Page 1

SKYRAIDER

40 - 46 Size Stand-off Scale A.R.F.

Instructions for Final Assembly

The Skyraider was designed to be a replacement for the naval dive bombers that were in use in the

1940's. It was felt that one aircraft could be designed that would be able to fill that role and much more,

and that reducing the crew to a single pilot would result in weight savings and speed increases, both

factors that would enable the aircraft to carry more ordinance more effectively.

This was exactly what happened when the prototype was first flown on March 18, 1945. The

Skyraider was a single seat ground attack aircraft. It carried two 20mm cannons and up to 6000lbs. of

externally stored weapons. The Skyraider was powered by one Wright Cyclone radial engine producing

2400 horsepower . Because of it's successes in the later parts of the V ietnam war and throughout the

Korean war, the U.S. Navy called the Skyraider "the best and most ef fective close support airplane in

the world."

Now you too can experience the same feeling with your new Global Skyraider ARF. The Global

Skyraider is built by master craftsmen, utilizing the finest grades of balsa, light ply , foam and fiberglass.

It's covered using heat shrink polyester material, just like you would buy at your local hobby shop.

Want to install retracts into your new Skyraider? We've already installed the hardwood rails, cut out

the wheel wells and strut channels to make it as easy as possible. Don't want to install retracts?

We've provided all the necessary hardware to install fixed main gear . In fact, we've provided all of the

hardware to finish the Skyraider. Fuel tank, wheels, pushrods, pull-pull cables, clevises and much

more. It's all in the kit. Don't worry about trying to find an aftermarket fiberglass cowl either. We've

provided a one piece fiberglass cowl that's even prepainted to match the covering! With this kind of

quality prefabrication, you'll be in the air and strafing ground targets in no time!

Version V1.0 9-99 MTN All Contents © Copyright 1999

1

Page 2

TABLE OF CONTENTS

Kit Contents.....................................................................2

Additional Items Required..............................................3

Tools and Supplies Needed..............................................3

Field Support Equipment Needed....................................3

Metric Conversion Chart.................................................3

Wing Assembly................................................................4

Hinging the Ailerons................................................4

Installing the Aileron Servos....................................4

Installing the Servo Hatches.....................................5

Installing the Dihedral Brace....................................6

Joining the Wing Halves...........................................6

Optional Fixed Main Gear...............................................7

Installing the Main Gear Struts.................................7

Installing the Main Gear Wheels..............................7

Optional Retract Main Gear.............................................8

Installing the Retract Mechanisms...........................8

Installing the Retract Servo......................................8

Installing the Retract Linkage..................................8

Installing the Retract Gear Covers...........................9

Installing the Wheels..............................................10

Wing Mounting..............................................................10

Installing the Wing.................................................10

Installing the Wing Bolt Doubler............................10

Installing the Wing Fairing.....................................11

Horizontal Stabilizer Installation...................................11

Aligning the Horizontal Stabilizer..........................11

Mounting the Horizontal Stabilizer........................12

Hinging the Elevator Halves..................................12

Vertical Stabilizer Installation.......................................12

Aligning the Vertical Stabilizer..............................12

Mounting the Vertical Stabilizer.............................13

Hinging the Rudder.................................................13

Tail Wheel Installation...................................................13

T ail Wheel Bracket Assembly..................................13

Mounting the Tail Wheel Assembly.......................13

Installing the Tail Wheel.........................................14

Engine Installation.........................................................14

Engine Installation Options....................................14

Installing the Engine to the Motor Mount..............14

Mounting the Engine to the Firewall

For 2 Cycle Engines Only....................................15

Mounting the Engine to the Firewall

For 4 Cycle Engines Only................................15

Fuel Tank.......................................................................16

Stopper Assembly...................................................16

Stopper Installation................................................17

Fuel Tank Installation.............................................17

Throttle Linkage............................................................18

Installing the Pushrod Housing..............................18

Installing the Pushrod Wire....................................18

Servo Installation...........................................................18

Installing the Fuselage Servos...............................18

Throttle Connection.......................................................19

Installing the Servo Connector...............................19

Rudder Pull-Pull Cables................................................19

Installing the Control Rod......................................19

Installing the Pull-Pull Cable.................................19

Elevator Pushrod...........................................................21

Installing the Control Horns..................................21

Installing the Elevator Pushrod..............................21

Aileron Linkages...........................................................22

Installing the Control Horns..................................22

Installing the Aileron Linkages..............................22

Canopy...........................................................................23

Canopy Preparation...............................................23

Mounting the Canopy............................................23

Cowl...............................................................................23

Installing the Cowl Blocks.....................................23

Mounting the Cowl................................................23

Installing the Fuel Filler........................................24

Installing the Fuel Lines.......................................24

Installing the Cowl Fairings..................................24

Final Assembly............................................................25

Installing the Receiver and Battery.......................25

Installing the Switch.............................................25

Applying the Decals...............................................25

Balancing......................................................................26

Lateral Balance......................................................26

Control Throws.............................................................26

Flight Preparation..........................................................26

Preflight Check.......................................................27

Flying.............................................................................27

Notes...............................................................................28

Trim Chart.....................................................................29

Product Evaluation........................................................30

Global guarantees this kit to be free from defects in both material and workmanship, at the date of purchase. This does

not cover any components parts damaged by use, misuse or modification. In no case shall Global's liability exceed

the original cost of the purchased kit.

In that Global has no control over the final assembly or material used for final assembly , no liability shall be assumed

for any damage resulting from the use by the user of the final user-assembled product. By the act of using the final

user-assembled product, the user accepts all resulting liability.

To make your modeling experience totally enjoyable, we recommend that you get experienced, knowledgable help

with assembly and during your first flights. Your local hobby shop has information about flying clubs in your area

whose membership includes qualified instructors. You can also contact the AMA at the address below.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN. 47302-9252

(800) 435-9262

www.modelaircraft.org

2

Page 3

This instruction manual is designed to help you build a straight, great flying airplane. Please read this manual

thoroughly before beginning assembly of your new Skyraider ARF . Use the parts listing below to identify and

separate all of the parts before beginning assembly.

ÄKIT CONTENTSÃ We have organized the parts as they come out of the box for better identification

during assembly . W e recommend that you regroup the parts in the same manner . This will ensure you have all

of the parts required before you begin assembly and will also help you familiarize yourself with each part.

KIT CONTENTS

AIRFRAME ASSEMBLIES

q {2} Wing Halves with Ailerons

q {1} Fuselage

q {1} Horizontal Stabilizer with Elevator Halves

q {1} Vertical Stabilizer with Rudder

q {1} Molded Plastic Wing Fairing

q {1} Molded Plastic Retract Gear Covers

q {1} Molded Fiberglass Cowling

q {2} Molded Plastic Cowl Fairings

q {1} Molded Clear Canopy

MAIN GEAR ASSEMBL Y

q {2} Prebent Main Gear Wires

q {2} 50mm Diameter Wheels

q {4} Landing Gear Straps

q {8} 2.5mm x 12mm Wood Screws

q {2} Wheel Collars w/Set Screws

q {2} Nylon Spacers

TAIL WHEEL ASSEMBL Y

q {1} Nylon Tail Wheel Bracket

q {1} Nylon Tail Wheel Tiller Arm

q {1} Prebent Tail Wheel Wire

q {1} 25mm Diameter Tail Wheel

q {1} 2mm x 40mm Wire Pin

q {2} 2mm Wheel Collars

q {2} Brass Bearing Inserts

q {2} 2mm x 5mm Machine Screws

q {3} 3mm x 10mm Wood Screws

ELEVA TOR CONTROL SYSTEM

q {1} 740mm Split Elevator Pushrod Assembly

q {2} Nylon Clevises

q {1} Adjustable Servo Connector Assembly

q {2} Nylon Control Horn w/Backplates

q {4} 2mm x 25mm Machine Screws

q {6} C/A Hinges

AILERON CONTROL SYSTEM

q {2} 2mm x 250mm Threaded Wires

q {2} Nylon Control Horns w/Backplates

q {4} 2mm x 25mm Machine Screws

q {2} Nylon Clevises

q {2} Adjustable Servo Connectors

q {6} C/A Hinges

q {4} 8mm x 15mm x 20mm Wood Blocks

q {8} 2.5mm x 12mm Wood Screws

RUDDER CONTROL SYSTEM

q {1} Stranded Wire Cable

q {2} Nylon Adjustable Control Horns

q {4} Nylon Clevises

q {1} 3mm x 50mm Threaded Rod

q {2} 3mm Flat Washers

q {2} 3mm Nuts

q {4} Brass threaded Couplers

q {4} Brass Crimp Collets

q {3} C/A Hinges

THROTTLE CONTROL SYSTEM

q {1} 1.5mm x 380mm Pushrod Wire

q {1} 3mm x 270mm Nylon Pushrod Housing

q {1} Adjustable Servo Connector Assembly

MOTOR MOUNT ASSEMBLY

q {2} Nylon Motor Mount Beams

q {4} 4mm x 20mm Machine Screws

q {4} 4mm x 35mm Machine Screws

q {8} 4mm Flat Washers

q {4} 4mm Split Washers

q {4} 4mm Hex Nuts

q {4} 4mm Blind Nuts

FUEL T ANK

q {1} 280cc Molded Fuel Tank

q {1} 4mm x 28mm Nylon Pick-Up Tube

q {2} 4mm x 28mm Prebent Nylon Vent Tube

q {1} 3mm x 18mm Self Tapping Screw

q {1} Length of Fuel Tubing

q {1} Metal Weighted Pick-Up

q {1) Nylon Fuel Cap

q {1} Rubber Stopper

q {1} Nylon Backplate

q {1} Nylon Fuel Filler Housing

q {1} Nylon Fuel Filler Snap Ring

q {1} Nylon Fuel Filler Plug

MISCELLANEOUS ITEMS

q {1} Plywood Dihedral Brace

q {1} Precovered Wing Bolt Doubler

q {2} Precovered Aileron Servo Hatches

q {5} 10mm x 10mm x 20mm Hardwood Blocks

q {3} 3mm x 10mm Wood Screws

q {2} 4mm x 40mm Socket Cap Screws

q {2} 4mm Plastic Flat Washers

q {2} Decal Sheet

3

Page 4

ADDITIONAL ITEMS REQUIRED

q {1}Hitec 4 or More Channel Radio w/5 Servos

q {2}Cirrus 12” Servo Extensions # 444713

q {1}Cirrus Y-Harness # 444728

q {1}Dubro Heat Shrink Tubing # 440

q {1}Dubro Foam Rubber # 513

q {1}Global Fuel Line # 115923

q {1}Dubro In-Line Fuel Filter # 340

q {1}Topflight Black Paint # TOPR7208

FOR 2 CYCLE ENGINE

q {1}Magnum XL .40 - .46 Two Cycle Engine

q {1}Propeller To Suit Engine

q {1}Thunderbolt Glow Plug # 115493

q {1}Magnum Chrome Spinner Nut # 237210

OPTIONAL RETRACTS

q {1}Mechanical Retracts (Robart or Hobbico)

q {1} Cirrus CS-100 Retract Servo # 444222

q {2}Dubro 12” Threaded Rod # 172

q {2}Dubro Adjustable Axles # 248

q {1}Package Dubro Nylon Clevises # 228

q {1}Package Dubro EZ Connectors # 121

TOOLS AND SUPPLIES NEEDED

FOR 4 CYCLE ENGINE

q {1}Magnum XL .52 - .80 Four Cycle Engine

q {1}Propeller To Suit Engine

q {1}Thunderbolt Glow Plug # 115490

q {1}Magnum Chrome Spinner Nut

For XL .52RFS # 237210

For XL .80RFS # 237212

OPTIONAL ITEMS

q {1}Ernst Charge Jack # 124

q {1} Cirrus On-Board Battery Indicator # 444762

Note - Part numbers for servo extensions, Y-harness,

retract servo and On-Board Battery Indicator are for

Hitec and JR radio systems. These items are also

available with different connectors for use with Futaba

and Airtronics radio systems.

