Page 1

INSTRUCTIONS FOR FINAL ASSEMBLY

To make your modeling experience totally enjoyable, we recommend that you get experienced, knowledgeable help

with assembly and during your first flights. Your local hobby shop has information about flying clubs in your area

whose membership includes qualified instructors. W e also recommend that you contact the AMA at the address below.

They will be able to help you locate a flying field in your area.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

(800) 435-9262

www.modelaircraft.org

Global guarantees this kit to be free from defects in both material and workmanship at the date of purchase. This does

not cover any component parts damaged by use, misuse or modification. In no case shall Global's liability exceed

the original cost of the purchased kit.

In that Global has no control over the final assembly or material used for final assembly, no liability shall be assumed

for any damage resulting from the use by the user of the final user-assembled product. By the act of using the final

user-assembled product, the user accepts all resulting liability.

The Fokker D-VII ARF is distributed exclusively by Global Hobby Distributors

18480 Bandilier Circle, Fountain Valley, CA 92728

All contents copyright © 2000, Global Hobby Distributors Version V1.0 9/00

1

Page 2

TABLE OF CONTENTS

Safety Warning ............................................................... 2

Introduction .................................................................... 3

Kit Contents....................................................................4

Additional Items Required ............................................. 5

Tools and Supplies Required ......................................... 5

Metric Conversion Chart................................................ 5

A Note About Covering ................................................. 6

Bottom Wing Assembly.................................................6

Installing the Dihedral Brace ..................................6

Joining the Wing Halves......................................... 7

Top Wing Assembly....................................................... 7

Installing the Dihedral Brace ..................................7

Joining the Wing Halves......................................... 8

Bottom Wing Mounting ................................................. 9

Aligning the Wing...................................................9

Installing the Blind Nuts ......................................... 9

Installing the Wing Bolt Doubler .........................10

Mounting the Wing ...............................................1 0

Horizontal Stabilizer .................................................... 10

Aligning the Stabilizer .......................................... 10

Mounting the Stabilizer ........................................ 11

Vertical Stabilizer .........................................................12

Aligning the Stabilizer .......................................... 12

Mounting the Stabilizer ........................................ 12

Installing the Triangle Stock................................. 12

Top Wing Mounting .....................................................13

Installing the Cabane Struts ..................................13

Installing the Outer N-Struts................................. 14

Aligning the Top Wing ......................................... 15

Mounting the Top Wing........................................ 15

Control Surface Hinging .............................................. 16

Hinging the Ailerons............................................. 16

Hinging the Elevator .............................................17

Hinging the Rudder............................................... 17

Tail Wheel Installation................................................. 18

Tail Wheel Bracket Assembly .............................. 18

Mounting the Tail Wheel Bracket ........................ 18

Installing the Tail Wheel.......................................19

Main Gear Installation ................................................. 19

Installing the Gear Bracket ................................... 19

Installing the Gear Wing....................................... 20

Installing the Main Gear Wheels ..........................20

Engine Installation ....................................................... 21

Mounting the Engine to the Motor Mounts.......... 21

Aligning the Motor Mount Assembly .................. 21

Mounting the Engine to the Firewall.................... 22

Fuel Tank ......................................................................23

Stopper Assembly ................................................. 23

Installing the Stopper Assembly ..................................23

Installing the Fuel Tank ........................................ 24

Servo Installation ......................................................... 24

Installing the Fuselage Servo Tray .......................24

Installing the Aileron Servo Tray ......................... 24

Installing the Servos ............................................. 25

Throttle Pushrod........................................................... 25

Installing the Servo Connector ............................. 25

Adjusting the Throttle Linkage ............................ 26

Rudder Pushrod............................................................ 27

Installing the Control Horn................................... 27

Installing the Pushrod ........................................... 27

Adjusting the Rudder Pushrod..............................28

Elevator Pushrod .......................................................... 29

Installing the Control Horn................................... 29

Installing the Pushrod ........................................... 29

Adjusting the Elevator Pushrod............................ 30

Aileron Pushrods.......................................................... 31

Installing the Pushrods.......................................... 31

Adjusting the Aileron Pushrods............................32

Windscreen................................................................... 32

Trimming the Windscreen ....................................32

Mounting the Windscreen ..................................... 32

Machine Gun ................................................................33

Joining the Machine Gun Halves ......................... 33

Mounting the Machine Gun.................................. 33

Cowling ........................................................................ 34

Aligning the Cowl................................................. 34

Mounting the Cowl ............................................... 34

Final Assembly............................................................. 35

Installing the Switch ............................................. 35

Installing the Battery and Receiver ...................... 36

Balancing...................................................................... 36

Balancing the Fokker D-VII ................................. 36

Lateral Balancing .................................................. 37

Control Throws ............................................................ 37

Preflight Check.............................................................3 7

Safety............................................................................ 37

Flying the Fokker D-VII .............................................. 38

Notes............................................................................. 38

Product Evaluation Sheet.............................................39

SAFETY WARNING

This R/C airplane is not a toy! If misused, it can cause serious bodily injury and/or damage to property. Fly only

in open areas and preferably at a dedicated R/C flying site. We suggest having a qualified instructor carefully

inspect your airplane before its first flight. Please carefully read and follow all instructions included with this

airplane, your radio control system and your engine.

2

Page 3

INTRODUCTION

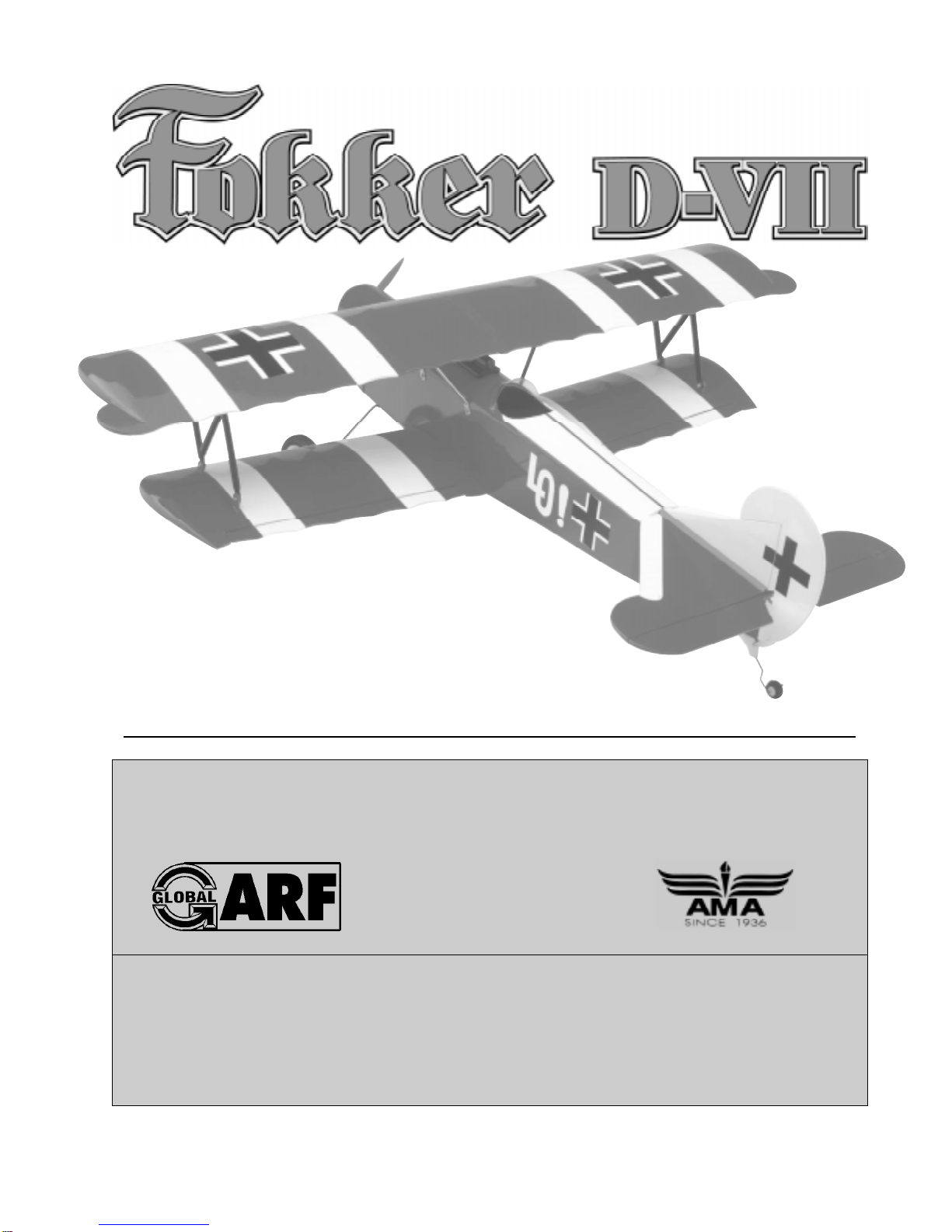

Thank you for choosing the Global Fokker D-VII ARF and welcome to the exciting world of WWI R/C

airplanes! W e are sure that you will appreciate the high quality , easy assembly and excellent flight characteristics

of the Fokker D-VII ARF.

The full size Fokker D-VII was a single seat fighter that featured fabric-covered wings with plywood ribs

and plywood leading edges. The fuselage was wire-braced steel tubing, completely fabric-covered except for

the cowling, which was sheet steel. The two most successful engines used in the Fokker D-VII were the

Mercedes 160 H.P. and the BMW 185 H.P. engines. The Fokker D-VII, designed by Reinhold Platz, was a

clean, simple-looking biplane, equipped with two Maxim 08/15 7.92mm machine guns.

The Fokker D-VIIs were so successful that, in August of 1918 alone, they shot down 565 Allied aircraft.

One thing that made the Fokker D-VII such a formidable opponent was the fact that it could hang 45 degrees on

its prop and shoot without stalling. By doing this, the Fokker D-VII could fly up under the bellies of enemy

aircraft and shoot them down. The Fokker D-VII could climb 5000 meters in 16 minutes, fly at a ceiling of

19,685 feet, and had an insurance of 90 minutes. The aircraft had an approximate top speed of 124 mph.

Now you too can feel what that was like with your own Stand-Off Scale R/C model of the Fokker D-VII.

When you open up the box, you'll notice that you won't have much left to do or to purchase to finish your new

airplane. The Fokker D-VII is a complete kit. Wire Spoke wheels, fuel tank, pushrods, clevises and other

hardware are all included. The airframe is completely prebuilt and covered by master craftsmen, who take their

time to ensure that every part is straight and properly glued.

W e hope you enjoy your new Fokker D-VII ARF as much as we have enjoyed designing and building it for

you. If you have any questions or comments, please feel free to contact us. We have also included a product

survey in the back of this manual. Please take the time to fill it out and send it to us. We would enjoy hearing

any comments or suggestions you may have.

This instruction manual is designed to guide you through the entire final assembly process of your new

Fokker D-VII ARF in the least amount of time possible. Along the way you'll learn how to properly

assemble your new airplane and also learn many tips that will help you in the future. We have listed some

of our recommendations below. Please read through them before going any further.

✔ Please read through each step before starting

assembly. You should find the layout very complete and simple. Our goal is to guide you through

assembly without any of the headaches and hassles

you might expect.

✔ There are check boxes next to each step. After

you complete a step, check off the box. This will

help you keep from losing your place.

✔ Cover your work table with brown paper or a

soft cloth, both to protect the table and to protect

the individual parts.

If you should find a part missing or damaged, or have any questions about assembly , please contact us at the

address below:

✔ Keep a couple of small bowls or jars handy to

put the small parts in after you open the accessory

bags.

✔ We're all excited to get a new airplane in the

air, but take your time. This will ensure that you

build a straight, strong and great flying airplane.

✔ If you come across this symbol , it means

that this is an important point or an assembly hint.

