GLI International F53 Operating Manual

OPERATING MANUAL

Model F53

Flow Monitor/Totalizer

(Universal-mount 1/2 DIN style)

Worldwide Headquarters and Sales:

GLI International, Inc.

9020 West Dean Road

Milwaukee, Wisconsin 53224

U.S.A.

In the interest of improving and updating its equipment, GLI reserves the right to alter specifications to equipment at any time.

Rev. 1-201 Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN)

Phone:

Fax:

E-mail:

Web:

Represented By:

[414] 355-3601

[414] 355-8346

info@gliint.com

www.gliint.com

Viridor Instrumentation

A company

1

This operating manual and other GLI operating manuals

are available on GLI’s web site at gliint.com. when viewed

using Adobe’s free Acrobat reader. To get this reader, link

to Adobe through GLI’s web site or visit Adobe’s web site

at adobe.com.

Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN) Rev. 1-201

2

IMPORTANT SAFETY INFORMATION

This analyzer is compliant with safety standards as outlined in:

FMRC Class Numbers 3600, 3611, and 3810 (U.S.A.)

CSA C22.2 No. 142 and C22.2 No. 213 (Canada)

EN 61010-1 (European Community)

Please read and observe the following:

•

Opening the analyzer door exposes you to line power voltage, if present, at terminals on TB2 and TB3

inside the enclosure. This may be hazardous. Always remove line power before entering this area in

the analyzer. However, the analyzer door assembly contains only low voltage and is completely safe

to handle.

•

Wiring or repairs should only be performed by qualified personnel and only to an unpowered analyzer.

•

Whenever it appears that analyzer safety is questionable, disable the analyzer to ensure against any

unintended operation. For example, an unsafe condition is likely when:

1) The analyzer appears visibly damaged.

2) The analyzer fails to operate properly or provide the intended measurements.

3) The analyzer has been stored for long periods at temperatures above 158°F (70°C).

•

This analyzer must be installed by personnel specially trained in accordance with relevant local codes

and instructions contained in this operating instruction manual. Observe the analyzer’s technical

specifications and input ratings. If one line of the line power mains is not neutral, use a double-pole

mains switch to disconnect the analyzer.

HELPFUL IDENTIFIERS

In addition to information on installation and operation, this instruction manual may contain

WARNINGS pertaining to user safety, CAUTIONS regarding possible instrument malfunction, and

NOTES on important, useful operating guidelines.

WARNING:

A WARNING LOOKS LIKE THIS. IT WARNS YOU OF THE POTENTIAL

FOR PERSONAL INJURY.

CAUTION:

A CAUTION LOOKS LIKE THIS. IT ALERTS YOU TO POSSIBLE

INSTRUMENT MALFUNCTION OR DAMAGE.

☞

NOTE: A note looks like this. It alerts you to important, useful operating

information.

Rev. 1-201 Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN)

3

Definition of Equipment Symbols

This symbol

means CAUTION

and alerts you to possible danger or

instrument malfunction. Refer to this manual before proceeding.

This symbol

means that this is a protective ground terminal

alerts you to connect an earth ground to it.

This symbol

means that there is alternating current present

alerts you to be careful.

and

and

GLI International, Inc. warrants the Model F53 to be free from defects in material

or workmanship for a period of 2 years (24 months) from the date of shipment of

this product from our facility. A warranty claim will not be honored if defects are

not reported within the warranty period, or if GLI International determines that

defects or damages are due to normal wear, misapplication, lack of maintenance, abuse, improper installation, alteration, or abnormal conditions. GLI

International’s obligation under this warranty shall be limited to, at its option, replacement or repair of this product. The product must be returned to GLI

International, freight prepaid, for examination. The product must be thoroughly

cleaned and any process chemicals removed before it will be accepted for replacement or repair. GLI International’s liability shall not exceed the cost of the

product. Under no circumstances will GLI International be liable for any incidental or consequential damages, whether to person or property. GLI International

will not be liable for any other loss, damage or expense of any kind, including

loss of profits, resulting from the installation, use, or inability to use this product.

Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN) Rev. 1-201

WARRANTY

4

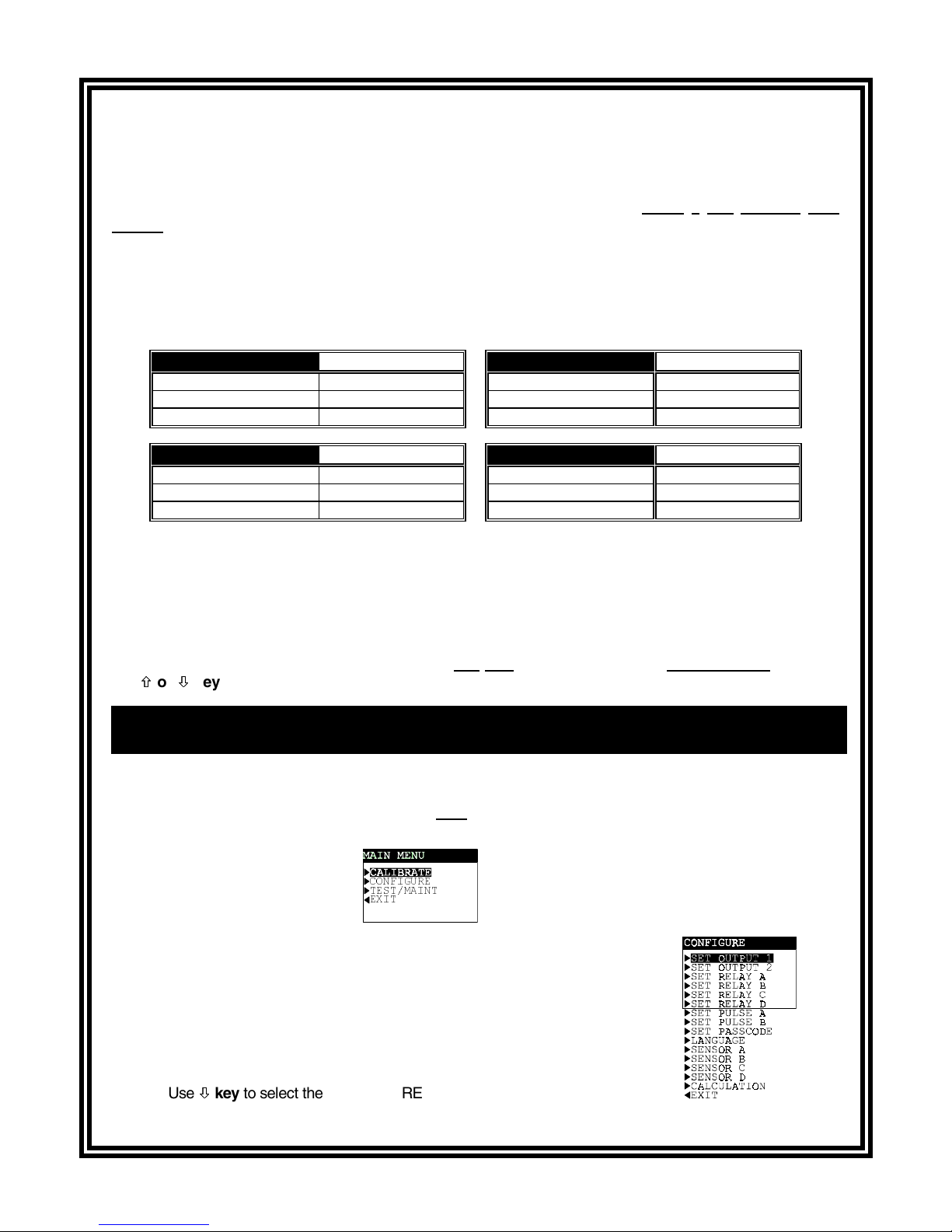

CONDENSED OPERATING INSTRUCTIONS

This manual contains details for all operating aspects of the instrument. The following condensed instructions are provided to assist you in getting the instrument started up and operating as quickly as

possible.

sensor.

These condensed instructions are only for basic operation using a

To obtain a calculated measurement, use a non-GLI flow sensor or specific features of the in-

strument, refer to the appropriate sections in this manual for instructions.

A. CONNECTING SENSOR(S)

After properly mounting the analyzer (PART TWO, Section 2), connect up to four GLI impeller flow

sensor(s), matching wire colors to terminals as indicated:

GLI impeller flow

Sensor A Wire Colors

Red Terminal #10 on TB1 Red Terminal #14 on TB1

Black Terminal #11 on TB1 Black Terminal #15 on TB1

Cable shield Grounding strip lug Cable shield Grounding strip lug

Sensor B Wire Colors

Red Terminal #12 on TB1 Red Terminal #16 on TB1

Black Terminal #13 on TB1 Black Terminal #17 on TB1

Cable shield Grounding strip lug Cable shield Grounding strip lug

Connect To

Connect To

Sensor C Wire Colors

Sensor D Wire Colors

Connect To

Connect To

B. CONNECTING LINE POWER

Important:

Follow instructions in PART TWO, Section 3.5 to connect line power to the analyzer.

C. ADJUSTING DISPLAY CONTRAST

Ambient lighting conditions may make it necessary to adjust display contrast to improve visibility.

With the MEASURE screen displayed, press and hold

×

Ø

×

or

until attaining the desired contrast.

key

Ø

ENTER key

the

and simultaneously press the

The following flow rate and volume readout instructions configure Sensor A.

Set up other sensors in the same way using their respective menu screens.

D. SETTING FLOW RATE READOUT (multiplier, decimal, and measurement unit annunciator)

Displayed flow rates are always shown with a user-set multiplier.

Select measured flow rates to

be whole numbers or decimals (XXX.X or XX.XX), and choose the measurement unit annunciators.

1. Press

2. Use

Rev. 1-201 Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN)

MENU key

Ø

to select the “CONFIGURE” line, and press

key

Ø

to display

&21),*8 5(

7(670$ ,1 7

(;,7

(continued on next page)

5

.

ENTER key

to display

.

