Global Hobby Global SST 09 ARF Instructions Manual

Electric Conversion Instructions Included

in This Manual - See Page 26 for Details!

INSTRUCTIONS FOR FINAL ASSEMBLY

The Global SST 09 ARF is in no way a primary trainer. If you have not flown an R/C airplane before, please

return this kit to the place of purchase before going any further. The SST 09 is designed for those pilots who are

already skilled at flying a basic trainer or sport airplane. Even though the SST 09 is small, it can be a very high

performance aircraft, depending upon which engine and radio accessories you use. These options are discussed

in further detail to help you make the right choice for your desired style of flying.

T o make your modeling experience totally enjoyable, we recommend that you get experienced, knowledgable

help with assembly and during your first flights. Your local hobby shop has information about flying clubs in

your area whose membership includes qualified instructors. W e also recommend that you contact the AMA at

the address below. They will be able to help you locate a flying field in your area also.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN. 47302-9252

(800) 435-9262

www.modelaircraft.org

The SST 09 ARF is distributed exclusively by Global Hobby Distributors 18480 Bandilier Circle Fountain Valley, CA 92728

All contents copyright © 2000, Global Hobby Distributors Version V1.2 6/00

1

TABLE OF CONTENTS

Introduction .....................................................3

Kit Contents.....................................................4

Metric Conversion Chart .................................5

Full Size Hardware Drawings .........................6

Additional Items Required ..............................7

Tools and Supplies Needed..............................7

Field Support Equipment Needed ...................7

Wing Mounting................................................8

Installing the Hardwood Dowels ..............8

Aligning the Wing.....................................8

Mounting the Wing...................................8

Horizontal Stabilizer Installation.....................9

Aligning the Horizontal Stabilizer............9

Mounting the Horizontal Stabilizer ........10

Hinging the Elevator...............................10

Vertical Stabilizer Installation ....................... 11

Mounting the Vertical Stabilizer.............11

Tail Skid Installation......................................11

Installing the Tail Skid ............................11

Landing Gear Installation ..............................12

Installing the Landing Gear Wires..........12

Installing the Wheels ..............................12

Engine Mounting ...........................................13

Installing the Exhaust Extension ............13

Aligning the Engine ................................13

Mounting the Engine ..............................13

Installing the Spinner ..............................13

Installing the Throttle Pushrod ...............14

Fuel Tank .......................................................14

Stopper Assembly ...................................14

Installing the Stopper ..............................14

Fuel Tank Installation .............................15

Servo Installation...........................................15

Installing the Servo Rails........................15

Installing the Fuselage Servos ................15

Installing the Aileron Servo Plates .........16

Installing the Aileron Servo....................16

Throttle Servo ................................................17

Installing the Servo Connector ...............17

Elevator Pushrod ...........................................17

Installing the Control Horn .....................17

Installing the Pushrod .............................18

Adjusting the Elevator Pushrod ..............19

Aileron Linkage.............................................19

Hinging the Ailerons...............................19

Installing the Aileron Linkage ................20

Adjusting the Aileron Linkage ...............21

Final Assembly ..............................................21

Installing the Fuel Lines .........................21

Installing the Switch ...............................21

Installing the Battery and Receiver.........21

Balancing .......................................................22

Control Throws..............................................23

Preflight Check ..............................................23

Flying the SST 09 ..........................................23

Glossary of Terms..........................................24

Notes..............................................................25

SST 09 Electric Conversion ..........................26

Trim Chart .....................................................30

Product Evaluation Sheet ..............................31

Global guarantees this kit to be free from defects in both material and workmanship, at the date of purchase.

This does not cover any components parts damaged by use, misuse or modification. In no case shall

Global's liability exceed the original cost of the purchased kit.

In that Global has no control over the final assembly or material used for final assembly , no liability shall be

assumed for any damage resulting from the use by the user of the final user-assembled product. By the act

of using the final user-assembled product, the user accepts all resulting liability .

2

INTRODUCTION

Thank you for choosing the Global SST 09 ARF for your next airplane. The SST 09 ARF is

designed to be powered with either an .09 size engine, like the AP Engines Hornet, or a .15 size

engine, like the AP Engines .15 Yellowjacket. Performance is excellent using either engine. The

smaller engine will allow the SST to be flown slower and in a much smaller space. Using the larger

engine, the SST turns into a high performance sport plane. The airplane uses three channel controlelevator, ailerons and throttle. Standard servos can be used in the fuselage, and a mini servo in the

wing. To make the airplane even lighter, micro servos can be used on all controls.

The SST 09 ARF is completely built up out of balsa and light ply. This really helps keep the weight

down, owing to its excellent performance. The airframe is then covered with lightweight polyester

covering material in an attractive color scheme. Included in the box is a full compliment of hardware,

including prebent main landing gear wires, prebent tail skid, lightweight wheels, wheel collars, fuel

tank, pushrods, and all of the nuts and bolts.

We hope you enjoy final assembly and flying of your new SST 09 ARF as much as we have

enjoyed designing and building it for you. If you have any questions or comments, please feel free

to contact us and let us know. W e have also included a product survey in the back of this instruction

manual. Please take the time to fill it out and send it to us. We always enjoy hearing any comments

or suggestions you may have.

This instruction manual is designed to guide you through the entire assembly process of your new SST 09

ARF in the least amount of time possible. Along the way you'll learn how to properly assemble your new

airplane and also learn many tips that will help you in the future. W e have listed some of our recommendations

below . Please read through them before going any further.

ü Please read through each step before starting assembly. You should find the layout very complete

and simple. Our goal is to guide you through assembly without any of the headaches and hassles you

might expect.

