Page 1

High

Models

Frequency

Operating Instructions

Global® Pneumatic

Roller Vibrators

GCL-4400 GCD-4400

GCL-5000 GCD-5000

GCL-5500 GCD-5500

GCL-6500 GCD-6500

AIR BLASTERSVIBRATORSVIBRATORS

GlobalManufacturing.com

GCD

GCL

Global Manufacturing Inc.

1801 East 22nd St

Little Rock, Arkansas 72206

501.374.7416 TEL

800.551.3569 TOLL FREE USA & CANADA

501.376.7147 FAX

®

GCL-GCD_03/02/16 Copyright © 2016 by Global Manufacturing, Inc

Page 2

Global Manufacturing, Inc ® 800.551.3569 TOLL FREE USA & CANADA

1801 East 22nd Street 501.374.7416 TEL 501.376.7147 FAX

Little Rock, AR 72206 USA www.GlobalManufacturing.com

Table of Contents Page

I. Introduction 2

II. Installation Procedures 3

III. Mounting 4 - 5

I V. Operation 6

V. Assembly & Disassembly Procedures 6 - 7

VI. Vibrating Wet Concrete 8 - 10

VII. Vibrator Orientation 11

VIII. Parts Explosion - GCD 12

IX. Parts Explosion - GCL 13

X. Vibrator Dimensions - GCD & GCL 14

XI. Bracket Dimensions 15

XII. Performance Data & Lubrication 16

XIII. Troubleshooting 17

I. Introduction

You have purchased a GCL-4400/GCD-4400, GCL-5000/GCD-5000, GCL-5500/GCD-5500, or GCL-6500/

GCD-6500 High Frequency vibrator manufactured by Global Manufacturing, Inc.® They are excellent

roller style high frequency pneumatic vibrators used on forms for concrete consolidation. The GCL model

ts the standard cradle lug brackets commonly used on concrete forms. The GCD models are bolt-on for

a more permanent mount, although they can also be attached to portable brackets.

For optimum performance, cycle the vibrator on and off. Vibrator act as a friction reducer and once the

bulk solid is set into motion, gravity does the rest. Do not operate the vibrator on an empty hopper as

this may cause structural damage to the hopper. Operate vibrators only when discharge gates are open.

Vibration will compact the material inside the structure if the discharge gate is closed.

Vibration has two important elements – Frequency and Amplitude. Frequency is the speed (RPM) or the

number of vibrations per minute. It is controlled by the air ow to a pneumatic vibrator. Amplitude is

the unbalance or amount of force produced by the eccentric weight. The faster the eccentric weights turn

the more force output generated. Force and frequency work together. It is not necessary to use a lot of

force when you have adequate frequency.

• Follow all mounting instructions.

• Always use a safety cable or chain for support.

• Do not operate vibrators when structure is empty.

• Do not operate vibrators when gate is closed or conveyor is stopped unless consolidation of

material is desired.

• Wear ear protection for 90+ decibel levels.

• Do not operate the pneumatic vibrators above 100 p.s.i.

• To prevent explosive hazard, do not use combustible gases to drive the pneumatic motor.

• Do not use hydrocarbons (fuel or kerosene) as a lubricant or de-icer.

• Always operate pneumatic vibrator with a regulator, lter, and lubricator.

• Always disconnect air line before maintenance.

SAFETY PRECAUTIONS

2

Page 3

Global Manufacturing, Inc ® 800.551.3569 TOLL FREE USA & CANADA

1801 East 22nd Street 501.374.7416 TEL 501.376.7147 FAX

Little Rock, AR 72206 USA www.GlobalManufacturing.com

II. Installation Procedures

Caution!

Do not mount the vibrator directly to the

structure wall. Use a channel iron stiffener for

proper mount rigidity and as the transducer of

the vibrational energy.

The key to successful

vibration is a proper mount

because rotary vibration

resonates the material

inside the structure, when

the vibrator is mounted

correctly. Rotary vibrators

should appear motionless

and make minimal noise.

Channel Irons - Size & Mounting

Stitch weld channel iron

Do not weld the ends of the channel

iron. This allows the vibrational force to

"escape". Solid welded ends trap the force

which can cause stress cracks.

Mounting GCL cradle lug model - Stitch weld a

GCL Bracket to the back of the channel iron. Do not

weld the ends. Mount the vibrator in the bracket by

sliding the foot into the GCL Bracket, lowering the

latch bolt into the ngers on the vibrator housing,

and securely tighten the nut.

Piggy-back

channel

Important!

Install a channel iron that is at least twothirds of the height of the sloped portion of

the hopper but no greater than 10 feet (3 m).

Install channel iron at least two-thirds the height

of the sloped portion of the hopper, but not less

than 6 feet (1.83 m) in length and the width not

less than the base width of the vibrator. See

chart below for recommended channel si zes. Do

not install more than one vibrator on the same

channel iron or use a channel iron shorter than the

recommended length. A short channel may ex

the bin wall.

Channel Iron Designation

Model

GC L- 4400

GCD-4400

GC L- 5000

GCD-5000

GC L- 5500

GC L- 6500

GCD- 5500

GCD- 6500

Channel

Iron

C4" x 5.4 lb/ft 60"

C100 x 8 kg/m 1524 mm

C4" x 5.4 lb/ft 72"

C100 x 8 kg/m 1829 mm

C4" x 7.25 lb/ft 72"

C100 x 11 kg/m 1829 mm

Attaching the vibrator to the channel iron.

Stitch weld nuts to the back of the channel iron

or the channel iron may be drilled and tapped to

accept the mounting bolts. An alternate method is

to cut a second channel iron slightly longer than

the footprint of the vibrator. Stitch weld the second

channel iron to the rst. Do not weld the ends.

Mount the vibrator to the second channel iron.

Minimum

Length

Stitch weld

GCL Bracket

Stitch weld

channel iron

Do not weld the ends of the

channel iron. This allows the

vibrational force to “escape”.

