Page 1

Blower HeElectric

Models: 653561 653560 6535

653558 653562 246067

g

globalindustrial.ca

Assembly Instructions Instrucciones de Ensambla

Customer Service

US: 1-800-645-2986

Servicio de atención al Clien

México: 01.800.681.6940

DE CFDistribucion Industrial Globales S DE RL

ectives d’assemblageDir

Service à la clientèle

Canada: 888-645-2986

THESE

050117

1

READ & SAVE

INSTRUCTIO

Wall Mount Models: 653566 653567 653568

653569 246068

HVLS BLDC Fan

READ & SAVE THESE

INSTRUCTIONS

Models:293042 293043 293044

293045 and 293046

Page 2

HVLS BLDC Fan

User’s Manual

2

GENERAL SAFETY INSTRUCTIONS

Read instructions carefully before assembling or installing

your fan. It is important that you observe all safety information

to help prevent personal injury and/or property damage.

TO REDUCE THE RISK OF SHOCK, THIS FAN

MUST BE INSTALLED WITH A GENERAL USE

ISOLATING WALL CONTROL/SWITCH.

1.Installation work and electrical wiring must be performed in

accordance with the requirement of NEC and CEC by

authorized personal only.

2.All wiring and installation procedures must satisfy National

Electrical Codes (ANSI/ NFPA 70) and Local Codes.

3.Use this fan only in the manner intended by the manufacturer.

This fan is intended for permanent installation and to be used

for circulation only.

4.The secondary support cable included with the fan must be

properly connected.

5.To Reduce The Risk Of Personal Injury, Do Not Bend The Blade

Brackets When Installing The Brackets, Balancing The Blades,

Or Cleaning The Fan. Do Not Insert Foreign Objects In Between

Rotating Fan Blades..

6.Before servicing or cleaning unit, switch power off at service

panel and lock service panel disconnecting means to prevent

power from being switched on accidentally. When the service

disconnecting means cannot be locked, securely fasten a

warning device, such as a tag, to the service panel.

7.Be careful of the fan and blades when cleaning, painting, or

working near the fan. Always turn off the power to the ceiling

fan before servicing.

8.Ceiling fans without guards are to be installed at least 3.05

Meters (10 Feet) above the floor with adequate clearance

between blades and adjacent walls, furnishings, etc.

9.When mounted in cathedral ceiling, blade tips should be at least

1 foot from the angled roof line or air turbulence may cause the

fan to sway.

10.The supporting beam must be capable of holding at least

600 KGS.

11.All set screws must be checked, and retightened where

necessary, before installation.

To Reduce The Risk Of Personal Injury, Do

Not Bend The Blade Brackets When Installing

The Brackets, Balancing The Blades, Or

Cleaning The Fan.

To Reduce The Risk Of Fire Or Electric Shock,

Do Not Use This Fan With Other Types Of

Solid-State Speed Control Devices.

Disconnect the fan from the power supply

before any servicing.

Do not insert foreign objects in between

rotating fan blades.

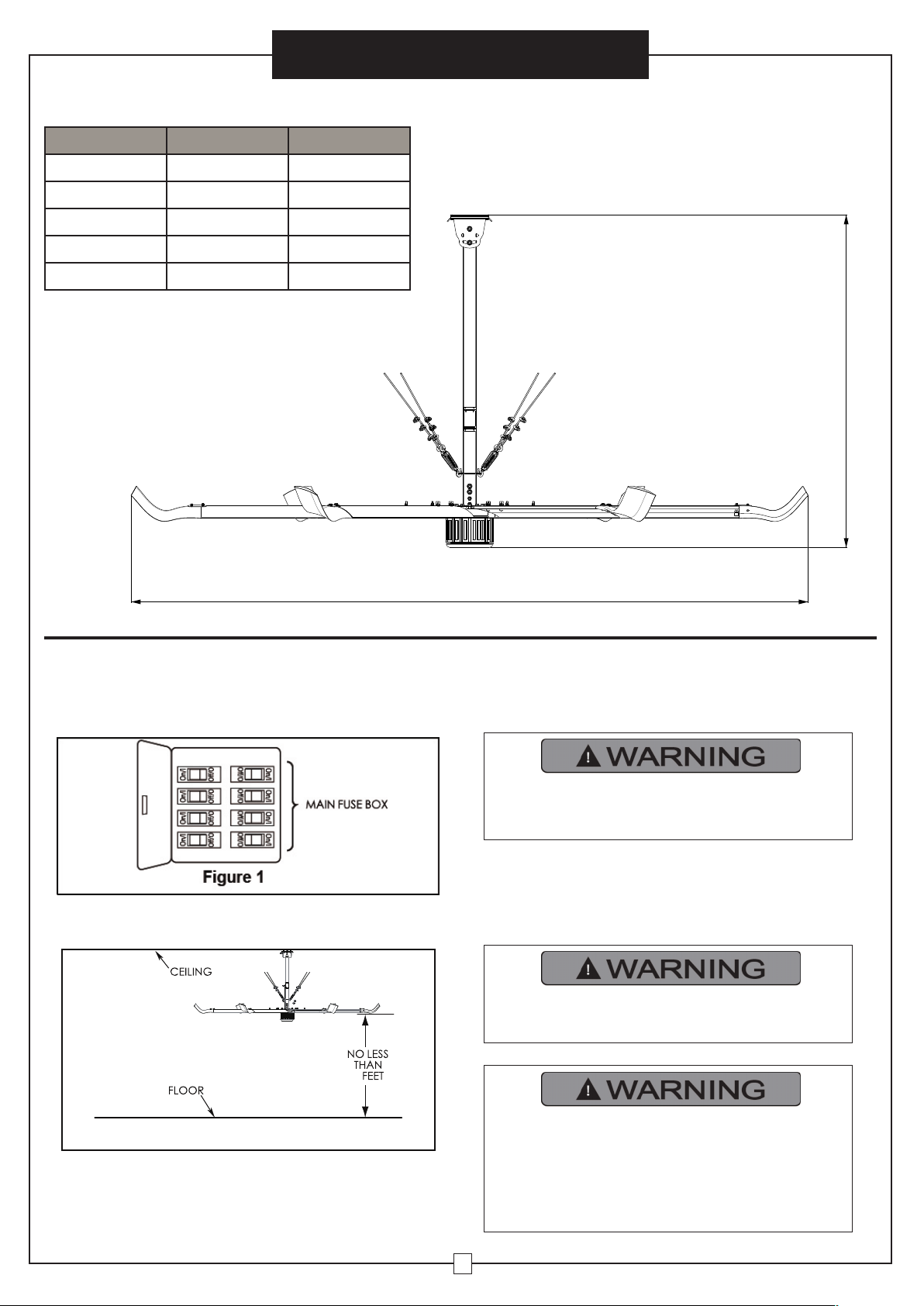

Model 293042 293043 293044 293045 293046

Size(ft) 12 14 16 18 20

Voltage(V) 240 240 240 240 240

Frequency(Hz) 60 60 60 60 60

Wattage(W) 680 600 820 930 810

RPM 20-88 20-65 20-78 20-65 20-55

AMPS(A) 4.8 4.3 5.7 6.3 5.6

Hanger Rod Dimensiond(inch) 20 20 60 60 60

Blades 6 6 6 6 6

Net Weight(KG) 75 78 115 118 123

Certification UL,cUL UL,cUL UL,cUL UL,cUL UL,cUL

SPECIFICATION

For commercial and industrial use only !

