Global Contract Diet Installation Manual

Installation Manual

2017

ISO 9001:2015OHSAS 18001:2007 ISO 14001:2015

REVISED: FALL 2017

Visit us on the Internet at globalcontract.com • (416) 739-5000

Global Contract Inc. 565 Petrolia Road

North York, Ontario, M3J 2X8

GLOBALContract

TABLE OF CONTENTS

• Summer 2017

Panels

Panel Connector

Off Module panel Connector

Wall Adapter

Diet to Boulevard Slot Connector

Diet to Boulevard Connecting Kit

Diet Freestanding Panel Mobile Kit

Diet Panel Gap Filler Installation

90 Degree Confi gurations

Electrical

Diet Electrical

Diet Electrical Components

Diet Electrical Installation

Diet Communication Installation

Cable management

Worksurfaces

Worksurface Support

Worksurface Universal Flat Bracket

Gable Leg

Pedestal Bracket / Corner Plate

Transaction Bracket

Combining Diet and Boulevard Worksurfaces

Off-Module Cantilever

P.03

3

4

5

6

8

9

10

11

P.12

12

13

14

16

18

P.20

20

21

22

23

24

25

26

Storage

Storage

Open Shelf

Off - Module Shelf

DSADA Easy-Up Diet Overhead

P.27

27

28

29

30

Please contact your Global Contract Service Representative at 416-739-5000 for

any questions or concerns.

NOTE: Any alterations to listed components will void the manufacturer’s warranty.

The manufacturer will not be responsible for any damage or bodily harm caused

by alterations in accordance with national or local electrical codes and manufac-

Page • globalcontract.com2

turer’s specifi cations. In accordance with the manufacturer’s policy of continual