Solid welded ends trap the force

which can cause stress cracks.

to channel

Hopper

Stitch weld the channel iron vertically to the

sloped portion of the bin wall. Weld 3 inches

(7.5 cm), skip 1 inch (2.5 cm), weld 3 inches (7.5

cm), etc... Leave 1 inch (2.5 cm) un-welded on

the ends and corners. This allows the vibration to

dissipate out the ends of channel without causing

stress cracks to the hopper or bin. By doing so,

should the weld fail, the entire mount will not fall

off. Do not mount the channel iron horizontally.

Secure the vibrator to the channel iron with

SAE coarse thread grade 8 plated bolts with

lock washers or an adhesive such as Loctite

®

262. Tighten bolts in a sequential process. At least

two passes are required in most situations. Give

all bolts the same torque value. Grade 8 bolts can

handle more torque than standard bolts. If Loctite

®

is not used, retorque the bolt after the vibrator has

operated for a few minutes and check tightness

often. If Loctite® is used do not retorque the bolts

as this will break the Loctite® bond.

Attach a safety cable to a stronghold (not the

channel iron mount), which is higher than the

mounted vibrator and capable of holding the

vibrator’s weight.

3

Page 4

Global Manufacturing, Inc ® 800.551.3569 TOLL FREE USA & CANADA

H

⅓

of H

⅔

of H

⅓

of H

⅔

of H

H

¾

of

H

¼

of H

½

of H

⅔

of H

⅓

of H

⅔

of

H

⅔

of H

H

1801 East 22nd Street 501.374.7416 TEL 501.376.7147 FAX

Little Rock, AR 72206 USA www.GlobalManufacturing.com

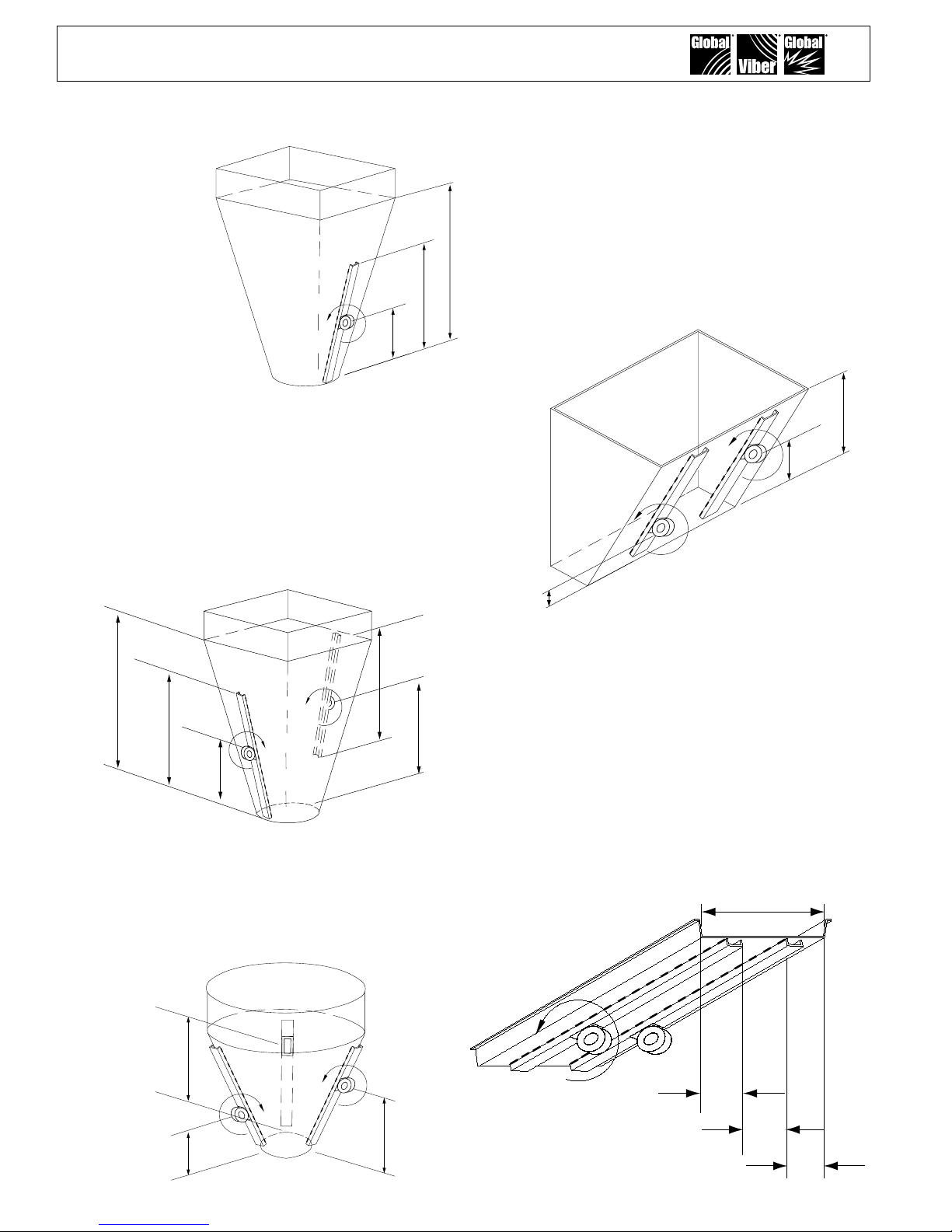

III. Mounting Locations

Single Vibrator

Install a channel

iron stiffener on

the outside of the

sloping wall 1⁄3 the

distance above the

discharge opening.

Multiple Vibrators

Use more than one vibrator when the diameter or

width of any wall is greater than 12 feet (3.66 m).

Always mount the vibrators on different planes.

Two Vibrators on Round or Square Hoppers

Install channel iron stiffeners 180° apart. Install

one vibrator on the outside of the sloping wall 1⁄3

the distance above the discharge opening. Install

the second vibrator on the outside of the opposite

sloping wall 2⁄3 the distance above the discharge

opening.

Two Vibrators on Rectangular Hoppers

Install channel iron stiffeners on opposite sides of

the long walls. Install one vibrator on the outside of

the sloping wall 1⁄3 the distance from the discharge

opening. Install the second vibrator on the outside

of the opposite sloping wall 2⁄3 the distance above

the discharge opening. When only one wall slopes,

mount both stiffeners on it. Equally space the

stiffeners on the wall. Place one vibrator 1⁄3 above

the discharge opening on one channel iron and the

other vibrator 2⁄3 above the bin’s discharge opening

on the second channel.