Page 3

HVLS BLDC Fan

User’s Manual

3

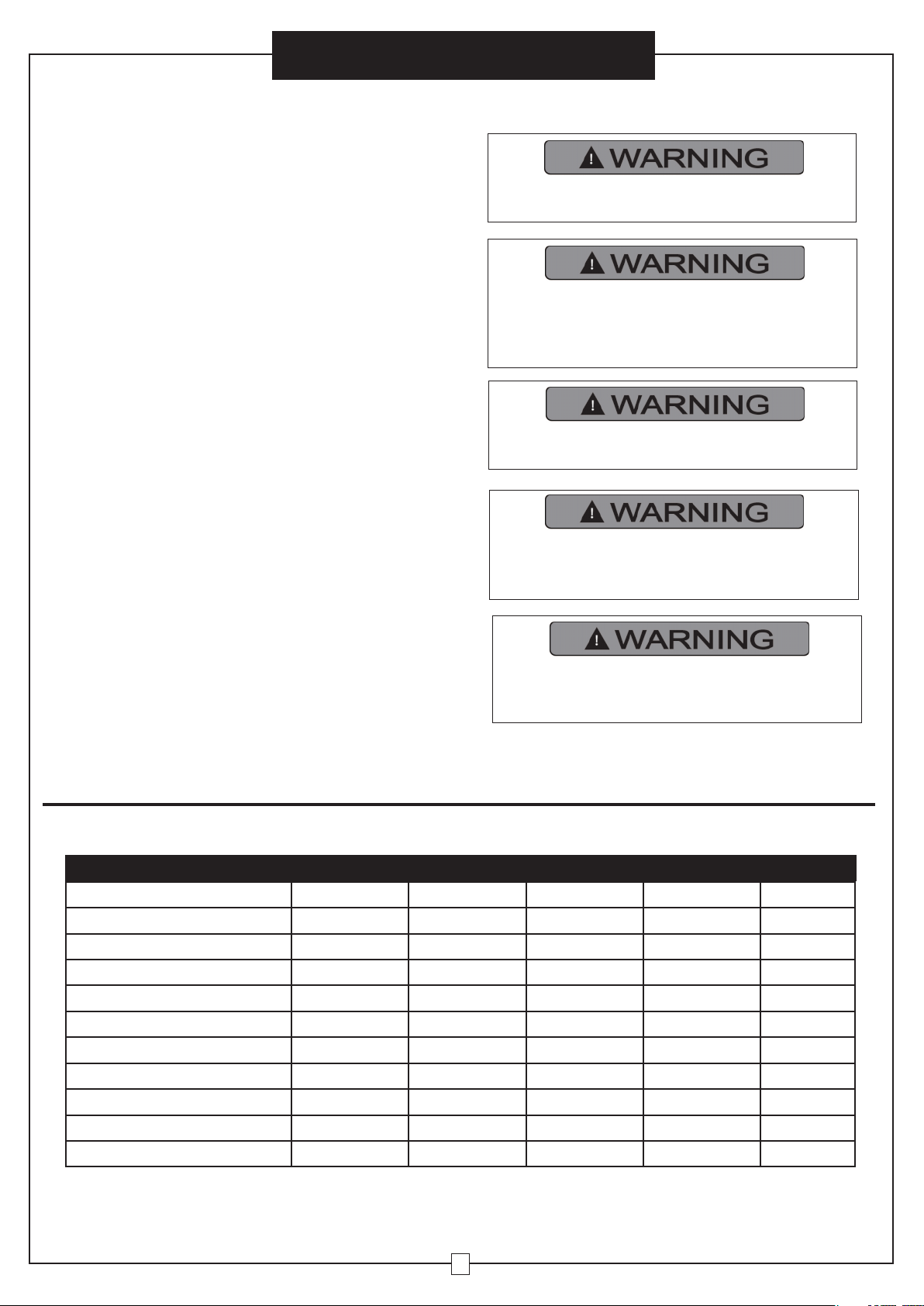

REF QTY DESCRIPTION

1 1 I-Beam Mounting Bracket

2 2 I-Beam Mounting Spacer 1

3 2 I-Beam Mounting Spacer 2

4 1 Hanger Rod

5 1 Fan Blade Holder

6 1 Motor Hanger Assembly

7 1 Motor

8 6 Fan Blade

9 6 Fan Blade Cap

10 6 Fan Blade Safety Gasket

11 1 Motor Cap

12 6 Fan Blade Cap Spacer

13 1 Control Box

1

2

3

4

6

5

8

7

11

9

12

13

10

PARTS OF THE FAN

OVERLOAD

PROTECTION

PRESS TO

RESET

SPEED

OFF

REV

FWD

ON

Page 4

HVLS BLDC Fan

User’s Manual

4

H1

H2

H3

H4

H5

H6

H8

H9

H13

H14

H15

H16

H17

H18

H19

H20

H21

H22

H23

H24

H7

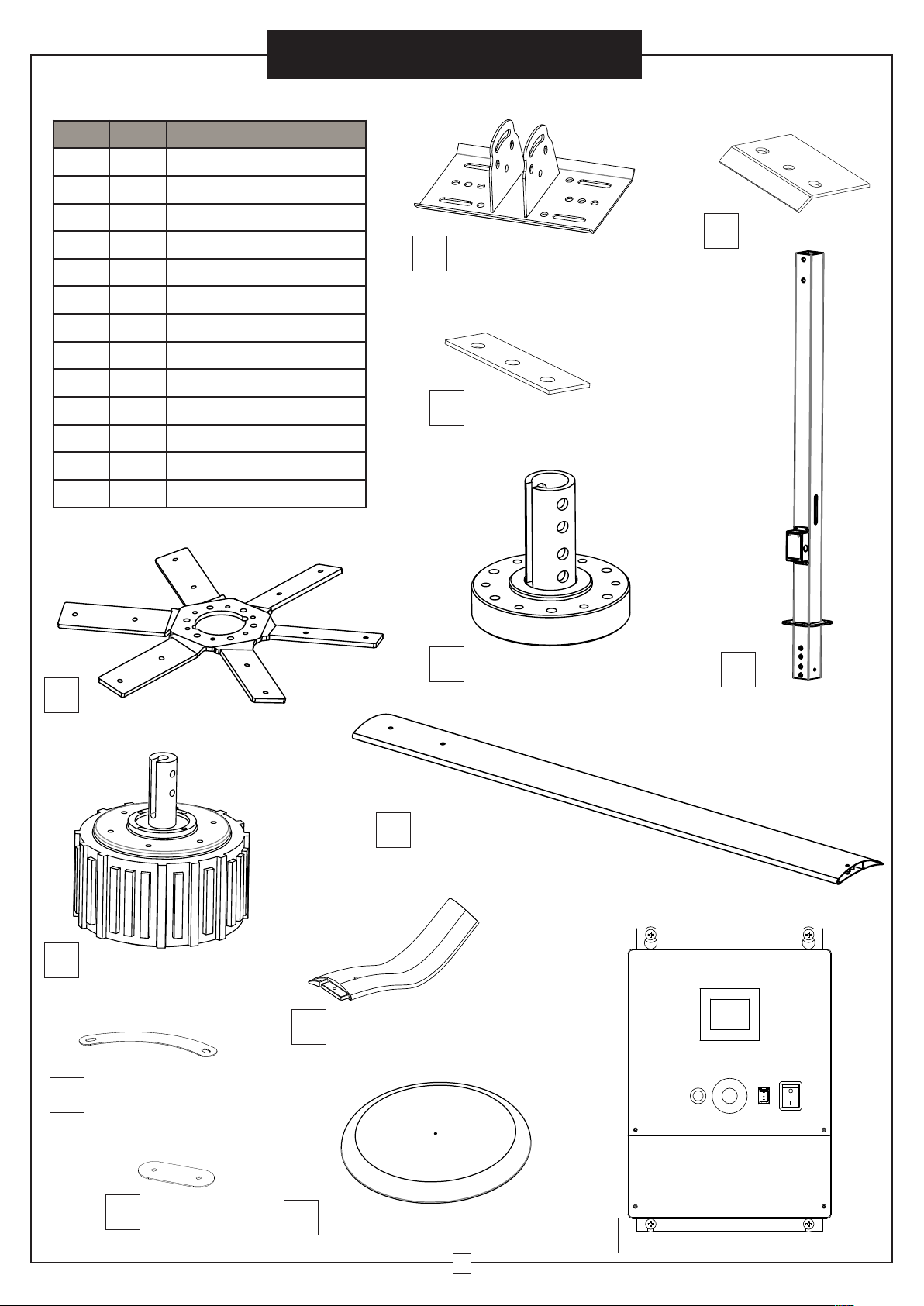

REF QTY DESCRIPTION

H1 1 4x16AWG Interconnecting Cord

H2 5 Safety Steelcable Ф6mmx10m

H3 4 Turnbuckle

H4 30 Steelcable lock

H5 6 Hex Screw M14x50mm

H6 6 Hex Screw M12x50mm

H7 2 Hex Socket Screw M14x120mm

H8 2 Hex Socket Screw M14x100mm

H9 2 Hex Socket Screw M12x90mm

H10 6 Hex Screw M8x70mm

H11 12 Hex Screw M8x45mm

H12 12 Hex Screw M6x35mm

H13 20 Flat Washer 14mm

H14 6 Flat Washer 12mm

H15 30 Flat Washer 8mm

H16 12 Flat Washer 6mm

H17 4 Spring Washer 14mm

H18 6 Spring Washer 12mm

H19 6 Spring Washer 8mm

H20 4 14mm Nut

H21 6 Self-tapping Nut 14mm

H22 2 Self-tapping Nut 12mm

H23 12 Self-tapping Nut 8mm

H24 12 Self-tapping Nut 6mm

H25 4 Plastic Anchor

H26 4 Screw ST4.2x50mm

PARTS OF THE FAN

H25 H26

H12

H11

H10

Page 5

User’s Manual

5

HVLS BLDC Fan

Dimensions(inch)

Model D H

293042 144 32

293043 168 32

293044 192 73

293045 216 73

293046 240 73

INSTALLATION INSTRUCTIONS

To avoid possible electrical shock, be sure

electricity is turned off at the main fuse box

before hanging. (Figure 1)

NOTE: If you are not sure if the outlet box is grounded,

contact a licensed electrician for advice, as it must be

grounded for safe operation.

The fan must be hung with at least 10´

of clearance from floor to blades. (Figure 2)

To Reduce The Risk Of Fire, Electric Shock,

And Injury To Persons, Ceiling-Suspended

Fan Must Be Installed With Blades That Are

Marked On Their Cartons To Indicate The

Suitability With This Model. Other Blades

Cannot Be Substituted.

