Global Contract Bridges II Installation Manual

Installation Manual

2012

OHSAS 18001:2007

CGSB #0HS-009

Visit us on the Internet at globalcontract.com • (416) 739-5000

ISO 9001:2008

CGSB #94613-5

ISO 14001:2004

CGSB #EMS-040

Global Contract Inc. 565 Petrolia Road

North York, Ontario, M3J 2X8

GLOBALContract

Required Tools:

Safety Glasses

Rubber Mallet

Flathead Screw

driver

Actuator

Pliers

10 mm Hex Bit

Phillips Bit

T-25 Torx Bit

Bit Adaptor /

Handle

Socket Wrench

13 mm Socket

TABLE OF CONTENTS

• Fall 2012

Structure and

Worksurfaces

Supporting Structure

Legs and Beams

Beam Applications

Telescopic Beam

120°

Storage Table Beam

Sliding Return

Round Table Supports

Pivoting Table Supports

Power, Data and Cable

Management

Power Delivery/Cable Management

Wire Basket

Below Worksurface Power Trough

Below Worksurface Power Trough Installation

Power Trough Supporting Structure

Power Trough 120° Installation

Power Trough Electric Components

Above Work Surface Power Trough

Ceiling Feed

Power Distribution Storage

Accessories

Dividers

Back 2 Back

Side 2 Side

Parallel with modesty panel

Perpendicular end of run

Modesty panel

Leg Gable

Storage

Shelves

Elevated

Storage Spine

Storage and Boulevard System

Storage and Evolve Systems

P.01

02

02

03

04

05

06

07

08

08

P.09

09

10

10

10

11

11

12

15

16

17

P.18

17

19

19

20

20

21

P.22

22

22

23

24

25

Bridges 2

Required Tools

Safety Glasses

Allen Key

Phillips Screwdriver

Wrench

Flathead Screwdriver

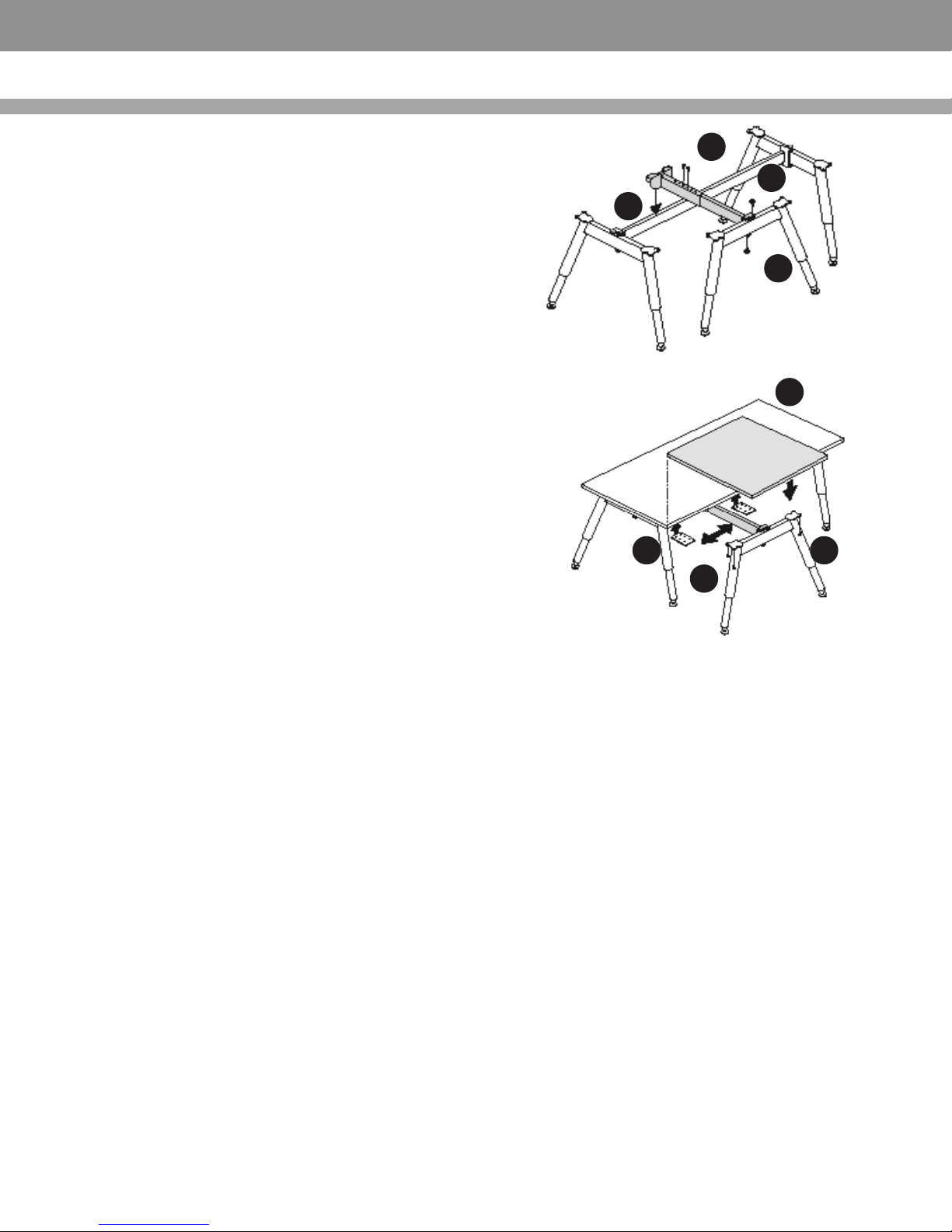

Bridges 2 Installation Sequence

NOTE: Although some illustrations depict round legs and some rectangular legs, the leg-to-beam and

leg-to-work surface assembly is the same.

