Page 1

GLGBAL

WF976

CYLINDER BED

COMPOUND

LOCKSTITCH

OPERATION I INSTRUCTION I PARTS MANUAL

SEWING MACHINE

TWIN

FEED

NEEDLE,

Page 2

Content

Operation

I.

Briefintroduction

2. Main

3.

4.lnstalling

5.

6.

7.

8.

9.

I

0.

II.

12.

I 3.

I 4.

15.

16. Winding adjustment.

I 7.

I 8.

I 9.

20.

21 . Adjusting

22.

23.

24.

25.

specification

Installing

Connecting

Installing

Installing

Installing

Operation

Lubrication

Trial

run

Installing

Coordination

Threading

Adjusting

Setting

Adjusting

Function

Adjusting

Timing

Adjusting

Relationship

Removing

Instruction

....................................

....................................................................................................

the

machine

the motor.

the clutch to the pedal..

the

presser

the

bobbin

the

thread

preparation

...........................................................................................................

................................................................................................................

the

needle

among

the

needle

the

tension

the stitch length and reverse

the

pressure

of

the

safety

the lift

the

feed adjustment..

the

and

amount

position

timing

between

installing

--·············--··············································-'

...............................................................................................

..................................................................................................

............................................................................

foot lift

winder.

spool

...............................................................................................

...............................................................................................

needle,

thread

of

...............................................................................................

between

control

......................................................................................

stand

thread

.....................................................................................

bobbin

of

presser

c I utch

....................................................................................

of

presser

of

the feed

.........................................................................................

the

rotating

the

rotating

plate

..................................................................

.................................................................................

and

thread and

sewing

foot

.......................................................................

foot with

dog

.......................................................................

needle

and

hook and hook

hook

materials

rotating

................................................................

......................................................

needle

..............................................................

thread

walking

hook

separator

...........................................

presser

....... ,

foot..

...........................

......................................

........................................

I

I

2

2

2

3

3

3

.4

.4

.4

5

5

5

6

7

7

7

8

8

8

9

9

9

Parts

1.

2.

3.

4.

5. Feed

6.

7.

8.

Manual

Arm

and

Upper

Presser

Lower

shaft

Upper

Threading

Accessories

bed

.......................................................................................................

shaft

and thread take-up parts

bar

and draw bar parts

shaft

and

rotating

parts

..................................................................................................

feed and

presser

parts

..................................................................................................

........................................................................................................

..............................................................................

hook

foot lifter parts

....................................................................

parts

.....................................................................

.................................................................

I 0-11

l2-13

14-1

16-1 7

18-19

Z0-21

22-23

24-25

5

Page 3

Operation

Instruction

Page 4

1.

Brief

This

series

rotating

seam.Upper

teeth-type

lever-type

series

avoid

occurs.

compound

with

needle

weight

They

products.

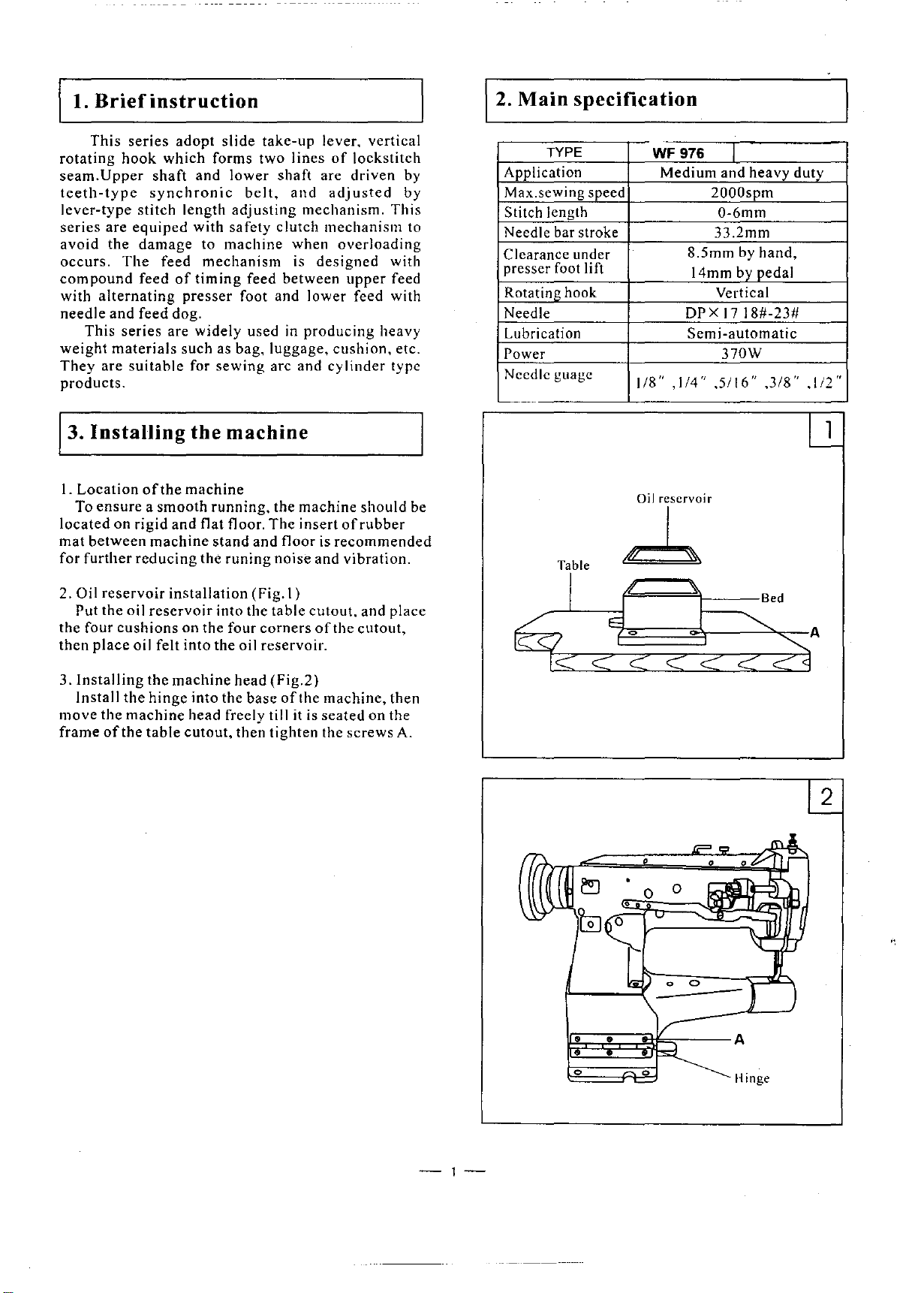

J3.

I.

To

located

mat

for

Oil

2.

Put the oil

the four

then

3.lnstalling

Install

move

frame

hook

are

the

The

alternating

and

This

series

materials

are

suitable

Installing

Location

ensure a smooth

on

between

further

reservoir

cushions

place

the

the

machine

of

the

instruction

adopt

which

shaft

synchronic

stitch length

equiped

damage

feed

feed

of

feed dog.

are

of

the

rigid

and flat floor.

machine

reducing

installation

reservoir

oil felt into the oil reservoir.

the

machine

hinge

table

slide

take-up

forms two lines

and

lower

adjusting

with safety clutch mechanism to

to

machine

mechanism

timing

presser

widely

such as bag, luggage,

for

sewing

the

machine

machine

running,

stand

the

runing

into

on the four

into the

head freely till it is

cutout,

shaft

belt,

foot and lower feed with

head

then

and

mechanism. This

when

is

designed

feed between

used in

and

(Fig. I)

the

base

producing

arc and

the machine should be

The

insert

floor is

noise

and vibration.

table

cutout,

corners

tighten

(Fig.2)

of

the

of

lever. vertical

of

lockstitch

are

driven

adjusted

overloading

upper

cushion,

cylinder

of

rubber

recommended

and

the

cutout,

machine,

seated

the screws A.

by

by

with

feed

heavy

etc.

type

place

then

on the

2. Main

Application

Max.sewing speed

Stitch length

Needle bar stroke

Clearance under

presser foot lift

Rotating hook Vertical

Needle

Lubrication

Power

Needle

specification

TYPE

guagc

1/8" , I

WF976

Medium and heavy duty

DPX

/4"

I

2000spm

0-6mm

33.2mm

8.5mm by hand,

14mm by pedal

17

18#-23#

Semi-automatic

370W

,5/16"

--

Oil

reservoir

~

/

IC

TTe

<

./

IS:

c:

E

"

0

c::

c::

...