☛

Global Hobby Distributors Customer Care

18480 Bandilier Circle

Fountain Valley, CA 92728

Phone: (714) 963-0329

Fax: (714) 964-6236

E-mail: service@globalhobby.net

3

Page 4

KIT CONTENTS

AIRFRAME ASSEMBLIES

❑ {1} Fuselage w/Pushrod Housings

❑ {1} Top Wing - Right & Left Halves

❑ {1} Bottom Wing - Right & Left Halves

❑ {1} Horizontal Stabilizer w/Elevator & Hinges

❑ {1} Vertical Stabilizer w/Rudder & Hinges

❑ {1} Molded Fiberglass Cowl

❑ {1} Molded Clear Windscreen

❑ {1} Molded Plastic Machine Gun

MAIN LANDING GEAR ASSEMBLY

❑ {2} Wire Spoke Main Gear Wheels

❑ {1} Precovered Landing Gear Wing

❑ {1} Wire Landing Gear Strut

❑ {2} Nylon Landing Gear Strap - Small Slot

❑ {2} Nylon Landing Gear Strap - Large Slot

❑ {8} 3mm x 12mm Wood Screws

❑ {2} Nylon Wheel Spacers

❑ {2} Wheel Collars w/3mm x 6mm Machine Screws

❑ {2} Nylon Landing Gear Wing Mounts

❑ {2} 3mm x 6mm Machine Screws

❑ {4} 2mm x 5mm Wood Screws

TAIL WHEEL ASSEMBLY

❑ {1} Prebent Tail Wheel Wire

❑ {1} 25mm Diameter Wheel

❑ {1} Nylon Mounting Bracket

❑ {1} Nylon Steering Arm

❑ {2} 1.5mm Wheel Collars

❑ {2} 3mm x 6mm Machine Screws

❑ {3} 3mm x 12mm Wood Screws

❑ {1} 2mm x 10mm Wood Screw

ELEVATOR CONTROL SYSTEM

❑ {1} Nylon Pushrod Tube

❑ {1} 2mm x 90mm Threaded Wire w/L-Bend

❑ {1} 2mm x 100mm Threaded Wire

❑ {1} Nylon Clevis

❑ {1} Nylon Snap Keeper

❑ {1} Nylon Control Horn w/Backplate

❑ {2} 2mm x 15mm Machine Screws

RUDDER CONTROL SYSTEM

❑ {1} Nylon Pushrod Tube

❑ {1} 2mm x 90mm Threaded Wire w/L-Bend

❑ {1} 2mm x 100mm Threaded Wire

❑ {1} Nylon Clevis

❑ {1} Nylon Snap Keeper

❑ {1} Nylon Control Horn w/Backplate

❑ {2} 2mm x 15mm Machine Screws

AILERON CONTROL SYSTEM

❑ {2} 2mm x 50mm Threaded Wires w/L-Bends

❑ {2} Nylon Clevises

❑ {2} Nylon Snap Keepers

THROTTLE CONTROL SYSTEM

❑ {1} 1.5mm x 350mm Wire w/Z-Bend

❑ {1} Adjustable Servo Connector Assembly

WING STRUT ASSEMBLIES

❑ {4} Aluminum Cabane Struts (2 left & 2 right)

❑ {4} Aluminum Wing Mounts (2 left & 2 right)

❑ {2} Upper Strut Stabilizer Rods (1 left & 1 right)

❑ {2} Lower Strut Stabilizer Rods (1 left & 1 right)

❑ {2} Aluminum Strut Stabilizer Rod Clamps

❑ {2} Precovered Outer N-Struts

❑ {8} 3mm x 12mm Wood Screws

❑ {4} 3mm x 15mm Machine Screws

❑ {4} 3mm Nylon Insert Nuts

❑ {4} 3mm x 10mm Wood Screws

❑ {8} 3mm Blind Nuts

❑ {4} 3mm Split Washers

❑ {12}3mm x 10mm Machine Screws

❑ {12}3mm Flat Washers

MOTOR MOUNT ASSEMBLY

❑ {2} Nylon Motor Mount Beams

❑ {4} 3mm x 20mm Machine Screws

❑ {4} 3mm x 25mm Machine Screws

❑ {4} 3mm Nylon Insert Nuts

❑ {4} 3mm Blind Nuts

❑ {12}3mm Flat Washers

FUEL TANK ASSEMBLY

❑ {1} Molded Fuel Tank

❑ {1} Rubber Stopper

❑ {1} 20mm Diameter Front Plate

❑ {1} 17mm Diameter Back Plate

❑ {1} 3mm x 18mm Machine Screw

❑ {1} Weighted Fuel Pick-Up

❑ {3} Aluminum Tubes

❑ {1} Silicon Fuel Tubing

MISCELLANEOUS ITEMS

❑ {1} Top Wing Dihedral Brace (W-25)

❑ {1} Bottom Wing Dihedral Brace (W-26)

❑ {2} Precovered Triangle Stock (RT-8)

❑ {1} Precovered Square Stock

❑ {1} Wing Bolt Doubler (W-30)

❑ {1} Aileron Servo Tray (W-9C)

❑ {1} Rear Aileron Servo Tray Block (W-9B)

❑ {1} Front Aileron Servo Tray Block (W-9A)

❑ {1} Fuselage Servo Tray (D-38)

❑ {6} 3mm x 6mm Wood Screws

❑ {2} 4mm x 25mm Machine Screws

❑ {2} 4mm Flat Washers

❑ {2} 4mm Blind Nuts

❑ {1} 40mm Clear Tubing

4

Page 5

ADDITIONAL ITEMS REQUIRED

❑ {1} Hitec Focus 4FM Radio w/4 Servos

❑ {1} Dubro 1/4" Foam Rubber # 868638

❑ {1} Global XX-Silicon Fuel Line # 115923

❑ {1} Magnum Fueling Valve # 237500

IF YOU USE A TWO CYCLE ENGINE...

❑ {1} Williams Bros. 2-5/8" Pilot # 592659

❑ {1} Ernst External Charge Jack # 223730

❑ {1} Cirrus On-Board Battery Indicator # 444762

❑ {1} Formula-U Flat Black Paint # 586859

OPTIONAL ITEMS

❑ {1} Goldberg 1/4" Black Trim Tape # 582023

❑ {1} Magnum XL .46ARNV Engine # 210746

❑ {1} APC 11 x 6 Propeller # 608560

❑ {1} Thunderbolt R/C Long Glow Plug # 115493

IF YOU USE A FOUR CYCLE ENGINE...

❑ {1} Magnum XL .52RFS Engine # 210980

❑ {1} APC 12 x 6 Propeller # 608660

The optional Ernst Charge Jack and Cirrus On-Board

Battery Indicator are for use with Hitec and JR Radio

systems. These items are also available for use with

Futaba and Airtronics radio systems. Please check with

your retailer for availability.

❑ {1} Thunderbolt 4-Cycle Glow Plug # 115490

For a more scale appearance we recommend that you paint the aluminum wing strut mount system flat black. If you

decide to do this you should first roughen each part using fine grade sandpaper (400 grit works well) then wash the parts

in soap and warm water to remove any oil residue. Paint the individual parts before mounting them to the airplane.

TOOLS AND SUPPLIES REQUIRED

❑ Kwik Bond Thin C/A # 887500

❑ Kwik Bond Thick C/A # 887510

❑ Kwik Bond 5 Minute Epoxy # 887560

❑ Kwik Bond 30 Minute Epoxy # 887565

❑ Formula-560 Canopy Glue # 339176

❑ Pacer Blue Thread Lock # 339162

❑ Wilhold Silicon Sealant # 335407

❑ Robart Incidence Meter # 561554

❑ Excel Modeling Knife # 692808

❑ Magnum Tubing Bender # 237474

❑ Ernst Airplane Stand # 223977

❑ Masking Tape # 229685

❑ Electric Drill

❑ Assorted Drill Bits

❑ Dremel T ool w/Assorted Bits

❑ Straight Edge Ruler

❑ Phillips Head Screwdriver

❑ Wire Cutters

❑ Needle Nose Pliers

❑ Scissors

❑ Pen or Pencil

❑ Builder's Triangle

❑ 220 Grit Sandpaper w/Sanding Block

❑ Paper T owels

❑ Rubbing Alcohol

❑ W axed Paper

❑ Machine Oil or Vaseline

❑ NHP Epoxy Mixing Sticks # 864204

❑ NHP Mixing Cups # 864205

METRIC CONVERSION CHART

To convert inches into millimeters: Inches x 25.4 = mm

1/64" = .4mm

1/32" = .8mm

1/16" = 1.6mm

3/32" = 2.4mm

1/8" = 3.2mm

5/32" = 4.0mm

3/16" = 4.8mm

1/4" = 6.4mm

3/8" = 9.5mm

1/2" = 12.7mm

5/8" = 15.9mm

3/4" = 19.0mm

1" = 25.4mm

2" = 50.8mm

3" = 76.2mm

6" = 152.4mm

12" = 304.8mm

18" = 457.2mm

21" = 533.4mm

24" = 609.6mm

30" = 762.0mm

36" = 914.4mm

5

Page 6

A NOTE ABOUT COVERING

The covering material used on the Fokker D-VII is a heat shrink polyester material. Because of this, it is

possible with heat and humidity changes that the covering on your airplane may wrinkle or sag. This trait is

inherent in all types of heat shrink material. T o remove the wrinkles you will need to purchase, or borrow from a

fellow modeler, a heat iron. If you need to purchase one, the Global Sealing Iron # 360900 is recommended.

Follow these simple steps to remove the wrinkles:

❑ 1) Plug in and turn on the sealing iron to the medium temperature setting. Allow the iron to heat up for

approximately 5 - 7 minutes.

❑ 2) After the iron has reached temperature, lightly apply the iron to the wrinkled section of the covering. Move the iron slowly over the wrinkled section until the covering tightens and the wrinkles disappear.

You will notice that the color of the covering will darken when it is heated. When the covering cools back

down, it will return to its normal color.

If the color layer smears from any of the seams, the temperature of the iron is too hot. Turn the tempera-

☛

ture dial down and wait about 5 minutes for the iron to adjust to the lower temperature. You can remove any

excess color streaks using a paper towel soaked with a small quantity of acetone.

BOTTOM WING ASSEMBLY

PARTS REQUIRED

❑ {1} Bottom Wing - Right & Left Halves

❑ {1} Bottom Wing Dihedral Brace (W-26)

TOOLS AND SUPPLIES REQUIRED

❑ Kwik Bond 30 Minute Epoxy

❑ Excel Modeling Knife

❑ Masking Tape

❑ Straight Edge Ruler

❑ Pen or Pencil

❑ 220 Grit Sandpaper w/Sanding Block

❑ Paper Towels

❑ Rubbing Alcohol

❑ NHP Epoxy Mixing Sticks

❑ NHP Epoxy Mixing Cups

INSTALLING THE DIHEDRAL BRACE

❑ 1) Look carefully at the surface of each root rib

on both wing halves. Notice how the excess covering material overlaps onto them. Using a modeling

knife, carefully trim and remove the excess from both

of the root ribs, leaving about 1/16" of covering material overlapping so it does not pull away later.

❑ 2) Using a straight edge ruler and a pen, locate

and mark the centerline of the plywood dihedral brace

(W-26). Draw one vertical line, on each side of the

brace, at this location. See photo # 1 below.

Photo # 1

❑ 3) Test fit the plywood dihedral brace into the

plywood dihedral brace box in each wing half. The

brace should slide into each wing half up to its centerline. If it does not, remove the brace and lightly

sand the edges and tips until the proper fit is obtained.