ü When you are ready to glue any parts together, test fit them first without using glue. This will ensure

you have the correct parts and that they fit together properly.

ü There are check boxes next to each step. After you complete a step, check off the box. This will help

you keep from losing your place.

ü If you come across this symbol , it means that this is an important point or an assembly hint.

ü Cover your work table with brown paper or a soft cloth, both to protect the table and to protect the

individual parts.

ü Keep a couple of small bowls or jars handy to put the small parts in after you open the accessory bags.

ü We have included a glossary of terms beginning on page # 24. Check it out if you come across a term

that is unfamiliar to you.

ü We're all excited to get a new airplane in the air, but take your time. This will ensure you build a

straight, strong and great flying airplane.

If you should find a part missing or damaged, or have any questions about assembly , please contact us at the

address below:

Global Hobby Distributors Customer Care

18480 Bandilier Circle

Fountain Valley, CA 92728

Phone: (714) 963-0329

Fax: (714) 964-6236

E-mail: service@globalhobby.com

3

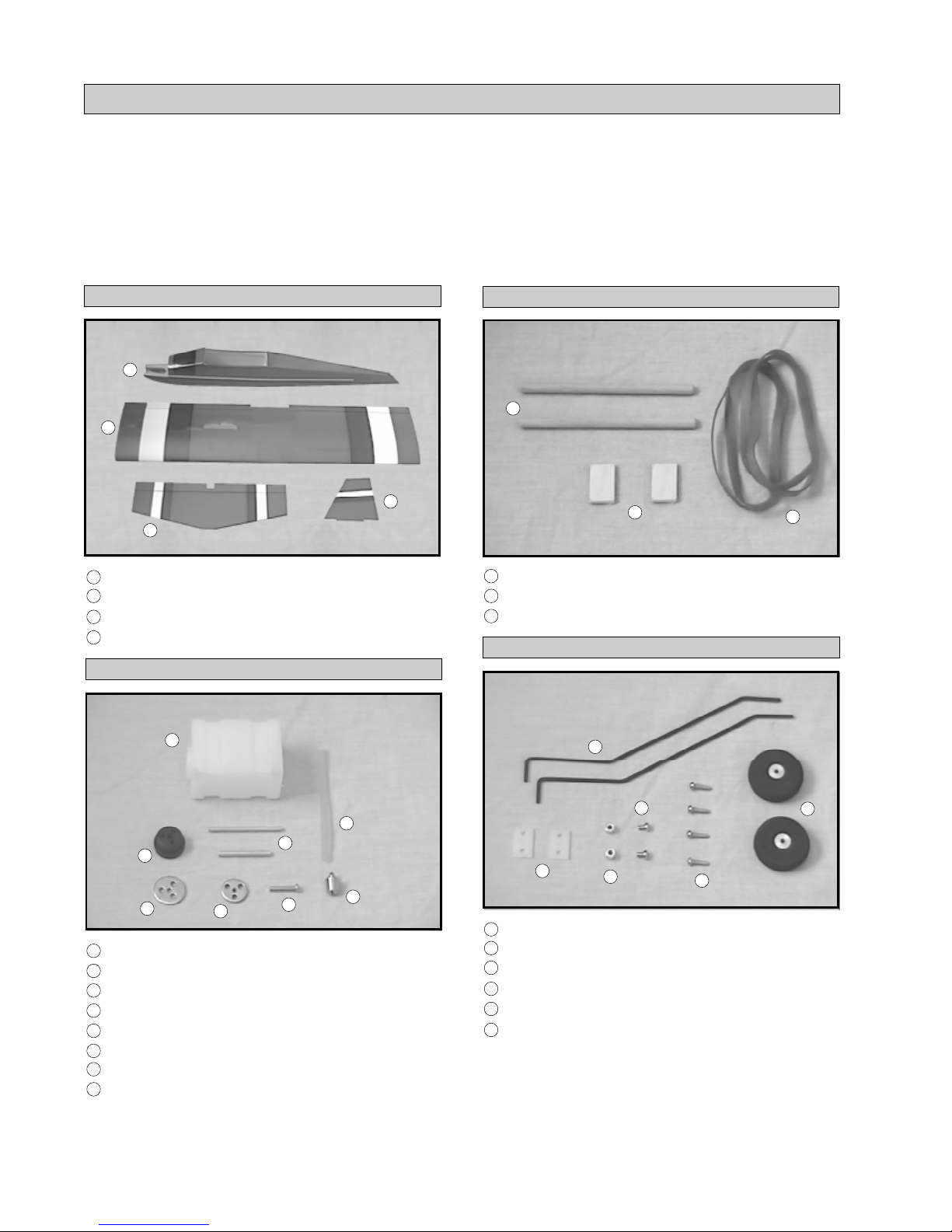

KIT CONTENTS

W e have organized the parts as they come out of the box for easier identification during assembly. Each photo

below represents the parts that are required in a main section of the assembly process. Before you begin

assembly , group the parts like we show . This will ensure you have all of the parts before you begin assembly . It

will also help you become familiar with each part. The corresponding part number is listed first, then the

quantity of that particular part, along with a short description of the part. As you proceed through assembly, you

will notice the same part number listed next to a particular part necessary for that step. If you have any

questions as to what that part might be, refer back to this section.

