Page 1

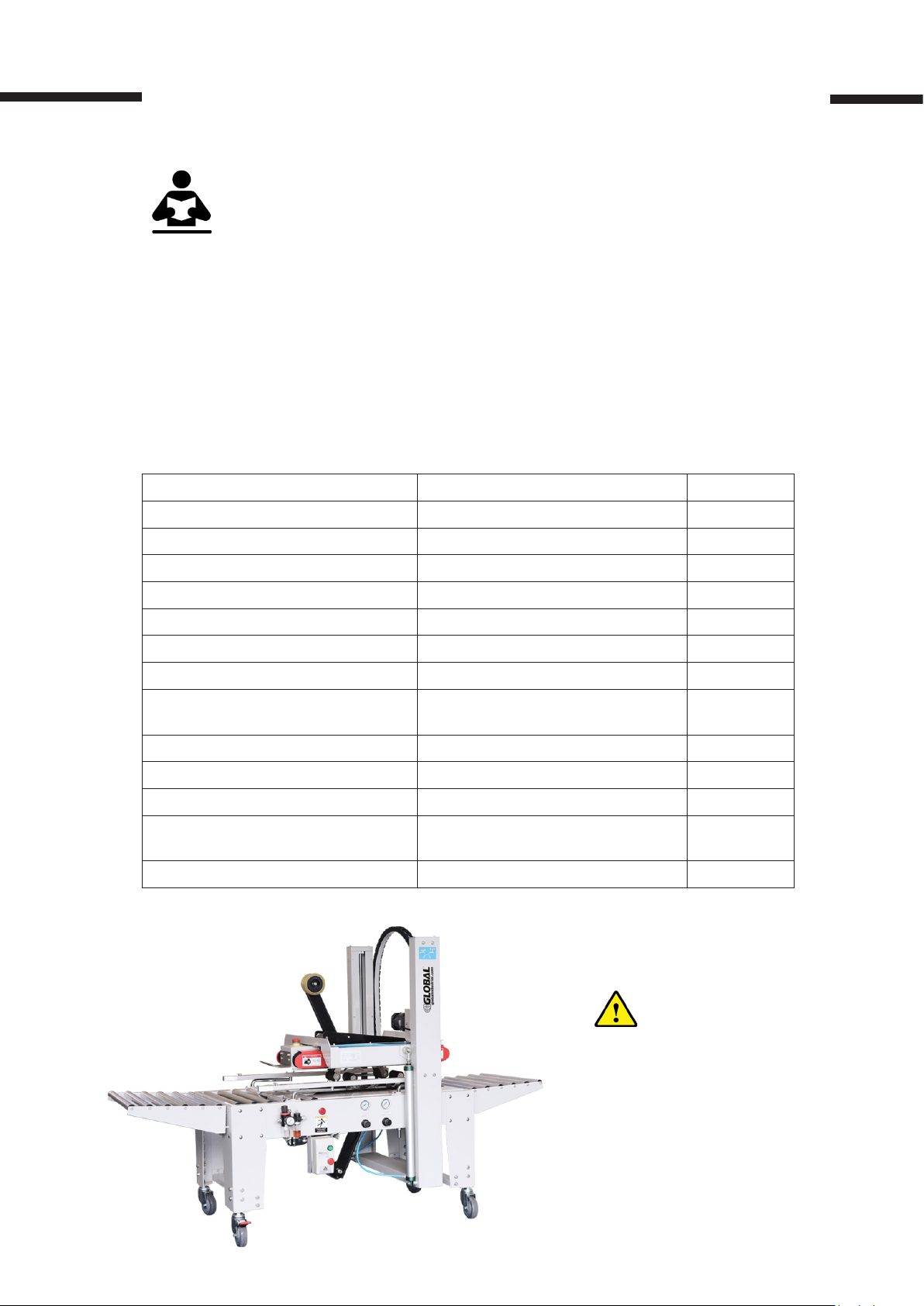

Semi-Automatic

Random Size Case Sealer

with Universal Heads

User manual

Model No. 412559

Table of Contents

Specications pg.2

SafetyInformation pg.3

Installation pg.4

• HeightAdjustment pg.4

• TapeInstallation pg.5

• AirSourceInstallation pg.6

• AirPressureAdjustment pg.7

OperationInstructions pg.8

Troubleshooting pg.10

Maintenance pg.11

PartsList pg.12

Replacement Parts pg.14

CircuitDiagram pg.18

PneumaticDiagram pg.19

Warranty pg.20

Page 2

2

PLEASE READ THESE INSTRUCTIONS COMPLETELY AND SAVE FOR REFERENCE. UPON

RECEIVING, INSPECT THE UNIT FOR ANY DAMAGE OR MISSING PARTS. IF DAMAGE IS

EVIDENT, NOTIFY THE CARRIER IMMEDIATELY TO FILE A CLAIM. THESE PRODUCTS

MUST BE HANDLED WITH CAUTION BY TRAINED OPERATORS WITH PROPER SAFETY

GEAR AND EQUIPMENT. FAILURE TO COMPLY WITH INSTRUCTIONS COULD RESULT IN

SERIOUS INJURY. PLEASE CONTACT GLOBAL INDUSTRIAL CUSTOMER SERVICE (1-800645-2986) FOR ANY ISSUES OR REPLACEMENT PARTS.

Specications

Specications Parameter Unit

Voltage AC 110/60 V/Hz

Power 220 W

Max. Carton Size (W x H x L) 19.6 × 19.6 × Unlimited inches

Min. Carton Size (W x H x L) 7.9 × 4.7 × 5.9 inches

Sealing Speed 65.62 ft/min

Height of Table 22.8 – 30.7 inches

Bleed Pressure 0.4-0.7 MPa

Compatible Adhesive Tape

Conveying Form Upper and lower conveyor belt drive -

Dimension (L×W×H) 77.6 x 70.1 x (50.4 to 57.5) inches

Weight 353 lb.

Maximum Outside Diameter of

Adhesive Tape

Compatible Adhesive Tape Widths 1-1/2” – 3” (38.1mm - 76.2mm) inches

BOPP, water-free adhesive tape,

PVC adhesive tape

9.8 inches

-

Figure 1

This safety alert symbol

identies import messages

in the manual.

READ AND UNDERSTAND

THEM BEFORE INSTALLING

OR OPERATING THIS

EQUIPMENT

Page 3

3

Safety Information

1. DO NOT use near explosive or ammable gasses.

2. DO NOT reach into any rotating parts unless the machine is OFF and disconnected

from a power source. Hands may be caught in the moving parts which can cause

serious injury.

3. Prevent accidental starting.

Ensure machine is OFF before connecting to a power source.

4. DO NOT touch the machine or the plug when hands are wet. Wet hands can increase

the risk of electric shock.

5. Always turn o the machine and unplug the power cord when not in use. Cover the

machine to protect it from dust.

6. Do NOT pull the power cord by the cable.

Always unplug the power cord by pulling the plug.

7. Always use outlets that match the power tool plug. Never remove the grounding plug

or make any other modications. Ensure the outlet is properly installed and grounded.

Do not use adapter plugs. Using unmodied plugs and outlets helps ensure grounding

and reduces chances of electrical shock.

8. Always use a GFCI protected supply when using the machine. GFCI reduces the risk

of an electric shock.

9. Machine will gradually lower itself automatically after shutting down as the air bleeds

out. Do NOT use in corrosive atmospheres. Do NOT use in temperatures lower than 41˚

F or higher than 86˚ F.