product improvement, the product presented in this document is subject to

change without notice or obligation.24

GLOBALContract

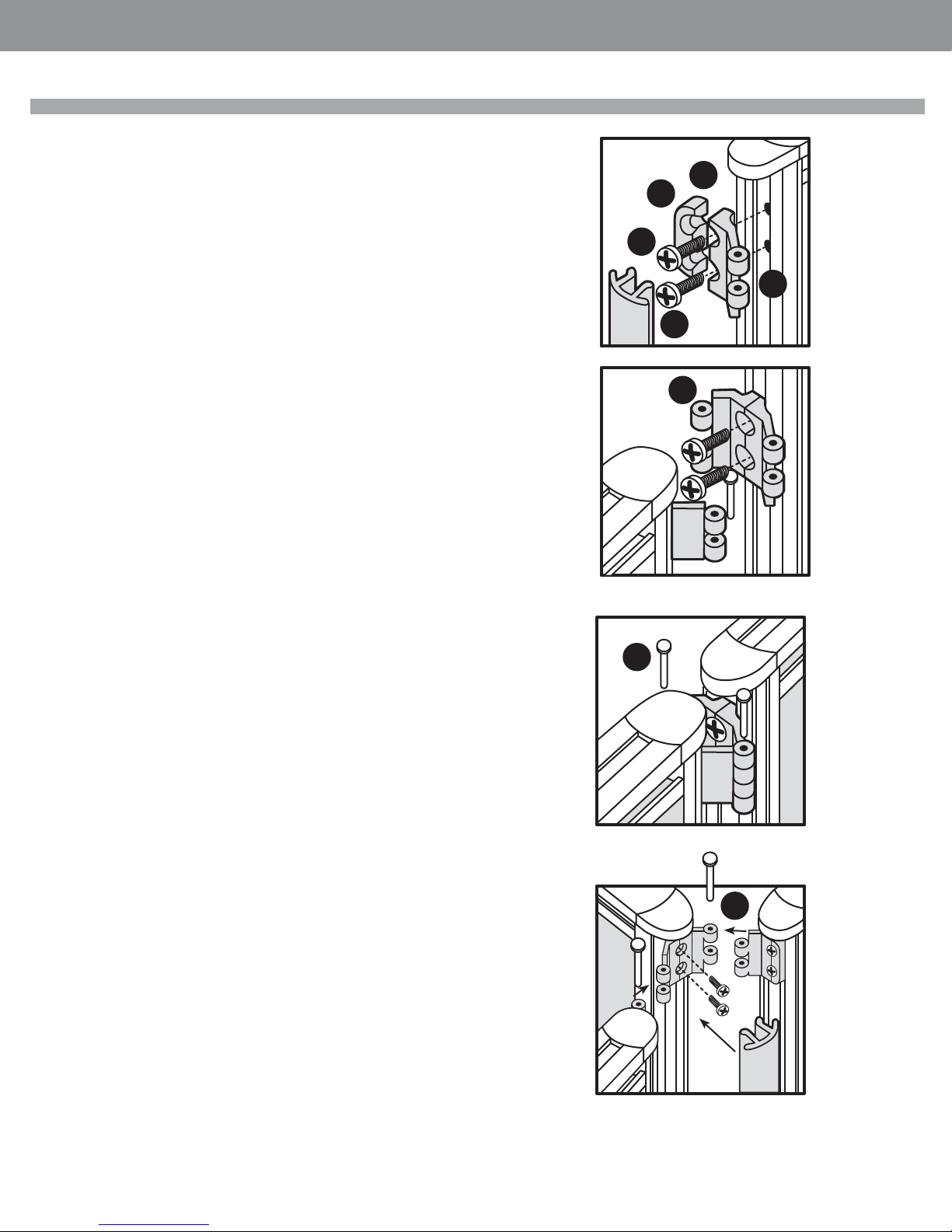

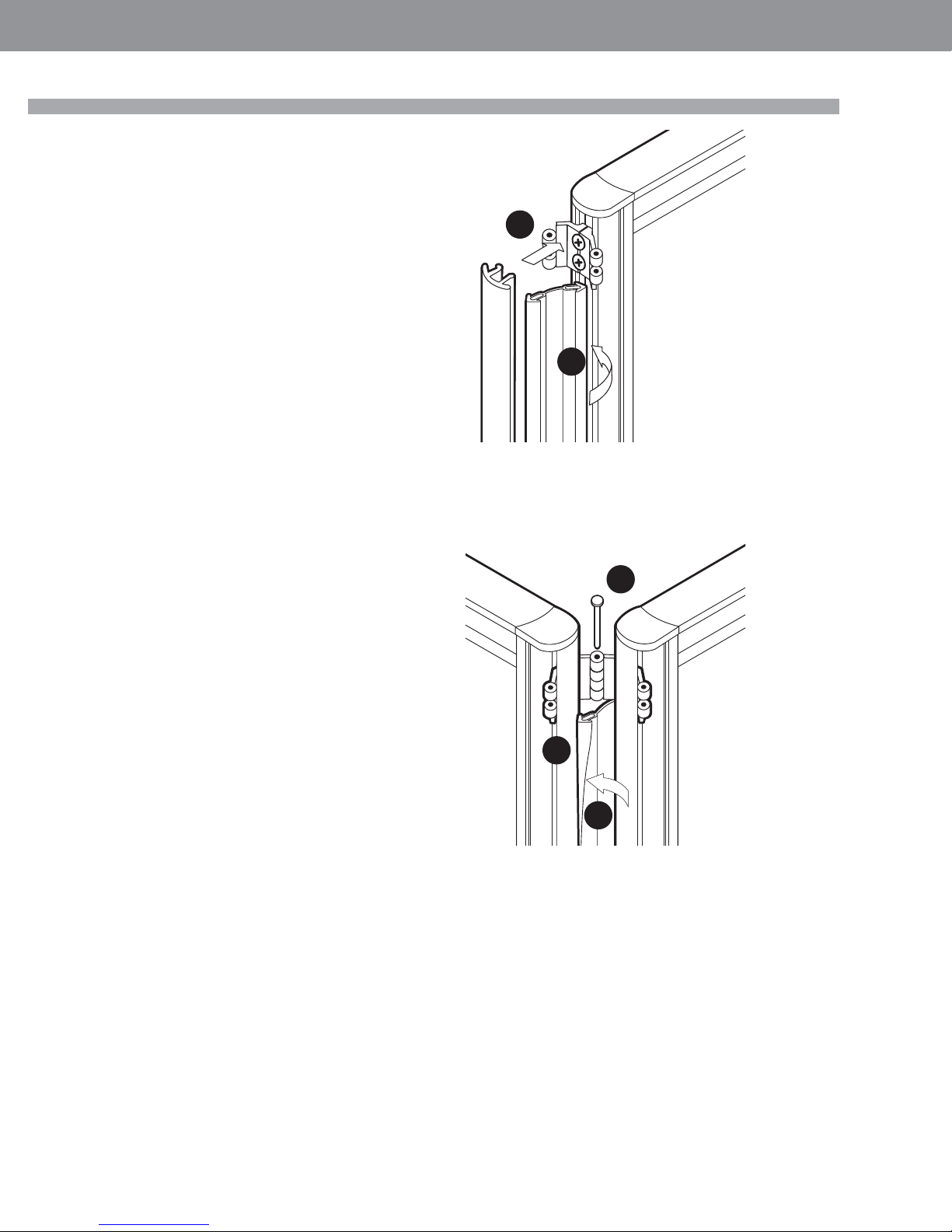

Panel Connector

Every panel ships with a connecting kit comprising hinges, spacers, screws and hinge

pins. Not all pieces included in the connecting kit might get used with every panel (connecting two stand alone panels at 90°, for example, will only require installation of two

hinge / spacer sets at the top and bottom of each panel). The remaining pieces included

in the connecting kit should be stored on site to be available for future reconfi gurations.

