Page 1

Page 2

Page 3

Page 4

Page 5

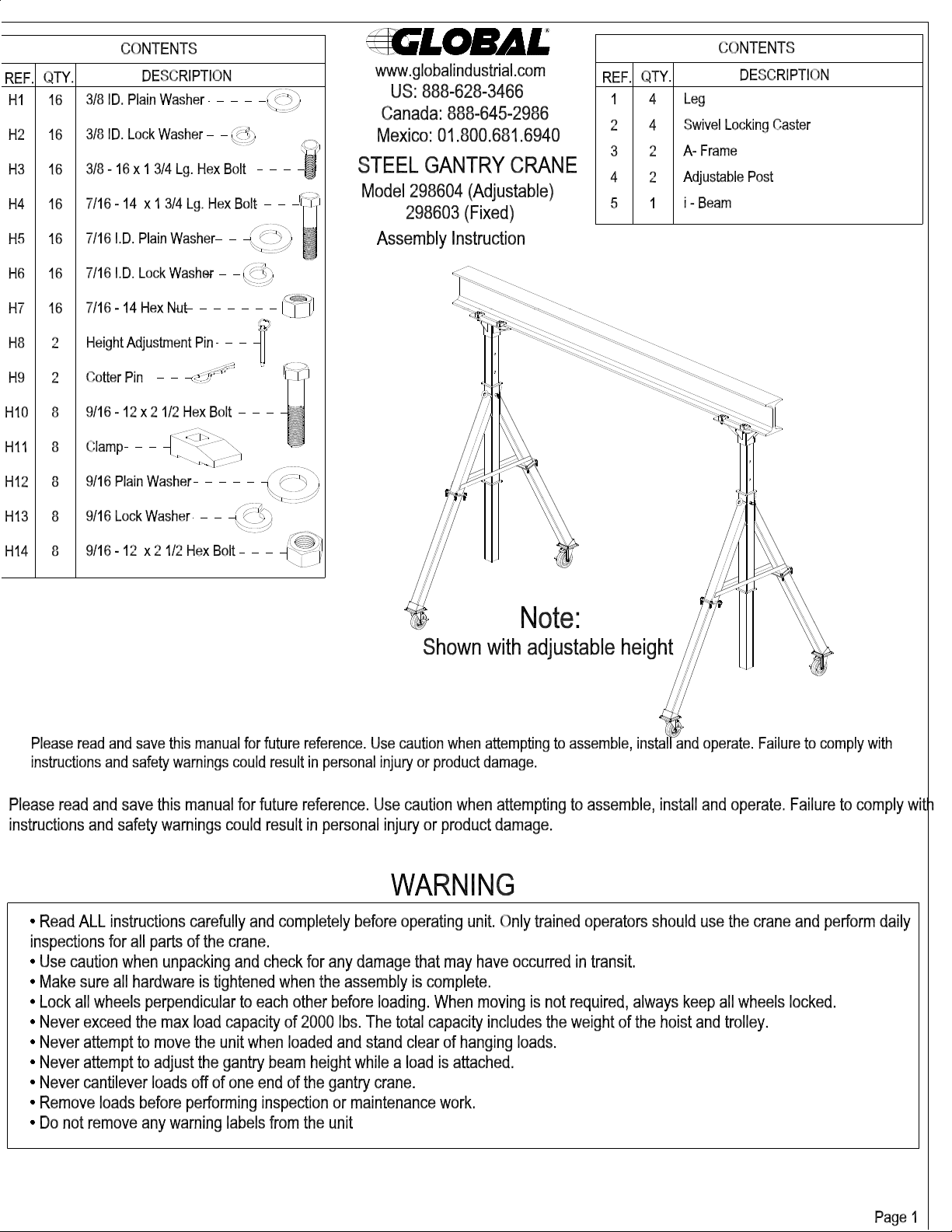

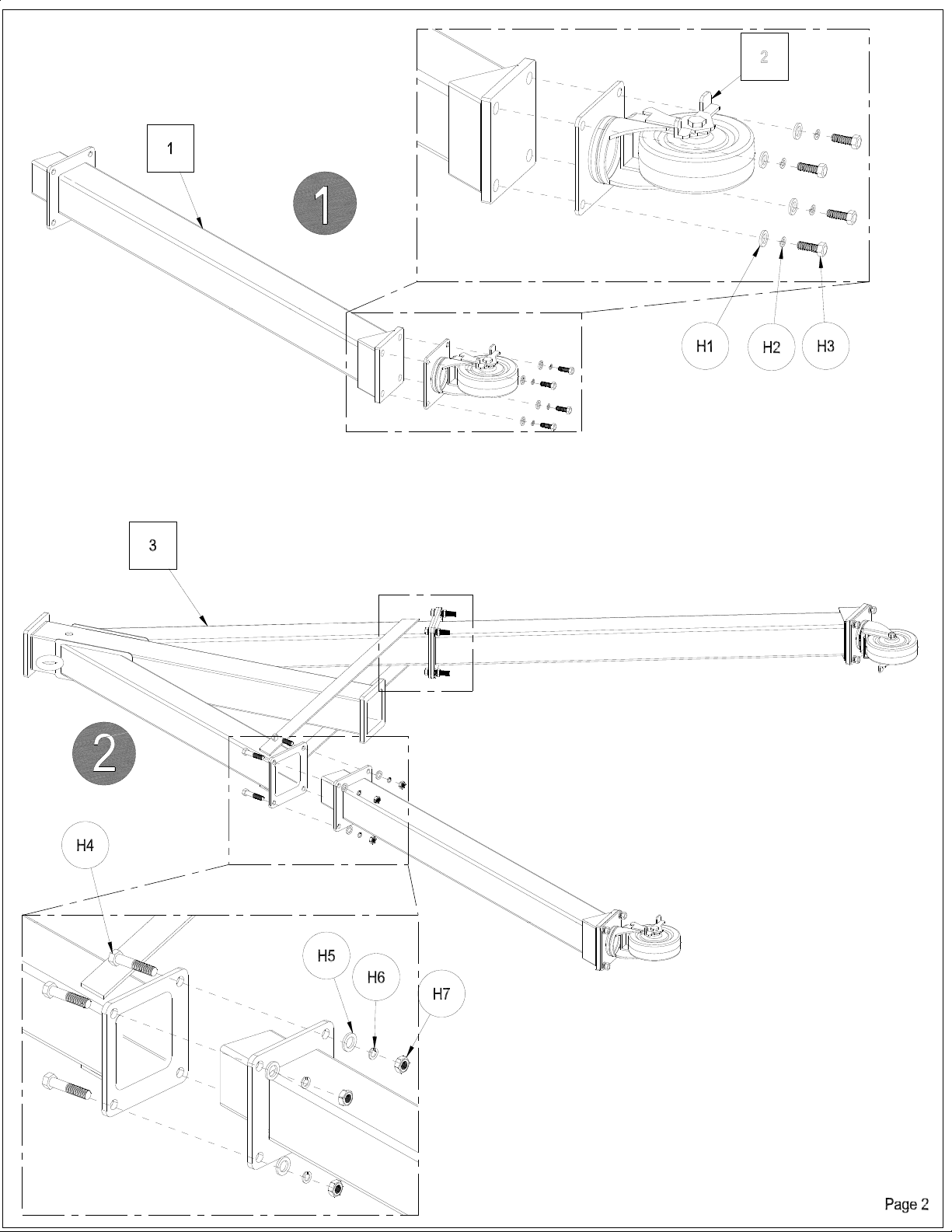

Steel Gantry Crane

Assembly Instructions

Inspection Guidelines – OSHA Regulations 1910.179

1910.179(j)(1) - Inspection Classification

• 1910.179(j)(1)(i) - Initial inspection. Prior to initial use all new

and altered cranes shall be inspected to insure compliance with

the provisions of this section.

• 1910.179(j)(1)(ii) - Inspection procedure for cranes in regular

service is divided into two general classifications based upon the

intervals at which inspection should be performed. The intervals

in turn are dependent upon the nature of the critical components

of the crane and the degree of their exposure to wear,

deterioration, or malfunction. The two general classifications are

herein designated as "frequent" and "periodic" with respective

intervals between inspections as defined below:

• 1910.179(j)(1)(ii)(a) - Frequent inspection - Daily to

monthly intervals.

• 1910.179(j)(1)(ii)(b) - Periodic inspection - 1 to 12-month

intervals.

1910.179(j)(2) - Frequent Inspection

The following items shall be inspected for defects at intervals as

defined in paragraph (j)(1)(ii) of this section or as specifically indicated,

including observation during operation for any defects which might

appear between regular inspections. All deficiencies such as listed

shall be carefully examined and determination made as to whether

they constitute a safety hazard:

• 1910.179(j)(2)(i) - All functional operating mechanisms for

maladjustment interfering with proper operation. Daily.

• 1910.179(j)(2)(ii) - Deterioration or leakage in lines, tanks,

valves, drain pumps, and other parts of air or hydraulic systems.

Daily.

• 1910.179(j)(2)(iii) - Hooks with deformation or cracks. Visual

inspection daily; monthly inspection with a certification record

which includes the date of inspection, the signature of the person

who performed the inspection and the serial number, or other

