Page 1

Semi-Auto Low Profile

Stretch Wrap Machine

User Manual

Model no. 412409

Globalindustrial.com

Customer Service

US: 1-800-645-2986

CA: 1-888-645-2986

OPTIONAL

Stretch Wrap Machine Ramp

Model no. 412410

Page 2

2

Table of Content

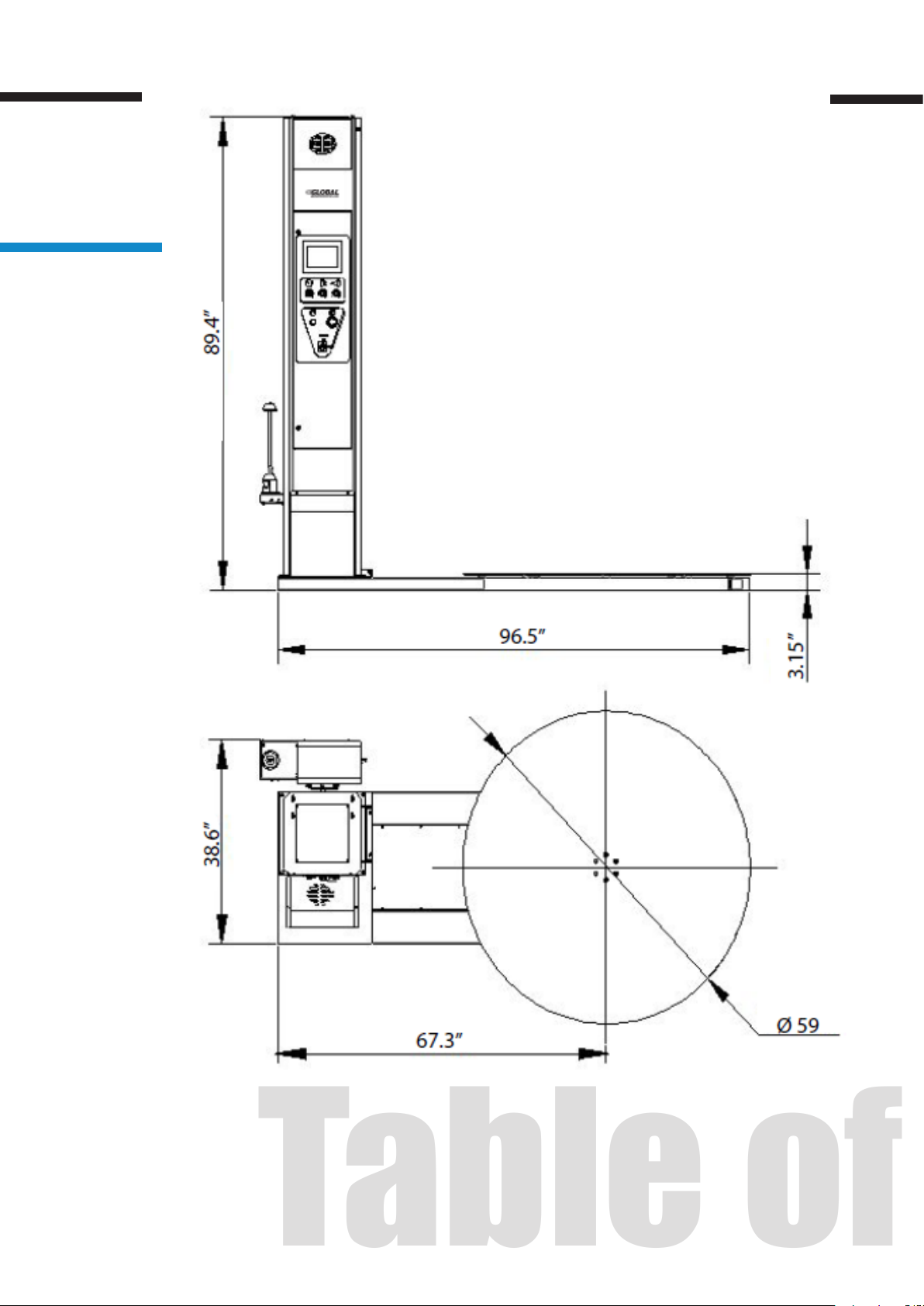

Machine Dimensions

Figure 1

Page 3

Table of Contents

3

1

2

3

4

System Specifications

System Set-up

2.1 Machine Set-up

2.2 Installation

Control Panel Buttons

Operator Controls

4.1 Manual

4.2 Auto

4.3 Input & Output (I/O)

4

6

7

8

10

12

12

13

14

5

6

4.4 Film Loading

4.5 Machine Operation

Maintenance & Troubleshooting

Components & Parts

14

16

18

20

Page 4

4

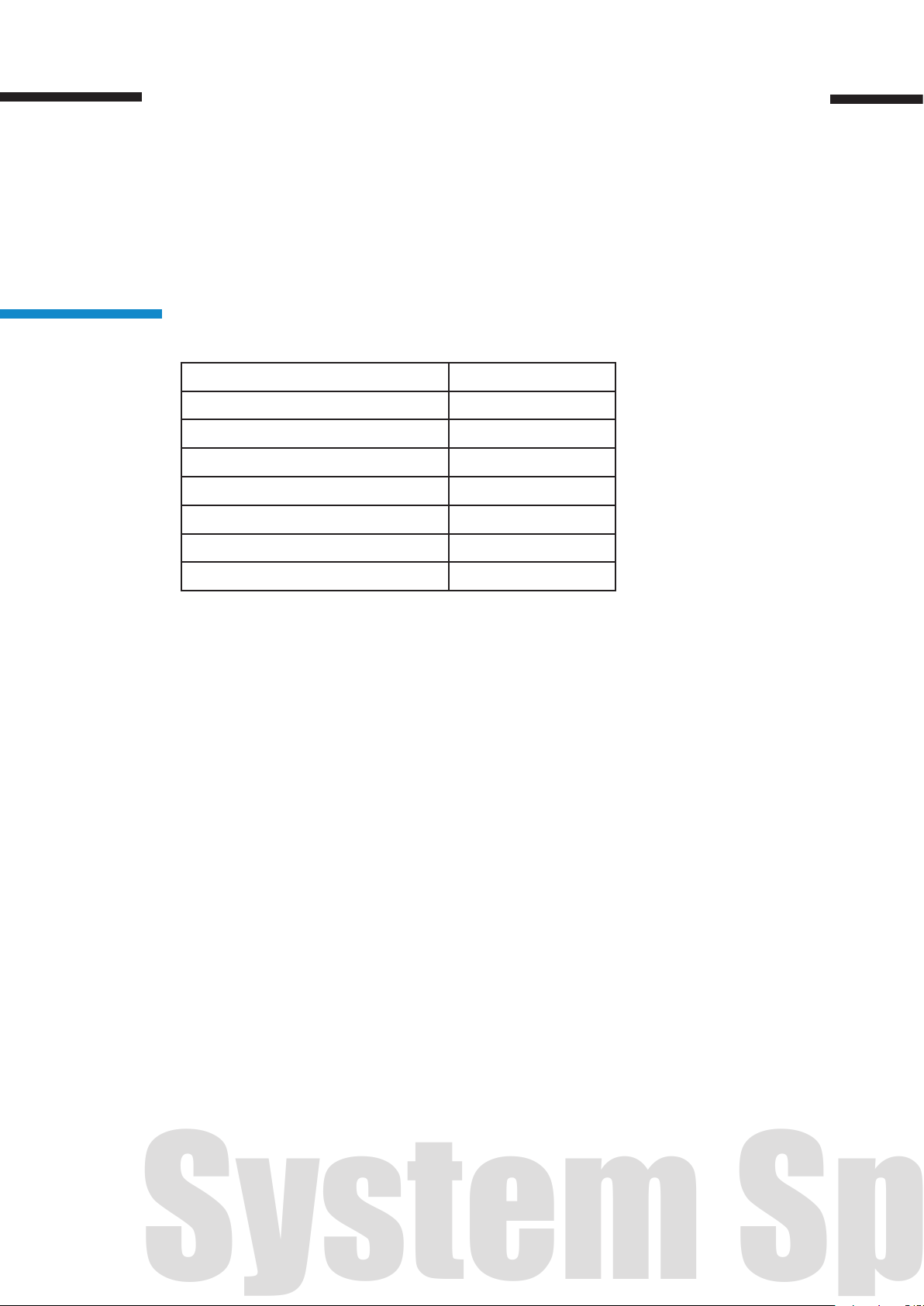

System Specication

1. System Specification

Machine Dimensions

(See Figure 1)

Length 96.5”

Width 59”

Height 89.4”

Turntable Diameter 59”

Turntable Height from Floor 3.15”

Wrapping Height 83”

Operation Space 97” x 60” x 90”

Maximum Load Size 52” x 52” x 82”

s

Table 1

Electrical Specications

• 110 VAC, 60 Hz, Single-phase, 9.1AMP

• Turntable motor: 550W

• Lift motor: 200W

• Pre-stretch Motor: 200W

Turntable System

• 13 RPM turntable maximum speed

• 4,400 lbs. turntable maximum load capacity

• 1-10 round/minute

• Clockwise rotating turntable direction

Film Delivery System

• Innite / Manual Stretch Adjustment

• 10” Diameter Roll Capacity

• 3” inner lm roll diameter

• 20” Roll Width Capacity

Page 5

Machine Features

• Programmable logic controller (PLC) user interface

• 6 modes: that’s 5 automatic modes + 1 manual mode.

• The lm carriage adopts close loop self-adjusting technology, to ensure each

package is evenly wrapped.

• Allowable package weight (22 lbs – 4400 lbs)

• SAFETY: The machine has an emergency stop button & sensor underneath the

lm carriage. Once an object is detected underneath the moving lm carriage, the

machine will stop.

CAUTION!

5

When servicing drive and controllers, there may be exposed components with

housings or protrusions at or above the line potential. Extreme care should be taken

to protect against shock.

The user is responsible for conforming to all applicable code requirements with

respect to grounding requirements. Do NOT use extension cords to operate the

equipment

Disconnect AC input power when the machine is not in use and before checking

components, performing maintenance, cleaning up, and. Do NOT connect or

disconnect wires and connectors while power is applied to the circuit.

Always plug into a grounded outlet with the rated voltage

110 V

WARNING!

Loose clothing must NOT be worn while the machine is in operation. Stay clear of

moving parts while the machine is running.