AIRFRAME ASSEMBLIES

1

2

3

1

q {1} Fuselage w/Pushrod Housing

2

q {1} Wing Assembly w/Ailerons & Hinges

3

q {1} Horizontal Stabilizer w/Elevator & Hinges

4

q {1} V ertical Stabilizer

FUEL TANK ASSEMBLY

5

WING ASSEMBLY

14

4

13

q {2} 3mm x 15mm x 25mm Plywood Plates

14

q {2} 7mm x 110mm Hardwood Dowels

15

q {4} Rubber Bands

13

15

MAIN GEAR ASSEMBLY

16

11

10

5

q {1} 115cc Fuel Tank

6

q {2} Aluminum Tubes

7

q {1} Weighted Fuel Pickup

8

q {1} Silicon Fuel Tubing

9

q {1} 17mm Diameter Rear Plate

10

q {1} 20mm Diameter Front Plate

11

q {1} Rubber Stopper

12

q {1} 3mm x 18mm Machine Screw

9

6

12

8

20

7

16

q {2} Prebent Main Gear Wires

17

q {2} 35mm Diameter Wheels

18

q {2} 3mm Wheel Collars

19

q {2} 3mm x 5mm Machine Screws

20

q {2} Nylon Landing Gear Straps

21

q {4} 3mm x 12mm Wood Screws

19

18

21

17

4

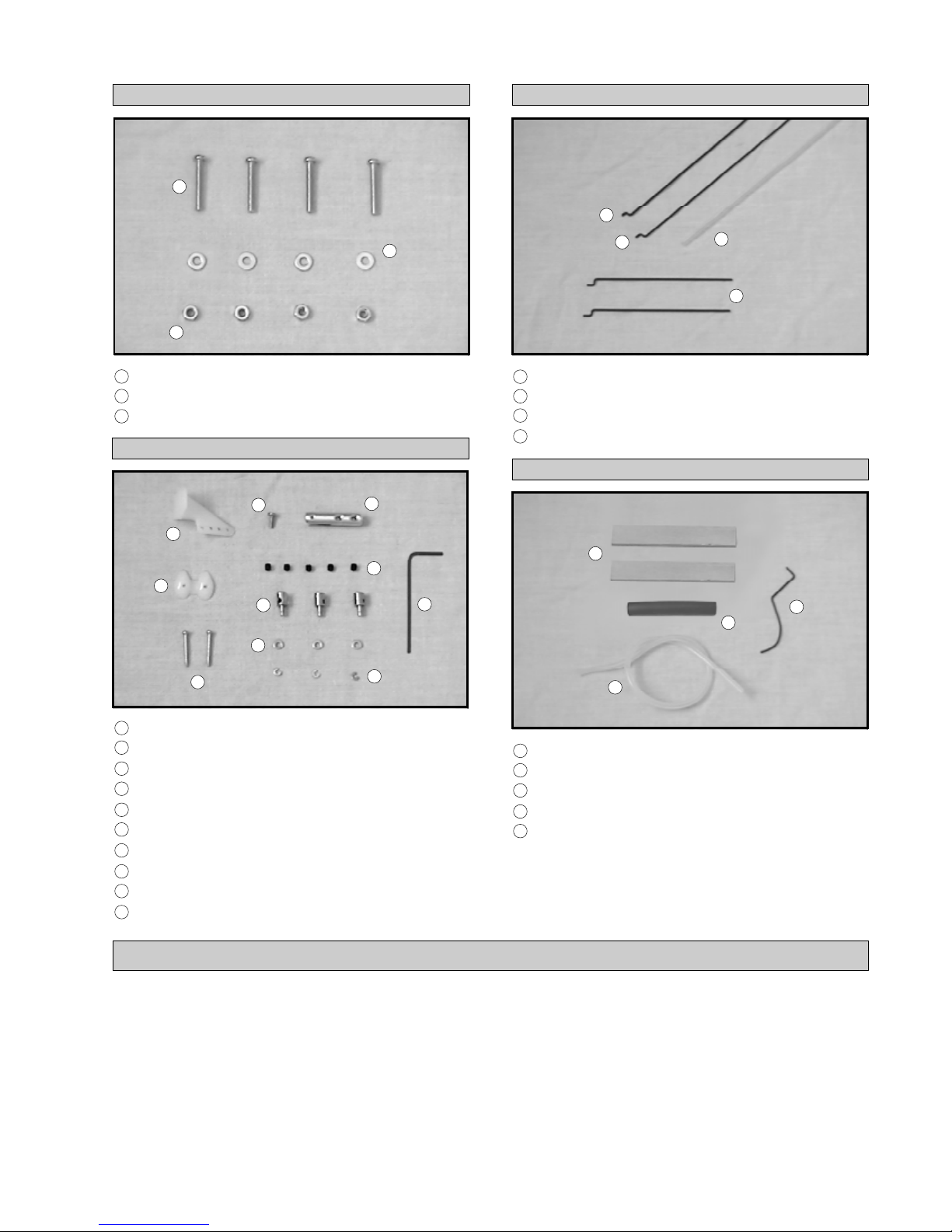

ENGINE MOUNTING

22

24

PUSHROD ASSEMBLIES

35

23

36

38

37

22

q {4} 3mm x 20mm Machine Screws

23

q {4} 3mm Flat Washers

24

q {4} 3mm Hex Nuts

PUSHROD CONNECTOR ASSEMBLIES

30

25

26

28

31

27

25

q {1} Nylon Control Horn

26

q {1} Nylon Control Horn Backplate

27

q {2} 2mm x 15mm Wood Screws

28

q {3} Adjustable Servo Connectors

29

q {1} Adjustable Clevis

30

q {1} 2mm x 6mm Machine Screw

31

q {3} 2mm Flat Washers

32

q {3} 2mm C-Clips

33

q {5} 2mm Set Screws

34

q {1} Allen Wrench

29

33

32

35

q {1} 2mm x 545mm Wire w/Z-Bend

36

q {1} 1.5mm x 330mm Wire w/Z-Bend

37

q {2} 1.5mm x 100mm Wires w/Z-Bends

38

q {1} 4mm x 200mm Nylon Pushrod Tube

MISCELLANEOUS

39

34

42

41

39

q {2} 3mm x 10mm x 65mm Plywood Servo Rails

40

q {1} Prebent Tail Skid

41

q {1} Silicon Fuel Tubing

42

q {1} Exhaust Extension Tube

43

q {1} Spinner Assembly (not pictured)