H

D

Figure 2

10

Page 6

User’s Manual

6

HVLS BLDC Fan

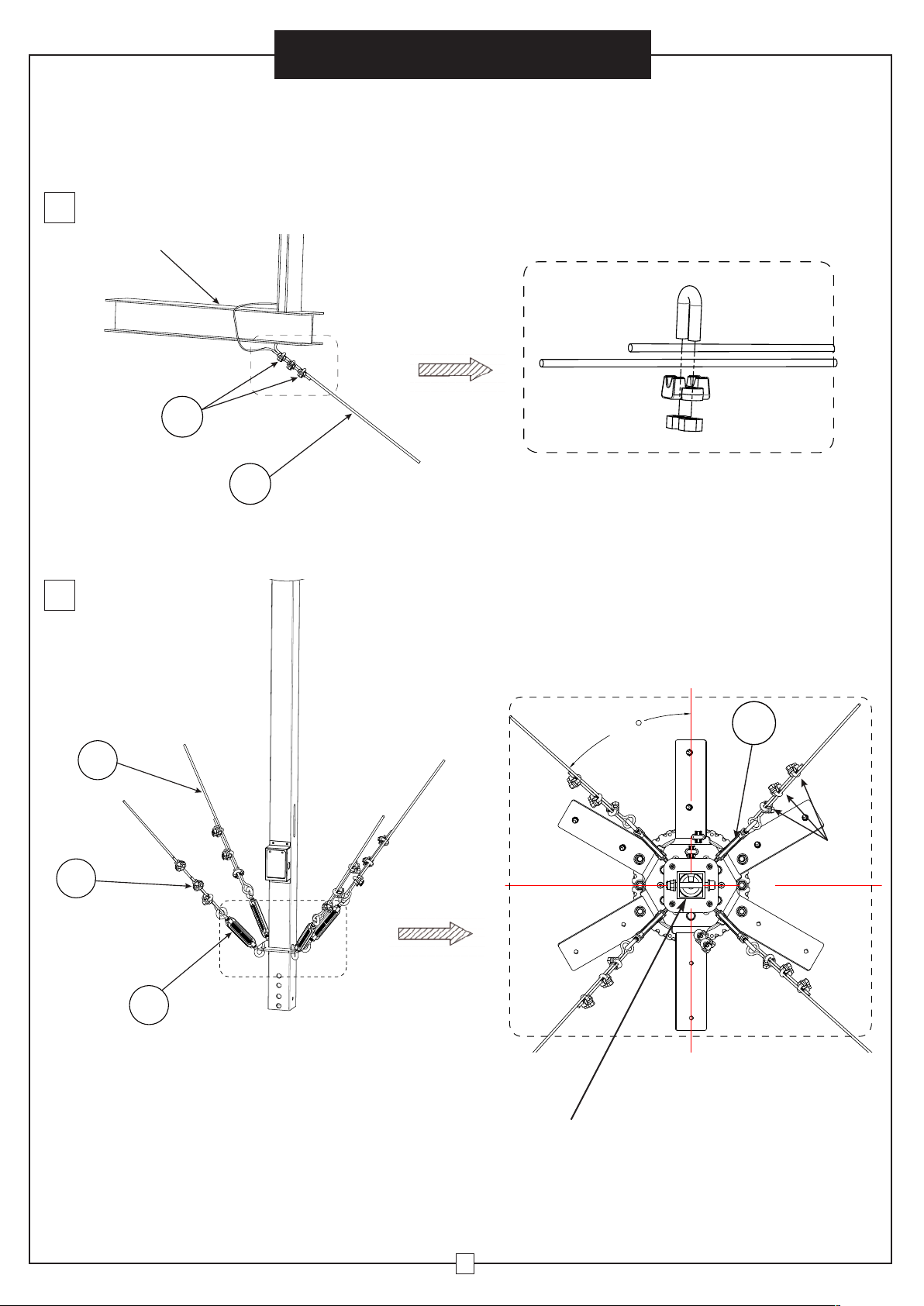

1. Loosen the 12 screws and washers which on the motor hanger

assembly.

2. Install the fan blade holder to the motor assembly with screws

and washers as below picture, make sure tighten all the screws

and washers.

Screws and washers must be installed in pairs.

(H10)M8x70mm Screw must be installed with (H19) 8mm spring

washer and (H15) 8mm flat washer.They should be tighten with

36N.M torgue.

(H6)M12x50mm Screw must be installed with (H18) 12mm

spring washer and (H14) 12mm flat washer.They should be

tighten with 135N.M torgue.

3. Install the I-Beam mounting bracket to the I-Beam with the IBeam mounting spacer 1&2 to the (H20) 14mm nuts, (H21) 14mm

Self-tapping Nut, (H17)14mm Spring Washer, (H13) 14mm flat

washer and (H5) M14x50mm screw, make sure all the screws and

washers are tighten with 135N.M torgue.

4. Install the hanger rod to the mounting bracket with (H7)

M14x110mm screws, (H13)14mm flat washers and (H21)14mm

self-tapping nuts.

H10

H19

H15

H6

H18

H14

H20

H17

H13

H21

3

2

H13

H5

H21

H7

1

5

H10

H19

H15

H6

H18

H14

H13

H13

4

Page 7

User’s Manual

7

HVLS BLDC Fan

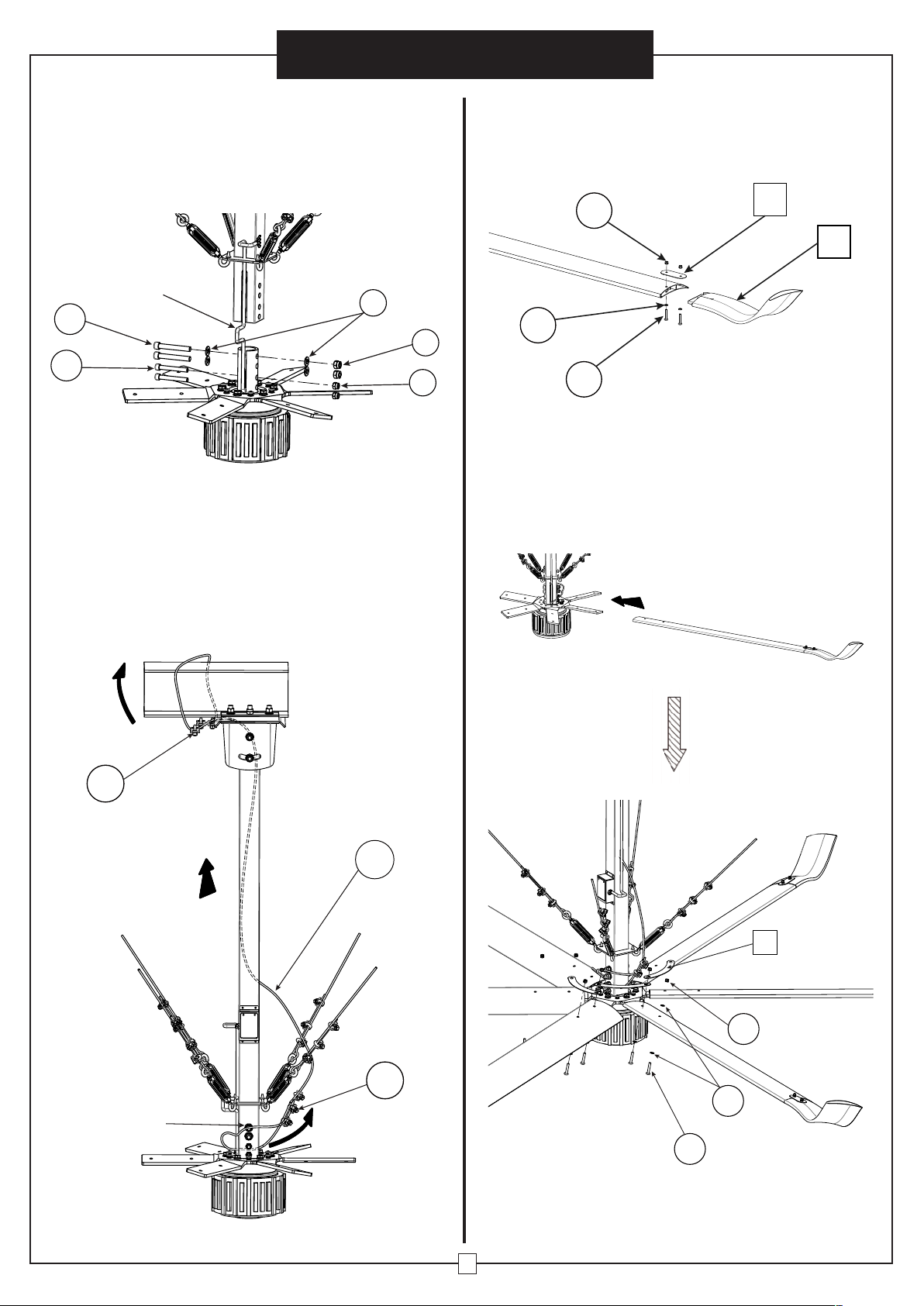

Reliable Fixing Structure

A

5.A.Encircle one end of the (H2) steel cable around the reliable fixing structure, then attach 3 (H4) steel cable lock onto the

cable for secure installation.

B.Hook the (H3) turnbuckle to the holes in the sheet of hanger rod , and connect the other end of the (H2) safety steel cable.

Attach the (H4) steel cable lock onto the cable for secure installation. Repeat step A and B, install all 4 steel cable.

B

Sheet of the

hanger rod

Loosen the nuts of the (H4) steel cable lock, attach

onto the cable and tighten them.

H4

H4

H2

H2

45

H3

H4

H3

Page 8

User’s Manual

8

HVLS BLDC Fan

6. Pass the motor lead wire through the slot of the hanger rod, and

tighten the motor assembly to the hanger rod with (H8)

M14x100mm screw, (H9) M12x90mm screw, (H13) 14mm flat

washer, (H21) 14mm self-tapping nut and (H22) 12mm

self-tapping nut.

Motor Lead

Wire

7.Pass the (H2) safety steel cable through the motor safety hole,

encircle one end of cable , and attach the (H4) steel cable lock

onto the cable for secure installation.

Pull the other end of the steel cable into the center hole of the

hanger rod and out through the hanger rod , encircle the cable

around the I-beam, and then attach the (H4) steel cable lock

onto the cable for secure installation.

8.Install the fan blade cap and fan blade cap spacer to the fan

blade with (H12) M6x35mm screw , (H16) 6mm flat washer and

(H24) 6mm self-tapping nut. Repeat this step for all 6 fan blades.

9. Install all the fan blade assembly to the fan blade holder. Then

place the fan blade safety gasket (10) onto the fan blade side by

side, align the screw holes and tighten with (H11) M8x45mm

screws, (H15) 8mm flat washer and (H23) 8mm self-tapping nut.

