Page 1

Glitch Works GW-OSI-RAM1

User’s Manual and Assembly Guide

Revision 1, 2017-09-04

Creative Commons “Attribution-NonCommercial-ShareAlike 4.0” license.

c

2017 The Glitch Works

http://www.glitchwrks.com/

This manual is licensed under a

Page 2

Contents

1 Introduction 2

2 Configuration 2

2.1 Configuring I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Memory Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Prototyping Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4 12-Bit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.5 Inverted and Non-Inverted Data Busses . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Assembly 5

3.1 Assembling the GW-OSI-RAM1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 0-64K Memory, no Memory Management or ROM Overlay . . . . . . . . . . . . . . . 6

3.3 Memory Management or ROM Overlay Support . . . . . . . . . . . . . . . . . . . . . 6

3.4 I/O Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.5 12-Bit Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.6 Insert Socketed ICs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Initial Checkout and Testing 8

4.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.2 Repair and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5 Parts List 9

Assembly Drawing 10

Schematics 11

1

Page 3

1 Introduction

The Glitch Works GW-OSI-RAM1 is a universal RAM/ROM board for the Ohio Scientific bus. It

includes the following features:

• Fully static operation

• No expensive or hard-to-get components (8T26 buffers, etc.)

• 8- and 12-bit support

• Support for inverted and non-inverted data bus

• Optional bank switching

• ROM support/overlay

• Mappable around existing RAM, ROM, and I/O in 4K segments

• Header for lamp register

• General purpose prototype area

The GW-OSI-RAM1 uses JEDEC pinout 32K x 8 memory devices, such as the 62256 SRAM, 27256

EPROM, or 28256 EEPROM. Memory can be enabled in 4K segments to map around existing RAM,

ROM, and I/O. The board can be configured to mix RAM and ROM in two separate banks. It can be

used with any system that uses the Ohio Scientific bus, including the SYS bus of the Ohio Scientific

560Z Processor Lab. Full 12-bit operation allows it to be used with the OSI 560Z in PDP-8 compatible

mode.

2 Configuration

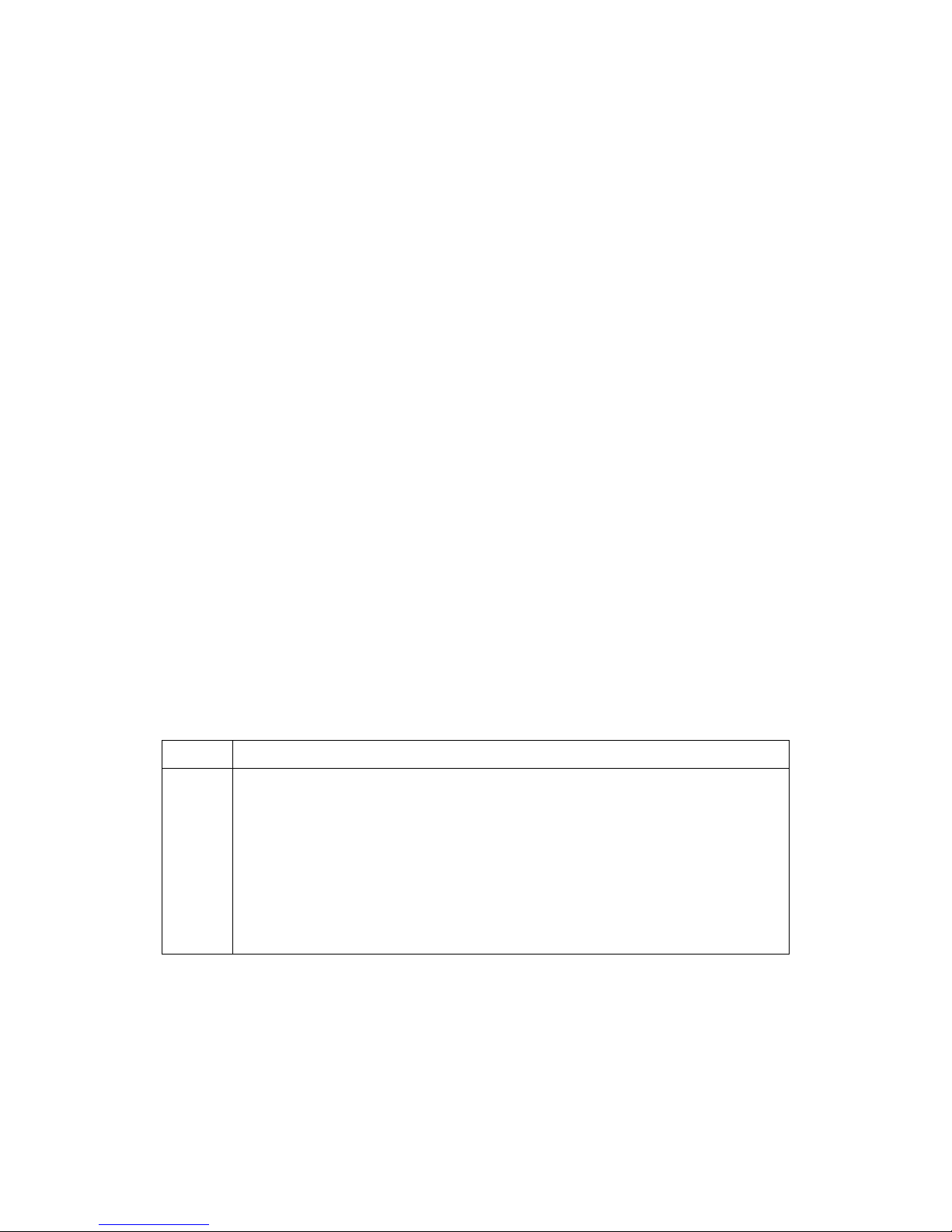

Due to its flexibility, the GW-OSI-RAM1 contains a large number of DIP switches and several

jumpers. Memory management requires jumper wires to be inserted. The following table explains

switch and jumper function. Please refer to the assembly drawing for the locations of switches and

jumpers.

