Global Contract Compile Installation Manual

Compile

Installation

2017

Manual

ISO 9001:2015OHSAS 18001:2007 ISO 14001:2015

REVISED: FALL 2017

Visit us on the Internet at globalcontract.com • (416) 739-5000

Global Contract Inc. 565 Petrolia Road

North York, Ontario, M3J 2X8

GLOBALContract

TABLE OF CONTENTS

• Summer 2017

Compile

Panels

Quick Connect Clips

Lock Clips

Panel Trims

CAPAS Privacy Glass

Post Base Covers

Electrical

Power Distribution Harness

Installing Through Corners

Ceiling Feed

Post Extension

Raceway Covers without Knockouts

Raceway Covers with Knockouts

Raceway Knockout Covers

Cantilevers Corner Brackets

Mid Span Support Bracket

Worksurface Mounting Option

CHMEG Metal End Gable

Centre Mounted Overhead

Pedestal Brackets

Overhead Storage Bins

Low Profi le Shelves

Tackboards

Load Bar

P.01

ADA Overhead

Mid Run Panel Removal & Top Horizontal Replacement

Core Replacement

Chicago J-Box

01

Module replacement

02

End Panel

02

Accessory Retainer

02

03

04

Required Tools

04

Safety Glasses

05

Wrench

05

Allen Key

06

Flathead Screwdriver

06

Phillips Screwdriver

07

Measuring Tape

07

07

08

08

08

09

10

11

12

13

14

14

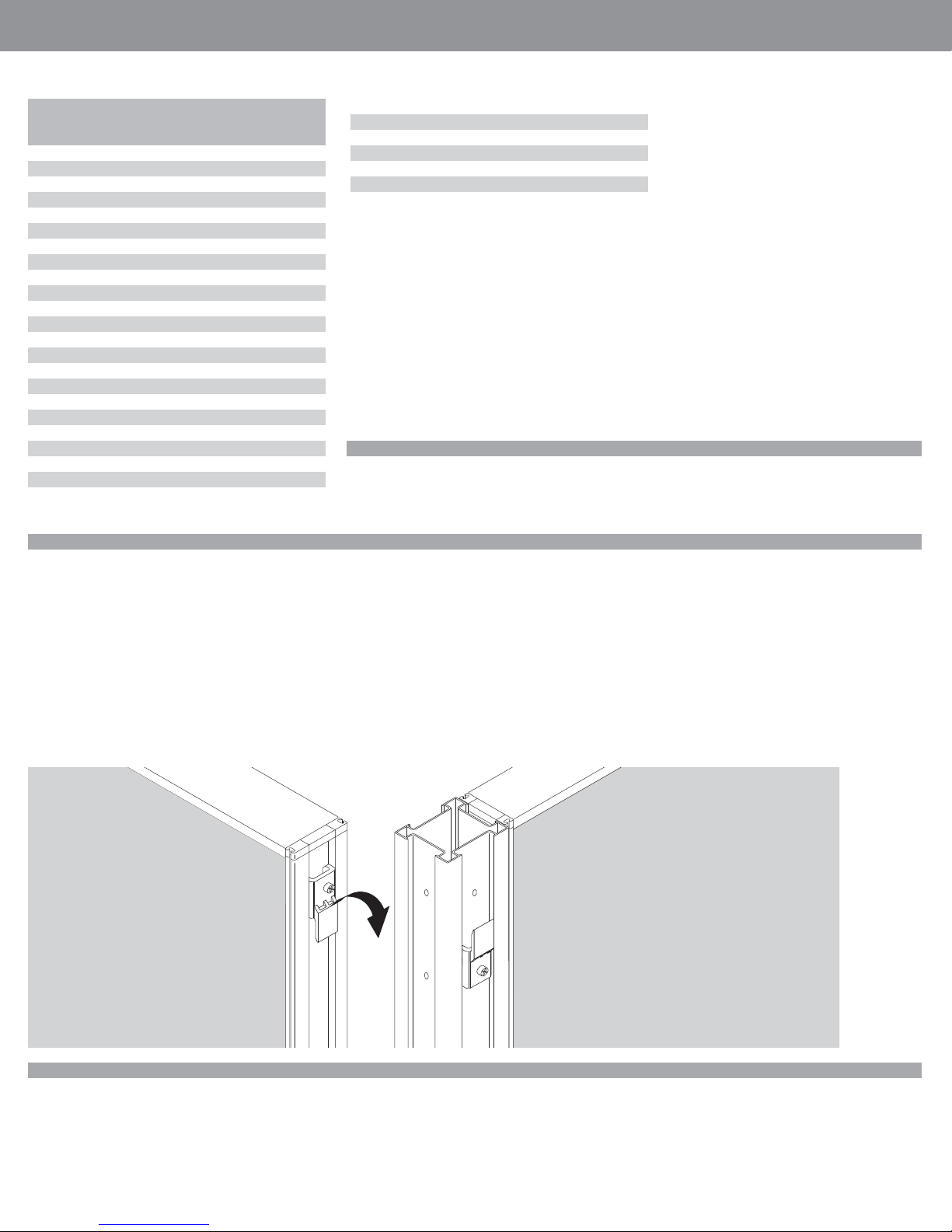

Panels

PANELS come from the factory with the “Quick Connect” clips pre-installed on both

sides of the panels. One side is pointing up and the other side is pointing down.

UNIVERSAL CORNER POSTS come from the factory with the “Quick Connect”

