Global Fire ZEOS-AD-S, ZEOS-AD-SH, ZEOS-AD-H, ZEOS-AD-SI, ZEOS-AD-SHI Instructions Manual

...

Instruction Manual V1 - 02/2014

FEATURES

ZEOS AD

Analogue Addressable Fire Detector

The ZEOS-AD series of Analogue Addressable Detectors

have been designed to be fully compatible with Global

Fire Equipment’s range of intelligent control panels,

JUNIOR and JUNO NET.

The ZEOS-AD series detectors must always be

connected to a compatible GFE Analogue Addressable

Fire Alarm Control Panel. The installation must be in

complian ce w ith the cont rol p anel’s syst em

installation manual.

GFE’s ZEOS-AD series is compliant to EN54-5 and EN547 and consists of: photoelectric smoke detectors, rate

of rise and fixed temperature/ heat detectors and

combined smoke and heat detectors. Optionally they

can be fitted with a short-circuit loop isolator.

WARNINGS

To prevent detector contamination and subsequent

invalidation of warranty, the smoke detector head

must remain with its protective cover fitted, until the

area covered is clean and dust free.

Detectors are intended for ceiling and wall mounting

and should always be installed in accordance with local

Fire Authority recomendations and regulations.

Do not install the detector head until the area is

thoroughly cleaned of construction debris, dusts, etc.

Please refer to the control panel’s installation manual

regarding the maximum number of detectors installed

on the same loop.

CAUTION: Do not attempt to disassemble the

detector. This is a sensitive device and is not intended

to be open for servicing by users. Opening the

detector head will void the warranty.

DO NOT PAINT DETECTOR HEAD

Dual LEDs for 360° visibility

Advanced detection and

communication protocols

Easy installation and maintenance

Sleek low-profile housing

Durable sensor head,

no need for replacement

SMD circuit board design.

High quality and reliability guaranteed

ORDER CODE

Loop Powered - 17V to 30V DC

450 uA max.

4 mA - Alarm LED Iluminated

According to EN54-5 and EN54-7

0.5-2.5 mm²

20 seconds max.

White / ABS

-10ºC to 50ºC / 95% RH Non-Condensing

100 mm (D) x 50 mm (H) inc. base / 144 g inc. base

TECHNICAL SPECIFICATIONS

SUPPLY VOLTAGE

CURRENT - QUIESCENT / SURGE

CURRENT - DEVICE IN ALARM

SENSITIVITY

CABLE SIZE

RESET/STAR-UP TIMES

COLOUR / CASE MATERIAL

OPER. TEMPERATURE / MAX. HUMIDITY

DIMENSIONS / WEIGHT

DESCRIPTION

Global Fire Equipment S.A. declares that this product is free from defects in materials and workmanship and it will repair or replace any

product or part thereof which proves to be defective in workmanship or materials during the life expectancy of the product. This period is

determined to be no longer than 10 years starting from the date of manufacture. Please visit Global Fire Equipment’s web site

(www.globalfire.pt) for a full description of Global Fire Equipment’s LIMITED WARRANTY, which, among other things, limits the duration of

warranties of merchantability and fitness for a particular purpose and excludes liability for consequential damages. Acceptance of order

and/ or original invoice which will become part of your sales agreement. Please contact Global Fire Equipment’s web site for details on how

to obtain a return Merchandise Authorization Number (RMA) before returning goods to the factory. Shipment must be prepaid and Global

Fire Equipment will repair or replace your returned detector.