<

.::::::: .:::::::

,3/8"

Bed

~

I ·o"

•

1.:..

lJ_

~A

<j

-1-

Page 5

A

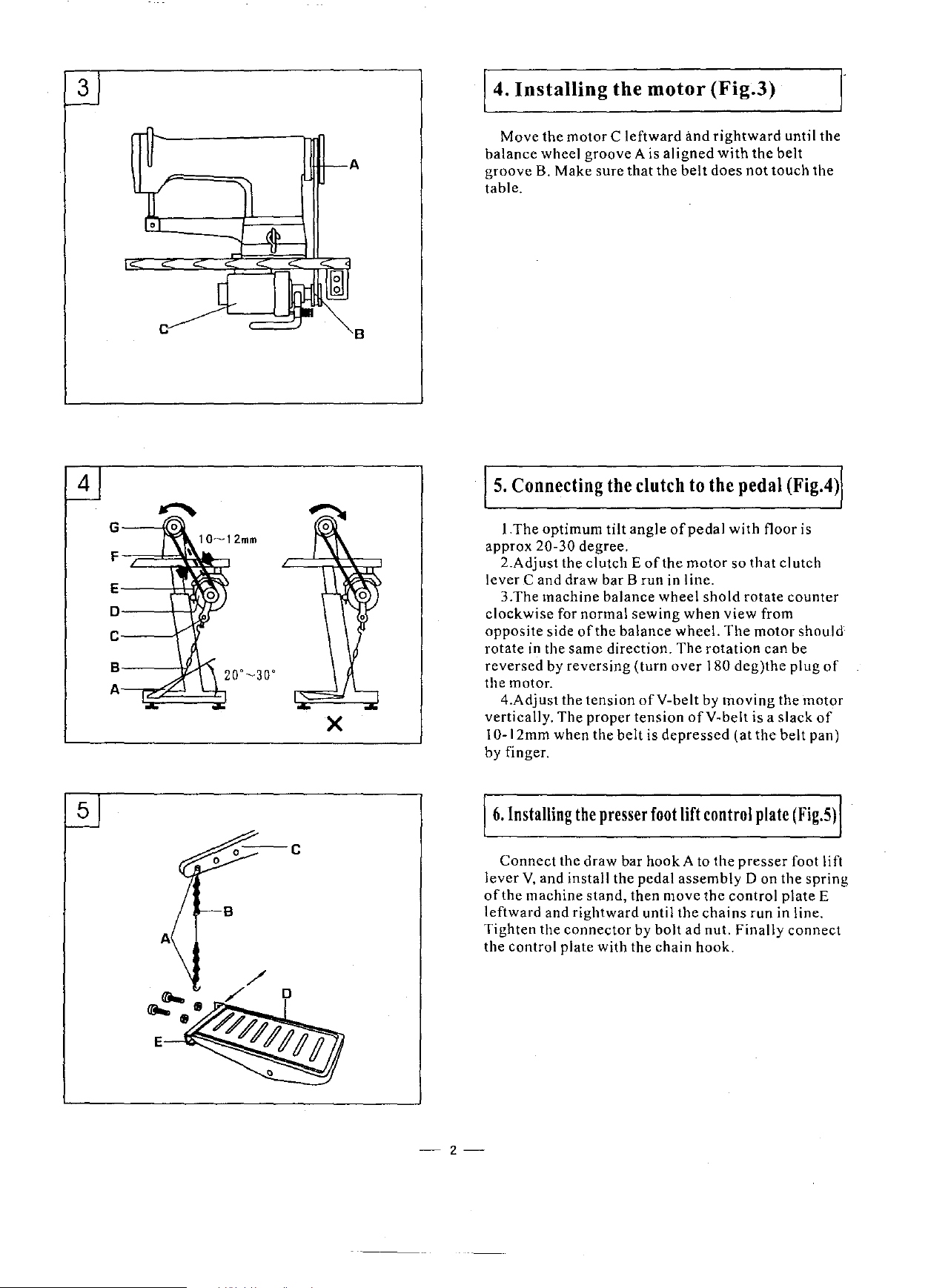

,4.

Installing

Move

the

motor

balance

groove B. Make sure that the

table.

wheel groove A is

the

motor

C leftward

aligned

and

belt

(Fig.3)

rightward

with

the

does

not

r

until the

belt

touch the

c

1

0-12mm

E---1+'~

D'---+----1-

C----1'

s.---tr...1r"\

A~~d::b

X

B

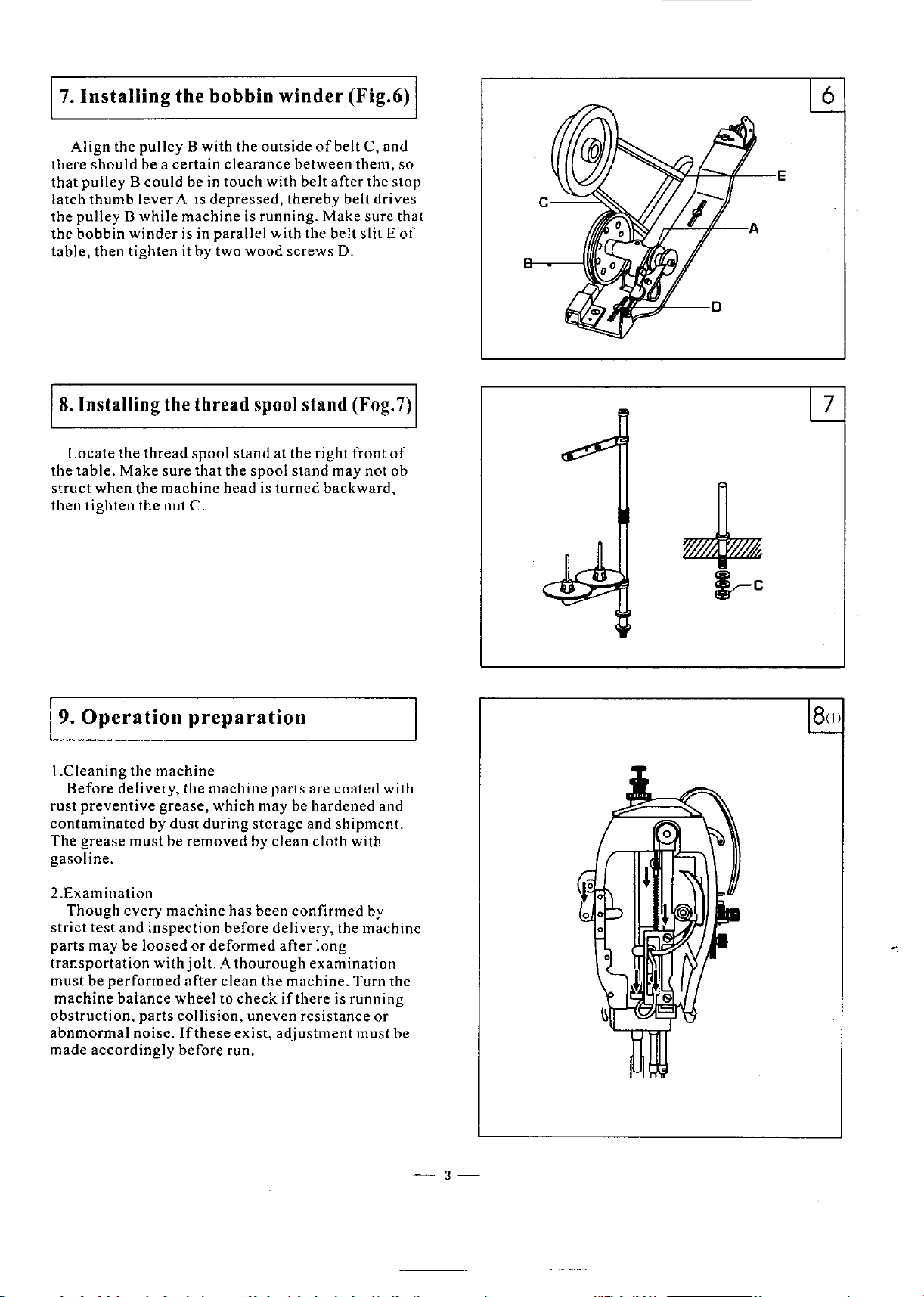

5.