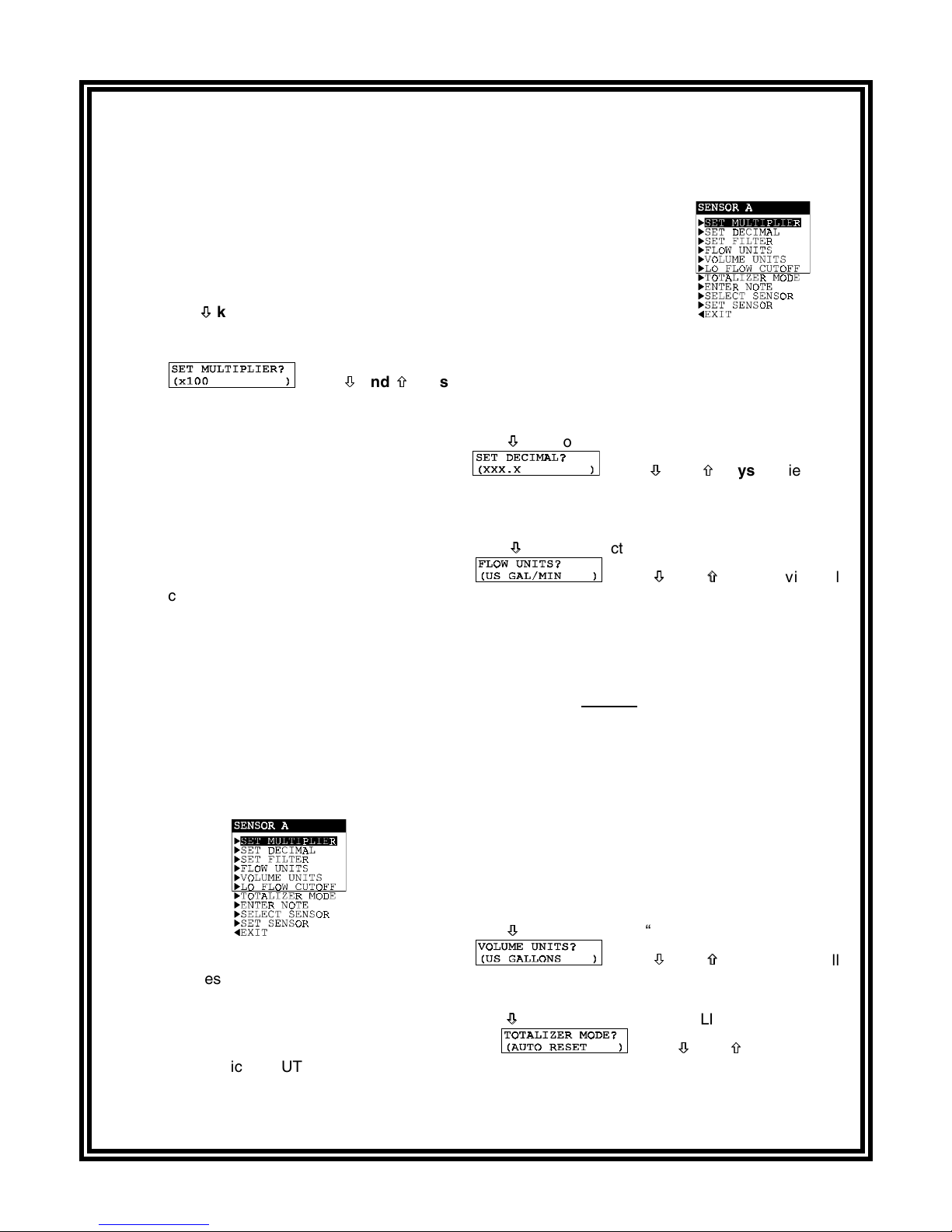

CONDENSED OPERATING INSTRUCTIONS

D. SETTING FLOW RATE READOUT -- (continued)

Ø

key

3. Use

Ø

to select the “SENSOR A” line, and press

ENTER key

to display

.

4. With the “SET MULTIPLIER” line selected, press

Ø

. Use

Ø

With the desired choice displayed press

5. After the “SENSOR A” screen re-appears, use

ENTER key

press

to display a screen like

and

×

keys

×

to view the choices (x1, x10, x100, x1000, or x10000).

ENTER key

Ø

Ø

choices (XXXX, XXX.X, or XX.XX). With the desired choice displayed, press

ENTER key

to display a screen like

to enter this selection.

key

to select the “SET DECIMAL” line, and

. Use

Ø

Ø

and

×

keys

×

to view the

ENTER key

this selection.

Ø

key

6. After the “SENSOR A” screen re-appears, use

ENTER key

press

to display a screen like

choices. With the desired choice displayed, press

Ø

to select the “FLOW UNITS” line, and

ENTER key

Ø

. Use

Ø

to enter this selection.

and

×

keys

×

to view all

E. SETTING VOLUME READOUT (volume unit annunciator and totalizer reset mode)

Unlike flow rate, volume is shown only as a whole number without a multiplier.

Choose from a

variety of volume measurement unit annunciators. The totalizer is factory-set for auto reset, which

resets the displayed volume to zero after reaching its maximum limit. After automatically resetting,

the totalizer starts a new count. Conversely, the totalizer can be set to a manual reset mode to preserve the total volume. In the manual reset mode, the totalizer can be manually reset back to zero at

any time by using the “RESET VOL” function in the TEST/MAINT menu.

to enter

1. With the

ENTER key

press

to display a screen like

choices. With the desired choice displayed, press

2. After the “SENSOR A” screen re-appears, use

and press

ENTER key

both choices (AUTO RESET or MANUAL RESET). With the desired choice displayed, press

ENTER key

Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN) Rev. 1-201

to enter this selection.

screen displayed, use

to display a screen like

(continued on next page)

6

Ø

key

Ø

to select the “VOLUME UNITS” line, and

Ø

. Use

ENTER key

Ø

key

Ø

to select the “TOTALIZER MODE” line,

to enter this selection.

Ø

. Use

and

Ø

and

Ø

×

keys

×

×

×

to view all

keys

to view

CONDENSED OPERATING INSTRUCTIONS

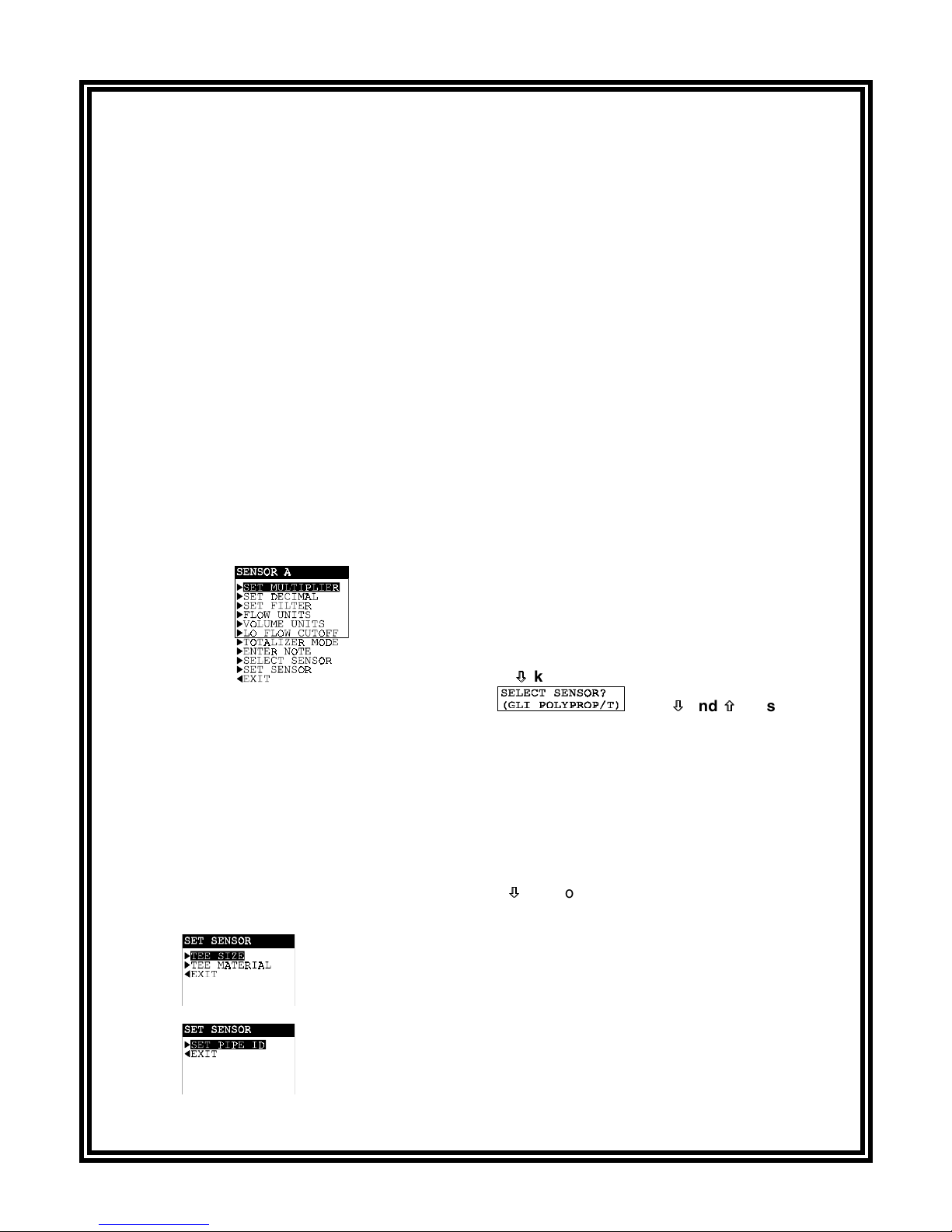

F. SELECTING SENSOR TYPE/ENTERING SENSOR DATA (calibration)

To configure/calibrate the analyzer so that measured values will accurately represent actual values,

you must select the sensor type and enter specific sensor-related data. This is a normal part of the

initial setup. The data you enter depends on the sensor being used:

•

GLI sensor mounted in tee:

•

GLI sensor mounted in pipe (using weldolet, pipe saddle or ball valve assembly):

the inside diameter of the pipe (SET PIPE ID).

•

Non-GLI sensor (any mounting):

OFFSET).

After entering appropriate sensor data, the analyzer is calibrated. Anytime thereafter, you can linearly offset measured flow readings by using the CALIBRATE menu.

only be considered when analyzer readings need to match a user-supplied “qualified reference” flow instrument.

See PART THREE, Sections 5.1 and 5.2 for complete adjustment details.

NOTE: The following configuration/calibration procedure is only for Sensor A and only for

GLI sensors. Configure/calibrate other sensors in the same way using their respective menu

screens. (To enter specific data for non-GLI sensors, see PART THREE, Section 4.2, subsection “SET SENSOR Data” under the “Non-GLI Sensor Setup” category.)

Enter the TEE SIZE and TEE MATERIAL.