Page 6

6

System Set-up

2. System Set-up

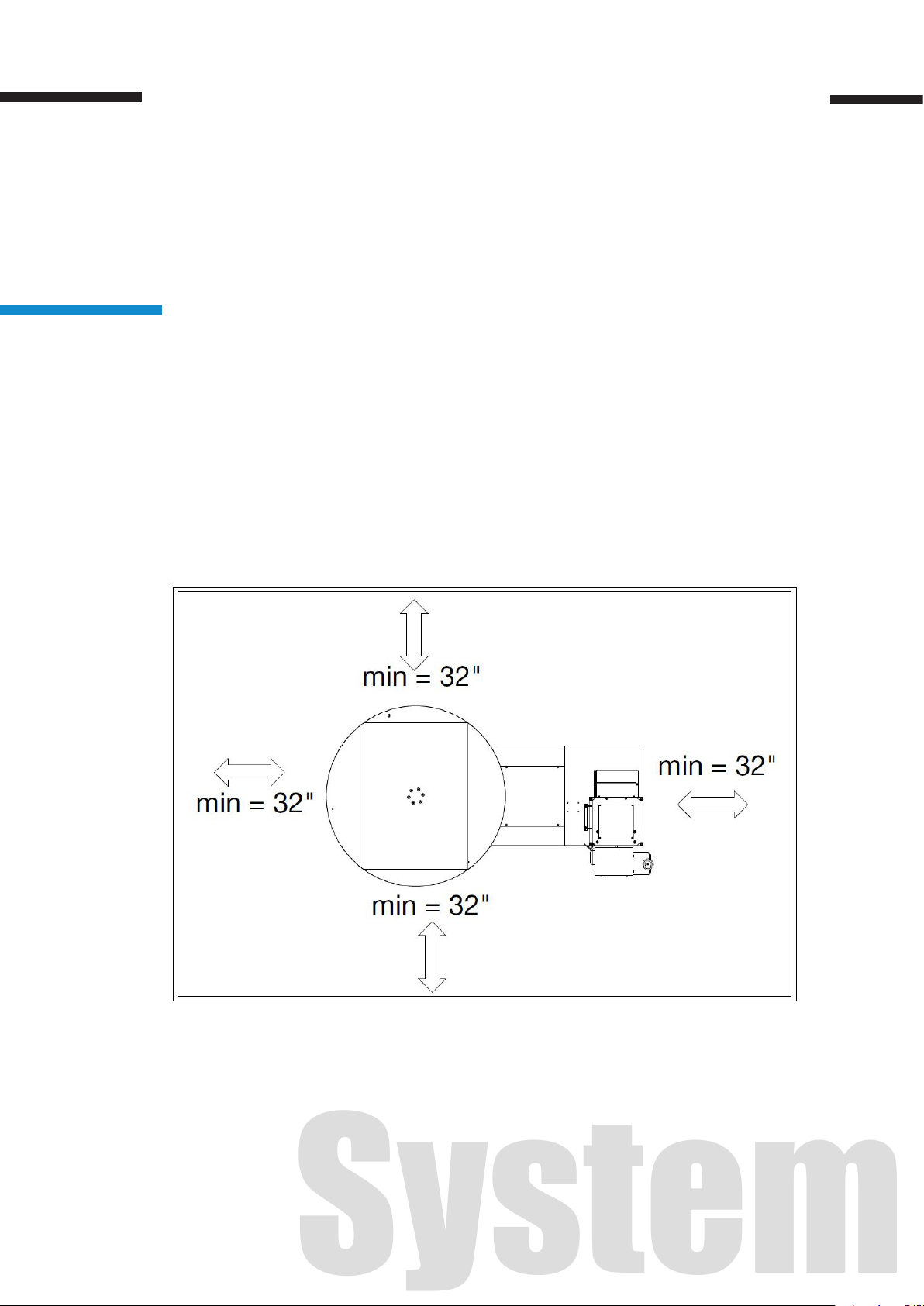

Machine Placement

Place the Semi-automatic Stretch Wrap Machine close to an area where you will

be wrapping your pallet loads. Refer to gure 2 t o insure the m achine meets the

minimum clearance space requirements. Make sure that there is sucient room to

load/unload the machine and that you do not stretch the wiring cable. Remember,

you will need to provide electrical service to a 110 VAC, 9.1-AMP outlet.

(See Figure 2)

Floor Weight Bearing Tolerance

The oor must be able to bear the weight of the machine, the weight of the maximum

load, plus a safety factor. The floor must also be able to tolerate the stress of the

machine operation. If the truck will operate on the same weight bearing area, add

the weight of the trucks to the weight bearing stress tolerance requirement.

