Global Contract Licence 2 Installation Manual

Licence 2

Installation

Manual

2017

ISO 9001:2015OHSAS 18001:2007 ISO 14001:2015

REVISED: FALL 2017

Visit us on the Internet at globalcontract.com • (416) 739-5000

Global Contract Inc. 565 Petrolia Road

North York, Ontario, M3J 2X8

GLOBALContract

INSTALLATION GUIDELINES

• Fall 2017

Table Of Contents

Assembly Hardware

Pre-Drilling Sheet

Product Installation

L2DRxxxxFB

L2DR-FB

L2DR-BL

L2DRHxxxxBR

L2ERxxxxFL

L2ERH-FL

L2GRxx

L2GB

L2GBxxL

L2GD

L2GDP

L2CRSxxxx

L2CRSHxxxx

L2RCxxxxL

L2RCHxxxxL

L2RCxxxxC

L2RCHxxxxC

L2ER R / L2ER L

L2ERH-L

L2Bxxxx

L2ECxxxxxxR

L2CC

L2CCxxxxxx

L2CK

L2CHK

L2TDHxxxxxx

L2TDxxxxxx

L2TCDxxxxxx

L2FDxxxxxx

P.01

04

P.05

06

08

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

52

54

56

58

60

61

L2PBBFxx

L2HHxxHxx

L2B2Hxxxx

L2BC2Hx02

Grommet Cut

Dimensions

Tackboards

89

90

92

94

P.96

P.97

Dimension Chart

Kadin Tables

Flip Top Tables

viceversa Tables

FreeFit

Please contact your Global Contract Service Representative at 416-739-5000 for

any questions or concerns.

NOTE: Any alterations to listed components will void the manufacturer’s warranty.

The manufacturer will not be responsible for any damage or bodily harm caused

by alterations in accordance with national or local electrical codes and manufac-

P.62

P.72

P.74

P.78

P.82

turer’s specifi cations. In accordance with the manufacturer’s policy of continual

product improvement, the product presented in this document is subject to

change without notice or obligation.

Page • globalcontract.com1

GLOBALContract

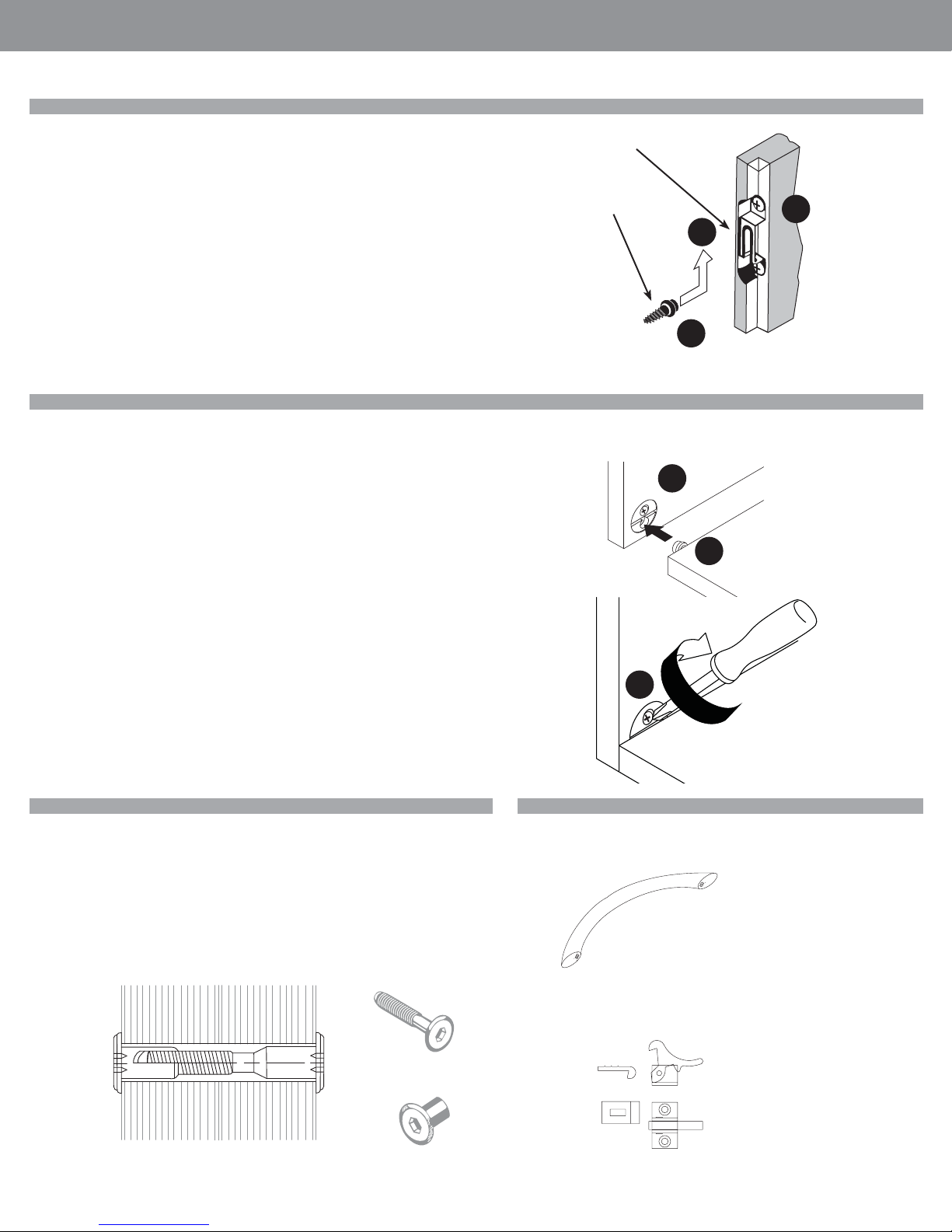

Assembly Hardware - Modular Connectors

Modular Connector (clip) and Shoulder Screw

• This connector offers a hidden connection between two panels.

• The modular connector and a connector screw are used in combination to

assemble panels.

• The modular connector is always pre-installed by the factory.

• The modular connector is always installed with the WIDE opening oriented at the

bottom of the part.

• The connecting shoulder screw is fi eld installed, based on the application of

components.

Steps to install modular connectors:

STEP 1: Install connecting shoulder screws at the pre-drilled location as per confi guration.

• Fall 2017

INSTALLATION GUIDELINES

Modular Connector (clip)

Shoulder Screw

3

1

STEP 2: Line up shoulder screws to the modular connector in another component.

STEP 3: Push components together and push down to lock component in place,

using a rubber mallet, if necessary.

Assembly Hardware - Blum Connectors

STEP 1: Install Blum Connector screws into the pre-drilled holes.

STEP 2: Line Blum connector screws to the exposed Blum Connectors

STEP 3: On the bottom of the surface turn the screw on Blum Connector ¼ turn, do

not over tighten.

2

1

2

3

Assembly Hardware - Joint Conncetor

This type of connector is used to attach the extrusion to the 1” end gables.

Steps to install connectors:

STEP 1: Press nut connector into pre-drilled hole of end gable from the exterior side

of the end gable.

STEP 2: Push bolt into extrusion holes.

STEP 3: Screw the nut and bolt together.

Assembly Hardware - Handels, Elbow Catch

Door / Drawer Handle

Install the handle(s) in the predrilled holes on the

doors or drawers by using the screws provided.

Elbow Catch

Install the elbow catch on the left hand door at

the upper right corner with the screws provided.

Joint Connector Bolt

Joint Connector Nut

•Pageglobalcontract.com 2

GLOBALContract

INSTALLATION GUIDELINES

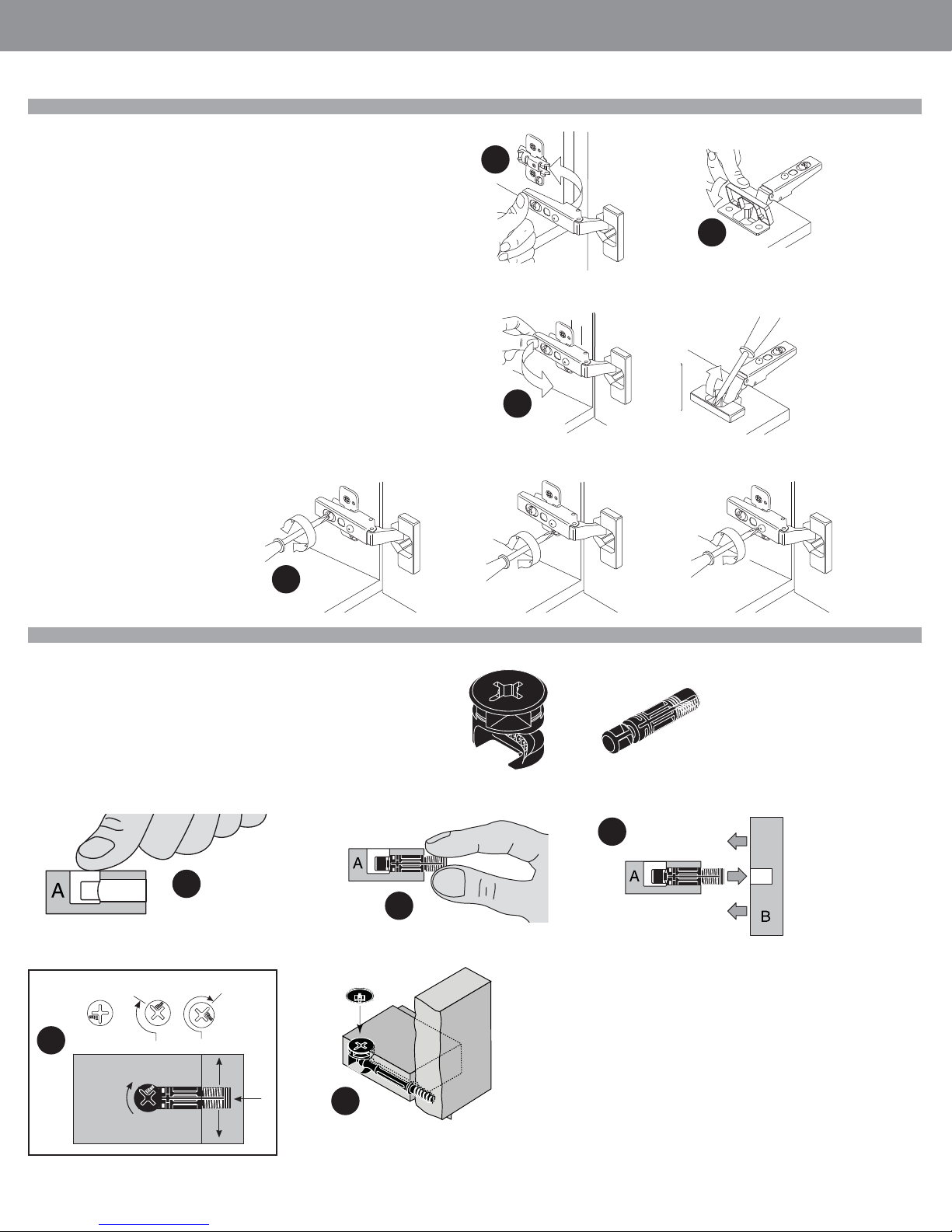

Assembly Hardware - Hinges

Hinge & Mounting Plate with Euro Screws

• The hinge is a tool-free attachment of hinge to door.

• Individual components and fi ttings do not need to be assembled until they reach

their fi nal destination.

• The mounting plate with Euro screws is easy to install.

• The spring loaded clip makes a simple connection between the door and the end

panel or divider.

Steps to install hinges:

STEP 1: Install all mounting plates using the predrilled holes of end panel and/or

dividers by fastening with the Euro screws.

Note: The mounting plate should be oriented with the arrow pointing towards

exterior of the unit.

STEP 2: Place the door face down. With the lever open press hinge into the predrilled holes. Press the lever on the hinge down with your thumb. By closing the

lever, the hinge is held fi rmly in place.

Assembly

Removal

• Fall 2017

1

2

STEP 3: Align hinges to mounting plates and push in until a click is heard.

STEP 4: Use adjusting screws on the hinge to level the door.

3

Height AdjustmentDepth Adjustment Side Adjustment

4

Assembly Hardware For Storage Components - Titus Connectors

STEP 1: Press the cam into the faceboard.

STEP 2: Insert the dowel into the side panel.

STEP 3: Assemble the panels.

STEP 4: Tighten the cam to lock the dowel.

STEP 5: Assemble the panels.

Universal Cam Quickfi t - TL Dowel

3

1

START MIN MAX

4

LOCK

Page • globalcontract.com3

2

5

GLOBALContract

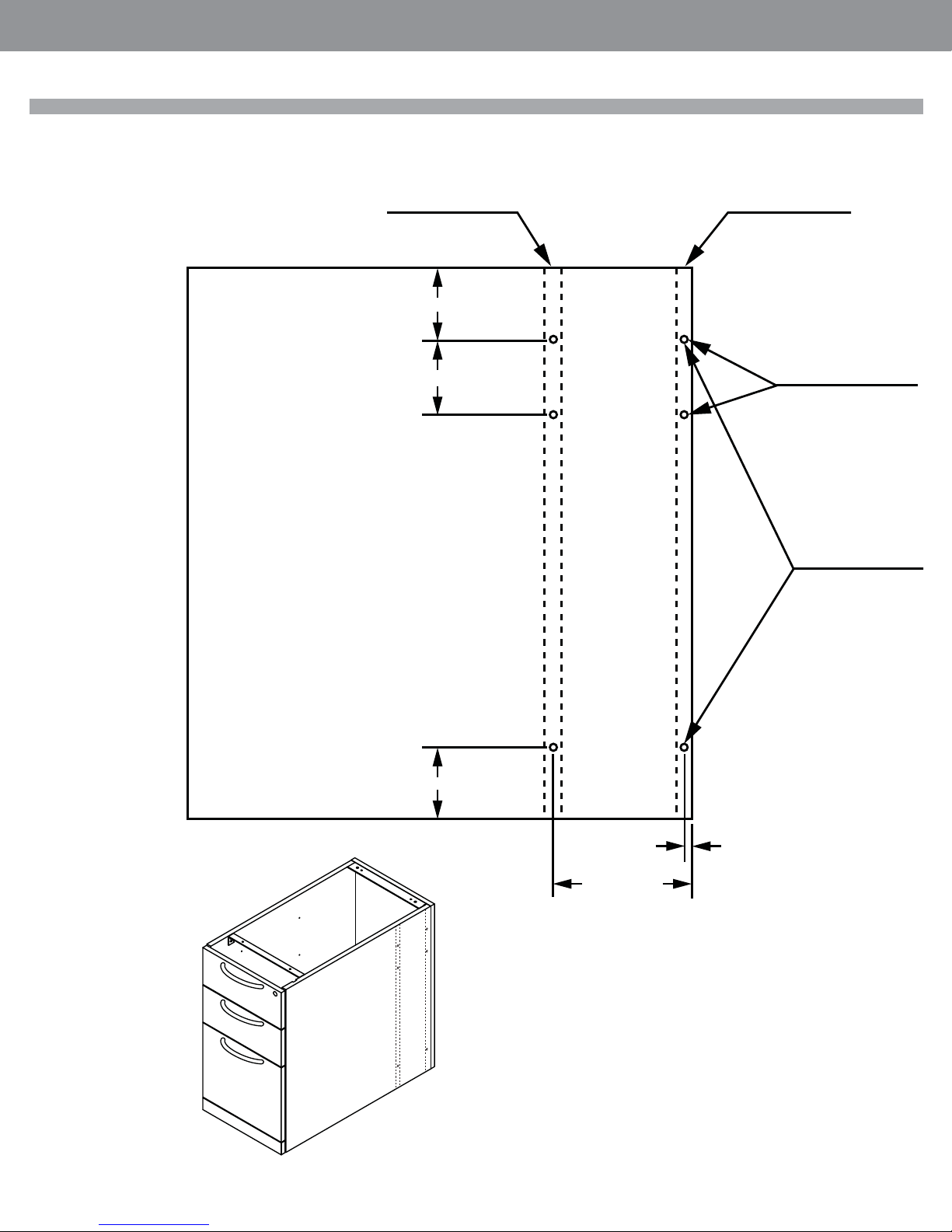

Pre-Drilling Location Sheet L2

Template for predrilling the hole location on the pedestals for use with modesty panels.