Enter a slope value (SET SLOPE) and an offset value (SET

Calibration adjustment should

Enter

Ø

key

1. With the screen displayed, use

and press

ENTER key

to display a screen like

Ø

the type of GLI sensor and mounting arrangement you are using:

•

GLI PIPE MOUNT--------for sensor mounted in pipe using weldolet, pipe saddle or ball valve

•

GLI POLYPROP/T -------for polypropylene sensor mounted in tee

•

GLI PVDF/T ---------------for PVDF sensor mounted in tee

•

GLI 316SS/T --------------for stainless steel-sleeved sensor with 2-inch NPT hex adapter mounted in tee

•

GLI BRASS/T -------------for brass-sleeved sensor with 2-inch NPT hex adapter mounted in tee)

2. With the appropriate choice displayed, press

3. After the “SENSOR A” screen re-appears, use

pending on the selected sensor, pressing

ENTER key

Ø

key

Ø

ENTER key

displays:

when “GLI POLYPROP/T,” “PVDF/T,” “316SS/T” or “BRASS/T” was selected.

when “GLI PIPE MOUNT” was selected.

to select the “SELECT SENSOR” line,

. Use

Ø

Ø

and

×

keys

×

to select

to enter this selection.

to select the “SET SENSOR” line. De-

Rev. 1-201 Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN)

(continued on next page.)

7

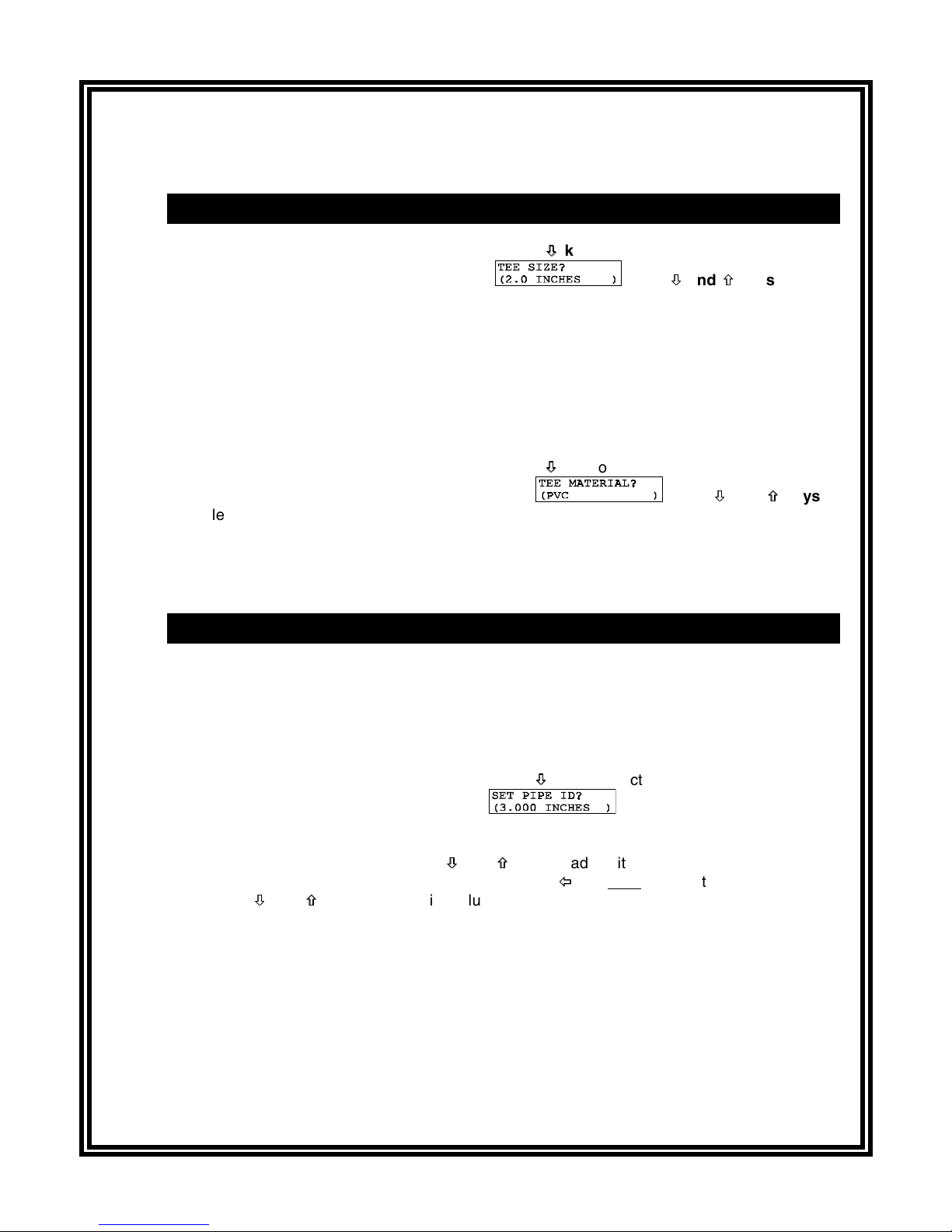

CONDENSED OPERATING INSTRUCTIONS

F. SELECTING SENSOR TYPE/ENTERING SENSOR DATA -- (continued)

GLI Tee Mount Sensor Setup (select TEE SIZE and TEE MATERIAL)

Ø

key

A. With the “SET SENSOR” screen displayed, use

Ø

to select the “TEE SIZE” line and

press

ENTER key

to display a screen like

. Use

Ø

Ø

and

×

keys

×

to select

the tee size in which the sensor is mounted:

0.5 INCHES

•

0.75 INCHES

•

1.0 INCHES

•

1 IN. MHF15L2*

•

*Select only when using a GLI PVC 1-inch MHF15L2 tee for higher flow range (up to 65 GPM).

B. With the appropriate tee size displayed, press

C. After the “SET SENSOR” screen re-appears, use

and press

ENTER key

to display a screen like

select the tee material, and press

1.25 INCHES

•

1.5 INCHES

•

2.0 INCHES

•

2.5 INCHES

•

ENTER key

3.0 INCHES

•

4.0 INCHES

•

ENTER key

Ø

Ø

to enter this selection.

key

to select the “TEE MATERIAL” line

Ø

and

. Use

Ø

×

keys

×

to

to enter this selection. (Selected tee size de-

termines available tee materials.)

This completes GLI tee mount sensor data entry/calibration. The analyzer is now ready to measure Sensor A flow/volume.

GLI Pipe Mount Sensor Setup (SET PIPE ID)

A. Determine actual inside pipe diameter. Actually measure it or refer to an appropriate table.

NOTE: Pipe IDs for commonly-used Schedule 40 and Schedule 80 pipes are listed in Ta-

bles A and B in PART THREE, Section 4.2 under the “SET SENSOR Data”

subheading.

B. With the “SET SENSOR” screen displayed, use

ENTER key

press

C. Adjust the displayed value to exactly match the actual pipe ID (inside diameter). Starting with

the extreme right blinking digit, use

pressed, the faster the value changes.) Then press

use the

Ø

Ø

and

×

keys

×

played, and press

This completes GLI pipe mount sensor data entry/calibration. The analyzer is now ready to measure

Sensor A flow/volume.

G. COMPLETING ANALYZER CONFIGURATION

To further configure the analyzer to your application requirements, use the appropriate CONFIGURE

screens to make selections and “key in” values. Refer to PART THREE, Section 4 for complete configuration details.

Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN) Rev. 1-201

Ø

key

Ø

to select the “SET PIPE ID” line and

to display a screen like

Ø

and

Ø

×

×

keys

to adjust its value. (The longer the key is

Õ

Õ

.

once to select the next digit, and

key

to adjust its value. Repeat this procedure until desired value is dis-

ENTER key

to enter it.

8

TABLE OF CONTENTS

PART ONE - INTRODUCTION

SECTION 1 GENERAL INFORMATION

1.1 Capability Highlights ........................................................................15-17

1.2 Modular Construction ............................................................................17

1.3 Retained Configuration Values .............................................................18

1.4 Analyzer Serial Number ........................................................................18

1.5 EMI/RFI Immunity..................................................................................18

SECTION 2 SPECIFICATIONS

....................................................................................19-20

PART TWO - INSTALLATION

SECTION 1 UNPACKING

SECTION 2 MECHANICAL REQUIREMENTS

2.1 Location................................................................................................. 21

2.2 Mounting...........................................................................................21-23

2.3 Conduit Hole Requirements ..................................................................23

SECTION 3 ELECTRICAL CONNECTIONS

3.1 Flow Sensor(s) .................................................................................25-26

3.2 Analog Outputs.................................................................................26-27

3.3 Relay Outputs...................................................................................27-28

3.4 Pulsed Outputs (contact closure) ..........................................................28

3.5 Closed Contact TTL Input .....................................................................28

3.6 Line Power ............................................................................................29

.................................................................................................21

PART THREE - OPERATION

SECTION 1 USER INTERFACE

1.1 Display .............................................................................................30-31

1.2 Keypad .............................................................................................31-32

1.3 MEASURE Screen (normal display mode).......................................32-33

SECTION 2 MENU STRUCTURE

2.1 Displaying Main Branch Selection Screen ............................................34

2.2 Displaying Top-level Menu Screens.................................................34-35

2.3 Displaying Submenu Screens ...............................................................35

2.4 Adjusting Edit/Selection Screen Values ................................................36

2.5 Entering (Storing) Edit/Selection Screen Values/Choices..................... 36

Rev. 1-201 Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN)

9

TABLE OF CONTENTS (continued)

SECTION 3 ADJUSTING DISPLAY CONTRAST

SECTION 4 ANALYZER CONFIGURATION

4.1 Selecting LANGUAGE to Operate Analyzer.......................................... 37

4.2 Configuring Sensors (A, B, C, and D):

SET MULTIPLIER (for displayed flow rate).................................38-39

SET DECIMAL (for displayed flow rate)........................................... 39

SET FILTER Time.......................................................................39-40

Select FLOW UNITS (for displayed flow rate) ............................40-41

Select VOLUME UNITS (for displayed volume)...............................41

Set LO FLOW CUTOFF Limit ..........................................................42

Select TOTALIZER MODE (auto or manual reset) .....................42-43

ENTER NOTE (top line of MEASURE screen).................................43

SELECT SENSOR Type.............................................................43-44

SET SENSOR Data:

GLI Tee Mount -- Select TEE SIZE and TEE MATERIAL......44-45

GLI Pipe Mount -- SET PIPE ID..................................................46