Connecting

!.The

optimum

approx

lever C and draw

clockwise

opposite

rotate in the same direction.

reversed

the motor.

vertically. The proper

I 0-12mm when the

by finger.

20-30 degree.

2.Adjust the clutch E

3.The machine balance wheel

for normal

side

by

4.Adjust the tension

the

clutch

tilt

angle

of

barB

run in line.

sewing

of

the balance wheel.

reversing

(turn

ofY-belt

tension

belt

is

the

depressed

to

of

pedal

motor

shold

when

The

over

by

ofY-belt

the

pedal

with

so that clutch

rotate

view

from

The

motor

rotation

180

deg)the

moving

is a slack

(at

the

(Fig.4)

floor is

counter

should

can

be

plug

the motor

belt

of

of

pan)

5

-2-

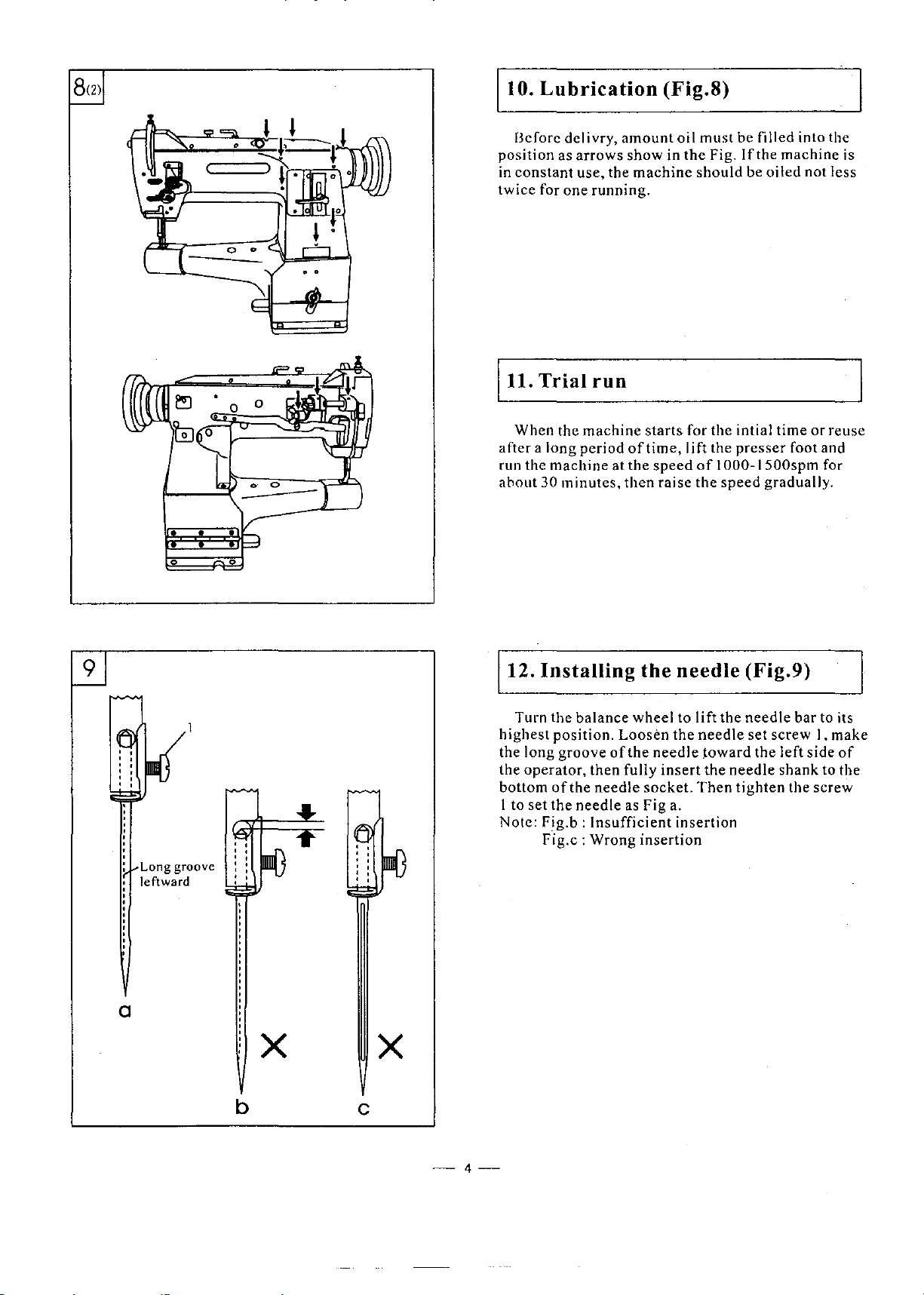

6.

Installing

Connect

lever

V,

of

the machine

leftward and

Tighten the

the control plate

the

the draw bar hook A

and install the pedal assembly

rightward

connector

presser

stand,

with

foot

lift

control

to

then move the

until the

by bolt ad nut. Finally

the chain

chains

hook.

the

presser

control

plate

Don

run in line.

(Fig.S)

foot lift

the

spring

plate

connect

E

Page 6

,7.

Installing

Align

the

there

should

that

pulley B could

latch

thumb

the

pulley B

the

bobbin

table,

8.

Installing the thread spool stand (Fog.

then

winder

tighten

the

bobbin

pulley B with

be a

lever

while

certain

A is

clearance

be in touch with belt

depressed,

machine

is in parallel with the

it by two

winder

the

outside

is running. Make sure that

wood

of

between

thereby

screws D.

(Fig.6)

belt

C, and

them,

after

belt

belt

slit E

so

the stop

drives

of

7)

I

6

e,~-

Locate

the

struct

then

19.

!.Cleaning

Before

rust

contaminated

The

gasoline.

the

table.

Make

when

the

tighten

Operation

the

delivery, the machine parts are

preventive

grease

must

thread

the nut C.

spool

sure

that

machine

preparation

machine

grease,

by

dust

be

removed

stand at the right front

the spool stand

head is

which may be hardened and

during

turned

storage

by

clean

may

backward,

coated

and

shipment.

cloth with

not ob

of

with

2.Examination

Though

strict

parts

transportation

must

machine

obstruction, parts

abnmormal

made

every

test

and

inspection

may

be loosed

with

be

performed

balance

noise.

accordingly

machine

wheel

collision,

If

before

has

been

before

or

deformed

jolt. A thourough

after

clean

to

check

uneven resistance or

these

exist,

run.