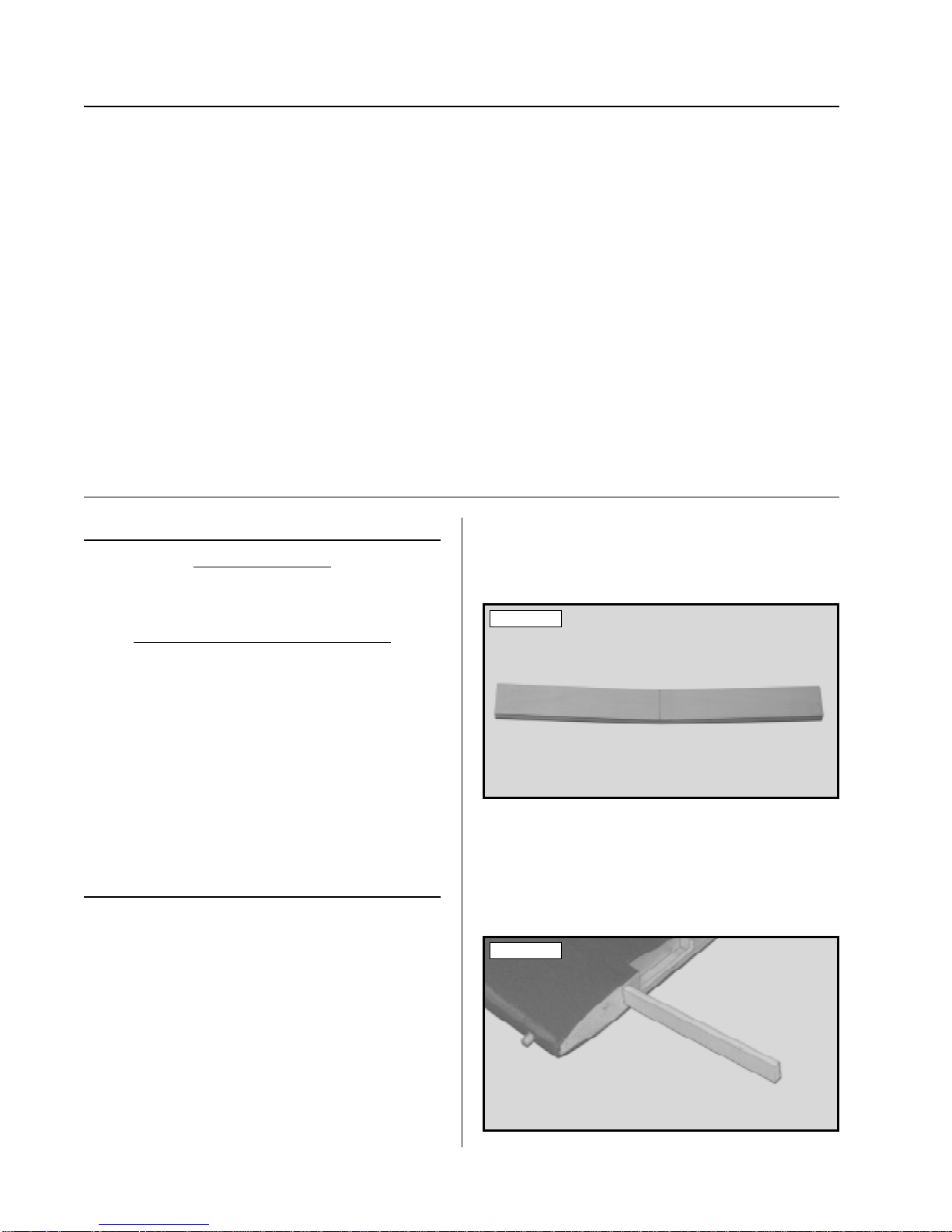

See photo # 2 below.

Photo # 2

Removing most of the covering from the two

☛

root ribs will expose more of the wood. This will

result in a stronger joint when the wing halves are

epoxied together later.

6

Page 7

The dihedral brace is cut in the shape of a "V".

☛

The "V" shape should face the top surface of the wing

when the brace is installed.

❑ 4) T est fit both of the wing halves together with

the dihedral brace temporarily installed (without using glue). Look carefully at the center section joint:

the wing halves should fit together tightly with few

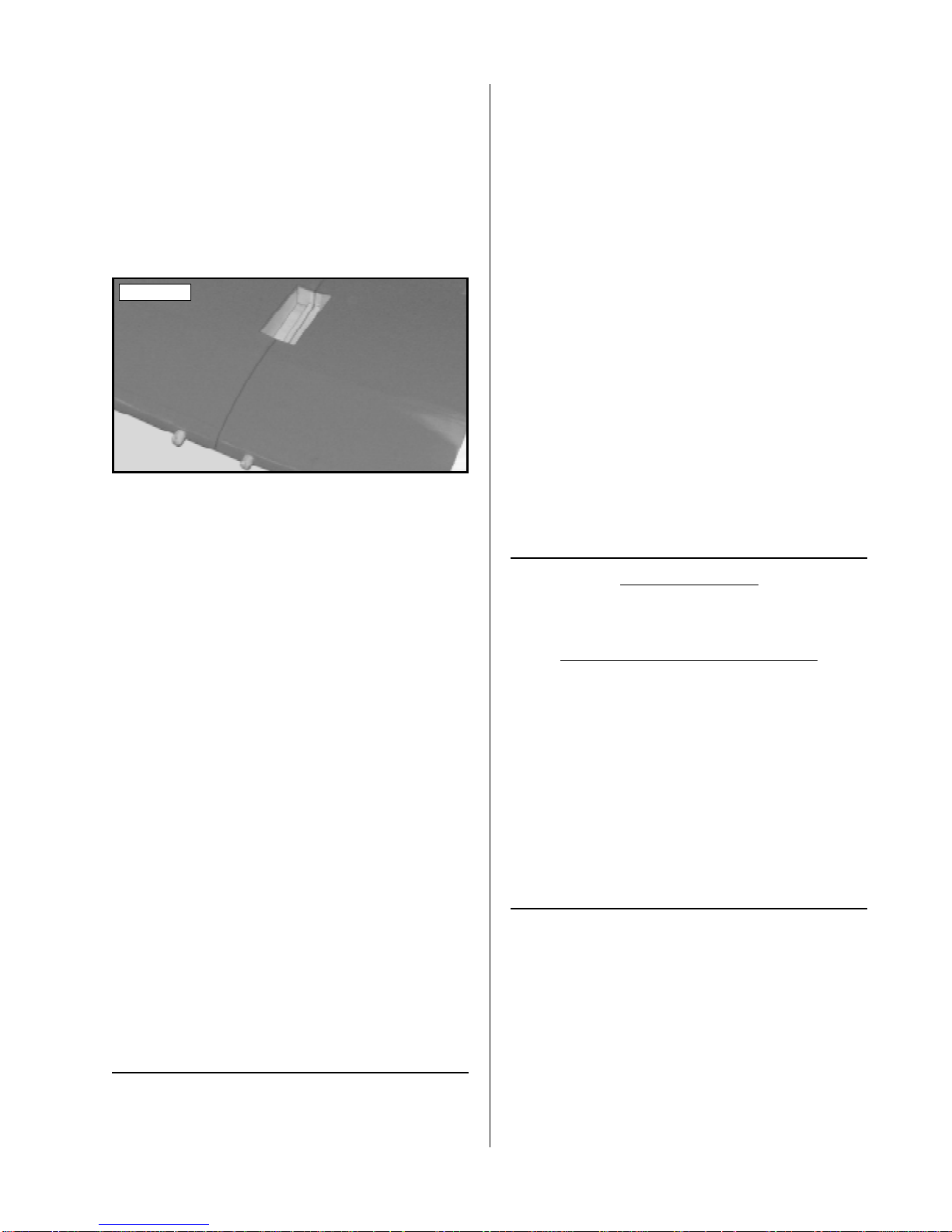

or no gaps in the joint. See photo # 3 below.

Photo # 3

❑ 10) Mix a generous amount of Kwik Bond 30

Minute Epoxy. Apply a thin layer of epoxy to the

exposed half of the dihedral brace, the inside of the

second wing half, and the entire surface of both root

ribs. Make sure to use enough epoxy to fill any gaps.

❑ 11) Slide the two wing halves together and carefully align them at both the leading and trailing edges.

Wipe away any excess epoxy, using a paper towel

and rubbing alcohol, and use several pieces of masking tape to hold the two wing halves aligned until the

epoxy fully cures.

❑ 12) Once the epoxy has fully cured, doublecheck the center section joint. If any gaps are present,

mix a small amount of Kwik Bond 30 Minute Epoxy

and carefully fill any remaining gaps. Remove any

excess epoxy using a paper towel and rubbing alcohol, and allow the epoxy to thoroughly cure.

❑ 5) If the center section joint is not tight, remove

the wing halves and the dihedral brace, and lightly

sand the edges and tips of the brace. T est fit the wing

halves together with the dihedral brace installed again

and repeat until you are satisfied with the fit. Once

you are satisfied with the fit, remove the wing halves

and the dihedral brace.

It is important that the wing halves fit together

☛

properly. The better the fit, the stronger the center

section joint will be.

❑ 6) Following the instructions on the packaging,

mix a generous amount of Kwik Bond 30 Minute

Epoxy. Mix the epoxy for about 1 minute. This will

ensure that both parts are thoroughly incorporated.

❑ 7) Working with only one wing half for now,

apply a thin layer of epoxy inside the plywood dihedral brace box and to only half of the dihedral brace.

Make sure to cover the top and bottom, as well as the

sides, and use enough epoxy to fill any gaps.

❑ 8) Slide the dihedral brace into the wing half

up to its centerline. Remove any excess epoxy before it dries, using a paper towel and rubbing alcohol.

Allow the epoxy to fully cure before proceeding.

❑ 13) Once the epoxy has fully cured, carefully

remove the masking tape from the wing.

TOP WING ASSEMBLY

PARTS REQUIRED

❑ {1} Top Wing - Right & Left Halves

❑ {1} Top Wing Dihedral Brace (W-25)

TOOLS AND SUPPLIES REQUIRED

❑ Kwik Bond 30 Minute Epoxy

❑ Excel Modeling Knife

❑ Masking Tape

❑ Straight Edge Ruler

❑ Pen or Pencil

❑ 220 Grit Sandpaper w/Sanding Block

❑ Paper Towels

❑ Rubbing Alcohol

❑ NHP Epoxy Mixing Sticks

❑ NHP Epoxy Mixing Cups

INSTALLING THE DIHEDRAL BRACE

❑ 1) Look carefully at the surface of each root rib

on both wing halves. Notice how the excess covering material overlaps onto them. Using a modeling

knife, carefully trim and remove the excess from both

of the root ribs, leaving about 1/16" of covering material overlapping so it does not pull away later.

JOINING THE WING HALVES

❑ 9) Once the epoxy has fully cured, trial fit both

wing halves together again to double check that the

wing halves still fit together properly.

Removing most of the covering from the two

☛

root ribs will expose more of the wood. This will

result in a stronger joint when the wing halves are

epoxied together later.

7

Page 8

❑ 2) Using a straight edge ruler and a pen, locate

and mark the centerline of the plywood dihedral brace

(W-25). Draw one vertical line, on each side of the

brace, at this location.

❑ 6) Following the instructions on the packaging,

mix a generous amount of Kwik Bond 30 Minute

Epoxy . Mix the epoxy for about 1 minute. This will

ensure that both parts are thoroughly incorporated.

❑ 3) Test fit the plywood dihedral brace into the

plywood dihedral brace box in each wing half. The

brace should slide into each wing half up to its centerline. If it does not, remove the brace and lightly

sand the edges and tips until the proper fit is obtained.

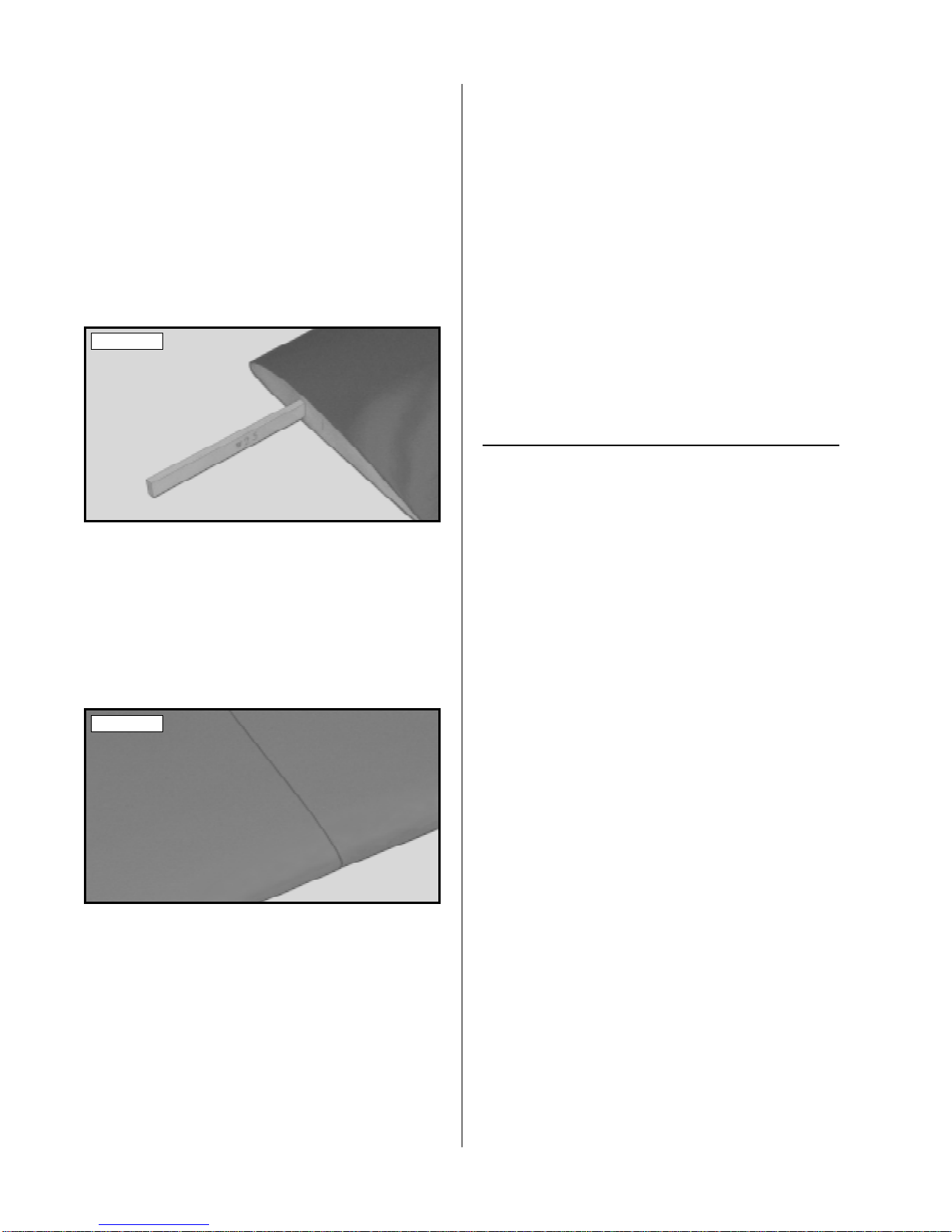

See photo # 4 below.