Figure 2

Page 7

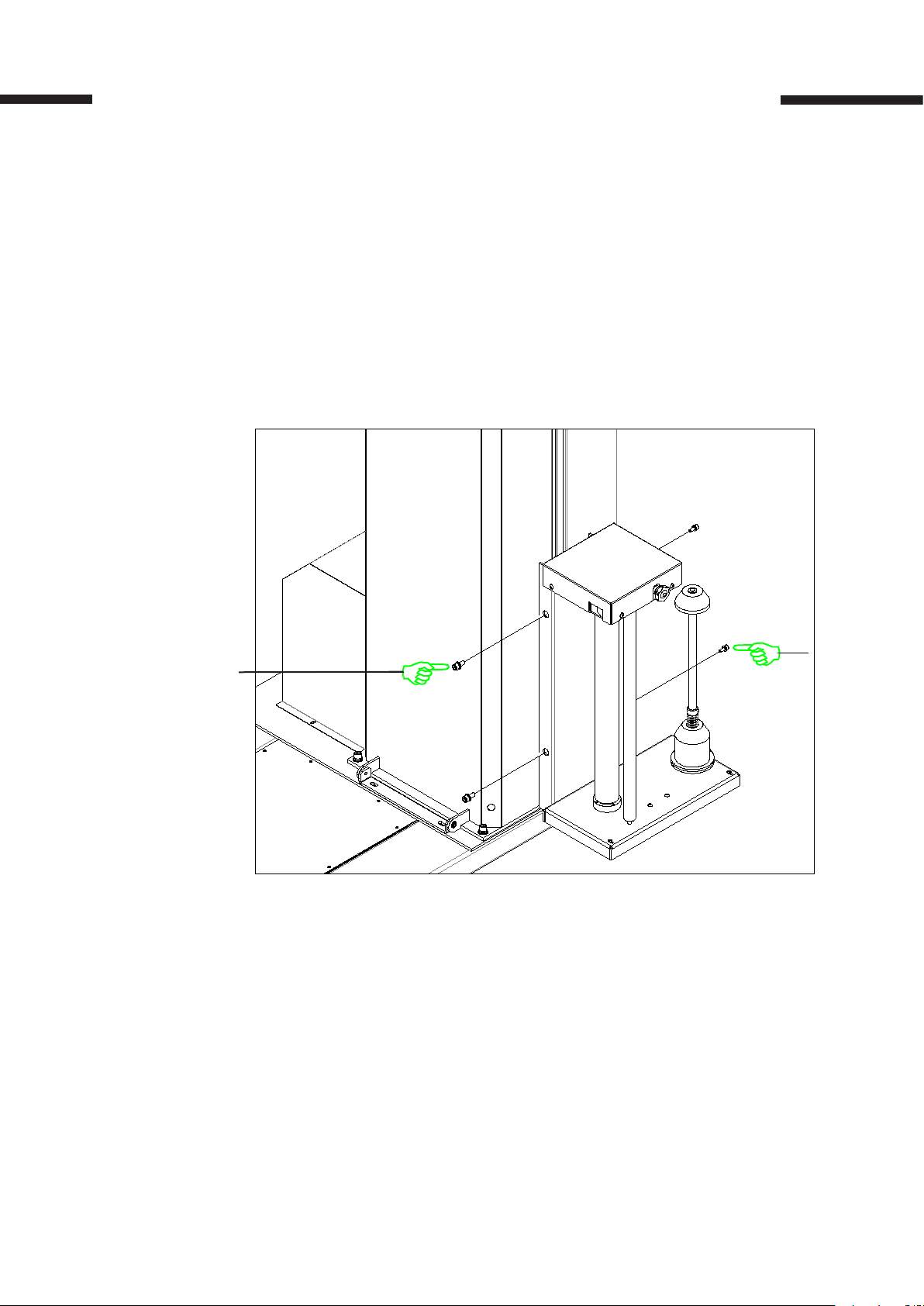

2.1 Machine Set-up

1. Place the crated machine close to the designated wrap area. Remove all shipping

fasteners holding the machine to the pallet. The machine may be crated with the tower

tilted down and the motor cover front carriage roller removed for shipping purpose.

2. Place forks of the forklift through the tubes provided at the rear base of the module,

remove the machine from the crate and place it at the designated wrap area.

3. Check all internal connections to ensure there is no loose/disconnected electrical

wiring,

4. Connect the motor wiring and sensor leads according to the corresponding wire

numbers.