L2ER - BL/BR

L2DR - BL/BR

L2DR - FB/BF

92.2mm

96mm

• Fall 2017

INSTALLATION GUIDELINES

FLUSH MOD6” REC MOD

HALF HEIGHT

MODESTY

102.7mm

FULL HEIGHT

MODESTY

9.5mm

162mm

•Pageglobalcontract.com 4

GLOBALContract

INSTALLATION GUIDELINES

• Fall 2017

Page • globalcontract.com5

GLOBALContract

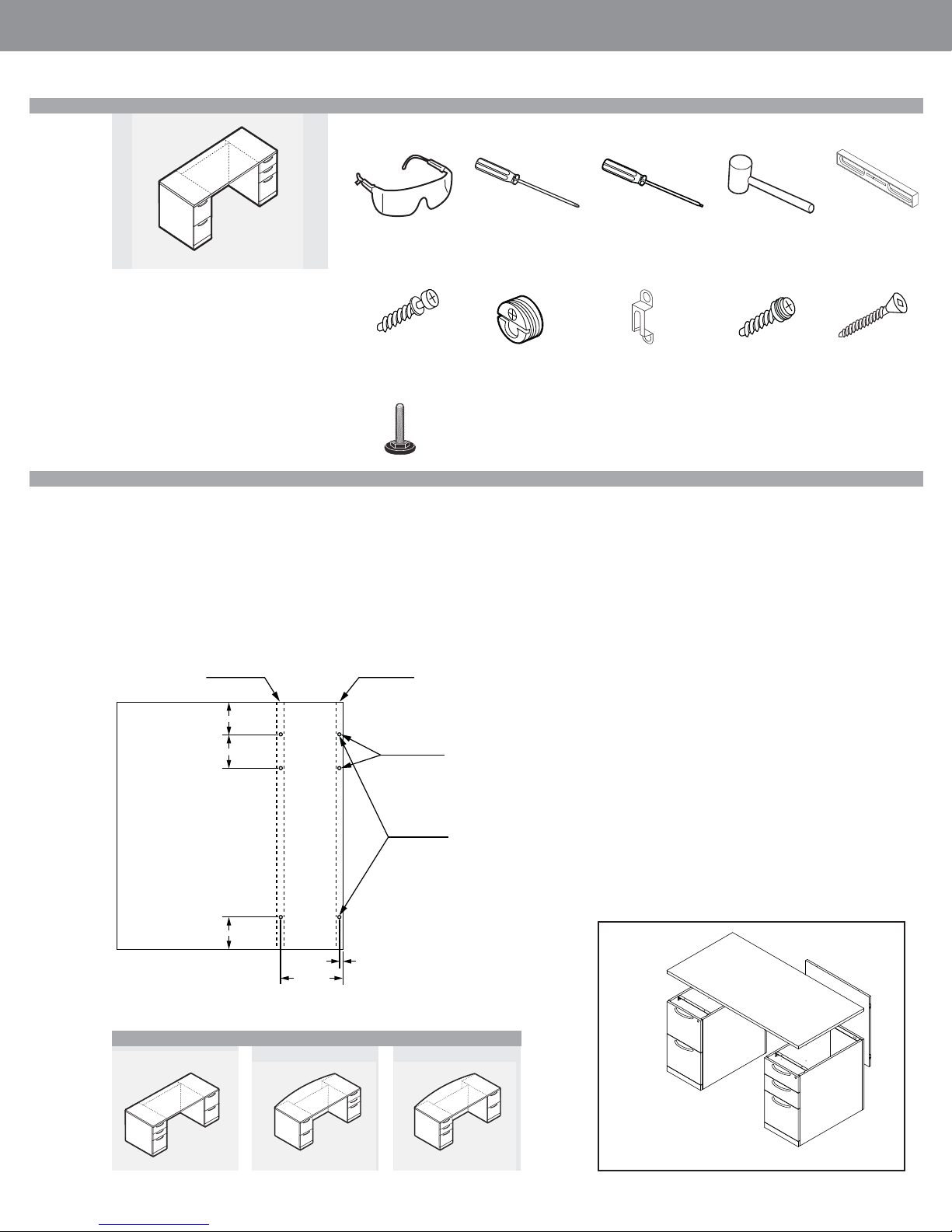

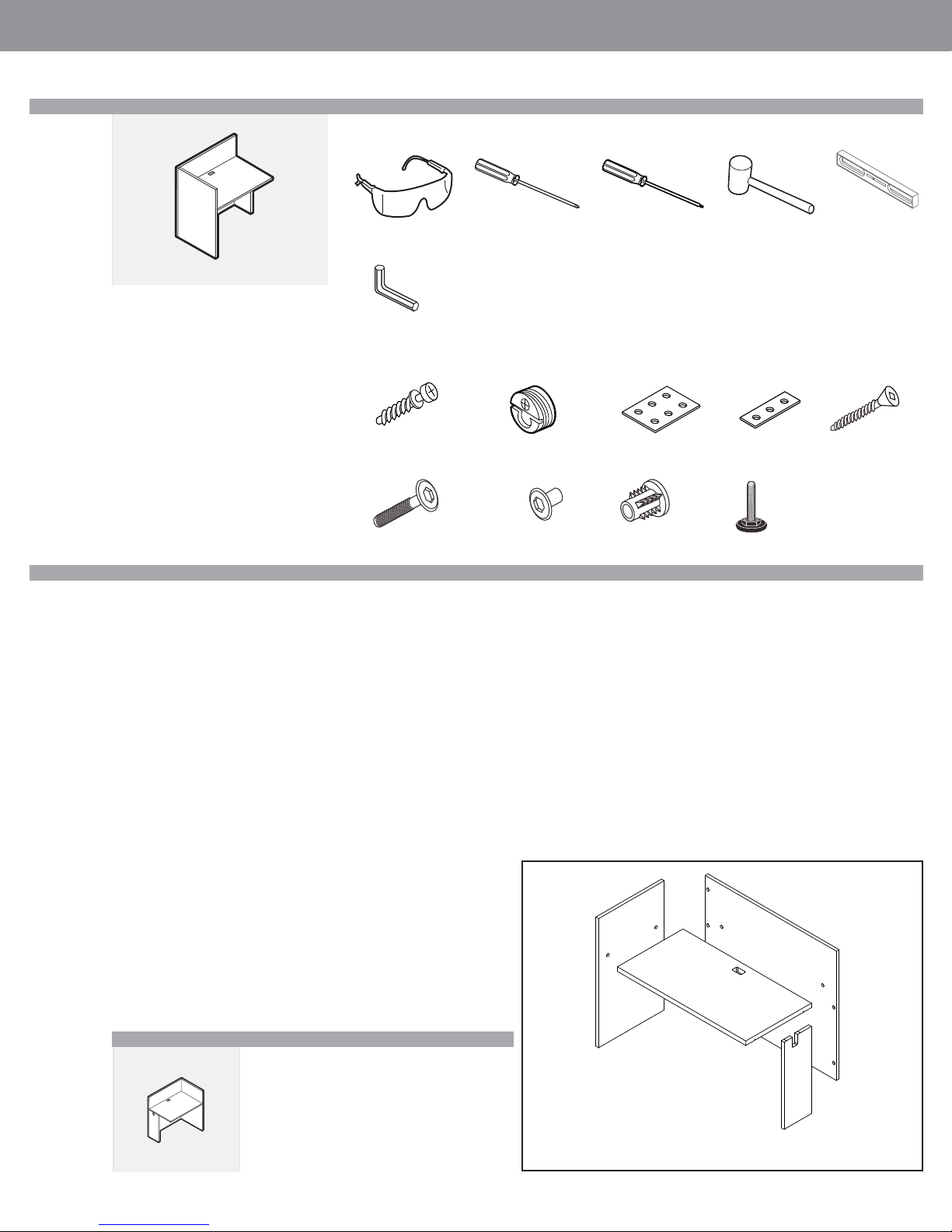

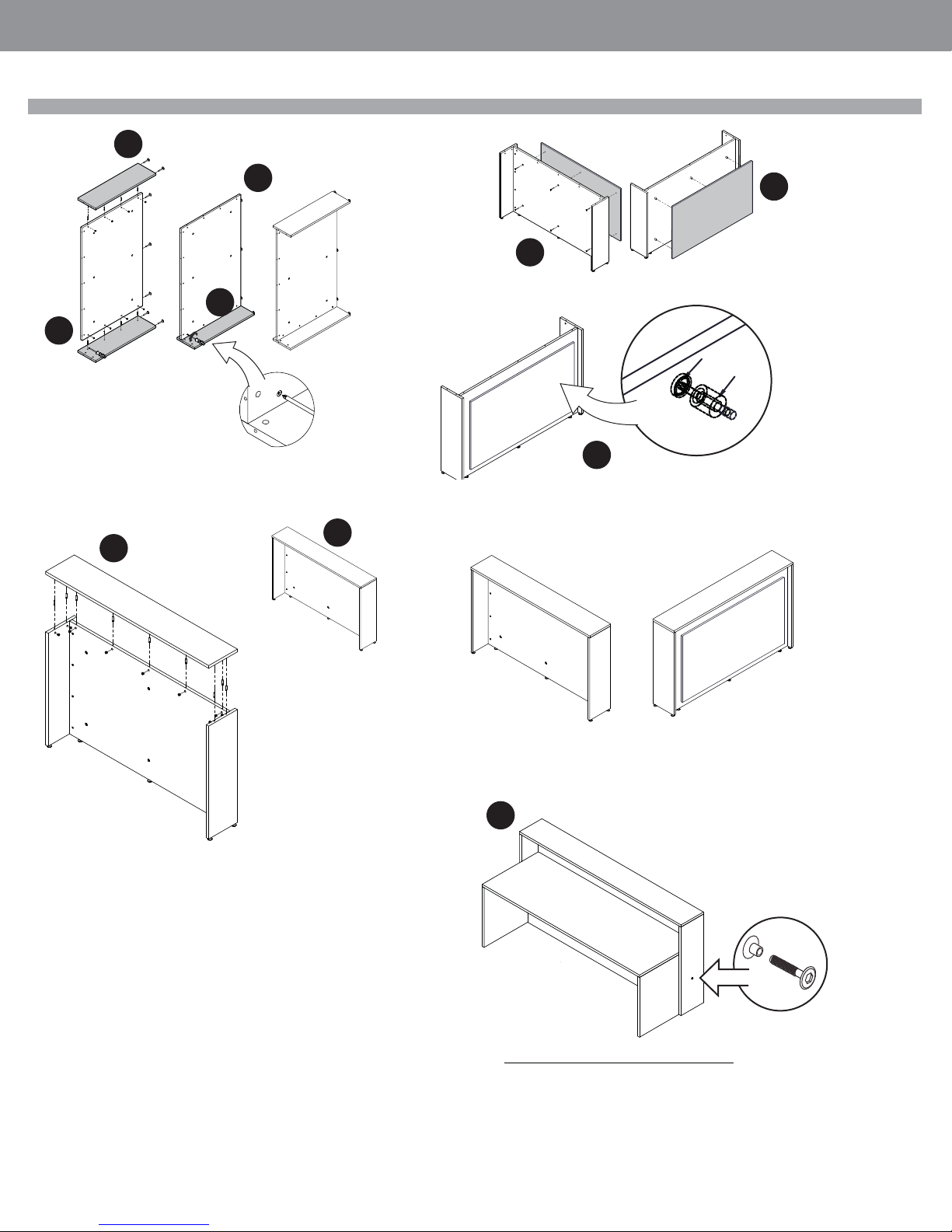

L2DRxxxxFB

NOTE: Open and assemble only one product

at a time to avoid a potential mix-up of parts

and hardware.

It is adviseable to assemble the unit on a

carpet to avoid scratches.

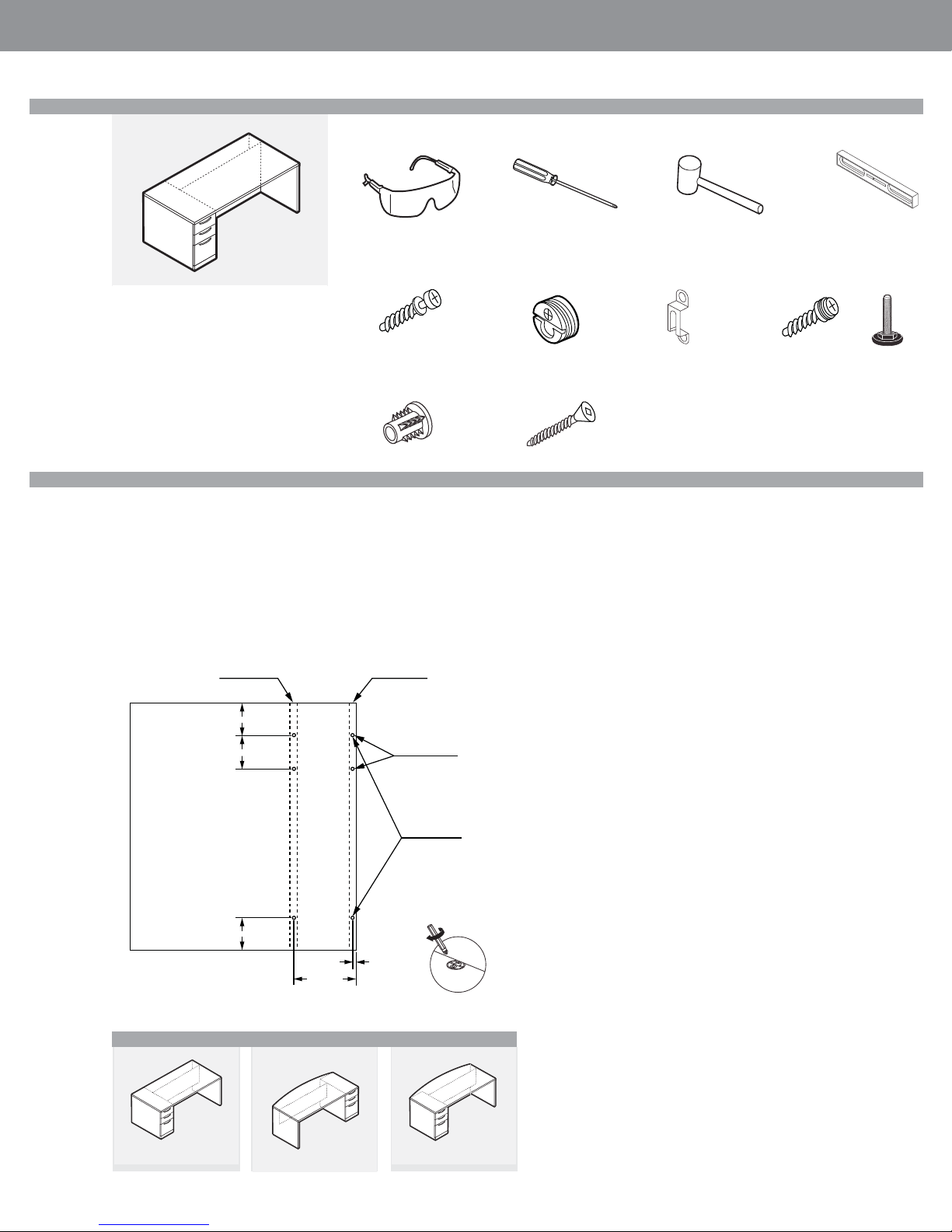

Required Tools

Safety Glasses

Included Hardware

Blum Connector

Screw L005650060

Leveler

L007250037

• Fall 2017

INSTALLATION GUIDELINES

Screwdriver #2 Phillips Rubber Mallet

Blum Connector

(installed) L005650061

Modular Connector

(installed) L004250001

Modular Screw

L007250001

LevelScrewdriver Roberson

Wood Screw #8 3/4

L007250032

Assembly

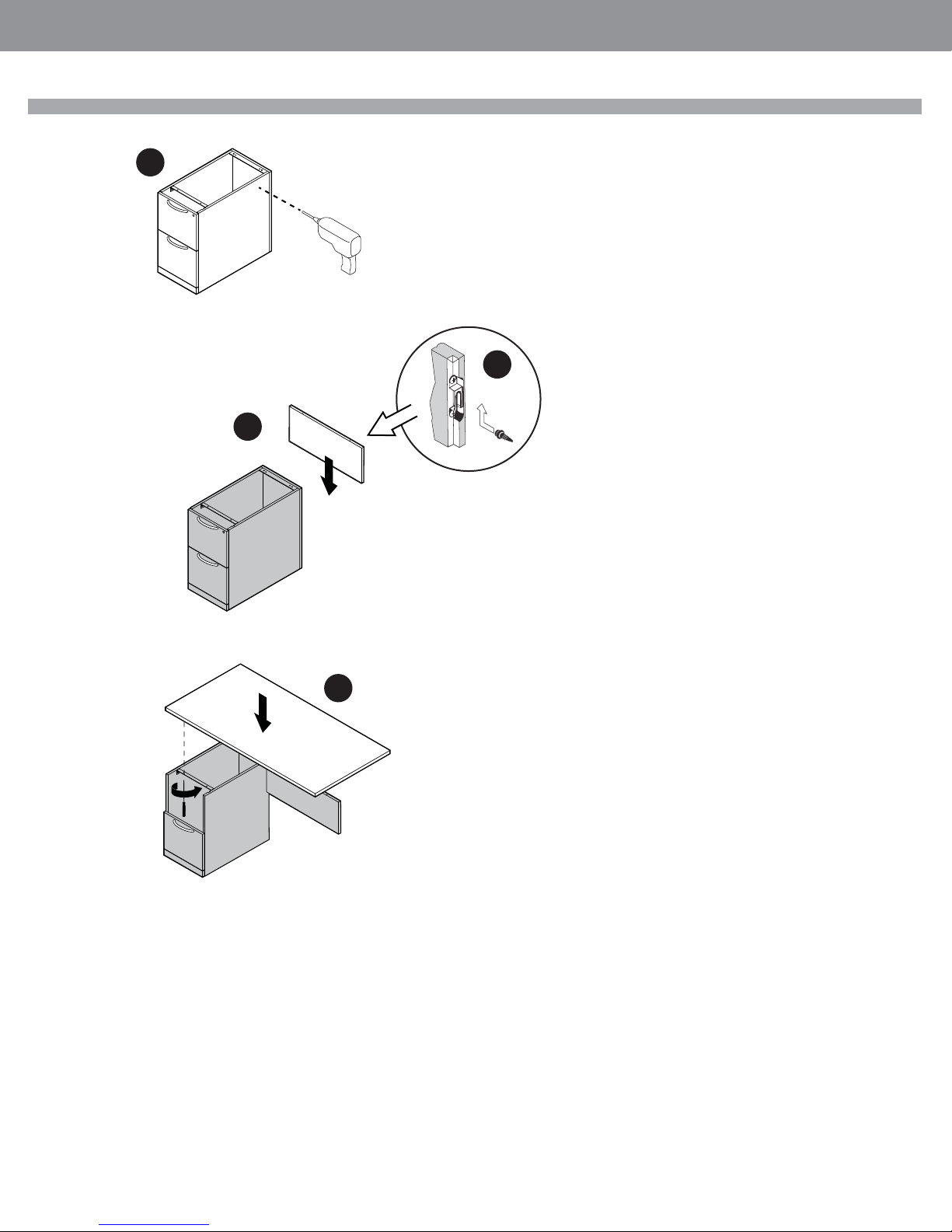

STEP 1: Unpack and inspect individual pieces for damages or missing hardware

STEP 2: Pick a clean unobstructed area to assemble desk. It is advisable to

assemble of this product upright.