confirmed

delivery, the machine

after

long

examination

the

machine. Turn the

if

there

adjustment

by

is

running

must be

-3-

Page 7

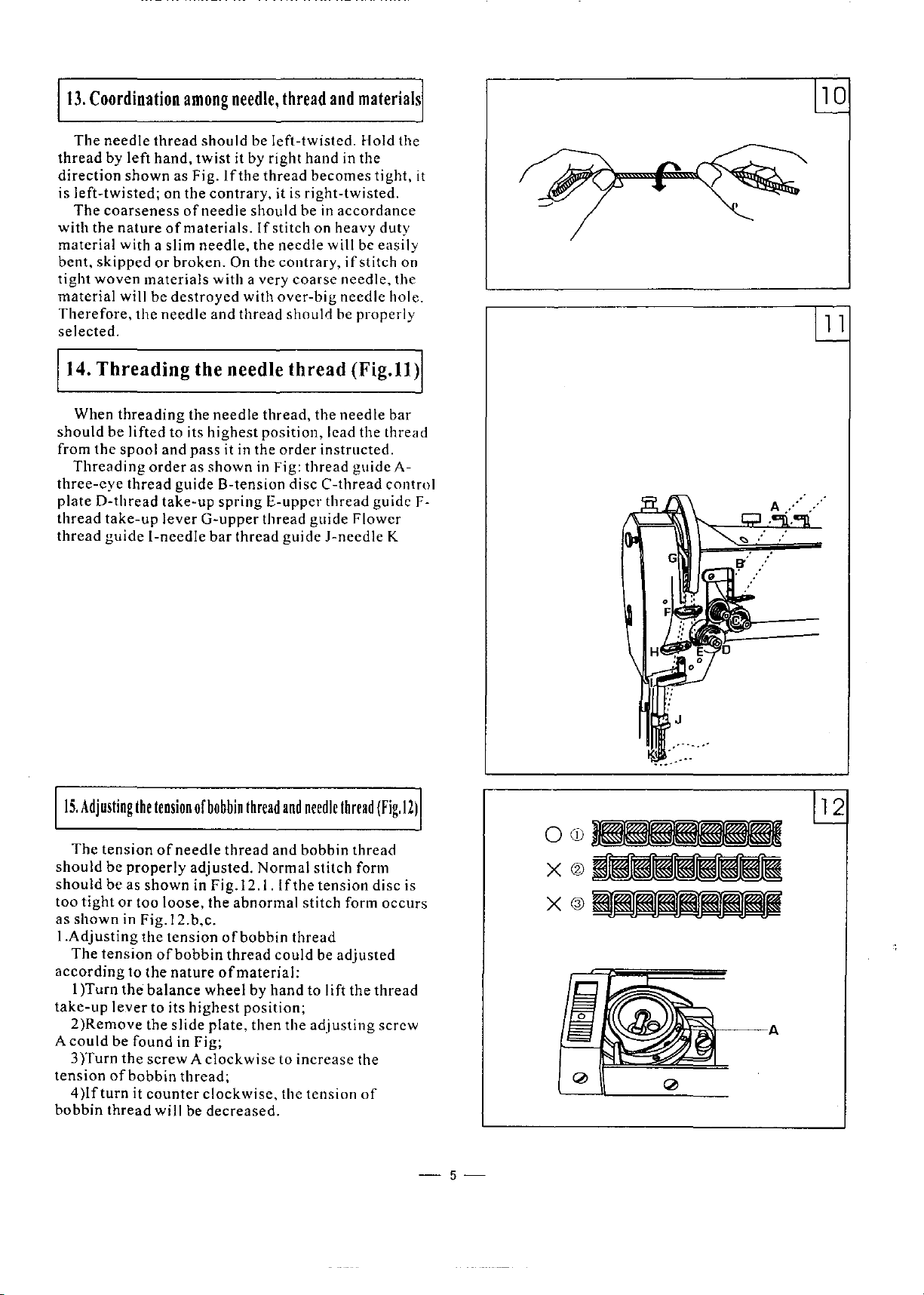

10.

Lubrication

(Fig.8)

Before dclivry,

position

in

twice

as

arrows

constant

use, the

for one running.

11. Trial run

When

the

machine

after

a long

run the

about

period

machine

30

minutes,

amount

show

machine

starts

of

time,

at the

then

oil

must

in

the

Fig.

should

for the intial time

lift

the

speed

of I 000-1500spm

raise

the

speed

be filled into the

If

the

machine

be

oiled

not less

or

reuse

presser

foot and

for

gradually.

is

9

Long groove

leftward

a

b

X

c

X

12.

Installing

Turn the

highest

the long

the

operator,

bottom

I to

set

Note:

Fig.b:

Fig.c:

balance

position.

groove

then

of

the

needle

the

needle

Insufficient

Wrong

the

wheel to

Loosen

of

the

fully

socket.

as Fig a.

insertion

needle

the

needle

insert

insertion

lift

the

needle

toward

the

needle

Then

(Fig.9)

needle

set screw I, make

tighten

bar

to its

the left side

shank

to the

the

screw

of

-4-

Page 8

13.

Coordination

The

needle

thread

direction

is

with

material

bent,

tight

material

Therefore,

selected.

should

from

three-eye

plateD-thread

thread

thread

by

left

shown

left-twisted;

The

coarseness

the

nature

with a slim

skipped

woven

will

the

14.

Threading

When

threading

be

lifted to its

the

spool

Threading

thread

take-up

guide

materials

among

thread

hand,

as

on the contrary, it is

of

ofmaterials.

or

broken.

be

destroyed

needle

needle,

should

twist

Fig.

needle

needle,

be

it by right

If

the

should

the

On the contrary,

with a very

with

and

thread

If

the needle

the

needle

highest

and

pass

it in the

order

as

guide

take-up

lever

!-needle

shown

G-upper

bar

in Fig:

B-tension

springE-upper

thread

thread

left-twisted.

hand

thread

becomes

right-twisted.

be in

stitch

on heavy duty

needle

coarse

over-big

should

thread

thread, the

position,

order

instructed.

thread

disc

C-thread

thread

thread

guide

guide

J-needle

and

materials

Hold the

in the

tight,

it

accordance

will be

lead the thread

if

stitch on

needle,

needle

be

properly

(Fig.

needle

guide A-

guide F-

Flower

easily

the

hole.

II)

bar

control

K

1 1

15.

Adjusting

The

tension

should

should

too

as

!.Adjusting

according

take-up

A

tension

bobbin

be

be

tight

or

shown

The

tension

I )Turn

lever

2)Remove

could

be

3)Turn

of

4

)lfturn

thread

the

tension

of

bobbin

of

needle

properly

as

shown

too

in

Fig.l2.b,c.

the

to

the

found in Fig;

the

bobbin

it

adjusted.

in

Fig.l2.1.

loose,

the

tension

of

bobbin

the

nature

balance

to its

the

screw A clockwise

counter

will be

wheel

highest

slide

thread;

clockwise,

plate,

decreased.

thread

thread

Normal

abnormal

of

bobbin

thread

of

material:

by

position;

then

and

and

If

the

thread

could

hand

the

to

the

needle

thread

bobbin

stitch

tension

stitch

be

adjusted

to lift the

adjusting

increase

tension

thread

form

disc is

form

thread

the

of

(Fig.l2)