Photo # 4

The dihedral brace is cut straight, so it doesn't

☛

matter which direction it is installed into the wing.

❑ 4) Test fit both of the wing halves together with

the dihedral brace temporarily installed (without using glue). Look carefully at the center section joint:

the wing halves should fit together tightly with few

or no gaps in the joint. See photo # 5 below.

Photo # 5

❑ 7) Working with only one wing half for now,

apply a thin layer of epoxy inside the plywood dihedral brace box and to only half of the dihedral brace.

Make sure to cover the top and bottom, as well as the

sides, and use enough epoxy to fill any gaps.

❑ 8) Slide the dihedral brace into the wing half

up to its centerline. Remove any excess epoxy before it dries, using a paper towel and rubbing alcohol.

Allow the epoxy to fully cure before proceeding.

JOINING THE WING HALVES

❑ 9) Once the epoxy has fully cured, trial fit both

wing halves together again to double check that the

wing halves still fit together properly.

❑ 10) Mix a generous amount of Kwik Bond 30

Minute Epoxy. Apply a thin layer of epoxy to the

exposed half of the dihedral brace, the inside of the

second wing half, and the entire surface of both root

ribs. Make sure to use enough epoxy to fill any gaps.

❑ 11) Slide the two wing halves together and carefully align them at both the leading and trailing edges.

Wipe away any excess epoxy using a paper towel

and rubbing alcohol and use several pieces of masking tape to hold the two wing halves aligned until the

epoxy fully cures.

❑ 5) If the center section joint is not tight, remove

the wing halves and the dihedral brace, and lightly

sand the edges and tips of the brace. T est fit the wing

halves together with the dihedral brace installed again

and repeat until you are satisfied with the fit. Once

you are satisfied with the fit, remove the wing halves

and the dihedral brace.

It is important that the wing halves fit together

☛

properly. The better the fit, the stronger the center

section joint will be.

8

❑ 12) Once the epoxy has fully cured, doublecheck the center section joint. If any gaps are present,

mix a small amount of Kwik Bond 30 Minute Epoxy

and carefully fill any remaining gaps. Remove any

excess epoxy , using a paper towel and rubbing alcohol, and allow the epoxy to thoroughly cure.

❑ 13) After the epoxy has fully cured, carefully

remove the masking tape from the wing. If any residue is left from the tape, it can be removed using a

paper towel soaked with a small amount of rubbing

alcohol.

Page 9

BOTTOM WING MOUNTING

PARTS REQUIRED

❑ 6) Remove the two ailerons from the wing and

set them aside for now.

❑ {1} Wing Bolt Doubler (W-30)

❑ {2} 4mm x 25mm Machine Screws

❑ {2} 4mm Flat Washers

❑ {2} 4mm Blind Nuts

TOOLS AND SUPPLIES REQUIRED

❑ Kwik Bond Thick C/A

❑ Excel Modeling Knife

❑ Ernst Airplane Stand

❑ Masking Tape

❑ Electric Drill

❑ 5/32" & 7/32" Drill Bits

❑ Straight Edge Ruler

❑ Phillips Head Screwdriver

❑ Needle Nose Pliers

❑ Pen or Pencil

ALIGNING THE WING

❑ 1) Set the fuselage upside down in your airplane

stand and place the bottom wing into the wing saddle.

Align the two hardwood dowels in the leading edge

of the wing with the two predrilled holes in the

fuselage's forward bulkhead.

❑ 2) Carefully slide the wing forward, making

sure that the two hardwood dowels fully engage the

two predrilled holes in the forward bulkhead.

❑ 3) Using a ruler and a pen, locate the centerline of the fuselage, at the back edge of the wing

saddle, and place a mark. See photo # 6 below.

❑ 7) Check that the wing is square to the fuselage. To do this use a ruler and carefully measure

from the trailing edge of each wing tip to the back

edge of the fuselage. Both of these measurements

should be the same. See figure # 1 below.

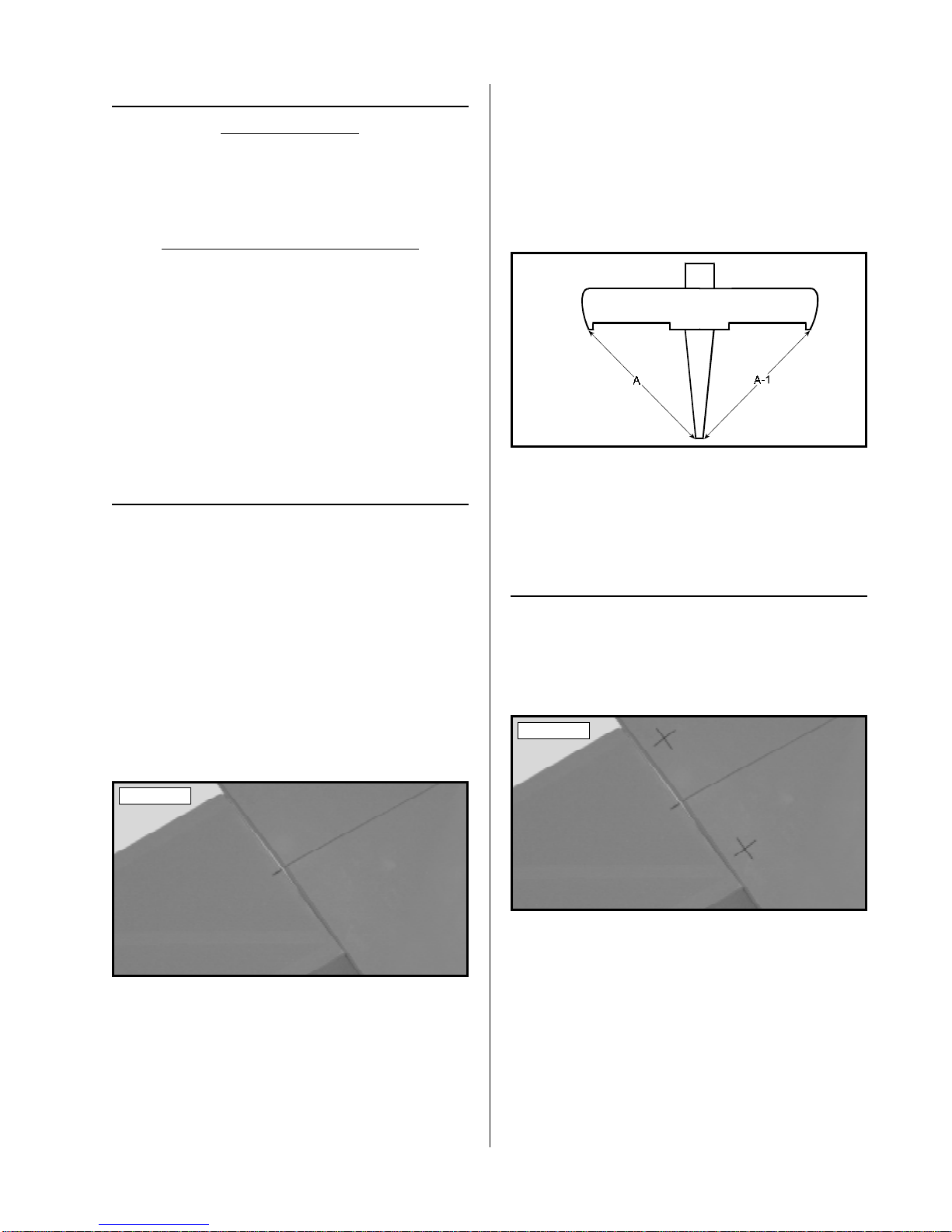

Figure # 1

A = A-1

❑ 8) If the two measurements are not the same,

carefully lift the masking tape and adjust the back of

the wing until they are. When you are satisfied with

the alignment, reattach the masking tape to hold the

wing securely in place.

INSTALLING THE BLIND NUTS

❑ 9) Using a ruler and a pen, measure 3/8" in front

of the trailing edge of the wing and place two marks,

one on each side of the centerline. Now measure

1-9/32" out from each side of the centerline and place

two marks. See photo # 7 below.

Photo # 7

Photo # 6

❑ 4) The joint where the two wing halves were

glued together is the centerline of the wing. Align

the centerline of the wing with the centerline you drew

on the bottom of the fuselage.

❑ 5) While holding the wing in alignment, use a

couple of pieces of masking tape to hold the wing

securely to the fuselage.

❑ 10) Using a drill with a 5/32" drill bit, carefully

drill two holes into the wing and down through the

plywood wing hold down block inside the fuselage.

Angle the drill bit so that the holes will be per-

☛

pendicular to the bottom of the wing.

❑ 11) Remove the wing from the wing saddle.

Using a drill with a 7/32" drill bit, enlarge only the

two holes in the plywood mounting block.

9

Page 10

❑ 12) Install the two 4mm blind nuts into the bottom of the plywood mounting plate. Use a pair of

needle nose pliers to squeeze the blind nuts up into

place. See photo # 8 below.

Photo # 8

A balsa filler block has been preinstalled onto

☛

the bottom of the plywood plate to make it easier to

install the blind nuts.

❑ 18) Apply a generous amount of Kwik Bond

Thick C/A to the bottom of the doubler. Set the doubler back into place and realign it. Hold the doubler

firmly in place until the C/A fully cures.

❑ 19) Remove the wing from the wing saddle.

Using a drill with a 5/32" drill bit, drill the two wing

mounting screw holes through the wing bolt doubler.

Use the holes you drilled through the wing as a guide.

MOUNTING THE WING

❑ 20) Place the wing back into the wing saddle

and bolt it in place using the two 4mm x 25mm machine screws and two 4mm flat washers. Tighten the

screws firmly using a phillips head screwdriver. See

photo # 10 below.

❑ 13) With the blind nuts fully seated, carefully

apply a bead of Kwik Bond Thick C/A around the

bottom of each blind nut to lock them into place. Be

careful not to get any glue into the threads and allow

the C/A to fully cure before proceeding.

INSTALLING THE WING BOLT DOUBLER

❑ 14) Place the wing back into the wing saddle

and realign it. Use a couple of pieces of masking

tape to hold it in place.

❑ 15) Set the wing bolt doubler (W-30) in place

on the bottom of the wing. The back edge of the

doubler should be about 1/16" in front of the trailing

edge and the sides of the doubler should be even with

the sides of the fuselage. See photo # 9 below.

Photo # 9

❑ 16) While holding the wing bolt doubler in

place, use a pen and outline the doubler onto the wing.

Photo # 10

HORIZONTAL STABILIZER

PARTS REQUIRED

❑ {1} Horizontal Stabilizer w/Elevator & Hinges

TOOLS AND SUPPLIES REQUIRED

❑ Kwik Bond 30 Minute Epoxy

❑ Excel Modeling Knife

❑ Ernst Airplane Stand

❑ Masking Tape

❑ Straight Edge Ruler

❑ Pen or Pencil

❑ Builder's Triangle

❑ 220 Grit Sandpaper w/Sanding Block

❑ Paper Towels

❑ Rubbing Alcohol

❑ NHP Epoxy Mixing Sticks

❑ NHP Epoxy Mixing Cups

ALIGNING THE STABILIZER

❑ 17) Remove the doubler from the wing. Using

a modeling knife, carefully remove the covering from

inside the outline you drew.

10

❑ 1) Remove the elevator and hinges from the

horizontal stabilizer and set them aside for now.