STEP 1: LAYOUT ORIENTATION

Orient the layout plan within the installation area, determine the location of table assemblies, power

source and main storage components; establish the highest point on the floor.

STEP 2: SUPPORTING STRUCTURE - legs, supporting beams

Identify type and size of required components and position them in accordance with layout plans. Proceed with connecting legs and structural beams (see the following pages for detailed instructions). Make

sure that all rails are leveled and securely connected before proceeding with installation of worksurfaces.

STEP 3: WORKSURFACES

STEP 4: ACCESSORIES - task and paper organizers

Determine type and location of accessories as specified in floor plans. Proceed with installation

of accessories.

STEP 5: STORAGE

STEP 6: ELECTRICS and DATA / COMMUNICATION - cable routing; cable management

Connect power feed harness to building power supply; check circuit assignments and functionality of

power delivery at each duplex receptacle.

Please contact your Global Contract Service Representative at 416-739-5000 for

any questions or concerns.

NOTE: Any alterations to listed components will void the manufacturer’s warranty.

The manufacturer will not be responsible for any damage or bodily harm caused

by alterations in accordance with national or local electrical codes and manufac-

STEP 7: WALK THROUGH / INSTALLATION INSPECTION

Page • globalcontract.com1

turer’s specifications. In accordance with the manufacturer’s policy of continual

product improvement, the product presented in this document is subject to

change without notice or obligation.

GLOBALContract

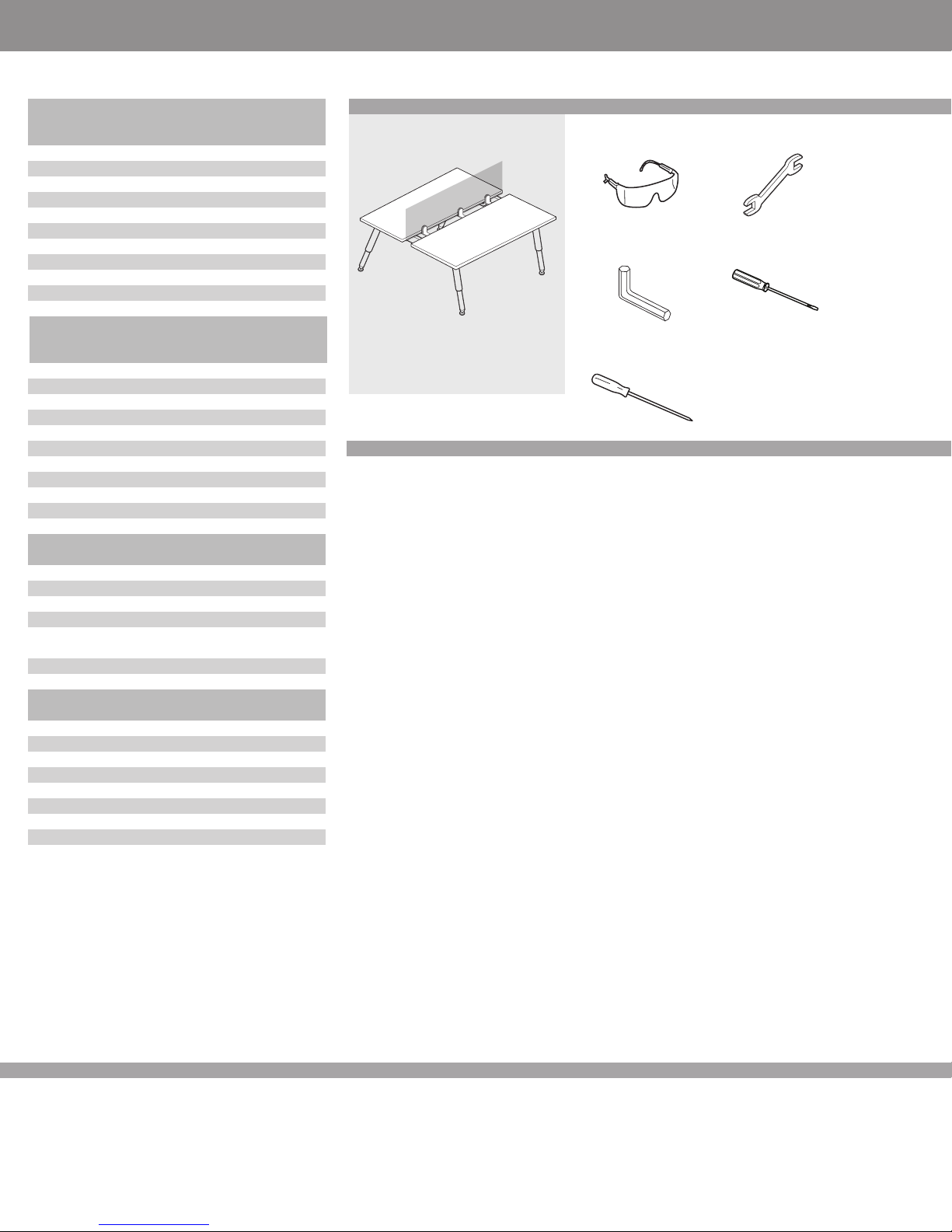

Supporting Structure Round Leg Height Adjustment

Set the legs to desired height.

The inner leg has two threaded holes.

STEP 1: The top threaded hole is typically used to secure legs with levelers.

• Fall 2012

INSTALLATION GUIDELINES

STEP 3: If the desired top surface height is 29” from the floor, for instance, and the

table structure is to be on levelers, align top threaded hole in the inner leg (1) with the

fourth hole in the table leg (3) as illustrated. When installing legs on casters, align the

lower (2) threaded hole in the inner leg with the same fourth hole (3) in the table leg

and secure with provided screws.