clips pre-installed on 3 sides. One side is pointing down, and 2 adjacent sides are

pointing up.

Slide connections together, and press fi rmly in place. Do not use hammer to try

to secure panels.

Leveling Tip:

• If panels don’t line up exactly, please lower the glide on the lower panel to level

the panels.

15

15

16

16

17

18

19

Corner Post Tips:

• Align the “Quick Connect” clips on the fi rst panel of a run so both sides point UP.

This will allow the Corner Post to be dropped onto one side, and the adjacent

panels to also be dropped on. Then the rest of the panels in the run can be easily

dropped onto each other.

• For 2 ways, remove one set of clips by loosening the set screw, and slide up and

out, through the channel. Snap in 2 Post Trim Strips to fi nish 2 open sides.

• For 3-ways, snap in Post Trim Strip to fi nish 4th side.

• For 4-ways, install the clips on the 4th side facing up, so the panel can be

dropped on.

Please contact your Global Contract Service Representative at 416-739-5000 for

any questions or concerns.

NOTE: Any alterations to listed components will void the manufacturer’s warranty.

The manufacturer will not be responsible for any damage or bodily harm caused

by alterations in accordance with national or local electrical codes and manufac-

Page • globalcontract.com1

turer’s specifi cations. In accordance with the manufacturer’s policy of continual

product improvement, the product presented in this document is subject to

change without notice or obligation.