Page 11

❑ 2) Using a ruler and a pen, locate and mark the

centerline of the horizontal stabilizer, at the trailing

edge, and place a mark. Using a builder's triangle,

extend this mark from front to back across the top

and bottom of the stabilizer.

❑ 3) Using a modeling knife, carefully remove the

covering from the tops of the stabilizer mounting sides

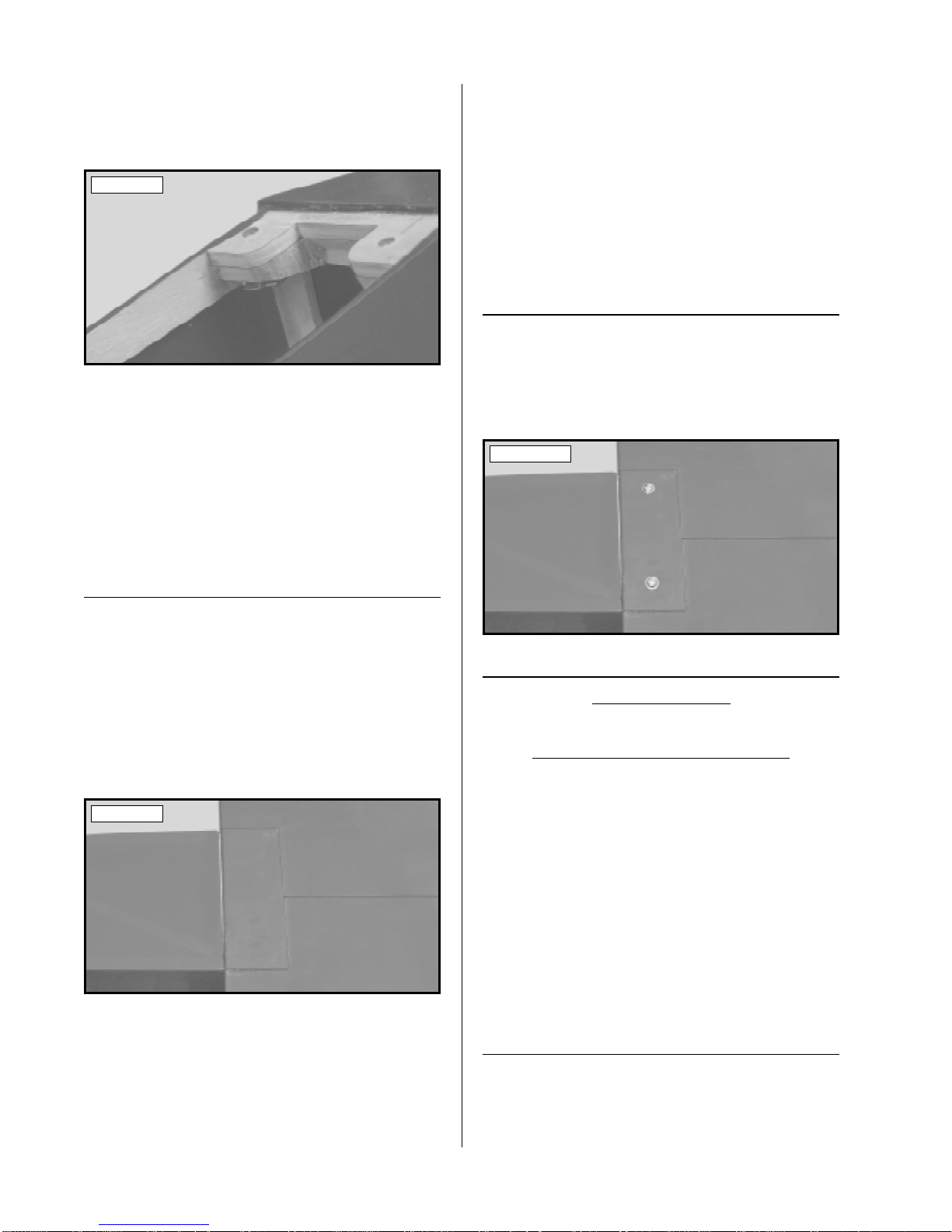

on the fuselage. See photo # 11 below.

Photo # 11

❑ 4) Mount the bottom wing to the fuselage. With

the fuselage securely in your airplane stand, set the

stabilizer onto the stabilizer mounting sides. The trailing edge of the stabilizer should be even with the

back edge of the fuselage.

❑ 5) Align the centerline mark on the trailing edge

of the stabilizer with the center of the back edge of

the fuselage. When that is aligned, hold the trailing

edge of the stabilizer in that position using a piece of

masking tape.

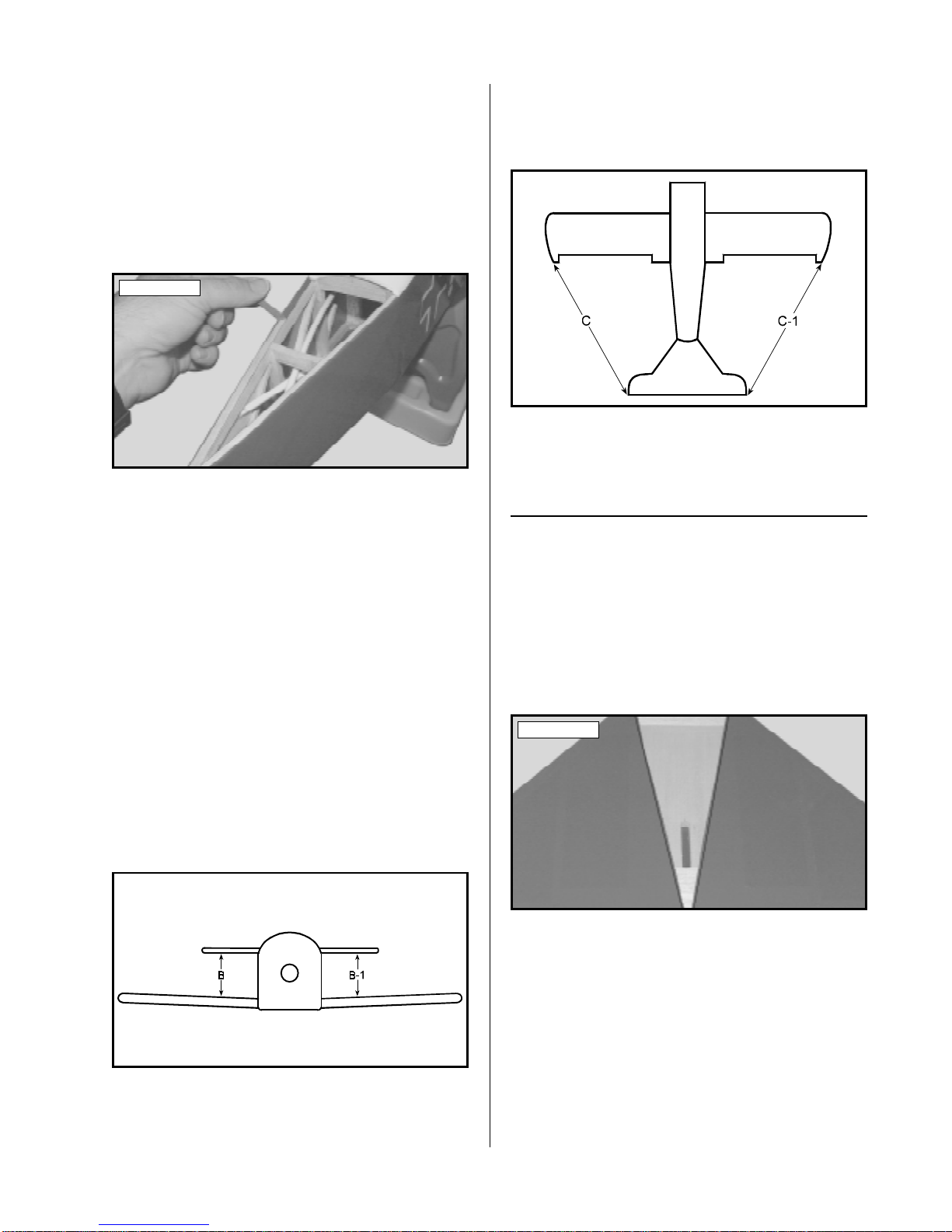

stabilizer tip on the same side. Do this for both

sides. When the stabilizer is aligned properly , both

of these measurements should be the same. See

figure # 3 below.

Figure # 3

C = C-1

❑ 8) When you are satisfied with the alignment,

hold the stabilizer firmly in place using a couple of

pieces of masking tape. Do not use glue yet!

MOUNTING THE STABILIZER

❑ 9) With the stabilizer held firmly in place, use a

pen to draw lines onto the bottom of the stabilizer

where it and the fuselage sides meet. Do this on both

the right and left sides.

❑ 10) Remove the stabilizer from the fuselage.

Using the lines you just drew as a guide, carefully

remove the covering from between them using a

modeling knife. See photo # 12 below.

❑ 6) With the stabilizer in place, look carefully

from the front of the fuselage at both the wing and

the stabilizer. When aligned properly, the stabilizer

should be level with the wing. If it is not level, use

220 grit sandpaper and a sanding block to sand down

the higher stabilizer mounting side until the correct

alignment is achieved. See figure # 2 below.

Figure # 2

B = B-1

❑ 7) Now check to make sure that the tips of the

stabilizer are equal distances from the tips of the wing.

Use a ruler and measure from one wing tip to the

Photo # 12

When cutting through the covering to remove

☛

it, cut with only enough pressure to cut through only

the covering itself. Cutting into the balsa will weaken

the stabilizer.

❑ 11) Mix a generous amount of Kwik Bond 30

Minute Epoxy. Apply a thin layer to the mounting

area on the bottom of the stabilizer and to the tops of

the stabilizer mounting sides and cross-member on

the fuselage.

11

Page 12

❑ 12) Set the stabilizer back into place and realign

it, double checking all of your measurements once

more. When satisfied with the alignment, hold the

stabilizer in place using several pieces of masking

tape and remove any excess epoxy using a paper towel

and rubbing alcohol before it cures. Allow the epoxy

to fully cure before proceeding.

VERTICAL STABILIZER

PARTS REQUIRED

❑ {1} Vertical Stabilizer w/Rudder & Hinges

❑ {2} Precovered Triangle Stock (RT-8)

TOOLS AND SUPPLIES REQUIRED

❑ Kwik Bond Thick C/A

❑ Kwik Bond 30 Minute Epoxy

❑ Excel Modeling Knife

❑ Ernst Airplane Stand

❑ Masking Tape

❑ Pen or Pencil

❑ Builder's Triangle

❑ Paper Towels

❑ Rubbing Alcohol

❑ NHP Epoxy Mixing Sticks

❑ NHP Epoxy Mixing Cups

lines you drew and from the bottom edge of the stabilizer. Also remove the covering from inside the

outline you drew on top of the horizontal stabilizer.

See photo # 13 below.

Photo # 13

When cutting through the covering to remove

☛

it, cut with only enough pressure to cut through only

the covering itself. Cutting into the balsa will weaken

the structure.