40

To convert inches into millimeters: Inches x 25.4 = MM

1/64” = .4mm

1/32” = .8mm

1/16” = 1.6mm

3/32” = 2.4mm

1/8” = 3.2mm

5/32” = 4.0mm

3/16” = 4.8mm

1/4” = 6.4mm

3/8” = 9.5mm

1/2” = 12.7mm

5/8” = 15.9mm

3/4” = 19.0mm

METRIC CONVERSION CHART

1” = 25.4mm

2” = 50.8mm

3” = 76.2mm

6” = 152.4mm

12” = 304.8mm

18” = 457.2mm

5

21” = 533.4mm

24” = 609.6mm

30” = 762.0mm

36” = 914.4mm

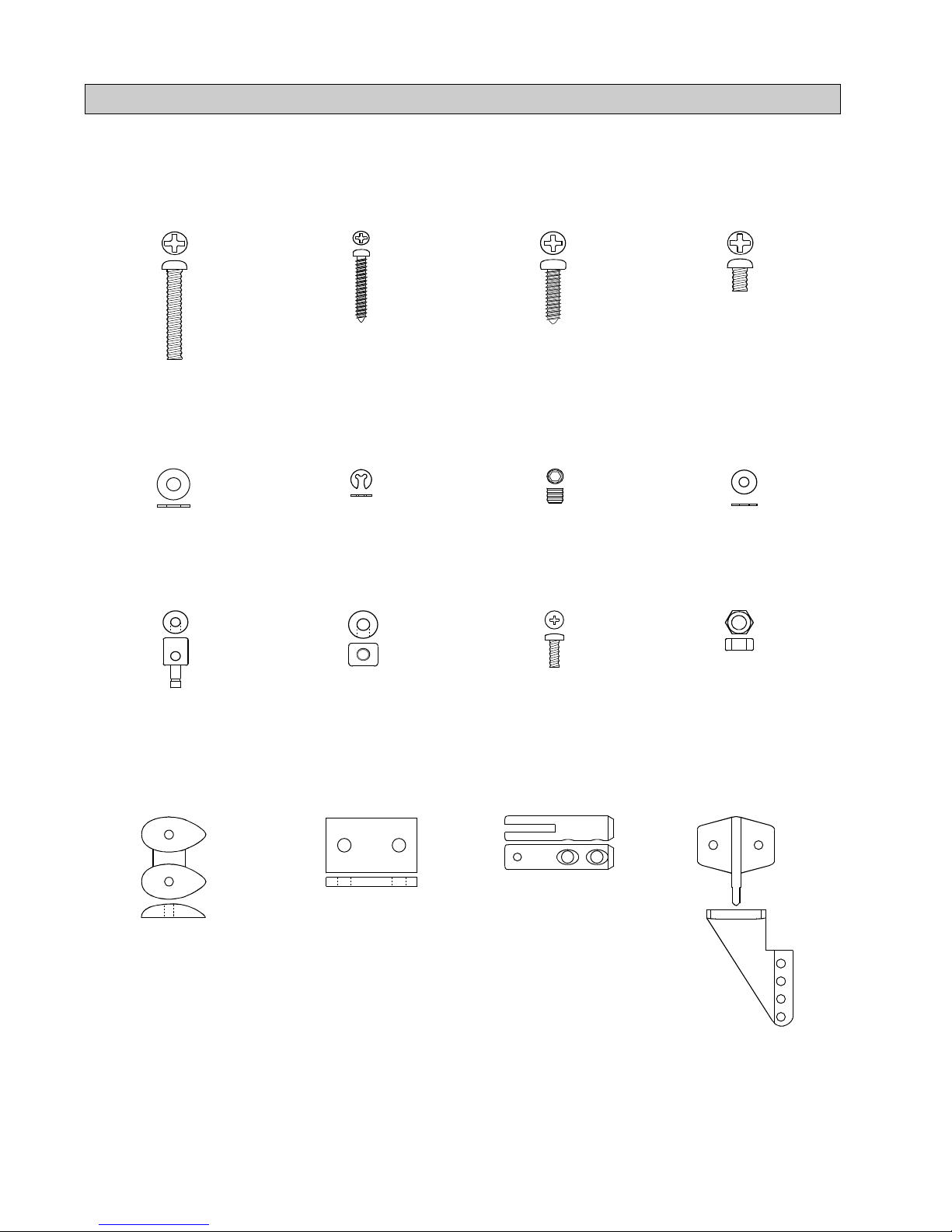

FULL SIZE HARDWARE DRAWINGS

Listed below are full size drawings of the small hardware items included with the SST 09 ARF. Use these

drawings to familiarize yourself with each of these parts. Please refer back to this page to locate the proper

hardware items when they are needed for a particular assembly step. These drawings are especially helpful

when trying to identify the different size screws or nuts used in a particular step.

