ranura de la bandeja del teclado.

1

14

7. El soporte de la CPU puede ser instalado por delante o por detrás

de la de columna fija de la barra elevadora. Para instalarlo, alinee

los orificios de los tornillos del soporte de la PU con los orificios de

inserción de tornillos en el lado de la columna, a continuación, inserte

9

19

cuatro tornillos hexagonales de cabeza redonda M6 x 15mm (10) y

apriete con una llave allen de 6 mm (21). El ancho del soporte de la

CPU también puede ajustarse con el destornillador Phillips.

21

12

10

Page 24

Estación de trabajo

móvil para computadora

Instrucciones de Ensamblaje

Instalación de Pantalla -

8. Seleccione la profundidad de los tornillos Phillips M4 x 12mm (15)

o M4 x 25mm (16) en relación con los agujeros de montaje en la parte

posterior de la pantalla. Coloque el soporte VESA (7) en la parte posterior

de la pantalla. Alinee los orificios de montaje con los insertos roscados.

Una vez que el soporte VESA está en posición, apriete con cuidado

los cuatro tornillos hasta que el soporte VESA está firmemente unido al

ADVERTENCIA - La CPU debe montarse en el carro antes de montar las pantallas.

monitor. Deténgase inmediatamente si encuentra alguna resistencia,

o puede dañar el monitor. Si se encuentra con la resistencia antes de

que el montaje esté bien conectado, es posible que tenga que utilizar

un tornillo a menor profundidad o espaciadores. Por favor consulte el

manual de operación de su monitor. Nota: los espaciadores ovales (17)

puede ser utilizados para monitores de visualización curvados u otros.

Colocación de Pantalla y Soporte para la CPU

10. Saque la cubierta de la columna de LCD (1), e inserte el monitor

con el soporte VESA, de arriba hacia abajo en la columna de la LCD.

9. Coloque la placa fija (8)

7

16 15

17

11. Una vez que el ensamblaje de la pantalla está en posición, apriete

los tornillos en ambos extremos del soporte VESA con una llave allen de

3 mm (18) en el sentido de las manecillas del reloj y ponga la tapa en la

parte superior de la columna de LCD.

sobre el soporte VESA.

8

Cover

1

Quite la tensión el

resorte del tornillo

de retención

Todas las

etiquetas

deben estar en

el mismo lado

que la etiqueta

en la base.

18

12. Después del montaje final, quite el resorte de retención de tornillos como se muestra en

la Fig. (A) y (B) a continuación. Tire de la palanca hacia arriba para cambiar la superficie de

trabajo a la altura deseada.

Base Móvil

Quite la tensión

el resorte del

tornillo de

retención

B A

Bajo la superficie de trabajo

13

Loading...

Loading...