Three Vibrators

Install channel iron stiffeners mounted 120° apart.

Install the rst vibrator on the outside of the

sloping wall ¼ the distance above the discharge

opening. Install the second vibrator on a separate

channel iron at ½ the distance above the discharge

opening. Install the third vibrator on the remaining

channel iron at ¾ the distance above the discharge

opening.

Installation on Chutes and Flow Pipes

Mount channel iron stiffeners vertically or in the

direction of material ow. Center the channel if the

chute is less than 6 ft (1.83 m) in width. If the

chute is greater than 6' in width, use two vibrators

on separate channel irons. To maximize each

vibrator’s radius of inuence; center each channel

iron in each half of the chute. Each channel iron

should be located ¼ of the chute width from the

edge and ½ of the chute width apart. (e.g. –

a chute 8' wide, the channel iron locations would

be 2' from each edge and 4' apart.) When wall

thickness is less than ⅛", additional reinforcement

may be required.

Width is more than 6'

¼ of Width

½ of Width

4

¼ of Width

Page 5

Global Manufacturing, Inc ® 800.551.3569 TOLL FREE USA & CANADA

1801 East 22nd Street 501.374.7416 TEL 501.376.7147 FAX

Little Rock, AR 72206 USA www.GlobalManufacturing.com

Placement on Channel Iron

Orient the direction-of-rotation of the unbalance

(roller weight) so that it turns in the direction of

material ow. Position lug bolt on the high side

(uphill side) of the channel iron.

R

o

t

a

t

i

o

Direction of Material Flow

Keyway

Inlet

Hopper

n

Lug

Bolt

Installation on Railcars

Place GCL vibrator in a GCL-GBMX Bracket or a

GCL-GBM Bracket. The vibrator on the bracket slides

into the standard railcar bracket on the hopper car.

If two vibrators are used on one railcar, use an air

regulator to run them at different speeds.

GCL-GBMX Bracket

Has handy handle

for ease of use.

Channel Iron

stitch welded

to hopper

Securing Vibrator to GCL Bracket

Attach the vibrator to the cradle lug bracket by

placing the tab at the base of the vibrator under

the bar on the end of bracket. Rotate the vibrator

towards the bracket until it is fully seated. Rotate

the bracket bolt until it ts between the two ngers

on the vibrator housing and secure it using the

cradle lug nut. Use a standard open-end or box

wrench to tightened. Repeated tightening with an

air wrench will eventually cause excessive wear to

the ngers on the vibrator housing.

Mounting on Truck Bed

Weld GCL bracket to an independent channel

iron. The GCL vibrator inserts quickly into bracket.

Locate the channel iron as close as possible to the

material flow problem area.

Channel Iron

Vibrator

For correct vibrator

rotation, the hose

barb is on the left side

of the handle.

GCL Vibrator

Keyway

GBF Bracket

Wedge Pocket Bracket is

standard on most railcars.

GCL-GBM

Bracket

GCD-GBM

Bracket

GCD Vibrator

Railcar

Wedge Pocket Bracket standard on most railcars

5

Page 6

Global Manufacturing, Inc ® 800.551.3569 TOLL FREE USA & CANADA

1801 East 22nd Street 501.374.7416 TEL 501.376.7147 FAX

Little Rock, AR 72206 USA www.GlobalManufacturing.com

IV. Operation

Global High Frequency External Vibrators are

pneumatic with dual rollers. Their ease of operation

and low maintenance is due in part to the fact that

these vibrators contain no bearings or motors.

The vibrator may run continuously at speeds

up to the rated running conditions shown in our

performance data. Use a ball valve or solenoid

valve to turn the vibrator on and off. A regulator

provides constant speed control even as the plant

air pressure varies.

Install a filter, regulator, gauge, and lubricator in

the air line within 10 to 12 feet (3 - 3.7 m).

Filtration

Do not connect the vibrator directly to plant air. Use

a 64 micron filter. Drain the airline filter regularly

and examine the element for signs of clogging.

Regulation

Operate the vibrator on ltered, regulated, lubricated

air between 40 - 80 psi (2.8 - 5.5 bar) at 45 - 60

cfm (21 - 28 Lps).

Lubrication

Use a lightweight lubricant. Replenish the airline

lubricator as required and set to give the following

drop rate minimum. Will operate in temperatures

of 32° F (0° C) to 250° F (120° C).

Filter & Lubrication Requirements

Pipe and Hose Connections

The vibrator has a barb tting to accept a ¾"

I.D. hose. Clamp the hose securely to the tting

with a Band-It, Punch-Lok

worm driven clamp is not recommended since the

vibration may cause the clamp to loosen and allow

the hose to blow off the fitting.

The table below shows the recommended hose size

according to the amount of air required.

Hose Length and I.D.

SCFM

Flow

(Lps)

20 (9)

30 (14)

60 (28)

80 (38)

0 - 25'

(7.6 m)

5

⁄16" ⅜" ½"

⅜" ½" ½"

½" ¾" ¾"

¾" 1" 1"

If the vibrator will be moved or disconnected

frequently, a hose whip is recommended (see

illustration below). The whip is a short piece of hose

(12" - 18") atttached to the shaft with a clamp.

Attach a quick coupling, such as a Dixon

coupling, to the free end of the whip. Add a ball

valve to the plant air line to shut off the air before

disconnecting the quick coupling.

®,

or a similar clamp. A

Hose Length

26' - 50'

(7.6 - 15 m)

50' - 200'

(15 - 61 m)

Hose I.D.

®

hose

Filtration Required Lubrication Required

64 Micron

10 -1 2 Drops per Minute

10 Weight Oil

Recommended Lubricants

Shell: Tellus 37

B.P.: Energol HL65

Castrol: Hyspin 70

Mobil: Alma oil No 1

®

Vibrator

6

Punch-loks

=

H

o

s

e

W

h

V. Assembly & Disassembly

For proper vibration operation, it may be necessary

to change the direction of rotation or the position

of the vane. Both the GCD and GCL models are

disassembled and assembled in the same manner.