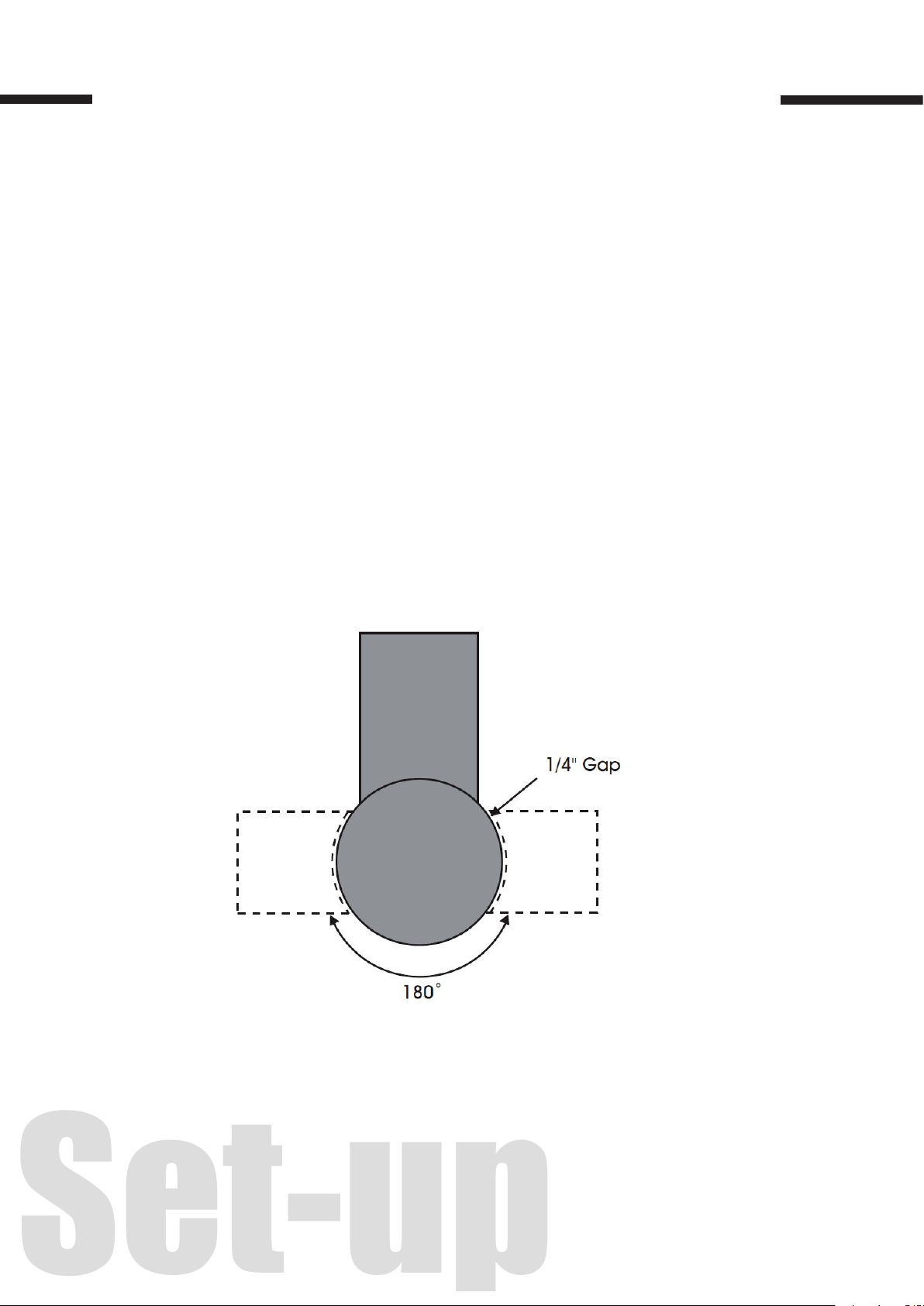

5. If the OPTIONAL ramp (Model no. 412410) is purchased: select a ramp position illus-

trated below. The ramp can be positioned anywhere in a 180 rotation around the front

of the turntable. There should be a ¼” gap between the turntable and the ramp. The

ramp should be fully supported by the oor. (See Figure 3)

7

Figure 3

Page 8

8

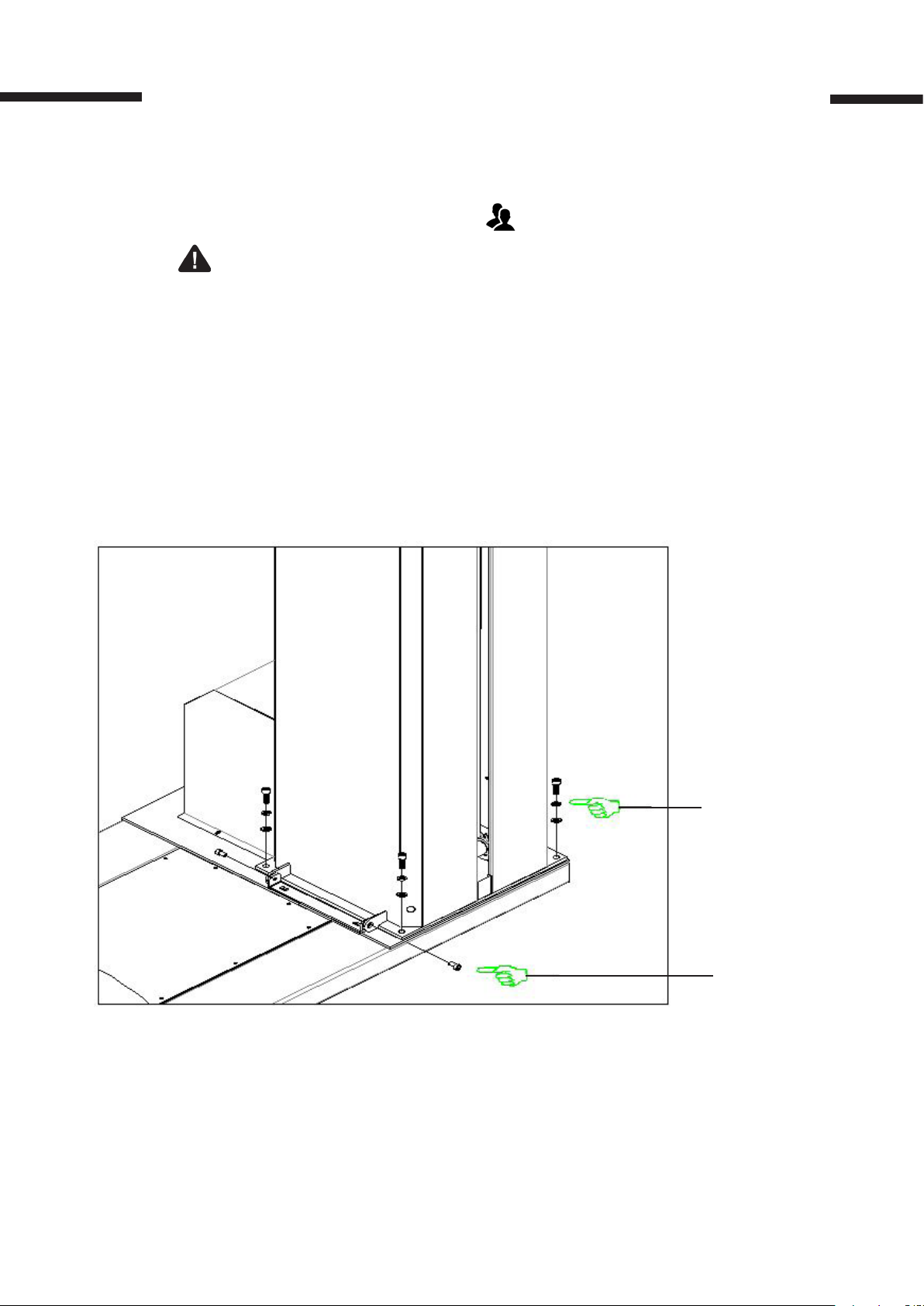

2.2 Installation

NOTE: Installation requires two people.