Motor Safety

Hole

H8

H9

H13

H21

H22

H24

12

9

H16

H12

H4

H2

10

H23

H4

H15

H11

Page 9

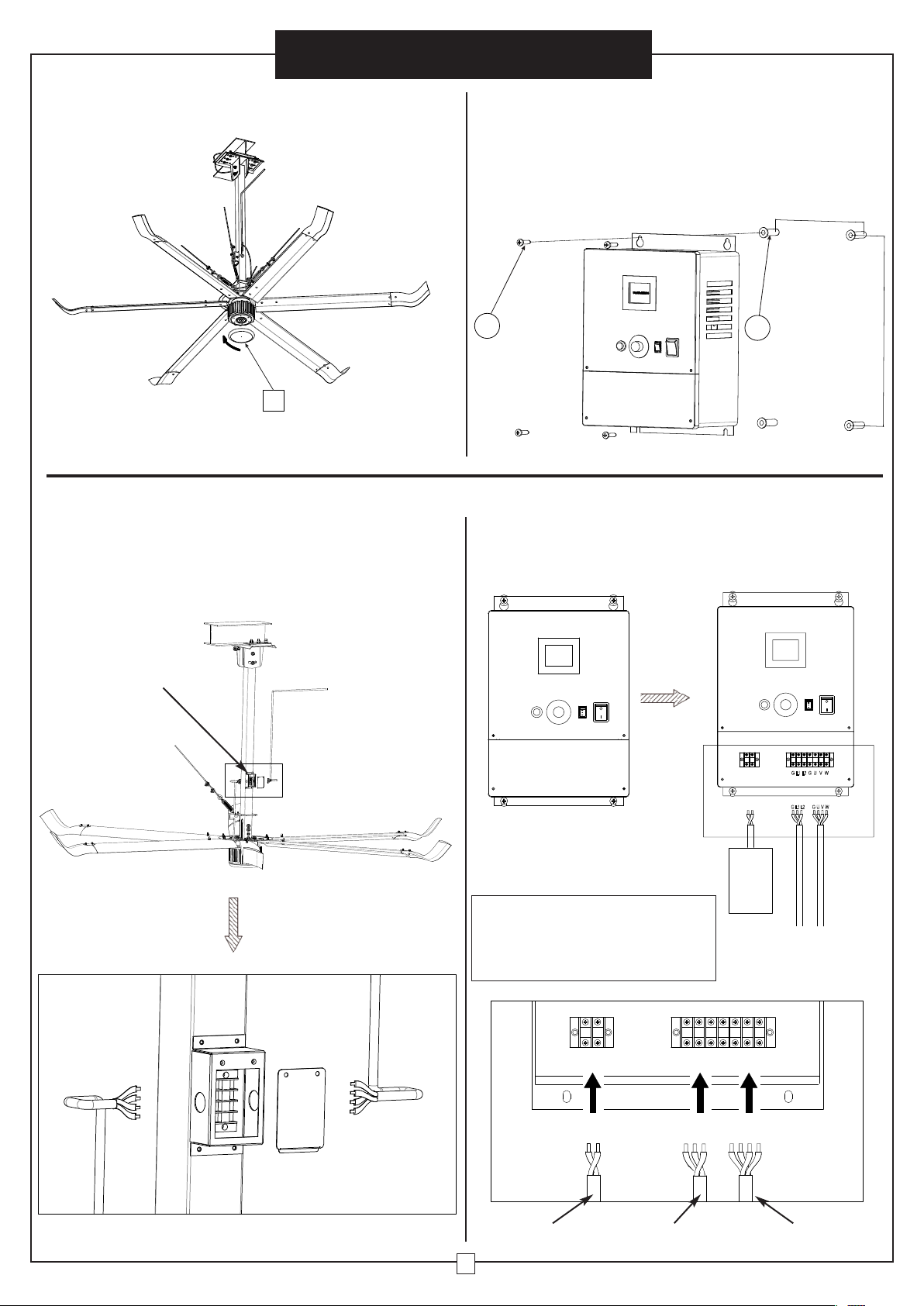

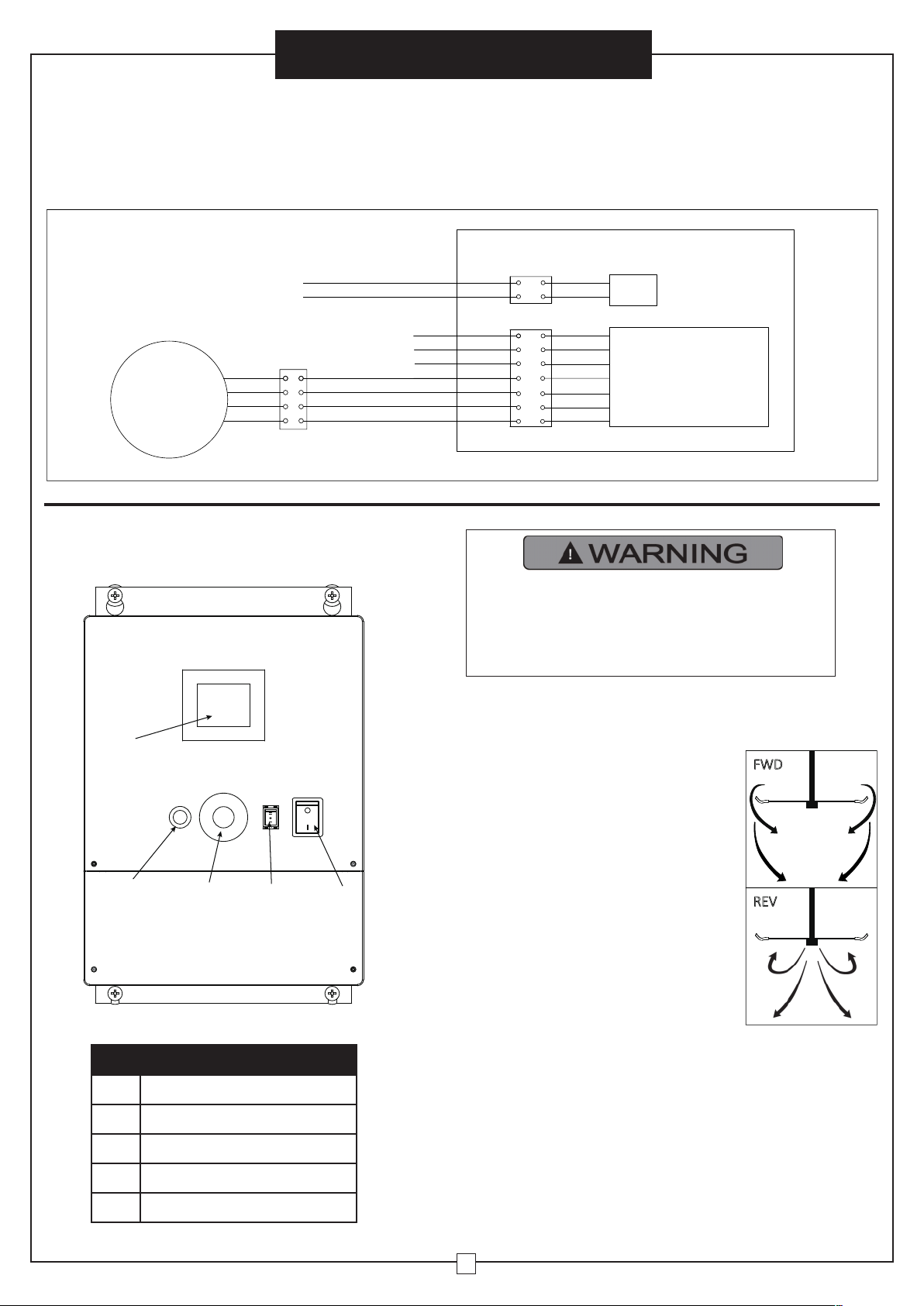

ELECTRICAL WIRING

1. Open the junction box cover on the hanger rod, and connect

the motor lead wire and 4x16AWG interconnecting cord to the

terminal as shown below, make sure tighten all the terminal

screws.

Junction Box

4x16AWG

Interconnecting

Cord

Motor Lead

Wire

User’s Manual

9

HVLS BLDC Fan

10. Rotate the motor cap (11) to the fan assembly until tighten.

11.Install the (H25) plastic anchor to the wall at the distance

shown as below. Then install the control box to the plastic anchor

with (H26) M6x60mm screw.

Warning: Do not install closer than 1 foot (0.3 m) from both sides

of the control box to any adjacent surface/wall.

2.Open the control box wiring cover, and connect the fire alarm

wire, 4x16AWG interconnecting cord and power-supply

conductor as shown below.

Connect the lead wire of the fire alarm

to the terminal 1, and then connect the

4x16AWG interconnecting cord and the

power-supply conductor to the terminal

2 as below picture.

Lead Wire of

Fire Alarm

4x16AWG

Interconnecting Cord

Power-Supply

Conductor

180mm

11

H26

H25

OVERLOAD

PROTECTION

PRESS TO

RESET

OVERLOAD

OFF

REV

FWD

ON

SPEED

PROTECTION

PRESS TO

RESET

_

+

OFF

REV

FWD

ON

SPEED

G

L1 L2

U V WG

330~335mm

FIRE

-

FIRE

ALARM

+

L1L2 G V WG U

MOTORPOWER

_

+

U

V

W

G

U

V

W

G

U

V

W

G

-

FIRE

+

G

L1 L2

L1L2

G

VWG

U

MOTORPOWER

UVWG

Page 10

User’s Manual

10

HVLS BLDC Fan

WIRING DIAGRAM

This wiring diagram is for all models.

Volt: 240 V

Frequency: 60 Hz

OPERATING INSTRUCTIONS

Before turning on or restarting the fan, you

must confirm that all the fan blades are

completely stationary. Never turn on the fan

while the fan blades are still moving, otherwise

the motor may be damaged.

A LED Display

B Overload Protection

C Speed Switch

D Direction Rocker Switch

E Power Switch

1. Press the Power Switch on, the LED display will light up and work

state show [STAND BY].

2. Press the Direction Rocker Switch to [FWD],

and turn on the Speed Switch slowly. The LED

display will show the current and speed. The fan

blade rotates counterclockwise and the air will

blow down.

A downward air flow creates a cooling effect.

This allows you to set your air conditioner on a

higher temperature setting without affecting your

comfort.

Press the Direction Rocker Switch to [REV],

and turn on the Speed Switch slowly.The LED

display will show the current and speed. The fan

blade rotates clockwise and the air will blow up.

An upward airflow moves warm air off the ceiling

area. This allows you to set your heating unit on

a lower setting without affecting your comfort.

Note: When the fan blades start rotating, a little sound and vibration

is normal. But if the motor makes a loud noise, please press

the Power Switch off immediately. Wait until the fan blades are

completely stationary, and check out each part of the fan’s

installation, make sure that the fan is ok. Then repeat the

steps above.

3. To shutdown the fan , please turn off the Speed Switch slowly.

Wait until the fan blades are completely stop, and then press the

Power Switch off.

Parts of the Control Box

control

Fire

MOTOR

A

OVERLOAD

PROTECTION

PRESS TO

RESET

SPEED

B

CD E

REV

FWD

POWER

240V/60Hz

G2

U

V

W

4x16AWG WIRE

OFF

ON

_

Fire PCB

PCBA

G1

L2

L1

+

G1

L2

L1

G2

U

V

W

FWD

REV

Page 11

User’s Manual

11

HVLS BLDC Fan

2.Clean the fan periodically to help maintain the appearance. Do not

use water when cleaning. This could damage the motor, or

possibly cause electric shock.

3.Use only a soft brush or lint-free cloth to avoid scratching the

finish.

4.There is no need to oil your fan. The motor has permanently

lubricated bearings.

MAINTAINANCE

TROUBLESHOOTING

If you have difficulty operating your new ceiling fan, it may be the result of incorrect assembly, installation, or wiring. In some

cases, these installation errors may be mistaken for defects.