STEP 3: Handles for pedestals are shipped installed on the inside of the cabinet.

Remove handle from the inside of the cabinet and re-install with the same screws

on the front of cabinet.

a. Levellers for pedestals are shipped inside the unit. These levellers should

be installed prior assembling complete unit.

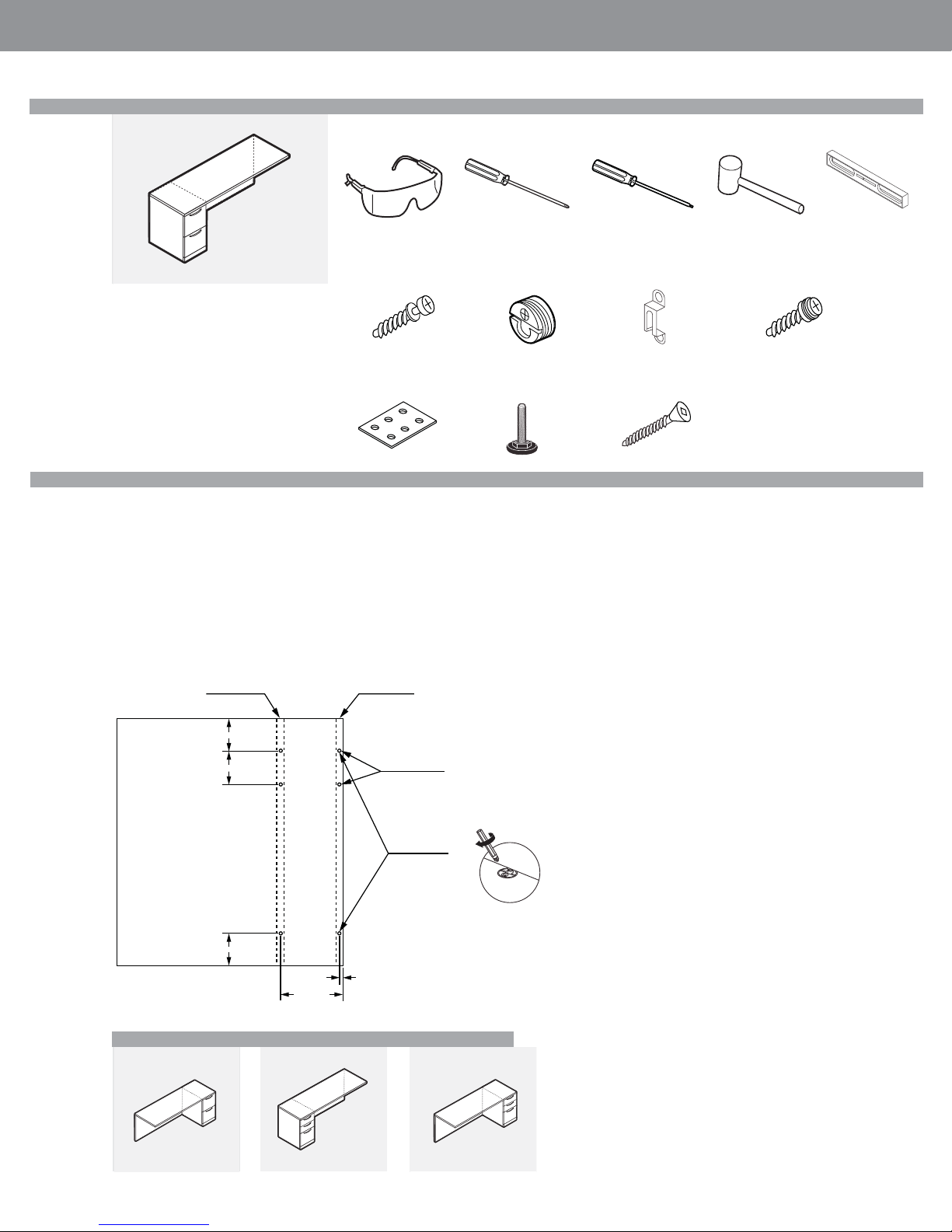

FLUSH MOD6” REC MOD

92.2mm

HALF HEIGHT

96mm

102.7mm

9.5mm

162mm

MODESTY

FULL HEIGHT

MODESTY

STEP 4: Arrange Pedestals as per the fi nal confi guration of the product.

a. Using a 1/8” drill bit, drill though holes into side of pedestal according to

the provided template on the side of the pedestal exposed to the underside

of the desk. For this application, use the half modesty and recessed panel location.

b. Modular screws are to be installed into these holes.

STEP 5: The modesty panel comes with Modular connectors installed on each

end of the panel.

On the top edge of the modesty panel, install Blum Connector screws into the

pre-drilled holes.

a. Attach the modesty panel to the pedestals by lining up modular con

nectors to screws installed on the pedestals, lift modesty and slide into

position ensuring to engage connectors to screws. You can use a mallet

to securely seat the modesty panel into position. Do this on both sides

STEP 6: To install the worksurface top.

The worksurface comes with Blum Connectors pre-installed on the bottom of

the surface. Lift worksurface over the assembly and line up Blum connectors to

the installed Blum connector screws on the back of the modesty panel. Turn the

screw on Blum Connector ¼ turn, do not over tighten.

a. You must also secure the worksurface top to the pedestals. Line up

the top fl ush to the side and front of the pedestals. Use #8 x 3/4 wood

screws provided, screw through the mounting bar on the pedestal to

secure the top. Note: Drawers need to be removed to access drilling location.

STEP 7: When fi nal position has been located, level the unit with the levellers

installed on both pedestals.