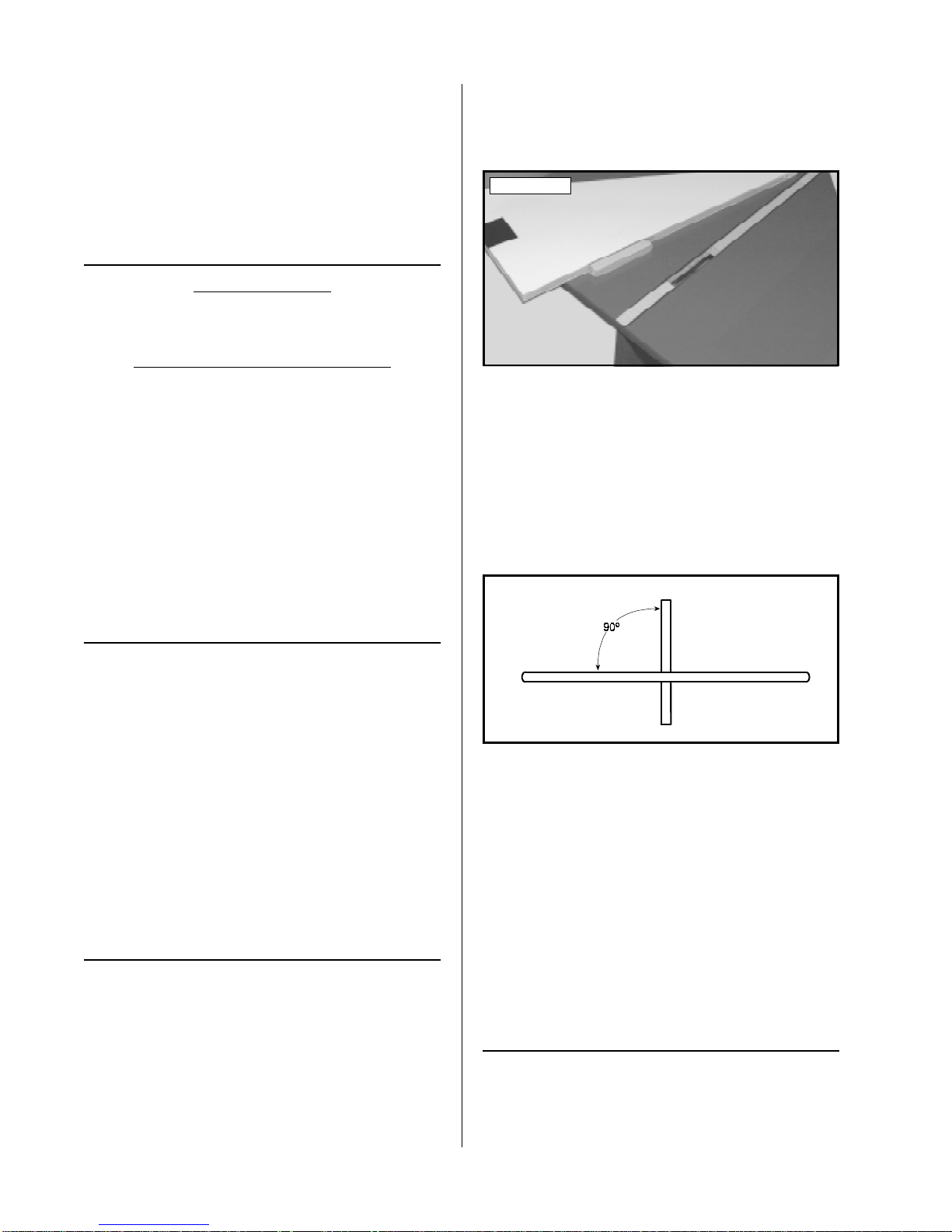

❑ 6) Set the vertical stabilizer back into place and

realign it. Using a builder's triangle, check to ensure

that the vertical stabilizer is aligned 90º to the horizontal stabilizer. See figure # 4 below.

Figure # 4

ALIGNING THE STABILIZER

❑ 1) Remove the rudder and the hinges from the

stabilizer and set them aside for now.

❑ 2) Using a modeling knife, remove the covering from over the top of the precut slot in the

horizontal stabilizer.

❑ 3) Set the vertical stabilizer in place, making

sure that the tab in the bottom of the stabilizer is

pushed down firmly into the precut slot. The front

of the stabilizer should also be lined up with the

centerline you drew previously on the horizontal

stabilizer.

MOUNTING THE STABILIZER

❑ 4) While holding the vertical stabilizer firmly

in place, use a pen to draw a line on each side of it

where it meets the top of the horizontal stabilizer.

Also draw a line on top of the horizontal stabilizer

around the base of the vertical stabilizer.

❑ 5) Remove the stabilizer. Using a modeling

knife, carefully remove the covering from below the

❑ 7) Mix a generous amount of Kwik Bond 30

Minute Epoxy. Apply a thin layer to the mounting

slot in the horizontal stabilizer and to the sides and

bottom of the vertical stabilizer mounting area. Also

apply epoxy to the top of the horizontal stabilizer.

❑ 8) Set the stabilizer back into place and realign

it, double checking all of your measurements. Hold

the stabilizer in place using several pieces of masking tape and remove any excess epoxy using a paper

towel and rubbing alcohol. Allow the epoxy to fully

cure before proceeding.

INSTALLING THE TRIANGLE STOCK

❑ 9) Using a modeling knife, remove the covering that overlaps onto the inner edges of the two pieces

of precovered triangle stock.

12

Page 13

❑ 10) W orking with one piece of triangle stock for

now, align it in the joint between the horizontal and

vertical stabilizers. When it's properly aligned, the

triangle stock should be even with the trailing edges

of the stabilizers. See photo # 14 below.

Photo # 14

❑ 11) When satisfied with the alignment, hold the

triangle stock in place and trace around it using a

pen.

❑ 12) Remove the triangle stock. Using a modeling knife, carefully remove the covering from inside

the outline you drew.

❑ 13) Glue the triangle stock into place using

Kwik Bond Thick C/A. Allow the C/A to cure completely before proceeding.

The triangle stock adds a lot of strength to the

☛

joint between the stabilizers. It is important that it be

glued in securely.

TOOLS AND SUPPLIES REQUIRED

❑ Kwik Bond 30 Minute Epoxy

❑ Pacer Blue Thread Lock

❑ Robart Incidence Meter

❑ Excel Modeling Knife

❑ Ernst Airplane Stand

❑ Masking Tape

❑ Electric Drill

❑ 5/64" & 1/8" Drill Bits

❑ Straight Edge Ruler

❑ Phillips Head Screwdriver

❑ Needle Nose Pliers

❑ Pen or Pencil

❑ NHP Epoxy Mixing Sticks

❑ NHP Epoxy Mixing Cups

INSTALLING THE CABANE STRUTS

Setting the proper wing incidence is important

☛

in any airplane; however, wing incidence is critical

in a biplane to achieve good flight performance. Incidence is the angle at which the flying surfaces (i.e.,

wings and stabilizer) flow through the air. The Fokker

D-VII should be set up with the stabilizer at 0º, the

bottom wing at 0º and the top wing at either 0º or -1º

incidence. We highly recommend that you use an

incidence meter to help you make these measurements. See figure # 5 below .

Figure # 5

❑ 14) Repeat steps # 10 - # 13 to install the second piece of triangle stock on the opposite side.

TOP WING MOUNTING

PARTS REQUIRED

❑ {4} Aluminum Cabane Struts (2 left & 2 right)

❑ {4} Aluminum Wing Mounts (2 left & 2 right)

❑ {2} Upper Strut Stabilizer Rods (1 left & 1 right)

❑ {2} Lower Strut Stabilizer Rods (1 left & 1 right)

❑ {2} Aluminum Strut Stabilizer Rod Clamps

❑ {2} Precovered Outer N-Struts

❑ {8} 3mm x 12mm Wood Screws

❑ {4} 3mm x 15mm Machine Screws

❑ {4} 3mm Nylon Insert Nuts

❑ {4} 3mm x 10mm Wood Screws

❑ {8} 3mm Blind Nuts

❑ {4} 3mm Split Washers

❑ {12}3mm x 10mm Machine Screws

❑ {12}3mm Flat Washers

❑ 1) Using a modeling knife, remove the cover-

ing from over the four predrilled holes in each side

of the fuselage. The first hole is located 5/8" back

from the firewall and 5/8" up from the bottom of the

fuselage. The second hole is located 5/8" back from

the firewall and 2-5/8" up from the bottom of the fuselage. The third and fourth holes are located 6-3/4"

and 11-1/2" back from the firewall and 5/8" down

from the start of the curve on the fuselage side.

❑ 2) Using a modeling knife, remove the covering from over the two predrilled holes in both ends

of each outer N-strut and the two predrilled holes in

each outer N-strut mounting tab on the bottom wing.

13

Page 14

The top wing does not have predrilled outer

☛

N-Strut mounting tabs.

❑ 3) Thread the two upper strut stabilizer rods

(shorter rods) into the two upper holes (one on each

side) in the front of the fuselage. Thread the rods

completely into place. When positioned properly the

bend in the top end of each rod should point down.

❑ 6) Install one aluminum wing mount onto each

of the two rear cabane struts using two 3mm x 10mm

machine screws, two 3mm split washers and two 3mm

nylon insert nuts. Do not completely tighten the

screws at this time.

Install the wing mounts on the outside of the

☛

cabane struts.

If the bends in the tops of the rods point up then

☛

the rods are on the wrong side of the fuselage.

❑ 4) Thread the two lower strut stabilizer rods

(longer rods) into the two lower holes (one on each

side) in the front of the fuselage. Thread the rods

completely into place. When positioned properly,

the bend in the top end of each rod should point up.

See photo # 15 below.

Photo # 15

❑ 5) Install the four aluminum cabane struts (2 left

& 2 right) onto the fuselage sides using four 3mm x

15mm machine screws and four 3mm flat washers.

Thread the screws through the elongated holes in each

strut and into the fuselage, but do not completely

tighten the screws at this time.

When installed properly, the cabane struts

☛

should be angled forward toward the firewall and

out from the fuselage sides. When you look at the

tops of the struts from the front of the fuselage the

struts should be nearly parallel with the fuselage

sides. If they are not, you may have them on the

wrong side. See figure # 6 below.

Figure # 6

❑ 7) Connect the two stabilizer strut rods on each

side of the fuselage to the two aluminum strut rod

clamps.

❑ 8) Install the two remaining aluminum wing

mounts to the two front cabane struts, along with the

two strut rod clamp assemblies. Use two 3mm x

10mm machine screws, two 3mm split washers and

two 3mm nylon insert nuts to secure them into place.

Do not completely tighten the screws at this time.

See photo # 16 below.

Photo # 16

INSTALLING THE OUTER N-STRUTS

❑ 9) Test fit the outer N-struts to the mounting

tabs on the bottom wing. The struts are universal

from right to left, but there is a difference between

the top and the bottom. If the holes in the mounting

tabs do not line up with the holes in the N-strut, turn

the N-strut over.

The N-struts should be installed on the inside of

☛

the mounting tabs.

❑ 10) When satisfied with the alignment, bolt the

outer N-struts to the bottom wing using four 3mm x

10mm machine screws, four 3mm flat washers and

four 3mm blind nuts. Tighten the screws firmly to

draw the blind nuts into place.

14

The blind nuts should be installed on the inside

☛

of the N-struts.

Page 15

ALIGNING THE TOP WING

❑ 11) Install the bottom wing onto the fuselage.

Set the fuselage in your airplane stand and use a

couple of large rubber bands or small weights to hold

the airplane firmly in place. It's important that the

fuselage not move during the remaining wing alignment process.

It may be necessary to bend or change the angle

☛

of the cabane struts to help align the wing.

❑ 15) At this point the top wing should be cen-

tered on the fuselage and parallel with the bottom

wing. Double check the incidence of the top wing.

It should be between 0º and -1º.

❑ 12) Attach your incidence meter to the bottom

wing. Adjust the airplane stand and/or fuselage until

the incidence meter reads 0º. See photo # 17 below.

Photo # 17

It may be necessary to use a block of wood or a

☛

book to prop up one end of the airplane stand. If you

need to prop it up, make sure it is secure. It's important that the stand doesn't move.

❑ 13) Set the top wing onto the cabane struts and

the outer N-struts. Use clothespins or small clamps

to hold the tops of the N-struts to the N-strut mounting tabs on the top wing. Pieces of masking tape will

work, too.

Make sure the N-struts are located on the inside

☛

of the strut mounting tabs.

❑ 14) Attach your incidence meter to the top wing.

Carefully adjust the cabane struts and aluminum

wing mounts until the incidence meter reads approximately 0º. When satisfied with the alignment,

tighten the cabane strut mounting screws only tight

enough so that the struts won't move easily. See

photo # 18 below.

Photo # 18

MOUNTING THE TOP WING

❑ 16) When satisfied with the alignment, use a pen

to mark the locations of the four N-Strut mounting

holes onto the mounting tabs on the top wing.

❑ 17) Remove the top wing and lay it upside down

on your work table. Using a 1/8" drill bit, carefully

drill the four holes through the N-strut mounting tabs.

Lay a towel over the wing to protect it while

☛

you drill the holes.

❑ 18) Set the top wing back into place and realign

it. Bolt the N-struts into place using four 3mm x

10mm machine screws, four 3mm flat washers and

four 3mm blind nuts. Tighten the screws firmly to

draw the blind nuts into place.

The blind nuts should be installed on the inside

☛

of the N-struts.

❑ 19) Reattach the incidence meter to the top

wing and double check the incidence. It should still

be between 0º and -1º. If it is not, remove the Nstruts and make small adjustments to the mounting

holes in the N-strut mounting tabs until the alignment is correct.

Wing alignment is important, but the integrity

☛

of the joints is also important. Be careful not to enlarge the N-strut mounting holes any more than

necessary. If there is too much play, the wing could

shift during flight.

❑ 20) With the top wing bolted to the N-struts, use

a pen and mark the screw locations of the four aluminum wing mounts onto the bottom of the wing.

❑ 21) Remove the top wing. Using a drill with a

5/64" drill bit, drill eight pilot holes into the wing at

the locations you marked.