q Kwik Bond Thin C/A # 887500

q Kwik Bond Thick C/A # 887510

q Kwik Bond 5 Minute Epoxy # 887560

q Kwik Bond 30 Minute Epoxy # 887565

q Wilhold Silicon Sealer # 00684

q Pacer RC256 Canopy Glue # PT-56

q 3M Fineline Masking Tape 1/8” # 218-06300

q Electric Drill

q Assorted Drill Bits

q Modeling Knife

q Machine Oil or Vaseline

FIELD SUPPORT EQUIPMENT NEEDED

q Magnum 12V Electric Starter (# 361006)

q Magnum 12V Fuel Pump (# 237377)

q Magnum Locking Glow Clip (# 237440)

q Global 12V Battery (# 110171 )

METRIC CONVERSION CHART

To convert inches into millimeters: Inches x 25.4 = MM

1/64” = .4mm

1/32” = .8mm

1/16” = 1.6mm

3/32” = 2.4mm

1/8” = 3.2mm

5/32” = 4.0mm

3/16” = 4.8mm

1/4” = 6.4mm

3/8” = 9.5mm

1/2” = 12.7mm

5/8” = 15.9mm

3/4” = 19.0mm

q Straight Edge Ruler

q Dremel T ool w/Assorted Bits

q Phillips Screwdriver

q Builders Triangle

q 220 Grit Sandpaper

q Standard Masking T ape

q Paper T owels

q Rubbing Alcohol

q Wire Cutters

q 4mm Hex Wrench

q Global 12V Charger (# 110270 )

q Magnum Power Panel (# 237390)

q Global Field Buddy Flight Box (# 233072)

q Magnum 4-W ay W rench (# 237420)

1” = 25.4mm

2” = 50.8mm

3” = 76.2mm

6” = 152.4mm

21” = 533.4mm

24” = 609.6mm

30” = 762.0mm

36” = 914.4mm

12” = 304.8mm

18” = 457.2mm

4

Page 5

If you should find a part missing or have questions about assembly, please call or write to the address below:

Customer Service Center

18480 Bandilier Circle

Fountain Valley, CA. 92728

Phone: (714) 963-0329

Fax: (714) 964-6236

E-Mail: service@globalhobby.com

ÄSUGGESTIONÃ To avoid scratching your new airplane, do not unwrap the pieces until they are

needed for assembly . Cover your workbench with an old towel or brown paper , both to protect the aircraft

and to protect the table. Keep a couple of jars or bowls handy to hold the small parts after you open the

bags.

ÄNOTEÃ Please trial fit all the parts. Make sure you have the correct parts and that they fit and are

aligned properly before gluing! This will assure proper assembly . Since the Skyraider is hand made from

natural materials, every airplane is unique and minor adjustments may have to be made. However, you

should find the fit superior and assembly simple.

WING ASSEMBLY

PARTS REQUIRED

q {2} Wing Halves with Ailerons

q {1} Plywood Dihedral Brace

q {6} C/A Hinges

q {4} 8mm x 15mm x 20mm Wood Blocks

q {8} 2.5mm x 12mm Wood Screws

q {2} Precovered Servo Hatches

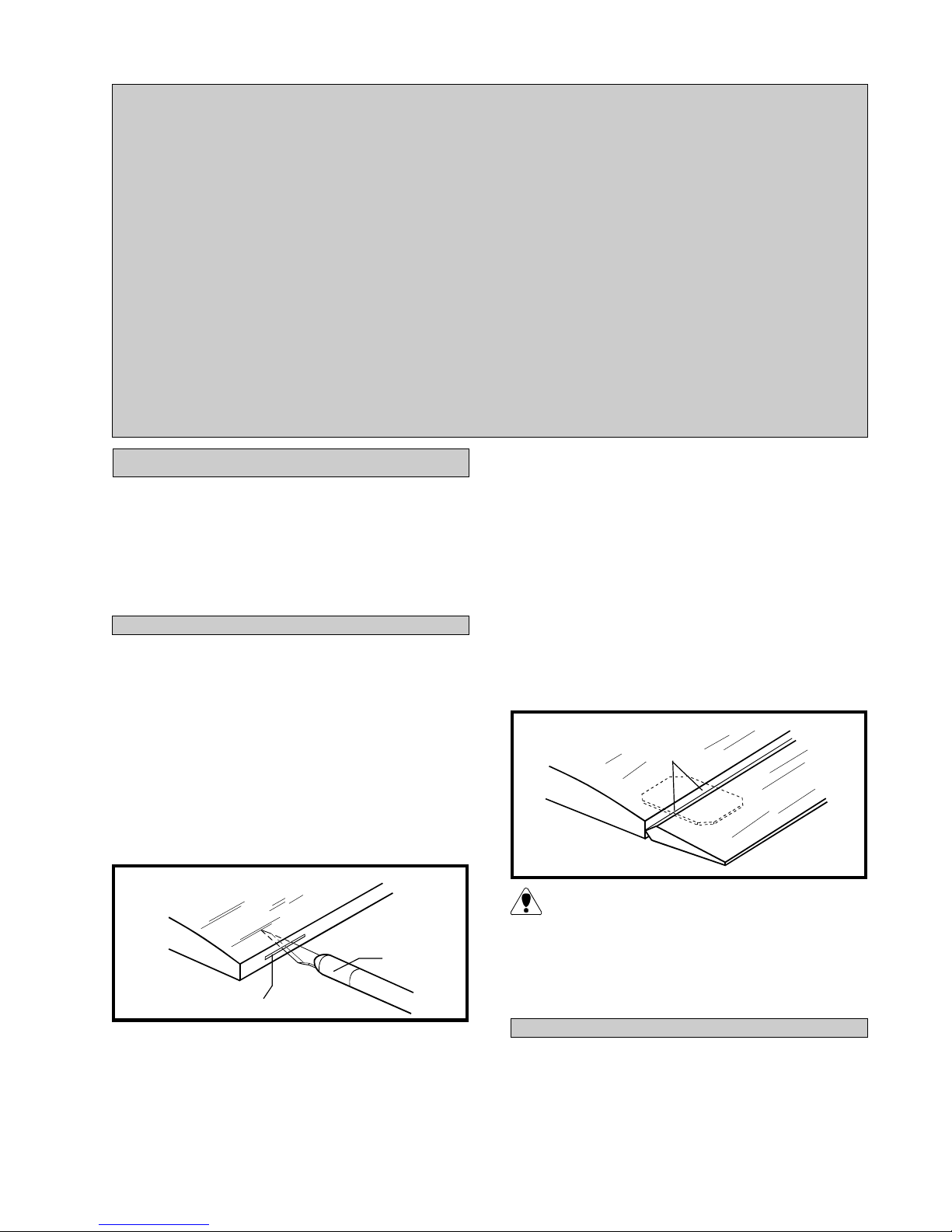

HINGING THE AILERONS

q 1) Locate the three precut hinge slots in the trailing edge of each wing half and the leading edge of

each of the two ailerons.

q 2) T est fit the six C/A hinges into the hinge slots

in each aileron. Each hinge should be able to be inserted far enough into the aileron so the centerline of

the hinge is flush with the leading edge of the aileron.

If the hinges cannot be inserted deep enough, use a

modeling knife and cut the hinge slots deeper. See

figure # 1 below.

Figure # 1

Modeling Knife

Hinge Slot

q 3) When satisfied with the fit of the hinges in

the ailerons, remove them and test fit the hinges into

the trailing edge of the wing halves. The centerline

of each hinge should be flush with the trailing edge

of the wing halves. If they are not, perform the same

technique as done in step # 2 above.

q 4) T est fit the ailerons to the wing halves, making sure the ailerons engage each hinge completely.

Push the ailerons tight up against the trailing edge of

the wing halves. Move the ailerons up and down to

ensure they move smoothly. The gap between the

leading edge of the ailerons and the trailing edge of

the wing halves should be no more that 1/32”.

q 5) Apply 6-8 drops of Kwik Bond Thin C/A to

the exposed area of both sides of each hinge. Allow a

few seconds between drops for the C/A to wick into

the hinge. See figure # 2 below.

Figure # 2

Apply C/A

Here

Be careful not to use too much C/A at one time

as the excess C/A may run down the length of

the hinge line. Once cured, the ailerons may be stiff

and difficult to move. This is normal. Gently move

the ailerons up and down about five to ten times to

free them up.

INSTALLING THE AILERON SERVOS

q 6) Locate the two aileron servos, two 12” aileron extensions, one Y-Harness and Dubro heat shrink

tubing that you purchased separately.

5

Page 6

q 7) Plug the two servos into your radio receiver

and center them both. Make sure the aileron trim tab

on your transmitter is centered as well. Install the

rubber isolation grommets and brass collets onto both

servos. The collets should be installed with the flanges

towards the bottom of the servo.

blocks into place on the servo tray . Allow the epoxy

to fully cure before proceeding.

It is important that you use epoxy in this situa-

tion. C/A glues will not adhere as well to the

hardwoods, and if used, the blocks could break loose

when installing the servo, or worse, during flight.

q 8) Install a single long servo arm onto each of

the servos. The arms should be mounted 90º to the

centerline of the servos. See figure # 3 below .

Figure # 3

Servo Arm

90º

q 9) Locate the two precovered aileron servo

hatches. Turn each of the two hatches upside down

(non-covered side) and you will notice precut oval

holes. Using a modeling knife, remove the covering

from over the two holes. These holes are where the

servo arms will exit and actuate the ailerons.

q 10) Working on the bottom of one servo hatch

for now, place one servo onto the hatch. The servo

arm should be inserted through, and centered in, the

precut hole. Notice the hole is angled. Make sure the

servo is parallel to the hole.

q 11) Holding the servo in proper alignment on

the hatch, temporarily place two of the 8mm x 15mm

x 20mm wood blocks in place behind the servo

mounting tabs. The blocks are positioned vertically

with the taller side up. See photo # 1 below.

Photo # 1

q 14) After the epoxy has cured, place the servo

back onto the hatch. Mark the locations of the four

mounting screws onto the two blocks using a pencil.

q 15) Remove the servo and drill 1/16” pilot holes

through the blocks for the servo mounting screws.

Drilling pilot holes into the wood before install-

ing the screws is important. It will keep the

wood from splitting when the screws are installed.

q 16) Place the servo back onto the servo hatch

and secure it in place with the mounting screws. Repeat steps # 10 - # 15 for the second aileron servo.