CAUTION

Be careful when standing on the turntable during the installation, as it may turn

when rotational force is applied.

1. Raise the tower upright safely with two people.

2. Tighten the screw between the tower and the turntable base. (See Figure 4)

3. Screw the lm carriage into the post. (See Figure 5)

4. Connect to the power supply and perform a ground test before using the machine.

Figure 4

Screw the set of (4)

screws, washers, and

lock washers through

the tower and into the

turntable base securely.

(M10 X 20 screw)

Screw the set of (2)

screws connecting the

tower and turntable.

(M8 x 10 screw)

Page 9

9

Mount the lm carriage

onto the post by fastening

a set of (2) screws.

( M8 x 20 screw)

Figure 5

Page 10

10

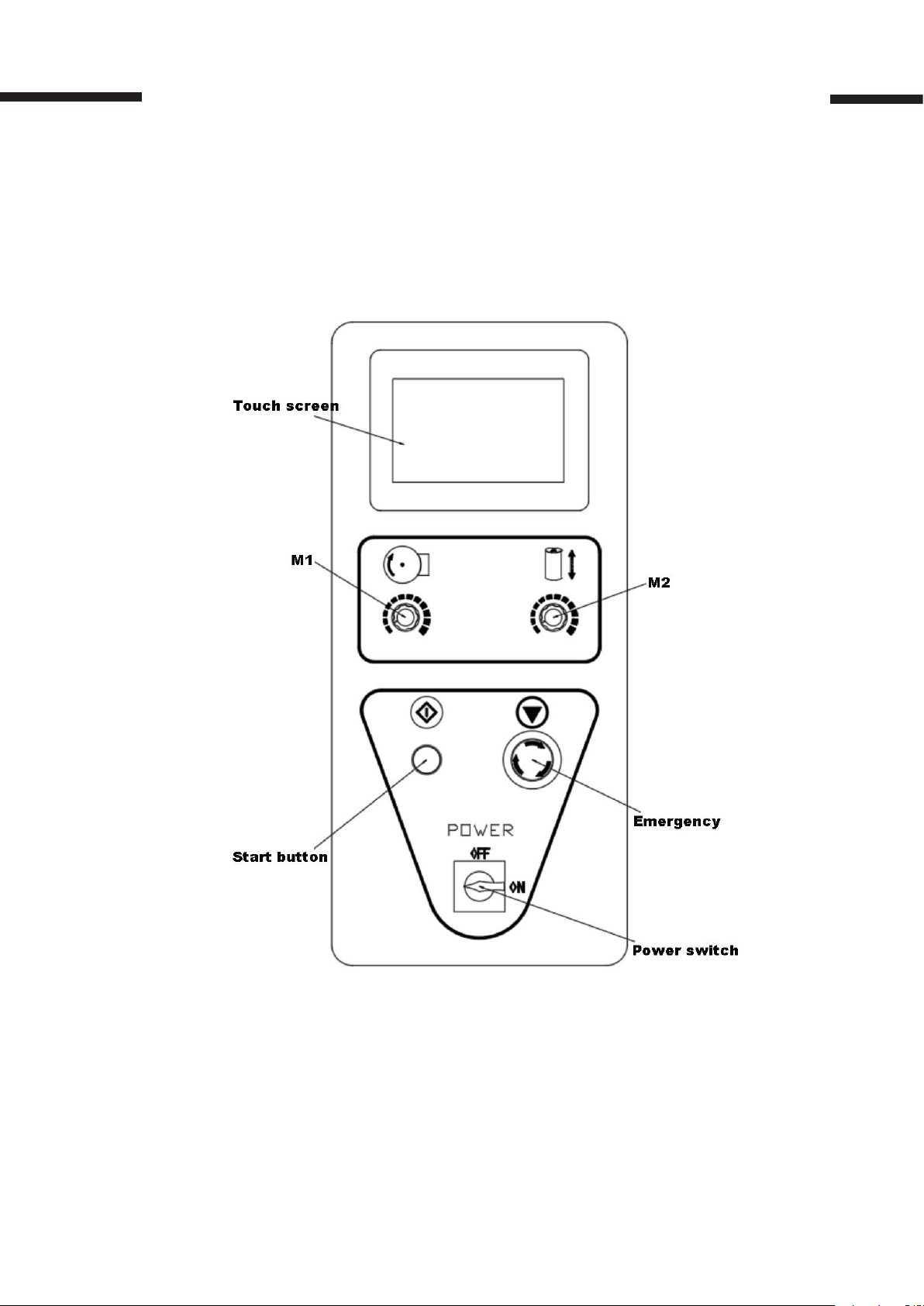

3. Control Panel Buttons

Figure 6

Control Panel Buttons

Page 11

Speed Controlled by M1, M2 Knob

• M1: Control the speed of the turntable motor. The speed range 1~ 10 rpm.

• M2: Control the lifting motor speed.

Start Button has three functions

• The start of the automatic mode starts

• Resume after emergency stop

• Use/cancel the central reinforcement

Emergnecy Stop Button

Press the emergency stop button to stop the machine immediately. Press the button when any emergency occurred during the packaging process. Turn the emergency stop button clockwise to reset the emergency stop button.

11

Power Switch

• OFF, power o the machine

• ON, power on the machine

Page 12

12

Operator Controls

4. Operator Controls

Figure 7 Main menu display

4.1 Manual

Press the manual Interface button in the main menu to display the manual operation.