GLOBALContract

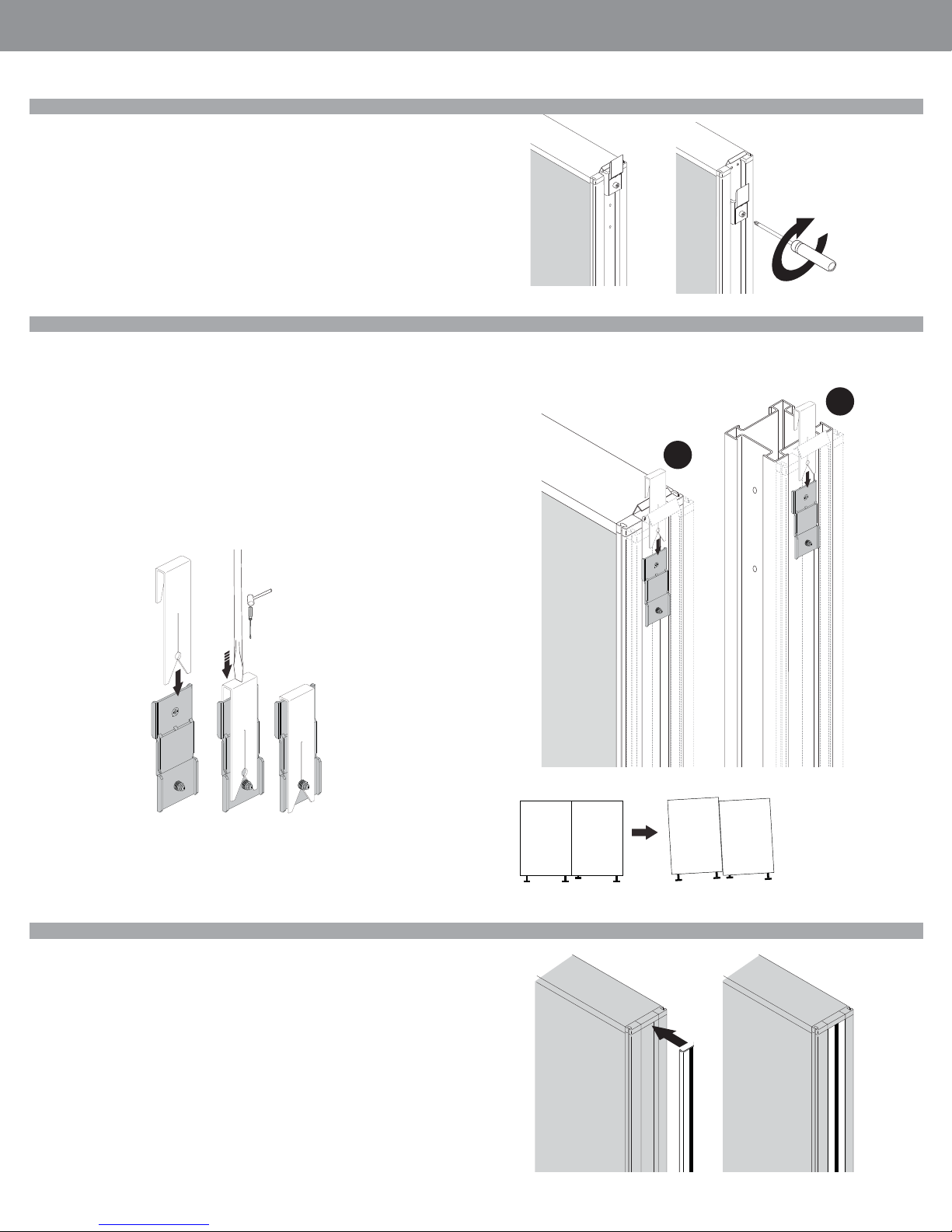

Quick Connect Clips

Add or remove “Quick Connect” clips with a Phillips screwdriver, by loosening the

screw enough to allow the clip to slide freely.

To remove clip, lift tab on top of panel and slide clips out of groove.

To change clip orientation, use the following hole confi gurations.

• Top hole to have clip point down.

• Bottom hole to have clip point up.

Lock Clips

Post: (a)

Put the lock clip in such a way that the short end of the clip is over the top connector

and the longer side is facing the panel (even if it’s on an angle). Using a mallet and a

fl at screwdriver, hammer the lock clip down until you feel it catch the lower screw.

Between Panels: (b)

Put the lock clip in such a way that the short end of the clip is over the top connector

and the longer side is facing the panel. Using a mallet and a fl at screwdriver, hammer

the lock clip down until you feel it catch the lower screw.

• Summer 2017

INSTALLATION GUIDELINES

a

b

Releasing the lock clip:

Pull the leveler (sdjustor) downat the panel that it’s connector is on top and push the

other panel down.

Panel Trims

Panel / Post Trims can snap or slide into place, to fi nish panel End of Runs, 2-way,

3-way and step down-variable height connections.

NOTE: End of Run Trims are approximately 5” longer than Post Trims.