On the bottom of each hatch place a mark so you know

which one is for the right and which one is for the

left. This will help keep you from mixing them up.

INSTALLING THE SERVO HATCHES

q 17) Turn one wing panel right side up. Using a

modeling knife and a razor saw, remove the portion

of the root rib above the precut servo exit hole and

cut a half circle in the top of the wing to allow the

servo wire to pass through. See photo # 2 below .

Photo # 2

Remove from

Top Sheeting

Remove from

Root Rib

Hardwood

Block

Servo

Hatch

q 12) Using a pencil, outline the locations of the

two hardwood blocks and the servo onto the bottom

of the servo hatch.

q 13) Remove the parts from the hatch. Using

Kwik Bond 5 Minute Epoxy, glue the two wood

Hardwood

Block

Precut

Hole

Servo

Arm

q 18) Attach one 12” aileron extension to one

servo lead. Cut one 1-1/2” length of heat shrink tubing and slide it over the servo lead. Place the tubing

over the servo plugs where the lead and the extension

are connected. Shrink the tubing using a heat gun to

secure the plugs securely . See figur e # 4 below.

Figure # 4

Install Heat Shrink

Tubing Around Plugs

Servo

Lead

Servo

6

Lead

Page 7

The heat shrink tubing will prevent the plugs

from coming apart during assembly and more

importantly during flight. If you don't use heat shrink

tubing, electrical tape works well also.

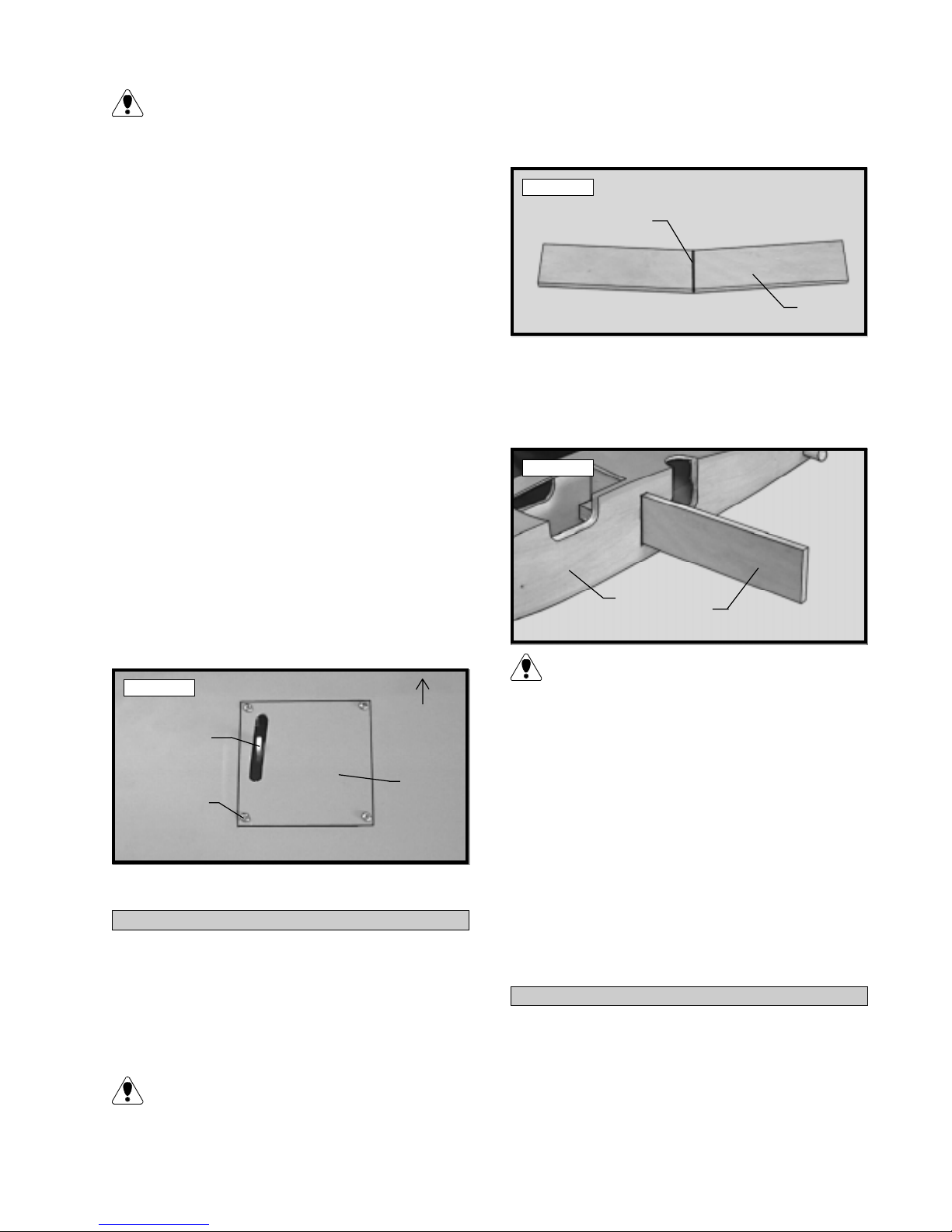

q 25) Using a ruler and a pen, locate and mark

the centerline of the plywood dihedral brace. Draw

one vertical line at this location on each side. See

photo # 4 below.

q 19) Using the throttle pushrod wire as a guide,

insert one end through the precut servo lead hole in

the root rib, through the center ribs and into the servo

bay in the middle of the wing. Using masking tape,

tape the servo lead to the end of the wire. Carefully

pull the wire out of the wing while guiding the servo

lead out. When you have pulled the servo lead out,

remove it and the masking tape from the wire.

q 20) Set the servo hatch in place on the bottom

of the wing. The hatch should be orientated with the

servo arm toward the wing tip and up towards the

leading edge.

q 21) Using a ruler and a pen, measure and mark

the four mounting hole locations onto the hatch. The

holes should be located 1/8” in from each edge.

q 22) Drill 5/64” pilot holes through the hatch and

into the hardwood blocks beneath it at the locations

marked. Be careful not to drill through the top of the

wing! Remove the hatch and enlarge the holes in

only the hatch using a 7/64” drill bit. Reinstall the

hatch using the four 2.5mm x 12mm wood screws.

See photo # 3 below.

Photo # 3

Leading

Servo

Arm

Wood

Screw

Edge

Servo

Hatch

q 23) Repeat steps # 17 - # 22 for the second servo

hatch assembly .

INSTALLING THE DIHEDRAL BRACE

q 24) Look at the surface of each root rib on both

wing halves. Notice how the excess covering material overlaps onto them. Using a modeling knife, carefully cut away the covering from both of the root ribs.

Leave about 1/16” of covering overlapping so it does

not pull away.

It is important that the covering be removed

from the root ribs. This will ensure an adequate

wood-to-wood glue joint and prevent wing failure

during flight.

Photo # 4

Draw

Centerline

Dihedral

Brace

q 26) Test fit the dihedral brace into the plywood

box in each wing half. The brace should slide into

each wing half up to the centerline. If it does not,

remove the brace and lightly sand the edges and tips

until the proper fit is obtained. See photo # 5 below.

Photo # 5

Root

Rib

Dihedral

Brace

The dihedral brace is cut in the shape of a "V".

The "V" shape should face the top surface of

the wing when the brace is installed.

q 27) T est fit both of the wing halves together with

the dihedral brace temporarily installed. Do not use

glue at this time! The wing halves should fit together tight with little or no gaps in the center section

joint. If the center section joint is not tight, remove

the wing halves and lightly sand the edges and tips of

the dihedral brace. Test fit the wing halves together

with the dihedral brace installed again. Repeat until

you are satisfied with the fit of the wing halves.

q 28) When satisfied with the fit of the wing

halves, remove the wing halves and the dihedral brace.

JOINING THE WING HALVES

q 29) Mix a generous amount of Kwik Bond 30

Minute Epoxy . Working with only one wing half for

now, apply a thin layer of epoxy inside the plywood

dihedral brace box and to only half of the dihedral

brace. Make sure to cover the top and bottom as well

as the sides, and use enough epoxy to fill any gaps.

7

Page 8

q 30) Slide the dihedral brace into the plywood

box up to the centerline. Remove any excess epoxy

before it dries using a paper towel and rubbing alcohol. Allow the epoxy to cure before proceeding.

q 31) Once the epoxy has cured, trial fit both wing

halves together to double check that the wing halves

still fit correctly.

Do not remove the covering from over the precut optional retract mounting holes, strut chan-

nels or wheel wells.

q 2) Insert the 90º bend of one main gear wire into

the rear hole in one mounting slot. The coiled spring

in the gear wire should be facing the trailing edge of

the wing.

q 32) Mix a generous amount of Kwik Bond 30

Minute Epoxy. Apply a thin layer of epoxy to the

exposed half of the dihedral brace, the inside of the

plywood box in the second wing half and the entire

surface of both root ribs. Make sure to use enough

epoxy to fill any gaps.

q 33) Slide the two wing halves together and carefully align them at the leading and trailing edges.

Wipe away any excess epoxy using a paper towel

and rubbing alcohol. Use masking tape to hold the

two wing halves in place until the epoxy cures. See

photo # 6 below.

Photo # 6

Wing

Servo

Lead

Exit

Joint

q 3) The gear wire is held in place using two landing gear straps and four 2.5mm x12mm wood screws.

The straps should be located equal distance from the

front of the gear wire and the back of it.

q 4) Using the landing gear straps as a guide, mark

the locations of the four 2.5mm x 12mm mounting

screws onto the wing.

q 5) Remove the straps and the gear wire. Drill

four 5/64” holes into the wing for the wood screws.

Be careful not to drill through the top of the wing!

q 6) Reinstall the gear wire and install the straps

using the four 2.5mm x 12mm wood screws. Tighten

them completely to secure the gear wire in place. See

photo # 7 below.

Photo # 7

Axle

Landing Gear

Wire

q 34) When the epoxy has fully cured, double

check the center section joint. If any gaps are present,

mix a small amount of Kwik Bond 30 Minute Epoxy

and carefully fill any remaining gaps. Allow the epoxy to fully cure before proceeding.

OPTIONAL FIXED MAIN GEAR

PARTS REQUIRED

q {2} Prebent Main Gear Wires

q {2} 50mm Diameter Wheels

q {4} Landing Gear Straps

q {8} 2.5mm x 12mm Wood Screws

q {2} Wheel Collars w/Set Screws

q {2} Nylon Spacers

INSTALLING THE MAIN GEAR STRUTS

q 1) Using a modeling knife, remove the covering from over the two main gear mounting slots located in the bottom of the wing. One slot is located

in each wing half, 8-3/4” out from the centerline of

the wing and 1-1/4” back from the leading edge. The

slot is 2-1/4” long.

Mounting

Strap

Trailing

Edge

Wood

Screw

q 7) Repeat steps # 2 - # 6 for the second landing

gear wire.

INSTALLING THE MAIN GEAR WHEELS

q 8) Slide one nylon spacer, then one wheel and

one wheel collar with set screw onto each axle. Make

sure the wheels spin free and tighten the set screws in

the wheel collars. See photo # 8 below.