3mm x 20mm

Machine Screw

3mm Flat

Washer

Adjustable Servo

Connector

2mm x 15mm

Wood Screw

2mm

C-Clip

3mm Wheel

Collar

3mm x 12mm

Wood Screw

2mm Set

Screw

2mm x 6mm

Machine Screw

3mm x 5mm

Machine Screw

2mm Flat

Washer

3mm Hex

Nut

Nylon Control

Nylon Landing

Horn Backplate

Gear Strap

Adjustable

Clevis

Nylon

Control Horn

6

ADDITIONAL ITEMS REQUIRED

q {1} Hitec 4 or More Channel Radio w/2 Stnd. Servos

q {1} Cirrus CS-26 Sub Micro Servo # 444238

q {1}Cirrus 12” Servo Extension # 444713

q {1}Dubro Foam Rubber # 868638

q {1}Dubro Hook & Loop Material # 568906

FOR 2 CYCLE .09 ENGINE

q {1}AP .09 R/C Hornet # 211300

q {1}Master Airscrew 7 x 4 Propeller # 244350

q {1} Thunderbolt R/C Short Glow Plug # 115535

q {1}AP NFX 15% Nitro Fuel # 211115

FOR 2 CYCLE .15 ENGINE

q {1}AP .15 R/C Y ellowjacket # 211315

q {1}Master Airscrew 8 x 4 Propeller # 244459

q {1} Thunderbolt R/C Short Glow Plug # 115535

q {1}AP NFX 15% Nitro Fuel # 211115

q {3}Cirrus CS-20 Micro Servos # 444232

q {1}Cirrus 270Mah Battery Pack # 444603

q {1} Cirrus On-Board Battery Indicator # 444762

q {1} Prather Prop Balancer # 520429

q {1}Dubro In-Line Fuel Filter # 568900

IMPORTANT The part numbers for the Cirrus

servos, On-Board Battery Indicator and battery

pack are for Hitec and JR radio systems. These

items are also available with different connectors

for use with Futaba and Airtronics radio systems.

OPTIONAL ITEMS

Please Read Below -

Important Infor mation

FOR YOUR INFORMATION The SST 09 can be set up a couple of different ways to suit your

particular flying needs. Set up stock using an .09 displacement engine and standard servos, the SST 09 is a

very docile flyer that is not too fast. Set up with a .15 displacement engine and micro servos and battery

pack will make the SST 09 a very fast and aerobatic flyer. Remember, the overall finished weight of the

airplane will be almost 4oz. lighter by using micro servos and a 270Mah battery pack. The lighter the

airplane is, the better it will fly. The SST 09 flies very well using the .09 and standard servos. It's an

extreme flyer using a .15 and micro servos. On page # 26 we have even included a section telling you how

to convert your SST 09 into electric! If you do decide to convert the SST 09 to electric, please read that

section before starting assembly of the airplane. Again, the electric conversion section can be found on

page # 26 along with a complete list of the extra items you'll need.