Tools Required:

• Press

• Torque Wrench

• ⅜" Wrench

Dixon

Hose Ends

p

i

Ball

Valve

Hose Whip Assembly

part number 260197

Hose

Nipple

Air Line

Page 7

Global Manufacturing, Inc ® 800.551.3569 TOLL FREE USA & CANADA

Roller

1801 East 22nd Street 501.374.7416 TEL 501.376.7147 FAX

Little Rock, AR 72206 USA www.GlobalManufacturing.com

Disassembly:

Note 1: The vibrator shaft is pressed into the

side plates. The side plates have a slip t in

the housing.

1. Remove the four ⅜" hex bolts and lock washers

from each side plate.

2. Opposite the air inlet, using a press, carefully

press against the backside of the shaft. This

will push out the (exhaust) side plate and the

shaft (as one assembly). Protect the air inlet

connection. The inner and outer rollers will

come out with the shaft. Remove blind side

plate if necessary.

3. Lift air vane from shaft. Inspect side plates,

shaft, and vane for wear. Any grooving on the

side plates or noticeable wear on the inner

roller, shaft, or vane requires component

replacement.

Assembly:

It is important to keep in mind the mounted

orientation of the vibrator. The vane and side plates

must be properly positioned to place the vane on

top of the shaft to give the proper direction of

rotation when mounted.

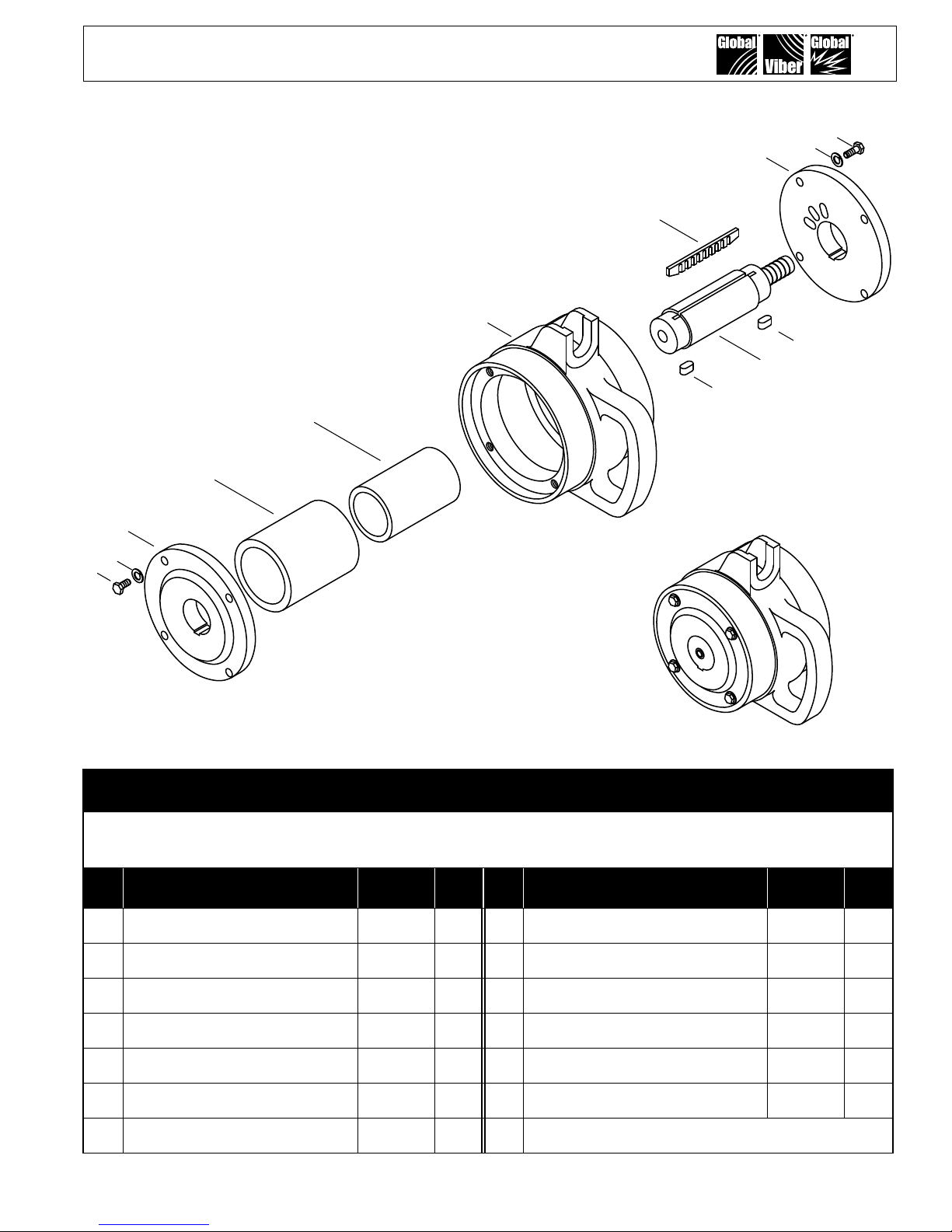

Note 2: Below is an exploded view of the GCD

vibrator. Notice the position of the blind side plate,

which has three slots milled halfway through

the plate, and the exhaust side plate, which has

three slots milled all the way through the plate.

The slots of the side plates must be directly

across from each other. These plates must be

positioned with the grooves in the vane facing

away from these three slots.

1. Assemble the shaft. Press or tap the keys into

the keyways in the shaft. Place the vane in the

shaft so that the grooves in the vane will be

facing away from the three milled slots of each

side plate. See page 11 for orientation of vane.

2. Exhaust side plate installation: Using the key as

a guide, align the shaft/key with the keyway on

the exhaust side plate. Press air inlet end of the

shaft into the exhaust side plate until it stops.