(See Figure 8)

Carriage up / Carriage down

Manually operate the carriage to move up or down. When this function is pushed, the

button will turn green. To pause the operation, simply push the button again. This

button may be used in conjunction with the Turntable start button.

Turntable start

The Turntable Start button allows you to manually operate the turntable. When this

button is pushed, the button will turn green. Pushing the button again will stop the

turntable. The button may be used in conjunction with the Carriage up/down button.

Reset

Push the Reset button to reset the system operation. The turntable will return to its

home position and the carriage will lower to the initial position.

Page 13

Figure 8 Manual display

4.2 Auto

Press the AUTO button in the main menu to set parameters through the interface

shown in gure 9 .

13

The parameters can be set according to the following packaging requirements:

Bottoms Laps, Top Laps, Lifting Time, Strengthening Laps, and electric eye delay.

Press the white box to set each parameter through the pop-up numerical keyboard

followed by pressing the Enter button.

Once the parameters are set, click the “Save” button on the screen to store the parameters for the assigned group number. A total of ve sets of parameters can be

stored. To use any of the saved parameters, select the group number. (See Figure 9)

NOTE: The parameters and function settings cannot be changed when the machine

is running.

Figure 9 Auto display

Page 14

14

4.3 Input & Output (I/O)

You can check the status of all the sensors and switches on the I/O interface shown

in Figure 10. This display can be used for routine maintenance on the machine.

(See Figure 10)

To return to the main menu, press the EXIT button.

Figure 10 I/O display

4.4 Film Loading

CAUTION!

Be sure EMERGENCY STOP is pushed in before threading the lm and pulled out

when the lm is threaded.

1. Load the lm roll in the lm carriage. (See Figure 11)

2. Follow the lm feed diagram and thread the lm all the way through the rollers.

(See Figure 12)

3. Attach the lm securely to the pallet. Tying the end of the lm in a knot often helps

secure the lm to the pallet.

4. Turn the emergency stop switch clockwise and turn the power on.

Page 15

15

Figure 11

Figure 12

Page 16

16

4.5 Machine Operation

Trial run – Normal System Start-up:

1. Place the packaged pallet on the machine turntable.

2. Thread the lm as instructed and attach it to the product.

3. Turn the power on.

4. Adjust the sensitivity of the photo switch. The machine is adjusted to the factory

setting before delivery.

5. Select either Manual or Auto mode to achieve the user’s packaging requirement.

6. Press the START button to initiate cycle.

NOTE: It is recommendwd to try a trail run to become familiar with the various

parameters, adjustments, and speed controls.

Emergency Stop Condition

1. In the event of an emergency, press the STOP button. This cancels the current

wrapping cycle and immediately stops the system. Figure 13 will display on the

screen.

2. Correct the problem.

3. Turn the STOP button clockwise to reset the stop button and perform the normal

system start-up procedure.

NOTE: If the weight of the package exceeds 1,100lbs. , turn the turntable adjustment

knob M1 counterclockwise prior to pressing the emergency stop button.

Figure 13

Page 17

17

Operation

1. Load the lm roll in the lm carriage and thread the lm according to gure 12.

2. Turn the power on.

3. Adjust the sensitivity of the photo switch. The machine is adjusted to the factory setting

before delivery.

4. Adjust the parameter according to the packing requirements.

5. Trial run: Place the packaged pallet, used for a trial run, on the machine turntable.

Adjust M1 & M2 speed controlled knobs to the desired speed. Packaging operation can be

adjusted by the multiple parameters to achieve the user’s packaging requirement. Once

the user is familiar with the various parameters and adjustments, the user is ready to

operate the machine.

Page 18

18

Maintenance & Troubleshooting

5. Maintenance & Troubleshooting

CAUTION!

All machine maintenance work must be performed with the power supply

disconnected.

1. Keep the machine clean. Use a dry cloth and cleaning agent to clean the machine.

Do not use solvent water to clean the machine to prevent rusting.

2. Regularly perform maintenance on the machine every 3 – 6 months; frequency

varies with the machine usage. Check for internal dust build up. Check the tightness

of the chain and lubricate the chain in routine maintenance inspections.

WARNING!

Make sure that only qualied personnel perform inspection, troubleshooting and

part replacement.

CAUTION!

Disconnect all power, including external control power that may be present before

servicing the frequency drive controllers.

Page 19

19

OPERATING ISSUES CAUSES RECOMMENDATIONS

Table 2

The machine is

not powering on

Turntable does

not run.

Main Power is turned o.

Machine not plugged into

110VAC outlet.

Faulty power supply

Internal battery not charged.

PLC Failure

No display on PLC screen

Fuse Burn Replace the fuse

Pallet overweight Reduce the pallet weight

Chain falls o

Loose chain

Check the power going into the machi-

ne. Verify that the switch is turned on.

Verify the voltage going to the machine

matches the power supply labels on the

power module.

Replace new PLC

Check the chain transmission mechanisn (loosen the chassis screws, remove

the turntable cover and check wheather

the chain and tension are abnormal.

Film carriage

malfunction

The output protection of the inverter

will ash the fault code on the inverter.

Inverter failure or damage

Limit switch failure or damage Overhaul or replace the limit switch

Photocell failure or damage Overhaul or replace the photocell

Loose chain or interference

PLC Failure

Carriage Up/Down button is

unresponsive

Inverter failure or damage

Motor Failure Overhaul the lifting motor

Look up the corresponding fault code and

troubleshoot method. Replace inverter if

damaged.