Location of connecting hinge / spacer and hinge / hinge set on panels is predetermined

by location of double holes, pre-drilled in panel verticals. There are pairs of holes located

always at the panels’ bottom and top. In addition, a 54” high panel will have a pair at 42”

height (to connect to 42” high adjacent panel) and a 66” high panel will have additional

pairs at 42” and 54” height (to connect to 42” and 54” adjacent panels).

NOTE: When connecting 66” high partly glazed panels, use additional set of connectors

at 42” height.

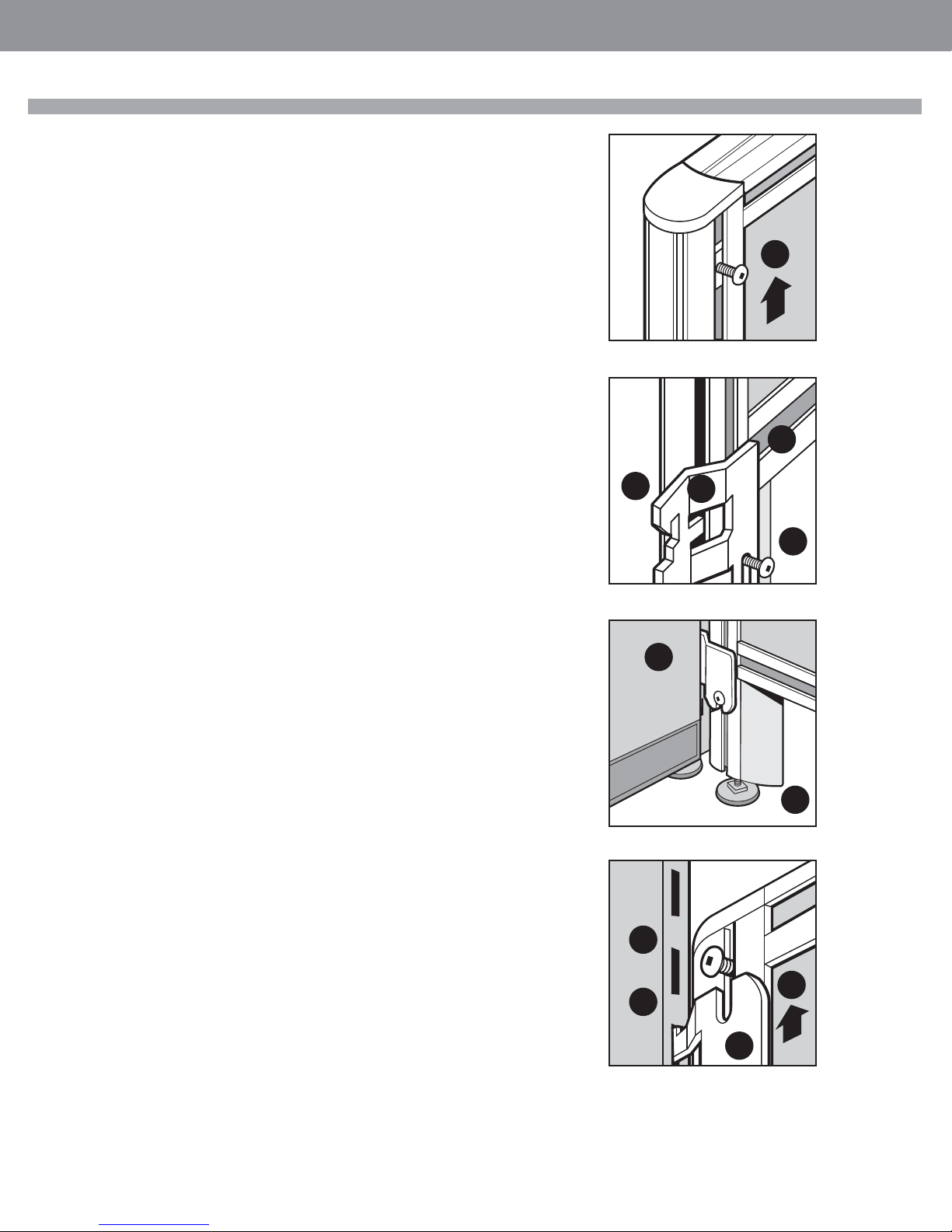

In order to install panel connectors to connect two panels at fl exible angle,

STEP 1: remove vertical edge trim,

STEP 2: position spacer A and hinge B over pre-drilled holes at desired height,

STEP 3: secure with two supplied screws (Do not over tighten!) and snap the

vertical edge trims back in place.

Set the panels to desired angle. Insert top and bottom pins. In order to connect two

straight panels (180°),

• Summer 2017

INSTALLATION GUIDELINES

2

A

3

B

1

4

STEP 4: Remove vertical edge trims, position two hinges over pre-drilled holes at

desired height and secure with two supplied screws on both panels. Do

not over tighten! Snap vertical edge trims back in place.