q Kwik Bond Thin C/A # 887500

q Kwik Bond Thick C/A # 887510

q Kwik Bond 30 Minute Epoxy # 887565

q Dubro T-Pins # 567685

q Electric or Hand Drill

q Assorted Drill Bits

q Excel Modeling Knife # 692808

q Machine Oil or Vaseline

q Phillips Head Screwdriver

q 220 Grit Sandpaper w/Sanding Block

q Ernst Airplane Stand # 223977

q Scissors

TOOLS AND SUPPLIES NEEDED

q W axed Paper

q Pen or Pencil

q Builders Triangle

q 3M Masking Tape # 229685

q Paper Towels

q Rubbing Alcohol

q Wire Cutters

q NHP Epoxy Mixing Sticks # 864204

q NHP Mixing Cups # 864205

q 36” Straight Edge Ruler

q Magnum 1/8” Tubing Bender # 237474

7

WING MOUNTING

PARTS REQUIRED

1

q {1} Fuselage w/Pushrod Housing

2

q {1} Wing Assembly w/Ailerons & Hinges

14

q {2} 7mm x 110mm Hardwood Dowels

15

q {4} Rubber Bands

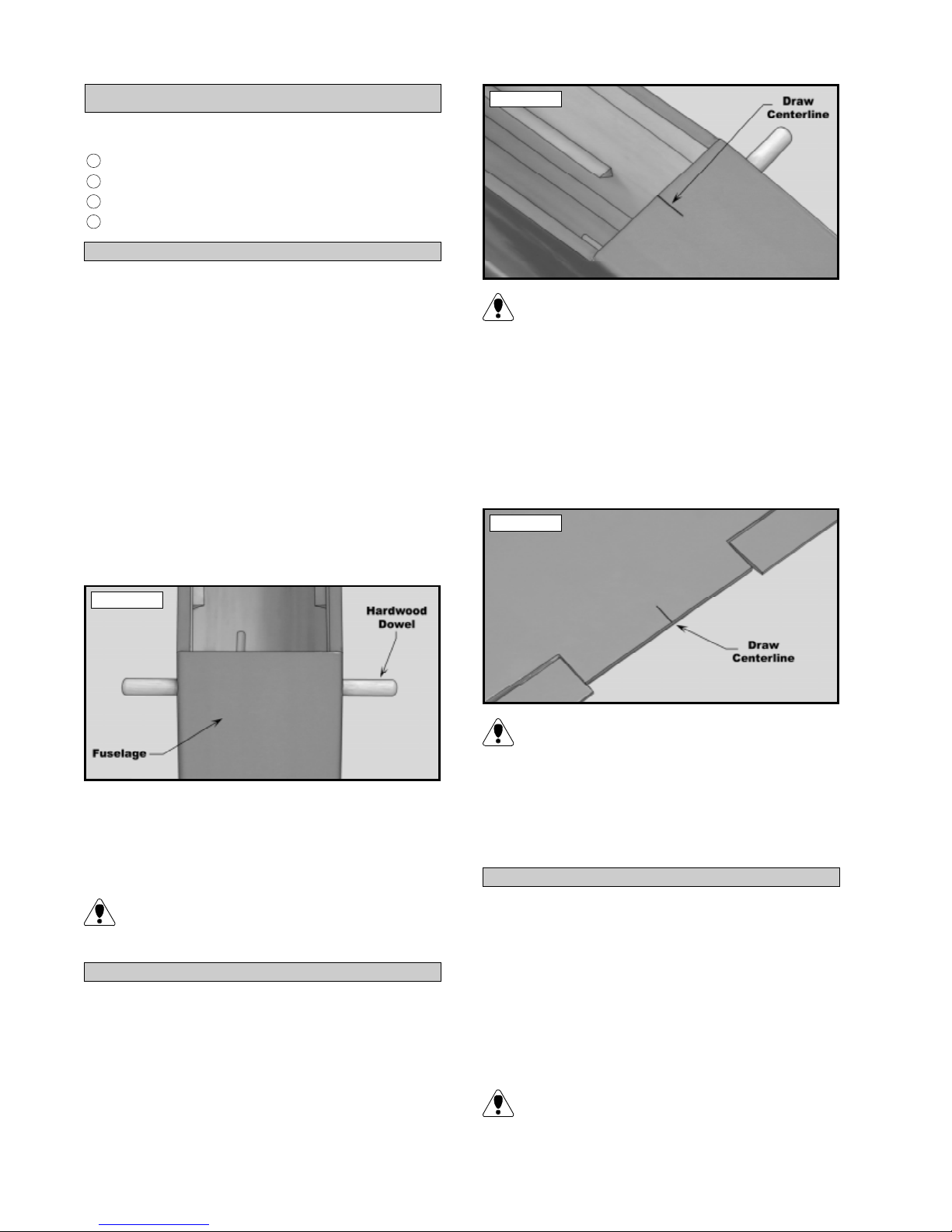

INSTALLING THE HARDWOOD DOWELS

Photo # 2

q 1) Using a modeling knife, carefully remove the

covering from over the four predrilled holes in the

fuselage sides. Two holes are located in front of the

wing saddle, 4-1/8” behind the firewall and 3/8” down

from the top of the fuselage. Two holes are located

in back of the wing saddle, 12-1/2” behind the firewall and 5/16” down from the top of the fuselage.

q 2) Slide one 7mm x 110mm hardwood dowel

through the two predrilled holes in front of the wing

saddle and one dowel through the two predrilled

holes in back of the wing saddle. Center the two

dowels in the fuselage. Both ends of each dowel

should protrude from the fuselage sides equal

amounts. See photo # 1 below.

Photo # 1

These two marks will help you align the wing

when you install it onto the fuselage. Y ou may

wish to make these marks in permanent ink so you

can align the wing correctly each time you install it.

This will ensure the wing is aligned properly every

time you fly the airplane.

q 6) Using a ruler and a pen, locate and mark the

centerline of the wing at both the leading edge and

the trailing edge. See photo # 3 below.

Photo # 3

You may wish to make these marks in perma-

nent ink so you can align the wing correctly

each time you install it.

q 3) With both wing dowels properly positioned,

apply a couple of drops of Kwik Bond Thin C/A to

the joint where each dowel exits the fuselage sides.

Allow the glue to fully cure before proceeding.

The thin C/A will wick into the joint, gluing

the dowels securely in place. Be careful not to

use too much C/A or it may run down the fuselage.

ALIGNING THE WING

q 4) Using a ruler and a pen, locate the centerline

of the fuselage at the front of the wing saddle and

place a mark.

q 5) Using a ruler and a pen, locate the centerline

of the fuselage at the back of the wing saddle and

place a mark. See photo # 2 at top right.

q 7) Place the wing onto the wing saddle. Align

the two centerline marks on the wing with the two

centerline marks on the fuselage.

MOUNTING THE WING

q 8) Temporarily mount the wing to the fuselage

using one rubber band per side. To properly install

the rubber bands, hook one rubber band over one side

of the front wing hold down dowel. Carefully pull it

back over the wing, and under the rear hold down

dowel on the same side, then pull it forward across

the top of the wing and hook it around the front wing

hold down dowel on the same side.

When installing the rubber bands, be careful not

to crush the trailing edge of the wing. Also make

sure that the wing stays centered on the fuselage.

8

HORIZONTAL STABILIZER

INSTALLATION

PARTS REQUIRED

3

q {1} Horizontal Stabilizer w/Elevator & Hinges

q 5) Slide the stabilizer into the mounting slot.

For now, push the leading edge of the stabilizer up

against the front of the slot and carefully align the

two marks at the trailing edge of the stabilizer with

the fuselage sides.