3. Install the exhaust side plate/shaft assembly

into the vibrator housing. Be sure its orientation

will place the vane on top of the shaft and

give the desired direction of rotation when the

vibrator is in the mounted position. Align the

bolt holes in the side plate with the threaded

holes in the vibrator housing. Install the hex

®

bolts and lock washers with Loctite

262 and

tighten the bolts to 33 ft·lb torque (44 Nm).

4. Make sure all foreign material is out of the

vibrator housing and the rollers. Place the

rollers on the shaft inside the housing. Place

smaller roller inside the larger roller.

5. Press the blind side plate onto the end of the

shaft and into the vibrator housing. Align the

bolt holes and the keyway of the blind side

plate. Install the hex bolts and lock washers

with Loctite® 262 and tighten the bolts to 33

ft·lb torque (44 Nm).

Exhaust

Vane

Ports

Blind

Side Plate

Sliding

Surface

Blind Slots

Housing

Keyway

n

o

i

t

R

Vane

Grooves

Shaft

Keys

a

t

o

Air

Inlet

Outer Roller

Inner

Roller

Outer

Through

Slots

Exhaust

Side Plate

Inner

Roller

Hose

Barb

Key

7

Page 8

Global Manufacturing, Inc ® 800.551.3569 TOLL FREE USA & CANADA

1801 East 22nd Street 501.374.7416 TEL 501.376.7147 FAX

Little Rock, AR 72206 USA www.GlobalManufacturing.com

VI. Vibrating Wet Concrete

Concrete Consolidation by vibration is achieved by

adding a mechanically-induced combination of force

and frequency allowing those forces to act on the

freshly-poured concrete within the vibrator's area

of inuence. The proper combination of force and

frequency will ensure that the concrete will retain

its homogeneity while allowing the entrapped air to

escape through the surface. A frequency of 9,000

– 12,000 vibrations per minute initiates resonance

in (or “excites”) the cement, causing the ultra-ne

cement particles to release the extremely small

air pockets that have adhered to the cement, so

that the mortar lls in all of the spaces around the

aggregate. Vibration evenly distributes the cement

and aggregates resulting in a more dense and a

smoother concrete nish.

When enough of the entrapped air has risen to the

surface to achieve concrete consistent with the

intended strength of the mixture, the vibration is

complete. In practical terms, it is neither possible

nor necessary to remove all of the entrapped air in

the consolidation process.

How to Select an External Vibrator

There is not an exact method or science when using

external vibrators for concrete consolidation. Mixes

vary, and therefore, consolidation procedures and

preferred vibrator styles vary. “Experts” become

experts through trial and error. What makes every

application different is that the mixes will vary due

to the slump, any chemical additives, aggregate

sizes/shape, cement content, consistency of the

mixture, weather conditions, and even the type of

form work used. Following these general rules may

be helpful in selecting the number and placement

of external vibrators for effective concrete consolidation.

In selecting External Vibrators, the contractor

should initially consider the workability of the

concrete and the rigidity of the forms. Plastic

concrete (slump > 3") responds better to high

frequency vibration, while stiffer mixtures

(slump < 3") require higher amplitude vibration to

initiate uidization. While properly-sized external

vibrators can be successfully used on virtually any

concrete formwork, using a too-powerful vibrator

on lightweight forms can cause damage to the

formwork. This has caused some contractors to

mistakenly believe that external vibrators cannot

be used on lightweight concrete formwork.

Vibrator Selection

Depending on specic conditions, external vibrators

with speeds between 3,000 and 12,000 rpm may be

suitable for form vibration. However, because the

natural resonant frequency of Portland Cement is

between 9,000 – 12,000 rpm, pneumatic vibrators

are often the only equipment capable of delivering

this necessary frequency.

After determining the approximate combined

weight of the formwork and concrete to be vibrated,

the contractor should select a vibrator producing the

amount of force specied by the table below. It will

often be necessary to use more than one vibrator

to produce the total amount of force required.

Note: If specific density of the concrete is

unavailable, use a standardized weight of 150 pounds

per cubic foot (2,400 kg / m3) for approximation.

Vibrator Selection

for Concrete Consolidation

Consistency Slump Vibrator Selection

Vibrator force output

Very stiff

concrete

Stiff

or

stiff plastic

concrete

Plastic

or

owing

concrete

<0.5"

0.5" - 2.0"

>2.0"

should be equal to

200-300% of the total

weight of the concrete

and form.

Vibrator force output

should be equal to

130-150% of the total

weight of the concrete

and form.

Vibrator force output

should be equal to

the total weight of the

concrete and form.

8

Page 9

Global Manufacturing, Inc ® 800.551.3569 TOLL FREE USA & CANADA

1801 East 22nd Street 501.374.7416 TEL 501.376.7147 FAX

Little Rock, AR 72206 USA www.GlobalManufacturing.com

Tips for using External Vibrators for

concrete consolidation:

Proper placement of the external vibrators is critical

to ensure that the vibration is distributed over the

desired area of the concrete. Depending on the

concrete consistency, density of embedments and

the quality of the mounting, External Vibrators

produce an Area-of-Inuence determined by the

force and frequency of the vibrator and the duration

of the vibrating time.

The following guidelines for spacing External

Vibrators have been developed, but contractors

should determine specic spacing requirements

for each project to ensure complete coverage of

vibration and successful consolidation.

Vibrator Spacing

for Concrete Consolidation

Distance

Consistency Slump

Very stiff or

stiff concrete

< 1.0"

< 25 mm

between

Vibrators

5' Apart

1524 mm

If the thickness of the concrete to be consolidated

is greater than the area of inuence of the vibrator,

or if a higher-quality nished surface is required on

both sides, the contractor should locate alternate

vibrators on opposite form walls. For instance, the

rst vibrator is placed on the front wall and the

next is 5' (1.5 m) away but on the back wall. See

illustration below.

Alternating the vibrators on a concrete form

Vibrators on the opposite

side of the form.

Vibrators on the near

side of the form.