STEP 2: The lower threaded hole is used for securing legs with casters.

1

3

2

Supporting Legs And Beams

To connect a beam to a leg, identify the correct type (Single, End of run and Interconnect Beam) first - in accordance with your desired table configuration.

STEP 1: Position beam’s end bracket over leg’s horizontal, rectangular tube.

STEP 2: Secure top and bottom bracket ends with two supplied screws.

Level the whole assembly.

STEP 3: Place worksurfaces on top of table structure, align them and interconnect

them using flat brackets.

STEP 4: Align this worksurface assembly with legs and secure with screws. Proceed

from one corner to the opposite one.

STEP 4: The height adjustment screws must be only used with the provided,

translucent cup/washer.

4

3

Offset beam

position on

30” rectangular legs

Offset beam

position

Back Edge Underside

Accessory

Holes

Front Edge

1

Central beam position on round

legs and 24” rectangular legs

4

2

•Pageglobalcontract.com 2

GLOBALContract

INSTALLATION GUIDELINES

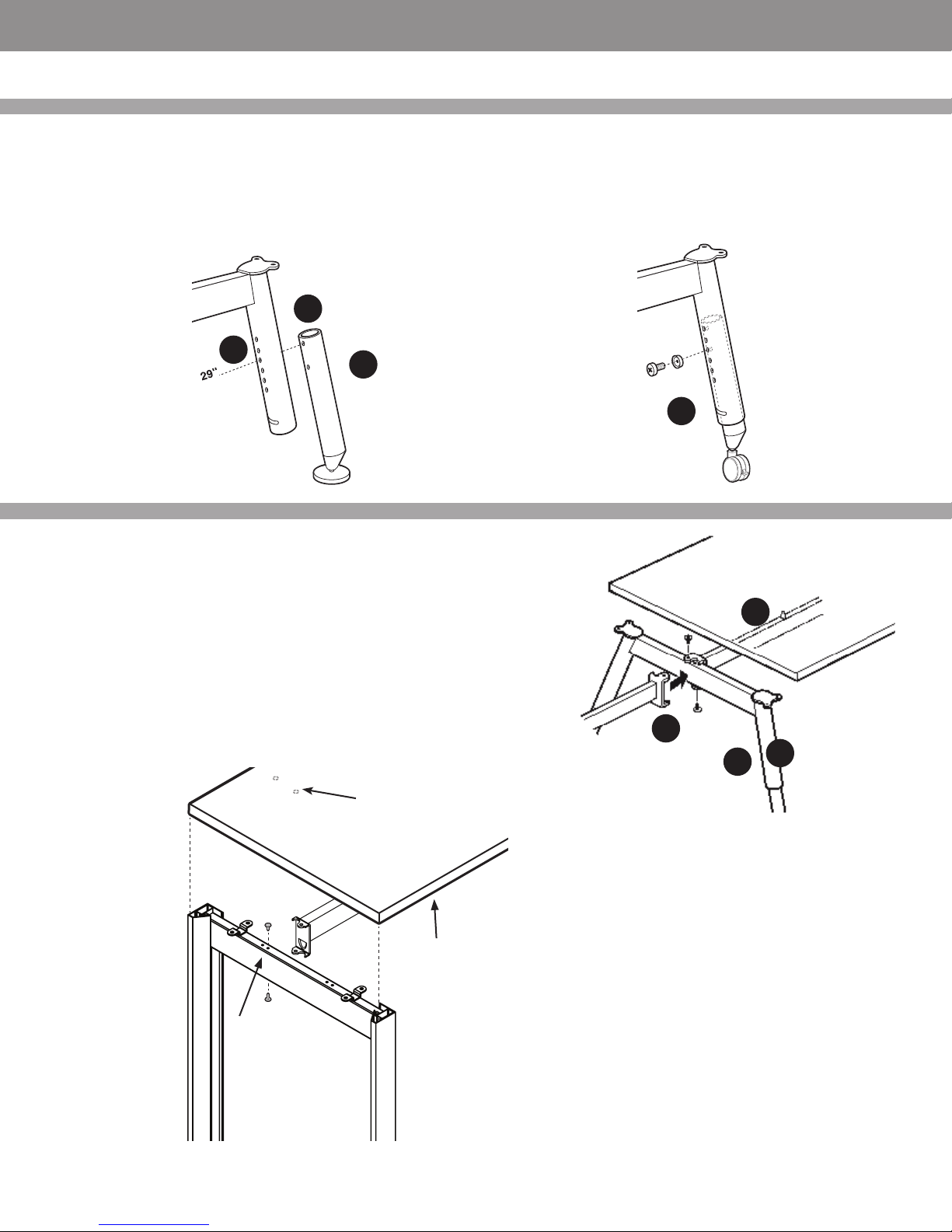

Beam Applications

Table supporting structures - BEAMS Legs are connected with supporting beams.

There is one beam for a single line of tables while two beams connect back 2 back

table structures. There are three types of beams whose application principles are

common to building support for single-line and back 2 back table assemblies:

Single table beam Designed to bridge two legs to form support for a single

table, or for two back 2 back work surfaces.

End of run table beam Supports table leg assemblies at the end of a table run,

with legs on one side tucked under the work surface. Longer by 2” than the

Single table Beam, thereby positioning one leg assembly so that it supports 2

adjoining work surfaces.

• Fall 2012

Interconnecting table beam A typical, multiple surface run begins with an End of

run beam, continues with Interconnecting beam(s) and finishes with another End

of run beam. Also, applies to multiple, back 2 back Assemblies.

Interconnecting beam is designed to bridge space between two table assemblies. Because the interconnecting beam is 4” longer than the standard beam,

it spreads supporting legs apart so that both could be shared by adjacent

worksurfaces.