LIFETIME WARRANTY

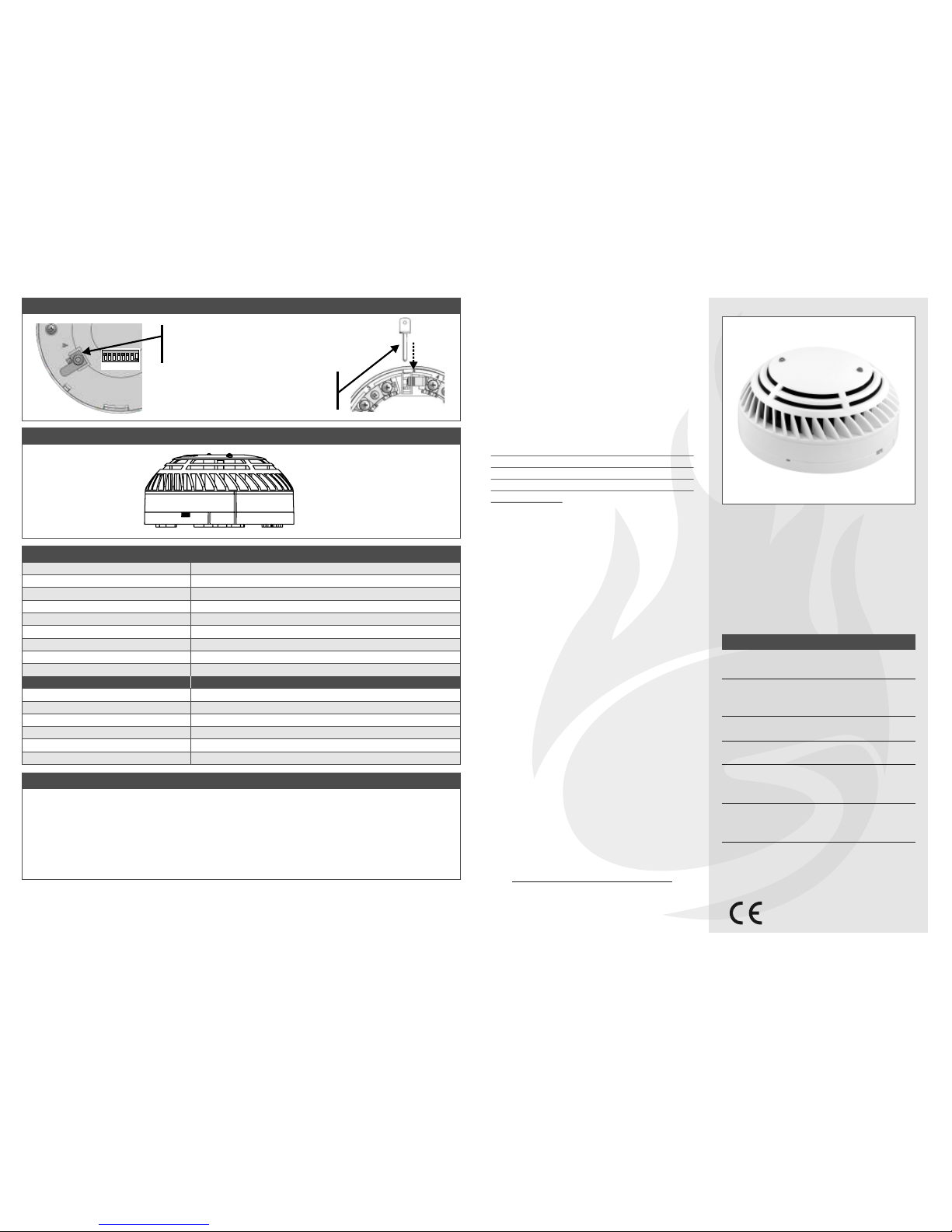

Detector Head

Detector Base

Alignment Marks

To lock detector remove pin available at

terminal 4 on the underside of the

sounder using a small screwdriver.

To unlock detector from its base push

unl ock key p rovide d th rough hol e

available on the base side wall as shown.

1 2

3

4

5

678

Address

DETECTOR BASE LOCK

MECHANICAL SPECIFICATION

Analogue Addressable Photoelectric Smoke Detector

Analogue Addressable Temperature/Heat Detector

Analogue Addressable Combined Smoke & Heat Detector

Analogue Addressable Photo. Smoke Detector inc. Isolator

Analogue Addressable Heat Detector inc. Isolator

Analogue Addr. Combined Smoke & Heat Detector w/ Isolator

ZEOS-AD-S

ZEOS-AD-H

ZEOS-AD-SH

ZEOS-AD-SI

ZEOS-AD-HI

ZEOS-AD-SHI

Made in Portugal-EU

GLOBAL FIRE EQUIPMENT S.A.