Name Function

SW1 First bank 0-32K, each position enables a 4K segment when ON

SW2 First bank 32-64K, each p osition enables a 4K segment when ON

SW3 Second bank 0-32K, each position enables a 4K segment when ON

SW4 Low byte of I/O address, ON = 1

SW5 High byte of I/O address, ON = 1

SW6 Second bank 32-64K, each p osition enables a 4K segment when ON

J1 I/O address size selection, 1-2 for 1 byte, 2-3 for 2 bytes

J2 I/O address decode enable, closed enables I/O deco de

For instance, if you wished to enable 12K of RAM starting at 0x0000 in the first bank, close positions

1, 2, and 3 of SW1.

Any memory segment that contains RAM, ROM, or I/O on another board should have its segment

disabled on the GW- OSI-RAM1. Consult your system’s documentation to determine which segments

are in use for the system and board set you have. Generally, the 4K segment at 0xF000 will be

required for I/O devices and boot ROMs, and should be disabled on the GW-OSI-RAM1. Video

systems should disable the two 4K segments at 0xD000 and 0xE000. Systems with ROM BASIC

should disable the two 4K segments at 0xA000 and 0xB000.

2

Page 4

For systems that include RAM on the CPU board, you must either disable the RAM on the CPU

board and use only the RAM on the GW-OSI-RAM1, or disable the segments occupied by CPU board

RAM. The procedure for disabling CPU board RAM will depend on the particular CPU board in

use. It is usually easier to disable those segments on the GW-OSI-RAM1, unless there are suspected

reliability problems with the CPU board’s onboard RAM.

2.1 Configuring I/O

SW4, SW5, J1, and J2 control I/O configuration. If no I/O is desired, remove the shunt from J2 –

all other I/O settings will be ignored if J2 is open.

If J2 is closed, SW4 specifies the low byte of the I/O address, while SW5 specifies the upper byte. If

the I/O device is write-only (for example, a GW-OSI-HLR1 Hex Lamp Register), it can be addressed

over existing RAM on the GW-OSI-RAM1 but not on another RAM board. I f the I/O device is read-

only or read/write, it must not overlap RAM. The GW-OSI-RAM1 provides memory management

inputs in the memory address decoding sections to allow a read-only or read-write I/O device to be

inserted into RAM on the GW-OSI-RAM1. These memory management inputs will not work for

RAM on other boards.

J1 selects the I/O size. Placing a shunt between pins 1 and 2 set it to one byte, a shunt between

pins 2 and 3 set it two two bytes. Determine this setting from the module you plan to install in J3,

or your own needs if using the prototype area.