Telescopic table beam Supports a return connected perpendicularly to a 24” or

30” deep primary work surface. The Telescopic beam is connected to a single

or back 2 back leg on one side and to any work surface-supporting beam on the

opposite side.

Storage table beam The Storage beam is connected to a single or back 2 back

leg on one side and to the work surface on the opposite side - thus saving one

leg assembly work surface is connected to storage units with included storage

brackets). Storage table beam’s flexibility allows for a single table application

(with the table leg tucked in under the work surface) as well as for a double table

installation (two adjacent tables supported by a shared leg in the middle and two

storage cabinets at the opposite ends).

Storage table beam adapter Connects to Storage table beam. This assembly

allows a work surface to be supported by a leg on one side and a spine (formed

by interconnected storage cabinets) on the opposite side.

Page • globalcontract.com3

GLOBALContract

Telescopic Beam

Designed to provide support for worksurfaces perpendicularly connected to a primary

table run. The telescopic beam is connected to the leg’s horizontal, rectangular tube

on one side, while the opposite side is secured off module to the perpendicular,

central beam and can be adjusted to accommodate 24” and 30” deep primary

worksurfaces.

STEP 1: Position beam’s end bracket over leg’s horizontal, rectangular tube.

STEP 2: Secure top and bottom bracket ends with two supplied screws.

STEP 3: Adjust the length of the telescopic beam in accordance with the depth of

primary worksurface. Completely contracted beam will support perpendicular side

table connected to 24” deep primary worksurface on Round and Rectangular legs.

Middle position is intended to support perpendicular side table connected to 30”

deep primary worksurface on Round legs. Fully extended telescopic beams supports

perpendicular side table connected to 30” deep primary worksurface on Rectangular

legs.

STEP 4: Position end bracket of the telescopic beam over the primary, perpendicular

beam. Level the whole assembly.

STEP 5: Install primary worksurface.

• Fall 2012

INSTALLATION GUIDELINES

3

2

4

1

5

STEP 6: Secure the secondary worksurface to legs first.

STEP 7: Adjust the secondary worksurface/telescopic beam position.

STEP 8: Secure the worksurfaces with flat brackets.

8

6

7

•Pageglobalcontract.com 4

GLOBALContract

INSTALLATION GUIDELINES

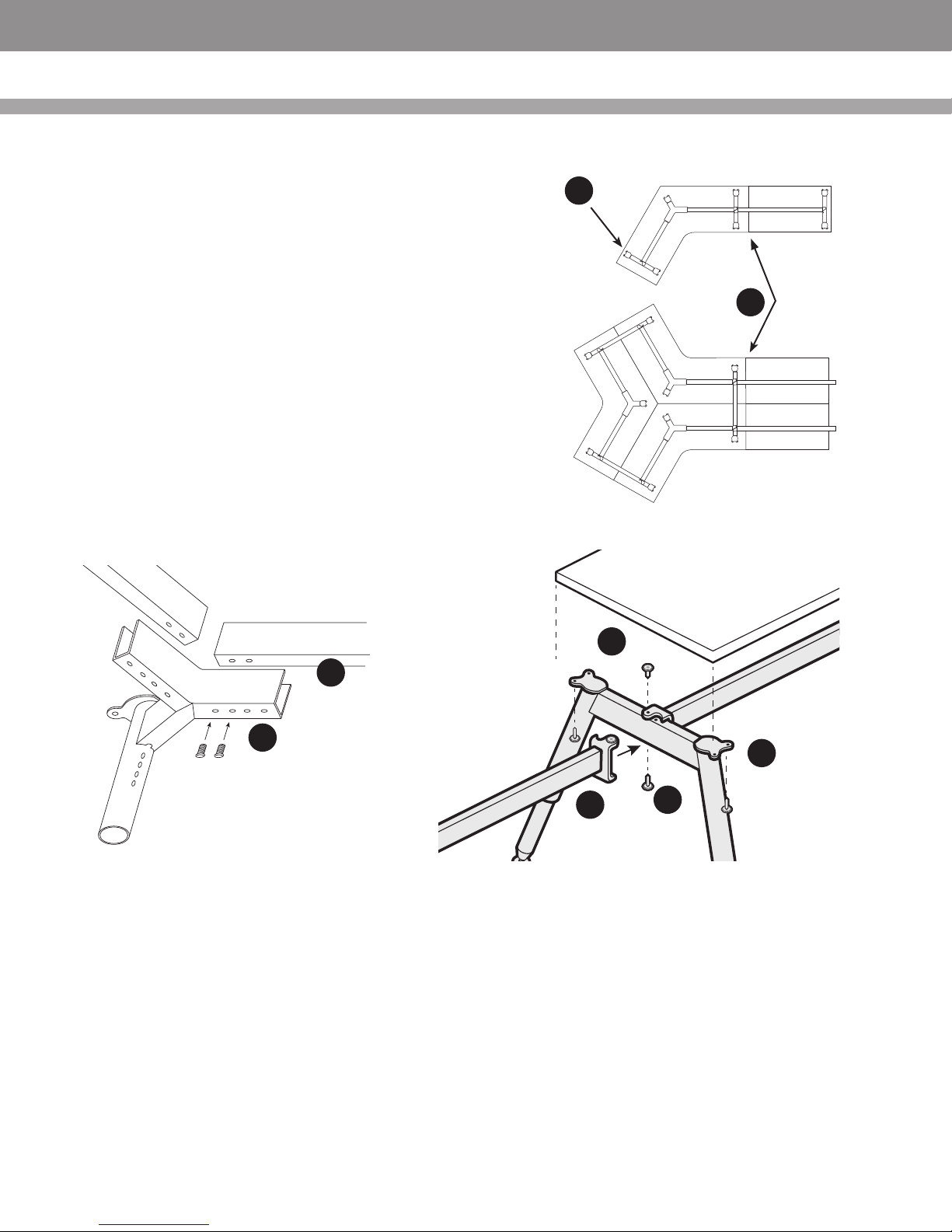

120° Leg

The integrated 120º beam bracket allows for the beam to be mounted in two positions:

A) end of run leg placement

B) shared leg placement

• Fall 2012

Identify the desired leg position (A or B)

STEP 1: Align two mounting holes in beam with two holes in the integrated 120º

beam bracket. Position beam’s end bracket over leg’s horizontal, rectangular tube.