STEP 5: Level the fi rst panel, position the second panel so that all hinges overlap

and insert four pins (two at the top; two at the bottom).

STEP 6: To connect 3 panels in a 90°, 3 way confi guration, remove panel vertical

edge trims and install two spacer / hinge sets (top and bottom) on both

wing panels.

Install two hinge / hinge sets (top and bottom) on the panel that is going

to be installed between the wing panels.

Replace vertical edge trims, level the fi rst panel, position wing panels so

that all hinges overlap and insert four pins (two at the top; two at the

bottom) as you go along.

STEP 7: To connect three panels in a 120°, three-way confi guration (or four

panels in a 90°, four-way confi guration.

Remove panel vertical edge trims and install two hinge / hinge sets (top and bottom) on all panels.

Replace vertical edge trims, level the fi rst panel, position remaining panels so that

all hinges overlap and insert four pins (two at the top; two at the bottom) as you

go along. Level the whole panel assembly.

5

6

•Pageglobalcontract.com 3

GLOBALContract

INSTALLATION GUIDELINES

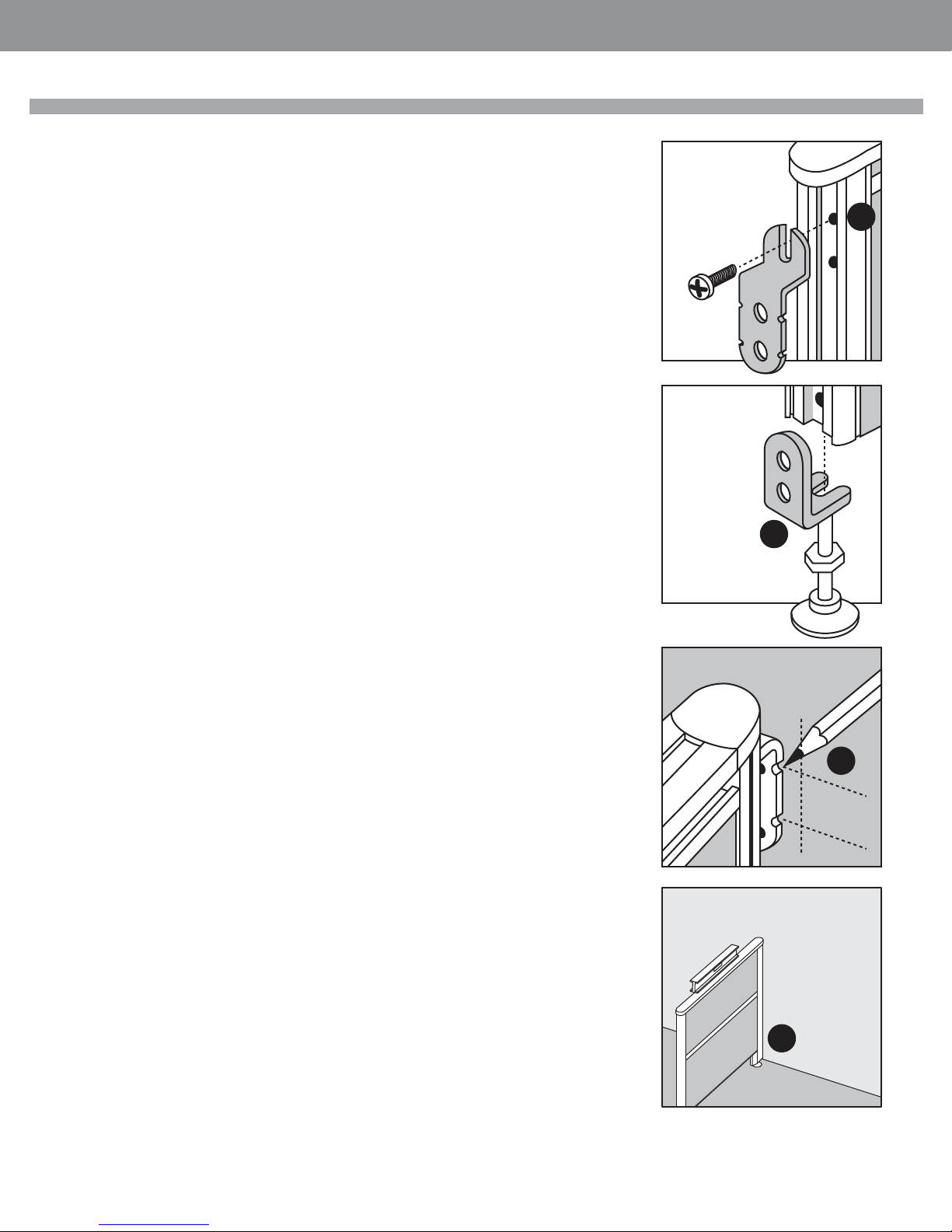

Off-Module Panel Connector

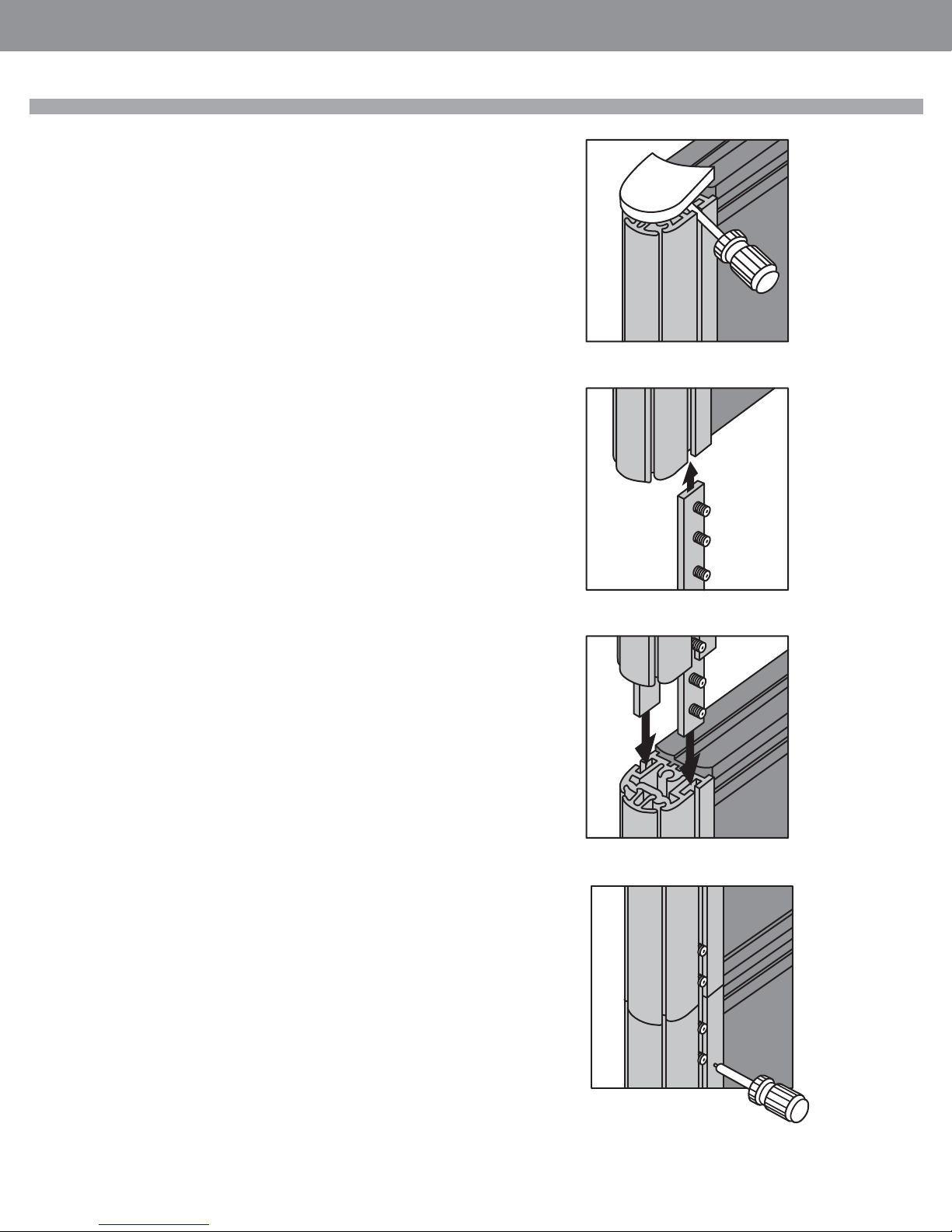

To connect two panels in an off-module, “T” confi guration remove panel vertical edge

trim and remove all connectors and spacers.

STEP 1: Secure top off-module bracket to panel vertical with supplied screws.

STEP 2: Drive levelers on the second panel all the way in and hold the panel in a tilted

position. Slide it carefully over the top bracket as illustrated, while making sure that the

bracket is seated inside of the top horizontal rail.

STEP 3: Bring the panel carefully into a vertical position and adjust its fi nal location.

STEP 4: Engage bottom off-module bracket in bottom horizontal panel rail.

STEP 5: Secure with supplied screws to panel vertical and level the whole assembly.

STEP 6: Install two set screws in the top bracket to prevent the top bracket from sliding

sideways and tighten carefully with supplied allan key. If the off-modularly connected

panel is higher then the perpendicular one, cut a vertical edge trim (removed earlier

from panel) and snap it onto the panel’s vertical, between top corner cap and top of the

upper, off-module bracket. If the perpendicular panel does not have base cable manager

installed, the bottom of the off-module panel will be exposed. In such instances cut 4

5/8” long pieces from the vertical edge trim and snap it onto the panel’s vertical at

the bottom.