Non-GLI Sensor -- SET SLOPE and SET OFFSET Values......47-48

4.3 Configuring CALCULATION Measurement:

SET VARIABLE X ............................................................................ 49

SET VARIABLE Y ............................................................................ 50

SET FORMULA (X/Y, X-Y, X+Y, or [X/Y] x 100) .............................. 50

Select DISPLAY FORMAT (decimal and multiplier)....................51-52

4.4 Configuring Analog Outputs (1 and 2):

SET PARAMETER (representation) ...........................................53-54

SET 0/4 mA and 20 mA VALUES................................................54-55

SET FILTER Time............................................................................ 55

Select SCALE 0 mA/4 mA (low endpoint) ........................................ 55

4.5 Configuring Relays (A, B, C, and D):

SET PARAMETER (representation) ...........................................56-57

SET FUNCTION Mode (alarm, control or status)............................. 57

ACTIVATION (configuration values) ...........................................58-59

4.6 Configuring Pulse Outputs (A and B):

SET PARAMETER (representation) ................................................60

SET VOLUME Increment ............................................................60-61

Set PULSE DURATION ...................................................................61

4.7 SET PASSCODE (feature enabled or disabled) ................................... 62

4.8 Configuration Setting Summary (ranges/choices and defaults) .......63-65

.............................................................36

SECTION 5 ANALYZER CALIBRATION

5.1 Important Information ............................................................................66

5.2 OFFSET BY or SET TO Calibration Adjustment ..............................67-68

5.3 Analog Outputs (1 and 2) Calibration...............................................68-69

Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN) Rev. 1-201

10

TABLE OF CONTENTS (continued)

SECTION 6 TEST/MAINTENANCE

6.1 STATUS Checking (analyzer, sensors, and relays) .........................70-71

6.2 RESET VOL (A, B, C, and D) ................................................................72

6.3 HOLD OUTPUTS ..................................................................................72

6.4 OVERFEED RESET (relay timers)........................................................ 73

6.5 OUTPUT (1 and 2) Analog Test Signals ..........................................73-74

6.6 RELAY (A, B, C, and D) Operating Test................................................74

6.7 PULSE (A and B) Operating Test..........................................................75

6.8 EPROM VERSION Checking ................................................................75

6.9 SELECT SIM Measurement .................................................................. 76

6.10 SIM Setting............................................................................................ 77

6.11 RESET CONFIGURE ............................................................................78

SECTION 7 RELAY OVERFEED TIMER FEATURE

7.1 Why Use an Overfeed Timer.................................................................79

7.2 Relay Overfeed Timer Setup Guidelines...............................................79

7.3 Overfeed Timer “Timeout” Operation .................................................... 79

7.4 Resetting Overfeed Timers ...................................................................79

7.5 Interactions with Other Analyzer Functions......................................79-80

SECTION 8 HART OPTION

8.1 Introduction ...........................................................................................81

8.2 Analyzer Operating Modes for HART Network.................................82-83

8.3 SINGLE MODE (Point-to-Point) Wiring Arrangement ...........................83

8.4 MULTI-DROP Wiring Arrangement .......................................................84

8.5 HART Preferences Setup:

Changing Polling Address ...............................................................85

Viewing Number of Required Preambles ....................................85-86

8.6 Device Preferences Setup:

Viewing Final Assembly Number .....................................................86

Viewing Model Number...............................................................86-87

Viewing Manufacturer ...................................................................... 87

Assigning a Tag ............................................................................... 87

Assigning a Descriptor .....................................................................88

Assigning a Message....................................................................... 88

Assigning User-defined Date ......................................................88-89

Viewing Identification (ID) ................................................................ 89

Viewing Revisions............................................................................ 89

8.7 “Master Reset” Function........................................................................90

8.8 “Refresh” Function ................................................................................ 90

8.9 Protocol Command Set for PC Programming ........................................90

Rev. 1-201 Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN)

11

TABLE OF CONTENTS (continued)

PART FOUR - SERVICE AND MAINTENANCE

SECTION 1 GENERAL INFORMATION

1.1 Inspecting Sensor Cables .....................................................................91

1.2 Replacing Fuse(s) .................................................................................91

1.3 Replacing Relays ..................................................................................91

SECTION 2 PRESERVING MEASUREMENT ACCURACY

2.1 Keeping Sensor(s) Clean ......................................................................92

2.2 Avoiding Electrical Interference............................................................. 92

SECTION 3 TROUBLESHOOTING

3.1 Checking Electrical Connections...........................................................92

3.2 Verifying Sensor Operation ...................................................................92

3.3 Verifying Analyzer Operation ...........................................................92-93

3.4 Verifying Interconnect Cable Integrity ...................................................93

SECTION 4 ANALYZER REPAIR/RETURN

4.1 Customer Assistance.............................................................................94

4.2 Repair/Return Policy .............................................................................94

PART FIVE - SPARE PARTS AND ACCESSORIES

......................................................................................................................95

Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN) Rev. 1-201

12

TABLE OF CONTENTS (continued)

ILLUSTRATIONS

Figure 1-1

Figure 2-1

Figure 2-2

Figure 2-3

Figure 2-4

Figure 2-5

Figure 2-6

Figure 2-7

Figure 2-8

Figure 3-1

Figure 3-2

Figure 3-3

Figure 3-4

EMI/RFI Immunity Diagram..............................................................................................18

Analyzer Mounting Arrangements ....................................................................................22

Analyzer Installation Dimension Details............................................................................23

Analyzer Terminal Block Designations .............................................................................25

Connecting Flow Sensor(s) ..............................................................................................26

Connecting Control/Alarm Device(s) to Electromechanical Relay(s).................................28

Connecting 115 Volt Single Phase Line Power (90-130 VAC)...........................................29

Connecting 230 Volt Single Phase Line Power (180-260 VAC).........................................29

Connecting 230 Volt Split Phase Line Power (180-260 VAC)............................................29

Analyzer Keypad..............................................................................................................31

Location of SINGLE MODE/MULTI-DROP Switch (HART-equipped analyzers only) ........83

HART SINGLE MODE (Point-to-Point) Wiring Arrangement (for single analyzer).............83

HART MULTI-DROP Wiring Arrangement (for multiple analyzer network)........................84

Table A

Table B

Table C

Table D

Table E

Rev. 1-201 Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN)

Schedule 40 Pipe IDs.......................................................................................................46

Schedule 80 Pipe IDs.......................................................................................................46

Relay Configuration Settings............................................................................................58

Analyzer Configuration Settings (Ranges/Choices and Defaults) .................................63-65

Relay Overfeed Timer Interactions with Other Analyzer Functions...................................80

TABLES

13

Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN) Rev. 1-201

14

PART ONE - INTRODUCTION SECTION 1 - GENERAL INFORMATION

PART ONE - INTRODUCTION

ECTION

1.1 Capability Highlights

Sensor Inputs

S

GENERAL INFORMATION

The analyzer has four sensor inputs to independently measure

up to four flow rates/volumes. Each input can accept:

•

Any GLI IMPELLER flow sensor

•

A NON-GLI SENSOR with a 0-2000 Hz. output

(paddle wheel, turbine, vortex, etc.). However, its

slope and offset values must be determined and

entered to calibrate the analyzer.

1

MEASURE Screen

Depending on the number of sensors used, the MEASURE

screen (normal display mode) can show up to 8 separate

sensor readouts, 8 combined data readouts, and a calcu-

ÕÕ or

lated value (if configured) by pressing

Separate Sensor Readouts

1. SENSOR A flow rate with multiplier

2. SENSOR B flow rate with multiplier

3. SENSOR C flow rate with multiplier

4. SENSOR D flow rate with multiplier

5. SENSOR A volume (no multiplier)

6. SENSOR B volume (no multiplier)

7. SENSOR C volume (no multiplier)

8. SENSOR D volume (no multiplier)

Combined Data Readouts

1. Sensor A flow rate and volume

2. Sensor B flow rate and volume

3. Sensor C flow rate and volume

4. Sensor D flow rate and volume

5. Sensor A and Sensor B flow rates

6. Sensor A and Sensor B volumes

7. Sensor C and Sensor D flow rates

8. Sensor C and Sensor D volumes

CALCULATED* Measurement Readout*

Calculation can be X-Y, X+Y, X/Y, or [X/Y] x 100 with selectable X and Y

variables representing specific sensor flow rates and volumes

ÖÖ key:

Rev. 1-201 Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN)

*Calculated measurement can only be provided when two sensors are

used and analyzer has been correctly configured for CALCULATION.

The bottom auxiliary display line, shown in reverse video on

the MEASURE screen, can be changed by pressing the

and

×× keys to show analog output 1 and 2 mA values.

15

Ø

Ø

PART ONE - INTRODUCTION SECTION 1 - GENERAL INFORMATION

Passcode-protected

Access

Calibration

For security, you can enable a passcode feature to restrict access to configuration and calibration settings to authorized

personnel only. See PART THREE, Section 4.7 for details.

Calibration is actually achieved by independently configuring each sensor, which is a normal part of the initial setup.

First, select the type of sensor being used:

•

GLI PIPE MOUNT -------for sensor mounted in pipe using weldolet, pipe

saddle or ball valve assembly

•

GLI POLYPROP/T ------- for polypropylene sensor mounted in tee

•

GLI PVDF/T ---------------for PVDF sensor mounted in tee

•

GLI 316SS/T --------------for stainless steel-sleeved sensor with 2-inch NPT

hex adapter mounted in tee

•

GLI BRASS/T -------------for brass-sleeved sensor with 2-inch NPT hex

adapter mounted in tee

•

NON-GLI Sensor---------for sensor with 0-2000 Hz. output (any mounting)

For GLI PIPE MOUNT, enter the internal diameter of the

pipe in which the sensor will be installed. When using a GLI

tee-mounted sensor, enter the tee size and tee material. For

a NON-GLI SENSOR, determine and enter appropriate

SLOPE and OFFSET values.

Analog Outputs

The CALIBRATE menu enables you to linearly offset measured flow readings one of two ways by using the:

•

OFFSET BY method to enter a “+” or “-” offset value.

•

SET TO method to enter a known measured value.

See PART THREE, Sections 5.1 and 5.2 for details. Also,

the mA values for each analog output can be calibrated

(Section 5.3).

The analyzer provides two isolated analog outputs (1 and

2). Each output can be set to be 0-20 mA or 4-20 mA, and

assigned to represent one of these

•

Sensor A flow rate

•

Sensor B flow rate

•

Sensor C flow rate

•

Sensor D flow rate

•

Sensor A volume

*An analog output can only represent the calculated measurement when two sensors

are used and the analyzer has been correctly configured for CALCULATION.