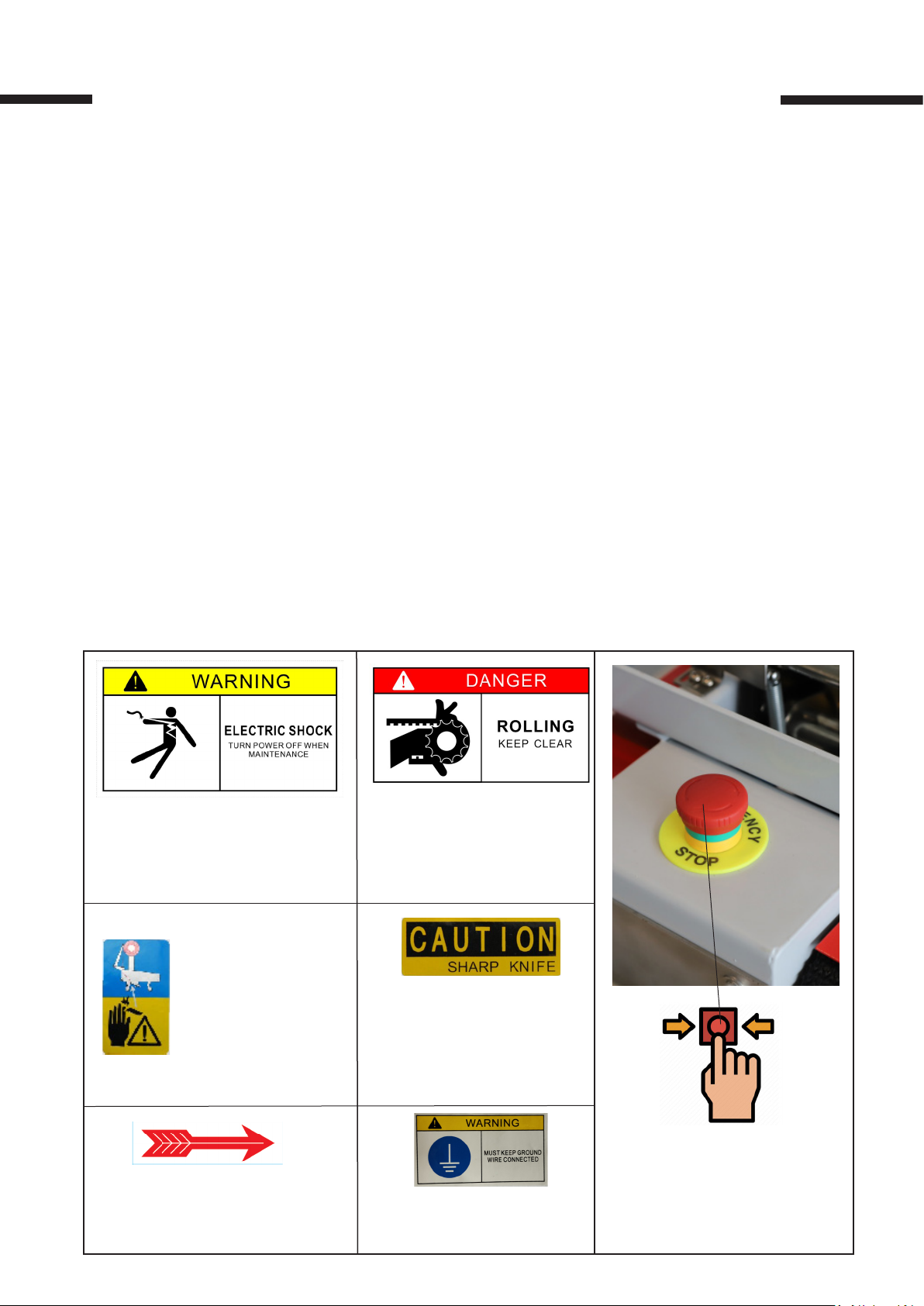

The “Warning-Electric Shock” is attached

to the electrical enclosure on the lower left

side of the machine frame. The warning

label warns service personnel to unplug

the power supply before attempting any

service work on the case sealer.

“Warning-Sharp Knife”

label is attached to the

upper conveyor belt

assembly. The label warn

operators and service

personnel of the very sharp

knife used to cut the tape

at the end of the tape

application.

The “arrow” located on each guide rail

indicate the direction where the carton

enters and exit through the conveyor.

The “Danger-pinch point” label is

attached to the center plate at the

exit end of the machine bed. The

label warns the operator to keep

hands out of this area when the

drive belts are running.

“Caution-Sharp Knife” label

warns operators and service

personnel of the extremely sharp

knife used to cut the tape. Keep

hands out of these areas except as

necessary to service the tape heads

or to load/thread tape.

The “Warning must keep ground wire

connected” warns operators to keep

the ground plug connected at all time

during operation.

The “Red” emergency switch is

located on the top/front of the upper

conveyor belt assembly. If you

encounter problems during the

packaging process, press the

emergency stop switch to stop the

machine.

Page 4

4

Installation

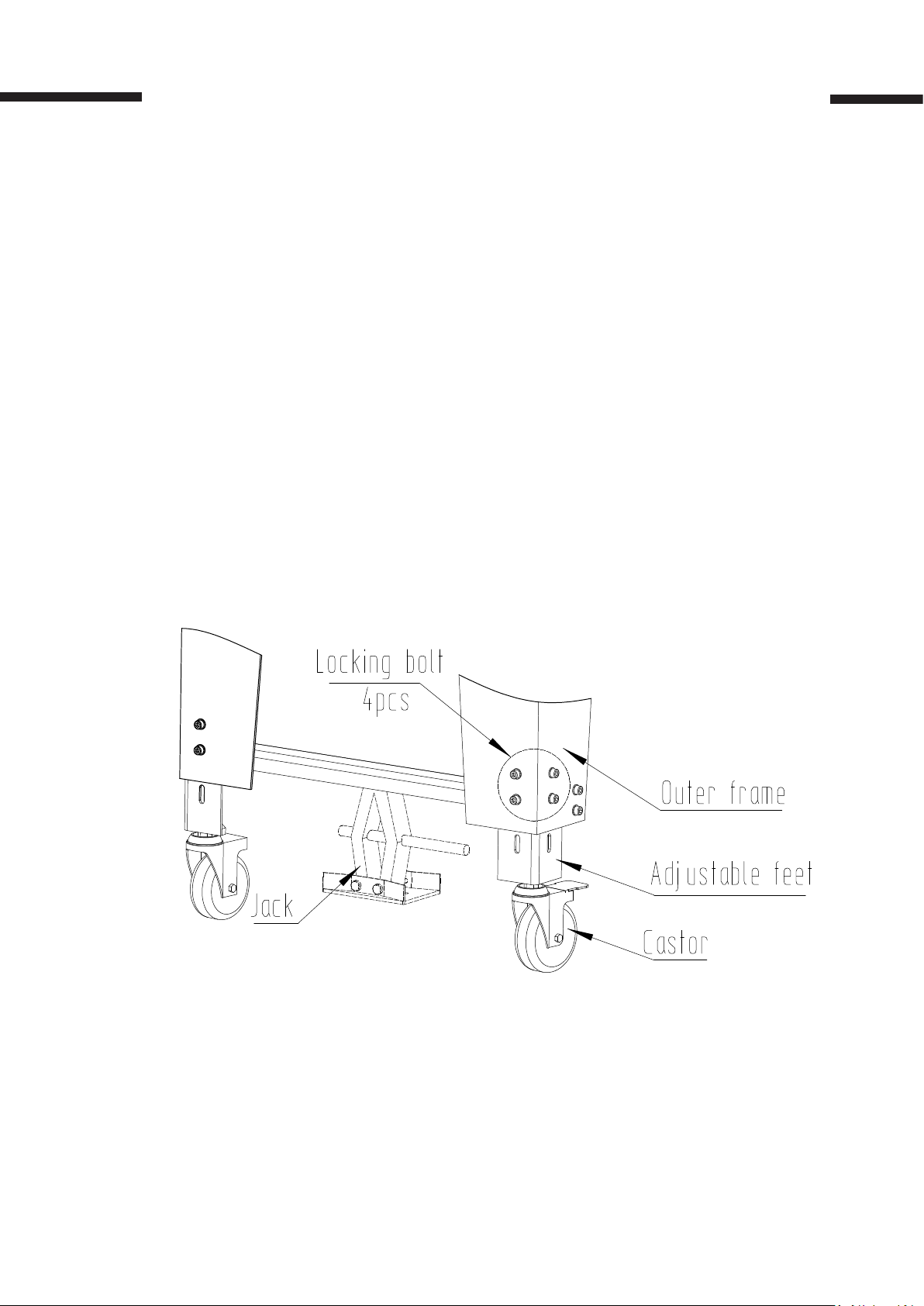

Height Adjustment

1. Raise one end of the machine by lifting the support rails between the casters with a

forklift, pallet jack, or scissor jack. Do NOT raise the machine too high to avoid turning

over the machine. NOTE: Scissor jack and additional equipments not included. Pallet

jack requires a wood block between the fork and support bar to lift the machine.