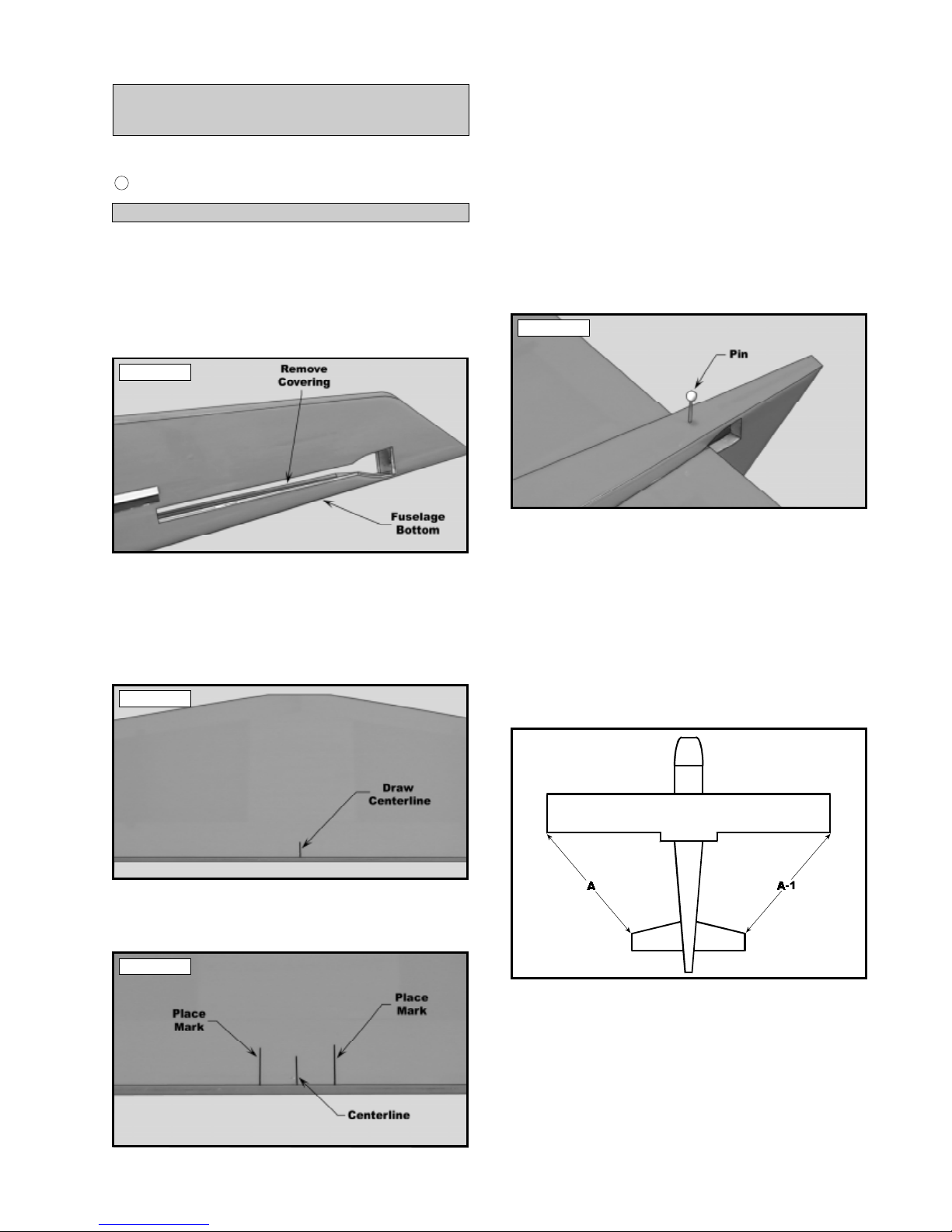

ALIGNING THE HORIZONTAL STABILIZER

q 1) Using a modeling knife, carefully remove

the covering from over the stabilizer mounting slot

in each fuselage side. The front of the slot is 6-3/4”

in front of the back edge of the fuselage and 3/8” up

from the bottom. The slot is about 5” long. See

photo # 4 below.

Photo # 4

q 2) Remove the elevator and hinges from the

horizontal stabilizer and set them aside for now.

q 3) Using a ruler and a pen, locate the centerline

of the horizontal stabilizer, at the trailing edge, and

place a mark. See photo # 5 below.

Photo # 5

q 6) While holding the trailing edge of the stabilizer aligned with the fuselage sides, insert a T-pin

through the bottom of the fuselage and into the stabilizer. This will keep the back of the stabilizer from

moving side-to-side. See photo # 7 below.

Photo # 7

q 7) With the wing still attached to the fuselage

and centered, remove both of the ailerons and hinges.

Set them aside for now.

q 8) Align the stabilizer to the wing. Using a long

ruler, measure from each wing tip to each stabilizer

tip. Both distances should be equal. If they are not,

adjust the stabilizer, making sure the trailing edge

stays centered, until you are satisfied with the alignment. See figure # 1 below.

q 4) Using a ruler and a pen, measure out 3/8”

from each side of the centerline and place a mark.

See photo # 6 below.

Photo # 6

Figure # 1

A=A-1

q 9) When you are satisfied with the alignment,

use several pieces of masking tape to hold the stabilizer firmly in place.

q 10) Now check to ensure that the horizontal stabilizer is level with the wing. When viewed from the

front, the horizontal stabilizer should be level with

the wing. If it is not level, remove the stabilizer and

9

use 220 grit sandpaper, with a sanding block, and sand

down the high side of the stabilizer mounting slot.

Remove small amounts at a time, checking your work

often, until the proper alignment is achieved. See

figure # 2 below.