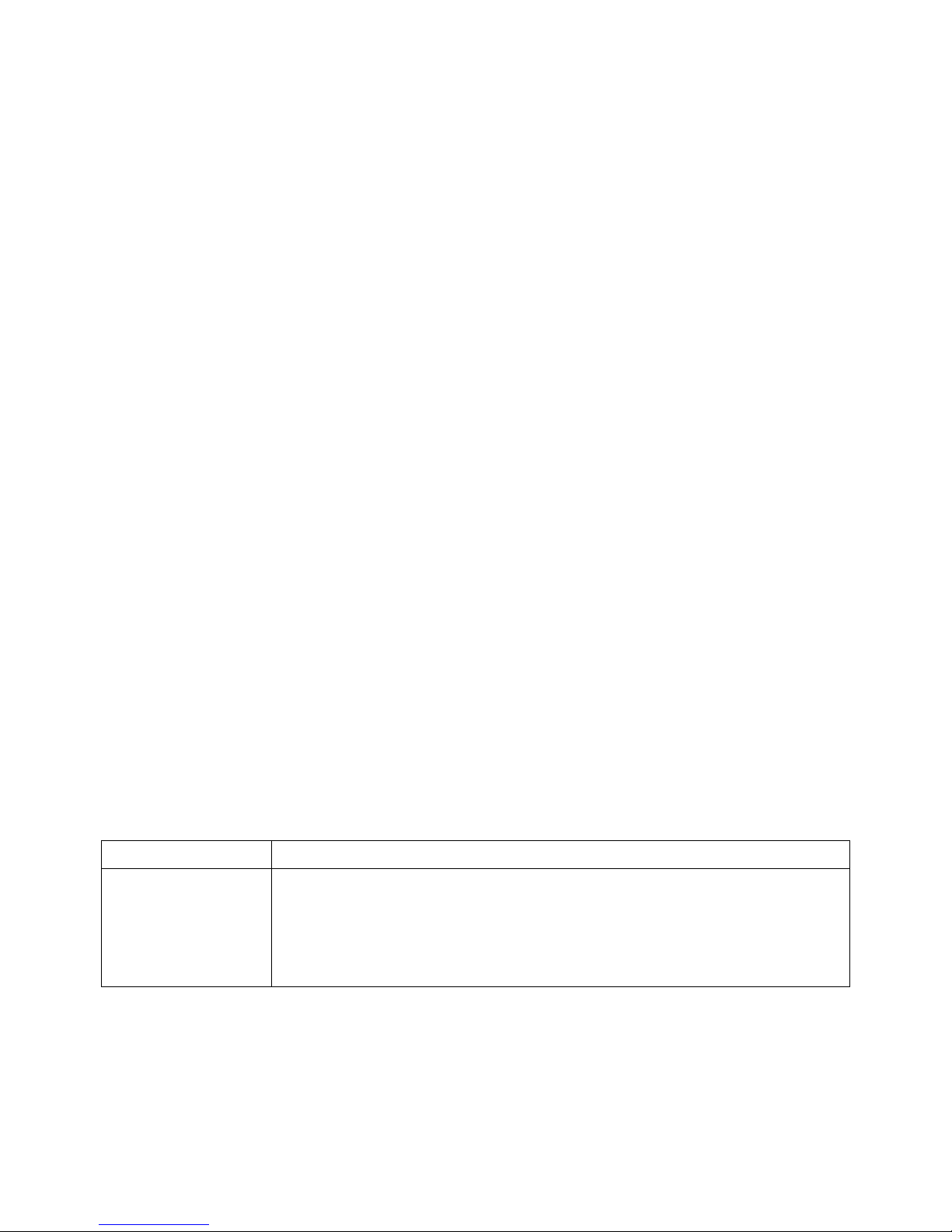

2.2 Memory Management

The GW-OSI-RAM1 supports Ohio Scientific 1 MB memory management, which is implemented on

some OSI CPU boards, such as the OSI 510. Most smaller systems will not use memory management

and will be limited to 64K of RAM, ROM, and I/O devices.

If OSI 1 MB memory management is not being used, the second bank on the GW-OSI-RAM1 can

be used for ROM overlays. This allows mixing RAM and ROM on the same b oard, in 4K segments.

Resistors R2 - R7 control which banks are active by default, and must be configured for ROM

overlays, if desired. The following table describes possible configurations of R2 - R7:

Resistors Installed Function

R2, R3 Default configuration, first bank enabled at 0x0000 - 0xFFFF

R4 Second bank 0-32K enabled, used for ROM overlay

R6 Second bank 32-64K enabled, used for ROM overlay

R5 Second bank 0-32K to be controlled by custom memory management

R7 Second bank 32-64K to be controlled by custom memory management

For a 64K system with no memory management, R2, R3, R4 and R6 are installed, allowing 0-64K of

RAM with 0-64K of ROM overlays. For a system with memory management, R2, R3, R5, and R7

are installed, and jumper connections are made from U3 and/or U6. Consult the schematics for 1

MB memory management jumpering.

3

Page 5

2.3 Prototyping Area

A prototyping area is provided on the GW-OSI-RAM1, and can be used whether or not a mezzanine

expansion module is to be installed, provided devices under the mezzanine module are short enough.

The prototyping area consists of a section of plated-through holes, siz ed to fit the leads of a 2 W

resistor without drilling. This allows multiple wires to be inserted in a single hole, making point-topoint prototyping very easy.

Header J3 provides buffered data lines, address lines A0 and A1, and read/write signals for both the

mezzanine modules and prototyping space. The *IOSEL signal is used by mezzanine modules, but

may be used by the prototype area if no mezzanine module is installed, or if the circuitry in the

prototype area is designed to co-exist with the mezzanine module in use.

Consult the schematics for J3 pinout and signal functions.

2.4 12-Bit Operation

The GW-OSI-RAM1 was designed with 12-bit operation in mind, for use on the SYS bus of the OSI

560Z Processor Lab. Addressing and configuration is the same as 8-bit mode, but the data buffer at

U24 must be installed, and RAM or ROM must be installed in U14 - U17 to provide the additional

upper 4 data bits. Refer to the assembly drawing for addresses covered by U14 - U17.

While extended memory management is techincally possible in 12-bit mode, no current boards implement it.

Expansion connector J3 supports 12-bit data operation, and modules such as the GW-OSI-HLR1

Hex Lamp Register will display 12-bit data if the system controlling the GW-OSI-RAM1 supports it.

Leaving 12-bit operation enabled when using the GW-OSI-RAM1 in an 8-bit system is acceptable,

as long as the four additional data lines used in 12-bit operation are not used for other purposes.

Consult your system documentation and/or schematics to determine this. If in doubt, remove the

data buffer at U24 to disable 12-bit operation.