If you experience any problems, please check the following trouble shooting guide. If a solution to the problem cannot be found,

please consult with a licensed electrician. Do not attempt any electrical repairs by yourself. For your own safety, turn off power at

fuse box or circuit breaker before trouble shooting your fan

Trouble Suggested Remedy

Fan does not start.

1.Check main and branch circuit fuses or circuit breakers.

2.Check wire connections as performed in ELECTRIAL WIRING.

Caution: Make sure main power is turned off!

3.If the fan still will not start, contact a licensed electrician. Do not attempt to troubleshoot internal

electrical connections by yourself.

Fan sounds noisy

1.Check to make sure all screws in the motor housing are snug (not over tightened).

2.Check to make sure the screws which attach the fan blade holder to the motor are tight.

3.Allow a “break-in” period of 24 hours. Most noise associated with a new fan will disappear after

this period.

Fan wobbles

The following procedures should eliminate most of the wobble. Check for wobble after each step.

1.Check that all blades are screwed firmly into the blade holder.

2.Check that all set screws attaching the motor to the hanger rod are tight.

3.Make sure that the hanger rod is tightened securely to the I-beam mounting bracket.

4.If blade wobble is still noticeable, interchanging two adjacent (side by side) blades can

redistribute the weight and possibly result in smoother operation.

Make sure the power is off before maintenance.

1.Because of the fan’s natural movement, some connections

and screws may become loose. Check the hanger rod, fan

blade holder, and fan blade cap at least twice a year to

make sure they are secure.

Page 12

Blower HeElectric

Models: 653561 653560 6535

653558 653562 246067

g

globalindustrial.ca

Assembly Instructions Instrucciones de Ensambla

Customer Service

US: 1-800-645-2986

Servicio de atención al Clien

México: 01.800.681.6940

DE CFDistribucion Industrial Globales S DE RL

ectives d’assemblageDir

Service à la clientèle

Canada: 888-645-2986

THESE

050117

1

READ & SAVE

INSTRUCTIO

Wall Mount Models: 653566 653567 653568

653569 246068

Ventilador HVLS BLDC

LEE Y GUARDA LAS

INSTRUCCIONES

Modelos:293042 293043 293044

293045 y 293046

Page 13

Ventilador HVLS BLDC

Manual del usuario

2

INSTRUCCIONES GENERALES DE SEGURIDAD

Lea las instrucciones atentamente antes de montar o instalar

su ventilador. Es importante observar todas las informaciones

de seguridad que pueden ayudarle a prevenir lesiones personales y/o daños a la propiedad.

PARA REDUCIR EL RIESGO DE CHOQUE

ELÉCTICO, ESTE VENTILADOR DEBE SER

INSTALADO CON UN CONTROL/ INTERRUP-

TOR AISLADO DE PARED DE USO GENERAL.

1.El trabajo de instalación y del cableado eléctrico deben realizarse

únicamente por personal autorizado de acuerdo con los requisitos de

NEC y CEC.

2.Todos los procedimientos de cableado e instalación deben cumplir

con los Códigos Eléctricos Nacionales (ANSI/ NFPA 70) y los Códigos

Locales.

3.Por favor utilice este ventilador sólo de la manera prevista por el

fabricante. Este ventilador está diseñado para la instalación

permanente y sólo puede ser usado para la circulación de aire.

4.El cable de soporte auxiliar incluido con el ventilador debe estar

conectado correctamente.

5.Para reducir el riesgo de lesiones personales, no doble los soportes

de aspa al instalar los soportes, equilibrar las aspas o limpiar el

ventilador. No inserte objetos extraños en las aspas giratorias del

ventilador.

6.Antes de mantenimiento o limpieza de la unidad, apague el panel

de servicio y bloquee los dispositivos de desconexión del panel de

servicio para evitar que la alimentación se encienda accidentalmente.

Cuando los dispositivos de desconexión del servicio no se pueden

bloquear, fije un dispositivo de advertencia de forma segura, como

una etiqueta, al panel de servicio

7.Tenga cuidado con el ventilador y las aspas al limpiar, pintar o

trabajar cerca del ventilador. Apague la alimentación del ventilador de

techo antes de realizar el mantenimiento.

8.Los ventiladores de techo sin protectores deben instalarse al menos

3,05 metros (10 pies) por encima del suelo con un espacio libre

adecuado entre las aspas y las paredes adyacentes, muebles, etc.

9.Cuando se monta en el techo de la catedral, las puntas de la aspa

deben estar al menos 1 pie de la línea del techo en ángulo, de lo

contrario la turbulencia de aire puede hacer que el ventilador se

tambalee.

10.La viga de apoyo debe tener capacidad de al menos 600 KGS.

11.Antes de la instalación, todos los tornillos de ajuste deben ser

revisados y reapretados cuando sea necesario.

Para reducir el riesgo de lesiones personales,

no doble los soportes de aspa al instalar los

soportes, equilibrar las aspas o limpiar el

ventilador.

Para reducir el riesgo de incendio o choque

eléctrico, no utilice este ventilador con otros

tipos de Dispositivos de control de velocidad

de estado sólido.

Desconecte el ventilador de la fuente de

alimentación antes de realizar cualquier

mantenimiento.

No inserte objetos extraños en las aspas

giratorias del ventilador.

Modelo 293042 293043 293044 293045 293046

Tamaño(ft) 12 14 16 18 20

Voltaje(V) 240 240 240 240 240

Frecuencia(Hz) 60 60 60 60 60

Vatiaje(W) 680 600 820 930 810

RPM 20-88 20-65 20-78 20-65 20-55

AMPS(A) 4.8 4.3 5.7 6.3 5.6

Barra de colgador

Dimensiones(pulgadas)

20 20 60 60 60

Aspas 6 6 6 6 6

Peso Neto(KG) 75 78 115 118 123

Certificación UL,cUL UL,cUL UL,cUL UL,cUL UL,cUL

Especificación

¡Sólo para uso comercial e industrial !

Page 14

Ventilador HVLS BLDC

Manual del usuario

3

REF QTY DESCRIPCIÓN

1 1 Soporte de Montaje de Viga I

2 2 Espaciador de Montaje de Viga I 1

3 2 Espaciador de Montaje de Viga I 2

4 1 Barra de Colgador

5 1 Portador de Aspa de Ventilador

6 1 Conjunto de Colgador de Motor

7 1 Motor

8 6 Aspa de Ventilador

9 6 Tapa de Aspa de Ventilador

10 6 Junta de Seguridad de Aspa de Ven-

tilador

11 1 Tapa de Motor

12 6 Espaciador de Tapa de Aspa de

Ventilador

13 1 Caja de Control

1

2

3

4

6

5

8

7

11

9

12

13

10

PIEZAS DEL VENTILADOR

OVERLOAD

PROTECTION

PRESS TO

RESET

SPEED

OFF

REV

FWD

ON

Page 15

Ventilador HVLS BLDC

Manual del usuario

4

H1

H2

H3

H4

H5

H6

H8

H9

H13

H14

H15

H16

H17

H18

H19

H20

H21

H22

H23

H24

H7

REF QTY DESCRIPCIÓN

H1 1 Cable de Interconexión 4x16AWG

H2 5 Cable de Acero de Seguridad Ф6mmx10m

H3 4 Tensor

H4 30 Cerradura de Cable de Acero

H5 6 Tornillo Hexagonal M14x50mm

H6 6 Tornillo Hexagonal M12x50mm

H7 2 Tornillo de Enchufe Hexagonal

M14x120mm

H8 2 Tornillo de Enchufe Hexagonal

M14x100mm

H9 2 Tornillo de Enchufe Hexagonal M12x90mm

H10 6 Tornillo Hexagonal M8x70mm

H11 12 Tornillo Hexagonal M8x45mm

H12 12 Tornillo Hexagonal M6x35mm

H13 20 Arandela Plana 14mm

H14 6 Arandela Plana 12mm

H15 30 Arandela Plana 8mm

H16 12 Arandela Plana 6mm

H17 4 Arandela de Resorter 14mm

H18 6 Arandela de Resorte 12mm

H19 6 Arandela de Resorte 8mm

H20 4 14mm Arandela

H21 6 Tuerca Autoroscante 14mm

H22 2 Tuerca Autoroscante 12mm

H23 12 Tuerca Autoroscante 8mm

H24 12 Tuerca Autoroscante 6mm

H25 4 Ancla de Plástico

H26 4 Tornillo ST4.2x50mm

PIEZAS DEL VENTILADOR

H25 H26

H12

H11

H10

Page 16

Manual del usuario

5

Ventilador HVLS BLDC

Dimensiones (pulgadas)

Modelo D H

293042 144 32

293043 168 32

293044 192 73

293045 216 73

293046 240 73

INSTRUCCIONES DE INSTALACIÓN

Para evitar una posible descarga eléctrica,

asegúrese de que la alimentación esté apagada

en la caja de fusible principal antes de colgarla.

(Figura 1)

NOTA: Si no está seguro de si la caja de salida está

conectada a tierra, póngase en contacto con un electricista con licencia para obtener asesoramiento, ya

que la unidad debe estar conectada a tierra para un

funcionamiento seguro

El ventilador debe colgarse con al menos 10′de

espacio libre desde el suelo hasta las aspas.

(Figura 2)

Para reducir el riesgo de incendio, choque

eléctrico y lesiones a las personas, el ventilador

de cielo debe instalarse con aspas adecuadas,

que en sus cajas deben indicar la idoneidad con

este modelo de ventilador. No se pueden usar

otras aspas.

H

TECHO

NO MENOS

PISO

DE 10 PIES

D

Figura 2

Page 17

Manual del usuario

6

Ventilador HVLS BLDC

1. Afloje los 12 tornillos y arandelas que en el conjunto de

colgador del motor.

2. Instale el soporte de aspa de ventilador en el conjunto del

motor con tornillos y arandelas como se muestra a continuación,

asegúrese de apretar todos los tornillos y arandelas

Los tornillos y arandelas deben instalarse en parejas

(H10) M8x70mm El tornillo debe instalarse con arandela de

resorte de 8 mm (H19) y arandela plana de 8 mm (H15). Deben

apretarse con 36N.M de par.