STEP 2: Secure both beams to the integrated 120º beam bracket with four supplied screws.

STEP 3: Position beam’s end bracket over leg’s horizontal rectangular tube.

STEP 4: Secure top and bottom bracket ends with two supplied screws.

STEP 5: Level the whole assembly.

STEP 6: Install work surfaces and secure with supplied screws by proceeding

from the central, 120º leg to the outside of the assembly in both directions.

NOTE: 24” deep worksurfaces are mounted centrally on top of the table structure. 30” deep worksurfaces are mounted off center, with a longer overhang

facing the user.

End of run leg position

A

B

Shared leg

position

4

1

2

6

3

4

Page • globalcontract.com5

GLOBALContract

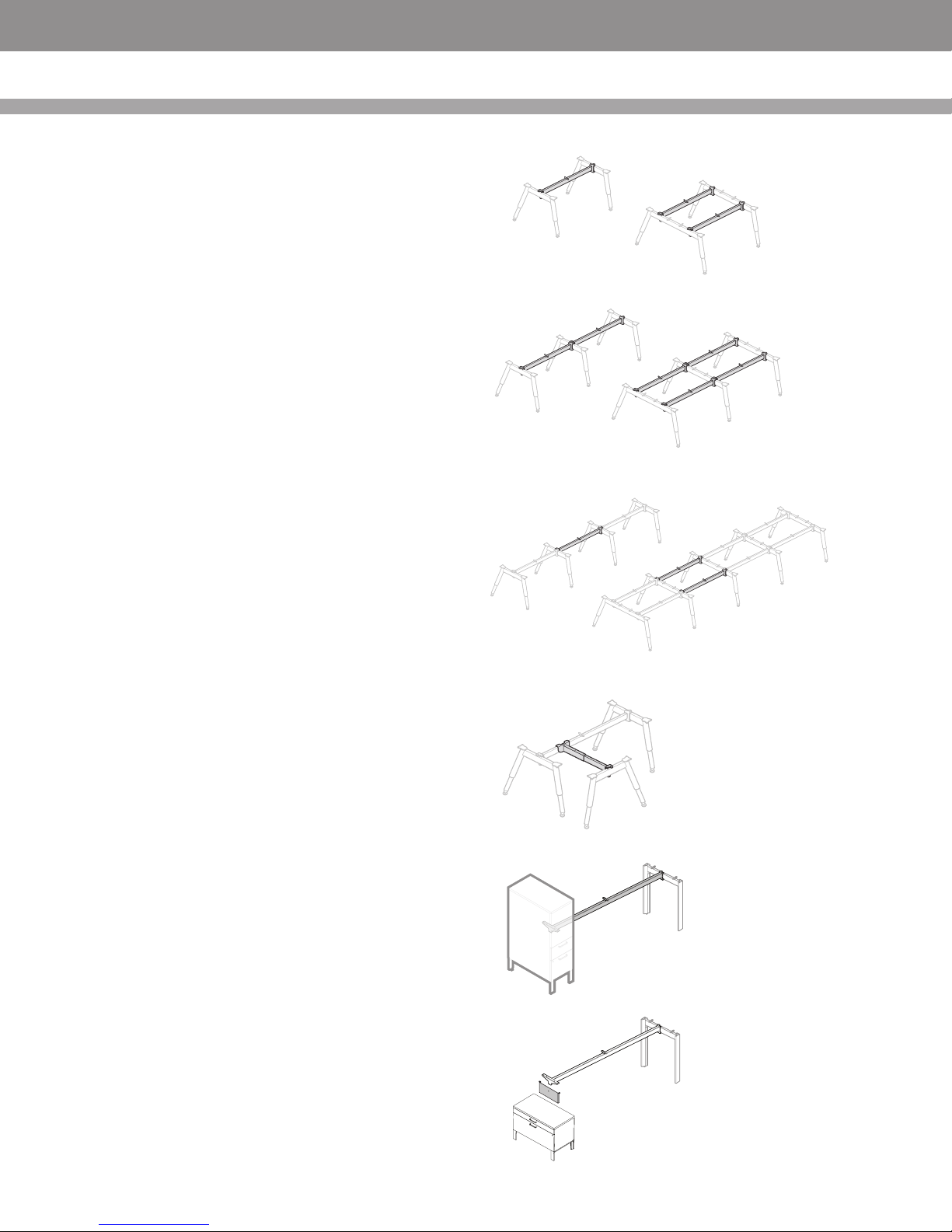

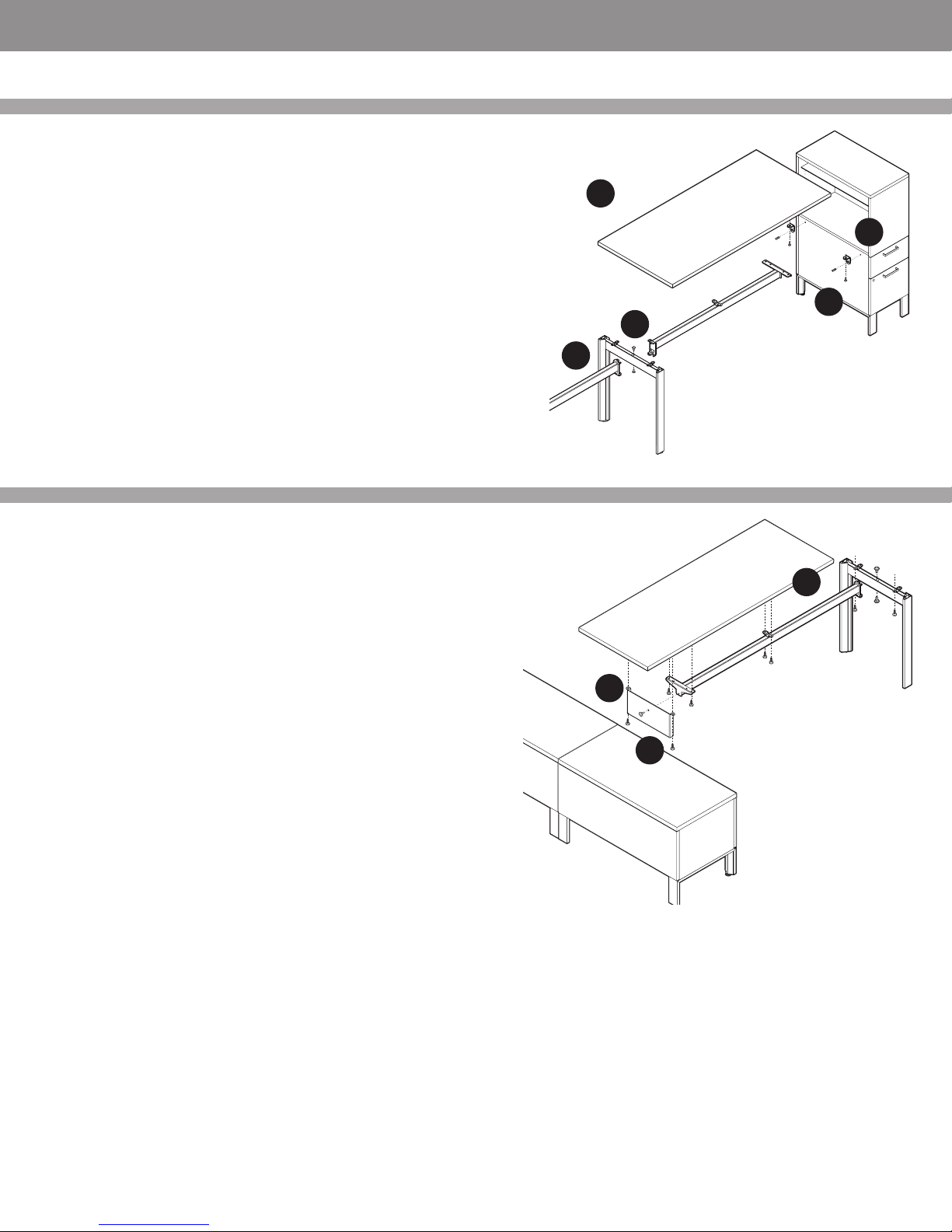

Storage Table Beam

Storage table beam’s flexibility allows for a single table application (with the table

leg tucked in under the work surface) as well as for a double table installation

(two adjacent tables supported by a shared leg in the middle (A) and two storage

cabinets at the opposite ends).

STEP 1: Position beam’s end bracket over leg’s horizontal, rectangular tube. Use

Allen keys to secure top and bottom bracket ends with two supplied screws.

Level the whole assembly.

STEP 2: Turn the work surface upside down on a smooth surface and secure it to

the leg/beam subassembly with supplied screws.

STEP 3: Mount two L brackets to the side of Storage tower. Drive two supplied

machine screws through the brackets into threaded inserts embedded in the storage tower side panel.

STEP 4: Place the Storage tower in its final location and position the leg/beam/

work surface assembly so that the work surface rests on the installed L brackets.