FULL MODESTY

WORKSURFACE

Installation For Similar Products

L2DRxxxxBF L2DBxxxxFB L2DBxxxxBF

FF PED

BBF PED

•Pageglobalcontract.com 6

GLOBALContract

INSTALLATION GUIDELINES

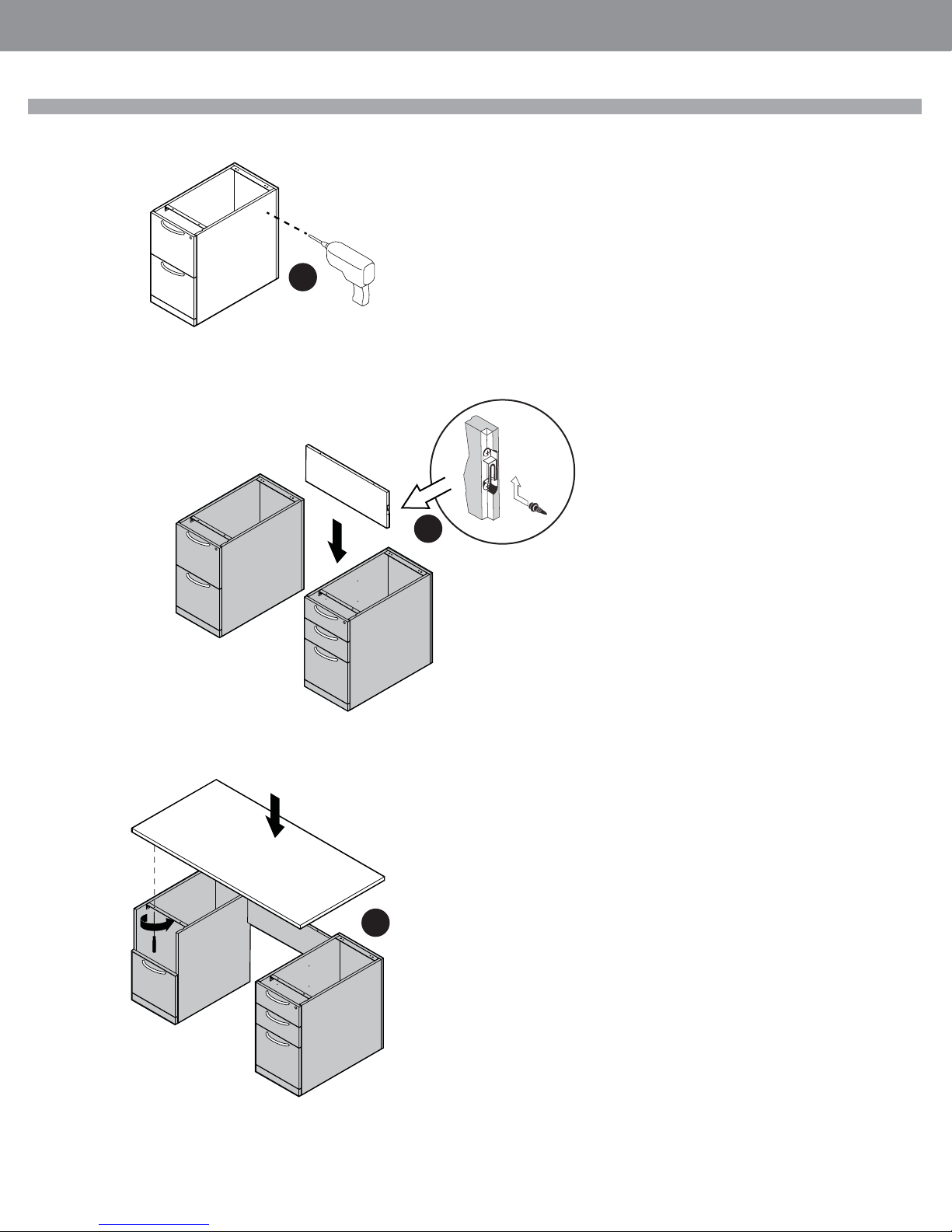

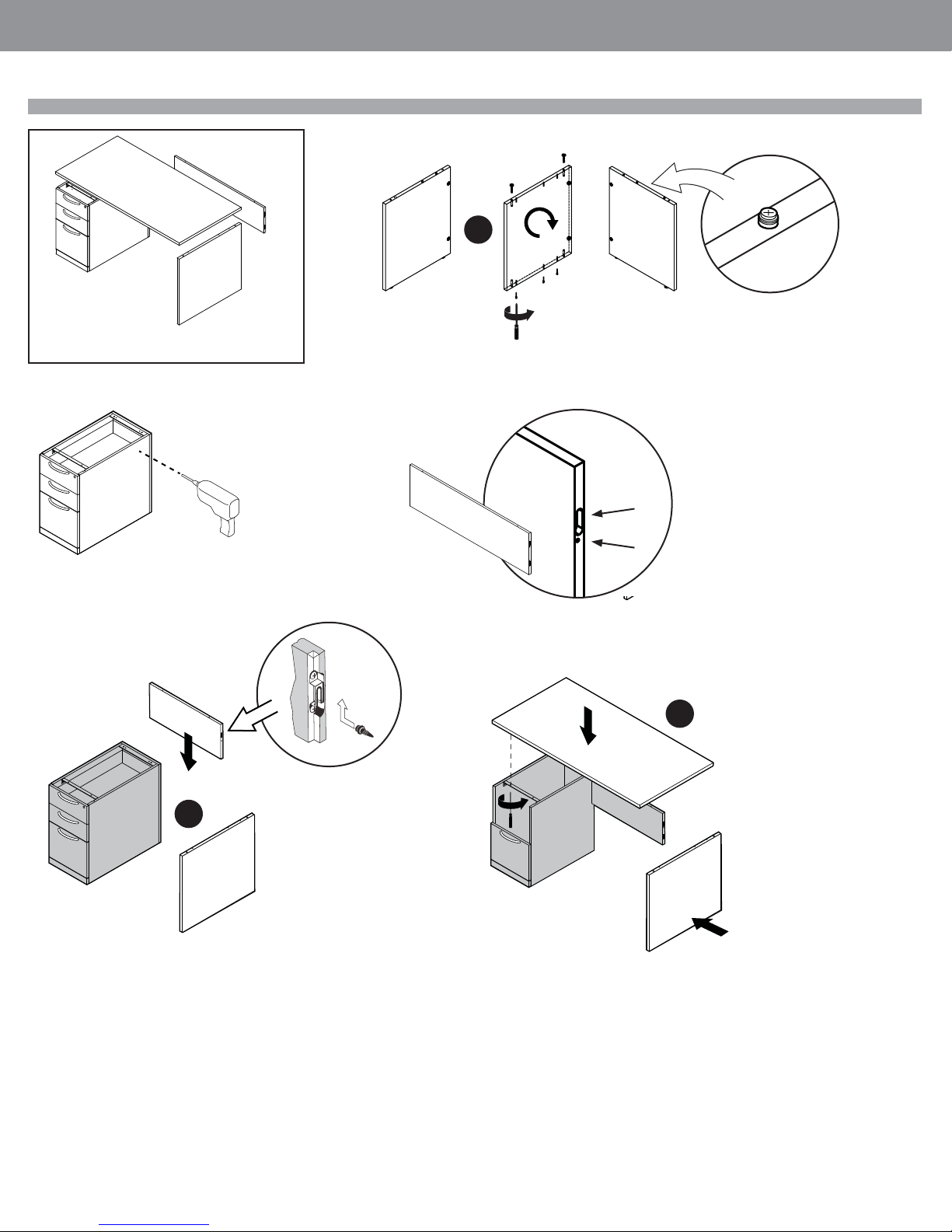

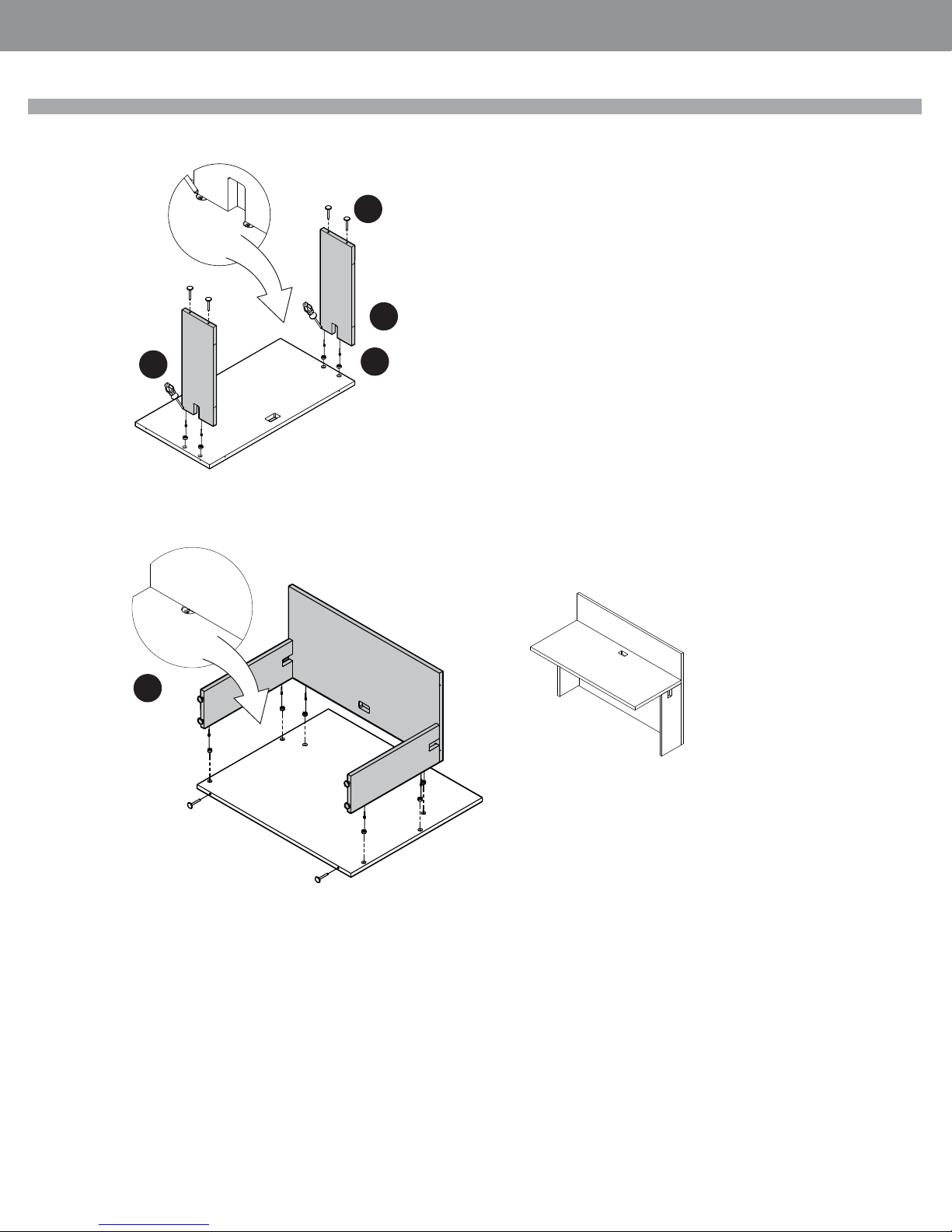

4

• Fall 2017

5

6

Page • globalcontract.com7

GLOBALContract

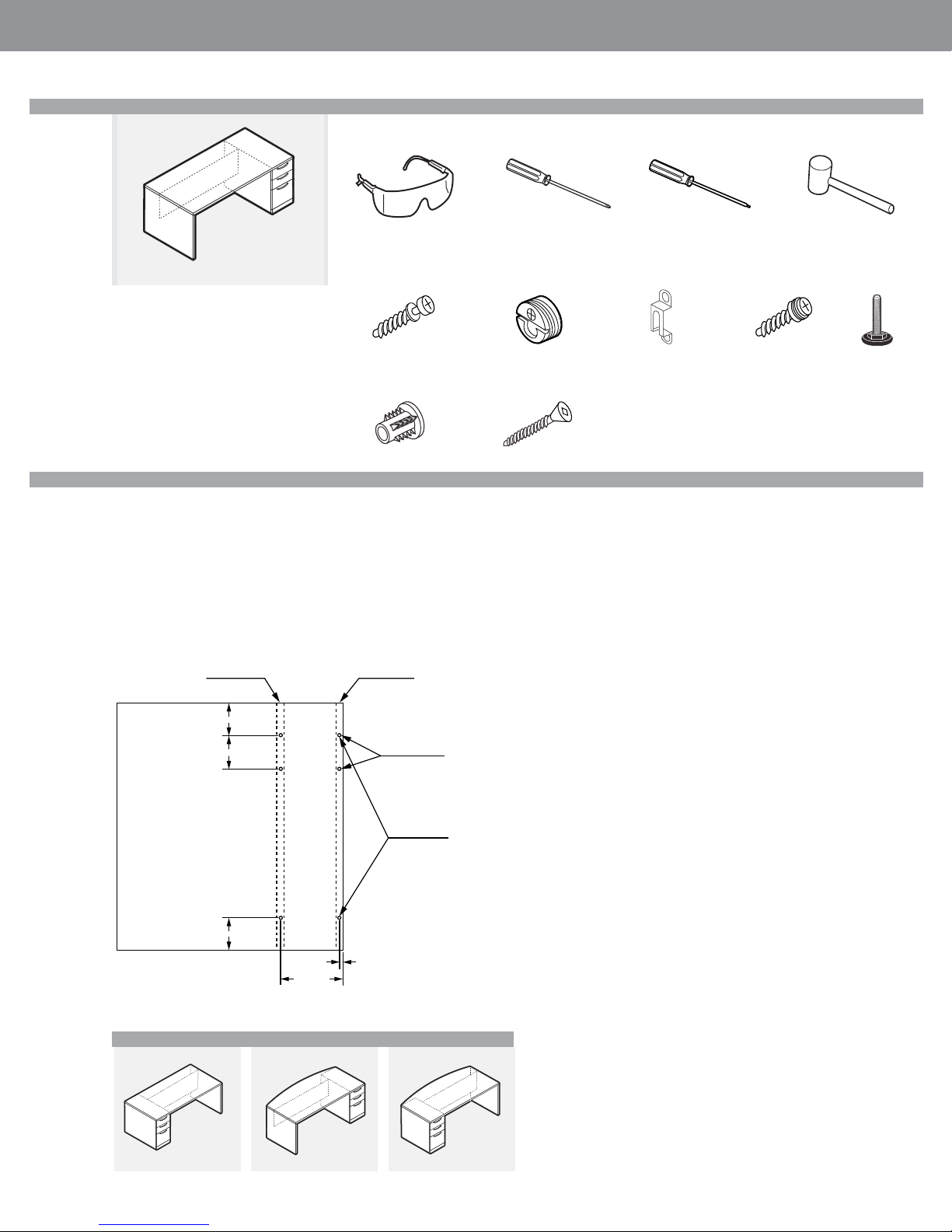

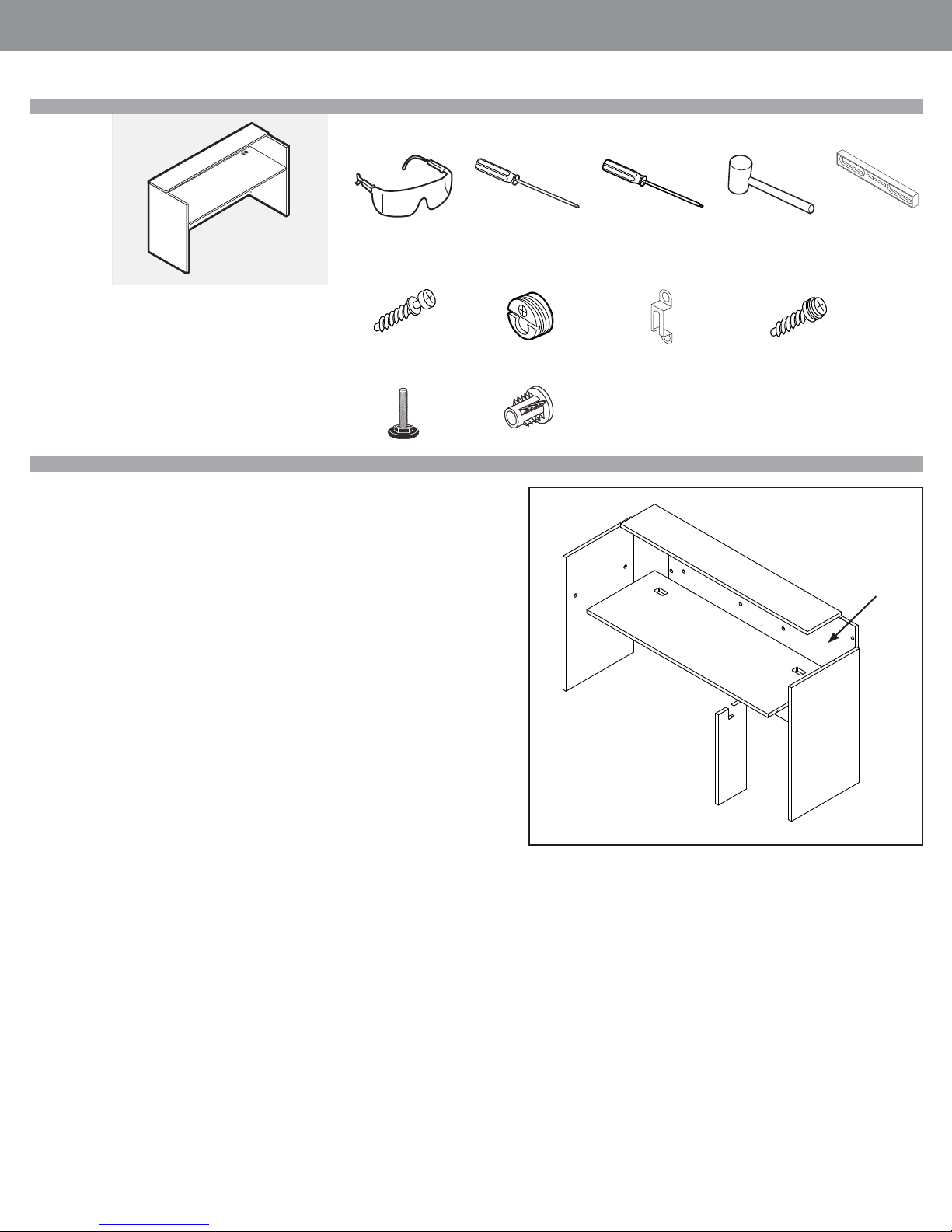

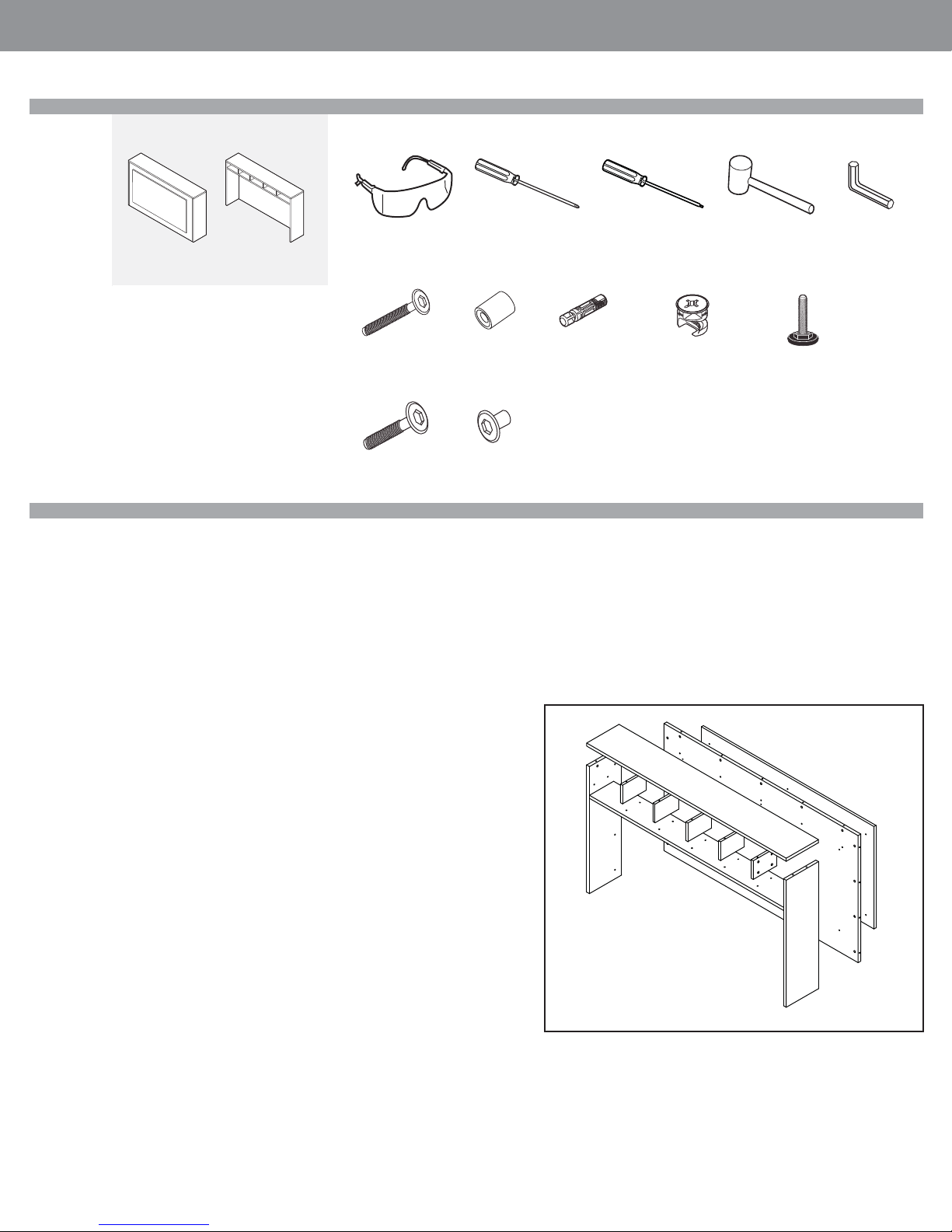

L2DR-FB Double Pedestal Desk

NOTE: Open and assemble only one product

at a time to avoid a potential mix-up of parts

and hardware.

It is adviseable to assemble the unit on a

carpet to avoid scratches.

Required Tools

Safety Glasses

Included Hardware

Blum Connector

Screw L005650060

Leveler

L007250037

• Fall 2017

INSTALLATION GUIDELINES

Screwdriver #2 Phillips Rubber Mallet

Blum Connector

(installed) L005650061

Wood Screw #8 3/4

L007250032

Modular Connector

(installed) L004250001

Modular Screw

L007250001

LevelScrewdriver Roberson

Assembly

STEP 1: Unpack and inspect individual pieces for damages or missing hardware

STEP 2: Pick a clean unobstructed area to assemble desk. It is advisable to assembly of this product upright.

STEP 3: Handles for pedestals are shipped installed on the inside of the cabinet.

Remove handle from the inside of the cabinet and re-install with the same screws

on the front of cabinet.

a. Levellers for pedestals are shipped inside the unit. These levellers should

be installed prior assembling complete unit.

FLUSH MOD6” REC MOD

92.2mm

HALF HEIGHT

96mm

102.7mm

9.5mm

162mm

MODESTY

FULL HEIGHT

MODESTY

STEP 4: Arrange Pedestals as per the fi nal confi guration of the product

a. Using a 1/8” drill bit, drill though holes into side of pedestal according to

the provided template on the side of the pedestal exposed to the underside

of the desk. For this application, use the half modesty and recessed panel location

b. Modular screws are to be installed into these holes

STEP 5: The modesty panel comes with Modular connectors installed on each end

of the panel. On the top edge of the modesty panel, install Blum Connector screws

into the pre-drilled holes.

a. Attach the modesty panel to the pedestals by lining up modular con

nectors to screws installed on the pedestals, lift modesty and slide into

position ensuring to engage connectors to screws. You can use a mallet to

securely seat the modesty panel into position. Do this on both sides

STEP 6: To install the worksurface top. The worksurface comes with Blum Connectors pre-installed on the bottom of the surface. Lift worksurface over the assembly

and line up Blum connectors to the installed Blum connector screws on the back of

the modesty panel. Turn the screw on Blum Connector ¼ turn, do not over tighten.

a. You must also secure the worksurface top to the pedestals. Line up the

top fl ush to the side and front of the pedestals. Use #8 x 3/4 wood screws

provided, screw through the mounting bar on the pedestal to secure the

top. Note: Drawers need to be removed to access drilling location.

7. When fi nal position has been located, level the unit with the levellers installed on

both pedestals.