identifier, of the hook inspected. For hooks with cracks or having

more than 15 percent in excess of normal throat opening or

more than 10° twist from the plane of the unbent hook refer to

paragraph (l)(3)(iii)(a) of this section.

• 1910.179(j)(2)(iv) - Hoist chains, including end connections,

for excessive wear, twist, distorted links interfering with proper

function, or stretch beyond manufacturer's recommendations.

Visual inspection daily; monthly inspection with a certification

record which includes the date of inspection, the signature of

the person who performed the inspection and an identifier of the

chain which was inspected.

• 1910.179(j)(3)(v) - Excessive wear on brake system parts,

linings, pawls, and ratchets.

• 1910.179(j)(3)(vi) - Load, wind, and other indicators over their

full range, for any significant inaccuracies.

• 1910.179(j)(3)(vii) - Gasoline, diesel, electric, or other

powerplants for improper performance or noncompliance with

applicable safety requirements.

• 1910.179(j)(3)(viii) - Excessive wear of chain drive sprockets

and excessive chain stretch.

1910.179(j)(3) - Periodic Inspection

Complete inspections of the crane shall be performed at intervals

as generally defined in paragraph (j)(1)(ii)(b) of this section,

depending upon its activity, severity of service, and environment, or

as specifically indicated below. These inspections shall include the

requirements of paragraph (j)(2) of this section and in addition, the

following items. Any deficiencies such as listed shall be carefully

examined and determination made as to whether they constitute a

safety hazard:

• 1910.179(j)(3)(i) - Deformed, cracked, or corroded members.

• 1910.179(j)(3)(ii) - Loose bolts or rivets.

• 1910.179(j)(3)(iii) - Cracked or worn sheaves and drums.

• 1910.179(j)(3)(iv) - Worn, cracked or distorted parts such

as pins, bearings, shafts, gears, rollers, locking and clamping

devices.

4

021317

Loading...

Loading...