Ensure that the work surface and the tower are aligned.

Secure the work surface to the L brackets with supplied screws.

• Fall 2012

INSTALLATION GUIDELINES

2

3

4

1

A

Spine / Storage Table Beam Adapter

Storage table beam adapter allows a work surface to be supported by a leg on

one side and a spine storage cabinet on the opposite side. A typical Storage

spine is formed by series of interconnected 21” or 25” high storage cabinets of

corresponding depth.

The Storage beam is connected to a single or back-2-back leg on one side and to

the work surface on the opposite side - thus saving one leg assembly.

The 21” or 25” adapters provide structural support - acting as supports between

top of the storage cabinet spine and the bottom of perpendicular work surfaces.

The flexible leg/beam/adapter assembly arrangement allows the leg to be tucked

in under the work surface or to be shared by two adjacent work surfaces.

Included hardware connects the adapter to the worksurface and to the storage

table beam.

STEP 1: Position beam’s end bracket over leg’s horizontal, rectangular tube. Use

Allen keys to secure top and bottom bracket ends with two supplied screws.

STEP 2: Attach Spine / Storage table beam adapter to the Storage table beam. Use

Allen key and the supplied screw to secure.

STEP 3: Turn the work surface upside down on a smooth surface and secure it to

the leg/beam/adapter subassembly with supplied screws.

STEP 4: Rest the leg/beam/adapter/work surface assembly on top of the storage

spine. Adjust the desired position. Secure the assembly by driving two supplied

screws through the bottom of the adapter, into the top of the storage cabinet.