Stiff plastic

concrete

Plastic

concrete

Flowing

concrete

1.0 − 2.0"

25 − 50 mm

2.0 − 5.0"

50 − 127 mm

> 5.0"

> 127 mm

6' Apart

1828 mm

7' Apart

2134 mm

8' Apart

2438 mm

Vibrating times for external vibrators may be

longer than for immersed internal vibrators. Most

operators will initially vibrate for approximately

two minutes per lift, and i n cr e as e or decrease

vibrating times as needed. Note that the same

criteria should be used to determine when the

consolidation is complete (no air bubbles at the top

surface, a thin lm of mortar on the top surface

and a stabilization of the speed of the vibrator).

Pour concrete into the forms in evenly dispersed

layers (lifts). Do not exceed a 20" lift height

otherwise the weight of the concrete can prevent

the entrapped air from escaping. Operate vibrators

in conjunction with each lift until the concrete is

fully consolidated. As each subsequent lift is placed,

locate additional vibrators for operation (or move

them from the previous level). Some operators

prefer to operate the previous lift’s vibrators for

a short period of time to promote “knitting” of the

two layers together.

In some cases, when the thickness of the concrete

to be consolidated is extraordinarily large,

contractors may choose to use Internal Vibrators

in the center section, with External Vibrators used

simultaneously along the outer edges.

Important!

Forms should be well made to withstand the

strains of vibration.

1. If using wooden forms, use screws instead of

nails (which may back out with vibration).

2. Forms need to be well braced to prevent bulging.

3. Joints need to be closely t to prevent leaking.

4. Monitor forms during placement of concrete.

Tighten as needed.

9

Page 10

Global Manufacturing, Inc ® 800.551.3569 TOLL FREE USA & CANADA

1801 East 22nd Street 501.374.7416 TEL 501.376.7147 FAX

Little Rock, AR 72206 USA www.GlobalManufacturing.com

Examples of Mounting External Vibrators

Poor Mount = Poorly Finished Concrete

The vibrator is mounted directly to the form wall.

Without a channel iron, the force output is

concentrated where the vibrator is attached,

causing the wall to ex and may cause stress

cracks. The vibration is not evenly distributed

resulting in a poor concrete nish.

Excellent Mount

Excellent Mount = Superior Finished Concrete

The vibrator is mounted on a channel iron, which

acts as the transducer of the energy. The vibration

is evenly distributed along the length of the channel

iron, which results in an excellent concrete nish.

Do not weld the channel iron to horizontal

stiffeners. Cut out the channel to t over stiffeners.

10

Excellent Mount

Page 11

Global Manufacturing, Inc ® 800.551.3569 TOLL FREE USA & CANADA

D

i

r

e

c

t

i

o

n

o

f

R

o

t

a

t

i

o

n

D

i

r

e

c

t

i

o

n

o

f

R

o

t

a

t

i

o

n

1801 East 22nd Street 501.374.7416 TEL 501.376.7147 FAX

Little Rock, AR 72206 USA www.GlobalManufacturing.com

VII. Vibrator Orientation

Whenever possible, mount the vibrator with the

shaft in the horizontal position.

To ensure proper direction-of-rotation, the GCL

vibrators are assembled for either a hopper or a

concrete form application. This only applies to the

GCL due to the way it sits in its bracket. To reverse

direction of rotation, the shaft and side plates must

be removed and swapped, so that, the shaft air

inlet is on the opposite side of the housing. Always

observe vane and exhaust port orientation. See

page 7, Note 2).

On a Hopper Wall: The direction of rotation is

in the direction of material ow - the roller weight

rotates toward the hopper and down. Facing the

hopper, the shaft/hose bard will be on the left.

GCL

The direction of rotation is determined by looking

at the side plate with the hose barb and exhaust

slots. The air enters the vibrator through the shaft

and pushes up the vane. (The vane is opposite the

keyway in the shaft.) The slots in the vane force

the air to one side only. The air carries the inner

roller with it as it travels around the shaft to get to

the exhaust slots. If the vane is facing the wrong

direction the air will have a direct path to the

exhaust without having to circle the shaft. If the

vane is not on the top of the shaft, but instead on

the side or bottom, the weight of the roller will not

press the vane back into the shaft and the vibrator

may not start.

On a Concrete Form: The rotation of

vibrator roller (weight) is counterclockwise.

This helps force the air bubbles to the surface.

Facing the concrete form the shaft/hose barb

will be on the right.

GCL

Material

Flow

Material

Flow

Hopper

Hopper

Vane

Key

Vane

Keyway

i

r

D

e

c

t

i

o

n

o

f

R

o

t

a

t

i

o

n

Hose Barb

i

r

D

e

c

t

i

o

n

o

f

R

o

t

a

t

i

o

n

Hose Barb

Key

Assembly Table

GCD GCD

Plan View

Assembly Table

Keyway

Assembly Table

Plan View

Assembly Table

Hose Barb

Vane

Key

Concrete Form

Air bubbles

rise to the

surface

GCLGCL

Concrete Form

Hose Barb

Vane

Key

Air bubbles

rise to the

surface

Plan View

Plan View

11

Page 12

Global Manufacturing, Inc ® 800.551.3569 TOLL FREE USA & CANADA

1801 East 22nd Street 501.374.7416 TEL 501.376.7147 FAX

Little Rock, AR 72206 USA www.GlobalManufacturing.com

VIII. Parts Explosion - GCD Models

6

5

4

3

2

1

9

7

10

8

7

2

1

Parts List for GCD High Frequency Vibrators

GCD-4400 (pn 522044)

GCD-5000 (pn 522050)

# Description PART # Qty # Description Part # Qty

1 Bolt Hex ⅜ - 16 x 1¼" 330212 8 5 Roller 192100 1

2 Lock Washer ⅜" 338106 8 6 Housing 141102 1

3 Side Plate - Blind 117000 1 7 Key 346205 2

4a Roller Weight - 4400* 192144 1 8 Shaft 205000 1

4b Roller Weight - 5000* 192150 1 9 Vane 270001 1

4c Roller Weight - 5500* 192155 1 10 Side Plate - Exhaust 117031 1

4d Roller Weight - 6500* 192165 1 * 1 weight per vibrator - determines force output

12

GCD-5500 (pn 522055)

GCD-6500 (pn 522065)