•

Sensor B volume

•

Sensor C volume

•

Sensor D volume

•

Calculated measurement*

measurements

:

Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN) Rev. 1-201

Parameter (or calculated measurement) values can be entered to define the endpoints at which the minimum and

maximum analog output values are desired. For analog output setup details, refer to PART THREE, Section 4.4.

16

PART ONE - INTRODUCTION SECTION 1 - GENERAL INFORMATION

Relays

☞

The analyzer has four electromechanical relays with SPDT

contacts. Each relay can be set to function as a CONTROL,

ALARM or STATUS relay. CONTROL and ALARM relays

can be assigned to be driven by one of these:

•

Sensor A flow rate

•

Sensor B flow rate

•

Sensor C flow rate

•

Sensor D flow rate

•

Sensor A volume

*A relay can only be driven by the calculated measurement when two sensors

are used and the analyzer has been correctly configured for CALCULATION.

•

Sensor B volume

•

Sensor C volume

•

Sensor D volume

•

Calculated measurement*

NOTE: When a relay is set to function as a STATUS relay,

it is no longer configurable. Instead, it becomes a

dedicated system diagnostic-only alarm relay that

automatically energizes when the “WARNING

CHECK STATUS” message flashes on the

MEASURE screen. This occurs when the analyzer

detects a “fail” diagnostic condition. See PART

THREE, Section 6.1 for more details.

Pulsed Outputs

1.2 Modular Construction

For relay setup details, refer to PART THREE, Section 4.5.

The analyzer provides two SPDT pulsed contact closure

outputs (A and B) for remote use such as counting or

pumping. Each pulsed output can be assigned to represent

any measured volume, and set to activate at a desired volume increment for a preset time duration. Refer to PART

THREE, Section 4.6 for setup details.

The modular construction of the analyzer simplifies field

servicing and provides electrical safety. The front door/

keypad assembly uses voltages no greater than 24 VDC,

and is completely safe to handle.

Opening the analyzer door accesses terminals inside the

enclosure for electrical connections. Line power must be

connected to specifically designated terminals on TB3.

Rev. 1-201 Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN)

WARNING:

REMOVE LINE POWER BEFORE NEARING THIS AREA

TO PREVENT ELECTRICAL SHOCK.

17

PART ONE - INTRODUCTION SECTION 1 - GENERAL INFORMATION

1.3 Retained

Configuration Values

1.4 Analyzer

Serial Number

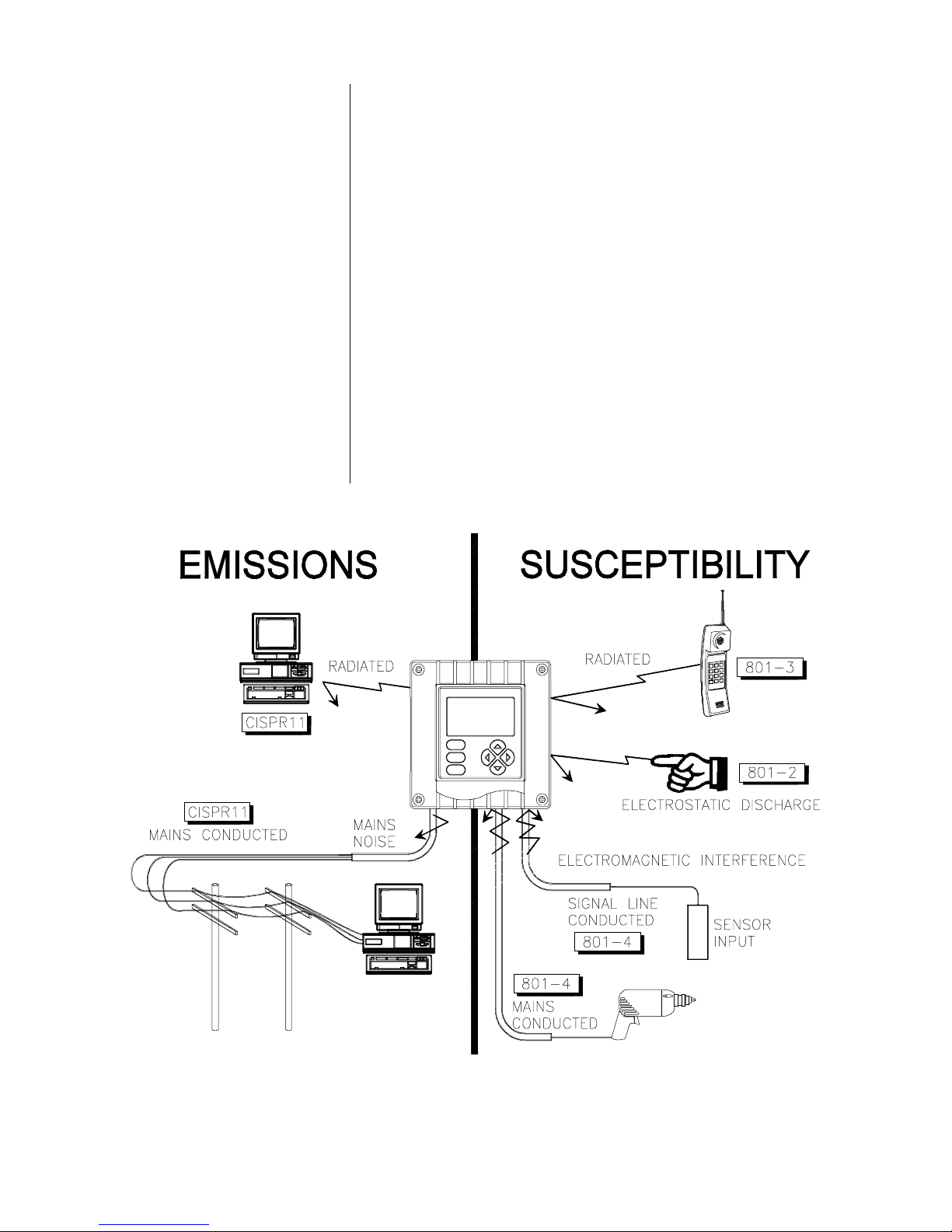

1.5 EMI/RFI Immunity

All user-entered configuration values are retained indefinitely, even if power is lost or turned off. The non-volatile

analyzer memory does not require battery backup.

A label with the analyzer model number, serial number,

build date, and other items is located on top of the enclosure.

The analyzer is designed to provide protection from most

normally encountered electromagnetic interference. This

protection exceeds US standards and meets European

IEC 801-series testing for electromagnetic and radio frequency emissions and susceptibility. Refer to Figure 1-1

and the specifications in Section 2.1 for more information.

Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN) Rev. 1-201

FIGURE 1-1 EMI/RFI Immunity Diagram

18

PART ONE - INTRODUCTION SECTION 2 - SPECIFICATIONS

ECTION

S

2

SPECIFICATIONS

2.1 Operational

Display....................................... Graphic dot matrix LCD, 128 x 64 pixels with

LED backlighting; 1/2 inch (13 mm) main

character height; 1/8 inch (3 mm) auxiliary

information character height; menu screens

contain up to six text lines

Measurement Selectable Ranges

Flow Rate (all sensors).......... 0-9999, 0-999.9 or 0-99.99 with selectable

flow rate units and multiplier

Volume (all sensors) ............. 0-999,999,999 with selectable volume units

Calculation (X and Y are selectable):

X-Y: Flow.......................... 0-9999, 0-999.9 or 99.99 w/selected multiplier

Volume..................... 0-999,999,999 in preset volume units

X+Y: Flow.......................... 0-9999, 0-999.9 or 99.99 w/selected multiplier

Volume..................... 0-999,999,999 in preset volume units

X/Y (flow or volume) .......... 0-9999, 0-999.9 or 99.99 (no units)

[X/Y] x 100......................... 0-999% pass ratio

Analog Outputs (1 and 2) ...... 0.00-20.00 mA or 4.00-20.00 mA

Ambient Conditions:

Operation.............................. -4 to +140°F (-20 to +60°C); 0-95% relative

humidity, non-condensing

Storage................................. -22 to +158°F (-30 to +70°C); 0-95% relative

humidity, non-condensing

Relays: Types/Outputs .................Four electromechanical relays; SPDT (Form C)

contacts; U.L. rated 5A 115/230 VAC, 5A @ 30

VDC resistive

Operational Mode ......... Each relay (A, B, C, and D) can be assigned

to be driven by one of these measurements:

•

Sensor A flow rate

•

Sensor B flow rate

•

Sensor C flow rate

•

Sensor D flow rate

•

Sensor A volume

Function Modes:

Control.................... Settings for high/low phasing, setpoint, dead-

band, overfeed timer, off delay, and on delay

Alarm .........................Settings for low alarm point, low alarm point

deadband, high alarm point, high alarm point

deadband, off delay, and on delay

Status.........................Not configurable; relay only activates when a

sensor or analyzer “fail” diagnostic WARNING

condition exists

Indicators.........................Relay A, B, C, and D annunciators indicate

respective relay status

Sensor-to-Analyzer Distance:

GLI Impeller Sensors ............ 2000 ft. (610 m) maximum

Non-GLI Sensors .................. 300 ft. (91 m) maximum

•

Sensor B volume

•

Sensor C volume

•

Sensor D volume

•

Calculated measurement

Rev. 1-201 Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN)

Power Requirements .................. 90-130 VAC, 50/60 Hz. (10 VA max.) or

180-260 VAC, 50/60 Hz. (10 VA max.)

19

PART ONE - INTRODUCTION SECTION 2 - SPECIFICATIONS

Calibration Adjust: Offset By ..... Enter a “+” or “-” offset value that is respec-

tively added to or subtracted from

measured flow readings for a linear offset

Set To ......... Enter measurement value (derived from

qualified reference instrument reading) to

linearly offset measured flow reading

NOTE:

Calibration is actually achieved by independently configuring each

sensor, which is a normal part of the initial setup.

Analog Outputs .......................... Two isolated 0/4-20 mA outputs; each with 0.004

mA (12-bit) resolution and capability to drive up

to 600 ohm loads; each output can be assigned

to represent one of these measurem ents:

•

Sensor A flow rate• Sensor B volume

NOTE:

•

Sensor B flow rate

•

Sensor C flow rate• Sensor D volume

•

Sensor D flow rate

•

Sensor A volume

Parameter (or calculated measurement) values can be entered to

•

Sensor C volume

•

Calculated measurement

define the endpoints at which the minimum and maximum mA output

values are desired (range expand).