Be careful not to drill through the top of the

☛

wing!

15

Page 16

❑ 22) One at a time, remove the aluminum wing

mounts from the cabane struts and install them into

their proper positions on the wing. Use eight 3mm x

12mm wood screws to secure them into place. See

photo # 19 below.

❑ 28) Mix a small quantity of Kwik Bond 30

Minute Epoxy. One at a time, remove the wood

screws that hold the aluminum wing mounts to the

top wing, apply a dab of epoxy to the screws, then

reinstall and tighten them securely .

Photo # 19

❑ 23) Install the top wing and check the alignment

one more time using your incidence meter. If the

wing is out of alignment loosen the four machine

screws that hold the cabane struts to the fuselage sides.

Adjust the cabane struts until you are satisfied with

the alignment and retighten the screws.

❑ 24) When you're satisfied with the alignment,

remove the four screws (one at a time) and reinstall

them using a couple of drops of Pacer Thread Lock.

Tighten the screws firmly to secure them in place.

Do not apply any thread lock to the outer N-strut

☛

mounting screws or to the screws that hold the aluminum wing mounts to the cabane struts.

❑ 25) Using a 5/64" drill bit, drill four pilot holes

into the fuselage sides using the predrilled holes in

the cabane struts (above the elongated holes) as a

guide.

The epoxy will secure the screws in place and

☛

prevent any chance of them loosening during flight.

CONTROL SURFACE HINGING

TOOLS AND SUPPLIES REQUIRED

❑ Kwik Bond Thin C/A

❑ Kwik Bond 30 Minute Epoxy

❑ Excel Modeling Knife

❑ Scissors

❑ Waxed Paper

❑ NHP Epoxy Mixing Sticks

❑ NHP Epoxy Mixing Cups

HINGING THE AILERONS

❑ 1) Locate the precut hinge slots in the trailing

edge of each half of the wing and the leading edge of

each aileron.

❑ 2) Using a modeling knife, carefully remove any

excess covering material from over each of the hinge

slots.

❑ 3) T est fit the C/A hinges into the hinge slots in

one aileron. Each hinge should be inserted far enough

into the slots so that the centerline of the hinges is

flush with the leading edge of the aileron. If the hinges

cannot be inserted deeply enough, use a modeling

knife and carefully cut the hinge slots deeper.

❑ 26) Install four 3mm x 10mm wood screws

through the predrilled holes in the cabane struts and

into the fuselage sides. Tighten the screws firmly.

These wood screws will lock the cabane struts

☛

in place, preventing them from moving back and forth

after you have removed the top wing.

❑ 27) Remove the top wing. T o do this properly,

first remove the four machine screws from the upper

N-strut mounts, then remove the four machine screws

and nylon insert nuts that hold the aluminum wing

mounts to the cabane struts.

16

❑ 4) With each of the hinges centered in the hinge

slots, apply 3-4 drops of Kwik Bond Thin C/A to the

joint where the hinges and the aileron meet. Allow a

few seconds between drops for the C/A to wick into

the hinges, then turn the aileron over and repeat this

procedure on the other side of each hinge. Let the

C/A dry for about 10 minutes before proceeding.

❑ 5) Using a pair of scissors, cut out a small

piece of waxed paper. Working with one wing half

for now, slide the waxed paper between the aileron torque rod and the trailing edge of the wing.

See photo # 20 at top right.

Page 17

Photo # 20

The waxed paper will prevent epoxy from glu-

☛

ing the torque rod to the trailing edge of the wing.

❑ 6) Using a modeling knife, carefully remove

the covering from over the predrilled hole and the

precut groove in the leading edge of the aileron.

❑ 7) Mix a small quantity of Kwik Bond 30

Minute Epoxy. Apply a thin layer of epoxy to the

aileron torque rod, and pack epoxy into the predrilled

hole and the precut groove in the leading edge of

the aileron.

❑ 8) Slide the aileron and its hinges into the hinge

slots in the trailing edge of the wing, making sure

that the torque rod is firmly seated in the leading edge

of the aileron. Adjust the aileron so the ends of the

aileron don't rub against the wing.

❑ 9) While holding the aileron tight against the

wing, rotate the aileron down about 45º. Apply 3-4

drops of Kwik Bond Thin C/A to the exposed area

of each hinge. Turn the wing over and repeat for

the other side of the hinges. Allow the C/A and

epoxy to fully cure. Once cured, the aileron may be

stiff and difficult to move. This is normal. Gently

move the aileron up and down about five to ten times

to free it up.

❑ 10) Repeat steps # 3 - # 9 to install the second

aileron onto the other half of the wing.

HINGING THE ELEVATOR

q 13) Test fit the C/A hinges into the hinge slots in

the elevator. Each hinge should be inserted far enough

into the slots so that the centerline of the hinges are

flush with the leading edge. If the hinges cannot be

inserted deeply enough, use a modeling knife to carefully cut the hinge slots deeper.

❑ 14) With each of the hinges centered, apply 3-4

drops of Kwik Bond Thin C/A to the joint where the

hinges and the elevator meet. Allow a few seconds

between drops for the C/A to wick into the hinges,

then turn the elevator over and repeat this procedure

on the other side. Let the C/A dry for about 10 minutes before proceeding.

❑ 15) Slide the elevator and its hinges into the

precut hinge slots in the trailing edge of the stabilizer. Adjust the elevator so that the elevator tips are

even with the stabilizer tips.

❑ 16) While holding the elevator tight against the

stabilizer, rotate the elevator down about 45º. Apply

3-4 drops of Kwik Bond Thin C/A to the exposed

area of each hinge. Turn the fuselage over and repeat for the other side of the hinges. Allow the C/A

to cure for about 10 minutes. Once cured, the elevator may be stiff and difficult to move. This is normal.

Gently move it up and down about five to ten times

to free it up.

HINGING THE RUDDER

❑ 17) Locate the precut hinge slots in the trailing

edge of the vertical stabilizer and the leading edge of

the rudder. A hinge slot is also located in the back

edge of the fuselage, below the horizontal stabilizer.

❑ 18) Test fit the C/A hinges into the hinge slots

in the rudder. Each hinge should be inserted far

enough into the hinge slots so that the centerline of

the hinges are flush with the leading edge. If the

hinges cannot be inserted deeply enough, use a modeling knife to carefully cut the hinge slots deeper.

❑ 11) Locate the precut hinge slots in the trailing

edge of the horizontal stabilizer and the leading edge

of the elevator.

❑ 12) Using a modeling knife, carefully remove

any excess covering material from over each of the

hinge slots.

❑ 19) With each of the hinges centered, apply 3-4

drops of Kwik Bond Thin C/A to the joint where the

hinges and the rudder meet. Allow a few seconds

between drops for the C/A to wick into the hinges,

then turn the rudder over and repeat this procedure

on the other side. Let the C/A dry for a few minutes

before proceeding.

17

Page 18

❑ 20) Using a modeling knife, remove the covering from over the precut notch in the leading edge of

the rudder. This notch allows room for the rudder to

clear the elevator joiner.

❑ 21) Slide the rudder and its hinges into the precut hinge slots in the trailing edge of the vertical

stabilizer. Adjust the height of the rudder so it does

not rub against the top of the vertical stabilizer.

Check that when you move the elevator up and

☛

down and the rudder right and left, the notch in the

rudder does not interfere with the elevator joiner.

❑ 22) While holding the rudder tight against the

stabilizer, rotate the rudder to the side about 45º.

Apply 3-4 drops of Kwik Bond Thin C/A to the exposed area of each hinge. Turn the fuselage over

and repeat for the other side of the hinges. Allow

the C/A to cure for about ten minutes. Once cured,

the rudder may be stiff and difficult to move. This

is normal. Gently move it back and forth about five

to ten times to free it up.

TAIL WHEEL INSTALLATION

PARTS REQUIRED

❑ {1} Prebent Tail Wheel Wire

❑ {1} 25mm Diameter Wheel

❑ {1} Nylon Mounting Bracket

❑ {1} Nylon Steering Arm

❑ {2} 1.5mm Wheel Collars

❑ {2} 3mm x 6mm Machine Screws

❑ {3} 3mm x 12mm Wood Screws

❑ {1} 2mm x 10mm Wood Screw

TOOLS AND SUPPLIES REQUIRED

❑ Ernst Airplane Stand

❑ Masking Tape

❑ Electric Drill

❑ 1/16" & 5/64" Drill Bits

❑ Phillips Head Screwdriver

❑ Wire Cutters

❑ Pen or Pencil

❑ 2) Thread one 3mm x 6mm machine screw

through the side of the nylon arm and into the wheel

collar. Do not tighten the screw at this time.

❑ 3) Slide the prebent tail wheel wire up through

the bottom of the nylon bracket, then slide the nylon

steering arm over the wire. Make sure that the mounting clasp is facing the bottom of the bracket. See

photo # 21 below.

Photo # 21

❑ 4) Push the tail wheel wire into the bracket until the bend in the wire fits into the recessed area in

the bracket, and adjust the wire so that it is parallel

with the steering arm.

❑ 5) When satisfied with the alignment, tighten

the 3mm x 6mm machine screw to secure the wire in

place. Cut off the excess wire flush with the top of

the steering arm, using a pair of wire cutters.

MOUNTING THE TAIL WHEEL BRACKET

❑ 6) T est fit the tail wheel bracket assembly onto

the bottom of the fuselage. To align the bracket

properly , be sure that the tail wheel wire is even with

the rudder hinge line and that the nylon bracket is

aligned with the centerline of the fuselage. The nylon clasp in the steering arm slides over the bottom

of the rudder.

It will be necessary to bend the nylon steering arm

☛

down so the clasp will engage the rudder properly.

❑ 7) While holding the mounting bracket in place,

use a pen to mark the locations of the three mounting

holes onto the bottom of the fuselage.

TAIL WHEEL BRACKET ASSEMBLY

❑ 1) Insert one 1.5mm wheel collar into the top

of the nylon steering arm, making sure that the

threaded hole in the side of the wheel collar lines up

with the predrilled hole in the side of the nylon arm.

18

❑ 8) Remove the bracket. Using a drill with a

5/64" drill bit, drill three pilot holes through the bottom of the fuselage at the marks you made. Set the

bracket back into place and secure it to the fuselage

using three 3mm x 12mm wood screws.

Page 19

❑ 9) Place a couple of pieces of masking tape between the rudder and the vertical stabilizer to hold

the rudder centered. Using a drill with a 1/16" drill

bit, carefully drill a hole through the rudder to accept the mounting screw for the nylon clasp. Use the

predrilled holes in the clasp as a guide.

It will be necessary to bend the nylon steering arm

☛

down so the clasp will engage the rudder properly.

❑ 10) To secure the steering arm to the rudder , use

one 2mm x 10mm wood screw threaded into the predrilled hole in one side of the clasp, through the

rudder, and into the predrilled hole in the opposite

side of the clasp. Tighten the screw , but do not overtighten it. Y ou don't want to crush the wood or break

the clasp. See photo # 22 below.

Photo # 22

INSTALLING THE TAIL WHEEL

MAIN GEAR INSTALLATION

PARTS REQUIRED

❑ {2} Wire Spoke Main Gear Wheels

❑ {1} Precovered Landing Gear Wing

❑ {1} Wire Landing Gear Strut

❑ {2} Nylon Landing Gear Strap - Small Slot

❑ {2} Nylon Landing Gear Strap - Large Slot

❑ {8} 3mm x 12mm Wood Screws

❑ {2} Nylon Wheel Spacers

❑ {2} Wheel Collars w/3mm x 6mm Set Screws

❑ {2} Nylon Landing Gear Wing Mounts

❑ {2} 3mm x 6mm Machine Screws

❑ {4} 2mm x 5mm Wood Screws

❑ {1} Precovered Square Stock

TOOLS AND SUPPLIES REQUIRED

❑ Kwik Bond 5 Minute Epoxy

❑ Robart Incidence Meter

❑ Excel Modeling Knife

❑ Ernst Airplane Stand

❑ Electric Drill

❑ 1/16" & 5/64" Drill Bits

❑ Straight Edge Ruler

❑ Phillips Head Screwdriver

❑ Pen or Pencil

❑ Paper Towels

❑ Rubbing Alcohol

❑ NHP Epoxy Mixing Sticks

❑ NHP Epoxy Mixing Cups

❑ 11) Slide the 25mm diameter tail wheel onto the

tail wheel wire. Thread one 3mm x 6mm machine

screw into the wheel collar, then slide the wheel collar up against the tail wheel.