•Page globalcontract.com 2

GLOBALContract

INSTALLATION GUIDELINES

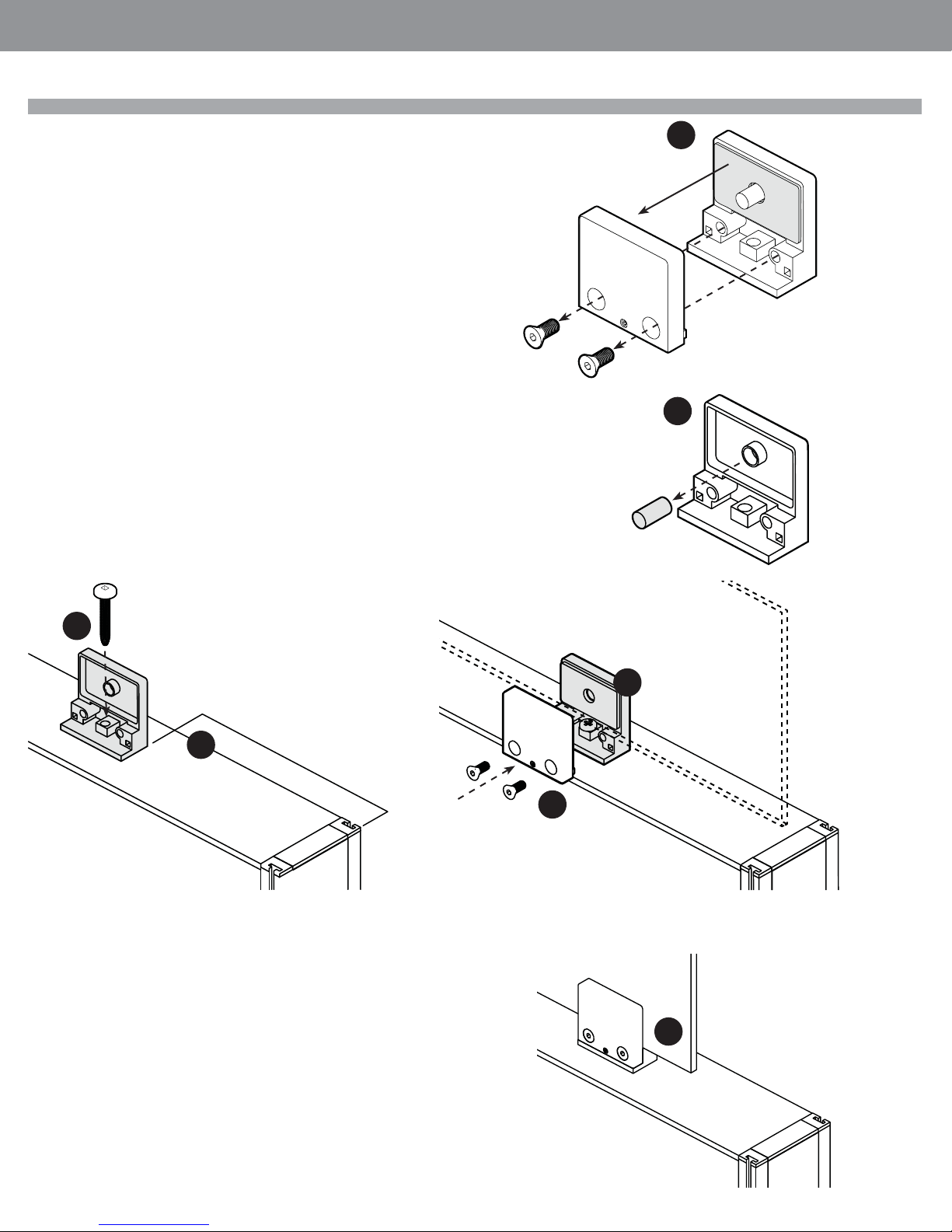

CAPAS Privacy Glass

STEP 1: Open the clamps.

STEP 2: Remove the pin.

STEP 3: Measure 5” from the edge.

STEP 4: Drill directly into the top of the panel. (use the provided #10 1 1/2” pan head

square drive type A screw.)

STEP 5: Use the thicker rubber pad if two different size pads are provided in the box.

STEP 6: Leave the clamps loose, carefully slide the glass in and then tighten both

clamps evenly so the glass is snug and vertical. the middle set screw will control the

pitch.

• Summer 2017

1

2

4

5

3

5”