Sítio dos Barrabés, Armazém Nave Y, Caixa Postal 908-Z, 8150-016 São Brás de Alportel - PORTUGAL

Tel: +351 289 896 560 • Sales: sales@globalfire.pt • Technical Support: techs@globalfire.pt • www.globalfire.pt

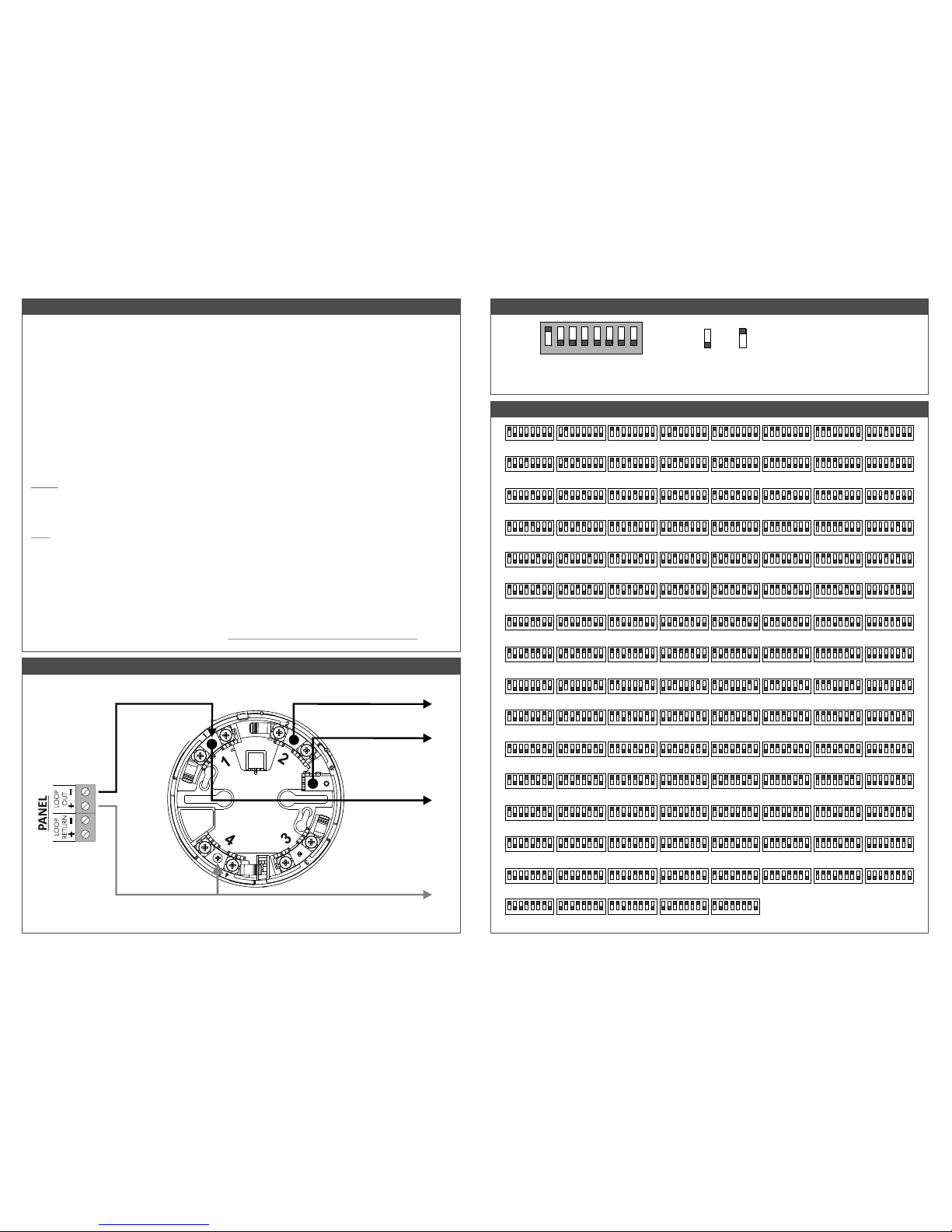

D.I.L. SWITCHES CONFIGURATION

INSTALLING THE BASE

To ensure proper fit of the detector head to the base, all wires should be properly dressed at installation by positioning