Photo # 8

Set

Nylon

Spacer

Wheel

Screw

Wheel

Collar

8

Page 9

OPTIONAL RETRACT MAIN GEAR

PARTS REQUIRED

q {2} 50mm Diameter Wheels

q {2} Molded Plastic Retract Gear Covers

INSTALLING THE RETRACT MECHANISMS

q 1) Using a modeling knife, remove the covering from over the two sets of precut wheel wells, gear

strut channels and retract mounting blocks in the bottom of the wing. See photo # 9 below.

Photo # 9

Wheel

Well

q 2) Working with one wing half at a time, trial

fit the retract mechanism onto the hardwood mounting rails.

Strut

Channel

Mounting

Blocks

q 5) Repeat steps # 2 - # 4 for installing the second retract mechanism.

INSTALLING THE RETRACT SERVO

q 6) Install the rubber isolation grommets and

brass collets onto your retract servo. Place the servo

onto the preinstalled rails in the servo compartment

in the top of the wing. The servo output shaft should

face the leading edge of the wing.

q 7) Using a 1/16” drill bit, drill pilot holes through

the rails for the mounting screws. Be careful not to

drill through the bottom of the wing!

q 8) Secure the servo in place on the rails using

the mounting screws provided with the servo. See

photo # 11 below.

Photo # 11

Retract

Servo

Output

Shaft

The spacing between the two hardwood rails

should be sufficient for most popular brands of

retracts. If your retract mechanism is wider, you will

need to trim equal amounts of material off of the inside edge of each hardwood rail. If this is necessary ,

we recommend using a Dremel Tool with a sanding

drum attachment.

q 3) When satisfied with the fit of the mechanism,

install the retract onto the rails. Drill 5/64” pilot holes

through the rails to prevent the wood from splitting

when you install the mounting screws. Be careful

not to drill through the top of the wing!

q 4) Install the retract using the mounting screws

provided with the retract. Tighten the screws completely. See photo # 10 below.

Photo # 10

Retract

Mechanism

(not included)

Mounting

Screw

Leading

Edgle

INSTALLING THE RETRACT LINKAGE

q 9) Using wire cutters, cut both 12” 2-56 threaded

rods (not included) to 5” long. Thread one nylon clevis (not included) onto each of the two rods.

q 10) Slide the two threaded rods, with the clevises attached, through the precut slots in the ribs, up

to the retract mechanism. Snap the clevises onto the

adjustable control horns. See photo # 12 below.

Photo # 12

Nylon

Clevis

Pushrod

Wire

Adjustable

Control

Horn

Retract

Arm

The easiest way to get the threaded rods through

the slots is to insert the clevis end first through

the retract servo opening. They will slide through the

slots, up to the retract mechanism without any bending necessary.

9

Page 10

q 11) Using a ruler, measure the distance your retract mechanism moves from the full up and locked

position to the full down and locked position. For

most retracts this measurement should be about 1”.

See figure # 5 below.

Figure # 5

X

X = Distance of

Actuator Arm

Travel

q 12) To secure the two pushrod wires to the servo

wheel, we suggest using EZ Connectors. For the

mechanism to work properly the EZ Connectors need

to be installed on the servo wheel the exact distance

apart as the distance your retract mechanism travels.

You may need to drill your own holes through the

servo wheel if there are no predrilled holes that fit the

proper measurement. See figure # 6 below .

Figure # 6

X = Measurement From Step # 11

q 15) Rotate the servo wheel 180º so the retracts

are in the full down and locked position. Use pliers

and carefully bend each of the wires to prevent them

from hitting the EZ Connectors. See figure # 7 below .

Figure # 7

EZ

Connector

Make

Bend

Make

Bend

EZ

Connector

When you make the bend in the two wires, this

will shorten the wires slightly. You may need to

readjust the length of the wires using the EZ Connector.

q 16) Rotate the servo wheel back and forth to test

the operation of the retracts. If any binding is present

make small bends or adjustments in the linkage.

It is important that the retract linkage operates

smoothly. Any binding can cause the retract

servo to stall and result in excessive battery drain.

INSTALLING THE RETRACT GEAR COVERS

X

q 13) With the EZ Connectors installed on the

servo wheel slide the threaded wires through the connectors. With the gear in the full UP and locked position, attach the servo wheel to the servo so that the

EZ Connectors and wires are opposite each other . If

necessary, use a modeling knife and remove a portion of the top sheeting to allow clearance for the servo

wheel and connector. See photo # 13 below.

Photo # 13

EZ

Connector

Remove

Sheeting

Pushrod

Wire

q 17) Using Lexan Canopy Scissors or a modeling knife, cut out both plastic retract gear covers, leaving about a 1/8” lip around the entire perimeter to use

as a gluing surface. Cut the two gear covers apart in

the center. See photo # 14 below.

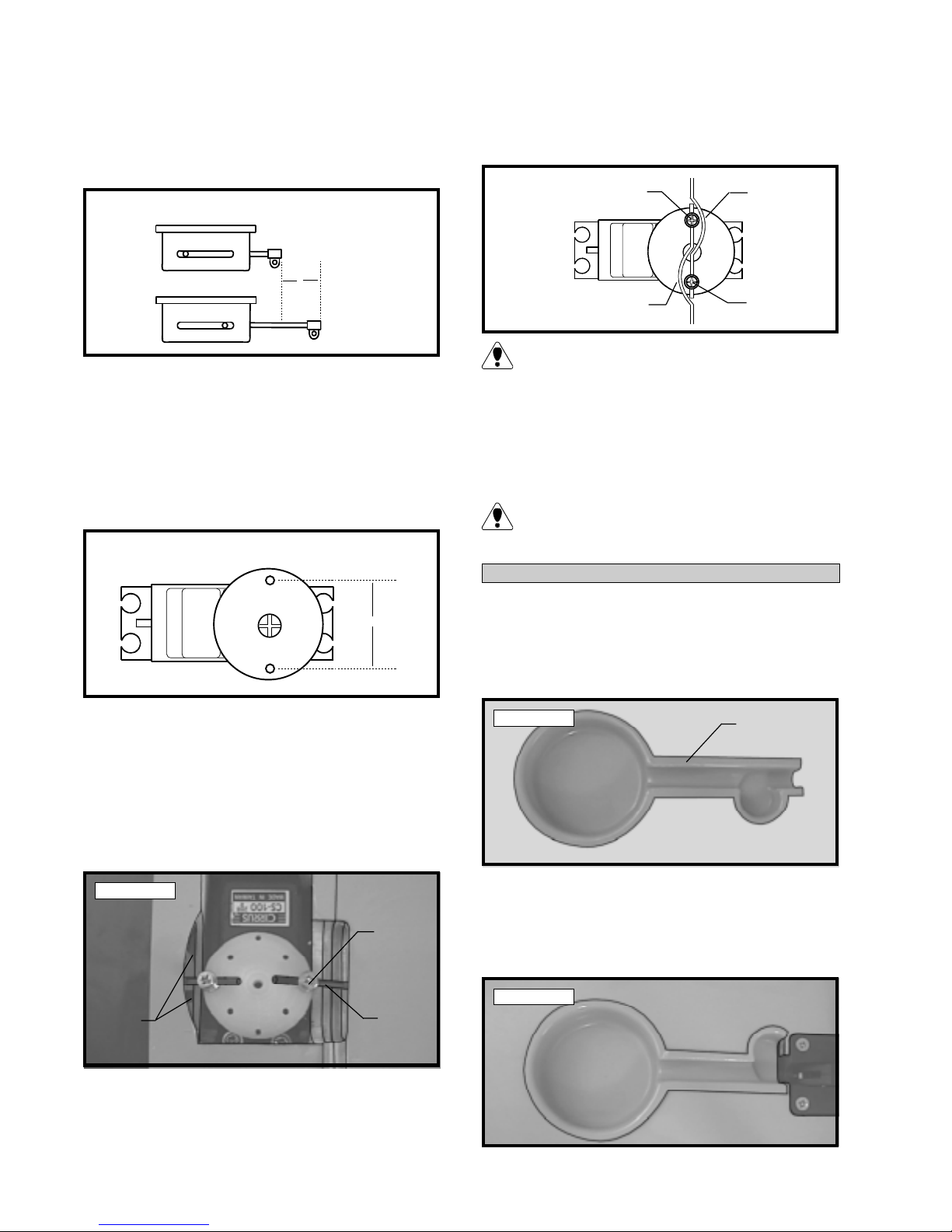

Photo # 14

1/8” Lip for

Gluing Surface

q 18) Test fit the two gear covers in place on the

wing. They should fit inside the gear cutout and the

lip should rest flush on the wing surface. You may

have to make minor adjustments to fit your particular

retract installation. See photo # 15 below.

Photo # 15

q 14) Double check that the retracts are in the full

up and locked position. Tighten the set screws in the

EZ Connectors and cut off the excess wires, leaving

5/16” beyond each EZ Connector as shown above.

10

Page 11

q 19) When satisfied with the fit, glue the plastic

gear covers into place using RC256 Canopy Glue.

Hold the covers in place using masking tape until the

glue fully cures.

INSTALLING THE WHEELS

q 20) If you haven't already done so, install the

strut wires into the retract mechanisms. The coil in

the wires should face the trailing edge of the wing.

q 21) Mount the wheels to the adjustable axle

assemblies.

If your brand of retracts did not include adjustable axle assemblies, Dubro Adjustable Axles

# 248 are recommended.

q 22) Slide the axle assemblies over the strut

wires and center the wheels in the wheel cover.

Tighten the set screws in the adjustable axles. Cut

off any excess wire using a Dremel Tool with a cutting disc attachment. See photo # 16 below.

Photo # 16

Strut

Wheel

Wire

q 2) Place the wing into the wing saddle and temporarily secure it in place using the two 4mm x 40mm

machine screws and 4mm plastic flat washers.

T wo 4mm blind nuts have been preinstalled into

the bottom of the wing mounting block.

INSTALLING THE WING BOLT DOUBLER

q 3) Remove the wing bolts and washers, but leave

the wing in place and aligned in the wing saddle. Hold

it in place with a couple of pieces of masking tape to

help keep it from moving.

q 4) With the wing held firmly in position, set

the wing bolt doubler in place. The rear edge of

the doubler should be flush with the trailing edge

of the wing and the sides of the doubler should be

centered over the centerline of the wing. See photo

# 17 below.

Photo # 17

Centerline

Wing Bolt

Doubler

Wheel

Cover

Adjustable

Axle

q 23) Rotate the servo wheel until the retracts are

in the full down position. Both wheels should point

straight ahead and be parallel with each other.

q 24) Using a modeling knife, carefully cut a hole

in the bottom of each plastic gear cover to allow the

wheel collar to pass through when the landing gear

are fully retracted. Be careful not to cut through the

top of the wing.