2. Unscrew the (4) locking bolts and adjust the height of the feet. Tighten the screws

when completed.

3. Lower the machine back to the ground.

4. Repeat the above 3 steps to the other end of the machine to adjust the height of the

other two feet.

5. Make any ne adjustments, if necessary, with the threaded caster(s) to ensure the

machine leveled.

Figure 2

Page 5

5

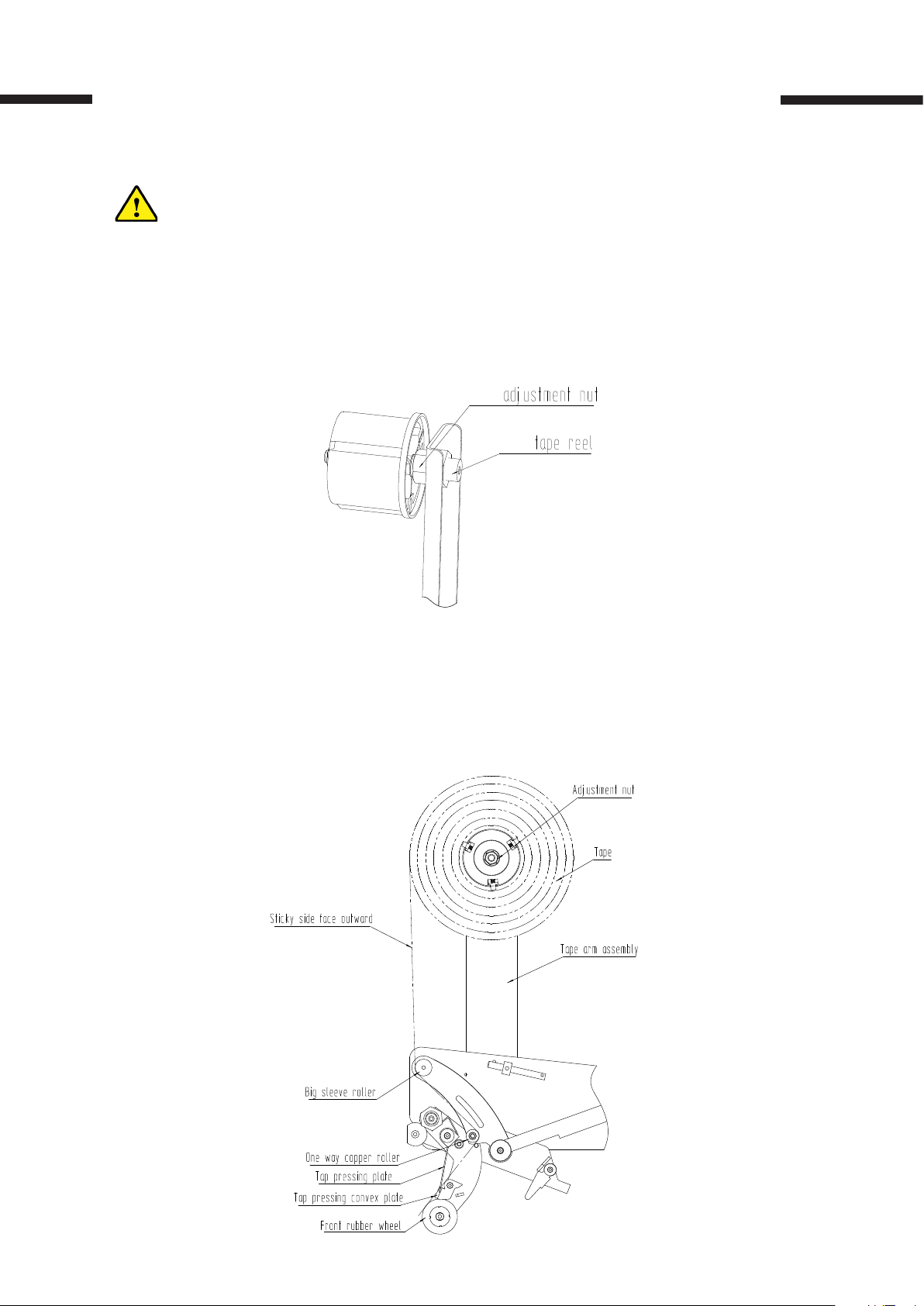

Tape Installation

Warning!

1. Ensure the machine is OFF and the power cord is unplugged. Attach the tape

roll to the reel so that the adhesive side faces outward when pulled. If the tape

doesn’t t onto the tape reel, loosen the adjustment nut. Then retighten when

the tape is installed. Ensure the tape can spin and there is adequate tape tension.

Figure 3

2. Pull the tape through to the copper roller, the tension roller, the copper wheel , the

tap pressing plate, and the front rubber wheel, respectively.

Figure 4

Page 6

6

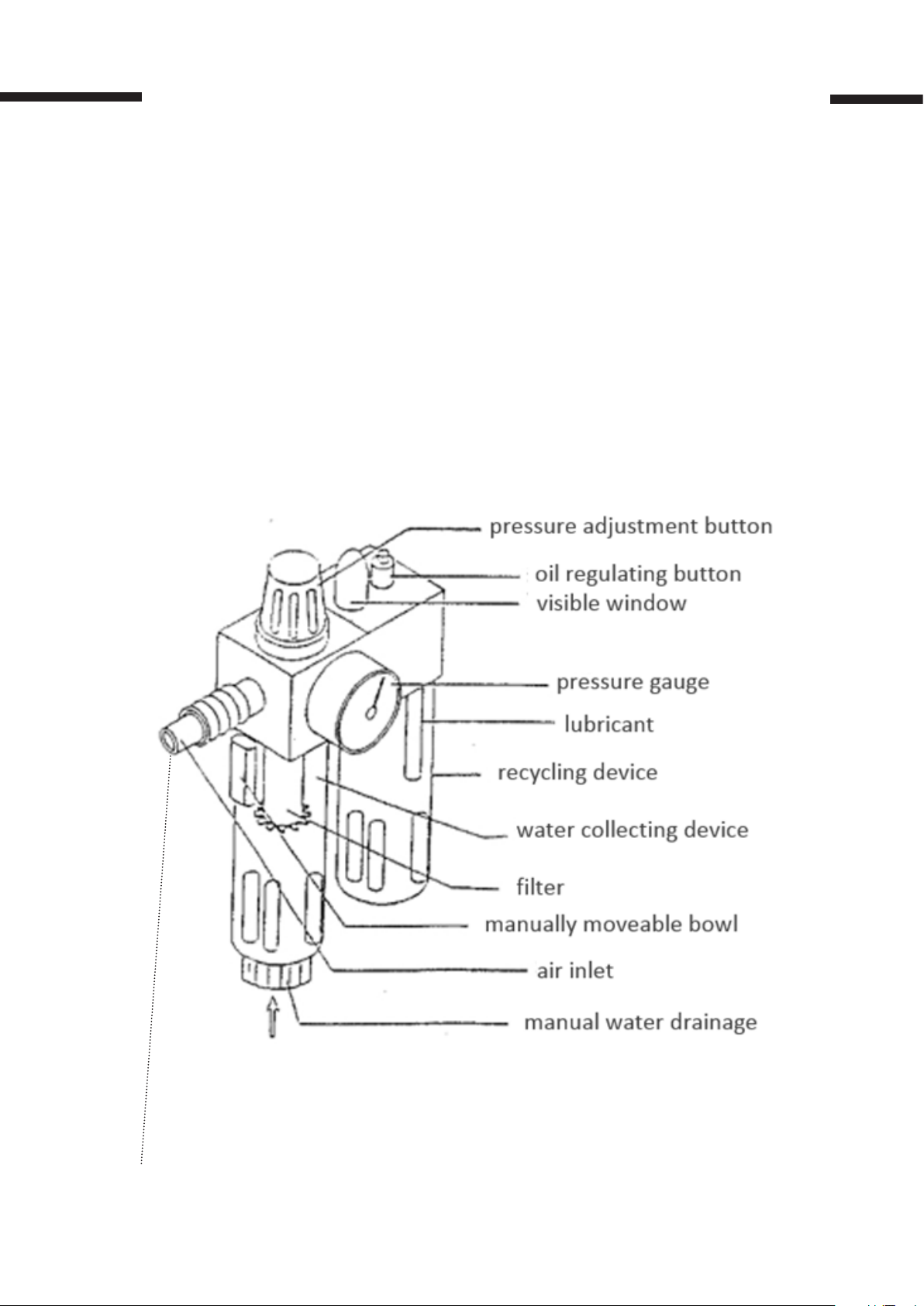

Air Source Installation

1. Clean all connecting pipes and joints to prevent dirt from entering the gas tubes

when installing the air regulator.