Page 13

Global Manufacturing, Inc ® 800.551.3569 TOLL FREE USA & CANADA

1801 East 22nd Street 501.374.7416 TEL 501.376.7147 FAX

Little Rock, AR 72206 USA www.GlobalManufacturing.com

IX. Parts Explosion - GCL Models

6

5

4

3

2

1

9

7

10

8

7

2

1

Parts List for GCL High Frequency Vibrators

GCL-4400 (pn 524044)

GCL-5000 (pn 524050)

# Description PART # Qty # Description Part # Qty

1 Bolt Hex ⅜ - 16 x 1¼" 330212 8 5 Roller 192100 1

2 Lock Washer ⅜" 338106 8 6 Housing 141104 1

3 Side Plate - Blind 117000 1 7 Key 346205 2

4a Roller Weight - 4400* 192144 1 8 Shaft 205000 1

4b Roller Weight - 5000* 192150 1 9 Vane 270001 1

4c Roller Weight - 5500* 192155 1 10 Side Plate - Exhaust 117031 1

4d Roller Weight - 6500* 192165 1 * 1 weight per vibrator - determines force output

GCL-5500 (pn 524055)

GCL-6500 (pn 524065)

13

Page 14

Global Manufacturing, Inc ® 800.551.3569 TOLL FREE USA & CANADA

1801 East 22nd Street 501.374.7416 TEL 501.376.7147 FAX

Little Rock, AR 72206 USA www.GlobalManufacturing.com

X. Dimensions of GCD and GCL Vibrators

GCD GCL

G

D

C

Vibrator

Model

GCD-4400

GCD-5000

GCD-5500

GCD-6500

GCL-4400

GCL-5000

GCL-5500

GCL-6500

G

A

F

E

B

A

D

B

High Frequency Dual Roller Vibrator Dimensions

Weight

lb in in in in in in in

kg mm mm mm mm mm mm mm

34.8 6.7 9.2 7.4 5.7 3/4 0.7 7.5 X 3.8

15.8 170 234 188 145 19 18 190 X 95

35.2 6.7 9.2 7.4 5.7 3/4 0.7 7.5 X 3.8

16.0 170 234 188 145 19 18 190 X 95

35.4 6.7 9.2 7.4 5.7 3/4 0.7 7.5 X 3.8

16.1 170 234 188 145 19 18 190 X 95

38.7 6.7 9.2 7.4 5.7 3/4 0.7 7.5 X 3.8

17.6 170 234 188 145 19 18 190 X 95

32.8 8.5 9.4 7.3 5.5 3/4

14.9 216 239 185 140 19

33.2 8.5 9.4 7.3 5.5 3/4

15.1 216 239 185 140 19

33.4 8.5 9.4 7.3 5.5 3/4

15.1 216 239 185 140 19

36.8 8.5 9.4 7.3 5.5 3/4

16.7 216 239 185 140 19

A B C D E F G

Height Length Width Hsg Width Inlet ID Bolt Hole Bolt Centers

E

N/A Fits GCL Bracket

N/A Fits GCL Bracket

N/A Fits GCL Bracket

N/A Fits GCL Bracket

C

14

Page 15

Global Manufacturing, Inc ® 800.551.3569 TOLL FREE USA & CANADA

1801 East 22nd Street 501.374.7416 TEL 501.376.7147 FAX

Little Rock, AR 72206 USA www.GlobalManufacturing.com

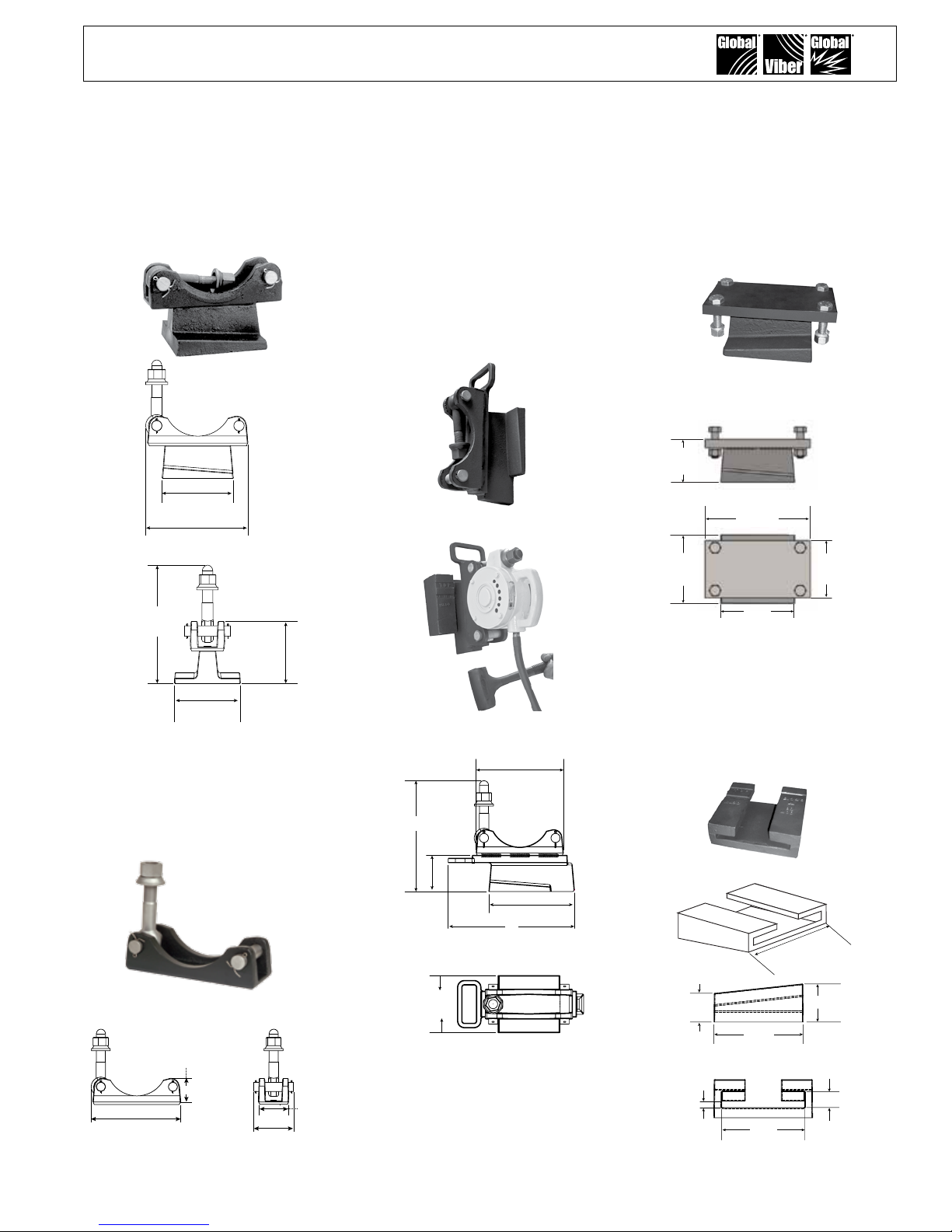

XI. Brackets Dimensions

GCL-GBM Bracket (pn 167020)

Bracket ts into the GBF Bracket

found on railcars.

6.50"

mm

165

9.44"

mm

240

B

10.81"

275

mm

6.00

152

5.51"

mm

140

A

"

mm

C

GCL Bracket (pn 168001)

Universal cradle-lug bracket.

Competitive vibrator brands with

cradle-lug housing prole t into

this bracket.

GCL-GBMX Bracket (pn 167120)

Bracket ts into the GBF Bracket

found on railcars. This bracket

has an unitized construction,

which helps it hold up to abuse.

It also has a hammer strike plate

to help when the bracket gets

stuck in railcar bracket. There is

a handle for ease of portability.

9.15"

232

mm

11.61"

A

295

mm

mm

3.80"

97

8.98"

228

B

13.23"

336 mm

mm

GCD-GBM Bracket (pn 167030)

Bracket ts into the GBF Bracket

found on railcars.

3.75"

mm

95

A

9.25"

532

mm

B

6.00

152

"

mm

C

6.50"

mm

561

5.00"

127

mm

D

GBF Bracket (pn 167071)

This bracket is the female wedge

pocket for the male brackets. The

bracket is often found on railcars.