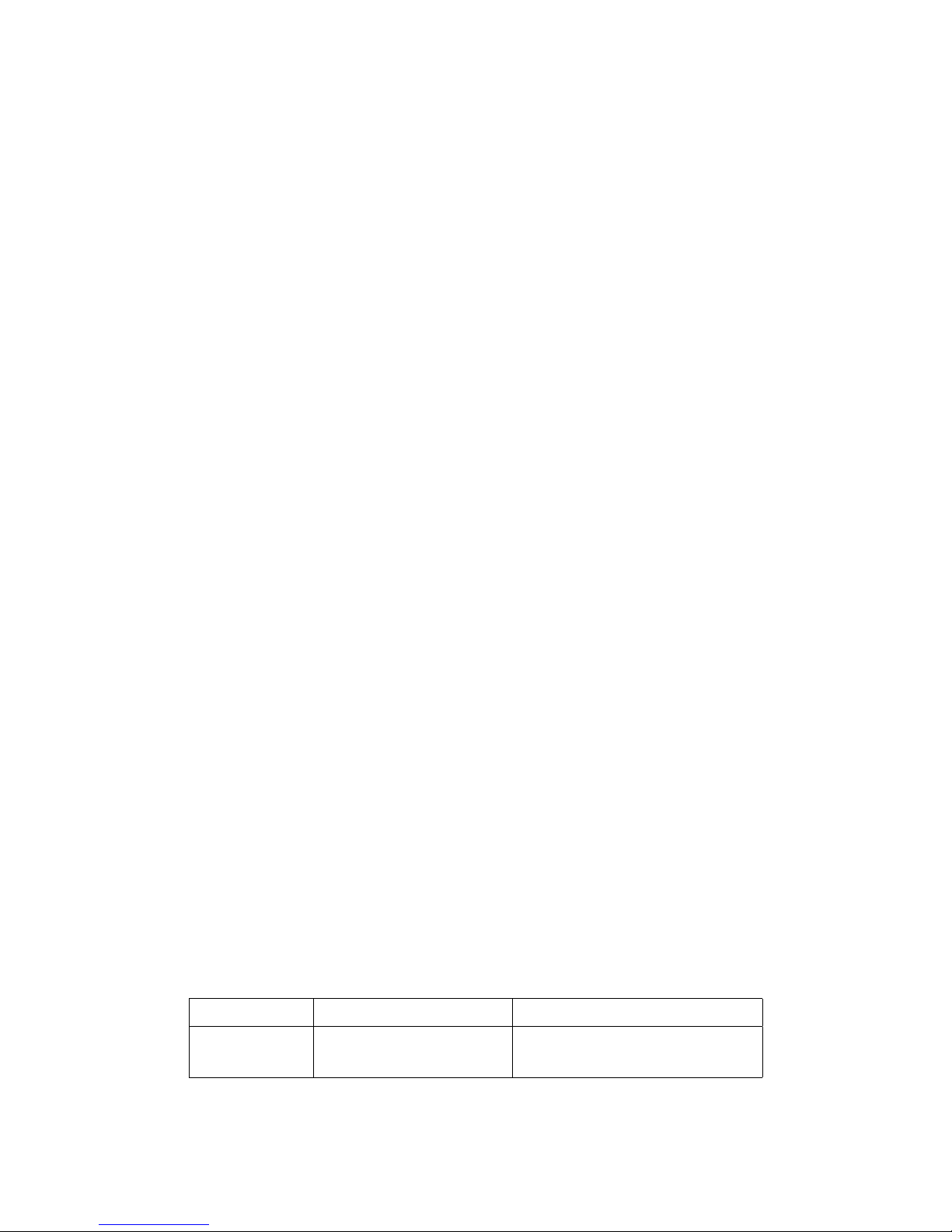

2.5 Inverted and Non-Inverted Data Busses

The GW-OSI-RAM1 can be used with either inverted or non-inverted data busses. Inverted busses

are typically found on larger or later OSI systems, which non-inverted data busses are found on some

of the smaller and earlier OSI systems. Most OSI boards can be configured for either operation.

Data bus polarity does not matter if the GW-OSI-RAM1 will only be used for RAM; however, it

should match the system’s data bus polarity if using ROM, mezzanine modules, or the prototyping

area. The following table describes which buffers should be used in U24, U27, and U28:

Bus Polarity Buffers on CPU Board Buffers in U24, U27 and U28

Inverted 8T26 or MC6880 74LS240

Non-Inverted 8T28 or MC6889 74LS244

4

Page 6

3 Assembly

The GW-OSI-RAM1 is designed to be easy to assemble for anyone with moderate soldering ability.

The following to ols will be required:

• Soldering iron, 20-40 W recommended, grounded tip

• Solder, 63/37 leaded solder recommended, Kester “44 Core” or similar

• Diagonal cutters or flush cutters

• Solder braid, solder sucker, or desoldering station, in the event errors are made

• Needle-nose pilers for bending component leads

• 1/4 and 1/8 W resistor lead forms (optional)

This manual does not cover basic soldering technique. If you are new to soldering, we recommend the

Adafruit soldering guide and plenty of practice on a piece of protoboard, before beginning assembly

of the GW-OSI-RAM1. The Adafruit guide can be found at:

https://learn.adafruit.com/adafruit-guide-excellent-soldering

3.1 Assembling the GW-OSI-RAM1

If you purchased a full Glitch Works parts kit, we recommend completing all assembly sections, since

extra features can be disabled as needed. If supplying your own parts, you may choose which sections

to complete based on the functionality required.

Note that pin 1 is designated with a square pad for all ICs, diodes, resistor packs, switches, and

connectors. Pin 1 faces away from the OSI bus connector for all ICs, diodes, resistor packs, and

switches. The component (top) side of the board is the side which contains the Open Source Hardware

gear logo. The following steps should always be completed:

Verify parts list against kit contents or builder-provided parts

Consult the assembly drawing for component locations and values

Bend all 0.01 µF bypass capacitors (yellow axial bead) – position 2 on a 1/8 W lead form

Install all 0.01 µF capacitors in positions marked C in assembly diagram

Bend and install 1N4148 diode at D1 – position 4 on a 1/8 W lead form

Install 74LS245 address buffers at U22, U23

Install 74LS30 at U25

Install 74LS00 at U26

Install 74LS04 at U9

Install resistor pack at RN7

Install 20-pin IC sockets at U27, U28

Install 22 µF 10V capacitor at C25, bend leads with needle-node pliers

Install four 12-pin Molex connectors at the board edge connector

5

Page 7

3.2 0-64K Memory, no Memory Management or ROM Overlay

The following components should be installed for a 0-64K system without memory management or

ROM overlay:

Install 74LS138 decoders at U1, U4

Install 74LS30 ICs at U2, U5

Install DIP switches at SW1, SW2

Install resistor packs at RN1, RN2

Bend two 10K resistors – position 1 on a 1/4 W lead form

Install 10K resistors at R2, R3

Install two 28-pin sockets at U20, U21

Complete the following steps only if no memory management or ROM overlay will be used:

Cut and bend two wire jumpers to link IC pads 7 and 8 on a 14-pin DIP IC – clipped capacitor

leads work well

Install wire jumpers on U8, U11, across pads 7 and 8

3.3 Memory Management or ROM Overlay Support

Complete the above sections, being sure not to install wire jumpers across U8 and U11, then install

the following:

Install 74LS138 decoders at U7, U10

Install 74LS30 ICs at U8, U11

Install DIP switches at SW3, SW6

Install resistor packs at RN1, RN2

Install two 28-pin sockets at U18, U19

Bend two 10K resistors – position 1 on a 1/4 W lead form

Consult the table on Page 3 of this manual and install 10K resistors at the positions required

for your needs

If OSI 1 MB memory management is required, complete the following steps:

Install 74LS138 decoders at U3, U6

Jumper outputs from U3 and/or U6 to memory management inputs on U7 and/or U10 – consult

schematic

6

Page 8

3.4 I/O Support

To enable support for an I/O mezzanine module or for use with the prototype area, complete the

following steps. Note that I/O can be disabled by jumper shunt if this section is populated:

Install 74LS688 comparators at U12, U13

Bend one 10K resistor – position 1 on a 1/4 W lead form

Install 10K resistor at R8

Install DIP switches at SW4, SW5

Install resistor packs at RN4, RN5

Install a three-pin jumper header at J1

Install a two-pin jumper header at J2

Install 20-pin header socket at J3, if mezzanine modules will be used

Complete the following steps only if the board will be used for I/O only (no memory at all):

Cut and bend four wire jumpers to link IC pads 7 and 8 on a 14-pin DIP IC – clipped capacitor

leads work well

Install wire jumpers on U2, U5, U8, U11, across pads 7 and 8

3.5 12-Bit Support

If 12-bit operation is required for either memory or I/O, complete the following steps:

Bend four 10K resistors – position 1 on a 1/4 W lead form

Install 10K resistors at R9 - R12

Install 20-pin IC socket at U24

Install 28-pin IC sockets at U16, U17 for 64K memory support with no memory management

or ROM overlay

Install 28-pin IC sockets at U14, U15 for memory management or ROM overlay

3.6 Insert Socketed ICs

Insert SRAM or ROM devices into appropriate sockets – consult assembly drawing

Insert 74LS240 or 74LS244 bus drivers into U24, U27, U28 – choose ICs based on the table on

Page 4

7

Page 9

4 Initial Checkout and Testing

Once the GW-OSI-RAM1 is assembled, configure it as described in the “Configuration” section,

starting on Page 2. It is recommended that initial testing be done with a minimum board set, and

boards reinstalled after operation is confirmed.

Double-check all ICs for proper orientation, check all solder joints for cold joints or solder bridges.

Insert the GW-OSI-RAM1 into your system’s backplane – this will require significant force, especially

the first time that the board is installed. If using a system with a horizontal card cage, support the

GW-OSI-RAM1 with a spacer in the corner hole near the “OSI Universal 128KW RAM Board”

text. Apply power to your system and press RESET. Using the ROM monitor, BASIC’s auto-size

function, or a dedicated RAM test program, verify that the RAM configured on the GW-OSI-RAM1

is detected and functioning.

4.1 Troubleshooting

If your system fails to come up with the GW-OSI-RAM1 installed, start by disabling all memory

segments – set SW1 - SW3 and SW6 to all off. Remove the jumper shunt on J2, if installed. If this

allows the system to come up, start enabling RAM segments one at a time, to determine where a

conflict may exist.

If setting all segment switches to off and opening J2 does not allow the system to come up, it is likely

that the bus tranceivers are being turned on when they should be off. This can occur if any of U2,

U5, U8, or U11 are not installed and no jumper has been placed across pins 7 and 8. It can also

occur if RN7 is not installed properly or if diode D1 is installed backwards. Recheck assembly and

try again.

4.2 Repair and Service

If you purchased an assembled GW-OSI-RAM1 from The Glitch Works, your board is warranted

to work in a system that is otherwise fully operational. If you have assembled a kit that fails to

work, you may return it to The Glitch Works for evaluation, repair, and testing. For questions concerning returns or configuration, please visit http://www.glitchwrks.com/ and click the “Contact”

link.

Do note that while we will attempt to help those who have purchased used boards, there is no

warranty extended.

8

Page 10

5 Parts List

The following substitutions may be made if you have purchased a bare board and are supplying your

own parts, or in a full Glitch Works parts kit:

• Any compatible 7400 series family logic ICs may be used (for example, a 74LS04 in the parts

list may be shipped as a 7404, 74S04, 74F04, 74LS04, 74ALS04, or 74HCT04)

• All resistors and resistor packs on the GW-OSI-RAM1 are pull-up or pull-down resistors, and

may be any value from 4.7K to 47K, even though they are indicated as 10K on the assembly

drawing

• Resistors may be of varying precision and body type – they are all the same on the GW-OSIRAM1 and can be used in any position

If you purchased a full Glitch Works parts kit, be sure it includes the following:

28x 0.01 µF axial ceramic capacitor (yellow bead)

9x 10K 1/4 W resistor (see above note)

1x 1N4148 diode

1x 22 µF 10V axial tantalum capacitor

7x 10K x 9 SIP resistor packs (see note above)