2. Ensure the air ow matches the direction indicated by the arrow on the body.

3. Drain the water from the lter by pushing the drain button upward.

4. The pressure is preset to 0.3-0.4 MPa. However, you can adjust the pressure by using

the pressure knob if needed. Pull the knob up to unlock the knob. Turn the knob

gradually (clockwise to increase outlet pressure and counterclockwise to decrease).

DO NOT change the pressure drastically too quickly. Press the knob down to x the

setting.

5. Fill the oil feeder with mechanical oil (ISO VG32 or equivalent) to no more than 80%

of capacity.

Figure 5

Note: Air inlet connects to 8mm OD x 5mm ID air pressure hose.

Page 7

7

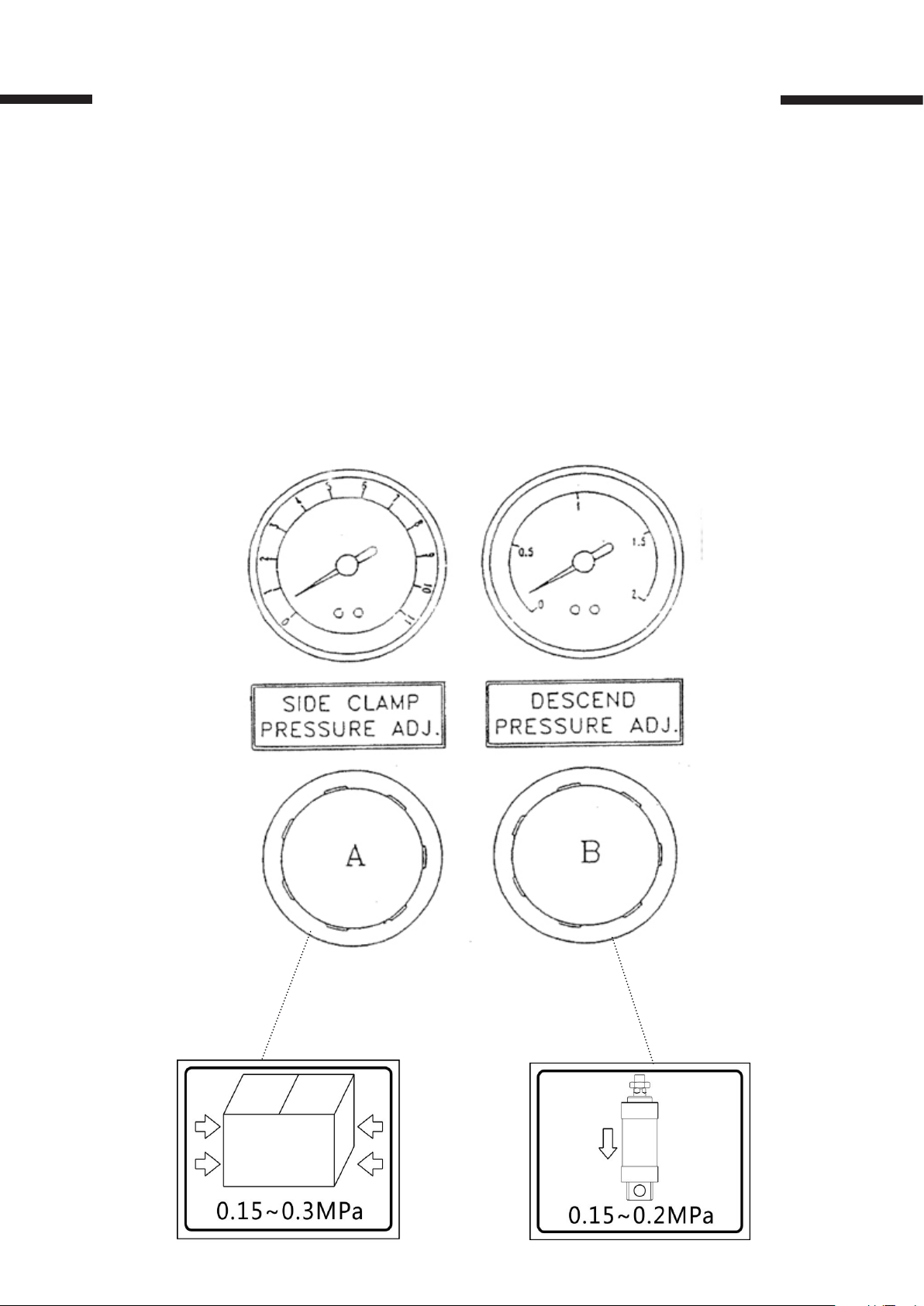

Air Pressure Adjustment

The button A (cylinder pressure regulating valve) is used to adjust the pressure (0.2 MPa) of

the guide rails on both sides. If the pressure is too high, the box can get damaged.

The button B (lifting cylinder buer pressure regulating valve) is used to adjust the pressure

of the upper sealing component against the carton (0.12~0.15 MPa). Increase the pressure

to prevent damaging a thin, light, or delicate box.

1. Pull the button outward away from the machine to unlock the knob.

2. Turn the button clockwise to increase the pressure, and counterclockwise to decrease

the pressure. After adjusting the pressure, press down the button to lock the setting.

Figure 6

Page 8

8

Operation Instructions

1. Ensure the machine is OFF.

Connect the machine’s power plug to a power source with a GFCI receptacle.

2. Press the power switch on the machine’s frame to start the machine.

3. Ensure the package isn’t creased or wet, and does not have plastic materials or dust

on the outside. Place the package on the rollers and gently push it forward towards

the lower switch A. See gure 7

4. When the package passes switch A, the side guide rails will automatically grab and

center the carton. See gure 8

5. The upper sealing component will automatically lower until the lever component is

pressed against the carton. The conveyor belt will activate and pull the box through

both the upper and lower sealing heads. See gure 9 & 10

6. If you encounter problems during the packaging process, press the emergency

stop switch to stop the machine. The upper sealing component will rise to its highest

position, the guiding rails will open to the widest position, and the motor will stop

working. Then take out the package and check the machine. Turn the emergency stop

switch clockwise until the green strip is revealed and press the power button to restart

the machine.

NOTE:

Rotate the stop switch button clockwise to resume operation.

Page 9

9

Figure 7

Figure 8

A

Figure 9

Figure 10

Page 10

10

Troubleshooting

Problem Potential Causes Solutions

Tape does not cut

throughly

Tape does not cut

Irregular tooth

shape on the

cutting area

(tearing).

Excess tape cutted.

Tape cut, but

package is not

sealed

Blade is not sharp enough Replace blade

Adhesive is attached to blade Clean blade

Screw is loose

Blade spring tightness Replace blade spring

Swing arm tension spring is

too loose

Blade is dull Replace blade

Blade is installed in wrong

direction.

Knife spring too weak Replace spring

The knife seat is stuck, the

movement is not exible or

the elasticity is not enough

The main tension spring is

too loose, and the rear rubber

roller rebound speed cannot

be synchronized with the belt

speed.