7.75"

196.85

mm

C

2.69"

mm

68.33

9.44"

240

A

mm

B

106

4.16"

C

mm

3.50"

88.9

D

mm

6.00"

152 mm

2.99"

mm

A

1.24"

31.5

75.95

mm

mm

C

2.26"

57.4

.51"

12.95

mm

mm

7.00"

177.8

mm

B

6.50"

165.10

D

15

Page 16

Global Manufacturing, Inc ® 800.551.3569 TOLL FREE USA & CANADA

1801 East 22nd Street 501.374.7416 TEL 501.376.7147 FAX

Little Rock, AR 72206 USA www.GlobalManufacturing.com

XII. Performance and Lubrication Charts

High Frequency Vibrators Performance Data

40 psi 60 psi 80 psi

2.8 bar 4.1 bar 5.5 bar

Start-Up

Pressure

Speed Flow Force Speed Flow Force Speed Flow Force

rpm

9,500

9,350

8,800

7,600

cfm lbf

46.0 1,538

47.0 1,986

48.0 3,079 9,000 59.0 3,221

49.0 4,593 8,200 60.0 5,347

rpm

12,000

11,800

Model

GCD-4400

GCL-4400

GCD-5000

GCL-5000

GCD-5500

GCL-5500

GCD-6500

GCL-6500

Unbalance

lb-in psi

kg-mm bar Lpm kN Lpm kN Lpm kN

0.60 12

7 0.8 1,303 6.8 1,529 10.9 1,727 18.0

0.80 14

9 1.0 1,331 8.8 1,614 14.1 1,784 21.2

1.40 15

16 1.0 1,359 13.7 1,671 14.3 1,812 23.4

2.80 20

32 1.4 1,388 20.4 1,699 23.8 1,897 35.4

cfm lbf

54.0 2,454

57.0 3,164

rpm

15,400

14,500

11,500

10,000

cfm lbf

61.0 4,041

63.0 4,777

64.0 5,258

67.0 7,952

Pneumatic Motor Filter & Lubrication Requirements

Filtration Required Lubrication Required

64 Micron

Recommended Lubricants: Shell - Tellus 37, B.P. - Energol HL65, Castrol - Hyspin 70,

Mobil - Alma oil No 1

10 -1 2 Drops per Minute

10 Weight Oil*

16

Page 17

Global Manufacturing, Inc ® 800.551.3569 TOLL FREE USA & CANADA

1801 East 22nd Street 501.374.7416 TEL 501.376.7147 FAX

Little Rock, AR 72206 USA www.GlobalManufacturing.com

XIII. Troubleshooting

Problem Probable Cause Solution

Vibrator will

not operate

Excessive noise

Airline blocked

Locate obstruction and remove. Check

for kinked airline. Check filter.

Increase regulator setting or reduce

Inadequate air supply

number of units in use at same time.

Check capacity of compressor.

Airline too small for

distance used

Contamination in

vibrator

Use larger airline.

Disassemble and clean.

Clogged filter Clean or replace filter.

Foreign matter in

vibrator jamming vane

Disassemble and clean.

Disassemble and position shaft and

Vane is in wrong position

vane according to this manual. Rollers

must set on top of vane.

Insufficient mount

Damaged housing or

covers

Replace with stronger mounting

apparatus.

Replace the housing or covers.

Vibrator

operates

slowly

Change in

vibrator sound

Airline leaking or

constricted

Airline too small for

distance used

Replace airline, valve, or filter.

Replace airline with larger size air line.

Filter clogged Clean, repair, or replace.

Contamination in

vibrator

Lack of lubrication or

oil has thickened due to

cold weather which may

cause vane to stick

Disassemble and clean.

Increase amount of lubrication. Thin oil

with alcohol or antifreeze. Switch to a

lighter weight oil.

Side plates are worn Replace or resurface side plates.

Insufficient mount

Check for loose bolts, broken welds,

and damaged brackets.

Worn vane or side plates Replace parts.

Insufficient lubrication Increase amount of lubrication.

17

Loading...

Loading...