• Summer 2017

Page • globalcontract.com4

GLOBALContract

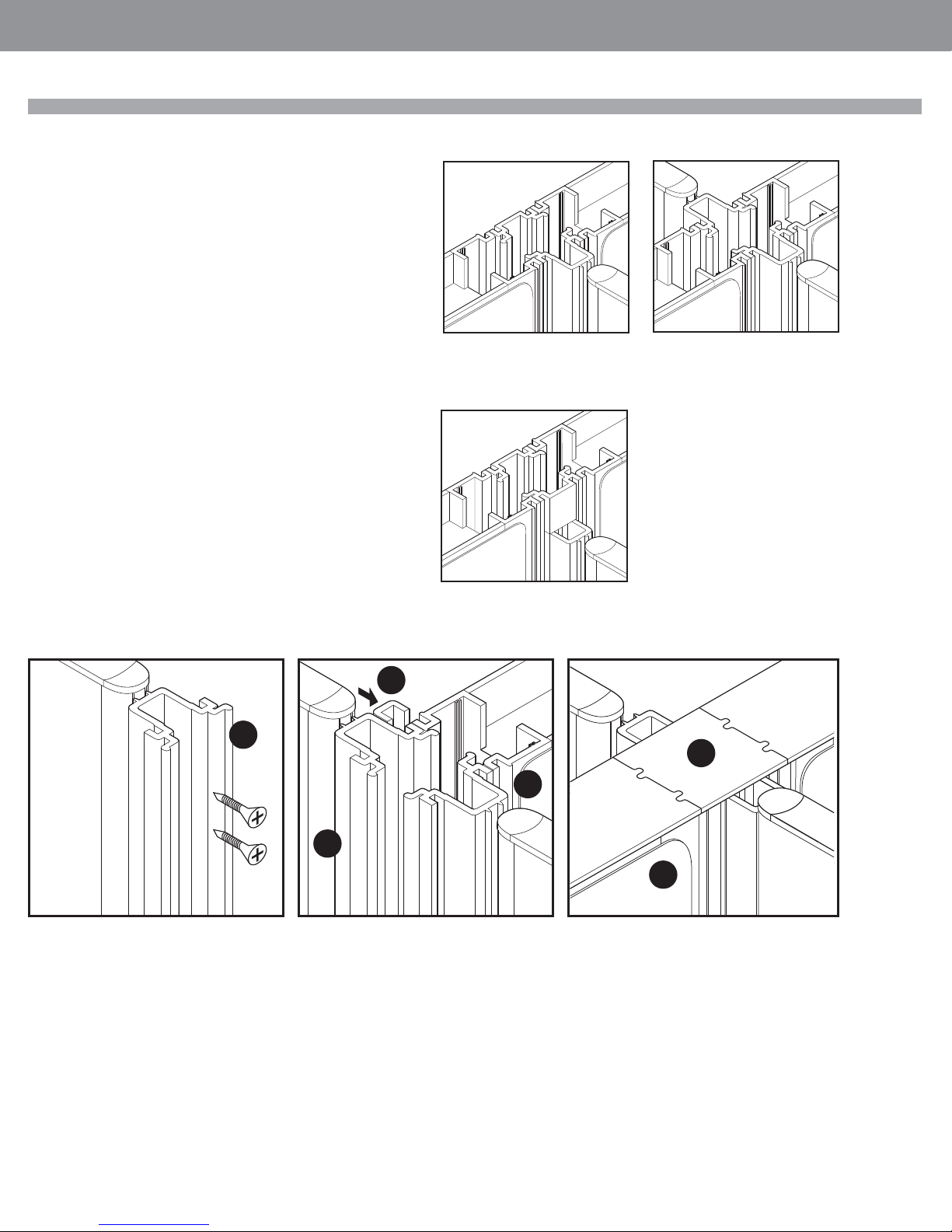

Wall Adapter

Remove panel vertical edge trim on the side facing the wall.

STEP 1: Secure temporarily top bracket to panel vertical member by driving supplied

screw into top hole.

STEP 2: Remove leveler, add supplied nut and lock the bottom bracket between the nut

and the bottom of panels vertical member.

STEP 3: Position levelled panel against the wall and mark the wall (both top and bottom

brackets have notches on either side to indicate anchor location). Use level to mark vertical line on the wall where centre of the panel is going to be, and install wall anchors, not

supplied. The choice of wall anchors depends on the construction and material of the

wall. ( ie. wood, steel, drywall etc..)

Loosen screw holding top bracket just enough to be able to slide the bracket down.

Drive the leveler with the nut out by 25 mm and slide the bottom bracket out.

Secure both brackets to the wall anchors.