(H6) M12x50mm El tornillo debe instalarse con arandela de

resorte de 12 mm (H18)y arandela plana de 12 mm(H14). Deben

apretarse con 135N.M de par.

3. IInstale el soporte de montaje de Viga I en la Viga I con el

espaciador de montaje de Viga I 1&2 a las tuercas de 14

mm(H20), tuerca autoroscante de 14 mm(H21), arandela de

resorte de 14mm (H17), arandela plana de 14 mm (H13) y tornillo

M14x50mm(H5), asegúrese de que todos los tornillos y arandelas

estén apretados con 135N.M de par.

4. Instale la varilla de colgador en el soporte de montaje con tornillos M14x110mm(H7), arandelas planas de 14mm (H13)y tuercas

autoroscantes de 14mm(H21).

H10

H19

H15

H6

H18

H14

H20

H17

H13

H21

3

2

H13

1

H5

H21

H7

5

H10

H19

H15

H6

H18

H14

H13

H13

4

Page 18

Manual del usuario

7

Estructura de Fijación Fiable

A

5. A. Rodee un extremo del cable de acero (H2) alrededor de la estructura de fijación confiable, a continuación, conecte 3 cer

raduras de cable de acero(H4) en el cable para una instalación segura

B.Enganche el tensor (H3) a los orificios de la lámina de la varilla de colgador y conecte el otro extremo del cable de acero de

seguridad (H2). Fije la cerradura del cable de acero (H4) al cable para una instalación segura. Repita los pasos A y B, instale los 4

cables de acero.

B

Lámina de varilla

de colgador

Afloje las tuercas de la cerradura del cable de acero

(H4), móntelas al cable y apriételas.

Ventilador HVLS BLDC

H4

H4

H2

H2

45

H3

H4

H3

Page 19

Manual del usuario

8

6. Pase el cable del motor a través de la ranura de la varilla de

colgador, y apriete el conjunto del motor a la varilla de colgador

con tornillo M14x100mm(H8), tornillo M12x90mm(H9), arandela

plana de 14 mm (H13), tuerca autoroscante de 14 mm (H21) y

tuerca autoroscante de 12mm (H22).

Cable del

motor

7. Pase el cable de acero de seguridad (H2) a través del orificio

de seguridad del motor, rodee un extremo del cable y conecte la

cerradura del cable de acero (H4) al cable para una instalación

segura..

Tire del otro extremo del cable de acero en el orificio central de

la varilla de colgador y hasta fuera de la varilla de colgador, rodee

el cable alrededor de la viga I,y a continuación, conecte la cerradura del cable de acero (H4) en el cable para una instalación

segura

8. Instale la tapa de aspa de ventilador y el espaciador de tapa de

aspa de ventilador en la aspa de ventilador con tornillo

M6x35mm(H12), arandela plana de 6 mm(H16) y tuercas

autoroscantes de 6 mm(H24). Repita este paso para las 6 aspas

de ventilador

9. IInstale todo el conjunto de aspa de ventilador en el soporte de

aspa de ventilador. A continuación, coloque la junta de seguridad

de aspa de ventilador (10) en la aspa de ventilador en cada lado,

alinee los orificios de los tornillos y apriete con tornillos

M8x45mm(H11), arandela plana de 8 mm (H15) y tuerca

autoroscante de 8 mm (H23)

Agujero de Seguridad de Motor

Ventilador HVLS BLDC

H8

H9

H13

H21

H22

H24

12

9

H16

H12

H4

H2

10

H23

H4

H15

H11

Page 20

CABLEADO ELÉCTRICO

1. Abra la cubierta de la caja de conexiones en la varilla de colgador y conecte el cable de motor y el cable de interconexión

4x16AWG al terminal como se muestra a continuación,

asegúrese de apretar todos los tornillos del terminal.

Caja de Conexión

Cable de interconexión

4x16AWG

Cable de

Motor

Manual del usuario

10. Gire la tapa del motor (11) al conjunto del ventilador hasta

que se apriete.

11. Instale la ancla de plástico (H25) en la pared a la distancia

que se muestra a continuación. A continuación, instale la caja de

control en la ancla de plástico con tornillo M6x60mm(H26)

Advertencia: No instale la caja de control menos de 1 pie (0,3

m) de ninguna superficie/pared adyacente.

2 .Abra la cubierta del cableado de la caja de control y conecte

el cable de alarma contra incendios, el cable de interconexión

4x16AWG y el conductor de la fuente de alimentación como se

muestra a continuación.

Conecte el cable la alarma contra

incendios al terminal 1 y, a

continuación, conecte el cable de

interconexión 4x16AWG y el conductor

de alimentación al terminal 2 como se

muestra a continuación.

Cable de alarma

de incendio

Cable de interconexión 4x16AWG

Conductor de

Alimentación

Ventilador HVLS BLDC

9

180mm

11

H26

H25

OVERLOAD

PROTECTION

PRESS TO

RESET

OVERLOAD

OFF

REV

FWD

ON

SPEED

PROTECTION

PRESS TO

RESET

OFF

REV

FWD

ON

SPEED

330~335mm

_

FIRE

ALARM

G

L1 L2

L1L2 G V WG U

U V WG

MOTORPOWER

+

FIRE

-

+

_

+

U

V

W

G

U

V

W

G

U

V

W

G

-

FIRE

+

G

L1 L2

L1L2

G

VWG

U

MOTORPOWER

UVWG

Page 21

Manual del usuario

10

DIAGRAMA DE CABLEADO

Este diagrama de cableado aplica a todos los modelos

Volt: 240 V

Frequency: 60 Hz

INSTRUCCIONES DE OPERACION

Antes de encender o reiniciar el ventilador, debe

confirmar que todas las aspas del ventilador

están completamente estacionarias. Nunca en-

cienda el ventilador mientras las aspas del venti-

lador todavía están en movimiento, de lo

contrario el motor puede dañarse.

A Pantalla LED

B Protección de sobrecarga

C Interruptor de velocidad

D Interruptor de direccional

E Interruptor de alimentación

1. Presione el interruptor de encendido, la pantalla LED se encenderá y

el estado de trabajo mostrará [STAND BY].

Presione el interruptor del balancín de dirección a [FWD] y encienda el

interruptor de velocidad lentamente. La pantalla

LED mostrará la corriente y la velocidad. La aspa

de ventilador gira en sentido contrario a las agujas del reloj y el aire sale..

Un flujo de aire hacia abajo crea un efecto de enfriamiento. Esto le permite ajustar su aire acondicionado en una temperatura más alta sin afectar

su comodidad.

2. Presione el interruptor de balanceo de dirección a [REV] y encienda el interruptor de velocidad lentamente. La pantalla LED mostrará la

corriente y la velocidad. La aspa de ventilador

gira en el sentido de las agujas del reloj y el aire

sale.Un flujo de aire hacia arriba mueve el aire

caliente fuera del área del techo. Esto le permite

ajustar la unidad de calefacción en una temperatura inferior sin afectar su comodidad.

Nota: Cuando las aspas del ventilador comienzan a girar, el sonido

ligero y la vibración son normales. Pero si el motor hace un ruido

fuerte, presione el interruptor de encendido inmediatamente. Espere hasta que las aspas del ventilador estén completamente estacionarias, y revise cada parte del ventilador, asegúrese de que el

ventilador esté en buen estado. A continuación, repita los pasos

anteriores.

3. Para apagar el ventilador, apague lentamente el interruptor de velocidad.

Espere hasta que las aspas del ventilador se detengan por completo, y

a continuación, presione el interruptor de encendido

Unidad de control

Ventilador HVLS BLDC

control

Fire

240V/60Hz

G2

U

MOTOR

V

W

4x16AWG WIRE

A

OVERLOAD

PROTECTION

PRESS TO

RESET

SPEED

B

CD E

FWD

OFF

REV

ON

POWER

_

Fire PCB

PCBA

G1

L2

L1

+

G1

L2

L1

G2

U

V

W

FWD

REV

Page 22

Manual del usuario

Ventilador HVLS BLDC

2.Limpie el ventilador periódicamente para mantener la apariencia.

No utilice agua para limpiar el ventilador. Esto podría dañar el

motor, o posiblemente causar una descarga eléctrica.

3.Sólo utilice un cepillo suave o un paño libre de pelusas para la

limpieza, para evitar rayar el acabado.

4.No hay necesidad de engrasar su ventilador. El motor tiene

rodamientos lubricados permanentemente.

MMANTENIMIENTO

TSOLUCIÓN DE PROBLEMAS

Si encuentra dificultades al operar su nuevo ventilador de techo, es posible que el montaje, la instalación o el cableado no son

correctos. En algunos casos, estos errores de instalación pueden confundirse con defectos.

Si experimenta algún problema, consulte la siguiente guía de resolución de problemas. Si no hay una solución al problema, consulte con un electricista con licencia. No intente ninguna reparación eléctrica por sí mismo. Por su propia seguridad, apague la

caja de fusibles o el disyuntor antes de revisar los problemas del ventilador.

Problema Soluciones Recomendadas

El ventilador no arranca.

1. Compruebe los fusibles o disyuntores del circuito principal y secundario.

2. Compruebe las conexiones de cables según el CABLEADO ELECTRICO.

Precaución: ¡Asegúrese de que la alimentación principal esté apagada!

3. Si el ventilador sigue sin arrancar, póngase en contacto con un electricista con licencia. No intente solucionar problemas de conexiones eléctricas internas por sí mismo.

El ventilador suena Rui-

doso.

1. Compruebe que todos los tornillos de la carcasa del motor estén ajustados (no demasiado

apretados).

2. Compruebe que los tornillos que sujetan el soporte de aspa de ventilador al motor estén

apretados.

3. Permita un período de "descanso" de 24 horas. La mayoría del ruido asociado con un nuevo

ventilador desaparecerá después de este período.

El ventilador se tambalea

Los siguientes procedimientos pueden eliminar la mayoría del tambaleo. Compruebe si hay

tambaleo después de cada paso.

1. Compruebe que todas las aspas estén firmemente atornilladas en el soporte de aspa de

ventilador.

2. Compruebe que todos los tornillos de fijación del motor a la varilla de colgador estén

apretados.

3. Asegúrese de que la varilla de colgador esté bien apretada al soporte de montaje de viga I.

4. Si el tambaleo de aspa no se elimina, intercambiar las dos aspas adyacentes (lado a lado)

puede redistribuir el peso y posiblemente dar lugar a un funcionamiento más suave.