all wires flat against terminals and fastening the wires away from connector terminals. The detector base can be

mounted directly onto most standard electrical junction boxes.

INSTALLING THE HEAD

Set the desired address via D.I.L. switch on the back of the detector. Please refer to D.I.L. Switch Configuration and

Address Settings sections. Allign detector components using provided allignment marks on both the head and base.

Allign detector mark and short allignment mark on base. Fit the detector head onto the base and twist clockwise to

secure it. After all detectors are installed, apply power to the control unit and activate the detection loop. Test the

detectors as described below.

TESTING

All remote signalling systems, releasing devices and extinguishing systems should be disconnected during the test

period and reconnected at the conclusion of testing.

SMOKE: Allow smoke from a cotton wick or test smoke aerosol to enter the detector’s smoke chamber for at least 10

seconds. When sufficient smoke has entered, the detector will signal an alarm. This will be indicated by the illumination

of the 2 RED LEDs provided. Make sure to clear smoke out of the chamber before resetting in order to keep the detector

at its current sensitivity setting.

HEAT: The detector to be tested should be subject to a flow of warm air at a temperature of between 65ºC and 80ºC.

This requirement can be met by some domestic hair dryers. Switch on the warm airflow and check that the temperature

is correct and stable. From a distance of several cms, direct the airflow at the guard protecting the thermistor. The

detector should alarm within 60 seconds. Upon alarm immediately remove the heat source and check that the RED

LEDs of the detector are illuminated. If a detector fails to activate within 60 seconds, confirm connections and

programming. If necessary replace unit. Note: After testing, check that the system is returned to normal operation.

Notify the appropriate authorities that the testing procedure has been completed and the system is active again.

MAINTENANCE

The recommended minimum requirement for detector maintenance consists of annual cleaning of dust from the

detector head using a low power vacuum cleaner. >> DO NOT ATTEMPT TO DISASSEMBLE THE DETECTOR

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

01 02 03 04 05 06 07 08

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

09 10 11 12 13 14 15 16

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

17 18 19 20 21 22 23 24

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

25 26 27 28 29 30 31 32

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

33 34 35 36 37 38 39 40

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

41 42 43 44 45 46 47 48

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

49 50 51 52 53 54 55

1

2

3

4 5 6 7 8

56

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

57 58 59 60 61 62 63

1

2

3

4 5 6 7 8

64

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

65 66 67 68 69 70 71 72

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

73 74 75 76 77 78 79 80

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

81 82 83 84 85 86 87 88

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

89 90 91 92 93 94 95 96

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

97 98 99 100 101 102 103 104

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

105 106 107 108 109 110 111 112

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

113 114 115 116 117 118 119 120

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

1

2

3

4 5 6 7 8

121 122 123 124 125

ADDRESS SETTINGS

4 on =8

5 on =16

6 on =32

7 on = 64

Address Switches binary weights

1 on =1

2 on =2

3 on =4

Switches 1-7

used to configure the module’s address

Switch 8

Not used

1 2

3

4

5

678

ON

OFF

ON

OFF

-Loop IN/ OUT

- REMOTE LED INDICATOR

+Loop IN/ OUT

-Loop IN/ OUT

SCREEN

INSTALLATION

DETECTOR BASE - LOOP CONNECTIONS

Note: Positive terminal of remote indicator should be connected to terminal 4 (+ Loop IN/ OUT)

To next device

in loop or return

to panel

Loading...

Loading...