Pulsed Outputs .......................... Two SPDT contact closures; each pulsed

output can represent a selected measured

volume, and activate at a user-set volume

increment for a desired time duration

Communication: RS-232 ........... Enables configuration and retrieval of measured

data for one analyzer using IBM-compatible PC

and optional GLI software tool kit

HART.............. Enables configuration and retrieval of measured

data for multiple analyzers over a communication link using appropriate hand-held terminal or

data system with HART software

2.2 Analyzer Performance

(Electrical, Analog Outputs)

2.3 Mechanical

Memory Backup (non-volatile) .... All user settings are retained indefinitely in

memory (EEPROM)

EMI/RFI Conformance................ Exceeds US and meets European standards

for conducted and radiated emissions and

immunity; certified CE compliant for applications as specified by EN 50081-1 for

emissions and EN 50082-2 for immunity

Electrical Certifications:

General Purpose (pending) ..... UL, C-UL, FM, and CENELEC

Class 1, Division 2 (pending) .. UL, C-UL, and FM: Groups A, B, C, D, F, and G

Zone 2 (pending) .................... CENELEC: Group IIC

Accuracy.................................... ± 0.1% of span

Sensitivity .................................. ± 0.1% of span

Repeatability .............................. ± 0.05% of span

Temperature Drift....................... Zero and Span: ± 0.02% of span per °C

Response Time .......................... 1-60 seconds to 90% of value upon step change

Enclosure................................... NEMA 4X; polycarbonate face panel, epoxy-

coated cast aluminum door and case with four

1/2 inch (13 mm) conduit holes; nylon mounting bracket, and stainless steel hardware

Mounting Configurations............. Panel, surface, and pipe (horizontal and

vertical) mounting

Net Weight................................. 3.5 lbs. (1.6 kg) approximately

Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN) Rev. 1-201

20

PART TW O - INSTALLATION SECTION 1 - UNPACKING

PART TWO - INSTALLATION

ECTION

S

UNPACKING

After unpacking, it is recommended to save the shipping

carton and packing materials in case the instrument must be

stored or re-shipped. Inspect the equipment and packing

materials for signs of shipping damage. If there is any evidence of damage, notify the transit carrier immediately.

ECTION

S

MECHANICAL REQUIREMENTS

1

2

2.1 Location

1. It is recommended to locate the analyzer as close as

possible to the installed flow sensor. Depending on the

sensor type, the maximum allowable distance between

the sensor and analyzer is:

Any GLI Sensor:

•

NON-GLI SENSOR:

•

2. Mount the analyzer in a location that is:

➥

Clean and dry where there is little or no vibration.

➥

Protected from corrosive fluids.

➥

Within ambient temperature limits (-4 to +140°F or

-20 to +60°C).

EXPOSING THE ANALYZER TO DIRECT

SUNLIGHT MAY INCREASE THE OPERATING

TEMPERATURE ABOVE ITS SPECIFIED

LIMIT, AND DECREASE DISPLAY VISIBILITY.

RECOMMENDATION: IN SEVERE CASES,

USE A GLI SUN SHIELD (P/N 1000G3088-001).

2000 feet (610 m)

300 feet (91 m)

CAUTION:

2.2 Mounting

Rev. 1-201 Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN)

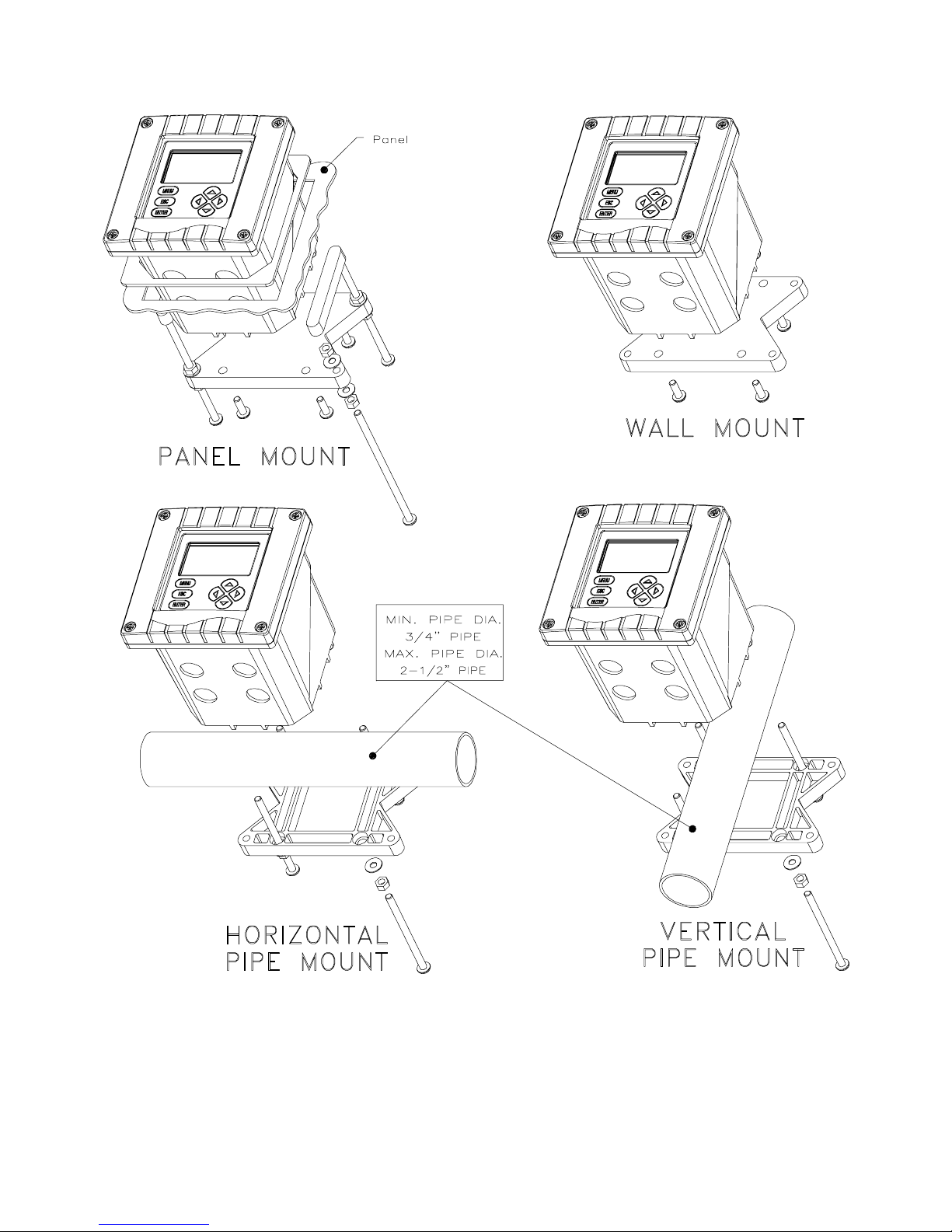

Figure 2-1 illustrates the various ways to mount the analyzer using the supplied bracket and hardware. Determine

the mounting method and attach the hardware as shown in

the respective illustration. Refer to Figure 2-2 for analyzer

installation dimension details.

21

PART TW O - INSTALLATION SECTION 2 - MECHANICAL REQUIREMENTS

FIGURE 2-1 Analyzer Mounting Arrangements

Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN) Rev. 1-201

22

PART TW O - INSTALLATION SECTION 2 - MECHANICAL REQUIREMENTS

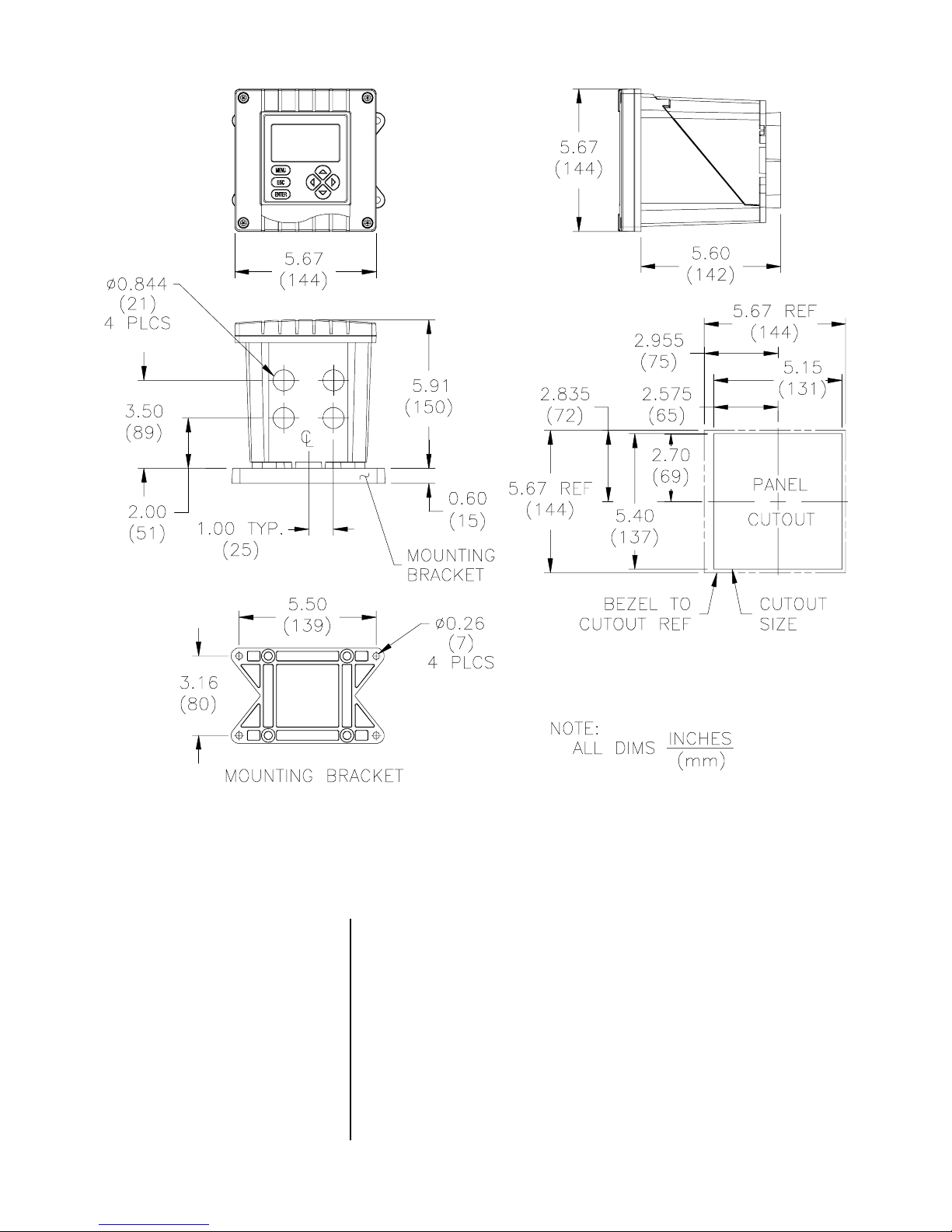

FIGURE 2-2 Analyzer Installation Dimensions Details

2.3 Conduit Hole

Requirements

☞

Rev. 1-201 Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN)

Recommendation:

inch, grounded metal conduits. If using only shielded cables, appropriate strain reliefs or cable grips are required.

