Global Industrial 534554 User Manual

globalindustrial.ca

User's manual Manual del usuario Manuel de l'utilisateur

Customer Service

US: 1-800-645-2986

Servicio de atención al Cliente

US: 1-800-645-2986

Battery Operated Backpack Sprayer Model 534554

HAZARDS

• You are required to read this manual and follow the proper

operation and safety instructions.

• The operator should wear a mask, gloves, and protective

clothing to avoid chemical exposure.

• In case of inhalation, exit to a well-ventilated location

immediately. If skin contact should occur, thoroughly flush

the affected area with water. If chemicals are ingested, induce

vomiting with clean or salt water and immediately seek

medical attention.

•

Do not spray pesticides near people, animals, or food. Do

not operate the unit at high temperatures for an extended

period of time.

WARNING

• This product is designed to apply chemicals that may be

harmful and cause serious injury if inhaled or brought into

contact with people or animals. Failure to read and follow the

user manual instructions prior to use may result in unit failure,

injury, and possible death.

• Never use strong solutions including acids or alkaline when

operating the sprayer. Do not use highly toxic or residual

pesticides on fruits, vegetables, gourds, medicinal herbs, etc.

• After use, be sure to clean the tank thoroughly removing all

existing chemical residue. If maintenance is not performed

properly, a chemical reaction may occur impacting the effects

of the pesticide.

ATTENTION

• Avoid operating the sprayer without water in the tank as this

may cause diaphragm damage over time.

Service à la clientèle

Canada: 888-645-2986

• If noise is heard inside the sprayer or poor performance

occurs after extended use, the battery may require charging.

Without removing the battery, connect the plug into an

electrical outlet. A charging time of at least 8 hours is required.

• The charger should be placed in a dry, well-ventilated area.

Unauthorized removal of the charger’s housing is prohibited.