occurs

screw

-5-

12

OCD

X®

X©

Page 9

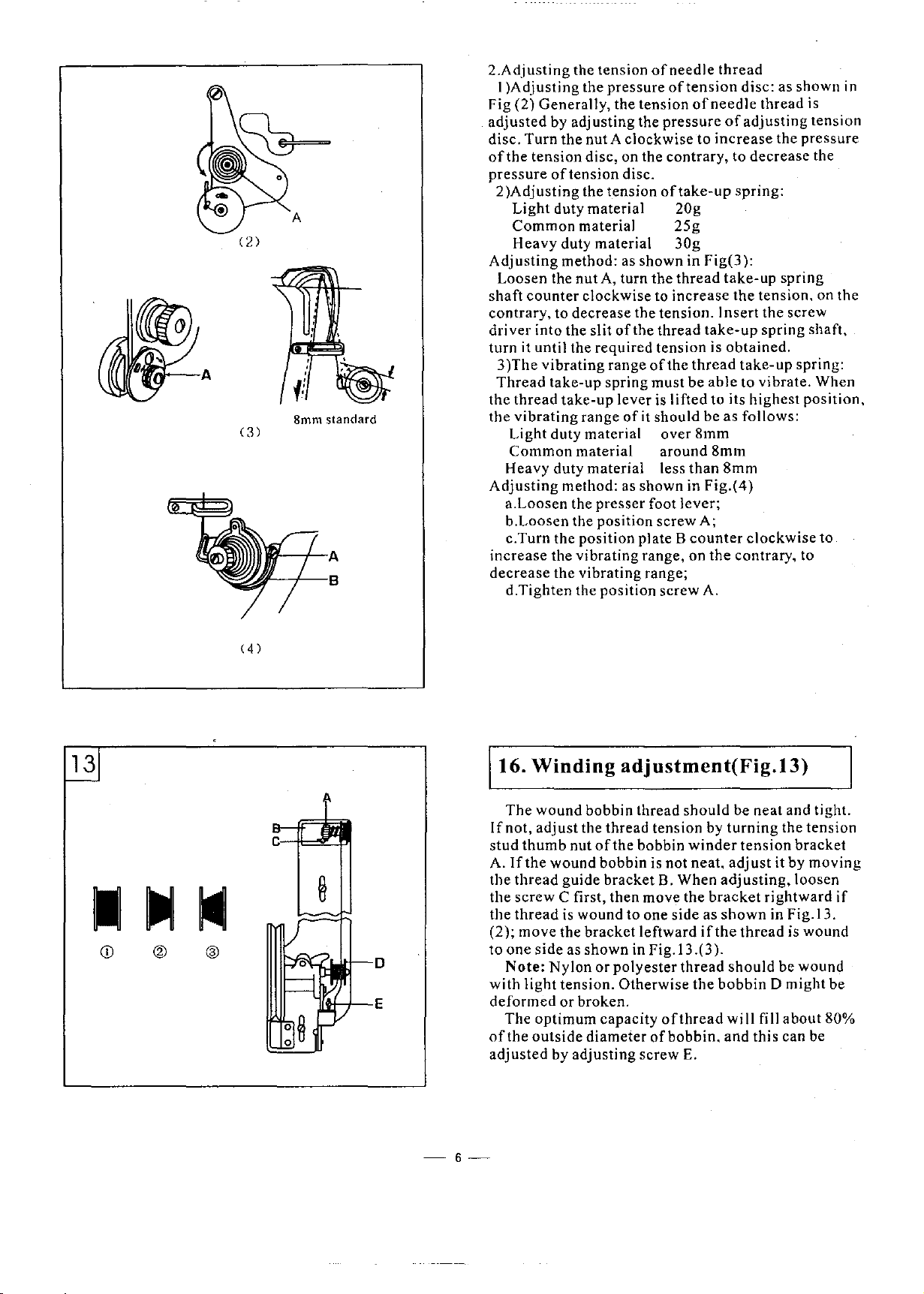

2.Adjusting

I

)Adjusting

Fig

(2)

adjusted

disc. Turn

of

the

pressure

2)Adjusting

Light

Common

Heavy duty material

Adjusting

Loosen the

shaft

counter

contrary, to decrease the tension. Insert the screw

driver

turn

it

3)The

Thread

the

thread

the

(

3)

8mm standard

vibrating

Light

Common

Heavy duty material less

Adjusting

a.Loosen

b.Loosen the position screw

c.Turn the

increase

decrease

d.Tighten the position screw A.

the tension

the pressure

Generally, the tension

by

adjusting

the

nut A clockwise to

tension

into the

until the required tension is

disc, on the contrary, to

of

tension disc.

the tension

duty material 20g

material 25g

method: as shown in

nut

A, turn

clockwise to increase

slit

vibrating

take-up spring

take-up

range

duty material over

material around 8mm

method: as shown in

the

presser

position

the

vibrating

the

vibrating

of

needle

of

tension

of

the

pressure

of

take-up

30g

Fig(3):

the

thread

of

the thread

range

of

must

lever is lifted to its

of

it

should

foot

plate B

range, on

range;

the

be

than

lever;

counter

take-up

thread

be

8mm

Fig.(4)

A;

thread

disc: as shown in

needle

increase

able

the

thread is

of

adjusting

the pressure

decrease

spring:

take-up

the

tension. on

spring

obtained.

take-up

to vibrate. When

highest

as

follows:

8mm

clockwise

contrary, to

tension

the

spring

the

shaft,

spring:

position.

to

13

CD

®

( 4 )

16.

Winding

The

wound

If

not,

adjust

stud

thumb

A.

If

the

the

thread

the

screw

the

thread

(2); move the

to

one

Note:

with

light

deformed

The

of

the

adjusted

nut

wound bobbin is not neat,

guide

C first, then move the

is wound to one

side

as

Nylon

tension.

or

optimum

outside

by

adjusting

adjustment(Fig.13)

bobbin thread

the thread tension by

of

the

bobbin

bracket

bracket

shown

broken.

diameter

in Fig. I 3

or

polyester

Otherwise

capacity

should

winder

B. When

side

leftward

thread

ofthread

of

bobbin.

screw

E.

bracket

as

if

.( 3 ).

the

be neat and tight.

turning

adjust

adjusting,

shown

the

should

bobbin

will

and

the tension

tension

it by

rightward

in Fig. I 3.

thread

is wound

be wound

D might be

fill

about

this can be

bracket

loosen

moving

if

80%

-6-

Page 10

17.

Setting

the

stitch

length

and

reverse

sewing

(Fig.l4)

14

Stitch

length

length

figure on

indicates

obtained

forward

reverse

accordance

materials

screw

pressure.

pressure

decrease

length

regulating

adjusting

feed

18.

Adjusting

Pressure

clockwise

the

the

when

sewing

to

While light materials to be sewn, turn the

regulating

the

could

be

adjusted

nut. When

position

stitch

stitch

reverse

can

lever

is released.

the

on

presser

with materials to be sewn.

be

sewn,

as

pressure.

block

length dial

length. Reverse

feed

be restored

pressure

foot is to be

turn

shown in

screw

by turning the stitch

the

scale on

is aligned with

plate,

sewing

lever

is

automatically

of

presser

adjusted

the

pressure

Fing.l5

counter

clockwise

the

stitch

some

then the figure

can be

depressed

foot

If

regulating

to increase the

and

when

(Fig.

in

heavy

to

IS)

Counter

clockwise

\

l

Clockwise

19. Function

When

the

thread

because

the

belt

load on

the

power

outside,

swtichs

hand,

balance

the

should

counter

its

synchronic

arrow on

synchronic

of

abnormal

clutch

When the arrow

center

button.

When

highest

will

wheel shaft. Turn

the

clutch.

of

the

on the

the

power

off, turn the

when

the

wheel

the

clutch

be

re-installed.

clockwise

position,

belt

the

position

belt.

of

the safety clutch (Fig.16)

is twisted into the

operation,

automatically

the

of

the

lower

clutch;

when

is stronger. When the safety clutch

balance

stop

plate

to make it switch on again, then loosen

switchs

to lift the

meanwhile,

wheel

should

plate. Then install the

get

eccentric

eccentric

shaft, it

the

arrow is

wheel

stops

off. the

First, turn the

thread

be

rotating

the

spring

off

the

pin to adjust the

pin is

indicates

toward

clockwise

the

wheel,

synchronic

balance

take-up lever to

the red arrow on the

aligned

hook

plate

bushing

aligned

the

weakest

the

by

turn the

belt

wheel

with

the

on

of

with

right

Arrow

Eccentric

l

pin

Red arrow

Position plate arrow

-7-

Page 11

17

20.

Adjusting

the

lift

amount

of

presser

foot

with

walking

presser

foot

(Fig.l1)

l

B

d>/lf'>!!',s:!-=

0.

Bmm

~l.Omm

~1.2mm

,~1.5mm

The lift

with

Loosen the wing

B between wing nut A

Shorten the

amount; widen the

lift amount.

the balance wheel

collision.