HALF MODESTY

WORKSURFACE

Installation For Similar Products

L2DRxxxxBF L2DBxxxxFB L2DBxxxxBF

FF PED

BBF PED

•Pageglobalcontract.com 8

GLOBALContract

INSTALLATION GUIDELINES

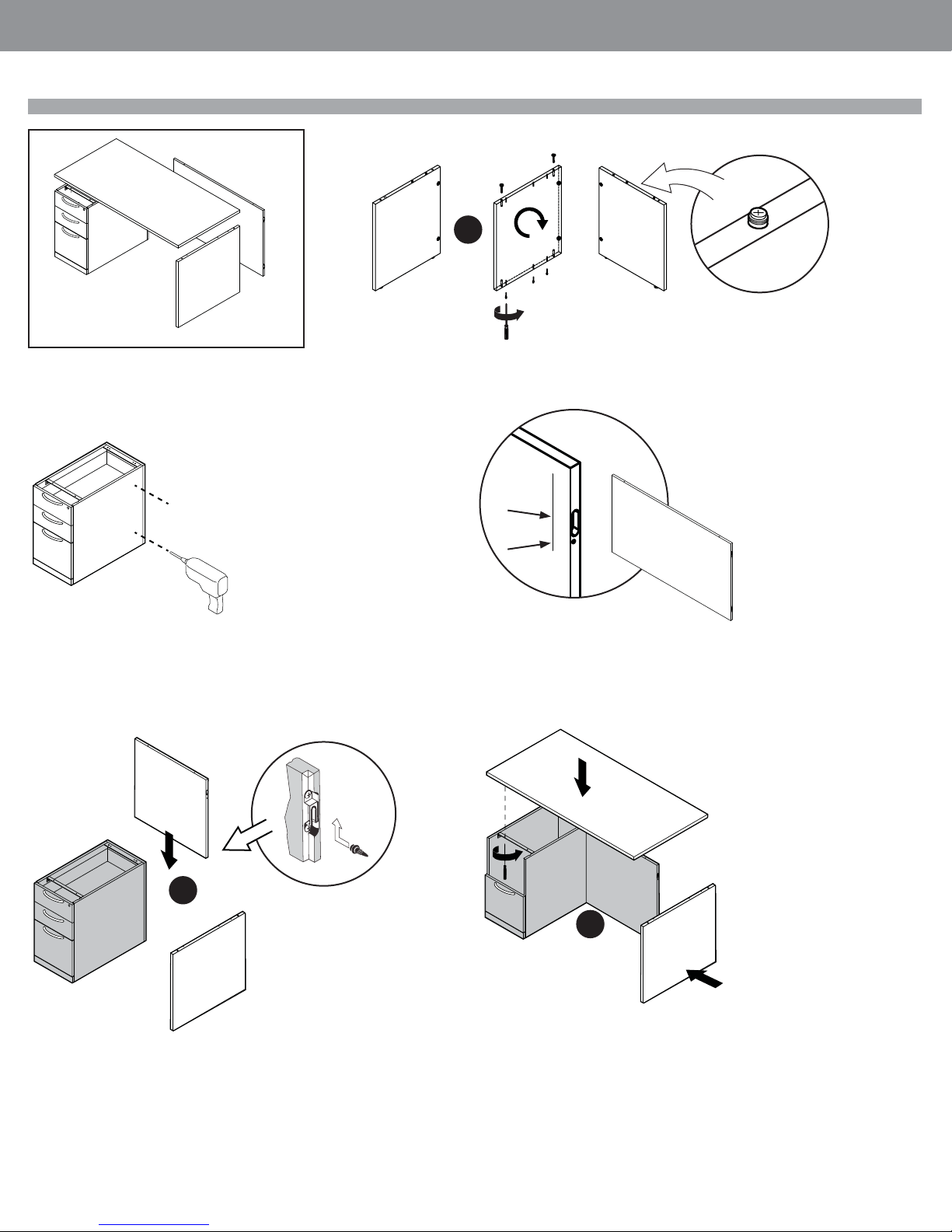

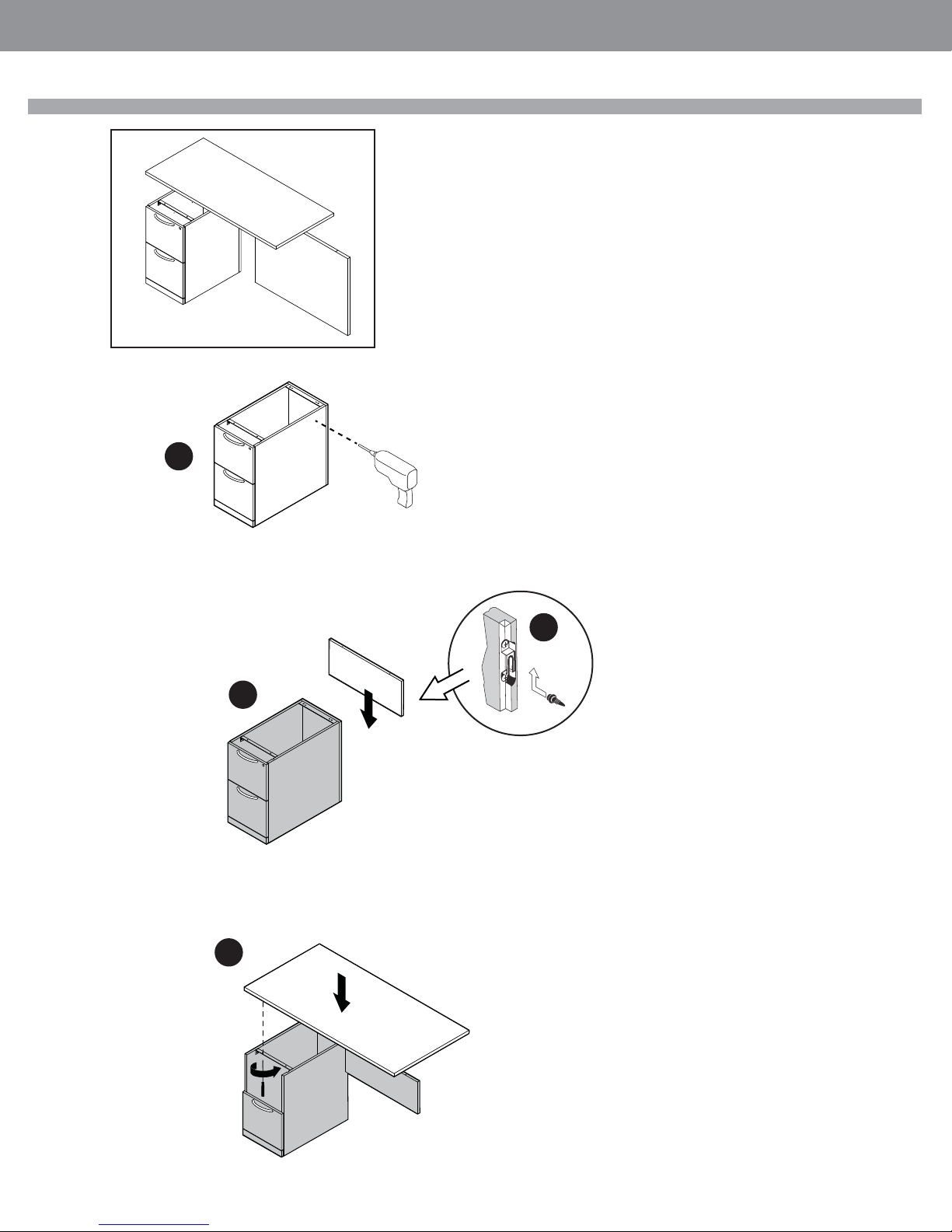

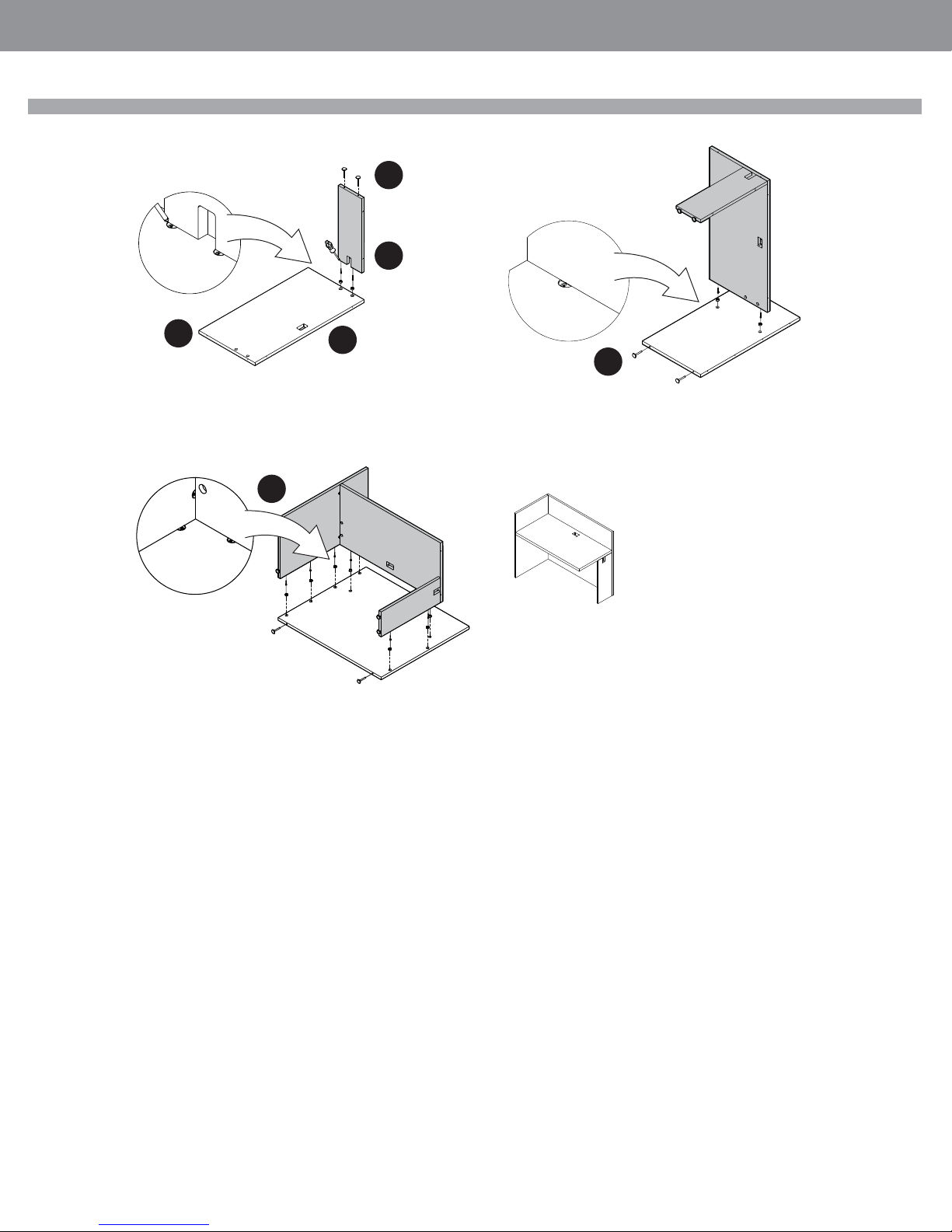

4

• Fall 2017

5

6

Page • globalcontract.com9

GLOBALContract

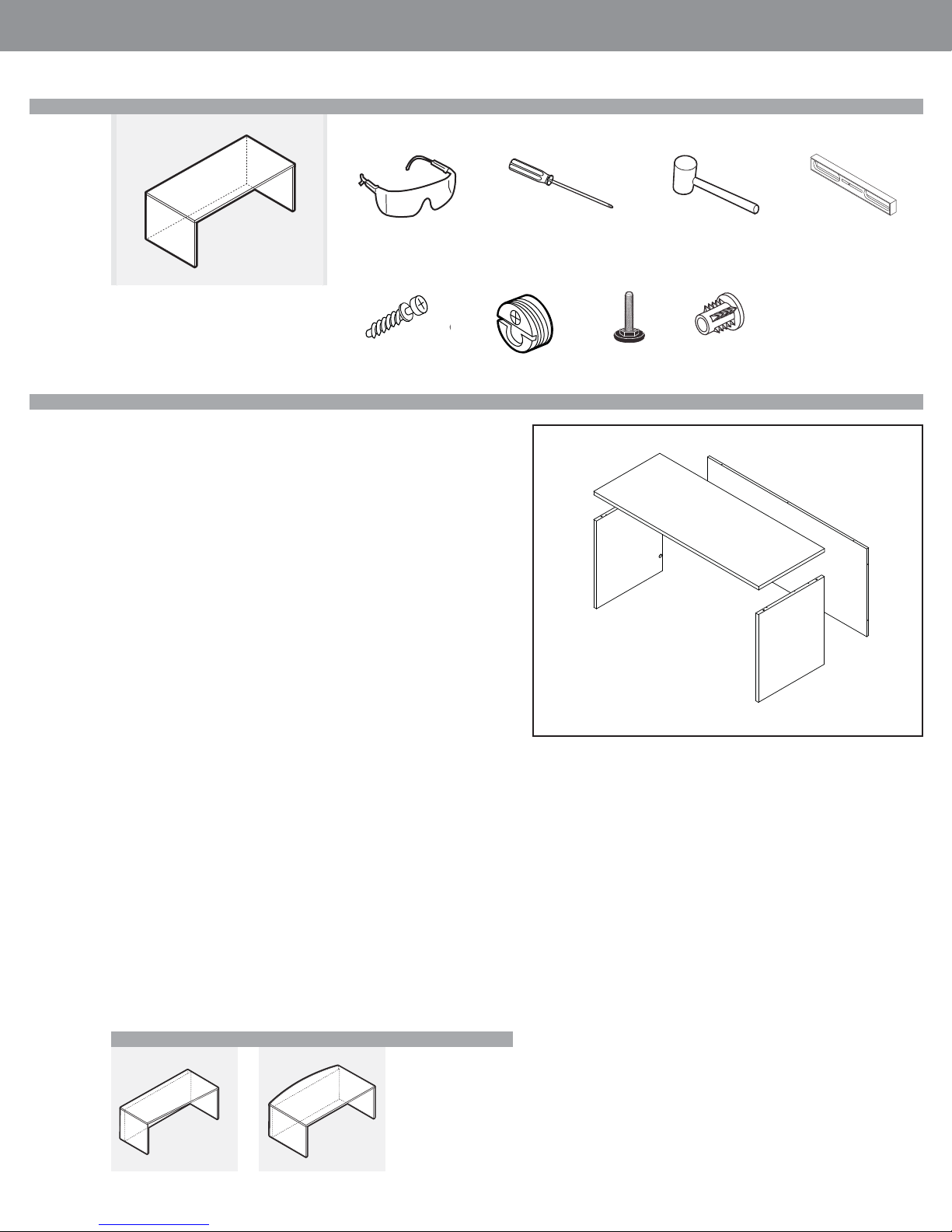

L2DR-BL Single Pedestal Desk

NOTE: Open and assemble only one product

at a time to avoid a potential mix-up of parts

and hardware.

It is adviseable to assemble the unit on a

carpet to avoid scratches.

INSTALLATION GUIDELINES

Required Tools

Safety Glasses Rubber Mallet

Included Hardware

Blum Connector

Screw L005650060

“T” Nut Insert

L007250039

Screwdriver #2 Phillips

Blum Connector

(installed) L005650061

Wood Screw #8 3/4

L007250032

Modular Connector

(installed) L004250001

Modular Screw

L007250001

• Fall 2017

Level

Leveler

L007250037

Assembly

STEP 1:Unpack and inspect individual pieces for damages or missing hardware.

STEP 2: Pick a clean unobstructed area to assemble desk. It is advisable to assembly of this product upright.

STEP 3: Handles for Pedestals are Shipped Installed on the inside of the cabinet.

Remove handle from the inside of the cabinet and re-install with the same screws

on the front of cabinet.

a. Levellers for pedestals are shipped inside the unit. These levellers should

be installed prior assembling complete unit.

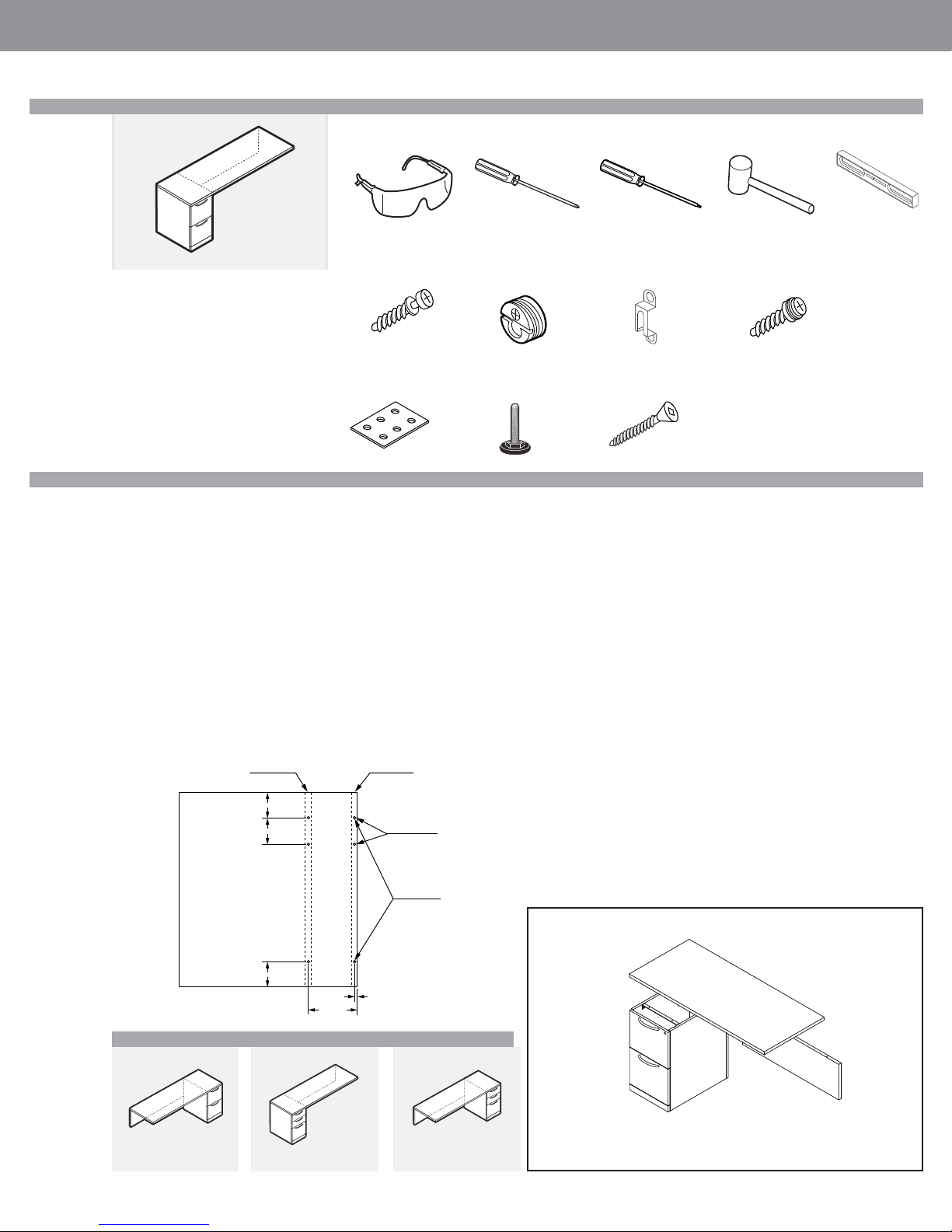

FLUSH MOD6” REC MOD

92.2mm

HALF HEIGHT

96mm

102.7mm

9.5mm

162mm

MODESTY

FULL HEIGHT

MODESTY

Back Panel

Top Underside

Installation For Similar Products

L2DRHxxxxBL L2DBHxxxxBR L2DBxxxxBL

STEP 4: IArrange Pedestal and gable as per the fi nal confi guration of the product.

a. Using a 1/8” drill bit, drill though holes into side of pedestal according to

the provided template on the side of the pedestal exposed to the underside

of the desk. For this application, use the full modesty and recessed panel

location.

b. Modular screws are to be installed into these holes

STEP 5: Gable has Blum connectors pre-installed. Orient gable with Blum Connectors facing inside of desk.