STEP 4: Position panel with the screw over the top bracket while making sure that the

leveler is located within the bottom bracket. Adjust leveler while making sure that the top

bracket is seated behind the top screw head.

• Summer 2017

INSTALLATION GUIDELINES

1

STEP 5: As soon as the top screw is fi rmly seated in the top bracket level the panel (using leveler on the opposite side) and tighten the nut on the leveler to secure the bottom

bracket.

2

3

5

•Pageglobalcontract.com 5

GLOBALContract

INSTALLATION GUIDELINES

Diet to Boulevard Slot Connector

The kit consists of : 2 brackets

2 screw anchors

2 # 10-24x3/8” pan head machine screws

2 # 10 lock washers

Ensure that the complete BOULEVARD panel run is level before proceeding

with connecting perpendicular Diet panels.

• Summer 2017

STEP 1: Slide one screw anchor into panel’s vertical groove and secure it temporarily

below the panel’s top corner cap.

STEP 2: Install the bottom bracket with downward pointing hooks.

STEP 3: Align top of the bottom bracket with the top of the horizontal gap in panel’s bottom rail as illustrated. ensure that both bracket tabs (A) are engaged behind aluminum

lip if panel’s vertical frame member.

STEP 4: Slide one screw with screw anchor up into panel’s vertical groove, into bracket’s

slot and secure by tightening the screw.

STEP 5: Lift the Diet panel and hook it with the secured bottom bracket into slots on

perpendicular Boulevard panel.

STEP 6: Level Diet panel.

STEP 7: Align top bracket’s upward pointing hooks with slots in perpendicular Boulevard

panel while making sure that both bracket’s tabs (B) are engaged behind aluminum lip of

Diet panel’s vertical frame member.

STEP 8: Slide the bracket up until it’s hooks are fully engaged in Boulevard panel slots.

STEP 9: Secure the bracket by tightening the top screw.

1

3

2

A

4

5

Page • globalcontract.com6

6

9

8

7

B

GLOBALContract

Diet to Boulevard Slot Connector

STEP 1: Remove panel’s top corner cap by carefully tapping the underside of the cap

through side vertical grooves.

STEP 2: Slide over panel connecting brackets halfway into over panel’s vertical groove

as illustrated.

Tighten only the top set screws in order to keep the brackets in place while leaving the

remaining set screws loose. (Ensure that the two lower set screws are not protruding

through the bracket as these would interfere with base panel’s vertical frame.

STEP 3: Slide the over panel with connecting brackets into the vertical grooves on the

base panel as illustrated.

STEP 4: Push the over panel down from the top while tightening remaining set screws

in all connecting brackets.

• Summer 2017

INSTALLATION GUIDELINES

•Pageglobalcontract.com 7

GLOBALContract

INSTALLATION GUIDELINES

Diet to Boulevard Connecting Kit

Diet - to - Boulevard connecting kit typically consists of two extruded aluminum

profi les. Boulevard strips, screws to secure connecting extruded profi le to Diet panel

and a cap.

There are three basic confi gurations (please note the position and the use of ‘Connector and Filler profi les):

STEP 1: Begin the actual installation by securing Connector profi le to Diet panel’s vertical with supplied screws. Note the asymmetrical shape of connector extrusion and

ensure that the larger side of the connector detail must be on the left side when facing

panel’s vertical extrusion or it would not engage with Boulevard panel interface.

STEP 2: Place Diet-Connector subassembly next to Boulevard panel. Ensure that

bottom of the Diet-BLVD Connector rests on top of self leveling feature at the bottom

of BLVD panels.

“T” (even height) “X” (even height

• Summer 2017

STEP 3: Install Boulevard capture strips.

STEP 4: Install Boulevard capture strips.

STEP 5: Install the next Boulevard panel or Aluminum vertical end trim.

STEP 6: Finish by installing top cap (injection molded cap for Boulevard 1 and 2;

aluminum cap for Boulevard System 3)

3

1

“T” (uneven height)