Figure # 2

B=B-1

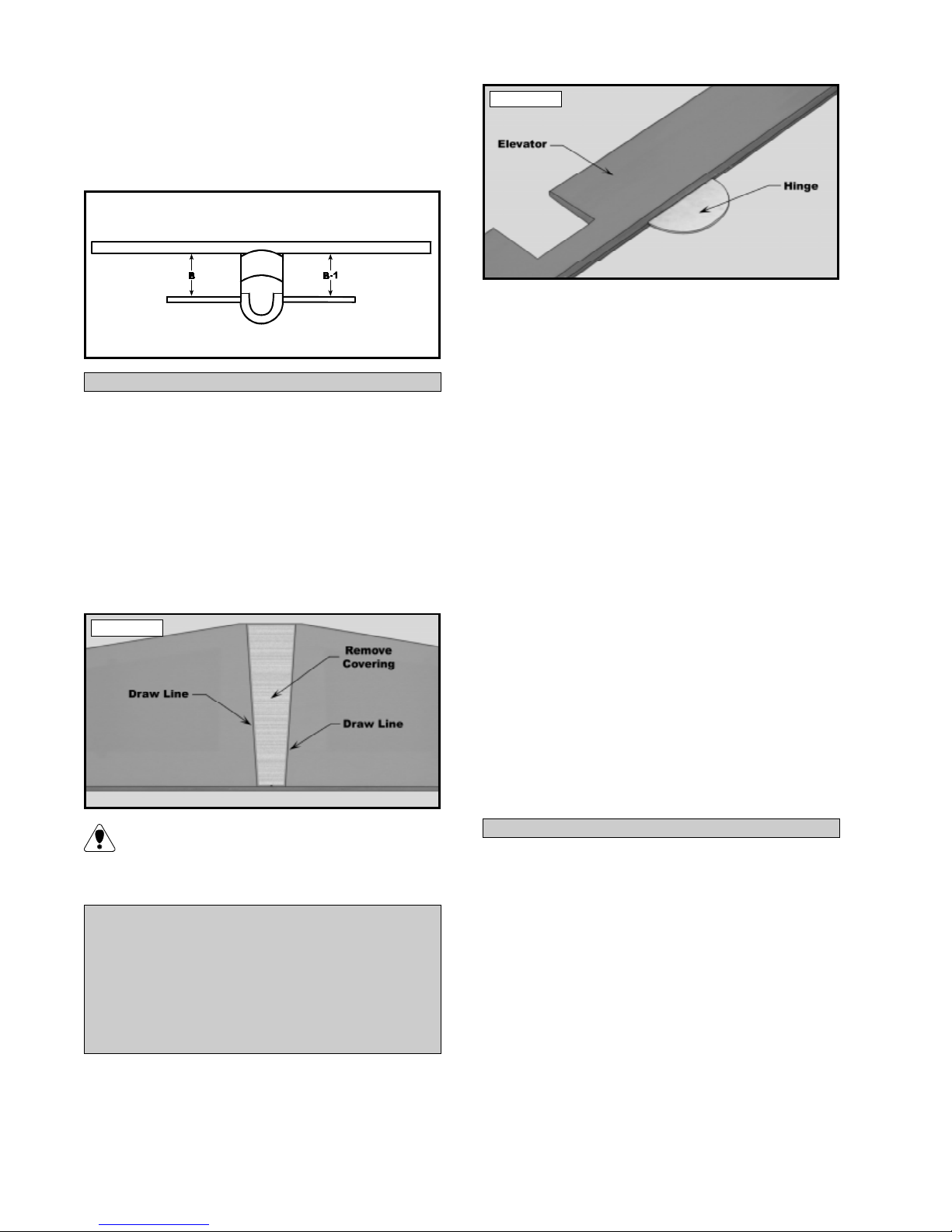

MOUNTING THE HORIZONTAL STABILIZER

q 11) With the stabilizer held firmly in place and

properly aligned, use a pen and draw lines onto the

stabilizer, where it and the fuselage sides meet. Do

this on both the right and left sides, on the top and

bottom of the stabilizer.

q 12) Remove the stabilizer from the fuselage.

Using the lines you just drew as a guide, carefully

remove the covering from between them using a

modeling knife. See photo # 8 below.

Photo # 8

Photo # 9

q 14) Carefully slide the elevator through the stabilizer mounting slot, making sure that the hinges are

facing forward and that the colored trim is facing up.

Push the elevator joiner back into the slot as far as

possible and let is set there for now.

q 15) Glue the horizontal stabilizer in place using Kwik Bond 30 Minute Epoxy. Because the

stabilizer has to slide in place through the fuselage,

we suggest you apply a liberal amount of epoxy to

only the gluing surface of the stabilizer. This will

prevent spreading epoxy over the entire length of

one half of the stabilizer when you slide it in place.

After applying the epoxy, slide the stabilizer into

place and realign it. Double check all of your measurements before the epoxy cures. Wipe away any

excess epoxy using paper towels and rubbing alcohol and hold the stabilizer in place using pieces

masking tape.

When cutting through the covering to remove

it, cut with only enough pressure to only cut

through the covering itself. Cutting into the balsa

may weaken the stabilizer.

Please follow the next few steps very closely.

They will lead you through the proper order

for gluing the stabilizer into place. If you don't

follow the order of these steps as they are listed

here, you will not be able to hinge the elevator

to the stabilizer.

q 13) Slide each of the four hinges into the leading edge of the elevator. The hinges should be

centered within each slot. Do not glue them in place

at this time. See photo # 9 at top right.

q 16) After the epoxy has cured, remove the

masking tape and use a small quantity of epoxy to

fill in any gaps that may exist that were not filled

previously.

HINGING THE ELEVATOR

q 17) Carefully push the elevator and its hinges

into the precut hinge slots in the trailing edge of the

stabilizer . Adjust the elevator so the tips are even the

tips of the stabilizer.

q 18) While holding the elevator tight against the

stabilizer, rotate the elevator down as far as it will

go. Apply six drops of Kwik Bond Thin C/A to the

exposed area of each hinge. Turn the fuselage over

and apply six drops of C/A to that side of each hinge.

Allow the C/A to cure for about ten minutes. Once

cured, the elevator may be stiff and difficult to move.

This is normal. Gently move it up and down about

five to ten times to free it up.

10

Loading...

Loading...