3

2

4

•Pageglobalcontract.com 6

GLOBALContract

INSTALLATION GUIDELINES

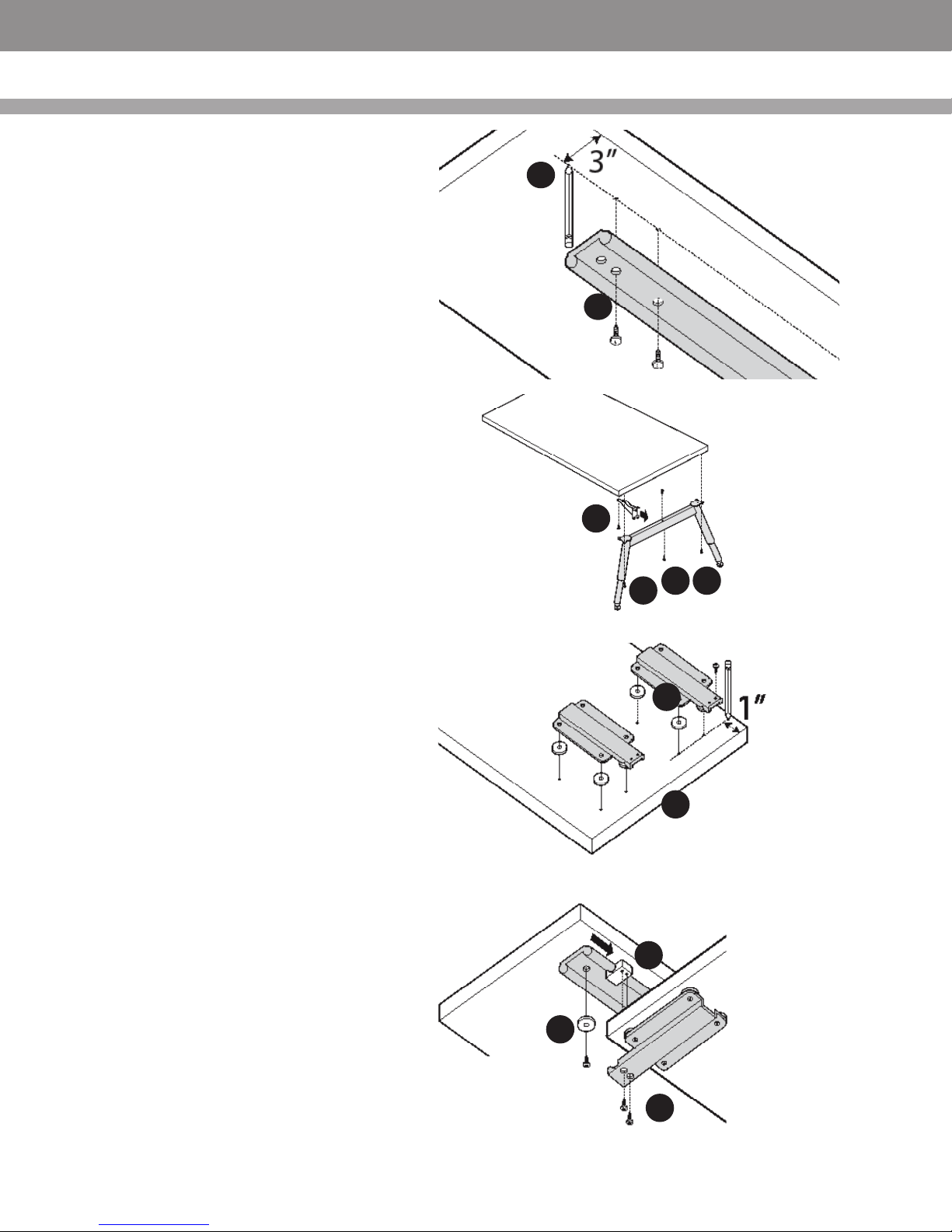

Sliding Return

NOTE:

Round legs:

Sliding Return can be installed anywhere along the front edge of work surface supported by round legs.

Rectangular legs:

Sliding Return can be installed along the front edge of work surface between

Rectangular legs.

Sliding return can be installed under a seam of two adjacent work surfaces

supported by recessed, 34” back 2 back leg.

Ensure that back-to-back table installation is complete, level and structurally

sound. Installation of Sliding Rail requires a special degree of accuracy of work

surface alignment. Failure to do so may result in binding of the sliding mechanism on the Sliding Rail.

Establish range of the Sliding Return.

STEP 1: Mark a line 3” in from (and parallel with) the front edge of work

surface.

STEP 2: Position the Sliding Rail and secure it with supplied screws. Always proceed from the second hole, leaving the first hole for installation of the Rail stop.

NOTE: the pair of screws provided to secure the rubber rail stops at either

end of the rail are longer than the screws for securing the rail to the work

surface. Do not use these longer screws to secure the rail as the screws may

penetrate through the top of the work surface.

• Fall 2012

1

2

STEP 3: Secure leg support bracket to a leg frame with supplied machine

screws (wide flat allen head).

STEP 4: Place the Sliding Return work surface upside down on a clean surface.

Secure the leg assembly to the work surface with supplied wood screws.

Ensure that the legs are set to the same height as the legs supporting the rest

of the table installation.

STEP 5: Place eight supplied rubber spacers over pre-drilled holes. If you are

converting an existing Return work surface to a Sliding Return, mark a line 1”

in from (and parallel with) the edge of the Return work surface.

STEP 6: Align supporting brackets with rubber spacers / pre-drilled holes (or

the marked line) and secure both brackets with supplied wood screws.

NOTE: In order to ensure a smooth sliding action, both brackets must be

perfectly perpendicular to the edge of the return work surface.

STEP 7: Slide the two glide blocks with bushings carefully onto the Rail as

illustrated.