21.

When

the height from the teeth

plate should be in

When

the

duty materials, the

when sewing

about

the height

position

A,

and

then tighten the screw.

amount

presser

center

Adjusting

the

sewing

height

should

I mm, when

should

of

feed dog, first

move

of

walking

foot

can

be

nut A and

and

distance

center

After

adjustment,

slowly

the

position

feed

dog

is

accordance

heavy

common

it

duty

be

about

height

sewing

be

about

vertical1y to reach its required height,

presser

adjusted

adjust

the

presser

B to

distance

tighten

to

check

of

the

raised

materials,

to its

point

to the

with

materials

1.2mm. when

should

extra

I.Smm.

loosen

foot

as follows:

its

center

foot lift shaft.

increase

B to

decrease

the

if

there

feed

dog

highest

surface

the

materials.

such

be

about

the

height

heavy

duty

when

the feed

together

distance

the

lift

the

screw, turn

is parts

(Fig.

IS)

position,

of

needle

as leather,

sewing

adjusting

dog

light

0.8mm.

should

materials,

screw

be

the

l

B

-8-

122.

Timing

!.Standard

When the feed

needle

move downward,

and is aligned

body.

position

2.Installing the feed

cover, turn the

right hand, the front oil A

basic point, when the A is

dog two screws

plate

Adjustment

of

First, adjust the

feed

position

dog

is

just

and

begin

feeding,

close

to

with

the

needle

can

be

feed dog cam and

dog

stitch

balance

Bare

wheel

symmetrical.

adjustment

above

the

surface

the

needle

the

surface

hole on

adjusted

vibrating

length

counter

hole

on

vertically

by

to

0, open

upper

of

the

adjusting

clockwise

upward.

(Fig.19)

of

should

needle

shaft

shaft

plate

feed dog

the

crank.

the

upper

is the

feed

I

by

Page 12

23.

Adjusting

the

timing

between

needle

and

rotating

hook

(Fig.20)

2

Turn the

lowest

from its

coincided

clearance

hole

move

then

side

be

position.

lowest

is

approx

the

tighten

clearance

0-0.05mm.

24.

Relationship

balance

position,

with

the

between

2mm.

needle

the

between

between

wheel to

Then

center

hook

bar

vertically

screw

the

lower

the needle bar to its

when the

hook

point

!fit

is not, loosen the screw A.

A. when

hook

rotating

needle

point

line

of

the needle. The

and upper end

to its

adjusting,

point and

hook

and

is lifted 2.5mm

should be

required

needle

hook

separator

of

needle

position,

note that the

should

(Fig.20)

A

B

0.0511111

21

!.Remove

2.Turn

distance

A is

3.Loosen

between

(Adjust

4.After

25.

If

the

it as follows:

I.Lift

remove

2.Remove

rear

}.Release

separator

4.Release

the

between

obtained;

separator

in

accordance

adjustment,

Removing

rotating

the

the

needle;

presser

B;

D·

5.Turn the hook

6.Release

Installing

l.Install

above;

2.Note

removing

the

the

that

direction.

the

slide

balance

the

the

adjusting

and

and

installing

hook

needle

the

slide

plate

and

the

adjusting

the

screw C and

base

the

screw

rotaing

rotating

installing

plate;

wheel and stop when the

hook

separator

screw B so that

rotating

with the

tighten

the

the

is

damaged

bar to its highest position and

plate,

needle plate, front and

bobbin;

screw

remove the

E slightly and take it out;

and

take

hook:

hook

in the reverse process

direction

and

hook is

thickness

rotating

during

out the hook body

0.15mm.

adjusting

hook

sewing, replace

A,

remove

is the

same

biggest

rotating

the

clearance

of

materials);

screw B.

(Fig.22)

the

presser

with

hook

plate

F.

=

IIIII o 1111

B

D

E

0.

1511111

22

.,

-9-

Page 13

Parts

Manual

Page 14

1. Arm and

bed

32

26

JJ;-~~25

I

4

3

49

-10-

Page 15

1.

Arm

No.

and

bed

Part

number

Name

Qt.

Remark

I

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

9!WF2-001

91WF2-002

22WF2-003

37T4-407

22WF2-004

37T4-409

22WF2-006

37T4-411

22WF2-020 Screw

91WF2-003

89WF2-006

89WF2-005

49WFI-006

89WF2-004

91WF2-004 Safety guard I

49WF2-009 Screw 2

91WF2-005

49WF2-012

49WF2-013 Seal gasket

49WF2-014

49WF2-015 Spring

7KT2-020

49WF2-016 Column

!3WF6-008

49WF2-017 Pin

49WF2-018

49WF2-019

17T5-016

49WF2-020 Pin

49WF2-021

16WF2-038

16WF2-059

90WF2-005 Trade mark

91WF2-006

16WF2-053

I

KTI-005

91WF2-007

91WF2-008

91WF2-009

91WF2-0IO

91

WF2-0

9!WF2-012

WF2-0 13

91

91WF2-014

22WF2-007

91WF2-015

16WF2-035

91WF2-016

91 WF2-0 17

91WF2-018

22WF2-018

11

Cylinder bed

Arm

Base

Hinge 1

Screw

Connecting hook I

Connecting hook screw assembly I

Washer I

Face plate I

Face plate hinge assembly

Hinge

screw

Rubber

Spring

Upper

Screw

Oil

Washer

Screw

Spring

Column

Screw

Oil

Oil

plug I

plate

cover

window

tube

wick

Oil retainer

Screw

Trade mark

Trade mark

Rivet

Trade mark

Needle plate

Screw

Slide

plate

assembly(L)

Slide

plate

assemblyO

Right

presser

Left

presser

presser

Right

Left

presser

Screw

Connecting presser plate

Screw

Safety ring

Connecting holder

Screw

Washer

Connecting

plate (long)

plate (short)

foot (long)

foot (short)

10

pin

I

I

1

6

I

1

8

I

I

8

1

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

4

I

I

2

I

I

I

I

I

I

8

2

I

I

2

2

2

11/64'X32

9/64'X40

ll/64'X40

--11-

Page 16

2.

Upper

shaft

and

th

read

take

_

-up

- s

part

14

12

4 3

7

s--LPf

6

r

1'

11

8

t

0.

i

10

J

20~

rl

18

-12-

Page 17

2.

Upper

shaft

No.

1

49WF!-003

2 49WF!-004

3

4

91WF!-002

5 215029

6

7

l6WFl-011

8 16WF!-Ol5

9 16WF1-016

10

16WFI-017

I I

12

13

14

15

16

17

16WF1-0IR

16WF1-019

16WF1-020

16WFI-021

16WF1-022

22WF1-005

18

19 103565

20 16WF1-025

21

22

22WF1-006

16WF1-004

23 16WF1-026

24

25

22WF1-047

22WF1-048

26

27

16WF1-029

28 22WF1-043

29

30

31

22WFI-011

22WF1-045

22WF1-046

32 037473

33

13WF

34 13WFl-078

35

16WF1-040

36 91WF1-017

37 22WF1-041

38 16WF1-019

39

22WF1-042

and

Part

1-077

thread

number

take-up

----

cad

Thr

Scr

Oil

Thr

Sli

Oil

Ne

Ne

Pos

Scr

Oil

Ne

Pos

Scr

Spa

Scr

Up

Oil

Fro

Oil

Mi

Scr

Re

Re

Scr

Rc

Ret

Syn

Scr

Scr

Scr

Bal

Scr

Scr

Scr

Syn

Mi

Scr

Nut

take-up

ew

wick

cad

take-up

de

blcok

wick

edle

bar

edlc

bar

ition

screw

ew

wick

cd]c bar crank

it

ion

screw

cw

ccr

ew

per

shaft

wick

nt

bushing

felt

ddle

bushing

ew

arbushing

ar

bushing

ew

ar

bushing

awmg

chronic

ew

ew

(short)

ew

(long)

a

nee

wheel

ew

ew

ew

chronic

ddle

bushing

ew

parts

Name

link

crank

gasket

bearing

ring

belt

belt

lever

lever

pin

wheel

gasket

pin

sh

aft

------

-

Qt.