Asegúrese de que la alimentación esté apagada

antes del mantenimiento..

1.Algunas conexiones y tornillos pueden aflojarse debido al

movimiento natural del ventilador. Compruebe la barra de

colgador, el soporte de aspa de ventilador y la tapa de

aspa de ventilador al menos dos veces al año para

asegurarse de que están seguros.

11

Page 23

Blower HeElectric

Models: 653561 653560 6535

653558 653562 246067

g

globalindustrial.ca

Assembly Instructions Instrucciones de Ensambla

Customer Service

US: 1-800-645-2986

Servicio de atención al Clien

México: 01.800.681.6940

DE CFDistribucion Industrial Globales S DE RL

ectives d’assemblageDir

Service à la clientèle

Canada: 888-645-2986

THESE

050117

1

READ & SAVE

INSTRUCTIO

Wall Mount Models: 653566 653567 653568

653569 246068

HVLS BLDC Ventilateur

LIRE ET CONSERVER

CES INSTRUCTIONS

Modèles:293042 293043 293044

293045 et 293046

Page 24

Manuel de l'utilisateur

2

INSTRUCTIONS IMPORTANTES

ReLisez attentivement les instructions avant d'assembler ou

d'installer votre ventilateur. Il est important que vous respectiez toutes les informations de sécurité pour éviter les

blessures corporelles et / ou les dommages matériels.

POUR RÉDUIRE LE RISQUE DE CHOC, CE

VENTILATEUR DOIT ÊTRE INSTALLÉ AVEC

UNE UTILISATION GÉNÉRALE COMMANDE /

COMMUTATEUR DE MUR ISOLANT.

1. Les travaux d’installation et de câblage électrique doivent être

effectués conformément aux exigences de NEC et CEC et seulement

par le personnel autorisé.

2. Toutes les procédures de câblage et d'installation doivent être conformes aux Codes électriques nationaux (ANSI/ NFPA 70) et aux

codes locaux.

3. Utilisez ce ventilateur uniquement de la manière prévue par le fabricant. Ce ventilateur est destiné à une installation permanente et à

être utilisé pour la circulation uniquement.

4. Le câble de support secondaire fourni avec le ventilateur doit être

correctement connecté.

5. Pour réduire le risque de blessures corporelles, ne pliez pas les

supports de lame lors de l'installation des supports, de l'équilibrage

des lames ou du nettoyage du ventilateur. N'insérez pas d'objets

étrangers entre les pales de ventilateur en rotation.

6. Avant l'entretien ou le nettoyage de l'unité, coupez l'alimentation

sur le panneau de service et verrouillez les moyens de déconnexion

du panneau de service pour éviter que l'alimentation ne soit accidentellement activée. Lorsque le moyen de déconnexion du service ne

peut pas être verrouillé, fixez solidement un dispositif d'avertissement, tel qu'une étiquette, au panneau de service.

7. Faites attention au ventilateur et aux pales lorsque vous nettoyez,

peignez ou travaillez à proximité du ventilateur. Coupez toujours l'alimentation du ventilateur de plafond avant de procéder à l'entretien.

8. Les ventilateurs de plafond sans protections doivent être installés

à au moins 3,05 mètres (10 pieds) au-dessus du sol avec un espace

suffisant entre les pales et les murs adjacents, le mobilier, etc.

9. Lorsqu'ils sont montés dans un plafond cathédrale, les pointes des

pales doivent être à au moins 1 pied de la ligne de toit inclinée, sinon

la turbulence de l'air peut faire osciller le ventilateur.

10. La poutre de support doit pouvoir supporter au moins 600 KGS.

11. Toutes les vis de réglage doivent être vérifiées et resserrées si

nécessaire avant l'installation.

Pour réduire le risque de blessures cor-

porelles, ne pliez pas les supports de lame lors

de l'installation des supports, de l'équilibrage

des lames ou du nettoyage du ventilateur.

Pour réduire le risque d'incendie ou de choc

électrique, n'utilisez pas ce ventilateur avec

d'autres types de dispositifs de contrôle de

vitesse à semi-conducteurs.

Débranchez le ventilateur de l'alimentation

avant tout entretien.

N'insérez pas d'objets étrangers entre les pales

du ventilateur en rotation.

Modèle 293042 293043 293044 293045 293046

Taille(ft) 12 14 16 18 20

Tension(V) 240 240 240 240 240

Fréquence(Hz) 60 60 60 60 60

Watt(W) 680 600 820 930 810

RPM 20-88 20-65 20-78 20-65 20-55

AMPS(A) 4.8 4.3 5.7 6.3 5.6

Tige de suspension (inch) 20 20 60 60 60

Lames 6 6 6 6 6

Poids net(KG) 75 78 115 118 123

Certification UL,cUL UL,cUL UL,cUL UL,cUL UL,cUL

Spécification

Pour usage commercial et industriel

uniquement!

HVLS BLDC Ventilateur

Page 25

HVLS BLDC Ventilateur

Manuel de l'utilisateur

3

REF QTY DESCRIPTION

1 1 I- poutre de support de montage

2 2 I- poutre d’entretoise de montage 1

3 2 I- poutre d’entretoise de montage 2

4 1 Tige de suspension

5 1 Support de pale de ventilateur

6 1 Ensemble de suspension de moteur

7 1 Moteur

8 6 Pale de ventilateur

9 6 Capuchon de pale de ventilateur

10 6 Joint de sécurité de pale de ventilateurt

11 1 Capuchon de moteur

12 6 Entretoise de capuchon de pale de ventilateur

13 1 Boîtier de commande

1

2

3

4

6

5

8

7

11

9

12

13

10

PIÈCES DU VENTILATEUR

OVERLOAD

PROTECTION

PRESS TO

RESET

SPEED

OFF

REV

FWD

ON

Page 26

HVLS BLDC Ventilateur

Manuel de l'utilisateur

4

H1 H2

H3 H4

H5

H6

H8

H9

H13

H14

H15

H16

H17

H18

H19

H20

H21

H22

H23

H24

H7

REF QTY DESCRIPTION

H1 1 Cordon d'interconnexion 4x16AWG

H2 5 Câble d’acier de sécurité2 Ф6mmx10m

H3 4 Ridoir

H4 30 Serrure de câble d’acier

H5 6 Vis hexagonale M14x50mm

H6 6 Vis hexagonale M12x50mm

H7 2 Vis à six pans creux M14x120mm

H8 2 Vis à six pans creux M14x100mm

H9 2 Vis à six pans creux M12x90mm

H10 6 Vis hexagonale M8x70mm

H11 12 Vis hexagonale M8x45mm

H12 12 Vis hexagonale M6x35mm

H13 20 Rondelle plate 14mm

H14 6 Rondelle plate 12mm

H15 30 Rondelle plate 8mm

H16 12 Rondelle plate 6mm

H17 4 Rondelle à ressort 14mm

H18 6 Rondelle à ressort 12mm

H19 6 Rondelle à ressort 8mm

H20 4 14mm Écrou

H21 6 Écrou auto-taraudeur 14mm

H22 2 Écrou auto-taraudeur 12mm

H23 12 Écrou auto-taraudeur 8mm

H24 12 Écrou auto-taraudeur 6mm

H25 4 Ancre en plastique

H26 4 Vis ST4.2x50mm

PIÈCES DU VENTILATEUR

H25 H26

H12

H11

H10

Page 27

Manuel de l'utilisateur

5

HVLS BLDC Ventilateur

Dimensions (pouce)

Model D H

293042 144 32

293043 168 32

293044 192 73

293045 216 73

293046 240 73

INSTRUCTIONS D'INSTALLATION

Pour éviter tout choc électrique, assurez-vous

que l'électricité est coupée au niveau de la

boîte à fusibles principale avant de suspendre.

REMARQUE: Si vous n'êtes pas sûr que la boîte de

sortie est mise à la terre, contactez un électricien

agréé pour obtenir des conseils, car elle doit être

mise à la terre pour un fonctionnement sûr

Le ventilateur doit être suspendu avec au

moins 10 pi d’espacement du sol aux pales.

Pour réduire les risques d'incendie, de choc

électrique et de blessures corporelles, le

ventilateur suspendu au plafond doit être

installé avec des lames marquées sur leurs

cartons pour indiquer la compatibilité avec

ce modèle. Les autres lames ne peuvent pas

être remplacées.

H

PLAFOND

D

ÉTAGE

Figure 2

PAS MOINS

DE 10 PIEDS

Page 28

Manuel de l'utilisateur

6

HVLS BLDC Ventilateur

1. Desserrez les 12 vis et rondelles qui se trouvent sur l'ensemble de suspension du moteur.

2. Installez le support de pale de ventilateur sur le moteur avec

des vis et des rondelles comme illustré ci-dessous, assurez-vous

de serrer toutes les vis et rondelles.

Les vis et les rondelles doivent être installées par paires.

La vis (H10) M8x70mm doit être installée avec une rondelle élastique (H19) 8mm et une rondelle plate (H15) 8mm. Elle doit être

serrée avec une torque 36N.M.

La vis (H6) M12x50mm doit être installée avec une rondelle élastique (H18) 12mm et une rondelle plate (H14) 12mm. Elles

doivent être serrées avec une torque 135N.M.

3.Installez l’I-poutre de support de montage sur le I-poutre avec

l'entretoise de montage IBeam 1 & 2 sur les écrous (H20) 14 mm,

(H21) Écrou auto-taraudeur 14 mm, (H17) Rondelle élastique 14

mm, (H13) Rondelle plate 14 mm et (H5) vis M14x50mm, assurezvous que toutes les vis et rondelles sont serrées avec une torque

135N.M.

4..Installez la tige de suspension sur le support de montage avec

(H7) vis M14x110 mm, (H13) rondelles plates 14 mm et (H21)

écrous auto-taraudeurs 14 mm.

H10

H19

H15

H6

H18

H14

H20

H17

H13

H21

3

2

H13

1

H5

H21

H7

5

H10

H19

H15

H6

H18

H14

H13

H13

4

Page 29

Manuel de l'utilisateur

7

HVLS BLDC Ventilateur

Structure de fixation fiable

A

5.A. Enroulez une extrémité du câble en acier (H2) autour de la structure de fixation fiable, puis fixez le verrou de câble en acier 3

(H4) sur le câble pour une installation sûre.