STEP 8: This step requires two people:

While the leg supported side of the Return rests on the floor have an assistant

position supporting brackets under sliding glide blocks, align the holes and

gently drive in two machine screws (metric M6 as provided). Do not tighten. In

the same manner secure the second bracket to the second glide block and test

smoothness of the slide. Carefully tighten all four metric screws while repeatedly testing smoothness of the slide. If the return binds on the Sliding Rail, then

your support bracket(s) are not perpendicular to the rail - causing the

glide blocks to jam.

4

4

3

4

6

5

7

STEP 9: Secure rail stops to both ends of the rail with supplied (longer) screws

to prevent disengagement.

Page • globalcontract.com7

9

8

GLOBALContract

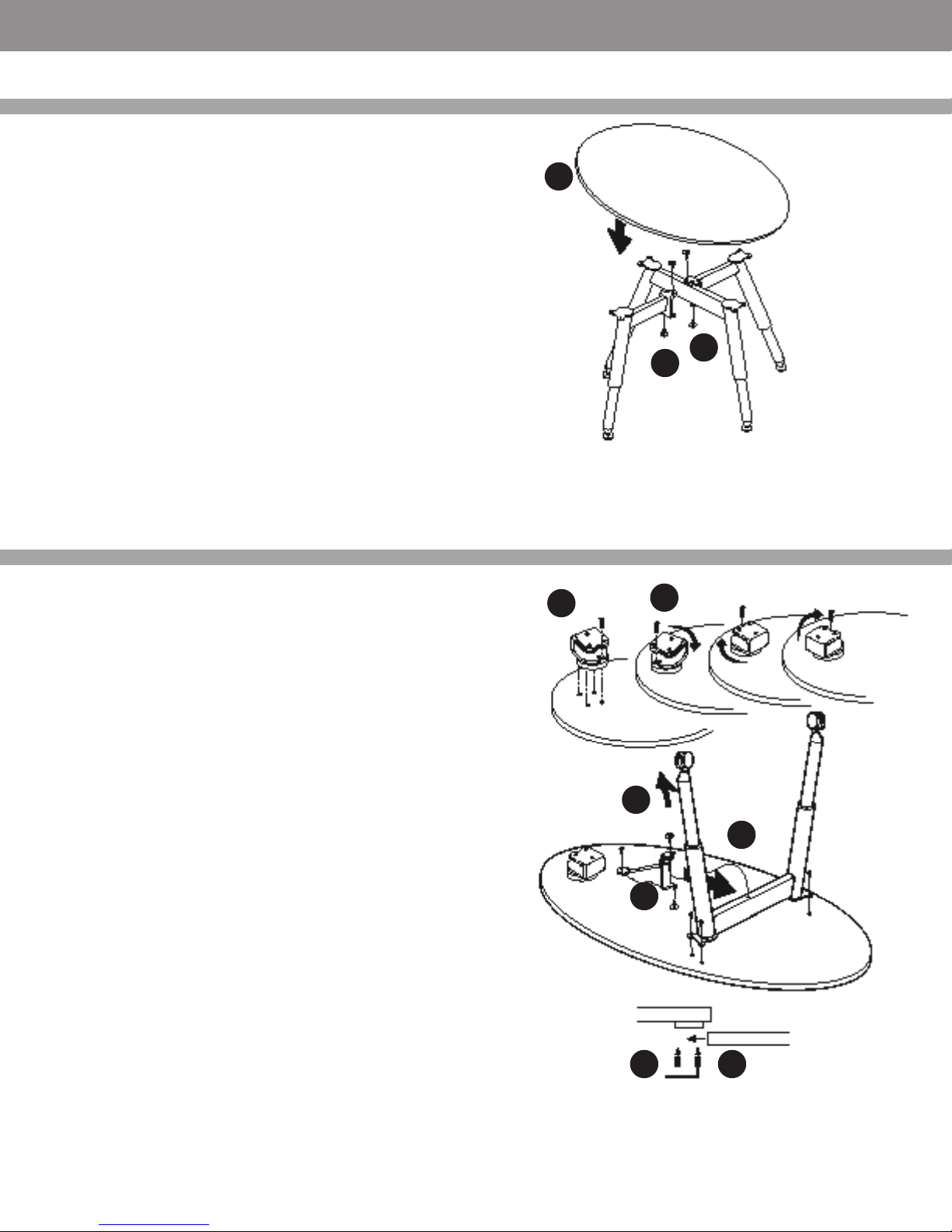

Round Table Supports

Round table structure consists of one main leg and two individual legs.

STEP 1: Position each individual leg’s end bracket over the main leg’s horizontal,

rectangular tube.

STEP 2: Secure top and bottom bracket ends with the supplied screws. Level the

whole assembly.

STEP 3: Install round worksurface.

• Fall 2012

INSTALLATION GUIDELINES

3

1

2

Pivoting Table Supports

Round and oval pivoting table structure consists of one main leg, leg bracket and a

pivoting clamp. Place oval worksurface upside down on a clean surface.

STEP 1: Align clamp over pre-drilled holes.

STEP 2: Rotate pivoting clamp over disc to reveal screw holes and drive in 4 supplied

screws (the clamp must be rotated 90º degrees to reveal the next screw hole).

STEP 3: Secure leg support bracket to leg with two screws.

STEP 4: Secure leg support bracket/leg assembly to worksurface with five supplied

screws.

STEP 5: Increase leg height by 2” (two increments) to compensate for the height of

the pivoting clamp. Rectangular legs (included in BRTPR2448C kit) designed specifically for this application are 2” taller.

Invert the table assembly.

STEP 6: Position table with pivoting bracket over the edge of the primary table as

illustrated.

STEP 7: Tighten the set screws of the pivoting clamp, securing it to the primary table.

1

2

5

4

3

ROUND / OVAL TABLE

PRIMARY TABLE

7

6

•Pageglobalcontract.com 8

Loading...

Loading...