WING MOUNTING

PARTS REQUIRED

q {2} 4mm x 40mm Socket Cap Screws

q {2} 4mm Plastic Flat Washers

q {1} Precovered Wing Bolt Doubler

q {1} Molded Plastic Wing Fairing

INSTALLING THE WING

q 1) Using a modeling knife, remove the covering from over the two predrilled wing mounting holes

in the trailing edge of the wing. The holes are located

5/8” forward of the trailing edge and 1-5/8” out from

the centerline. Remove the covering from over the

holes on both the top and bottom of the wing.

q 5) While holding the doubler in place, use a pen

and draw around the doubler to outline it onto the

wing surface.

q 6) Remove the doubler. Using a modeling knife,

carefully remove the covering from just inside the

outline.

q 7) Mix up a small amount of Kwik Bond 5

Minute Epoxy and use it to glue the wing doubler to

the wing. Any excess epoxy can be removed using a

paper towel and rubbing alcohol before the epoxy

cures.

q 8) After the epoxy has fully cured, remove the

wing and drill out the wing mounting holes through

the doubler using an 11/64” drill bit. Use the holes

already drilled through the wing as a guide.

q 9) Place the wing back into the wing saddle. Secure the wing in place using the two 4mm x 40mm

machine screws and two 4mm plastic flat washers.

11

Page 12

INSTALLING THE WING FAIRING

q 10) Using a modeling knife, or Lexan Canopy

Scissors, cut out the plastic wing fairing along the

molded scribe line. See photo # 18 below.

Photo # 18

the fuselage sides out to the stabilizer's tips. Both

measurements should be equal when the stabilizer is

centered. See figure # 8 below.

Figure # 8

A = A-1

Leave 1/8”

Wing

Fairing

Material

q 11) Test fit the fairing to the bottom of the wing.

There should be about 1/16” gap between the front

edge of the fairing and the back edge of the fuselage.

q 12) Using a modeling knife, carefully trim the

forward edges of the fairing to match the contour of

the wing's leading edge.

q 13) When satisfied with the fit, glue the fairing

to the wing using RC256 Canopy Glue. Use pieces

of masking tape to hold the fairing in place until the

glue completely cures. See photo # 19 below.

Photo # 19

Wing

Fairing

A

A-1

q 3) When satisfied that the stabilizer is centered,

place a mark on each side of the top and bottom of

the stabilizer where it and the fuselage sides meet.

Doing this will help you realign the stabilizer later.

q 4) With the stabilizer centered in the fuselage,

use a couple of pieces of masking tape or a T-pin to

secure the stabilizer in place at the trailing edge only .

q 5) Align the stabilizer to the wing. When viewed

from the rear, the stabilizer should be level with the

wing. If it is not, remove the stabilizer and use 220 grit

sandpaper to sand down the high side of the stabilizer

mounting platform in the fuselage until the stabilizer is

level with the wing. Measure the distance from each

wing tip to each stabilizer tip. These distances should

be equal. See figures # 9 and # 10 below.

Bottom

Surfaces

Flush

1/16” Gap

HORIZONTAL STABILIZER

INSTALLATION

PARTS REQUIRED

q {1} Horizontal Stabilizer with Elevator Halves

q {6} C/A Hinges

ALIGNING THE HORIZONTAL STABILIZER

q 1) Using a ruler and a pen, locate the centerline

of the horizontal stabilizer, at the trailing edge, and

place a mark. Use a triangle and extend this mark,

from back to front, across the top of the stabilizer.

q 2) Slide the stabilizer into place in the precut

slot in the rear of the fuselage. To center the stabilizer from side to side, measure the stabilizer from

Figure # 9

B

Figure # 10

C C-1

B-1

B = B-1

C = C-1

q 6) When you are satisfied with the alignment,

hold the stabilizer in place using a couple of pieces of

masking tape or a couple of T-pins.

12

Page 13

q 7) On the top and bottom of the stabilizer, draw

a line where it and the fuselage sides meet. Do this

on both the right and left sides.

q 8) Remove the stabilizer. Using the lines you

drew as a guide, remove the covering from between

them using a modeling knife. See photo # 20 below.

Photo # 20

Draw

Line

Remove

Covering

Draw

Line

When using the modeling knife, be careful not to

cut too deep. Only use enough pressure to cut

the covering. Cutting deeper into the wood can weaken

the structure and cause the stabilizer to fail in flight.

MOUNTING THE HORIZONTAL STABILIZER

q 9) When you are sure that everything is aligned

correctly , glue the horizontal stabilizer in place using

Kwik Bond 30 Minute Epoxy. Double check all of

your measurements once more before the epoxy cures.

Wipe away any excess epoxy using paper towels and

rubbing alcohol and hold the stabilizer in place using

masking tape or T-pins.

VERTICAL STABILIZER

INSTALLATION

PARTS REQUIRED

q {1} Vertical Stabilizer with Rudder

q {3} C/A Hinges

ALIGNING THE VERTICAL STABILIZER

q 1) Slide the vertical stabilizer into the slot in the

top of the fuselage. The rear edge of the stabilizer

should be even with the rear edge of the fuselage and

the bottom of the stabilizer should be firmly pressed

against the top of the horizontal stabilizer. The dorsal fin should be centered with, and pressed firmly

against, the top of the fuselage.

q 2) While holding the vertical stabilizer firmly

in place, use a pen and draw a line on each side of the

vertical stabilizer where it meets the top of the fuselage. Also draw a line on the top of the fuselage where

it and the dorsal fin meet.

q 3) Remove the stabilizer. Using a modeling

knife, remove the covering from below the lines you

drew. Also remove the covering from the bottom edge

of the stabilizer, the bottom edge of the dorsal fin and

between the lines you drew on top of the fuselage.

See photo # 21 below.

Photo # 21

Remove

Covering

Draw

Line

Because the stabilizer has to slide in place

through the fuselage, we suggest you apply a

liberal amount of epoxy to only the gluing surface of

the stabilizer . This will prevent spreading epoxy over

the entire length of one half of the stabilizer when

you slide it in place. After the epoxy has cured, use

more epoxy to fill in any gaps that may exist that were

not filled previously.

HINGING THE ELEVATOR HALVES

q 10) Hinge the two elevator halves using the same

technique as with the ailerons.

Be careful not to use too much C/A at one time

as the excess C/A may run down the length of

the hinge lines. Once cured, the elevator halves may

be stiff and difficult to move. This is normal. Gently

move them up and down about five to ten times to

free them up.

When cutting through the covering to remove

it, cut with only enough pressure to only cut

through the covering itself. Cutting into the balsa

structure may weaken it.

q 4) Slide the vertical stabilizer back in place.

Using a triangle, check to ensure that the vertical stabilizer is aligned 90º to the horizontal stabilizer. See

figure # 1 1 below.

Figure # 11

Horizontal

Stabilizer

90º

Vertical

Stabilizer

13

Page 14

MOUNTING THE VERTICAL STABILIZER

q 5) When you are sure that everything is aligned

correctly , mix up a generous amount of Kwik Bond

30 Minute Epoxy . Apply a thin layer to the mounting slot in the top of the fuselage and to the sides

and bottom of the vertical stabilizer mounting area.

Apply epoxy to the bottom edge of the dorsal fin

and to the top of the fuselage also. Set the stabilizer

in place and realign. Double check all of your measurements once more before the epoxy cures. Hold

the stabilizer in place with T-pins or masking tape

and remove any excess epoxy using a paper towel

and rubbing alcohol. Allow the epoxy to fully cure

before proceeding.

HINGING THE RUDDER

q 2) Insert one 2mm wheel collar into the molded

recess in the tail wheel tiller arm. Align the hole in

the wheel collar with the hole in the side of the tiller

arm. Install the 2mm x 5mm machine screw .

q 3) Slide the tail wheel tiller arm onto the tail

wheel wire. The arm should be positioned straight

back from the bracket and 90º to the axle The coil in

the wire should face forward. Tighten the machine

screw to secure the assembly in place. See photo #

22 below .

Photo # 22

Tail Wheel

Bracket

Set

Screw

Tiller

Arm

q 6) Hinge the rudder using the same technique

as with the ailerons and elevator halves.

Be careful not to use too much C/A at one time

as the excess C/A may run down the length of

the hinge line. Once cured, the rudder may be stiff

and difficult to move. This is normal. Gently move

it back and forth about five to ten times to free it up.

TAIL WHEEL INSTALLATION

PARTS REQUIRED

q {1} Nylon Tail Wheel Bracket

q {1} Nylon Tail Wheel Tiller Arm

q {1} Prebent Tail Wheel Wire

q {1} 25mm Diameter Tail Wheel

q {1} 2mm x 40mm Wire Pin

q {2} 2mm Wheel Collars

q {2} Brass Bearing Inserts

q {2} 2mm x 5mm Machine Screws

q {3} 3mm x 10mm Wood Screws

TAIL WHEEL BRACKET ASSEMBLY

q 1) Slide one brass bearing, flange side down,

onto the tail wheel wire. Insert the wire up through

the bottom of the tail wheel bracket. Slide the second

brass bearing, flange side up, onto the wire. Push

firmly on each bearing to seat them into the top and

bottom of the bracket. See figure # 12 below.

Tail Wheel

Wire

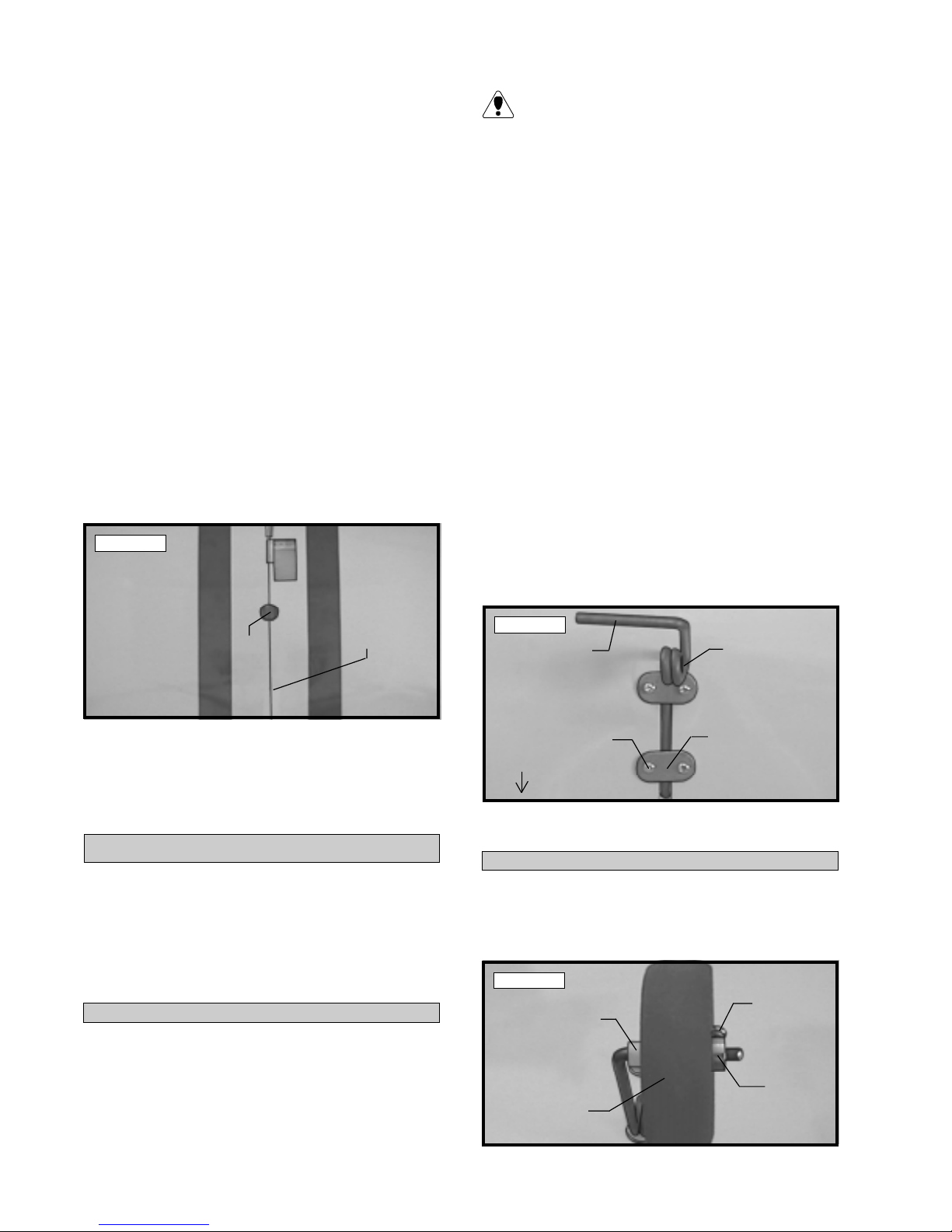

MOUNTING THE TAIL WHEEL ASSEMBLY

q 4) Set the tail wheel assembly in place. The

pivot point of the tiller arm should be even with the

rudder hinge line and the tail wheel bracket should be

centered on the bottom of the fuselage.