❑ 12) Slide the wheel collar on enough so it is up

against the tail wheel, but not so tight that the tail

wheel won't turn. The tail wheel should rotate without binding. When you are satisfied with the

alignment, securely tighten the machine screw using

a phillips screwdriver. See photo # 23 below.

Photo # 23

INSTALLING THE GEAR BRACKET

❑ 1) Place the wire landing gear bracket onto the

bottom of the fuselage. To align the bracket properly, the larger diameter wire should be toward the

front of the fuselage and the smaller diameter rear

wire should be positioned 11/16" in front of the wing

saddle.

❑ 2) While holding the gear bracket in position,

place the two nylon small-slot landing gear straps over

the rear wire and the two large-slot landing gear

straps over the front wire. Adjust them so that the

center of each strap is 1/2" in from the fuselage sides.

❑ 3) Using a pen, mark the locations of the eight

mounting holes onto the bottom of the fuselage.

❑ 4) Remove the nylon straps and the gear bracket.

Using a 5/64" drill bit, drill pilot holes through the

fuselage at the eight locations you marked.

19

Page 20

❑ 5) Set the gear bracket back into place and realign it. Install the four nylon straps using eight

3mm x 12mm wood screws. Tighten the screws

firmly to secure the gear bracket into place. See

photo # 24 below.

Photo # 24

INSTALLING THE GEAR WING

❑ 6) Using a modeling knife, remove the covering from over the precut slot in the top of the gear

wing. Also remove the covering from over both ends

of the slot. See photo # 25 below.

Photo # 25

❑ 10) Remove the gear wing from the wire. Using a drill with a 1/16" drill bit, drill four pilot holes

into the ends of the gear wing at the four locations

you marked previously.

❑ 11) Place the gear wing back onto the wire and

realign it. Secure the two nylon mounts to the ends

of the gear wing using four 2mm x 5mm wood

screws. See photo # 26 below.

Photo # 26

❑ 12) Partially thread two 3mm x 6mm machine

screws into the bottoms of the two nylon gear wing

mounts.

❑ 13) Using your incidence meter, carefully set the

incidence of the gear wing to 0º or -1º. When satisfied with the alignment, tighten the machine screws

in the nylon mounts to secure the gear wing into position.

❑ 7) Set the gear wing onto the wire between the

two landing gear axles, making sure that the slot in

the gear wing faces up.

❑ 8) Slide one nylon gear wing mount onto each

landing gear axle and push them up against the ends

of the gear wing.

Make sure the flat sides of both nylon mounts

☛

are up against the edges of the gear wing and that the

holes for the set screws are facing the bottom of the

gear wing.

❑ 9) Adjust the nylon mounts so that the two

mounting holes are parallel to the bottom of the wing.

While holding the mounts in place, use a pen and

mark the locations of the mounting holes onto the

edges of the gear wing.

❑ 14) Mix a small amount of Kwik Bond 5 Minute

Epoxy . Apply a thin layer of epoxy to the precovered

square stock and press the stock into the slot in the

top of the gear wing. Remove any excess epoxy using a paper towel and rubbing alcohol and allow the

epoxy to cure before proceeding.

INSTALLING THE MAIN GEAR WHEELS

❑ 15) Push one nylon spacer onto each of the two

landing gear axles. Push the spacers up against the

nylon gear wing mounts.

❑ 16) Slide one wheel onto each axle. Push the

wheels up against the nylon spacers, then slide one

wheel collar onto each axle and push them up against

the wheels. Adjust the depths of the wheel collars

until the wheels spin without binding, then tighten

the machine screws using a phillips screwdriver.

You may wish to apply a thin layer of grease to

☛

the axles to prevent the wheels from squeaking.

20

Page 21

ENGINE INSTALLATION

PARTS REQUIRED

❑ {2} Nylon Motor Mount Beams

❑ {4} 3mm x 20mm Machine Screws

❑ {4} 3mm x 25mm Machine Screws

❑ {4} 3mm Nylon Insert Nuts

❑ {4} 3mm Blind Nuts

❑ {12} 3mm Flat Washers

❑ {1} 1.5mm x 350mm Wire w/Z-Bend

TOOLS AND SUPPLIES REQUIRED

❑ Ernst Airplane Stand

❑ Electric Drill

❑ 1/8", 5/32" and 1/4" Drill Bits

❑ Straight Edge Ruler

❑ Phillips Head Screwdriver

❑ Needle Nose Pliers

❑ Pen or Pencil

❑ 4) Install the engine onto the mounting beams

using four 3mm x 25mm machine screws, eight 3mm

flat washers and four 3mm lock nuts. Tighten the

screws and nuts completely to hold the engine firmly

in place.

ALIGNING THE MOTOR MOUNT

Whether you are using a two or a four cycle

☛

engine, the engine will be mounted at an angle (as

described below) so that the muffler assembly will

clear the side of the fuselage.

❑ 5) Using a ruler and a pen, draw a vertical

centerline on the firewall.

❑ 6) Using a ruler and a pen, measure up from the

bottom of the firewall 2-1/16" and draw a horizontal

line at this point.

MOUNTING THE ENGINE TO THE

MOTOR MOUNT BEAMS

❑ 1) Using a clamp or a vise, align the two nylon

motor mount beams and clamp them together. The

beam halves are universal and the webbing should

face the outside edges. It's also important that the

back edges of both beams be perfectly even. See

photo # 27 below.

Photo # 27

❑ 2) Using a ruler and a pen, mark the locations

of the four engine mounting holes onto the two beams.

So that the engine will line up properly with the front

of the cowl (when it is installed later), it is important

that the front edge of the engine's drive washer be

4-1/4" in front of the rear edge of the mounting beams.

The point at which these two lines intersect is

☛

the crankshaft centerline point.

❑ 7) Using a ruler and pen, measure up 5/8" from

the horizontal line (at the right side of the fuselage)

and place a mark. Measure down 5/8" from the horizontal line (at the left side of the fuselage) and place

a mark. Draw a straight line connecting these two

marks. See photo # 28 below.

Photo # 28

❑ 8) Using a ruler and pen, draw a line through

the crankshaft centerline point, perpendicular to the

angled line you just drew. See photo # 29 below.

Photo # 29

❑ 3) When satisfied with the alignment, remove

the beams from the clamp. Using a drill with a 1/8"

drill bit, drill four holes through the mounting beams

at the marks you made.

Make sure that you drill the holes straight down

☛

through the beams and not at an angle.

21

Page 22

❑ 9) Using a ruler and a pen, measure up 3/16"

from the angled horizontal line you drew and draw a

line parallel to it.

❑ 14) Hold the motor mount/engine assembly up

to the firewall (the motor is mounted upright). Double

check that the four predrilled holes in the motor mount

beams line up with the four intersecting lines.

❑ 10) Using a ruler and a pen, measure 1/8" to the

right of the perpendicular line you drew and draw a

line parallel to it. See photo # 30 below.

Photo # 30

❑ 11) Using a ruler and a pen, measure 15/32" up

from the second angled horizontal line and draw a

line parallel to it. Now measure down 1-7/16" from

the second angled horizontal line and draw a second

line parallel to it.

❑ 12) Using a ruler, measure the width between

the predrilled mounting holes in the backs of the two

motor mount beams. See photo # 31 below.

Notice that the motor assembly is offset from

☛

the centerline to compensate for the built-in right and

down thrust in the firewall. Offsetting the engine

ensures that the crankshaft lines up with the cowl.

MOUNTING THE ENGINE

TO THE FIREWALL

❑ 15) When satisfied with the alignment, use a

drill with a 5/32" drill bit and drill four holes through

the firewall for the motor mount screws.

❑ 16) Hold the motor mount/engine assembly up

to the firewall and align it with the mounting holes.

Using a pencil, mark the location of the throttle pushrod exit hole onto the firewall.

If you are using a 2 cycle engine, the throttle

☛

pushrod exit hole should be about 1/4" above the top

motor mount hole. If you are using a 4 cycle engine,

the throttle pushrod exit hole should be right behind

the throttle arm.

Photo # 31

❑ 13) Divide the measurement found in step # 12

in half. Using a ruler and a pen, measure this resulting distance and draw one line to the right and

one to the left of the second angled vertical line.

See photo # 32 below.

Photo # 32

❑ 17) Using a drill with a 1/4" drill bit, drill a hole

through the firewall for the throttle pushrod wire at

the mark you made.

❑ 18) Attach the Z-bend in the 1.5mm x 350mm

throttle pushrod wire into the outermost hole in the

engine's throttle arm.

❑ 19) Slide the plain end of the pushrod wire

through the pushrod exit hole and install the motor

mount/engine assembly using four 3mm x 20mm

machine screws, four 3mm flat washers and four 3mm

blind nuts. Tighten the screws firmly to draw the

blind nuts into place. See photo # 33 below.

Photo # 33

22

Page 23

FUEL TANK

❑ 5) Using the Magnum Tubing Bender, carefully

bend the longer of the two tubes up at a 45º angle.

PARTS REQUIRED

❑ {1} Molded Fuel Tank

❑ {1} Rubber Stopper

❑ {1} 20mm Diameter Front Plate

❑ {1} 17mm Diameter Back Plate

❑ {1} 3mm x 18mm Machine Screw

❑ {1} Weighted Fuel Pick-Up

❑ {3} Aluminum Tubes

❑ {1} Silicon Fuel Tubing

TOOLS AND SUPPLIES REQUIRED

❑ Wilhold Silicon Sealant

❑ Magnum Tubing Bender

❑ Straight Edge Ruler

❑ Phillips Head Screwdriver

❑ Scissors

❑ 220 Grit Sandpaper w/Sanding Block

STOPPER ASSEMBLY

❑ 1) The fuel tank assembly incudes 3 different

length aluminum tubes. Discard the shortest of the

three tubes. It will not be used.

When the stopper assembly is installed in the

☛

fuel tank, the top of the vent tube should rest inside

the bubble in the top of the tank.

❑ 6) Secure one end of the silicon fuel tubing onto

the end of the weighted fuel pick-up.

❑ 7) Slide the silicon fuel tubing, with the fuel

pick-up attached, onto the end of the aluminum fuel

pick-up tube (straight tube). While holding the aluminum tube in place, adjust the length of the silicon

tubing until the fuel pick-up is 4-3/8" back from the

rear of the stopper assembly. See photo # 35 below .

Photo # 35

❑ 2) Using 220 grit sandpaper, carefully smooth

each end of the two remaining tubes. This will prevent the fuel tubing from being accidentally cut when

it is installed later.

❑ 3) Push the two aluminum tubes through the

rubber stopper. Slide the 20mm diameter front plate

over the tubes at the front of the stopper and slide the

17mm diameter back plate over the tubes at the rear

of the stopper.

❑ 4) Using a ruler, measure the distance that the

two aluminum tubes protrude from the front of the

stopper assembly. This distance should be 3/8". If it

is not, adjust the tubes by pushing them forward or

backward until you are satisfied with the alignment.

See photo # 34 below.

Photo # 34

❑ 8) Push the 3mm x 18mm machine screw

through the center hole in the front of the stopper

assembly and partially thread it into the metal stopper back plate. See photo # 36 below.

Photo # 36

INSTALLING THE STOPPER ASSEMBLY

❑ 9) Carefully push the stopper assembly into the

molded hole in the front of the fuel tank. Gently rotate the stopper assembly until the aluminum vent

tube rests inside the molded bubble in the top of the

fuel tank.

If you have trouble seeing the vent tube, hold

☛

the fuel tank assembly up to a bright light. This will

illuminate the inside of the tank.

23

Page 24

❑ 10) When satisfied with the alignment of the

stopper assembly, tighten the machine screw using a

phillips screwdriver until the rubber stopper expands

and seals the fuel tank opening. Do not overtighten

the screw. This could cause the front of the fuel tank

to split.

INSTALLING THE FUEL TANK

❑ 11) Carefully apply a generous bead of silicon

sealant onto the front of the fuel tank.

❑ 12) Slide the fuel tank into place, making sure

that the stopper assembly fits into the predrilled hole

in the firewall. When aligned properly, the front of

the tank should be pushed firmly against the back of

the firewall and the bottom of the tank should rest on

the fuel tank support floor.

When installing the fuel tank, make sure that

☛

the molded bubble in the top of the tank faces the top

of the fuselage.

the two preinstalled balsa support rails glued to the

fuselage sides. Position the tray so that the front edge

of the tray is 1-1/2" behind the forward bulkhead.

See photo # 37 below.

Photo # 37

❑ 2) When satisfied with the fit, use a pencil and

mark the location of the servo tray . Remove the tray