Tighten the screws on the

cartridge

Adjust the swing arm spring

screw

Re-install

Check the screws on each part

of the sealing head to adjust the

tension of the tension spring

Moderately tighten the main

tension spring screw

Main tension spring is too

tight

Tape roller adjustment nut is

Package is blocked

Tape is broken or

cut o while sealing

carton

Package is not

centered during

sealing

Too long tape leg Blade is positioned too low Raise the position of blade

Too short tape leg Blade is positioned too high Lower the position of blade

too tight

Improper adjustment of drive

unit and carton height and

width

Blade is positioned too high Lower the position of blade

Package was not pushed or

guided towards the sealers

Adjust the main tension spring

Adjust the adjustment nut

Re-adjust the height and width

of the drive unit

Align the package so the sides

are parallel to the guide rails

before pushing

Page 11

Problem Potential Causes Solution

Tension spring on tape head

Tape doesn’t

adhere to the

package

is too weak

Friction of tape roller

lessened after use

Adjust the friction of the tape

mount

11

The machine does

not start

Drive belt

does not turn

Machine alarm Package stuck Take out the package

Power switch is damaged Replace the power switch

Loose wires Rewiring

No power Check the power supply

Geared motor damage Replace the geared motor

Chain shedding Reinstall the chain

Bearing damage Replacement bearing

Conveyor belt is damaged

Conveyor belt is too loose

Replace the damaged

conveyor belt.

Adjust the tension of the

conveyor belt

Maintenance

Warning! Danger of electric shock!

The power must be completely disconnected before servicing the machine.

If the machine is used frequently (<4 hours a day), then professional maintenance is

recommended every six months. If usage does not exceed 4 hours per day, a complete

maintenance is recommended once per year. Keep the inside and outside of the machine

clean and dry at all times.

Frequency Maintenance

Every Day Clean o any residues on the cutting blade

Check oil levels and drain water. Wipe the cylinder piston to

Every Week

Every Two Months Check all the screws and nuts. Tighten if needed.

Every Six Months

Every Year Replace the conveyor belts. Model no. 412565 & 412566

prevent dust from entering the piston cylinder or creating air

leaks.

Replace the cutting blade. Model no. 412572

Page 12

12

1

1

2 3 4

5

6

7

8

9

10

11

12

13

14

15

1617182021 19

22

Parts List

Major Components

Figure 12

Ref. No Part Name

1 Infeed/Exit Conveyor

2 Guide rails

3 Lower switch – width adjustment

4 Lower conveyor belt

5 Lower Tape Head, 3”

6 Upper Switch – Height Adjustment

7 Emergency stop switch

8 Upper conveyor belt

9 Upper Tape Head, 3”

10 Upper tape (not included)

11 Upper Seal Assembly

12 Vertical Column Frame

Page 13

Ref. No Part Name (cont.)

13 Corner Leg Frame

14 Telescopic frame

15 Lifting cylinder buer pressure gauge (0.12-0.15Mpa)

16 Lifting cylinder buer pressure regulating valve

17 Lifting cylinder

18 Width adjustment cylinder pressure regulating valve

19 Width adjustment cylinder pressure gauge (0.2Mpa)

20 Lower Tape (not included)

21 Power switch

22 Support rail

13

Hardwares and Accessories Content

Ref. No. Description Qty.

H1 M4, 3mm Hexagon Spanner 1

H2 M5, 4mm Hexagon Spanner 1

H3 M6, 5mm Hexagon Spanner 1

H4 M8 Hexagon Spanner 1

H5 Slotted head screwdriver 1

H6 Phillips head screwdriver 1

H7 Wrench (8-10) 1

H8 Wrench (14-17) 1

H9 Wrench (17-19) 1

H10 1-1/2” Nylon Brush 1

H11 M8x25 Hex. Head Bolt – C Level 8

H12 8mm ID x 16mm OD Gasket 16

H13 M8 Hex Nut - C Level 8

H14 8mm Spring Washer 8

Images not provided

Page 14

14

Replacement Parts

Figure 13

Model # Ref. no Descriptions

412560 6 Upper Tape Head, 3”

412561 3 Lower Tape Head, 3”

412562 1 Infeed/Exit Conveyor

412563 11 Threaded Swivel Caster

412564 10 Threaded Brake Caster

412565 2 Bottom Conveyor Belt

412566 5 Top Conveyor Belt

412567 7 Driving wheel

412568 4 Roller wheel

412575 9 Pulling rod cylinder

412576 8 Aluminum alloy mini cylinder

Page 15

15

Figure 14

Model # Ref. no Descriptions

412569 3 Front rubber roller assembly 2”

412570 1 Back rubber roller assembly

412571 4 Knife frame pullback spring

412572 2 Blade

412573 5 Upper tape head, Carton sealing head pullback spring

412574 6 Lower Tape Head, Carton sealing head pullback spring

Page 16

16

Order at www.globalindustrial.com or call 1-800-645-2986

Model no. 412560 Model no. 412561

Model no. 412562

Model no. 412564

Model no. 412563

Model no. 412565 & 412566

Model no. 412567 Model no. 412568

Page 17

Model no. 412569 Model no. 412570

17

Model no. 412571 Model no. 412572

Model no. 412573

Model no. 412574

Model no. 412575 Model no. 412576

Page 18

18

Circuit Diagram

Diagram 1

Page 19

Pneumatic Diagram

19

Diagram 2

Page 20

20

Over 1,000,000 products. Industrial strength service.

We can supply that.

REGISTER ONLINE AT

http://www.globalindustrial.com/wr or http://www.globalindustrial.ca/wr

Global Limited 1 Year Warranty

1. LIMITED WARRANTY

Global Equipment Company Inc. (DBA Global Industrial) (“Global”) hereby

warrants to you, the original purchaser and end user (“you” or “your”), that

the products that you purchased which accompany this Limited Warranty

(“Products”) shall be free from defects in materials and workmanship under

normal use consistent with the accompanying documentation for 1 year

commencing upon the date of purchase (the “Warranty Period”).

Global will repair or replace any Product determined to be defective and which

has been returned, as set forth in section 3 herein, to Global. A Product may

be replaced with a new or used product and/or current or prior revision. Where

Global determines in its sole judgment that repair or replacement of such

Product is not reasonable, Global will keep the non-conforming Product and

refund to you the amount you paid for such Product. Returned Products shall

be subject to the balance of the Warranty Period otherwise applicable. Any

reconditioned parts used by Global shall be subject to all the same provisions

as otherwise applicable to new parts.

THE FOREGOING DESCRIBES THE SOLE LIABILITY OF GLOBAL, AND YOUR SOLE

REMEDY, FOR ANY BREACH OF WARRANTY. IF YOU DO NOT AGREE WITH THE

TERMS OF THIS LIMITED WARRANTY, YOU MUST RETURN THE PRODUCTS

UNUSED AND IN THEIR ORIGINAL PACKAGING WITHIN THREE (3) DAYS AND

YOUR PURCHASE PRICE WILL BE REFUNDED.

2. WARRANTY EXCLUSIONS AND LIMITATION OF LIABILITY

This Limited Warranty does not cover: (i) defects or damages resulting from

acts of God, casualty, accident, misuse or abuse, overloading, exceeding the

recommended weight capacity, neglect, alterations, modification, service or

repair by other than Global or its independent third party service providers,

including without limitation by you; (ii) improper assembly or installation or deinstallation, operation or maintenance, improper connections with peripherals

or other causes not arising out of defects in the materials or workmanship of

Products; (iii) any Product for which the warranty sticker has been removed,

modified or defaced; (iv) shipping containers, batteries, cabinets, media,

software or accessories; (v) normal wear and tear; (vi) damage to or loss of

repaired or replaced Products during shipping by Global except when such

damage or loss is caused by poor or inadequate packaging by Global; or (vii)

Products purchased outside the United States or Canada.

UNDER NO CIRCUMSTANCES WILL GLOBAL BE LIABLE FOR ANY LOSS OF

USE, INTERRUPTION OF BUSINESS OR ANY INDIRECT, SPECIAL, INCIDENTAL,

PUNITIVE OR CONSEQUENTIAL DAMAGES OF ANY KIND (INCLUDING LOST

PROFITS) REGARDLESS OF THE FORM OF ACTION WHETHER IN CONTRACT,

TORT (INCLUDING NEGLIGENCE), STRICT PRODUCT LIABILITY OR OTHERWISE,

EVEN IF GLOBAL HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

IN NO EVENT SHALL THE TOTAL LIABILITY OF GLOBAL HEREUNDER EXCEED

THE GREATER OF $50 OR THE AMOUNT YOU ACTUALLY PAID FOR THE PRODUCT

GIVING RISE TO SUCH LIABILITY, REGARDLESS OF THE CAUSE OF ACTION, IN

CONTRACT, TORT, STRICT LIABILITY OR OTHERWISE. NOT ALL JURISDICTIONS

ALLOW SUCH LIMITATIONS OF DAMAGES SO THE FOREGOING LIMITATIONS

MAY NOT APPLY TO YOU.