(GLI offers accessory cable grips, part number 3H1091, and

watertight locknuts, part number 3H1230, for cable entries.)

Seal unused cable entry holes with appropriate plugs.

NOTE:

Use NEMA 4-rated fittings and plugs to maintain the

Run all wiring to the analyzer in 1/2-

watertight integrity of the NEMA 4X enclosure.

23

PART TW O - INSTALLATION SECTION 3 - ELECTRICAL CONNECTIONS

ECTION

S

ELECTRICAL CONNECTIONS

To access terminals for electrical connections, open the lefthinged enclosure door by unscrewing the four fasteners.

Figure 2-3 shows the terminal arrangement and their designations.

3

☞

☞

NOTE: All terminals are suitable for single wires up to 14

AWG (2.5 mm2).

Wiring Tip!

electromagnetic compatibility requirements, follow these

general wiring guidelines:

1. Keep all cable shields as short as possible inside

the analyzer, and connect them to the ground terminals provided. Performance may be improved by

using cable glands that enable the shield to directly

contact the analyzer chassis.

2. Use Steward ferrite 28 B0590-000 or equivalent on

the sensor cable -- two turns required.

3. In harsh conducted RF conditions, connect the earth

ground of the analyzer to a local, known earth

ground source.

To comply with European Community (CE)

☞

Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN) Rev. 1-201

NOTE: For easier wiring, connect line power and relay out-

puts through the back conduit holes before

connecting the sensors, analog outputs, and pulse

outputs through the front holes.

24

PART TW O - INSTALLATION SECTION 3 - ELECTRICAL CONNECTIONS

FLOW ANALYZER

5

HART

OUT 1

21 43

OUT 2

4-20 mA

TB2

TX

RELAY A

COMNC

21

876 111091615141312 191817

RX

RS-232

TTL

RELAY B

NO

COMNC COMNCNO

POWER

90-130 VAC

180-260 VAC

10VA 50/60 Hz

RELAY C

8674533411 12910

RELAY D

COMNCNO

F1F

T

NO

230

100mA80mA

FIGURE 2-3 Analyzer Terminal Block Designations

20

2221

2423

TB1

NC

NC

NO

NO

COM

COM

N115

TB3

23

2

T

3.1 Flow Sensor(s)

☞

☞

The analyzer can be used with up to four GLI impeller or

non-GLI flow sensors in any combination. Non-GLI sensors

must have a 0-2000 Hz. output such as provided by a paddle wheel, turbine, vortex, and other flow sensors.

Wiring Tip!

Route each sensor cable in 1/2-inch,

grounded metal conduit to protect it from moisture,

electrical noise, and mechanical damage.

For installations where the distance between sensor and

analyzer exceeds the sensor cable length, indirectly

connect the sensor to the analyzer using a junction box

and interconnect cable.

NOTE:

Do not route the sensor cable in any conduit containing AC or DC power wiring (“electrical noise”

may interfere with the sensor signal).

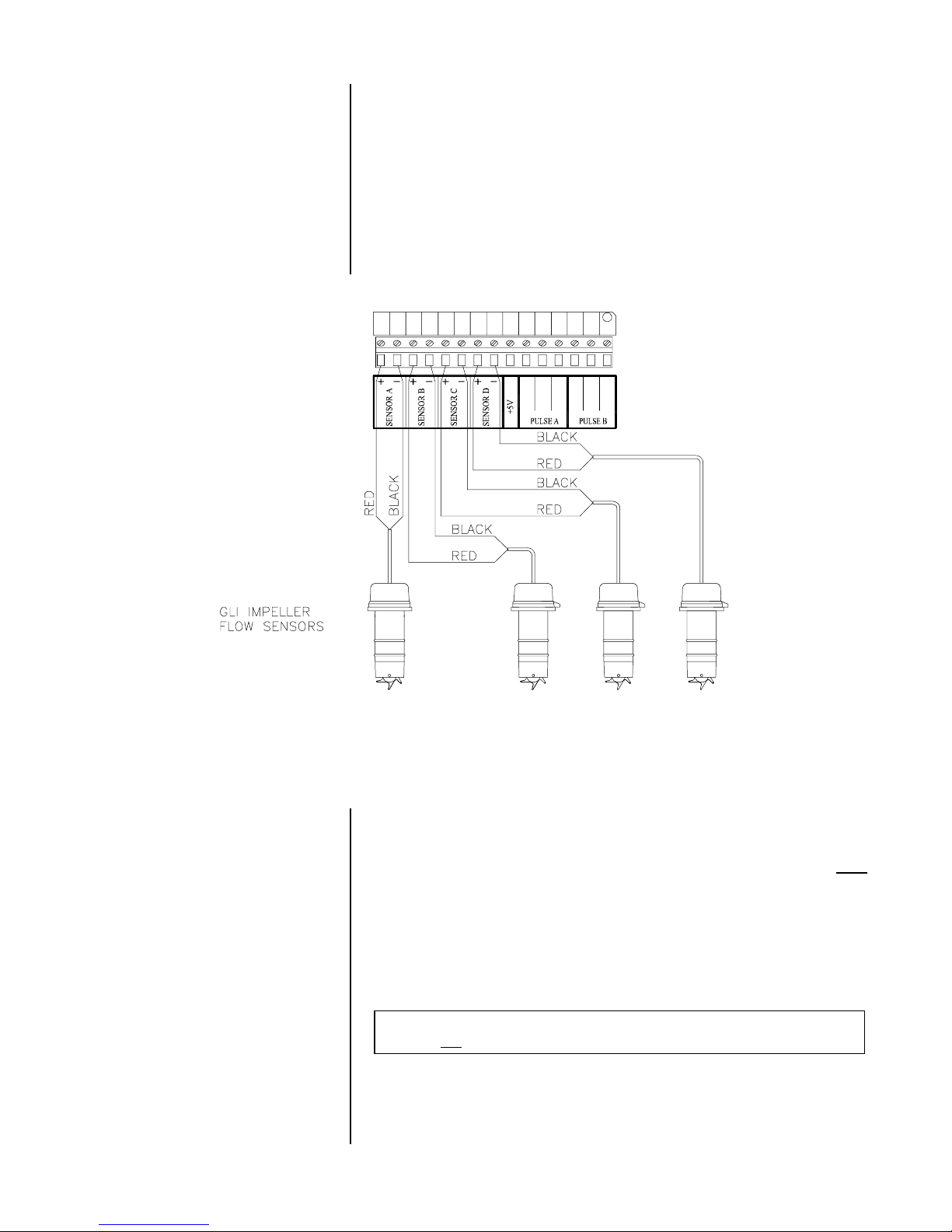

Refer to Figure 2-4 and connect the Sensor A cable (or interconnect) wires to Terminals 10 and 11 on TB1, matching

polarity as indicated. Connect additional sensors to their

respectively-marked terminals.

Rev. 1-201 Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN)

25

PART TW O - INSTALLATION SECTION 3 - ELECTRICAL CONNECTIONS

☞

NOTE: For best immunity to electromagnetic interference,

connect each sensor cable’s shield wire to the

grounding strip at bottom of case (5 open holes).

For non-GLI sensors that require up to +5 VDC

power, connect its additional wire to Terminal 18 on

TB1. A separate external power supply is required

for higher voltages.

10 11 12 13 14 15 16 17 18 19 20

21 22

23 24

TB1

NO

NC

NO

COM

NC

COM

3.2 Analog Outputs

FIGURE 2-4 Connecting Flow Sensor(s)

Two isolated analog outputs (1 and 2) are provided. Each

output can be set to be 0-20 mA or 4-20 mA and, depending

on the number of sensors used, assigned to represent one

of these measurements:

•

Sensor A flow rate

•

Sensor B flow rate

•

Sensor C flow rate

•

Sensor D flow rate

•

Sensor A volume

*An analog output can only represent the calculated measurement when two sensors

are used and the analyzer has been correctly configured for CALCULATION.

•

Sensor B volume

•

Sensor C volume

•

Sensor D volume

•

Calculated measurement*

The outputs are isolated from the inputs and earth

ground, but not from each other.

For output configuration

details, see PART THREE, Section 4.4.

Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN) Rev. 1-201

26

PART TW O - INSTALLATION SECTION 3 - ELECTRICAL CONNECTIONS

☞

☞

Wiring Tip!

cable for connecting the analog outputs. To protect the

output signals from EMI/RFI, connect cable shields to

the grounding strip at bottom of case (5 open holes).

Each 0/4-20 mA output can drive a load of up to 600 ohms.

Output 1:

•

matching polarity as indicated.

Output 2:

•

matching polarity as indicated.

NOTE: When using the HART communication option, a

Use high quality, shielded instrumentation

Connect the load to Terminals 2 and 3 on TB1,

Connect the load to Terminals 4 and 5 on TB1,

digital signal is encoded onto the 4-20 mA analog

Output 1 signal. In a HART SINGLE MODE wiring

configuration, Output 1 remains available for normal

use. However, in a HART MULTI-DROP wiring configuration, Output 1 becomes dedicated to that

function and cannot be used. See PART THREE,

Section 8 for more HART communication information.