2x 74LS245 tranceiver

3x 74LS240 inverting bus tranceiver

1x 74LS00 quad 2-input NAND gate

1x 74LS04 hex inverter

5x 74LS30 8-input NAND gate

6x 74LS138 1-of-8 decoder

2x 74LS688 magnitude comparator

2x JEDEC 62256-type 32K x 8 static RAM

6x 8-position DIP switch

1x 2-pin jumper header

1x 3-pin jumper header

2x jumper shunt

8x 28-pin IC socket

3x 20-pin IC socket

4x Molex KK-156 12-pin right angle connector

1x 20-pin header socket

9

Page 11

Page 12

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

A

B

C

D

E

A

B

C

D

E

Date: 2017-09-04

KiCad E.D.A. kicad 4.0.4-stable

Rev: 1Size: USLedger

Id: 1/3

Title: Ohio Scientific Universal RAM Board

File: osi_12bit.sch

Sheet: /

The Glitch Works

J. Chapman

http://www.glitchwrks.com/osi

BD9

OEa

1

I0a

2

O3b

3

I1a

4

O2b

5

I2a

6

O1b

7

I3a

8

O0b

9

I0b

11

O3a

12

I1b

13

O2a

14

I2b

15

O1a

16

I3b

17

O0a

18

OEb

19

U28

74LS240

BD0

BD1

BD2

BD3

BD0

BD1

BD2

BD3

D0

D1

D2

D3

D0

D1

D2

D3

/WAIT

1

/NMI

2

/IRQ

3

DD

4

D0

5

D1

6

D2

7

D3

8

D4

9

D5

10

A18

20

A7

30

R//W

40

D6

11

A16

21

A5

31

VMA

41

D7

12

A17

22

A8

32

VMA*PHI2

42

D8

13

+12V

23

A9

33

A10

43

D9

14

-9V

24

A1

34

A11

44

D10

15

+5V

25

A2

35

A12

45

D11

16

+5V

26

A3

36

A13

46

/RESET

17

GND

27

A4

37

A14

47

UNDEF

18

GND

28

A0

38

A15

48

A19

19

A6

29

PHI2

39

BUS1

OSI_BUS

BD0

BD1

BD2

BD3

BD4

BD5

BD6

BD7

OEa

1

I0a

2

O3b

3

I1a

4

O2b

5

I2a

6

O1b

7

I3a

8

O0b

9

I0b

11

O3a

12

I1b

13

O2a

14

I2b

15

O1a

16

I3b

17

O0a

18

OEb

19

U27

74LS240

BD4

BD5

BD6

BD4

BD5

BD6

BD7

D4

D5

D6

D7

D4

D5

D6

D7

OEa

1

I0a

2

O3b

3

I1a

4

O2b

5

I2a

6

O1b

7

I3a

8

O0b

9

I0b

11

O3a

12

I1b

13

O2a

14

I2b

15

O1a

16

I3b

17

O0a

18

OEb

19

U24

74LS240

BD8

BD9

BD10

BD11

BD8

BD10

BD11

D8

D9

D10

D11

D8

D9

D10

Data Bus Tranceivers

Pin 1 LOW = Internal Bus to MOS Bus

Pin 19 LOW = MOS Bus to Internal Bus

BD8

BD9

BD10

BD11

BA0

BA1

BA2

BA3

BA4

BA5

BA6

BA7

BA8

BA9

BA10

BA11

BA12

BA13

BA14

BA15

A14

1

A12

2

A7

3

A6

4

A5

5

A4

6

A3

7

A2

8

A1

9

A0

10

CS

20

D0

11

A10

21

D1

12

OE

22

D2

13

A11

23

A9

24

D3

15

A8

25

D4

16

A13

26

D5

17

WE

27

D6

18

D7

19

U21

32K x 8 SRAM OR ROM

D0

D1

D2

D3

D4

D5

D6

D7

A0

A1

A2

A3

A4

A5

A6

A7

A8

A10

A11

A12

A13

A14

A->B

1

A0

2

A1

3

A2

4

A3

5

A4

6

A5

7

A6

8

A7

9

B7

11

B6

12

B5

13

B4

14

B3

15

B2

16

B1

17

B0

18

CE

19

U23

74LS245

A->B

1

A0

2

A1

3

A2

4

A3

5

A4

6

A5

7

A6

8

A7

9

B7

11

B6

12

B5

13

B4

14

B3

15

B2

16

B1

17

B0

18

CE

19

U22

74LS245

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

BA0

BA1

BA2

BA3

BA4

BA5

BA6

BA7

BA8

BA9

BA10

BA11

BA12

BA13

BA14

BA15

VCC

VCC

GND

GND

GND

VCC

BR**W

*RD

*WR

BR**W

*RD

*WR

D1

1N4148

*WR

DD

*BUSWRITE

*BUSREAD

BRDENA

DD

*BUSWRITE

*BUSREAD

*BUSWRITE

*BUSREAD

*BUSWRITE

*BUSREAD

D12PU

D13PU

D14PU

D15PU

R12

10K

R11

10K

R10

10K

R9

10K

VCC

Pullups for unused data lines

VMA*PHI2

*CS0

A15 *A15

Decode Logic

decode.sch

A9

A14

1

A12

2

A7

3

A6

4

A5

5

A4

6

A3

7

A2

8

A1

9

A0

10

CS

20

D0

11

A10

21

D1

12

OE

22

D2

13

A11

23

A9

24

D3

15

A8

25

D4

16

A13

26

D5

17

WE

27

D6

18

D7

19

U17

32K x 8 SRAM OR ROM

D8

D9

D10

D11

D12PU

D13PU

D14PU

D15PU

A0

A1

A2

A3

A4

A5

A6

A7

A8

A10

A11

A12

A13

A14

*RD

*WR

*CS0

A9

A14

1

A12

2

A7

3

A6

4