6

6

Page • globalcontract.com3

GLOBALContract

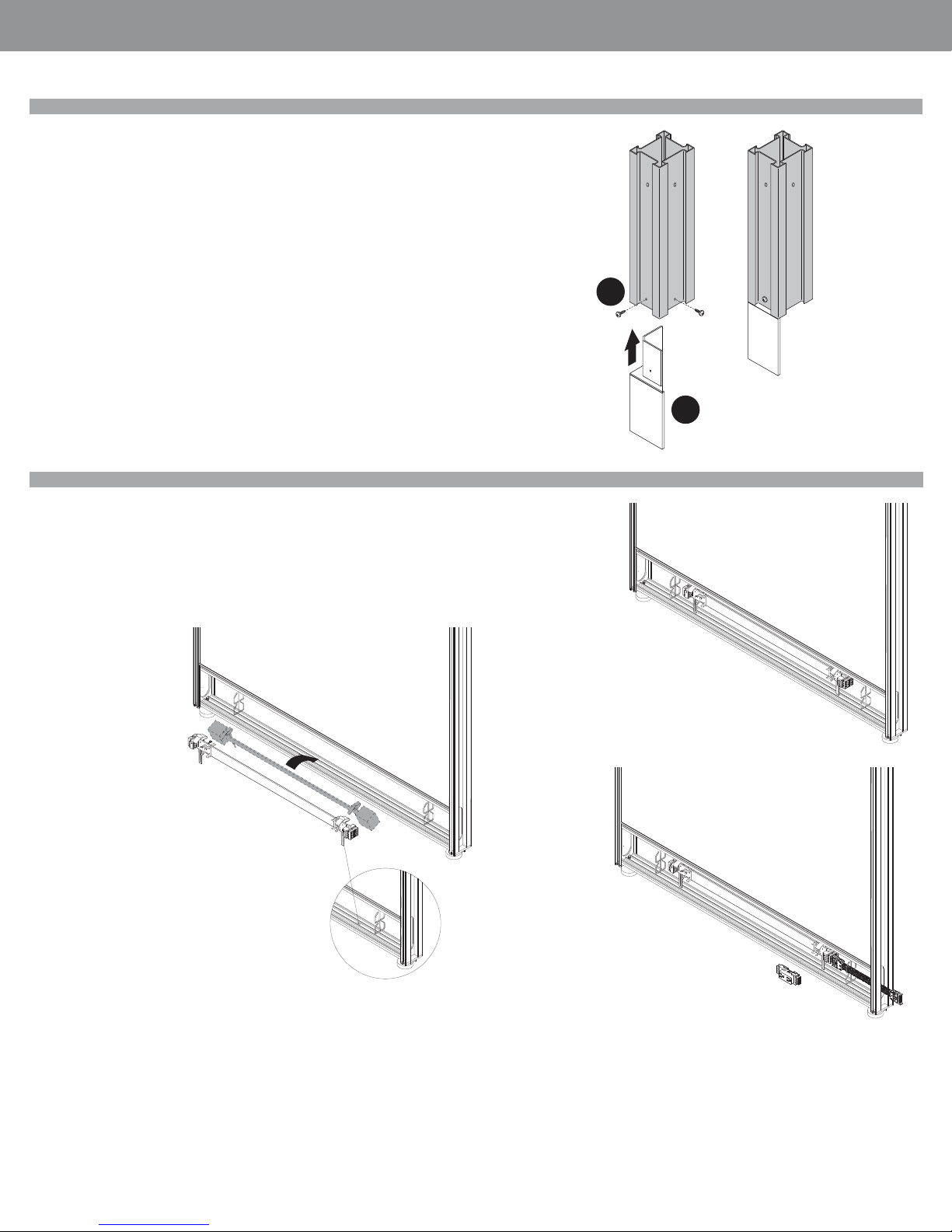

Post Base Covers

STEP 1: Slide Post Base Cover into bottom of Universal Corner Post.

STEP 2: Secure into place on 2 sides, with two small black screws.

• Summer 2017

INSTALLATION GUIDELINES

2

1

Electrical - Adding Power Distribution Housing

Align Power Distribution Housing so the bottoms tabs drop into the pre-cut slots in the

panel base. Be sure to align the spring clips on top, so they are facing you.

Rotate Power Distribution Harness into place until the spring snap securely into

place.

Included cable managers can be slid to the side, or removed.