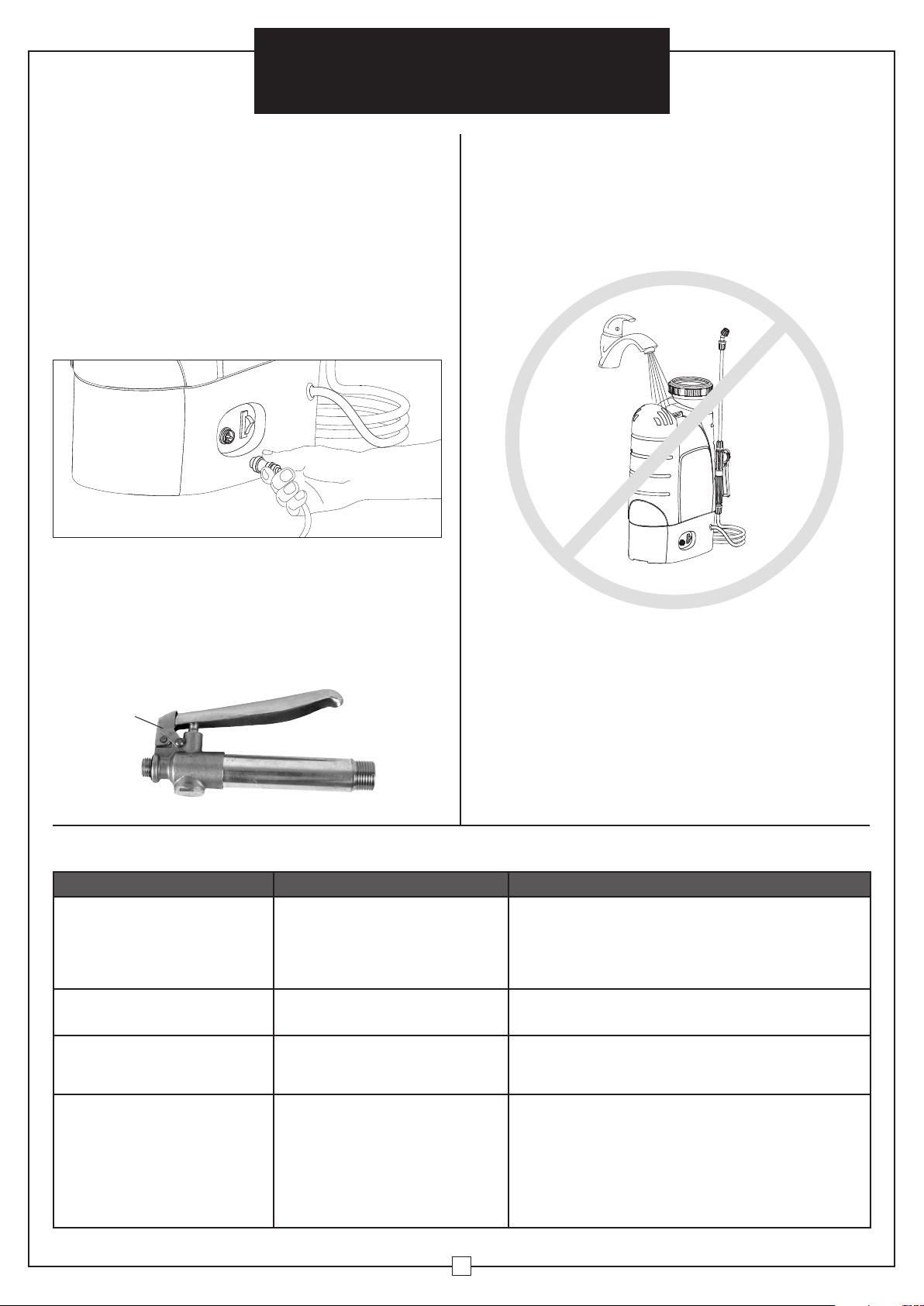

• Do not immerse sprayer in water for maintenance or refilling

purposes.

• Do not place unit near flammable materials at any time.

• Do not expose base to water.

PACKAGE CONTENTS

Ref. Description Qty.

1 Tank & Base 1

2 Tank Lid 1

3 30° Brass Nozzle 1

4 Brass Handle Bar w/Lock Switch 1

5 Brass Lance (Spray Boom) 1

6 Rubber Hose 1

7 Shoulder Strap 2

8 Battery Charger 1

9 O-Rings Set

CHARGER

1 Connect

+ Polarity

2

1

3

Fan-Out

Spray Tank

On/Off Switch

Fuse Holder

Charging Socket

Strap

Voltage

Regulation Knob

Input

End

Battery Pump Strainer Voltmeter Base

Spray

Tank Lid

Nozzle

Spray

Boom

Switch

Hose

1

080518

Battery Operated

Backpack Sprayer

PARAMETERS

1. Container Capacity: 4 gallon, 15 liters

2. Pump: mini-diaphragm

3. Maximum pressure: 65 psi

4. Charger: Input AC100-240v 50/60hz, Output DC12v 2a

5. Battery: 12v10ah

6. Net weight: 7.4kg

OPERATING INSTRUCTIONS

• After unpacking the sprayer carton, verify that all parts

conform to the packing list.

• Be sure to fully charge the battery prior to operation

User's Manual

CLEANING AND MAINTENANCE

• After use, be sure to wash the sprayer surface. The tank

should be cleaned thoroughly with water to prevent sprayer

corrosion or spray head clogging.

• Clean the sprayer surface with a wet cloth.

Charge Indicator

• Prior to use, twist off the tank’s cap and slowly pour the fluid

through the filter into the tank.

• Close the cap securely and turn on the power switch.

• Place the sprayer carefully on your back.

• Squeeze the handle to begin spraying.

• Squeeze the handle for point-and-spray operation, or slide

down the lock switch for a continuous spray.

Continuous

Spray Switch

TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

• The battery needs to be charged.

The motor fails to run after

being powered on.

• The power cable

has disconnected.

• The power switch has

been damaged.

STORAGE

• Power off the unit before storing.

• The sprayer should be stored in a dry, indoor area out of the

reach of children.

• To avoid battery damage, make sure to stand the sprayer

upright at all times.

• Recharge.

• Disassemble the base to reconnect the

cables securely.

• Replace the switch.

Abnormal sound heard in

the motor.

Leakage occurs in the bottom of

the base.

Poor performance

The pump fastening screws

are loose.

• The inlet and outlet tubes of the

pump are damaged.

• Loose tube connection.

• The nozzle is clogged.

• Spraying hole and O-ring is worn.

• Seal is upside down.

• Filter screen is clogged.

• Leakage occurs at tube joints.

• Low battery.

• Air remains in the pump.

2

Tighten the screws.

Disassemble the base and tighten the

tube's connection.

• Remove and clean the nozzle.

• Replace O-rings.

• Place the seal in the proper position.

• Wash with clean water.

• Tighten screws.

• Charge the battery.

• Remove the nozzle or lance to discharge the air.

Loading...

Loading...