Install levelers into T nut inserts on the bottom of the Gable.

a. Install Blum Connector screws into pre-drilled holes on top edge of the gable

STEP 6: The modesty panel comes with Modular connectors installed on to connect to the Pedestal.

On the top edge of the modesty panel, install Blum Connector screws into the predrilled holes.

On side of Modesty panel lining up with the gable, install Blum Connector screws

into pre-drilled holes.

• There are 2 holes here, select hole closest to underside of assembly to

correctly line up with the Blum Connectors.

a. Attach the modesty panel to the pedestals by lining up modular con

nectors to screws installed on the pedestal, lift modesty and slide into

position ensuring to engage connectors to screws. You can use a mallet to

securely seat the modesty panel into position.

b. Connect the gable to the modesty panel by lining up Blum Connector

screws to the Blum connectors. Turn the screw on Blum Connector ¼ turn,

do not over tighten.

STEP 7: To install the worksurface top. The worksurface comes with Blum Connectors pre-installed on the bottom of the surface. Lift worksurface over the assembly

and line up Blum connectors to the installed Blum connector screws on the modesty panel and gable. Turn screw on Blum Connector ¼ turn, do not over tighten.

a. You must also secure the worksurface top to the pedestal. Line up the

top fl ush to the side and front of the pedestal. Use #8 x 3/4 wood screws

provided, screw through the mounting bar on the pedestal to secure the

top. Note: Drawers need to be removed to access drilling location.

STEP 8: When fi nal position has been located, level the unit with the levellers

installed on Gable and pedestal

•Pageglobalcontract.com 10

GLOBALContract

INSTALLATION GUIDELINES

FULL MODESTY

WORKSURFACE

• Fall 2017

BBF PED

5

GABLE

LEFT HAND RIGHT HAND

Connection for pedestal

Connection for gable

6

Page • globalcontract.com11

7

GLOBALContract

L2DRHxxxxBR • Single Pedestal Desk Resessed Half Modesty

NOTE: Open and assemble only one product

at a time to avoid a potential mix-up of parts

and hardware.

It is adviseable to assemble the unit on a

carpet to avoid scratches.

Required Tools

Safety Glasses

Included Hardware

Blum Connector

Screw L005650060

“T” Nut Insert

L007250039

• Fall 2017

INSTALLATION GUIDELINES

Screwdriver #2 Phillips

Blum Connector

(installed) L005650061

Wood Screw #8 3/4

L007250032

Screwdriver Roberson

Modular Connector

(installed) L004250001

Rubber Mallet

Modular Screw

L007250001

Leveler

L007250037

Assembly

STEP 1: Unpack and inspect individual pieces for damages or missing hardware

STEP 2: Pick a clean unobstructed area to assemble desk. It is advisable to assembly of this product upside down.

STEP 3: Handles for Pedestals are Shipped Installed on the inside of the cabinet.

Remove handle from the inside of the cabinet and re-install with the same screws

on the front of cabinet.

a. Levellers for pedestals are shipped inside the unit. These levellers should

be installed prior assembling complete unit.

FLUSH MOD6” REC MOD

92.2mm

HALF HEIGHT

96mm

102.7mm

9.5mm

162mm

MODESTY

FULL HEIGHT

MODESTY

Installation For Similar Products

L2DRHxxxxBL L2DBHxxxxBR L2DBxxxxBL

STEP 4: Arrange Pedestal and gable as per the fi nal confi guration of the product.

a. Using a 1/8” drill bit, drill though holes into side of pedestal according to

the provided template on the side of the pedestal exposed to the underside

of the desk. For this application, use the full modesty and recessed panel location.

b. Modular screws are to be installed into these holes

STEP 5: Gable has Blum connectors pre-installed. Orient gable with Blum Connectors facing inside of desk.

Install levellers into T nuts, using mallet install into pre-drilled holes on the bottom of gable.

a. Install Blum Connector screws into pre-drilled holes on top edge of the gable.

STEP 6: The modesty panel comes with Modular connectors installed on to

connect to the Pedestal. On the top edge of the modesty panel, install Blum Connector screws into the pre-drilled holes. On side of Modesty panel lining up with

the gable, install Blum Connector screws into pre-drilled holes.

• There are 2 holes here, select hole closest to underside of assembly to

correctly line up with the Blum Connectors.

a. Attach the modesty panel to the pedestals by lining up modular con

nectors to screws installed on the pedestal, lift modesty and slide into po

sition ensuring to engage connectors to screws. You can use a mallet to

securely seat the modesty panel into position.

b. Connect the gable to the modesty panel by lining up Blum Connector

screws to the Blum connectors. Turn the screw on Blum Connector ¼

turn, do not over tighten

STEP 7: To install the worksurface top. The worksurface comes with Blum

Connectors pre-installed on the bottom of the surface. Lift worksurface over the

assembly and line up Blum connectors to the installed Blum connector screws on

the modesty panel and gable. Turn screw on Blum Connector ¼ turn, do not over

tighten.

a. You must also secure the worksurface top to the pedestal. Line up the

top fl ush to the side and front of the pedestal. Use #8 x 3/4 wood screws

provided, screw through the mounting bar on the pedestal to secure the

top. Note: Drawers need to be removed to access drilling location

STEP 8: When fi nal position has been located, level the unit with the levellers

installed on Gable and pedestal.

•Pageglobalcontract.com 12

GLOBALContract

INSTALLATION GUIDELINES

HALF MODESTY

TOP

• Fall 2017

BBF PED

5

GABLE

LEFT HAND RIGHT HAND

Connection for pedestal

Connection for gable

7

6

Page • globalcontract.com13

GLOBALContract

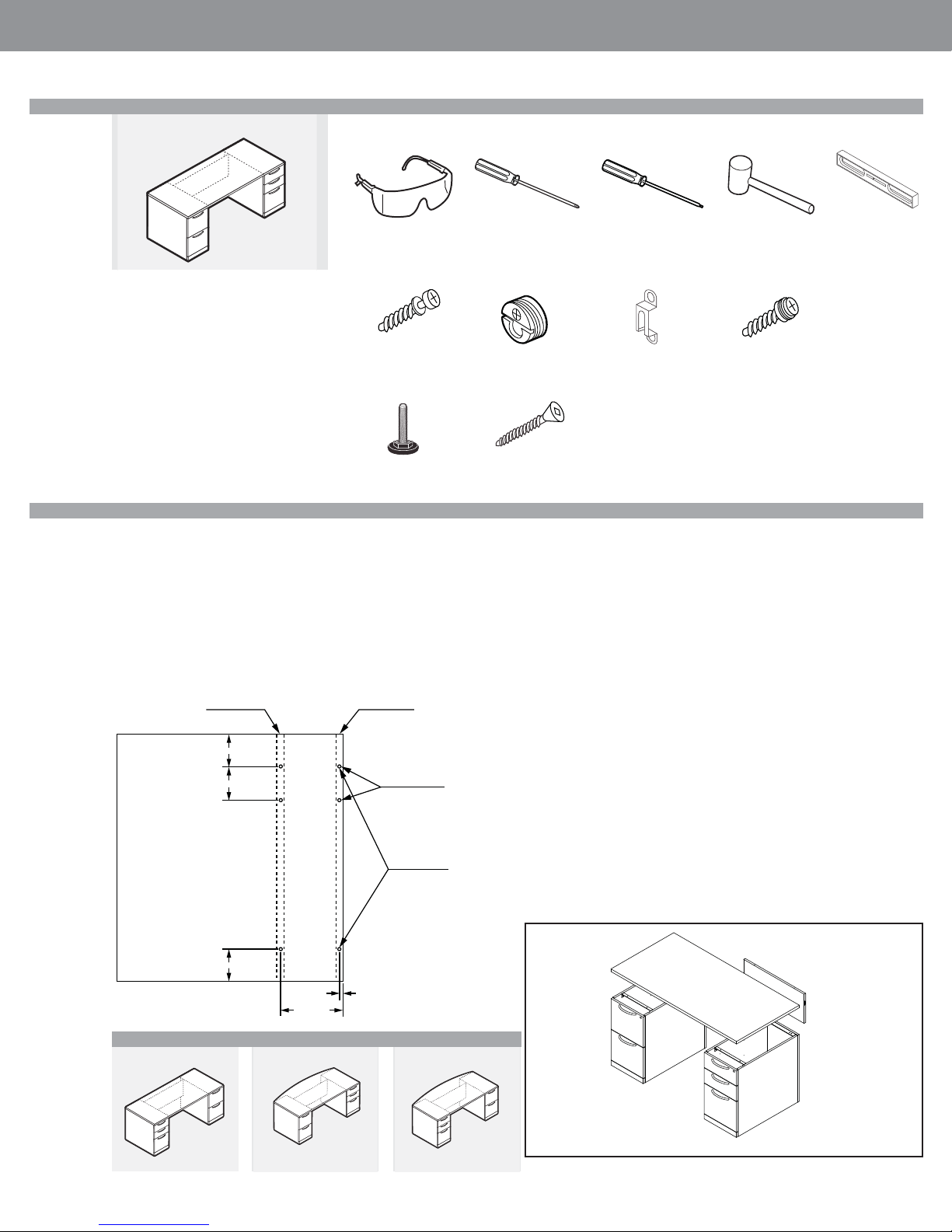

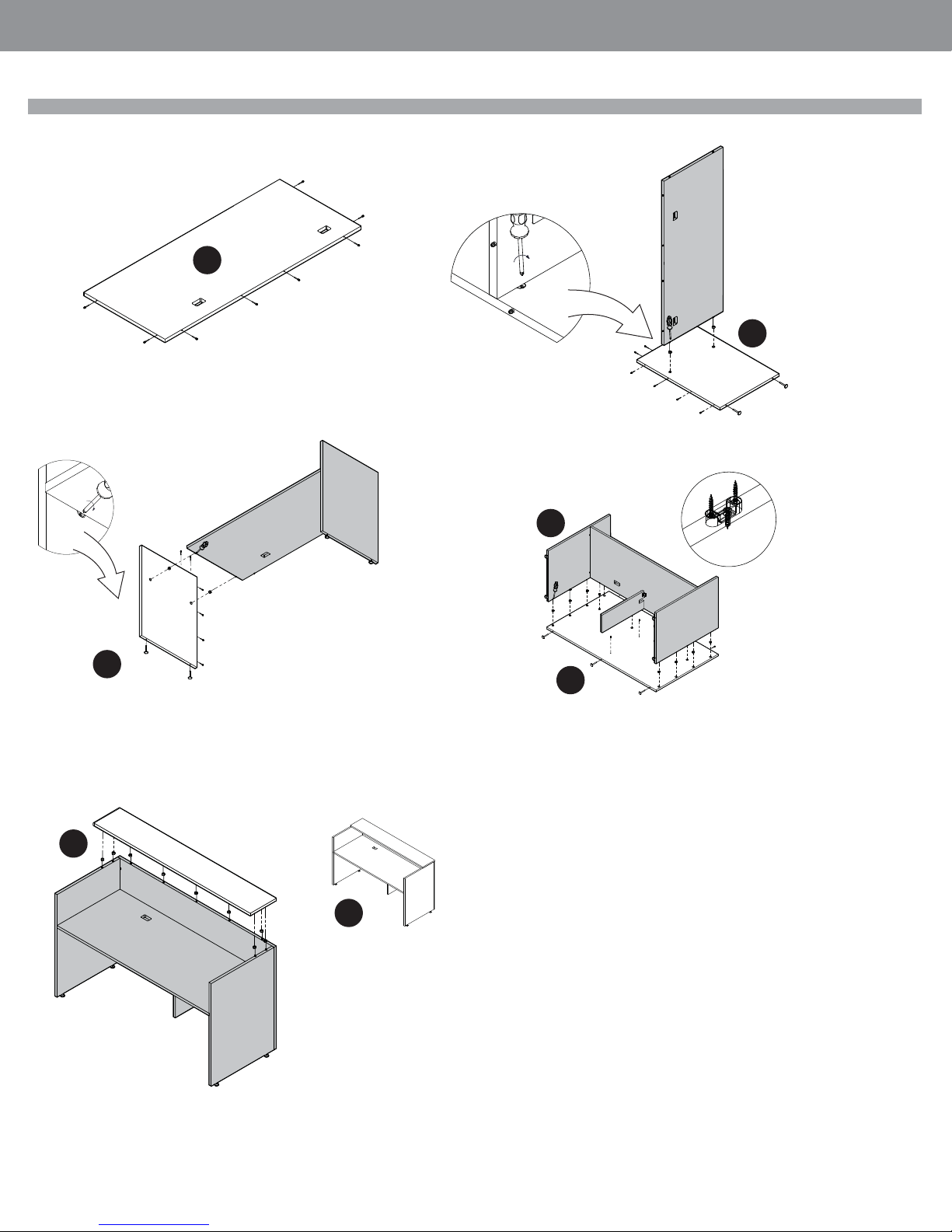

L2ERxxxxFL

NOTE: Open and assemble only one product

at a time to avoid a potential mix-up of parts

and hardware.

It is adviseable to assemble the unit on a

carpet to avoid scratches.

Required Tools

Safety Glasses

Included Hardware

Blum Connector

Screw L005650060

Flat Bracket

L005650025

• Fall 2017

INSTALLATION GUIDELINES

Screwdriver #2 Phillips Rubber MalletScrewdriver Roberson Level

Blum Connector

(installed) L005650061

Leveler

L007250037

Modular Connector

(installed) L004250001

Wood Screw #8 3/4

L007250032

Modular Screw

L007250001

Assembly

STEP 1: Unpack and inspect individual pieces for damages or missing hardware

STEP 2: Pick a clean unobstructed area to assemble desk. It is advisable to assembly of this product upright.

STEP 3: Handles for Pedestals are Shipped Installed on the inside of the cabinet.

Remove handle from the inside of the cabinet and re-install with the same screws

on the front of cabinet.

a. Levellers for pedestals are shipped inside the unit. These levellers should

be installed prior assembling complete unit.

FLUSH MOD6” REC MOD

92.2mm

HALF HEIGHT

96mm

102.7mm

MODESTY

FULL HEIGHT

MODESTY

Top Underside

STEP 4: Arrange Pedestal and gable as per the fi nal confi guration of the product.

a. Using a 1/8” drill bit, drill though holes into side of pedestal according to

the provided template on the side of the pedestal exposed to the underside

of the desk. For this application, use the full modesty and fl ush panel location.

b. Modular screws are to be installed into these holes.

STEP 5: The modesty panel comes with Modular connectors installed to connect to

the Pedestal.

On the top edge of the modesty panel, install Blum Connector screws into the predrilled holes. There are 2 holes here, select hole closest to underside of assembly to

correctly line up with the Blum Connectors.

STEP 6: Attach the modesty panel to the pedestals by lining up modular connectors

to screws installed on the pedestal, lift modesty and slide into position ensuring to

engage connectors to screws. You can use a mallet to securely seat the modesty

panel into position.

STEP 7: To install the worksurface top. The worksurface comes with Blum Connectors pre-installed on the bottom of the surface. Lift worksurface over the assembly

and line up Blum connectors to the installed Blum connector screws on the modesty panel. Turn screw on Blum Connector ¼ turn, do not over tighten.

a. You must also secure the worksurface top to the pedestal. Line up the

top fl ush to the side and front of the pedestal. Use #8 x 3/4 wood screws

Back Panel

provided, screw through the mounting bar on the pedestal to secure the

top. Note: Drawers need to be removed to access drilling location.

8. This unit is intended to be attached to an adjoining assembled unit at the open

end using the provided Flat Brackets. The Flat Brackets are screwed into ganged

assemblies at the worksurface joint using #8 x ¾ wood screws.

9.5mm

162mm

Installation For Similar Products

L2DRxxxxFR L2ERxxxxBL L2ERxxxxBR

9. When fi nal position has been located, level the unit with the levellers installed on

the pedestal.