•Page globalcontract.com 4

GLOBALContract

INSTALLATION GUIDELINES

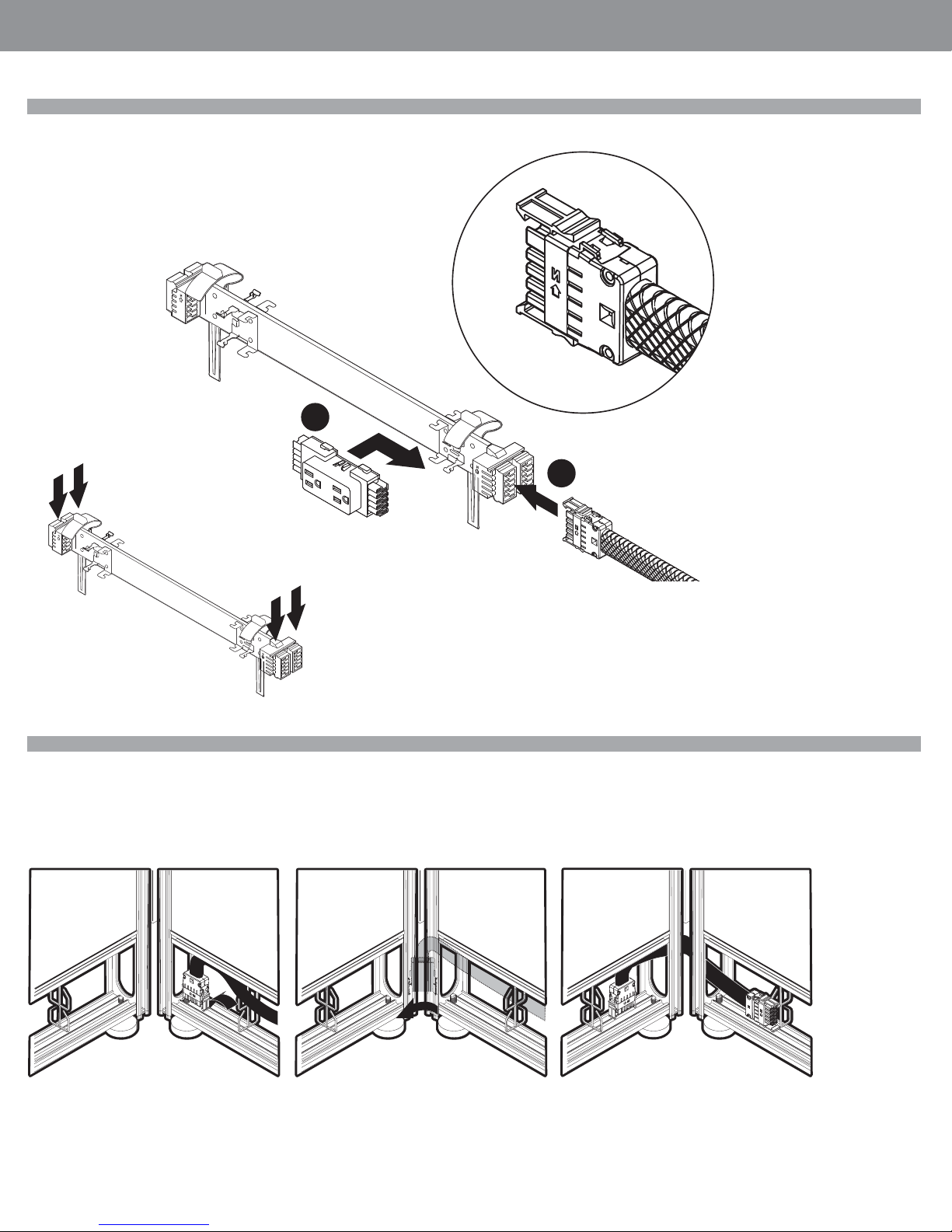

Electrical - Power Distribution Harness and Duplexes

STEP 1: Plug Jumper into Power Distribution Harness, until it clicks fi rmly into place.

The arrow above the embossed “N”, should be pointing up.

STEP 2: Slide Duplex into place, until it clicks fi rmly into place.

2

• Summer 2017

1

Power Distribution Harness has two

ports on each side to plug in additional

Jumpers or Ceiling Feeds.

Electrical - Installing Through Corners

Installation Tip: When routing jumpers around corners, in a 2-way, 3-way or

4-way connection.

Bend connection of 17” fl exible Mesh Jumper downward, at a 90 degree angle.

Slide connector through opening and pass through openings in both panels.

Straighten connector.