A5

5

A4

6

A3

7

A2

8

A1

9

A0

10

CS

20

D0

11

A10

21

D1

12

OE

22

D2

13

A11

23

A9

24

D3

15

A8

25

D4

16

A13

26

D5

17

WE

27

D6

18

D7

19

U20

32K x 8 SRAM OR ROM

D0

D1

D2

D3

D4

D5

D6

D7

A0

A1

A2

A3

A4

A5

A6

A7

A8

A10

A11

A12

A13

A14

*RD

*WR

*CS1

A9

A14

1

A12

2

A7

3

A6

4

A5

5

A4

6

A3

7

A2

8

A1

9

A0

10

CS

20

D0

11

A10

21

D1

12

OE

22

D2

13

A11

23

A9

24

D3

15

A8

25

D4

16

A13

26

D5

17

WE

27

D6

18

D7

19

U16

32K x 8 SRAM OR ROM

D8

D9

D10

D11

D12PU

D13PU

D14PU

D15PU

A0

A1

A2

A3

A4

A5

A6

A7

A8

A10

A11

A12

A13

A14

*RD

*WR

*CS1

A9

A14

1

A12

2

A7

3

A6

4

A5

5

A4

6

A3

7

A2

8

A1

9

A0

10

CS

20

D0

11

A10

21

D1

12

OE

22

D2

13

A11

23

A9

24

D3

15

A8

25

D4

16

A13

26

D5

17

WE

27

D6

18

D7

19

U19

32K x 8 SRAM OR ROM

D0

D1

D2

D3

D4

D5

D6

D7

A0

A1

A2

A3

A4

A5

A6

A7

A8

A10

A11

A12

A13

A14

*RD

*WR

*CS2

A9

A14

1

A12

2

A7

3

A6

4

A5

5

A4

6

A3

7

A2

8

A1

9

A0

10

CS

20

D0

11

A10

21

D1

12

OE

22

D2

13

A11

23

A9

24

D3

15

A8

25

D4

16

A13

26

D5

17

WE

27

D6

18

D7

19

U15

32K x 8 SRAM OR ROM

D8

D9

D10

D11

D12PU

D13PU

D14PU

D15PU

A0

A1

A2

A3

A4

A5

A6

A7

A8

A10

A11

A12

A13

A14

*RD

*WR

*CS2

A9

A14

1

A12

2

A7

3

A6

4

A5

5

A4

6

A3

7

A2

8

A1

9

A0

10

CS

20

D0

11

A10

21

D1

12

OE

22

D2

13

A11

23

A9

24

D3

15

A8

25

D4

16

A13

26

D5

17

WE

27

D6

18

D7

19

U18

32K x 8 SRAM OR ROM

D0

D1

D2

D3

D4

D5

D6

D7

A0

A1

A2

A3

A4

A5

A6

A7

A8

A10

A11

A12

A13

A14

*RD

*WR

*CS3

A9

A14

1

A12

2

A7

3

A6

4

A5

5

A4

6

A3

7

A2

8

A1

9

A0

10

CS

20

D0

11

A10

21

D1

12

OE

22

D2

13

A11

23

A9

24

D3

15

A8

25

D4

16

A13

26

D5

17

WE

27

D6

18

D7

19

U14

32K x 8 SRAM OR ROM

D8

D9

D10

D11

D12PU

D13PU

D14PU

D15PU

A0

A1

A2

A3

A4

A5

A6

A7

A8

A10

A11

A12

A13

A14

*RD

*WR

*CS3

A9

A15

BD7

D11

11

12

13

U26D

74LS00

1

2

3

U26A

74LS00

4

5

6

U26B

74LS00

8

9

10

U26C

74LS00

5 6

U9C

74LS04

C1CC4CC7CC10CC13CC16CC19CC22

C

C24

C

C3CC6CC9CC12CC15CC18CC21

C

C2CC5CC8CC11CC14CC17CC20CC23

C

GND

VCC

C25

22uF

BA19

BA18

BA16

BA17

C26

C

C27

C

Decoupling and Bypass Capacitors

*RD *WR Generation and Bus Buffer Control

Address Buffering

Memory Banks

OSI Bus

I/O Circuits

io.sch

C28

C

C29

C

W1 W2 W3 W4

GND

Mezzanine Mounting Holes

Page 13

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

A

B

C

D

E

A

B

C

D

E

Date: 2017-09-04

KiCad E.D.A. kicad 4.0.4-stable

Rev: 1Size: USLedger

Id: 2/3

Title: Ohio Scientific Universal RAM Board

File: decode.sch

Sheet: /Decode Logic/

The Glitch Works

J. Chapman

http://www.glitchwrks.com/osi

VCCVCCVCC

A0

1

A1

2

A2

3

E1

4

E2

5

E3

6

O7

7

O6

9

O5

10

O4

11

O3

12

O2

13

O1

14

O0

15

U7

74LS138

1

2

3

4

5

6

7

8 9

10

11

12

13

14

15

16

SW3

BANK 1 0-32K

1

2

3

4

5

6

8

11

12

U8

74LS30

RN3

10K

VCC

A12

A13

A14

VMA*PHI2

A15

*MM1A

R5

10K

*CS2

A0

1

A1

2

A2

3

E1

4

E2

5

E3

6

O7

7

O6

9

O5

10

O4

11

O3

12

O2

13

O1

14

O0

15

U1

74LS138

1

2

3

4

5

6

7

8 9

10

11

12

13

14

15

16

SW1

BANK 0 0-32K

1

2

3

4

5

6

8

11

12

U2

74LS30

RN1

10K

VCC

A12

A13

A14

VMA*PHI2

A15

*MM0A

GND

R2

10K

*CS0

A0

1

A1

2

A2

3

E1

4

E2

5

E3

6

O7

7

O6

9

O5

10

O4

11

O3

12

O2

13

O1

14

O0

15

U4

74LS138

1

2

3

4

5

6

7

8 9

10

11

12

13

14