q 5) Using a pen, mark the locations of the three

mounting screws. Remove the tail wheel bracket and

drill 5/64” pilot holes at the locations marked.

q 6) Secure the tail wheel bracket in place using

three 3mm x 10mm wood screws. Be careful not to

overtighten the screws. See photo # 23 below.

Photo # 23

Tiller

Arm

Tail Wheel

Bracket

Figure # 12

Brass

Bearing

Brass

Bearing

Tail Wheel

Bracket

q 7) Using a ruler and a pen, measure back and

place a mark on the bottom edge of the rudder 1-1/4”

back from the rudder's leading edge.

q 8) Rotate the tiller arm to the side. Using a 5/64”

drill bit, drill a hole into the bottom of the rudder at

the mark made. Drill the hole at least 3/4” deep and

parallel with the rudder hinge line.

14

Page 15

q 9) Mix up a small amount of Kwik Bond 5

Minute Epoxy. Using a toothpick, pack epoxy into

the hole. Rotate the tiller arm so the slot in the arm is

even with the hole in the bottom of the rudder.

q 10) Insert the 2mm x 40mm wire pin through the

slot and into the hole. The wire should extend about

7/8” beyond the bottom edge of the rudder. Allow the

epoxy to fully cure. See photo # 24 below.

Photo # 24

Wire

Pin

Tiller

Arm

For four cycle engines we recommend a .60 - .80 displacement engine mounted inverted. This is a very

clean installation and use of an in-cowl muffler is unnecessary. The exhaust can simply be directed out

the bottom of the cowling. Which ever system you

choose, the following assembly steps layout the specific crankshaft location for both two cycle and four

cycle engines. Engines are mounted with 0º thrust.

INST ALLING THE ENGINE TO THE MOTOR MOUNT

For both 2 cycle and 4 cycle engines

q 1) Use a clamp and a spacer to hold the two

mounting beams together. The beams should be level

with each other and parallel. The predrilled mounting holes are not the same distance from the beam

surface. The engine should be mounted on the "tall"

side of the beams. See photo # 25 below.

q 11) Loosen the machine screw in the side of the

tiller arm and align the tail wheel wire with the rudder. When satisfied with the alignment, tighten the

machine screw securely .

INSTALLING THE TAIL WHEEL

q 12) Install the 25mm diameter tail wheel onto

the tail wheel wire. Secure the tail wheel in place

using one 2mm wheel collar and one 2mm x 5mm

machine screw . Slide the wheel collar on enough so

it is up against the tail wheel, but not so tight that the

tail wheel won't turn. The tail wheel should rotate

without binding.

ENGINE INSTALLATION

PARTS REQUIRED

q {2} Nylon Motor Mount Beams

q {4} 4mm x 20mm Machine Screws

q {4} 4mm x 35mm Machine Screws

q {8} 4mm Flat Washers

q {4} 4mm Split Washers

q {4} 4mm Hex Nuts

q {4} 4mm Blind Nuts

ENGINE INSTALLATION OPTIONS

Several options can be used for the engine and

style of installation you choose. For two cycle

engines, we recommend a .40 - .53 displacement engine mounted sideways. The Skyraider will accept a

two cycle engine with a stock muffler, but trimming

of the cowl to fit the muffler will be necessary . For a

cleaner and more scale appearance the use of an incowl Pitts style muffler, compatible with the engine

you're using, is highly recommended.

Photo # 25

Motor

Mount

Beams

Clamp

Spacer

q 2) Mark the locations of the four engine mounting holes on the beams using a pencil. For the engine

to align properly with the front of the cowling, it is

important that the front edge of the engine's drive

washer be 4-1/2” forward back surface of the mounting beams.

q 3) When satisfied with the alignment of the engine, remove the beams from the clamp and drill 3/32”

pilot holes through the mounting beams at the four

engine mounting hole locations. Double check the

alignment of the engine and then drill out the holes

through the beams using a 5/32” drill bit.

q 4) Mount the engine to the mounting beams using the four 4mm x 35mm machine screws, four 4mm

flat washers, four 4mm split washers and four 4mm

hex nuts. The flat washers and split washers are installed on the bottom of the beams only . Tighten the

screws and nuts completely. See photo # 26 below.

Photo # 26

15

Page 16

If using an engine equipped with a remote needle

valve we recommend mounting the needle valve

to the engine after installing the motor mount/engine

assembly to the firewall.

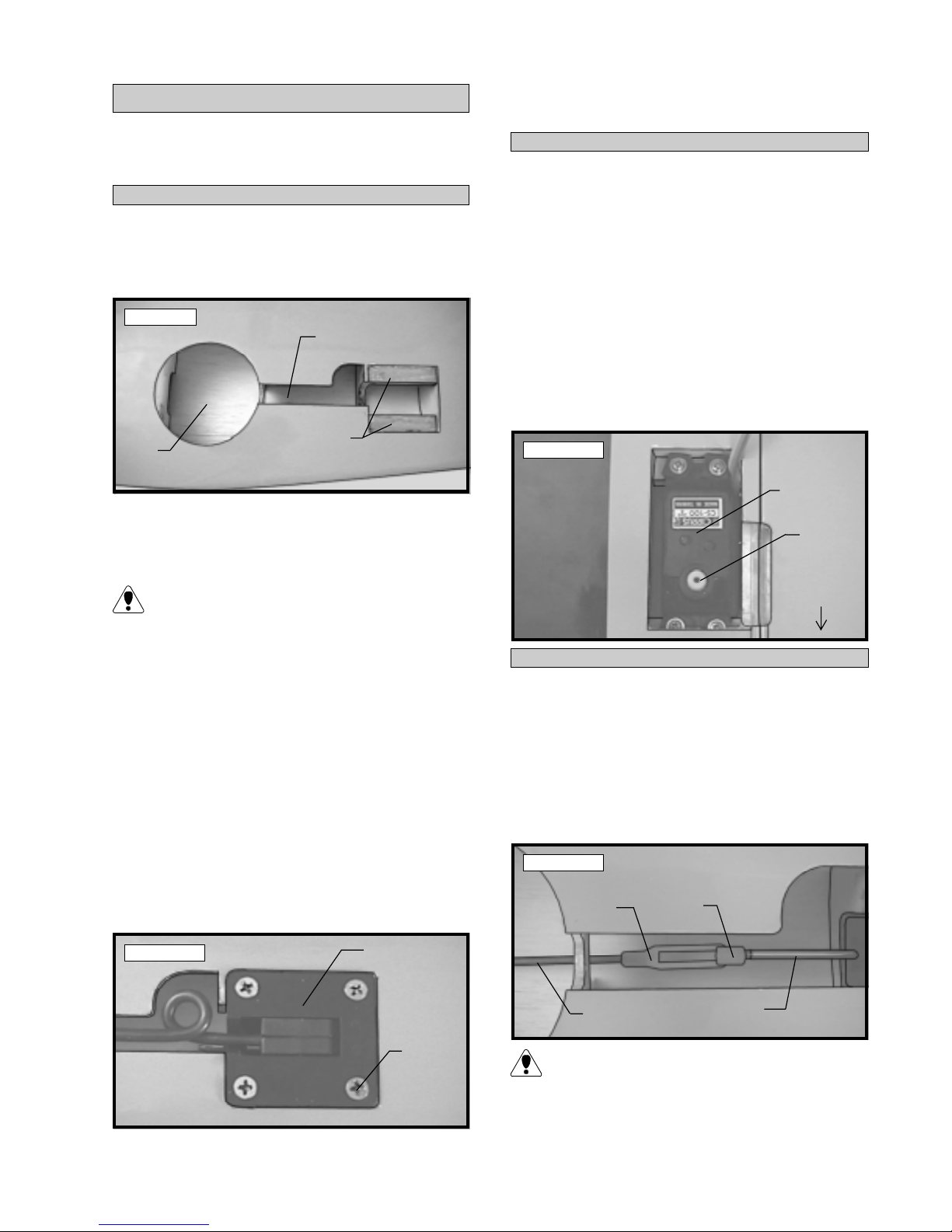

MOUNTING THE ENGINE TO THE FIREWALL

For 2 cycle engines only

q 5) The engine is mounted at a 90º angle in relation to the firewall. The motor mount beams should

be parallel with the bottom of the firewall. Using a

ruler and a pen, measure and draw a vertical centerline on the firewall.

q 6) Using a ruler and a pen, measure up from

the bottom of the firewall 1-1/2” and place two

marks. Draw a horizontal line at these two marks.

See photo # 27 below.

Photo # 27

Vertical

Centerline

q 9) On the two horizontal lines you just drew,

measure and place two marks 5/8” to the left of the

vertical centerline and two marks 1-1/16” to the right

of the vertical centerline (looking at the firewall). See

photo # 29 below.

Photo # 29

q 10) Hold the motor mount assembly up to the

firewall and double check that the four intersecting

lines line up with the four predrilled holes in the

mounting beams.

q 11) Using a 7/32” drill bit, drill the four mounting holes through the firewall for the four motor mount

beam screws.

Horizontal

Centerline

q 7) With your engine still installed on the mounting beams, use a ruler and measure the width between the predrilled mounting holes in the motor

mount beams. This distance will vary depending on

the brand and size of the engine you have chosen.

See photo # 28 below.

Photo # 28

X = Distance

between beam

mounting holes

X

q 8) Divide the measurement found in step # 7

in half. Measure and mark this resulting distanceand

place marks above and below the horiztonal centerline. Draw one horizontal line at the marks made

above and below the horizontal centerline.

q 12) Mount the motor mount assembly to the

firewall using the four 4mm x 20mm machine

screws, four 4mm flat washers and four 4mm blind

nuts. Tighten the screws securely to draw the blind

nuts into the back of the firewall completely. See

photo # 30 below.