Page • globalcontract.com5

GLOBALContract

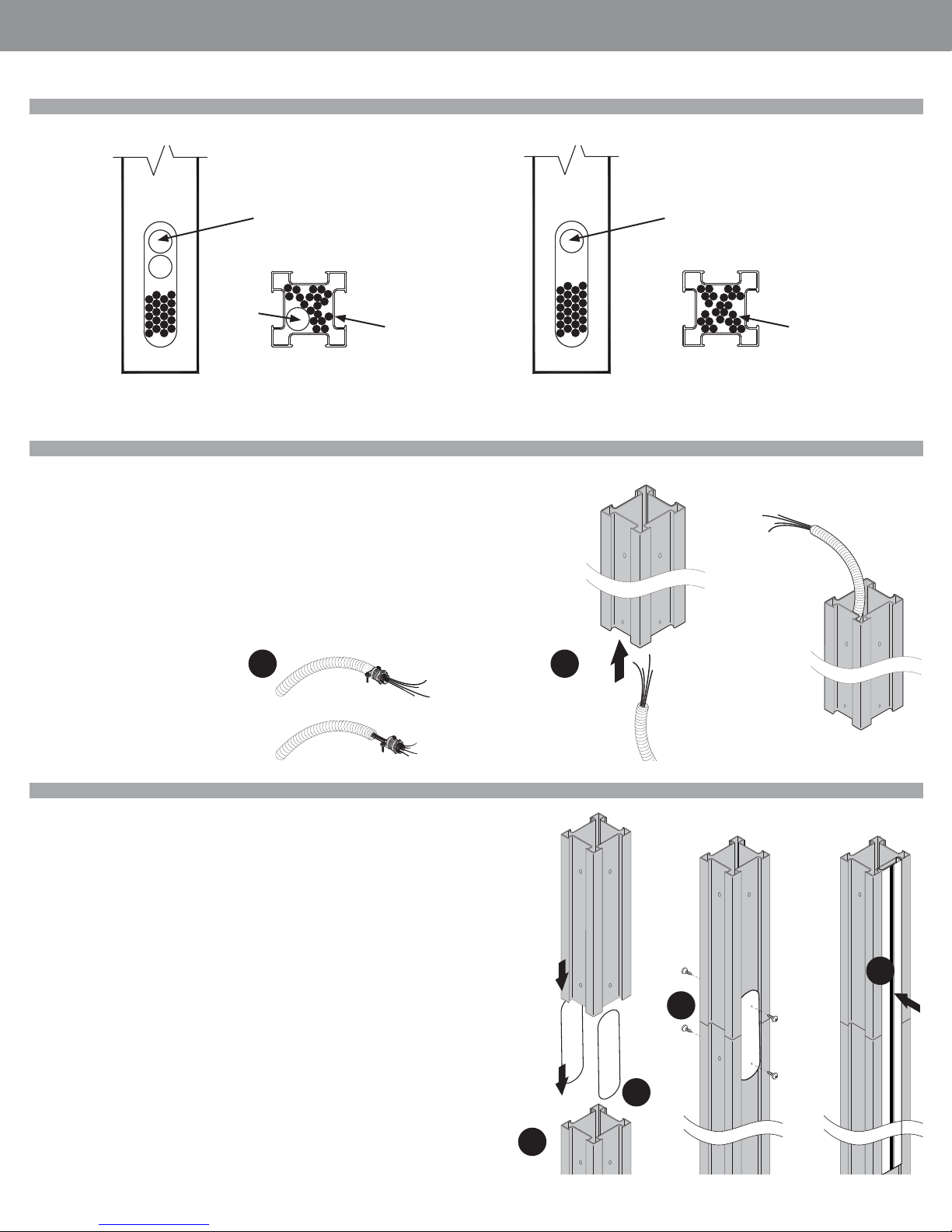

Electrical - 90 degree post cable capacity

Typical application, recommended maximum

• Summer 2017 rev:Winter 2018

• Summer 2017

INSTALLATION GUIDELINES

With Power

Panel Frame

Pass Through Cable

Power Feed

(0.73” dia)

20x CAT6 Cables

0.25” dia

Post

* THESE ARE GUIDELINES ONLY, ACTUAL NUMBERS MAY VARY BASED ON SITE

CONDITIONS AND CLIENT REQUIREMENTS *

Electrical - Ceiling Feed

STEP 1: Disconnect clamp at top of ceiling feed, and remove, tape the wires together.

STEP 2: Lay the Universal Corner Post on the fl oor. Slide top of ceiling feed

through Universal Corner Post, starting at the bottom of the post.

STEP 3: Lay Post Extension inline with the Universal Corner Post. Slide Ceiling

Feed through the Post Extension. Attach Post Extension connector plates as

indicated in Post Extension instructions, on this page, below.

STEP4: Reattach connector clamp to top of ceiling feed. Install completed Power

Pole onto panels, and into ceiling.

Without Power

Panel Frame

Pass Through Cable

25x CAT6 Cables

0.25” dia

Post

1

Post Extension

STEP 1: Drill a 6mm hole, screw bottom of attachment plates into universal

corner post. Use two plates, opposite to each other for each post extension.

STEP 2: Slide Post Extension Post between attachment plates.

STEP 3: Drill a 6mm hole. Screw top of attachment plates into post extension.

STEP 4: Snap Trims into grooves on all 4 sides of Post Extension. Trim dimension

matches post dimension.

2

4

3

2

1

•Page globalcontract.com 6

Loading...

Loading...