15

16

SW2

BANK 0 32-64K

RN2

10K

VCC

A12

A13

A14

VMA*PHI2

*A15

*MM0B

A0

1

A1

2

A2

3

E1

4

E2

5

E3

6

O7

7

O6

9

O5

10

O4

11

O3

12

O2

13

O1

14

O0

15

U10

74LS138

1

2

3

4

5

6

7

8 9

10

11

12

13

14

15

16

SW6

BANK 1 32-64K

1

2

3

4

5

6

8

11

12

U11

74LS30

RN6

10K

VCC

A13

A14

VMA*PHI2

*A15

*MM1B

VCC

R4

10K

GND

1 2

U9A

74LS04

89

U9D

74LS04

1011

U9E

74LS04

CS0

CS2

CS1

CS3

*CS1

3 4

U9B

74LS04

*CS3

A12

1

2

3

4

5

6

8

11

12

U5

74LS30

1

2

3

4

5

6

8

11

12

U25

74LS30

*CS0

*CS1

*CS2

*CS3

BRDENA

VCC

R3

10K

GND

R7

10K

R6

10K

GND

VCC

A0

1

A1

2

A2

3

E1

4

E2

5

E3

6

O7

7

O6

9

O5

10

O4

11

O3

12

O2

13

O1

14

O0

15

U3

74LS138

A0

1

A1

2

A2

3

E1

4

E2

5

E3

6

O7

7

O6

9

O5

10

O4

11

O3

12

O2

13

O1

14

O0

15

U6

74LS138

BA19

BA19

BA16

BA17

BA18

BA16

BA17

BA18

1

2

3

4

5

6

7

8

P1

BANK 0-7

1

2

3

4

5

6

7

8

P2

BANK 8-15

*BANK0

*BANK1

*BANK2

*BANK3

*BANK4

*BANK5

*BANK6

*BANK7

*BANK8

*BANK9

*BANK10

*BANK11

*BANK12

*BANK13

*BANK14

*BANK15

*DECODE_ENAB

*DECODE_ENAB

VCC

GND

R1

10K

Board Enable Control

Bus buffers are active when any input goes low

Extended Memory Management

Jump outputs to *MM input to enable

memory management up to 1 MB.

*DECODE_ENAB can be pulled low to disable

memory for memory-mapped I/O devices.

Segment Select Logic

Closing a DIP switch enables the 4K memory segment associated with it.

Pulling a *MM line low enables the 32K block it is associated with.

Jump to memory management *BANK outputs for 1 MB management features.

Install pull-up resistor to Vcc if the bank is to be disabled by default.

Install pull-up resistor to GND if the bank is to be enabled by default.

Omit resistors and jumper to *BANK outputs if memory management is used.

*IOSEL

RN7

10K

Page 14

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

A

B

C

D

E

A

B

C

D

E

Date: 2017-09-04

KiCad E.D.A. kicad 4.0.4-stable

Rev: 1Size: USLedger

Id: 3/3

Title: Ohio Scientific Universal RAM Board

File: io.sch

Sheet: /I/O Circuits/

The Glitch Works

J. Chapman

http://www.glitchwrks.com/osi

G

1

P0

2

R0

3

P1

4

R1

5

P2

6

R2

7

P3

8

R3

9

P4

11

R4

12

P5

13

R5

14

P6

15

R6

16

P7

17

R7

18

P=R

19

U12

74LS688

G

1

P0

2

R0

3

P1

4

R1

5

P2

6

R2

7

P3

8

R3

9

P4

11

R4

12

P5

13

R5

14

P6

15

R6

16

P7

17

R7

18

P=R

19

U13

74LS688

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

1 2

3 4

5 6

7 8

9 10

20

11 12

13 14

15 16

17 18

19

J3

EXPANSION

VCC

GND

D0

D2

D4

D6

D8

D10

D1

D3

D5

D7

D9

D11

*WR*RD

A0

1

2

3

4

5

6

7

8 9

10

11

12

13

14

15

16

SW4

I/O ADDRESS LO

RN4

10K

GND

VCC

*IOSEL

*IOSEL

123

J1

I/O SIZE

GND

1

2

3

4

5

6

7

8 9

10

11

12

13

14

15

16

SW5

I/O ADDRESS HI

RN5

10K

GND

VCC

*LOWIOSEL

*LOWIOSEL

1213

U9F

74LS04

*VMA*PHI2VMA*PHI2

*VMA*PHI2

Expansion Header

Low Address Select

Jumper 1-2 for single I/O address, 2-3 for two I/O addresses.

High Address Select

Provides VMA*PHI2 conditioned address select.

NOTE: A write-only port (e.g. lamp register) may be overlaid with RAM

which will provide a readback register. If using a readable port, *IOSEL

must be jumpered to memory management inputs to disable the RAM

address overlaid by the port.

If using the I/O port in a segment with no RAM, jumper to a board enable pin on U25.

For two I/O addresses, leave SW4-1 open.

1

2

J2

I/O ENABLE

Close J2 to enable I/O decode

R8

10K

VCC

Loading...

Loading...