Remark

1

1

1

1

I

1

1

1

1

I

1

1

1

1

I

1

I

1

I

:l

1

2

I

1

2

I

I

1

1

I

I

1

I

I

I

1

1

1

1

I

··13~

Page 18

3.

Presser

bar

and

draw

bar

parts

30

·---·---·-··

-·------------------~

~~

r

26 25

0

2

u--··---

------14

---13

24

29--

--"@""'

28

--14-

---

Page 19

3.

Presser

bar

and

draw

bar

pat"ts

No.

1-----1-----------11-·~---

I

2

3

4

5

6

7

8

9

IO

I 1

12

13

14

15

16

17

18

Part number

I6WF4-00I

I6WF4-002

22WF3-00I

I6WF3-059

22WF3-002

22WF3-003

22WF3-004

I6WF4-009

I6WF4-023

I6WFI-009

16WF4-00R

037522

22WF3-005

16WF4-027

22WF3-006

16WF3-025

I6WF3-025

16WF4-021

Name

Presser

Presser foot lift

Spring

Screw

Presser

Screw

Nut

Spring

Spring

Screw

Screw

Screw

Presser bar

Presser

Presser bar

Screw

Screw

Guide bracket

foot lift

foot

lift

bracket

bar

upper

lower

lever

lever

bar

hushing

hushing

sha ft

Qt.

Remark

1

1

I

1

I

1

2

I

I

1

I

1

1

1

I

2

1

1

19 16WF4-022

20

21

22

23

24

25

16WF4-020

22WF3-007

16WF2-033

22WF3-008

22WF3-00\J

22WF3-0IO

26 22WF3-0 l l

27

22WF3-012

28

22WF3-0I3

29 22WF3-0I4

30 22WF3-015

Screw

Guide shaft

Guide

bracket

Screw

Spring

Presser

Presser

Screw

Presser plate pin

foot lift

plate

Preser foot

Screw

Position

plate

releasing

plate

1

I

1

1

1

I

I

I

I

I

I

1

'-----'-----~------

-----

---15--

Page 20

4.

Lowers

41-~

haft

~

and

ro

tating

------

hoo

k

a •·ts

P

---

------

I

~~~l',

I

I

~~~~i

I

13

2

-

---16

---

11

12

~

;-14

~----

~10

9

Page 21

4.

Lower

shaft

No.

I

90WFI-002

91WFI-003

2

3

4

5

6

22WFI-010

16WFI-013

22WFI-OII

22WFI-012

22WFI-013

7 22WFI-014

8

9

10

11

12

13

22WFI-015

22WFI-016

22WFI-017

22WFI-018

22WFI-019

ZZWFI-020

14

I 5

16

91WF1-001

22WFJ-022

I 7 380637

18

22WF4-046

19

20

21

22

23

24

25

26

27

28

29

30

31

91WFI-005

21WFI-043

91WFI-006

22WF1-005

91WFI-007

50WFI-046

91WFI-008

91WFI-009

91WFI-OIO

16WFI-059

91WFI-011

9IWFI-Ol2

32 91WF1-013

33 91WFI-018

34

22WFI-050

35 ZZWFI-036

36

37

38

39

22WFI-037

91WFI-OI4

91WFI-020

91WFI-0\5

40 9IWFI-016

41

42

43

44

88WF2-0I2

9\WFI-019

16WF3-016

22WFI-039

45

46 22WFI-040

47

48

16WFI-054

16WF1-053

and

Part

rotating

number

hook

. -

-------

Lower

shaft

Lower

Synchronic

Retainer

Bushing

Screw

Spring

Spring

Eccentric

Stop

Connecting

Stop

Pin

Screw

Split

Front

Screw

Screw

Rear

Oil felt

Lower

Lower

Screw

Collar

Screw

Gear

Gear

Screw

Screw

Rotating

Rotating

Slide

Slide

Set

Set

Adjusting screw

Adjusting

Eccentric plate

Eccentric

Screw

Screw

Rotating

Rotating

Screw

Screw

Washer

Washer

Oil

Oil

Rotating

Rotating

Screw

Screw

Washer

Washer

Rotating

Rotating

Bobbin

Bobbin

Button

Spring

Stop

Split

Button

Screw

Screw

shaft

plate

plate

plate

pin

hush

bushing

shaft

shaft

block

block

plate

plate

felt

felt

wheel

pin

bushing

parts

----·

Name

--

-- - -

belt

wheel

shaft

pin

piece

in~

gear

gear

hook

separator

hook

separator

assembly

assembly

screw

plate

hook

bracket

hook

bracket

hook

bracket

hook

bracket

hook

hook

---

-

(left)

(right)

bushing

bushing

Qt

1

I

3

I

2

I

I

I

I

I

I

1

2

I

1

I

l

1

I

2

1

1

2

2

2

2

2

2

2

2

4

I

I

1

4

2

2

2

2

2

2

I

I

I

I

I

I

I

Remark

I I 4 X

32

KRTS-IlL

--

17

-··

Page 22

5. Feed

shaft

------=~

1-'P

1

• arts

~-~1

"'8

@~@I

40

c:;---<-.

~--

~---48

47

---42

49

0

I

2

11

-

···-

18

--

Page 23

5.

Feed

No.

I

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

2ft

25

26

27

28

29

30

31

32

33

34

35

36

:17

38

39

10

41

12

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

shaft

parts

22WF4-00I

22WF1-002

91WF4-001

22WF4-004

22WF1-005

22WF4-006

22WF4-007

22WF4-00B

22WF4-009

91WF4-002

22WF1-012

16WF2-025

91WF4-00:l

16WF2-020

91WF4-004Al

91WF4-004A2

91WF4-004A3

16WFI-O

91WF4-005

91WF4-006

91

wr-i-007

91WF1-00R

91WF4-009

91WF4-0IO

91Wf4-0ll

22WF4-021

22Wr4-022

22WF4-02:l

91WF1-012

22WF4-025

22WF4-026

22WF1-027

22WF4-028

13WF1-027

22WF1-0:JO

91WF4-013

22WF1-032

91WF1-011

22WF4-031

22WF4-035

22WF4-036

22WF4-037

22WF4-038

22WF4-039

22WF1-040

91WF4-015

22WF4-020

22WF4-042

22WF1-023

]0.0.81

91WF1-006

22WF1-005

Part number

-·--··

59

-

---

--

---

-

Feed

Sere

Cam

Sere

Sere\

Feed

Sere

Oil

Conn

Feed

Oil f

Sere

Feed

Sere

Feed

Feed

Press

Sere

Conn

Sere

Colu mn

Colu1

Sere

Sere w

Sprin

Sprin

Split

Cont

Bolt

Sere

Posit

Nut

Revc

Sere w

Sprin g

Sprin g

Stitcl 1 length dial

Sere

Feed

Stitc h length adju

Oil f

Sere

Felt

Slide

Oil f

Sprin

Feed

Sere

Conn

Oilw

Feed

Sere

Colla

Sere

Nam

eccentric

w

w

v

crank

w Sere

w

wick

ccting

connecting

nut

cit

w

dol(

w

dog support

dog support

cr

plate

w

cit Oil f

ecting

w

1111

w

brack

p1n

cr Wash

g

g hook

ptn

rol block

w

ion hlock

rsc

feed I eve

ball

w

link

cit

w

block

cit

g

shaft

w

ecting pin

ick

shaft

bushit

w

r

w

--

c

w

heel

shaft

bracket

ct

r

sting block

lg

·-----

...... -

Qt.

Remark

1

2

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

I

2

1

1

2

1

1

1

1

1

1

1

1

1

1

I

I

I

I

2

I

I

I

4

1

1

2

2

1

1

1

1

1

1

I

I

1

1

1

1

----·

19-

Page 24

6.