Photo # 30

MOUNTING THE ENGINE TO THE FIREWALL

For 4 cycle engines only

q 13) The engine is mounted 180º down in relation to the firewall. The motor mount beams should

be parallel with the fuselage sides. Using a ruler and

a pen, measure and draw a vertical centerline on the

firewall.

16

Page 17

q 14) Using a ruler and a pen, measure up from

the bottom of the firewall 1-1/2” and place two

marks. Draw a horizontal line at these two marks.

See photo # 31 below.

q 18) Hold the motor mount assembly up to the

firewall and double check that the four intersecting

lines line up with the four predrilled holes in the motor mount beams.

Photo # 31

Vertical

Centerline

Horizontal

Centerline

q 15) With your engine still installed on the motor mount beams, use a ruler and measure the width

between the predrilled mounting holes in the motor

mount. This distance will vary depending on the

brand and size of the engine you have chosen. See

photo # 32 below.

Photo # 32

q 19) Using a 7/32” drill bit, drill the four mounting holes through the firewall for the motor mount

beams.

q 20) Mount the motor mount assembly to the firewall using the four 4mm x 20mm machine screws,

four 4mm flat washers and four 4mm blind nuts.

Tighten the screws securely to draw the blind nuts

into the back of the firewall completely.

FUEL TANK

PARTS REQUIRED

q {1} 280cc Molded Fuel Tank

q {1} 4mm x 28mm Nylon Pick-Up Tube

q {2} 4mm x 28mm Prebent Nylon Vent Tube

q {1} 3mm x 18mm Self Tapping Screw

q {1} Length of Fuel Tubing

q {1} Metal Weighted Pick-Up

q {1) Nylon Fuel Cap

q {1} Rubber Stopper

q {1} Nylon Backplate

STOPPER ASSEMBLY

q 1) Identify each of the parts that make up the

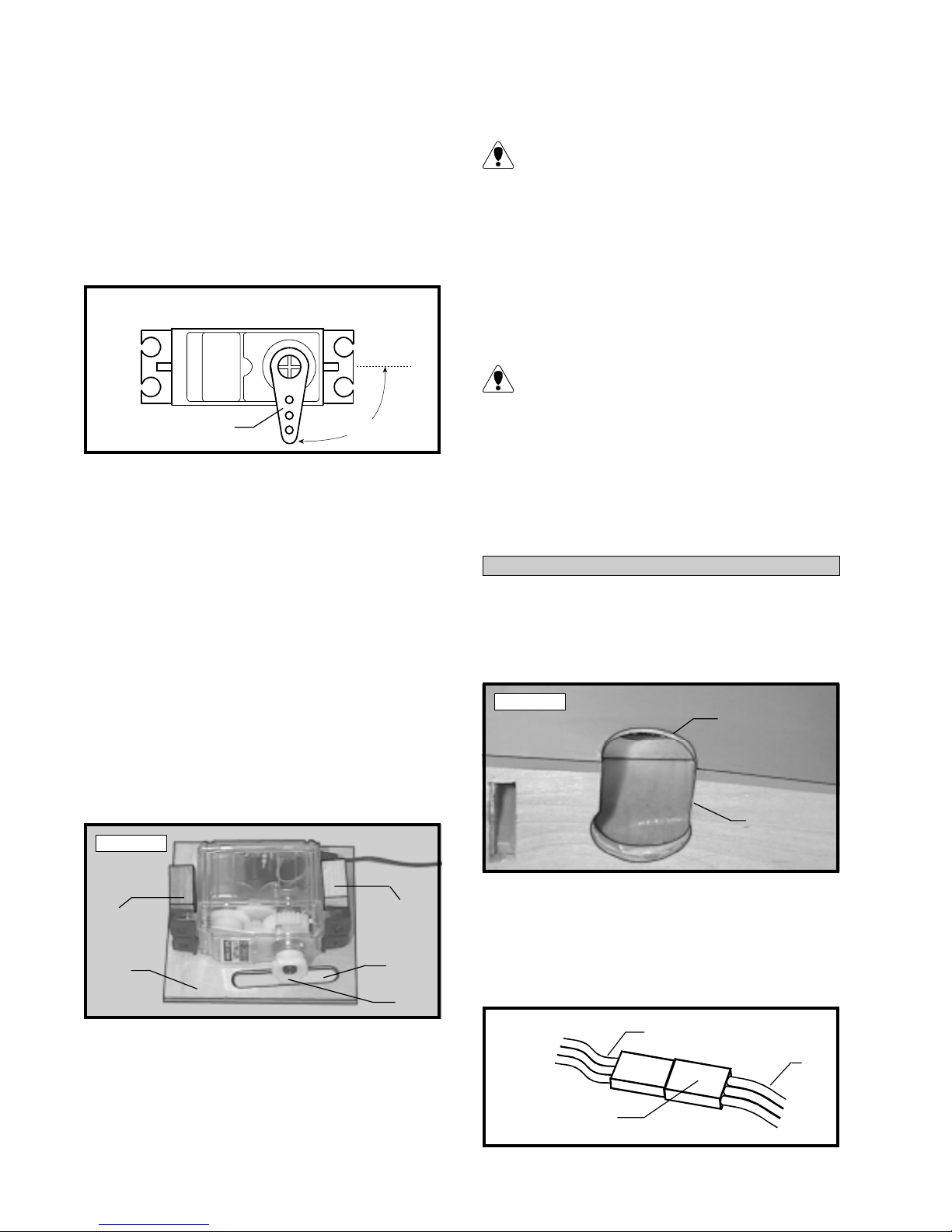

fuel tank assembly. See photo # 34 below.

X = Distance

Between Beam

Mounting Holes

X

q 16) Divide the measurement found in step # 15

in half. Measure and mark this resulting distanceand

place marks to the right and left of the vertical centerline. Draw one vertical line at the marks made to the

right and left of the vertical centerline.

q 17) On the two vertical lines you just drew,

measure and place two marks 5/8” below the horizontal centerline and two marks 1-1/16” above the

horizontal centerline (looking at the firewall). See

photo # 33 below.

Photo # 33

Photo # 34

Silicon

Tube

Cap

Screw

Rubber

Stopper

Backplate

Pickup

Tube

Vent

Tubes

Tank

Clunk

q 2) Using a modeling knife, cut the silicon fuel

tubing to 3-3/4” long. Connect one end of the tubing

to the weighted pick-up.

There are three molded holes in the rubber fuel

tank stopper. Two are opened and one is covered by a thin layer of rubber on the front of the stopper. Using a modeling knife, remove the thin layer of

rubber to completely open the third hole.

q 3) Push the single 4mm x 28mm nylon pickup

tube through one hole in the rubber stopper until 3/8”

protrudes from the front of the stopper. Slide the nylon backplate over the tube at the back of the stopper.

17

Page 18

q 4) Push one 4mm x 28mm prebent nylon vent

tube through the nylon backplate and through the rubber stopper until it protrudes 3/8” from the front of

the stopper.

q 5) Using a modeling knife, remove part of the

second nylon vent tube as shown below . This will be

the fill tube. Push it through the nylon backplate and

through the rubber stopper until it protrudes 3/8” from

the front of the stopper. It is used in conjunction with

the fuel filler that will be installed later. Orientate the

tubes as shown. See figure # 13 below.

Figure # 13

Nylon

Backplate

Fill

Tube

Vent

Tube

Pickup

Tube

(Drawing is Full Size)

q 6) Slide the nylon fuel cap over the three tubes

at the front of the stopper. Insert the 3mm x 18mm

self tapping screw into the center hole in the cap. Push

the screw through the stopper and into the nylon backplate. Begin to tighten the screw, but do not completely tighten it at this time.

q 7) Slide the silicon fuel tubing, with the

weighted pickup attached, onto the rear portion of the

nylon pickup tube. See photo # 35 below.

Fill

Pickup

Silicon

Tube

Photo # 35

Machine

Screw

Rubber

Stopper

Vent

Cap

Tube

Tube

Backplate

STOPPER INSTALLATION

q 8) Press fit the stopper assembly into the tank

opening. The stopper should be rotated so the nylon

vent tube is pointing straight up towards the top of

the tank. See photo # 36 at top right.

Photo # 36

Pickup

Tube

Top

Vent

Tube

Fill

Tube

q 9) With the stopper assembly in place, the

weighted pickup should be about 3/8” from the rear

of the tank and move freely within the tank. Adjust

the length of the tube accordingly.

q 10) When satisfied with the alignment of the

stopper assembly , tighten the 3mm x 18mm self tapping screw until the stopper expands and seals the

tank opening. Do not overtighten the screw as this

could cause the tank to split.

For added security you may wish to apply a thin

bead of silicon sealer around the fuel cap where

it seals around the front of the tank. Make sure not to

get any sealer in the nylon fuel tubes.

FUEL TANK INSTALLATION

q 11) Install three lengths of silicon fuel tubing

onto the vent, fuel pickup and fuel filler tubes at the

front of the tank. Slide the fuel tank into position in

the tank compartment while feeding the fuel lines out

the predrilled hole in the firewall. The tank should

be installed so that the top of the tank faces the top of

the fuselage and the stopper assembly should engage

the predrilled hole in the firewall.

Do not permanently secure the tank in place until

after balancing the airplane. It may be necessary to mount the receiver or the battery pack inside

the tank compartment to help balance the airplane.

After you have completed balancing, secure the tank

in position using a couple of dabs of silicon sealer

between the tank and the forward bulkhead. W e also

recommend sealing the predrilled hole in the firewall

with silicon sealer to prevent exhaust residue from

entering the fuselage.

18

Page 19

THROTTLE LINKAGE

Photo # 37

PARTS REQUIRED

q {1} 1.5mm x 380mm Pushrod Wire

q {1} 3mm x 270mm Nylon Pushrod Housing

INSTALLING THE PUSHROD HOUSING

q 1) Mark and drill a hole through the firewall for

the throttle pushrod housing using a 1/8” drill bit.

Position the hole level with the throttle arm and just

to the outside edge of the motor mounting beam. Be

careful not to drill through the fuel tank!

q 2) Mark and drill a 1/8” hole through the forward bulkhead at the approximate location shown.

See figure # 14 below.

Figure # 14

Drill 1/8”

Hole

Forward

Bulkhead

Fuselage

Side

Pushrod

Wire

Make

Bends

SERVO INSTALLATION

PARTS REQUIRED

q {2} 10mm x 10mm x 20mm Hardwood Blocks

INSTALLING THE FUSELAGE SERVOS

q 1) Using Kwik Bond Thick C/A, glue the two

10mm x 10mm x 20mm hardwood blocks in place on

the two servo rails. The blocks should be positioned

in the center of each rail. See photo # 38 below.

Photo # 38

Throttle

Pushrod

Pushrod

Housing

q 3) Slide the 3mm x 270mm pushrod housing

through the hole in the firewall, through the hole in

the forward bulkhead, and into the servo compartment. Leave about 1/4” of the housing extending

beyond the front of the firewall.

q 4) Apply a couple of drops of Kwik Bond Thin

C/A to the pushrod housing where it exits the firewall and where it passes through the forward bulkhead. This will secure the housing in place.

q 5) Using a modeling knife, cut off the nylon

pushrod housing 1” in front of the forward servo rail.