“X” uneven height requires one

more fi ller profi le

6

4

Page • globalcontract.com8

2

5

GLOBALContract

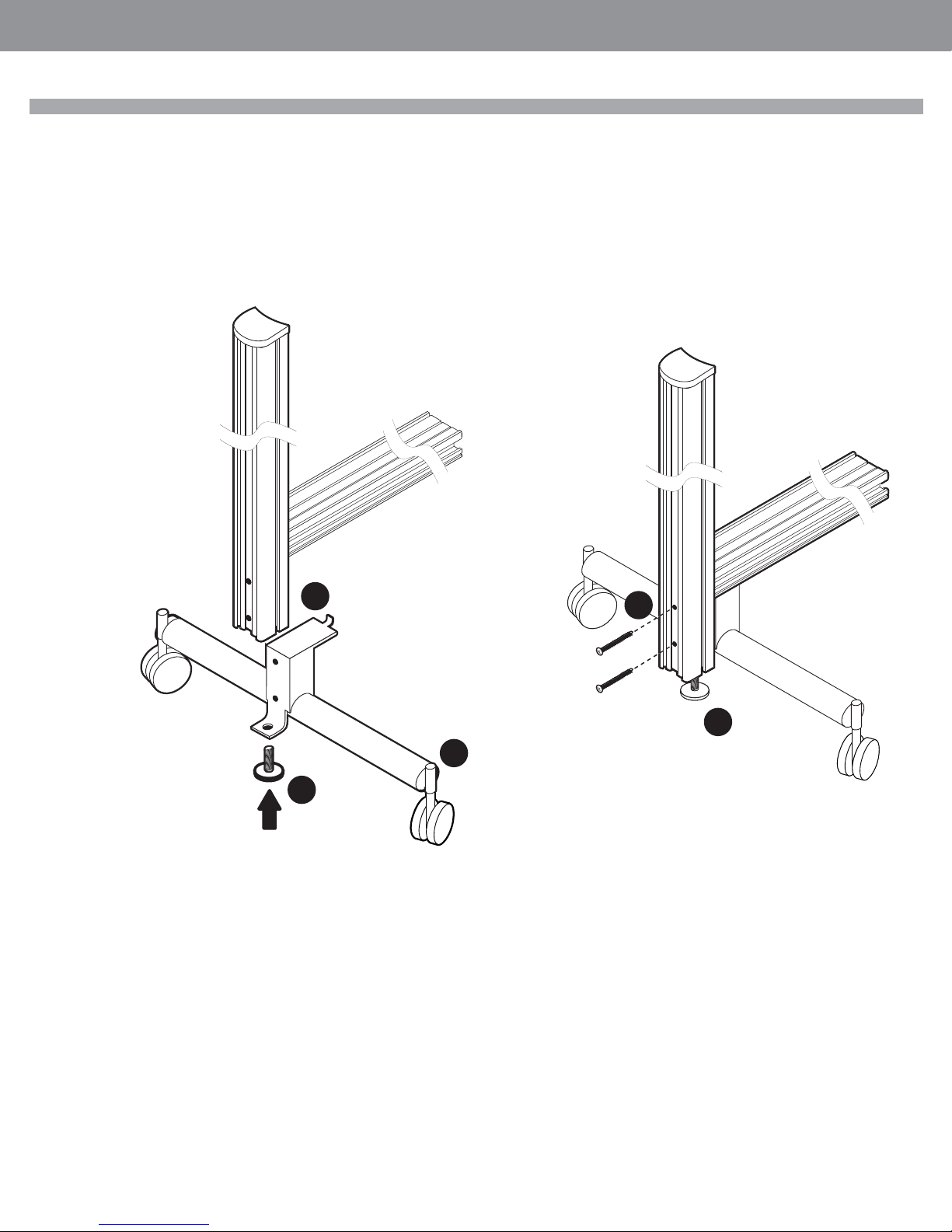

Diet Freestanding Panel Mobile Kit

STEP 1: Remove levelers from the bottom of the panel vertical extrusion.

STEP 2: Align the bracket so the legs with the casters run perpendicular to the length

of the panel.

STEP 3: Slide the bracket up until it fi ts into the horizontal bottom rail.

STEP 4: Remove the PVC cover and screw the bracket to the panel vertical through

the second bottom hole.

STEP 5: Re-attach the levelers.

• Summer 2017

INSTALLATION GUIDELINES

3

4

5

5

2

1

•Pageglobalcontract.com 9

GLOBALContract

INSTALLATION GUIDELINES

Diet Panel Gap Filler Installation

The Diet gap fi ller is installed into the groove between panel’s aluminum vertical frame

member and extruded PVC end trim. It is the same gap through which panel hinge

connectors protrude. The gap fi ller fi lls the gap between Diet panels, from the bottom

edge of the top hinge connector to the top edge of the bottom connector. If there are

more then two hinges connecting the two adjacent panels then trim the length of the

fi ller so that it fi lls the gaps between top and the middle hinge and, again, between the

middle hinge and the bottom hinge.

STEP 1: Hold the fi ller so that one arm of the ‘arrow’ is engaged behind the front edge

of panel’s aluminum vertical frame member.

STEP 2: Snap the extruded PVC end trim onto the panel’s vertical frame member while

ensuring that the second arm of the ‘arrow’ remains engaged behind the extruded

PVC trim.

• Summer 2017

2

STEP 3: Connect panels with connector pins.

STEP 4: Arrange the opposite end of the fi ller so that one ‘arrow’ is engaged along the

full height between the aluminum vertical frame member and extruded PVC end trim.

STEP 5: Proceed from top of the fi ller and tack the other ‘arrow’ behind the aluminum

frame member and the extruded PVC end trim.

1

3

4

Page • globalcontract.com10

5

Loading...

Loading...