Upper

37

feed

42

and

presser

foot

l"ft 1

cr

parts

38

40

4 5

48--

SJ"e

~

,~-50

--47

.eJ~--

49

8 1

15

13

~

20---

Page 25

6.

Upper

feed

No.

1

2

3

4

5

6 215120

7

8

9

10

11

12 91WF5-002

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40 22WF5-029

41

42

43 22WF5-031

44

45

46

47

48

49

50

51

52

53

and

presser

Part number

91WF5-00l

22WF5-002

16WF1-0ll

!WF5-009

!WF5-010

foot

liftct·

Needle

Pin

Screw

Guide plate

Screw

bar

vibrating

Name

Guide rail

16WF1-059

22WF5-001

22WF5-005

22WF6-006

22WF1-020

Screw

Needle

Slide

Slide

Screw

bar

vibrating

block

block shaft

Crank

22WF3-0

11

215121

91WF5-003

22WF5-011

22WFJ-0042

Screw

Slide block

Needle

Screw

Nut

bar

vibrating

Oil wick

22WF5-0!2

22WF5-013

22WF5-014

22WF5-015

22WF5-016

22WF5-017

16WF3-030

22WF5-018

16WF2-023

22WF5-019

22WF5-020

22WF5-021

22WF5-022

22WF5-023

22WF5-021

22WF4-002

22WF5-026

22WF5-027

22WF5-028

Presser foot I ift shaft

Bushing

Link

Screw

Nut

Crank I

Screw

Screw

Washer

Gasket

Wing

nut

Eccentric

Eccentric

link

link

Eccentric wheel

Screw

Collar

Screw

Presser foot lift vibrating plate

Screw

Link

Oil wick

Presser

bar

Oil wick

22WF5-030

Spring

Spring bar

91WF5-004 WalKing

presser

22WF5-033 Screw

49WF5-009

Screw

88WF2-002 Needle bar

88WF2-001 Needle clamp

22WF!-003 Screw

!6WFJ-007 Screw

!F-009

91WFJ-OO!

16WF!-009

Needle

Needle

Screw

Oil

wick

bar

connector

pa.-ts

--~-

-----~--

bearing

foot

bracket

shaft

link

Qt.

1

l

2

I

I

2

1

2

2

2

2

2

I

l

1

1

1

1

I

I

1

I

l

l

I

1

1

I

1

1

I

1

l

l

I

I

1

I

1

1

1

I

1

1

1

1

1

1

1

I

I

1

Remark

.,

DPX17

--

-21---

Page 26

7.

Threading

r------------------

parts

------------------------,

27

-'-

~-31

10

9

8

!_

________________________________

---

22

---

~

Page 27

7.

Threading

parts

No.

f----f---------·

1

2

3

4

5

6

7

8

9

10 037536

II

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27 16WF2-049

28

29

30 13WF2-067

31

Part

number

25057

16WF2-013

16WF2-014

16WF2-015

89WF2-017

25WF2-009AI

16WF2-046AI

16WF2-016A2

16WF2-046A3

153029

16WF2-046A5

16WF2-046A6

19WF2-014

16WF2-046A8

1WF1-010RI

25WF2-009A2

16WF2-046All

16WF2-046AI2

19WF2-0ll

19WF2-012

115955

16WF2-046AI4

16WF2-046AI5

103723

16WF2-020

13WF2-008

16WF2-050

13WF2-066

49WF2-022

Name

·-----·-····-···-··

Upper

Lower

Felt

Screw

Thread

Set

Set

Screw

Screw

Nut

Nut

Stop

Stop

Spring

Spring

Thread

Thread

Thread

Thread

Thread

Thread

Thread

Screw

Thread

Nut

Thread

Pin

Thread

Thread

Thread

Screw

Thread

Screw

Screw

Position

Screw

Thread

Screw

Three-eye

thread

thread

guide

plate

plate

plate

plate

releasing

releasing

tension

tension

take-up

control

control

take-up

separatine

(long)

releasing

releasing

erecting

releasing

plate

guide

thread

guide

guide

plate

plate

plate

plate

spring

assembl

assemhl

springs

pin (sl

pin

plate

bar

finger

pin

(lo

y

y

haft

wrt)

ng)

Qt

Remark

I

I

I

3

I

I

2

2

2

2

2

4

I

2

I

I

I

I

I

I

I

I

2

I

I

1

1

I

2

2

--

--

23---

Page 28

8.

Accessories

,--------==----------------·-------------,

15-----1

--18

~r---24

23 22

~-B

9

20

14-

---i

~

T--25

®---26

©---27

29-~11\

2

7

31

1

34

--24-

Page 29

8.

Accessories

No.

2

3

4

5

6

7

8

9

10

II

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

Part number

91WF6-00J

91WF6-002

91WF6-003

36WF5-003

2KT2-026

21WF1-036

88WF2-012

91WF6-004

1F-014

S14420020

33TF-Ol7

33TYF-018

1F-009

33TF-011

33TF-012

33TF-OJ3

33TF-014

22WF2-008

16WF3-005

22TZ-004

Safety

Safety

gua

gua

Connectin

Screw

Nut

Washer

Arrow

mar

Bobbin

Bobbin

Box wrcnc

Double

en

Spanner

Spanner

Spanner

Needle

Thread

spo

Bobbinwi

Screw

Washer

Oil

tank

Oil pot

Scrcwdriv

Screwdriv

Screwdriv

Accessory

Screw

Washer

Spring

Pedal

was

ass em

Chain

Chain

hook

Cover

V-belt

Oil

rcservo

Screw

Screw

Name

rd

(I)

rd (2)

gplate

k

h

ded

spanner

ol

stand

ndcr

assembly

cr

(big)

er

(medium)

er

(small)

bag

her

bly

tr

assembly

Qt.

-

1

I

2

2

2

2

1

12

J

I

I

I

I

I

6

I

OX

S=3mm

S=2.

S=l.

DPX

J

2

2

I

I

J

I

I

1

M8X75GB68-85

4

GB96-85-8

4

GB93-87-8

4

1

I

2

1

I

1

I

I

Remark

11

5mm

5mm

17

22#

-·-

25

-·-

Page 30

TABLE

OF

GAUGE

PARTS

inch

1):

1/8"

I

1/4"

5/16"

3/8"

1/2"

STANDARD

GAUGE

SIZE

mm

3. 2

6. 4

7. 9

9.

1 2. 7

0

~

NEEDLE

CLAMP

88WF2-001A

88WF2-001 91WF5-004

88WF2-001D

5

88WF2-001E

88WF2-001G 91WF5-004D 91WF3-001D

GAUGE

SIZE:1/4"

[

WALKING

FOOT

91WF5-004A 91WF3-001A 91WF2-007A 91WF4-003A

91WF5-004B 91WF3-001B 91WF2-007B 91WF4-003B

91WF5-004C 91WF3-001C 91WF2-007C 91WF4-003C

I~

~--=

PRESSER

FOOT

91WF3-001 91WF2-007 91WF4-003

~

NEEDLE

PLATE

91WF2-007D

tf!!!!!i!_

~

FEED

DOG

91WF2-013A 91WF2-014A

91WF2-011B 91WF2-012B

91WF2-013B 91WF2-014B

91WF2-011C 91WF2-012C

91WF2-013C 91WF2-014C

91WF4-003D

91WF2-011D 91WF2-012D

91WF2-013D 91WF2-014D

tJ!!!!!!

~

PRESS

PLATE(L)

91WF2-011A

91WF2-011 91WF2-012

91WF2-013 91WF2-014

~

PRESS

PLATE(R)

91WF2-012A

~

SLIDE

PLATE(L)

91WF2-009A

91WF2-009

91WF2-009B

91WF2-009C

91WF2-009D

~

SLIDE

PLATE(R)

91WF2-010A

91WF2-010

91WF2-010B

91WF2-010C

91WF2-010D

Loading...

Loading...