B. Accrochez le tendeur (H3) aux trous de la feuille de la tige de suspension et connectez l'autre extrémité du câble de sécurité

en acier (H2) Fixez le verrou de câble en acier (H4) sur le câble pour une installation sûre. Répétez les étapes A et B, installez les

4 câbles en acier

B

Feuille de la tige

de suspension

Desserrez les écrous du verrou de câble en acier

(H4), fixez-le au câble et serrez-les.

H4

H4

H2

H2

45

H3

H4

H3

Page 30

Manuel de l'utilisateur

8

HVLS BLDC Ventilateur

6. Faites passer le fil conducteur du moteur à travers la fente de la

tige de suspension et serrez l'ensemble du moteur à la tige de

suspension avec une vis (H8) M14x100 mm, (H9) une vis M12x90

mm, (H13) une rondelle plate de 14 mm, (H21) une auto-fixation

de 14 mm écrou taraudeur et (H22) écrou autotaraudeur 12 mm.

Fil du conducteur de moteur

7.Passez le câble de sécurité en acier (H2) à travers le trou de

sécurité du moteur, encerclez une extrémité du câble et fixez le

verrou de câble en acier (H4) sur le câble pour une installation

sûre.

Tirez l'autre extrémité du câble en acier dans le trou central de la

tige de suspension et sortez-la à travers la tige de suspension,

entourez le câble autour de la poutre en I, puis fixez le verrou de

câble en acier (H4) sur le câble pour une installation sûre.

8.Installez le capuchon de pale de ventilateur et l'entretoise de

capuchon de pale de ventilateur sur la pale de ventilateur avec

une vis (H12) M6x35 mm, une rondelle plate (H16) de 6 mm et

un écrou auto-taraudeur (H24) de 6 mm. Répétez cette étape

pour les 6 pales de ventilateur.

9. Installez l'ensemble de la pale de ventilateur sur le support de

pale de ventilateur. Placez ensuite le joint de sécurité de la pale

de ventilateur (10) côte à côte sur la pale de ventilateur, alignez

les trous de vis et serrez avec les vis (H11) M8x45 mm, (H15)

rondelle plate de 8 mm et (H23) écrou auto-taraudeur de 8 mm.

Trou de sécurité

du moteur

H13

H8

H21

H9

H22

H24

12

9

H16

H12

H4

H2

10

H23

H4

H15

H11

Page 31

CÂBLAGE ÉLECTRIQUE

1. Ouvrez le couvercle de la boîte de dérivation sur la tige de

suspension et connectez le fil conducteur du moteur et le cordon d'interconnexion 4x16AWG à la borne comme illustré cidessous, assurez-vous de serrer toutes les vis de la borne.

Boîte de dérivation

Cordon d'inter-

connexion

4x16AWG

Fil du conducteur de

moteur

Manuel de l'utilisateur

10.Tournez le capuchon du moteur (11) sur le ventilateur

jusqu'à ce qu'il soit serré.

11.Installez l'ancrage en plastique (H25) au mur à la distance indiquée ci-dessous. Installez ensuite le boîtier de commande sur

l'ancrage en plastique avec une vis (H26) M6x60mm.

Avertissement: ne pas l’installer à moins de 1 pied (0,3m) entre

les deux côtés du boîtier de commande et tous les adjacents surfaces/mur.

2.Ouvrez le couvercle de câblage du boîtier de commande et

connectez le fil d'alarme incendie, le cordon d'interconnexion

4x16AWG et le conducteur d'alimentation comme indiqué cidessous.

Connectez le fil conducteur de l'alarme

incendie à la borne 1, puis connectez

le cordon d'interconnexion 4x16AWG

et le conducteur d'alimentation à la

borne 2 comme illustré ci-dessous.

Fil conducteur

d'alarme incendie

Cordon d'intercon-

nexion 4x16AWG

Conducteur

d'alimentation

9

HVLS BLDC Ventilateur

180mm

11

H26

H25

OVERLOAD

PROTECTION

PRESS TO

RESET

OVERLOAD

OFF

REV

FWD

ON

SPEED

PROTECTION

PRESS TO

RESET

OFF

REV

FWD

ON

SPEED

330~335mm

_

FIRE

ALARM

G

L1 L2

L1L2 G V WG U

U V WG

MOTORPOWER

+

FIRE

-

+

_

+

U

V

W

G

U

V

W

G

U

V

W

G

-

FIRE

+

G

L1 L2

L1L2

G

VWG

U

MOTORPOWER

UVWG

Page 32

SCHÉMA DE CÂBLAGE

Ce schéma de câblage est pour tous les modèles.

Volt: 240 V

Frequency: 60 Hz

Instructions Opérationnelles

A Affichage LED

B Protection de surcharge

C Commutateur de vitesse

D Interrupteur à bascule de direction

E Interrupteur

Pièces du boîtier de commande

HVLS BLDC Ventilateur

Avant d'allumer ou de redémarrer le ventilateur, vous

devez confirmer que toutes les pales du ventilateur sont

complètement stationnaire. N'allumez jamais le ventila-

teur pendant que les pales du ventilateur sont toujours

en mouvement, sinon le moteur pourrait être endom-

magé.

1. Appuyez sur l'interrupteur d'alimentation, l'écran LED s'allumera et fonctionnera spectacle d'état [STAND BY].

2. Appuyez sur l'interrupteur à bascule de direction sur [FWD] et activez

lentement l'interrupteur de vitesse. L'écran LED affichera le courant et la vitesse. La pale du ventilateur tourne dans le sens antihoraire et l'air va

souffler.

Un flux d'air vers le bas crée un effet de refroidissement. Cela vous permet de régler votre climatiseur

sur une

réglage de température plus élevé sans affecter

votre confort.

Appuyez sur l'interrupteur à bascule de direction sur

[REV] et allumez lentement l'interrupteur de vitesse.

Un flux d'air vers le haut déplace l'air chaud hors du

plafond. Cela vous permet de régler votre unité de

chauffage sur un réglage plus bas sans affecter

votre confort.

Remarque: Lorsque les pales du ventilateur commencent à tourner, c’est

normal d’avoir un petit bruit et des vibrations. Mais si le moteur fait un bruit

fort, veuillez immédiatement éteindre l'interrupteur d'alimentation. Attendez

que les pales du ventilateur soient complètement stationnaire, et vérifiez

chaque partie de l'installation du ventilateur, assurez-vous que le ventilateur est ok. Répétez ensuite les étapes ci-dessus.

3. Pour arrêter le ventilateur, veuillez éteindre lentement le commutateur

de vitesse.

Attendez que les pales du ventilateur soient complètement arrêtées, puis

appuyez

(Coupez l'alimentation).

10

Manuel de l'utilisateur

control

Fire

MOTOR

A

OVERLOAD

PROTECTION

PRESS TO

RESET

SPEED

B

CD E

REV

FWD

POWER

240V/60Hz

G2

U

V

W

4x16AWG WIRE

OFF

ON

_

+

G1

L2

L1

G1

L2

L1

G2

U

V

W

Fire PCB

PCBA

FWD

REV

Page 33

Manuel de l'utilisateur

11

HVLS BLDC Ventilateur

2. Nettoyez régulièrement le ventilateur pour aider à maintenir l'apparence. N'utilisez pas d'eau pour le nettoyage. Cela pourrait endommager le moteur ou provoquer un choc électrique.

3. Utilisez uniquement une brosse douce ou un chiffon non

pelucheux pour éviter de rayer la finition.

4. Il n'est pas nécessaire de lubrifier votre ventilateur. Le moteur a

des roulements lubrifiés en permanence.

ENTRETIEN

DÉPANNAGE

ISi vous éprouvez des difficultés à faire fonctionner votre nouveau ventilateur de plafond, cela peut être le résultat d'un assemblage, d'une installation ou d'un câblage incorrects. Dans certains cas, ces erreurs d'installation peuvent être confondues avec des

défauts.

Si vous rencontrez des problèmes, veuillez consulter le guide de dépannage suivant. Si aucune solution au problème ne peut être

trouvée, veuillez consulter un électricien agréé. N'essayez pas d'effectuer vous-même des réparations électriques. Pour votre propre sécurité, coupez le courant au niveau de la boîte à fusibles ou du disjoncteur avant de dépanner votre ventilateur.

Problème Solution suggérée

Le ventilateur ne démarre

pas

1.Vérifiez les fusibles ou les disjoncteurs du circuit principal et de dérivation.

2.Vérifiez les connexions des câbles comme indiqué dans CÂBLAGE ÉLECTRIQUE.

Attention: Assurez-vous que l'alimentation principale est coupée!

3.Si le ventilateur ne démarre toujours pas, contactez un électricien agréé. N'essayez pas de dépanner vous-même les connexions électriques internes.

Le ventilateur est bruyant

1.Vérifiez que toutes les vis du boîtier du moteur sont bien ajustées (pas trop serrées).

2.Vérifiez que les vis qui fixent le support de pale de ventilateur au moteur sont bien serrées.

3. Accordez une période de «rodage» de 24 heures. La plupart du bruit associé à un nouveau

ventilateur disparaîtra après cette période.

Le ventilateur vacille

Les procédures suivantes devraient éliminer la plupart des oscillations. Vérifiez l'oscillation après

chaque étape.

1.Vérifiez que toutes les pales sont bien vissées dans le support de pales du ventilateur.

2.Vérifiez que toutes les vis de fixation fixant le moteur à la tige de suspension sont serrées.

3.Assurez-vous que la tige de suspension est solidement fixée au support de montage de la

poutre en I.

Si l'oscillation de la lame est encore perceptible, l'échange de deux lames adjacentes (côte à côte)

peut redistribuer le poids et éventuellement entraîner un fonctionnement plus fluide.

Assurez-vous que l'alimentation est

coupée avant l'entretien..

1. En raison du mouvement naturel du ventilateur, certaines

connexions et vis peuvent se desserrer. Vérifiez la tige de

suspension, le support de pale de ventilateur et le capuchon

de pale de ventilateur au moins deux fois par an pour vous

assurer qu'ils sont bien fixés.

Loading...

Loading...