•Pageglobalcontract.com 14

GLOBALContract

INSTALLATION GUIDELINES

WORKSURFACE

FF PED

FULL MODESTY

3

• Fall 2017

4

5

6

Page • globalcontract.com15

GLOBALContract

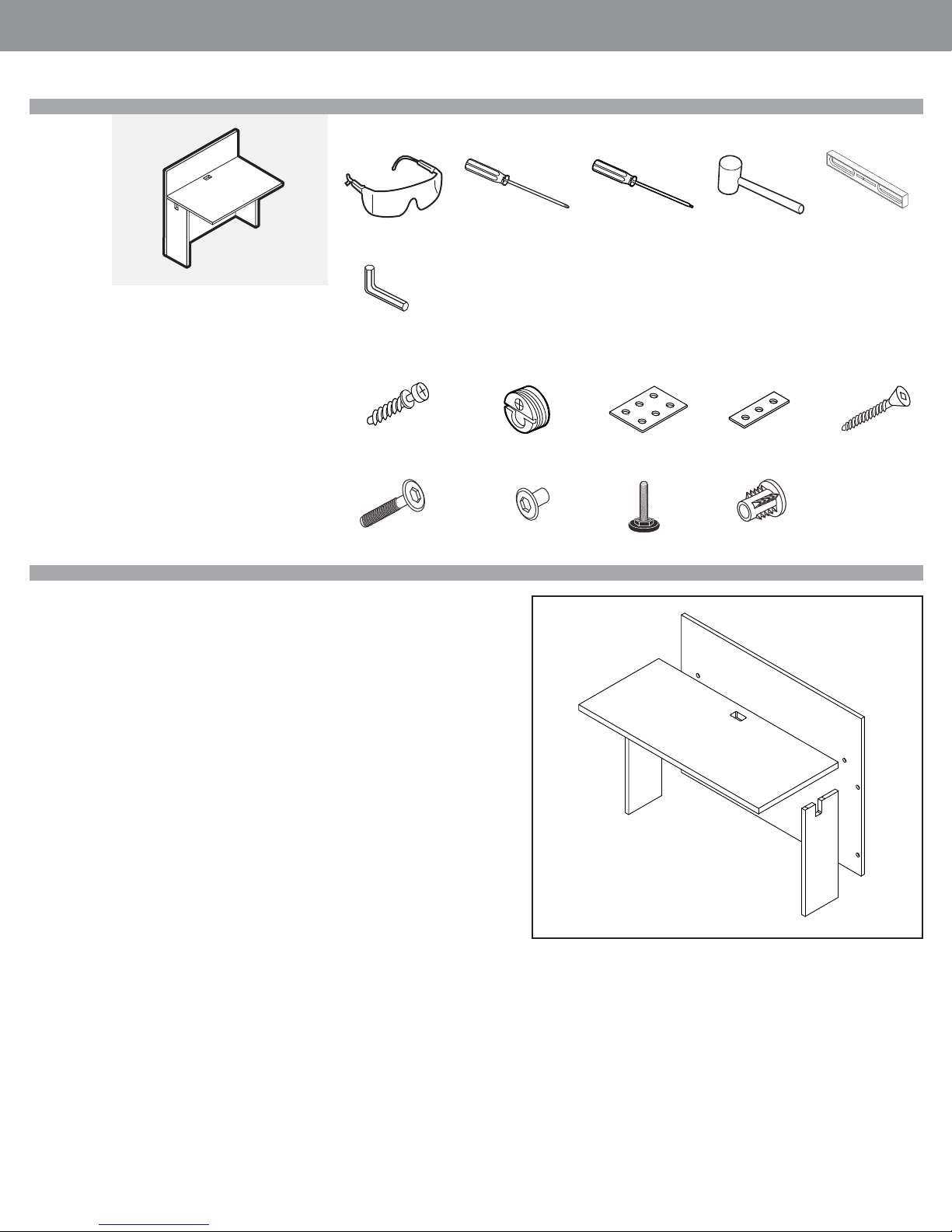

L2ERH-FL

NOTE: Open and assemble only one product

at a time to avoid a potential mix-up of parts

and hardware.

It is adviseable to assemble the unit on a

carpet to avoid scratches.

Required Tools

Safety Glasses

Included Hardware

Blum Connector

Screw L005650060

Flat Bracket

L005650025

• Fall 2017

INSTALLATION GUIDELINES

Screwdriver #2 Phillips Rubber Mallet Level

Blum Connector

(installed) L005650061

Leveler

L007250037

Screwdriver Roberson

Modular Connector

(installed) L004250001

Wood Screw #8 3/4

L007250032

Modular Screw

L007250001

Assembly

STEP 1: Unpack and inspect individual pieces for damages or missing hardware

STEP 2: Pick a clean unobstructed area to assemble desk. It is advisable to assembly of this product upright.

STEP 3: Handles for Pedestals are Shipped Installed on the inside of the cabinet.

Remove handle from the inside of the cabinet and re-install with the same screws

on the front of cabinet.

a. Levellers for pedestals are shipped inside the unit. These levellers should

be installed prior assembling complete unit.

STEP 4: Arrange Pedestal and gable as per the fi nal confi guration of the product.

a. Using a 1/8” drill bit, drill though holes into side of pedestal according to

the provided template on the side of the pedestal exposed to the underside

of the desk. For this application, use the half modesty and fl ush panel location.

b. Modular screws are to be installed into these holes.

FLUSH MOD6” REC MOD

92.2mm

HALF HEIGHT

96mm

MODESTY

FULL HEIGHT

MODESTY

STEP 5: The modesty panel comes with Modular connectors installed to connect

to the Pedestal. On the top edge of the modesty panel, install Blum Connector

screws into the pre-drilled holes.

• There are 2 holes here, select hole closest to underside of assembly to

correctly line up with the Blum Connectors.

STEP 6: Attach the modesty panel to the pedestals by lining up modular connectors to screws installed on the pedestal, lift modesty and slide into position

ensuring to engage connectors to screws. You can use a mallet to securely seat

the modesty panel into position.

STEP 7: To install the worksurface top. The worksurface comes with Blum

Connectors pre-installed on the bottom of the surface. Lift worksurface over the

assembly and line up Blum connectors to the installed Blum connector screws on

the modesty panel. Turn screw on Blum Connector ¼ turn, do not over tighten

a. You must also secure the worksurface top to the pedestal. Line up the

top fl ush to the side and front of the pedestal. Use #8 x 3/4 wood screws

provided, screw through the mounting bar on the pedestal to secure the

top. Note: Drawers need to be removed to access drilling location.

STEP 8: This unit is intended to be attached to an adjoining assembled unit at the

open end using the provided Flat Brackets. The Flat Brackets are screwed into

ganged assemblies at the worksurface joint using #8 x ¾ wood screws.

STEP 9: When fi nal position has been located, level the unit with the levellers

installed on the pedestal.

102.7mm

Installation For Similar Products

L2ERHxxxxFR L2ERHxxxxBL L2ERxxxxBR

L2ERHxxxxBL

9.5mm

162mm

WORKSURFACE

FF PED

HALF MODESTY

•Pageglobalcontract.com 16

GLOBALContract

INSTALLATION GUIDELINES

3

5

• Fall 2017

4

6

Page • globalcontract.com17

GLOBALContract

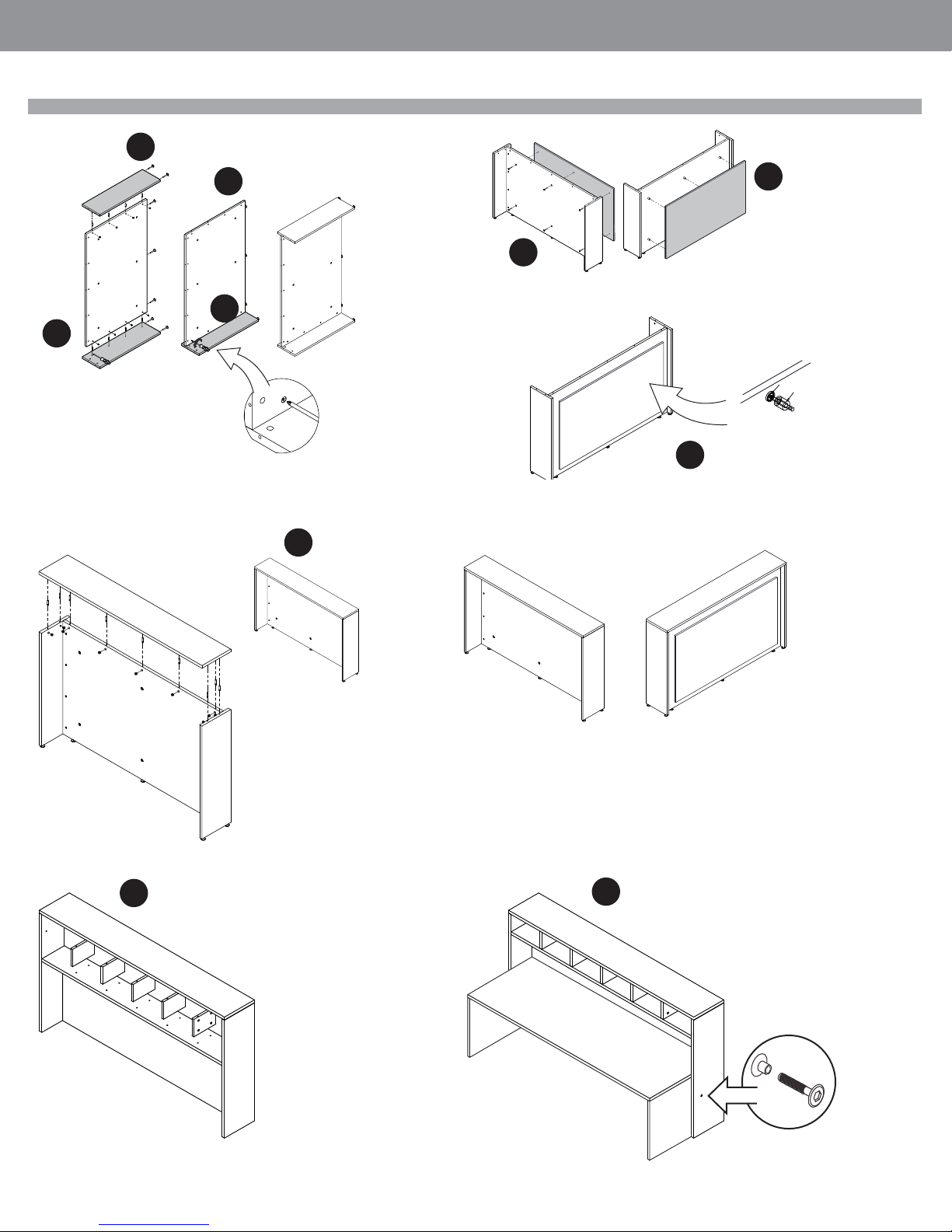

L2GRxx

NOTE: Open and assemble only one product

at a time to avoid a potential mix-up of parts

and hardware.

Required Tools

Safety Glasses

Included Hardware

Blum Connector

Screw L005650060

• Fall 2017

INSTALLATION GUIDELINES

Screwdriver #2 Phillips Rubber MalletScrewdriver Roberson Level

Blum Connector

(installed) L005650061

Modular Connector

(installed) L004250001

Modular Screw

L007250001

It is adviseable to assemble the unit on a

carpet to avoid scratches.

Leveler

L007250037

“T” Nut Insert

L007250039

Assembly

STEP 1: Unpack and inspect individual pieces for damages or missing hardware

STEP 2: Pick a clean unobstructed area to assemble desk. It is advisable to assembly of this product upright.

STEP 3: Install provided levellers into T nut inserts on the bottom of both left and

right hand end panels as well as half gable. Install T nuts, using mallet install into

pre-drilled holes on the bottom of gable. On the back and top edge of the end

panels, install Blum connector screws in pre-drilled holes.

STEP 4: On the worksurface, install Blum Connector screws in pre-drilled holes on

the back and side edges.

STEP 5: Lay the back panel on clean unobstructed surface with Blum Connectors

facing up. On the bottom edge, install the levellers into the T nut inserts. On the

top edge, install Blum connector screws into pre-drilled holes.

a. To attach the half gable mid support, install 2 modular connector screws in the

holes provide along center line. The half gable will connect to the back panel by

lining up modular connectors to the connector screws and slide down to engage. A

mallet may be used to properly seat the half gable.

TRANSACTION TOP

BACK PANEL

WORKSURFACE

HALF GABLE GABLE

STEP 6: lay either left or right end panel on the ground with exposed Blum connectors facing up. Connect the side of worksurface by lining up the Blum connector

screws to the Blum connectors. Tighten screws on Blum Connectors ¼ turn, do not

over tighten.

a. with the assistance of another person, turn assembly upright and connect opposite end panel by connecting Blum Connector screws.

STEP 7: Pick up assembly of the worksurface and end gables and line up Blum

Connector screws along the back end to the Blum connectors on the Back panel.

Tighten Blum Connector screws ¼ turn, Do not over tighten. Stand Assembly

upright.

STEP 8: To install transaction top, line the Blum Connectors installed on the bottom

of the top and line up with Blum connecting screws installed on the top edges of the

assembly. Tighten Blum Connector screws ¼ turn, Do not over tighten.

STEP 9: When in fi nal position, level the unit.

•Pageglobalcontract.com 18

GLOBALContract

INSTALLATION GUIDELINES

4

• Fall 2017

6

7

6a

5

8

9

Page • globalcontract.com19

GLOBALContract

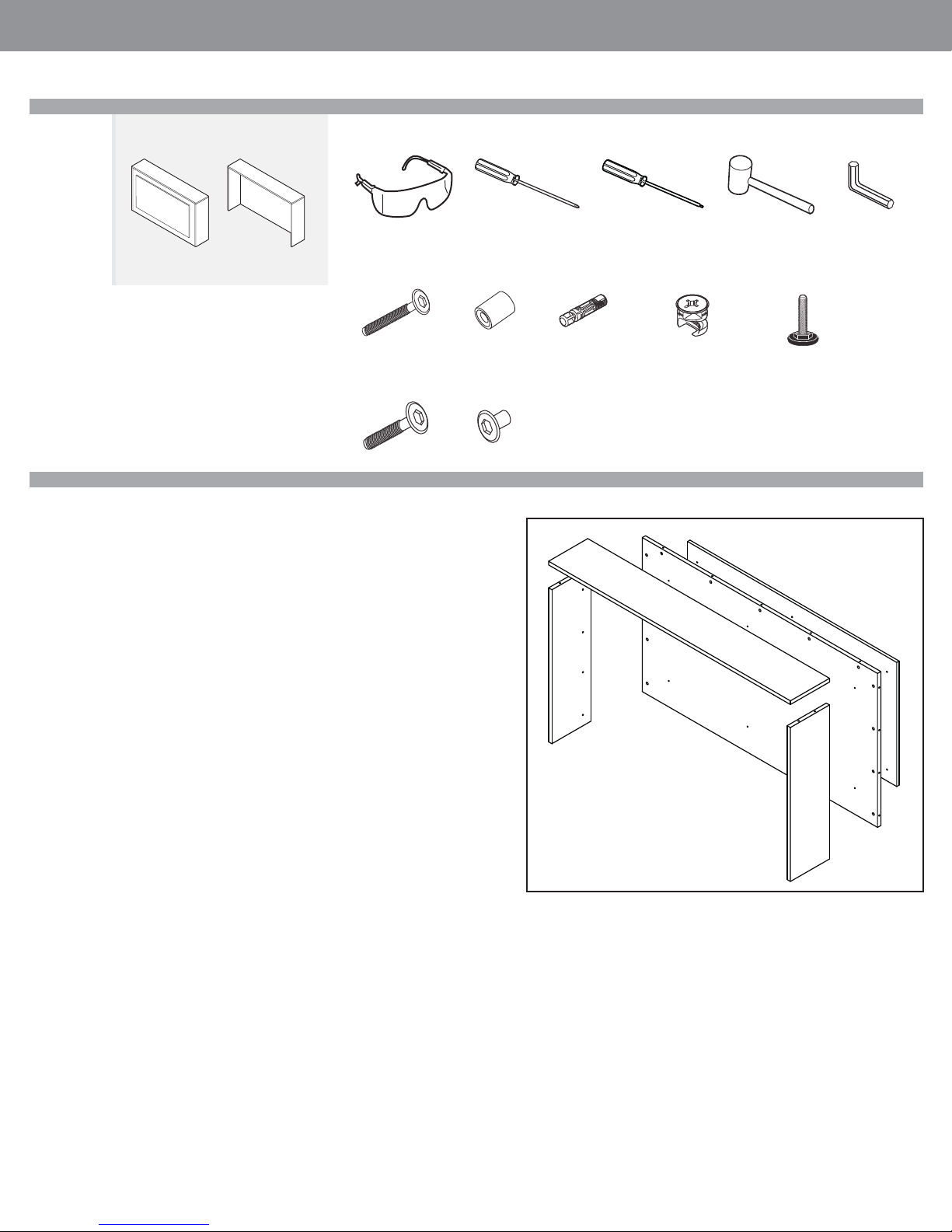

L2GB

NOTE: Open and assemble only one product

at a time to avoid a potential mix-up of parts

and hardware.

It is adviseable to assemble the unit on a

carpet to avoid scratches.