INSTALLING THE THROTTLE PUSHROD WIRE

q 6) Notice one end of the 1.5mm x 380mm pushrod wire has a Z-Bend premade in it and the other

end is plain. Slide the plain end of the wire into the

end of the pushrod housing at the firewall. Remove

the throttle arm from the engine and attach the Z-Bend

to the hole farthest out in the throttle arm. Reattach

the throttle arm to the engine.

Hardwood

Block

Servo

Rail

Hardwood

Block

Servo

Rail

q 2) Locate the servos you intend to use for the

elevator, rudder and throttle controls. Install the rubber grommets and brass collets onto the servos. The

brass collets should be installed with the flange facing the bottom of the servo.

q 3) Position the servos onto the preinstalled servo

rails as shown below. Drill 1/16” pilot holes for each

of the mounting screws to prevent the rails from splitting. Note the locations of the servos and their output

shafts. The rudder servo mounts on top of the two

hardwood blocks. See photo # 39 below.

Photo # 39

T

R

q 7) Using a pair of pliers, carefully bend the

throttle pushrod wire until it is aligned with the throttle

arm and does not bind when the throttle barrel is rotated. See photo # 37 at top right.

19

T = Throttle

R = Rudder

E = Elevator

E

Front

Page 20

THROTTLE CONNECTION

RUDDER PULL-PULL CABLES

PARTS REQUIRED

q {1} Adjustable Servo Connector

INSTALLING THE SERVO CONNECTOR

q 1) Install one adjustable servo connector through

the third hole out from the center of one servo arm.

You may have to enlarge the hole in the servo arm to

accommodate the servo connector. Remove the excess material from the arm. See figure # 15 below .

Figure # 15

Servo

Arm

Set

Screw

Nut

Servo

Connector

Washer

Washer

After installing the adjustable servo connector

apply a small drop of Kwik Bond Thin C/A to

the nut. This will prevent the connector from loosening during flight.

q 2) Plug the throttle servo into the receiver and

turn on the radio system. Check to ensure that the

throttle servo output shaft is moving in the correct

direction. When the throttle stick is moved forward

from idle to full throttle the servo should rotate counterclockwise.

PARTS REQUIRED

q {1} Stranded Wire Cable

q {2} Nylon Adjustable Control Horns

q {4} Nylon Clevises

q {1} 3mm x 50mm Threaded Rod

q {2} 3mm Flat Washers

q {2} 3mm Nuts

q {4} Brass threaded Couplers

q {4} Brass Crimp Collets

INSTALLING THE CONTROL ROD

q 1) Using a ruler and a pen, measure 7/8” up from

the bottom of the rudder, at the leading edge, and 3/8”

back from the hinge line and place a mark.

q 2) Using a 1/8” drill bit, drill a hole through the

rudder at the mark made.

q 3) Insert the 3mm x 50mm threaded rod through

the hole. Install one 3mm flat washer and one 3mm

nut on each side of the threaded rod. Being careful to

keep the threaded rod centered, tighten both nuts.

Do not overtighten the nuts. Y ou do not want to

crush the wood.

q 4) Apply a couple of drops of Kwik Bond Thin

C/A to each nut to prevent the threaded rod from turning and the nuts from coming loose.

q 3 Slide the adjustable servo connector/servo

arm assembly over the plain end of the pushrod wire.

Position the throttle stick and the throttle trim at their

lowest positions.

q 4) Manually push the carburetor barrel fully

closed. Angle the arm back about 45º from center

and attach the servo arm to the servo. With the carburetor barrel fully closed, tighten the set screw in

the adjustable servo connector.

q 5) Remove the excess throttle pushrod wire using wire cutters and install the servo arm retaining

screw. See photo # 40 below.

Photo # 40

Connector

Servo

Pushrod

Wire

Servo Arm

q 5) Thread one adjustable nylon control horn onto

each side of the threaded rod. The end of each horn

should be flush with the ends of the threaded rod.

See figure # 16 below.

Figure # 16

Threaded

Rod

Rudder

Washer

Adjustable

Control

Horn

Nut

INSTALLING THE PULL-PULL CABLE

q 6) Using a modeling knife, remove the covering from over the two rudder cable exit slots in the

rear of the fuselage. The center of each slot is located

on each side of the fuselage, 4” in front of the rudder

hinge line and 2-1/8” below the horizontal stabilizer .

Each slot is 1-1/2” long and 3/16” tall.

20

Page 21

q 7) Using wire cutters, cut the length of wire cable

exactly in half. If the wire begins to unravel, carefully twist the wire back into shape and apply a drop

of Kwik Bond Thin C/A to the end of the wire.

q 8) Install one threaded coupler onto only one

end of each wire cable. See figure # 17 and steps

A - D below.

Figure # 17

Clevis

Wire

Cable

Crimp

Collet

q 12) Thread two nylon clevises onto the two remaining threaded couplers. For security, thread the

clevises on no less than 5/16”.

q 13) Hold the rudder in neutral using a couple of

pieces of masking tape. Plug the rudder servo into

the receiver and center the servo. The servo arm

should be perpendicular to the fuselage sides.

q 14) Working with the right side first, install one

nylon clevis/threaded coupler assembly into the outer

hole in the servo arm.

Threaded

Coupler

Loop

q A) Slide one crimp collet onto the cable,

non-flange side first.

q B) Thread one end of the cable through the

predrilled hole in the end of the threaded coupler,

then thread the cable back into the crimp collet.

q C) Loop the cable around and thread it back

through the crimp collet. Pull the cable tight to

eliminate the slack in the loop.

q D) Squeeze the crimp collet with pliers to

secure the cable in place. Apply a couple of drops

of Kwik Bond Thin C/A to the collet to lock it in

place. After the glue has cured, pull on the cable

to ensure the crimp collet is secure.

q 9) Thread one nylon clevis onto each of the two

threaded couplers. For security thread the clevises

on no less than 5/16”.

q 10) Attach one clevis to each adjustable control

horn and thread the other end of the cable through the

exit slots in the sides of the fuselage and into the servo

compartment. See photo # 41 below.

q 15) Slide one crimp collet, non-flange side first,

over the length of cable on the right side. Thread the

cable through the predrilled hole in the threaded coupler.

Make sure the two cables do not cross inside

the fuselage. The cable from the right side of

the rudder should attach to the right side of the servo

arm.

q 16) While keeping the rudder and the rudder

servo centered, pull the cable tight and secure it in

place using the same technique as previously. Remove the excess cable using wire cutters.

q 17) Repeat steps # 14 - # 16 for the opposite

cable. See photo # 42 below.

Photo # 42

Crimp

Collet

Threaded

Coupler

Cable

Clevis

Servo

Arm

Photo # 41

Clevis

Adjustable

Control

Horn

Threaded

Coupler

q 11) Install a long dual-arm servo arm onto the

rudder servo. Use wire cutters to remove the excess

arms.

Cable

q 18) Remove the masking tape from the rudder.

With you radio system turned on and the rudder servo

and rudder centered, check for slack in the cables.

They should be fairly tight. Move the rudder to one

side, then let go of the stick. The rudder should come

back to center. Do this a couple of times in each direction. If the rudder does not come back to center,

the cables are too tight. You can change the tension

of the cables by adjusting the clevises. For best results, you want the cables to be as tight as possible,

but not so tight that the linkage binds or does not center when the rudder goes to neutral.

21

Page 22

ELEVATOR PUSHROD

PARTS REQUIRED

q {1} 740mm Split Elevator Pushrod Assembly

q {2} Nylon Clevises

q {1} Adjustable Servo Connector Assembly

q {2} Nylon Control Horn w/Backplates

q {4} 2mm x 25mm Machine Screws

INSTALLING THE CONTROL HORNS

Make sure that when you install the pushrod, it

is installed below the rudder cables and that the

cables do not get wrapped around the pushrod wires

or dowel.

q 6) Thread two nylon clevises onto the threaded

ends of both elevator pushrods. For security, thread

the clevises on no less than 5/16”.

q 1) Position one elevator control horn on the bottom of each elevator half. The centerline of each

horn should be 5/8” out from the fuselage sides at

the hinge line. Position the control horns so the clevis attachment holes are directly in-line with the

hinge lines. The control horns should be angled towards the fuselage sides. See figure # 18 below.

Figure # 18

Control

Horn

Control

Horn

q 2) When satisfied with the alignment, use a

3/32” drill bit, and the control horns as a guide, and

drill the mounting holes through the elevator halves.

q 3) Mount the control horns to the elevators by

inserting the four 2mm x 25mm machine screws

through the control horn mounting bases, through the

elevator halves and into the backplates. Tighten the

screws, but do not overtighten them. Y ou do not want

to crush the wood.

INSTALLING THE ELEVATOR PUSHROD

q 4) Using a modeling knife, remove the covering from over the two elevator pushrod exit slots in

the rear of the fuselage. The center of each slot is

located on each side of the fuselage, 4” in front of the

rudder hinge line and 1” below the horizontal stabilizer. Each slot is 1-1/2” long and 3/16” tall.

q 5) Slide the elevator pushrod assembly through

the fuselage and out the two pushrod exit holes. To

make this easier, drop two pieces of string through

the exit holes and into the servo bay. T ie one piece of

string to each wire and carefully pull the string. This

will guide the pushrod wires out the exit holes.

q 7) Attach each clevis to the outermost hole in

each control horn. See photo # 43 below .

Photo # 43

Clevis

Control

Horn

Pushrod

Wire

q 8) Install one adjustable servo connector through

the fourth hole out from the center of one servo arm.

You may have to enlarge the hole in the servo arm to

accommodate the servo connector. Remove the excess material from the arm. See figure # 19 below .

Figure # 19

Servo

Arm

Servo

Connector

Washer

Set

Screw

Washer

Nut

After installing the adjustable servo connector

apply a small drop of Kwik Bond thin C/A to

the nut. This will prevent the connector from loosening during flight.

q 9) Slide the elevator pushrod wire through the

hole in the adjustable connector .

q 10) Use a couple of pieces of masking tape to

hold each elevator half in neutral.

q 11) Plug the elevator servo into the receiver and

center the servo. Place the servo arm onto the servo.

The servo arm should be perpendicular to the fuselage

sides and point towards the middle of the fuselage.

22

Page 23

q 12) With both elevator halves and the servo arm

centered, tighten the set screw in the adjustable servo

connector. Remove the excess wire using wire cutters. See photo # 44 below.

INSTALLING THE AILERON LINKAGES

q 4) Thread one nylon clevis onto one 2mm x

250mm threaded wire. For security thread the clevis

on no less than 5/16”.

Photo # 44

Servo

Arm

Servo

Connector

Elevator

Pushrod

q 13) Remove the masking tape from the elevator

halves. Adjust each elevator half by turning the clevises in or out until both elevator halves are centered.

AILERON LINKAGES

PARTS REQUIRED

q {2} 2mm x 250mm Threaded Wires

q {2} Nylon Control Horns w/Backplates

q {4} 2mm x 25mm Machine Screws

q {2} Nylon Clevises

q {2} Adjustable Servo Connectors

INSTALLING THE CONTROL HORNS

q 1) The centerline of the control horns are located

2-5/8” out from the inside edge of each aileron. Position the control horns on the bottom of the ailerons