3. PROCEDURE FOR WARRANTY SERVICE

Prior to returning any Products to Global for warranty service, you must first

contact Global, by telephone at (800) 645-2986 (US) or (888) 645-0878

(Canada) to confirm that such Products are covered by this Limited Warranty. If

such Products are so covered, you shall obtain from Global a return materials

authorization (“RMA”) number and shipping instructions prior to any shipment

of such Products to Global, and you must include such RMA number with any

corresponding Product shipment, along with a true and correct copy of the

original receipt showing the date of Product purchase by you, and a detailed,

written description of any associated Product problems.

Please note that you are responsible for all shipping charges incurred in

returning an item for exchange or repair. Global shall pay for return shipping

of repaired and/or replaced Products to addresses within the United States and

Canada only, and return shipments to all other addresses outside of the United

States or Canada is your responsibility. If Global determines that any Product is

not covered by this Limited Warranty, you must pay all parts, labor charges and

return shipping for such Product.

4. WARRANTY DISCLAIMER AND LIMITATIONS

EXCEPT AND TO THE EXTENT EXPRESSLY SET FORTH ABOVE THERE ARE NO

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO, ANY

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

AND GLOBAL EXPRESSLY DISCLAIMS ALL WARRANTIES NOT STATED HEREIN.

EXCEPT AND TO THE EXTENT EXPRESSLY SET FORTH ABOVE, THE PRODUCTS

ARE PROVIDED ON AN “AS IS” BASIS, AND GLOBAL MAKES NO ADDITIONAL

WARRANTIES, EXPRESS, IMPLIED, ARISING FROM COURSE OF DEALING OR

USAGE OF TRADE, OR STATUTORY, AS TO THE PRODUCTS OR ANY MATTER

WHATSOEVER. THIS IS A LIMITED WARRANTY AND IS THE ONLY WARRANTY

MADE BY GLOBAL. THE AGENTS, EMPLOYEES, DISTRIBUTORS, AND DEALERS

OF GLOBAL ARE NOT AUTHORIZED TO MAKE MODIFICATIONS TO THIS LIMITED

WARRANTY, OR MAKE ADDITIONAL WARRANTIES BINDING ON GLOBAL.

ACCORDINGLY, ADDITIONAL STATEMENTS SUCH AS DEALER ADVERTISING

OR PRESENTATION, WHETHER ORAL OR WRITTEN, DO NOT CONSTITUTE

WARRANTIES BY GLOBAL AND SHOULD NOT BE RELIED UPON. GLOBAL DOES

NOT WARRANT THAT THE PRODUCTS WILL OPERATE WITHOUT FAILURE, OR

THAT THE PRODUCTS WILL MEET YOUR NEEDS OR EXPECTATIONS. NOT ALL

JURISDICTIONS ALLOW SUCH WARRANTY LIMITATIONS SO THE FOREGOING

LIMITATIONS MAY NOT APPLY TO YOU.

5. CHOICE OF LAW AND JURISDICTION

FOR PURCHASES WITHIN THE US - This Limited Warranty shall be subject solely

to the laws of the State of New York as applied to contracts entered into in the

State of New York between New York residents. Any dispute arising hereunder

shall be subject to the sole jurisdiction of the State and Federal Courts located

in Nassau County, New York. The parties hereby consent to the personal

jurisdiction of such courts.

FOR PURCHASES WITHIN CANADA - This Limited Warranty shall be subject

solely to the laws of the Province of Ontario. Any dispute arising hereunder

shall be subject to the sole jurisdiction of Ontario, Canada. The parties hereby

consent to the personal jurisdiction of such courts.

Page 21

21

http://www.globalindustrial.com/wr or http://www.globalindustrial.ca/wr

Garantía global limitada de 1 año

1. GARANTÍA LIMITADA

Global Equipment Company Inc. (DBA Global Industrial) (“Global”) por la presente garantiza al comprador original y

usuario final (“usted” o “su”), que los productos adquiridos por usted que incluyen esta Garantía limitada (“Productos “) se

considerarán libres de defectos respecto de sus materiales y mano de obra en condiciones normales de uso de conformidad

con la documentación adjunta durante 1 año a partir de la fecha de compra (el” Plazo de duración de la garantía “).

Global reparará o reemplazará todo producto calificado como defectuoso y que hubiere sido devuelto a Global,

según lo establecido en la sección 3 de la presente garantía. Un Producto puede ser reemplazado por un

producto nuevo o usado y/o quedar sujeto a una revisión actual o previa. En los casos que Global establezca,

a su exclusivo criterio, la inviabilidad de la reparación o el reemplazo de dicho Producto, Global conservará

el Producto no conforme y le reembolsará a usted el monto abonado por dicho Producto. De ser aplicable,

los Productos devueltos estarán sujetos al tiempo restante del “Plazo de Duración de la Garantía. Todas las

piezas reacondicionadas utilizadas por Global estarán también sujetas a dichas disposiciones mencionadas

anteriormente, aplicables de igual modo a las piezas nuevas, si correspondiere

LA CLÁUSULA MENCIONADA ANTERIORMENTE DESCRIBE LA RESPONSABILIDAD EXCLUSIVA DE GLOBAL,

Y SU ÚNICO RECURSO, POR CUALQUIER INCUMPLIMIENTO DE LA PRESENTE GARANTÍA. SI USTED NO ESTÁ

DE ACUERDO CON LOS TÉRMINOS Y CONDICIONES DE LA PRESENTE GARANTÍA LIMITADA, USTED DEBERÁ

DEVOLVER LOS PRODUCTOS SIN HABERLOS UTILIZADO Y EN SU EMBALAJE ORIGINAL EN EL PLAZO DE TRES

(3) DÍAS Y USTED RECIBIRÁ EL REEMBOLSO DEL DINERO DE SU COMPRA.

2. EXCLUSIONES DE LA PRESENTE GARANTÍA Y LIMITACIÓN DE RESPONSABILIDAD

La presente Garantía limitada no cubre los siguientes supuestos: (i) defectos o daños causados por fuerza mayor,

accidentes, uso inapropiado o excesivo, sobrecarga que supere la capacidad del peso recomendado, negligencia,

alteraciones, modificación, reparación o mantenimiento realizados por proveedores técnicos independientes

o ajenos a Global, entre los que se incluyen las siguientes acciones realizadas por usted ; (ii) ensamblaje o

instalación o desinstalación inadecuados, operación o mantenimiento, conexiones periféricas, funcionamiento o

mantenimiento incorrectos, o cualquier otra causa que no surja de un defecto en los materiales o en la mano de obra

del Producto; (iii) todo Producto que no contenga el sticker de garantía o cuando dicho sticker haya sido retirado,

modificado o esté dañado; (iv) contenedores de envío, baterías, gabinetes, medios, software o accesorios; (v)

desgaste normal por el paso del tiempo; (vi) daño o pérdida de los Productos reparados o reemplazados durante el

envío por parte de Global en los casos en que dicho daño o pérdida se hubieren producido por un mal o inadecuado

embalaje por parte de Global; o (vii) Productos adquiridos fuera de los Estados Unidos o Canadá.

EN NINGÚN CASO GLOBAL SERÁ RESPONSABLE POR LA PÉRDIDA DE USO, INTERRUPCIÓN DE NEGOCIOS O

CUALQUIER TIPO DE DAÑO INDIRECTO, ESPECIAL, INCIDENTAL, PUNITIVO O CONSECUENTE (INCLUIDA LA PÉRDIDA

DE GANANCIAS), INDEPENDIENTEMENTE DEL TIPO DE ACCIÓN LEGAL, YA SEA EMANADOS DE UN CONTRATO, DE UN

ACTO ILÍCITO (INCLUIDA LA CULPA), RESPONSABILIDAD OBJETIVA SOBRE EL PRODUCTO U OTROS. LO ANTERIOR SE

APLICARÁ AÚN EN LOS CASOS EN QUE GLOBAL HAYA SIDO ADVERTIDA SOBRE LA POSIBILIDAD DE DICHOS DAÑOS.