Overhaul the vertical lifting chain

system

Replace the PLC

Troubleshoot and replace inverter if

damaged

Page 20

20

Components & Parts

6. Components & Parts

Turntable

Figure 14

Page 21

Table 3

Turntable

No. Part no. Description Qty.

1 GB/T825 Hook M10 1

2 GB/T70.3 Hex scew M10x25 3

3 10000000510 Disc 1

4 GB/T70.2 Hex at cap head screw M5 x 10 4

5 XT4505-0126 Protection cover 1

6 GB/T70.1 Hex screw M10x50 4

7 10000000486G Motor chain pulley: 12B, 14 teeth 1

21

8 CV-32-750-30S Gear motor 1

9 GB/T1243 Chain: 12B, 174 keys 1

10 10000000695 Chain noise reducer 2

11 XT45N-0110 Switch holder 1

12 PL-O5PN Switch 1

13 XT4505-0129-V1 Tension pulley: 12BZ11 1

14 XT4505-0135-V1 Protection cover support block 1

15 10000000693 Center turntable pulley 1

16 10010000617 Turntable roller 12

17 8020-0506 Motor base 4

18 10000000698 Tension pulley bracket 1

Page 22

22

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

18

19

20

21

22

23

24

25

26

17

Film Carriage

Figure 15

Page 23

Table 4

Film Carriage

No. Part No. Description Qty.

1 XT15Z-02-V2 Bottom xed plate assembly 1

2 XT45M-19 Film roll: welding assembly 1

3 10000000033 Film roll: bottom seat 1

4 10000000035-VI Spring plate 1

5 10000000030 Spring 1

6 20545000404-V1 Lock ring 1

7 10000000034 Film roll: top seat 1

8 XT45Z-06-V1 Rubber roller unit 1

9 GB/T1096 6*6*25 key 1

10 GB/T276 Bearing 6004 2

23

11 XT45M-12-V3 Rubber roller bearing seat 2

12 XT4508A-0205 Lock sleeve 1

13 XT45Z-010-V2 Film carriage top plate 1

14 XT45Z-11-V1 Brake shaft 1

15 XT45Z-11-1 Rubber belt 218L*12W*2T mm 1

16 XT45Z-03-V1 Top lm carriage cover 1

17 XT45Z-09 Shaft lock ring 1

18 10000000046 Tension friction wheel 1

19 XT45Z-10-V1 Belt holder 1

20 FR-2MX Photocell 1

21 M8X20 Star knob 1

22 XT45M-14 Guide roller 2

23 XT45Z-16 Swith install plate 1

24 KW3-0Z-2 Microswitch w/ wheel 1

25 QB/T3876 Hinge: 50 x 38 2

26 XT45Z-15-V3 Safety plate 1

Page 24

24

18

19

22 23 24

15

16

2120

17

14

26

28

27

13

30

29

313233

1

4

5

6

7

8

9

10

11

12

2

3

34

25

Tower and Lift

Figure 16

Page 25

Table 5

Tower and Lift Assembly

No. Part No. Description Qty.

1 XT45O5-0201-V2 Tower body 1

2 Z15G 1703 15A Door safety switch 1

3 XT45O5-0206 Z type holder 1

4 XT4505-0204 Tower body top cover 1

5 XT45O5-0203 Tower body top protection plate 1

6 XT4515-02-002 Door 1

7 Locker 2

8 HMIGXU3500 Touch screen (Schneider) 1

25

9

10 HB1-BA31 Start button 1

11 HB2-BS542 Emergency stop switch 1

12 TCS4S295 Power switch 1

13 10000000549 Lifting motor chain wheel: 14 teeth 2

14 08B P12.7 Chain 08B (12.7), 314 joint 2

15 GB/T893.1 D35 Locking ring 35 2

16 GB/T276 Bearing: 6202-zz 2

17 XT4505S-0113 Chain wheel: 08b 14 teeth 2

18 XT4505S-0110-V2 Electrical housing 1

19 XT4505S-0115-V2 L Channel bracket 1

20 XT4505S-0105 Electrical component storage 1

21 XT4505S-01-17-V2 Bottom limit switch seat 1

22 TZ-8108 Limit switch 2

RV24YN 20S B502 +

MF-A03

Potentiometer + Knob 3

23 XT4505S-010702-V4 Inner tower assembly 1

24 XT4505S-0104 Guide rail 2

25 XT4505S-0103G Sliding block 4

26 XT4505S-0102-V1 Drive shaft 1

27 XT4505S-0109-V1 Connection board assembly 1

28 XT4505S-0111 Screw 4

29 GB/T1095 Key 6*6*25 2

30 XT4505S-0101 Shaft 1

31 XT4505S-0108 Top lifting board 1

32 XT4505S-010701 Motor seat 1

33 NMRV050 Lifting assembly 1

Page 26

26

Electrical Components

Figure 17

Page 27

Table 6

Electrical Floor Components

No Part no. Description Qty.

1 RT18-32,2P,16A,Fuse 10X38 Circuit Breaker 2

2 RT18-32,1P,2A,Fuse 10X38 Circuit Breaker 1

3 LRS-50-24 Switch power 1

4 218LDA24DRN PLC 1

5 ATV12H075M2 Turntable inverter 1

27

6 ATV12H037M2 Lifting inverter 1

8 Z15G1703 Safety Switch 1

9 30 port Terminal block 1

Page 28

28

Electrical Diagram

Page 29

29

Diagram 1

Page 30

30

Power Supply: AC110V, 60 Hz

Page 31

31

Diagram 2

Page 32

Loading...

Loading...