Required Tools

Safety Glasses

#4 & 5 Hex Wrench

Included Hardware

Blum Connector

Screw L005650060

• Fall 2017

INSTALLATION GUIDELINES

Screwdriver #2 Phillips Rubber MalletScrewdriver Roberson Level

Blum Connector

(installed) L005650061

Flat Bracket

L005650025

Flat Bracket

L005651035

Wood Screw #8 3/4

L007250032

Connector Bolt

L005650114

Connector Nut

L005650117

Assembly

STEP 1: Unpack and inspect individual pieces for damages or missing hardware

STEP 2: Pick a clean unobstructed area to assemble desk. It is advisable to assembly of this product upright.

STEP 3: Install levellers into T nuts, using mallet install into pre-drilled holes on the

bottom of gable. Orient the gables as left and right with exposed drill holes on back

edge facing back.

Install Blum Connector screws into pre-drilled holes on back edge closest to underside of desk assembly.

a. install Blum Connector Screws on top edge of partial gables into pre drilled holes closest to underside of desk assembly.

STEP 4: On the worksurface, install Blum Connector screws in pre-drilled holes on

the back edge.

STEP 5: Lay worksurface bottom side up on clean unobstructed surface with Blum

Connectors facing up.

Install partial gables into Blum Connectors on the bottom of the surface. Insure

that the gables have Blum Connector screws facing underside of desk as confi gured

in step 3. Tighten Blum connectors ¼ turn, do not over tighten.

HALF GABLE

Leveler

L007250037

WORKSURFACE

“T” Nut Insert

L007250039

BACK PANEL

HALF GABLE

STEP 5: Lay the back panel on clean unobstructed surface with Blum Connectors

facing up. On the bottom edge, Install levellers into T nuts, using mallet install into

pre-drilled holes.

STEP 6: Pick up assembly of the worksurface and end gables and line up Blum

Connector screws along the back end to the Blum connectors on the Back panel.

Tighten Blum Connector screws ¼ turn, do not over tighten. Stand Assembly

upright.

STEP 7: This unit is intended to be attached to an adjoining assembled unit at both

ends using the provided Flat Brackets. The fl at brackets are screwed into ganged

assemblies at the worksurface joint using #8 x ¾ wood screws

half fl at bracket will be installed in “cableway” opening of partial gable.

a. Using Murikoshi Connector screw and ¼ - 2—2 Bolt, join half gables of

adjoin units though pre-drilled hole on the side of the gable.

•Pageglobalcontract.com 20

GLOBALContract

INSTALLATION GUIDELINES

3

3a

• Fall 2017

5

6

4

Page • globalcontract.com21

GLOBALContract

L2GBxxL

NOTE: Open and assemble only one product

at a time to avoid a potential mix-up of parts

and hardware.

It is adviseable to assemble the unit on a

carpet to avoid scratches.

Required Tools

Safety Glasses

#4 & 5 Hex Wrench

Included Hardware

Blum Connector

Screw L005650060

• Fall 2017

INSTALLATION GUIDELINES

Screwdriver #2 Phillips Rubber MalletScrewdriver Roberson Level

Blum Connector

(installed) L005650061

Flat Bracket

L005650025

Flat Bracket

L005651035

Wood Screw #8 3/4

L007250032

Connector Bolt

L005650114

Connector Nut

L005650117

Assembly

STEP 1: Unpack and inspect individual pieces for damages or missing hardware

STEP 2: Pick a clean unobstructed area to assemble desk. It is advisable to assembly of this product upright.

STEP 3. Install levellers into T nuts, using mallet install into pre-drilled holes on the

bottom of gable.

Orient the gables as left and right with exposed hole on back edge facing back, note

that the large end panel is handed.

a. Install Blum Connector screws into pre-drilled holes on back and top

edge of both the partial gable. Please note that the half gable is non

handed, there will be 2 holes for each Blum connector screw location.

Install screws in position closest to underside of assembled desk.

STEP 4: On the worksurface, install Blum Connector screws in pre-drilled holes on

the back edge and side matching the full height end panel.

STEP 5: Lay worksurface face down on Clean unobstructed surface with Blum

Connectors exposed.

Attach half gable to worksurface linming Blum Connectors screws with Blum Connectors. Tighten Blum Connector ¼ turn, do not over tighten.

a. Lay full end panel on clean unobstructed surface with exposed Blum

Connectors facing up. Connect worksurface to full end panel by lining up

Blum connecter screws to the Blum connectors on end panel. Tighten Blum

connectors ¼ turn, do not over tighten.

“T” Nut Insert

L007250039

STEP 6: Lay the back panel on clean unobstructed surface with Blum Connectors

facing up. On the bottom edge, install the levellers into the T nut inserts.

STEP 7: Pick up assembly of the worksurface and end gables and line up Blum

Connector screws along the back edge to the Blum connectors on the back panel.

Tighten Blum Connector screws ¼ turn, do not over tighten. Stand Assembly

upright.

STEP 8: This unit is intended to be attached to an adjoining assembled unit at open

side using the provided Flat Brackets. The Flat Brackets are screwed into ganged

assemblies at the worksurface joint using #8 x ¾ wood screws

Half fl at bracket will be installed in “cableway” opening of half gable.

a. Using Connector Bolt screw and Connector Nut, join half gables of

adjoin units though pre-drilled hole on the side of the gable.

STEP 9: When fi nal position has been located, level the unit with the levellers

installed on the pedestal.

END GABLE

WORKSURFACE

Leveler

L007250037

BACK PANEL

Installation For Similar Products

L2GRxxR

HALF GABLE

•Pageglobalcontract.com 22

GLOBALContract

INSTALLATION GUIDELINES

3

3a

• Fall 2017

5

6

4

5a

3

Page • globalcontract.com23

GLOBALContract

L2GD

NOTE: Open and assemble only one product

at a time to avoid a potential mix-up of parts

and hardware.

It is adviseable to assemble the unit on a

carpet to avoid scratches.

Required Tools

Safety Glasses

Included Hardware

Socket Screw

L005650180

Connector Bolt

L005650114

• Fall 2017

INSTALLATION GUIDELINES

Screwdriver #2 Phillips Rubber MalletScrewdriver Roberson #4 & 5 Hex Wrench

Spacer

L005650117

Connector Nut

L005650117

Connecting Dowel

L004250004

Connecting Cam

L002250002

Leveler

L007250037

Assembly

STEP 1: Unpack and inspect individual pieces for damages or missing hardware

STEP 2: Pick a clean unobstructed area to assemble desk.

STEP 3 Orient left and right side panels, note that the holes for connectors face

underside of desk with the CONNECTING CAMS to the back.

a. install LEVELERS into T NUTS on the bottom of both side gables.

b. Install CONNECTING DOWELS in pre-drilled holes exposed near back edge.

STEP 4: Back panel, Install LEVELERS into T NUT inserts on the bottom of the

panel. Orient panel with holes for hardware to the underside of the desk.

STEP 5: Connect the side panels aligning the CONNECTING DOWELS with the

CONNECTING CAM. Turn cam to 2 o’clock position to secure. Do this to both sides.

Lay assembly down with outside facing up.

STEP 6: There are 6 exposed through holes with routered out “seats” for SPACERS.

Place each of the 6 SPACERS into these positions.

STEP 7: Pick up decorative panel, align installed nutserts on the back of this panel

with the spacers and place into position.

a. From under the assembly, insert the SOCKET SCREWS through exposed

holes and spacers into the T NUT inserts on the decorative panel, tighten

using hex wrench.

b. Stand assembly upright.

STEP 8: Insert the SOCKET SCEWS into the pre-drilled holes on the bottom of the

surface. Place top panel onto assembly aligning the CONNECTING DOWEL with the

CONNECTING CAMS. Turn cam to 2 o’clock position to secure.

STEP 9: This product is intended to be installed over a standard Licence shell.

Place into position and level both units together.

a. Drill a through hole using a 9.5mm bit though the side panel and gable

on the desk you attaching too. This hole should be centered front to back

and 12-15” from fl oor. Using the CONNECTOR BOLT & NUT, secure each

side and tighten with hex wrench.

•Pageglobalcontract.com 24

GLOBALContract

SPACER

BOLT

INSTALLATION GUIDELINES

3a

• Fall 2017

3b

4

6

5

7a

7b

8

7

Page • globalcontract.com25

9

GLOBALContract

L2GDP

NOTE: Open and assemble only one product

at a time to avoid a potential mix-up of parts

and hardware.

It is adviseable to assemble the unit on a

carpet to avoid scratches.

Required Tools

Safety Glasses

Included Hardware

Socket Screw

L005650180

Connector Bolt

L005650114

• Fall 2017

INSTALLATION GUIDELINES

Screwdriver #2 Phillips Rubber MalletScrewdriver Roberson #4 & 5 Hex Wrench

Spacer

L005650117

Connector Nut

L005650117

Connecting Dowel

L004250004

Connecting Cam

L002250002

Leveler

L007250037

Assembly

STEP 1: Unpack and inspect individual pieces for damages or missing hardware

STEP 2: Pick a clean unobstructed area to assemble desk.

STEP 3: Orient left and right side panels, note that the holes for connectors face

underside of desk with the quick fi x cams to the back.

a. install levellers into T nuts on the bottom of both side gables.

b. Install connecting dowels in pre-drilled holes exposed near back edge

and horizontally to connect lower shelf.

STEP 4: Back panel, Install levellers into T nut inserts on the bottom of the panel.

Orient panel with holes for hardware to the underside of the desk.

a. Install Connecting dowels into row of pre-drilled holes horizontally

approximately 8” from the top.

STEP 5: Pigeon hole lower shelf, line up connecting dowels on back panel to quick

fi x cams on lower shelf. Insure that Quick fi x cams are facing down, turn quick fi x

cam to 2 o’clock position to secure.

STEP 6: Connect the side panels aligning the connecting dowels with the quick fi x

cams. Turn quick fi x cam to 2 o’clock position to secure. Do this to both sides. Lay

assembly down with outside facing up.

STEP 7: There are 6 exposed through holes with routered out “seats” for Spacers.

Place each of the 6 spacers into these positions.

STEP 8: Pick up decorative panel, align installed nutserts on the back of this panel

with the spacers and place into position.

a. From under the assembly, insert the socket screws through exposed

holes and spacers into the T nut inserts on the decorative panel, tighten

using hex wrench.

b. Stand assembly upright.

a. place top panel onto assembly aligning the connecting dowels with the

quick fi x cams. Turn quick fi x cam to 2 o’clock position to secure.

STEP 11: This product is intended to be installed over a standard Licence shell.

Place into position and level both units together.

a. Drill a through hole using a 9.5mm bit though the side panel and gable

on the desk you attaching too. This hole should be centered front to back

and 12-15” from fl oor. Using the Connector Bolt cap and Connector Nut,

secure each side and tighten with hex wrench.

STEP 9: On lower shelf, install connecting dowels and wood dowels. Starting from

left to right , connecting dowels will be used for the fi rst divider, the second panel

will use wood dowels. Continue with pattern.

a. On the top of the shelf dividers, install wood dowels into pre-drilled holes

for divider 2 & 4.

STEP 10: Insert the connecting dowels into the pre-drilled holes on the bottom of

the surface. Note that positions 2 & 4 will connect with wood dowels, do not install

connecting dowels in these corresponding locations.

•Pageglobalcontract.com 26

GLOBALContract

INSTALLATION GUIDELINES

3a

• Fall 2017

3b

4

6

5

8a

8b

7

BOLT

SPACER

10

Page • globalcontract.com27

11

GLOBALContract

L2CRSxxxx

NOTE: Open and assemble only one product

at a time to avoid a potential mix-up of parts

and hardware.

It is adviseable to assemble the unit on a

carpet to avoid scratches.

Assembly

STEP 1: Unpack and inspect individual pieces for damages or missing hardware

STEP 2: Pick a clean unobstructed area to assemble desk. It is advisable to assembly of this product upside down.

INSTALLATION GUIDELINES

Required Tools

Safety Glasses Rubber Mallet LevelScrewdriver #2 Phillips

Included Hardware

Blum Connector

Screw L005650060

Blum Connector

(installed) L005650061

Leveler

L007250037

• Fall 2017

“T” Nut Insert

L007250039

STEP 3: Determine position of left and right gables with exposed Blum connectors

facing inside of assembly.

a. install levellers into the T nut inserts, use mallet to install in pre-drilled

holes on the bottom of the gables.

b. On the top edge, install Blum Connector screws into the pre-drilled

holes. Since the Gables can be used either left or right, 2 holes are pre drilled, select the hole that is closest to underside of completed assembly

to insure proper alignment.

STEP 4: Full Modesty Panel, Install Blum Connector screws in pre-drilled holes on

the top edge and both sides.

STEP 5: Connect gables to the modesty panel by lining up Blum connector screws

with the Blum connectors. Turn the screw on Blum Connector ¼ turn, do not over

tighten.

STEP 6: Place worksurface top face down on clean unobstructed area. Pick up

chassis assembly and line Blum connector screws to the exposed Blum Connectors

on the bottom of the surface. Turn the screw on Blum Connector ¼ turn, do not

over tighten.

STEP 7: Turn product upright. When fi nal position has been located, level the unit

with the levellers installed on both gables.

FULL MODESTYWORKSURFACE

GABLE

GABLE

Installation For Similar Products

L2DBxxxx L2DWxxxxxx

•Pageglobalcontract.com 28

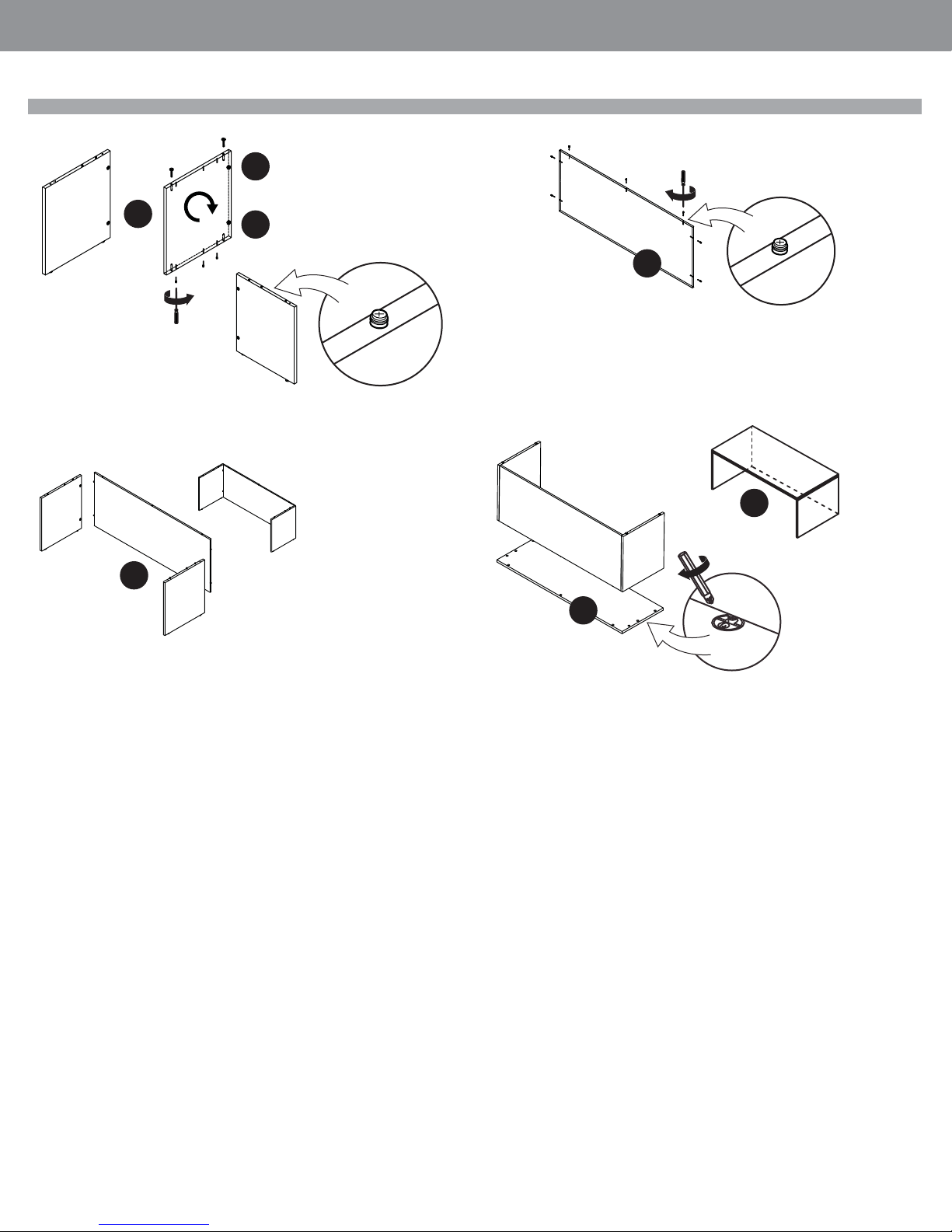

GLOBALContract

INSTALLATION GUIDELINES

a

• Fall 2017

LEFT HAND

3

b

RIGHT HAND

Modesty Panel

4

7

5

6

Back Panel

top Underside

Page • globalcontract.com29

Loading...

Loading...