EN NINGÚN CASO, EN VIRTUD DE LA PRESENTE GARANTÍA, EL MONTO INDEMNIZATORIO POR RESPONSABILIDAD DE

GLOBAL PODRÁ EXCEDER LOS USD 50.00 O LA SUMA QUE USTED HAYA PAGADO POR EL PRODUCTO OBJETO DE DICHA

RESPONSABILIDAD, INDEPENDIENTEMENTE DE LA CAUSAL DE LA ACCIÓN LEGAL, POR EL CONTRATO, ACTO ILÍCITO,

RESPONSABILIDAD OBJETIVA U OTRAS. DADO QUE NO EN TODAS LAS JURISDICCIONES RIGEN DICHAS LIMITACIONES

EN LAS INDEMNIZACIONES, LAS LIMITACIONES ANTERIORES PUEDEN NO SER APLICABLES EN SU CASO.

REGISTRARSE EN LÍNEA EN

3. PROCEDIMIENTO PARA EL SERVICIO DE GARANTÍA

Antes de devolver un Producto a Global para obtener el servicio de garantía, Usted debe contactar a Global, por teléfono al

(800) 645-2986 (Estados Unidos) ó 888) 645-0878 (Canadá) a los fines de confirmar que dicho Producto esté contemplado

en la presente Garantía Limitada. Si dicho Producto estuviera cubierto por la Garantía, usted recibirá un número de

autorización de devolución de materiales de Global (en adelante, “ADM”) y las instrucciones de envío previas al envío del

Producto mencionado a Global. Usted deberá incluir su número de ADM con el envío del Producto correspondiente, junto con

una copia fiel del recibo original que incluya la fecha de la compra del Producto realizada por usted.

Por favor tenga en cuenta que usted será responsable de todos los gastos de envío resultantes de la

devolución de un artículo para su reemplazo o reparación. Global deberá abonar el envío de devolución del

Producto reparado o reemplazado a direcciones dentro de Estados Unidos y Canadá solamente. Los gastos de

envío a todas las demás direcciones fuera de Estados Unidos y Canadá quedan bajo su responsabilidad. En el

caso de que Global estableciera que un Producto no se encuentra contemplado en la presente Garantía Limitada,

usted deberá pagar todos los repuestos, la mano de obra y los gastos de envío por la devolución de dicho Producto

4. EXCLUSIONES Y LIMITACIONES DE LA GARANTÍA

SALVO EN LA MEDIDA EXPRESAMENTE ESTABLECIDA ANTERIORMENTE, NO EXISTEN DENTRO DE LA PRESENTE GARANTÍAS

EXPRESAS O IMPLÍCITAS, INCLUIDAS, AUNQUE SIN LIMITACIÓN, GARANTÍAS IMPLÍCITAS DE COMERCIABILIDAD O IDONEIDAD

PARA UN PROPÓSITO DETERMINADO Y GLOBAL RECHAZA CUALQUIER TIPO DE GARANTÍA NO INCLUIDA EN LA PRESENTE.

SALVO EN LA MEDIDA EXPRESAMENTE ESTABLECIDA ANTERIORMENTE, LOS PRODUCTOS SON ENTREGADOS

EN EL “ESTADO EN QUE SE ENCUENTRAN”. GLOBAL NO OFRECE GARANTÍA ALGUNA, NI EXPRESA NI IMPLÍCITA,

QUE PUDIERA SURGIR DURANTE EL TRANSCURSO DE UNA NEGOCIACIÓN O EL USO O QUE SEAN ESTABLECIDAS

POR LEY, EN LO QUE RESPECTA A LOS PRODUCTOS O A CUALQUIER OTRO ASUNTO. LA PRESENTE CONSTITUYE

UNA GARANTÍA LIMITADA Y ES LA ÚNICA GARANTÍA OTORGADA POR GLOBAL. LOS MANDATARIOS, EMPLEADOS,

DISTRIBUIDORES Y COMERCIANTES DE GLOBAL NO PODRÁN REALIZAR MODIFICACIONES A LA PRESENTE GARANTÍA

LIMITADA NI PRESTAR GARANTÍAS ADICIONALES QUE OBLIGUEN LEGALMENTE A GLOBAL. EN CONSECUENCIA,

TODA DECLARACIÓN ADICIONAL, TALES COMO PUBLICIDADES O PRESENTACIONES DEL COMERCIANTE, YA SEAN

ORALES O ESCRITAS, NO CONSTITUIRÁN GARANTÍAS OTORGADAS POR GLOBAL Y NO DEBERÁN CONSIDERARSE

VÁLIDAS. GLOBAL NO GARANTIZA QUE LOS PRODUCTOS FUNCIONEN SIN FALLAS O QUE SATISFAGAN SUS

NECESIDADES O EXPECTATIVAS. DADO QUE NO EN TODAS LAS JURISDICCIONES RIGEN DICHAS LIMITACIONES EN

LAS INDEMNIZACIONES, LAS LIMITACIONES DE LA CLÁUSULA PUEDEN NO SER DE APLICACIÓN EN SU CASO.

5. ELECCIÓN DE LA LEGISLACIÓN Y JURISDICCIÓN

PARA COMPRAS REALIZADAS DENTRO DE LOS ESTADOS UNIDOS, la presente Garantía Limitada estará sujeta

únicamente a las leyes del Estado de Nueva York, según se aplica a los contratos celebrados en el Estado de Nueva

York entre residentes del Estado de Nueva York. Toda controversia que surja en virtud de la presente Garantía quedará

sujeta a la sola jurisdicción de los Tribunales Estatales y Federales ubicados en el Condado de Nassau, Nueva York.

Por medio de la presente Garantía, las partes acuerdan someterse a la jurisdicción personal de dichos tribunales.

PARA COMPRAS REALIZADAS EN CANADÁ - La presente Garantía Limitada quedará sujeta únicamente a las

leyes de la Provincia de Ontario. Toda controversia que surja en virtud de la presente Garantía quedará sujeta

a la sola jurisdicción de Ontario, Canadá. Por medio de la presente Garantía, las partes acuerdan someterse a la

jurisdicción personal de dichos tribunales.

http://www.globalindustrial.com/wr or http://www.globalindustrial.ca/wr

Garantie globale limitée de 1 an

1. GARANTIE LIMITÉE

Global Equipment Company Inc. (DBA Global Industrial) («Global») vous garantit, l’acheteur initial et à l’utilisateur

(«vous» ou «votre»), que les produits que vous avez achetés et qui accompagnent cette garantie limitée

(«produits») sont exempts de tout défaut de matériaux et fabrication dans des conditions normales d’utilisation

conformément à la documentation suivant pour une période d’un an débutant à la date d’achat (la «période de

garantie»).

Global réparera ou remplacera tout produit jugé défectueux et qui a été retourné, tel que stipulé à la section 3

ci-dessous, à Global. Un produit peut être remplacé par un produit neuf ou usagé et/ou par une révision actuelle

ou antérieure. Lorsque global détermine à son seul jugement que la réparation ou le remplacement de ce produit

n’est pas raisonnable, Global gardera le produit non conforme et vous remboursera le montant que vous avez

payé pour ce produit. Les produits retournés sont soumis au reste de la période de garantie applicable par

ailleurs. Toutes les pièces reconditionnées utilisées par Global sont soumises à toutes les mêmes dispositions

que celles qui s’appliquent autrement aux nouvelles pièces.