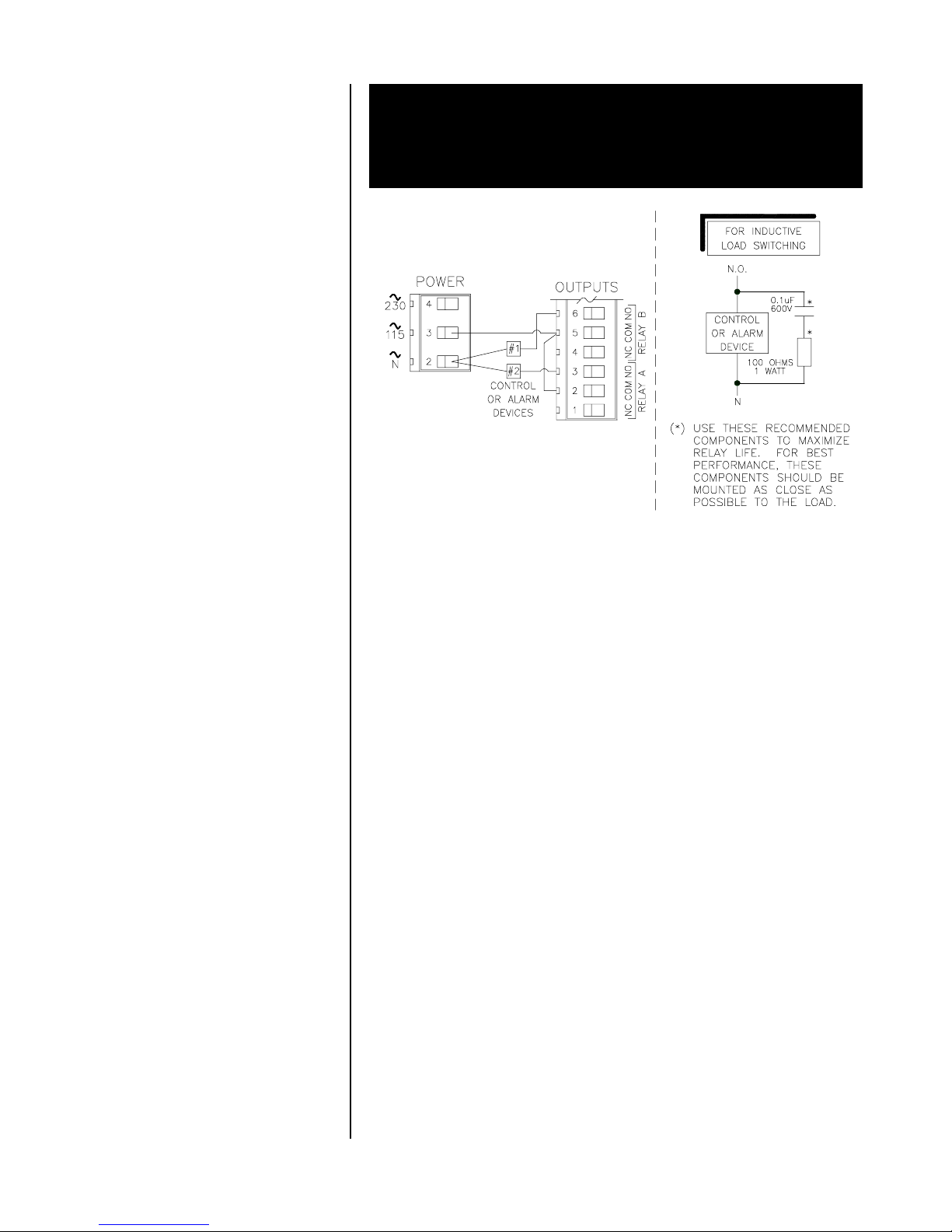

3.3 Relay Outputs

The analyzer is equipped with four electromechanical relays.

For relay setup details, see PART THREE, Section 4.5.

CAUTION:

DO NOT EXCEED THE CONTACT RATING FOR

EACH RELAY (5A 115/230 VAC). WHEN SWITCHING

LARGER CURRENTS, USE AN AUXILIARY RELAY

SWITCHED BY THE ANALYZER RELAY TO EXTEND

ANALYZER RELAY LIFE. WHEN USING RELAY

OUTPUTS, MAKE SURE THAT LINE POWER WIRING

CAN ADEQUATELY CONDUCT THE CURRENT

DRAW OF THE SWITCHED LOAD(S).

Four sets of SPDT relay outputs (Relays A, B, C, and D) are

provided at Terminals 1 through 12 on TB2.

puts are not powered.

analyzer may also be used to power control/alarm devices

with these relay contacts. See Figure 2-5 for a general wiring arrangement. Always check control wiring to insure that

line power will not be shorted by the relay switching action,

and that wiring conforms to local codes.

The line power used to power the

The relay out-

Rev. 1-201 Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN)

27

PART TW O - INSTALLATION SECTION 3 - ELECTRICAL CONNECTIONS

WARNING:

MAKE SURE LINE POWER IS NOT PRESENT WHILE

CONNECTING WIRES TO TB2 RELAY TERMINALS.

3.4 Pulsed Outputs

(contact closure)

3.5 Closed Contact

TTL Input

FIGURE 2-5

Connecting Control/Alarm Device(s) To Electromechanical Relay(s)

Two sets of SPDT pulse contact closure outputs (A and B)

are provided at Terminals 19 through 24 on TB1. Connect

remote devices such as counters or pumps to appropriate

terminals. For pulsed output configuration details, see

PART THREE, Section 4.6.

The closed contact input feature of the analyzer enables

you to conveniently:

•

Hold the analog outputs at their last measured values.

•

Hold CONTROL and ALARM relays in their present

“on/off” states.

☞

Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN) Rev. 1-201

To initiate these actions, momentarily connect TTL Terminals 8 and 9 on TB1, either locally or remotely.

NOTE:

During calibration, the selected output state

(“HOLD,” “XFER” or “ACTIVE”) overrides the TTL

input hold feature.

28

PART TW O - INSTALLATION SECTION 3 - ELECTRICAL CONNECTIONS

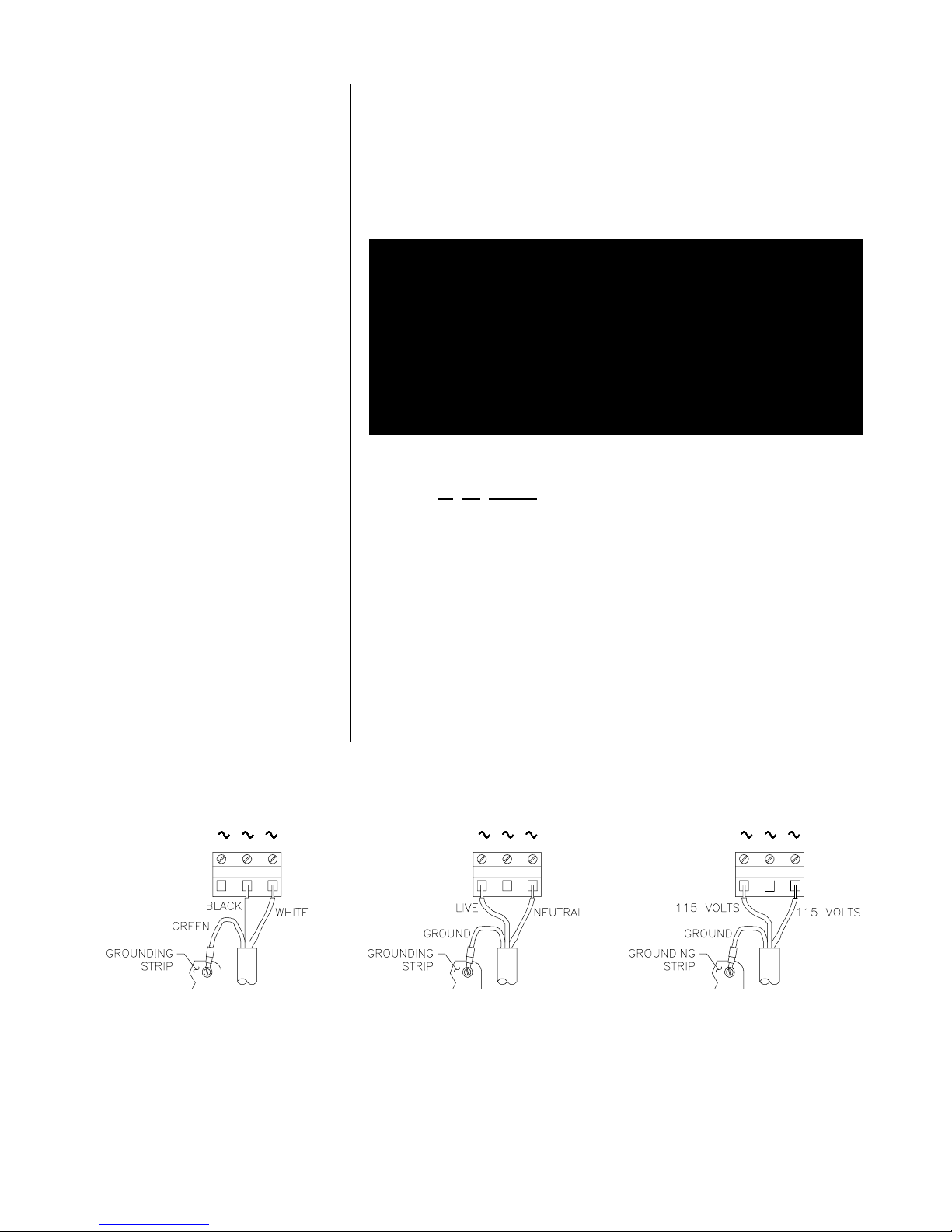

3.6 Line Power

☞

Refer to Figure 2-6, 2-7 or 2-8 and connect line power to

appropriate terminals on TB3 using the standard three-wire

connection arrangement.

form to local codes

Use wiring practices which con-

(example: National Electric Code

Handbook in the U.S.A.).

WARNING:

REMOVE LINE POWER WHILE CONNECTING LINE

POWER WIRES TO THE TB3 TERMINALS. ALSO,

USE ONLY THE STANDARD THREE-WIRE CONNECTION ARRANGEMENT FOR SINGLE-PHASE LINE

POWER TO PREVENT AN UNSAFE CONDITION, AND

TO ENSURE PROPER ANALYZER OPERATION.

NOTE: In all cases, connect the line power cable ground

wire (usually green) to the grounding strip at bottom

of case (5 open holes).

☞

115230 N

342

FIGURE 2-6

Connecting 115 Volt Single Phase

Line Power (90-130 VAC)

The “115” and “230” voltage circuits are protected with internal, board-mounted slow-blow fuses.

NOTE: For 230 volt split phase line power, be sure to con-

form to local codes with regard to fusing the 115

volt line connected to the “N” terminal.

230 115 N

234

FIGURE 2-7

Connecting 230 Volt Single Phase

Line Power (180-260 VAC)

FIGURE 2-8

Connecting 230 Volt Split Phase

Line Power (180-260 VAC)

N115230

234

Rev. 1-201 Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN)

29

Loading...

Loading...