CE QUI PRÉCÈDE DÉCRIT LA RESPONSABILITÉ EXCLUSIVE DE GLOBAL, ET VOTRE SEUL RECOURS, POUR TOUT

MANQUEMENT À LA GARANTIE. SI VOUS N’ÊTES PAS D’ACCORD AVEC LES TERMES DE CETTE GARANTIE

LIMITÉE, VOUS DEVEZ RETOURNER LES PRODUITS INUTILISÉS ET DANS LEUR EMBALLAGE D’ORIGINE DANS

LES TROIS (3) JOURS ET VOTRE PRIX D’ACHAT SERA REMBOURSÉ.

2. EXCLUSIONS DE GARANTIE ET LIMITATION DE RESPONSABILITÉ

La présente garantie limitée ne couvre pas: (i) les défauts ou dommages résultant d’actes de Dieu, d’accident, de

mauvais usage ou d’abus, de surcharge, du dépassement de la capacité de poids recommandée, de négligence,

des altérations, modification, service ou réparation par autre que Global ou ses fournisseurs de services tiers

indépendants, y compris sans vos limites; (ii) d’un montage ou d’une installation ou d’une désinstallation, d’un

fonctionnement ou d’un entretien incorrects, des connexions incorrectes avec des périphériques ou d’autres

causes ne résultant pas de défauts dans les matériaux ou la fabrication de produits; (iii) tout produit pour lequel la

vignette de garantie a été enlevée, modifiée ou défigurée; (iv) des conteneurs, piles, armoires, supports, logiciels

ou accessoires d’expédition; (v) d’une usure normale; (VI) des dommages ou la perte de produits réparés ou

remplacés pendant l’expédition par Global, sauf si ces dommages ou pertes sont causés par des emballages

pauvres ou inadéquats par Global; ou (vii) des produits achetés en dehors des États-Unis ou du Canada.

GLOBAL NE POURRA EN AUCUN CAS ÊTRE TENU RESPONSABLE DE TOUTE PERTE D’UTILISATION,

D’INTERRUPTION D’ACTIVITÉ OU DE TOUT DOMMAGE INDIRECT, SPÉCIAL, ACCIDENTEL, PUNITIF OU CONSÉCUTIF

DE QUELQUE NATURE QUE CE SOIT (Y COMPRIS LES PERTES DE PROFITS), QUELLE QUE SOIT LA FORME

D’ACTION CONTRACTUELLE, DÉLICTUELLE ( Y COMPRIS LA NÉGLIGENCE), LA RESPONSABILITÉ STRICTE DU

PRODUIT OU AUTRE, MÊME SI GLOBAL A ÉTÉ AVISÉ DE LA POSSIBILITÉ DE TELS DOMMAGES. EN AUCUN CAS LA

RESPONSABILITÉ ENTIÈRE CI-DESSOUS DE GLOBAL NE DÉPASSERA CE QUI EST PLUS ÉLEVÉ ENTRE $50 OU LE

MONTANT QUE VOUS AVEZ EFFECTIVEMENT PAYÉ POUR LE PRODUIT DONNANT LIEU À CETTE RESPONSABILITÉ,

INDÉPENDAMMENT DE LA CAUSE D’ACTION, DANS LE CONTRAT, LE DÉLIT, LA RESPONSABILITÉ STRICTE OU

AUTREMENT. TOUTES LES JURIDICTIONS N’AUTORISENT PAS CES LIMITATIONS DE DOMMAGES, DE SORTE QUE

LES LIMITATIONS QUI PRÉCÈDENT PEUVENT NE PAS S’APPLIQUER À VOUS.

INSCRIVEZ-VOUS EN LIGNE AU

3. PROCÉDURE DE SERVICE SOUS GARANTIE

Avant de retourner tous les produits à Global pour le service de garantie, vous devez d’abord contacter Global, par

téléphone au (800) 645-2986 (US) ou (888) 645-0878 (Canada) pour confirmer que ces produits sont couverts

par cette garantie limitée. Si ces produits sont ainsi couverts, vous obtiendrez de Global un numéro d’autorisation

de retour de matériel («ARM») et des instructions d’expédition avant toute expédition de ces produits à global et

vous devez inclure ce numéro ARM avec n’importe quelle expédition correspondante de produit, ainsi qu’une

copie exacte et correcte du reçu original indiquant la date d’achat de l’achat de votre produit, ainsi qu’une

description détaillée et écrite de tout problème de produit associé.

Veuillez noter que vous êtes responsable de tous les frais d’expédition engagés pour retourner un article pour un

échange ou une réparation. Global doit payer pour l’expédition de retour des produits réparés et/ou remplacés

aux adresses aux États-Unis et au Canada seulement ainsi que pour les expéditions de retour à toutes les autres

adresses à l’extérieur des États-Unis ou du Canada en revient de votre responsabilité. Si Global détermine que

n’importe quel produit n’est pas couvert par cette garantie limitée, vous devez payer toutes les pièces, frais de

main-d’œuvre et expédition de retour pour ce produit.

4. DÉNI DE GARANTIE ET LIMITATIONS

SAUF ET DANS LA MESURE EXPRESSÉMENT ÉNONCÉE CI-DESSUS IL N’Y A AUCUNE GARANTIE, EXPRESSE OU

IMPLICITE, Y COMPRIS MAIS SANS S’Y LIMITER À TOUTE GARANTIE DE QUALITÉ MARCHANDE OU D’ADAPTATION

À UN USAGE PARTICULIER ET GLOBAL DÉCLINE EXPRESSÉMENT TOUTES LES GARANTIES NON MENTIONNÉES

DANS LE PRÉSENT DOCUMENT.

SAUF ET DANS LA MESURE EXPRESSÉMENT ÉNONCÉE CI-DESSUS, LES PRODUITS SONT FOURNIS SUR UNE BASE

«TEL QUEL» ET GLOBAL NE FAIT AUCUNE GARANTIE ADDITIONNELLE, EXPRESSE, IMPLICITE, DÉCOULANT DE

COURS DE TRAITEMENT OU D’UTILISATION DU COMMERCE OU STATUTAIRE, QUANT AUX PRODUITS OU QUELQUE

MATIÈRE QUE CE SOIT. IL S’AGIT D’UNE GARANTIE LIMITÉE ET EST LA SEULE GARANTIE FAITE PAR GLOBAL. LES

AGENTS, LES EMPLOYÉS, LES DISTRIBUTEURS ET LES CONCESSIONNAIRES DE GLOBAL NE SONT PAS AUTORISÉS

À APPORTER DES MODIFICATIONS À CETTE GARANTIE LIMITÉE, OU À FAIRE DES GARANTIES SUPPLÉMENTAIRES

CONTRAIGNANTES POUR GLOBAL. PAR CONSÉQUENT, DES DÉCLARATIONS SUPPLÉMENTAIRES TELLES QUE

LA PUBLICITÉ OU LA PRÉSENTATION DES CONCESSIONNAIRES, QU’ELLES SOIENT ORALES OU ÉCRITES, NE

CONSTITUENT PAS DES GARANTIES GLOBALES ET NE DEVRAIENT PAS ÊTRE INVOQUÉES. GLOBAL NE GARANTIT

PAS QUE LES PRODUITS FONCTIONNERONT SANS DÉFAILLANCE, OU QUE LES PRODUITS RÉPONDRONT À VOS

BESOINS OU À VOS ATTENTES. PAS TOUTES LES JURIDICTIONS NE PERMETTENT DE TELLES LIMITATIONS DE

GARANTIE AINSI LES LIMITATIONS CI-DESSUS PEUVENT NE PAS S’APPLIQUER À VOUS.

5. CHOIX DE LA LOI ET DE LA JURIDICTION

POUR LES ACHATS AUX ÉTATS-UNIS : cette garantie limitée est soumise aux seules lois de l’état de New York, telles

qu’appliquées aux contrats conclus dans l’état de New York entre les résidents de New York. Tout litige découlant

des présentes est soumis à la seule compétence de l’État et des tribunaux fédéraux situés dans le comté de

Nassau, New York. Les parties consentent par la présente à la compétence personnelle de ces tribunaux.

POUR LES ACHATS AU CANADA : cette garantie limitée est assujettie uniquement aux lois de la province de

l’Ontario. Tout différend découlant des présentes est assujetti à la seule compétence de la province de l’Ontario,

au Canada. Les parties consentent par la présente à la compétence personnelle de ces tribunaux.

Page 22

Loading...

Loading...