OPERATING INSTRUCTION MANUAL

Accu4™

Low-range

Turbidimeter System

(Model T53 Analyzer and 8320 Sensor)

Worldwide Headquarters and Sales:

GLI International, Inc.

9020 West Dean Road

Milwaukee, Wisconsin 53224

U.S.A.

In the interest of improving and updating its equipment, GLI reserves the right to alter specifications to equipment at any time.

Rev. 2-300 Accu4™ Low-range T urbidimeter Sys tem

Phone:

Fax:

E-mail:

Web:

Represented By:

[414] 355-3601

[414] 355-8346

info@gliint.com

www.gliint.com

Viridor Instrumentation

A company

1

Accu4™ Low-range Turbidimeter System Rev. 2-300

2

IMPORTANT SAFETY INFORMATION

This measurement system is compliant with safety standards as outlined in:

FMRC Class Numbers 3600, 3611, and 3810 (U.S.A.)

CSA C22.2 No. 142 and C22.2 No. 213 (Canada)

EN 61010-1 (European Community)

Please read and observe the following:

•

Opening the analyzer door exposes you to line power voltage, if present, at terminals on TB2 and TB3

inside the enclosure. This may be hazardous. Always remove line power before entering this area in

the analyzer. However, the analyzer door assembly and the sensor contain only low voltages and are

completely safe to handle.

•

Wiring or repairs should only be performed by qualified personnel and only to an unpowered analyzer.

•

Whenever it appears that analyzer safety is questionable, disable the analyzer to ensure against any

unintended operation. For example, an unsafe condition is likely when:

1) The analyzer appears visibly damaged.

2) The analyzer fails to operate properly or provide the intended measurements.

3) The analyzer has been stored for long periods at temperatures above 158°F (70°C).

•

This measurement system must be installed by specially trained personnel in accordance with relevant

local codes and instructions contained in this operating instruction manual. Observe all technical

specifications of the system. If one line of the line power mains is not neutral, use a double-pole mains

switch to disconnect the analyzer.

HELPFUL IDENTIFIERS

In addition to information on installation and operation, this instruction manual may contain

WARNINGS pertaining to user safety, CAUTIONS regarding possible instrument malfunction, and

NOTES on important, useful operating guidelines.

WARNING:

A WARNING LOOKS LIKE THIS. IT WARNS YOU OF THE POTENTIAL

FOR PERSONAL INJURY.

CAUTION:

A CAUTION LOOKS LIKE THIS. IT ALERTS YOU TO POSSIBLE

INSTRUMENT MALFUNCTION OR DAMAGE.

☞

NOTE: A note looks like this. It alerts you to important operating

information.

Rev. 2-300 Accu4™ Low-range Turbidimeter System

3

Definition of Equipment Symbols

This symbol

means CAUTION

and alerts you to possible danger or

instrument malfunction. Refer to this manual before proceeding.

This symbol

means that this is a protective ground terminal

alerts you to connect an earth ground to it.

This symbol

means that there is alternating current present

alerts you to be careful.

and

and

WARRANTY

GLI International, Inc. warrants the Accu4™ Low-range Turbidimeter System to be free

from defects in material or workmanship for a period of 2 years (24 months) from the

date this product was shipped from our facility. A warranty claim will not be honored if

defects are not reported within the warranty period, or if GLI International determines that

defects or damages are due to normal wear, misapplication, lack of maintenance, abuse,

improper installation, alteration, or abnormal conditions. GLI International’s obligation

under this warranty shall be limited to, at its option, replacement or repair of this product.

The product must be returned to GLI International, freight prepaid, for examination. The

product must be thoroughly cleaned and any process chemicals removed before it will be

accepted for replacement or repair. GLI International’s liability shall not exceed the cost

of the product. Under no circumstances will GLI International be liable for any incidental

or consequential damages, whether to person or property. GLI International will not be liable for any other loss, damage or expense of any kind, including loss of profits,

resulting from the installation, use, or inability to use this product.

Accu4™ Low-range Turbidimeter System Rev. 2-300

4

CONDENSED OPERATING INSTRUCTIONS

This manual contains details for all operating aspects of the Accu4™ Low-range Turbidimeter System.

The following condensed instructions are provided to assist you in getting the system started up and operating as quickly as possible.

measurement operation.

To use specific analyzer features, refer to the appropriate sections in this

manual for instructions.

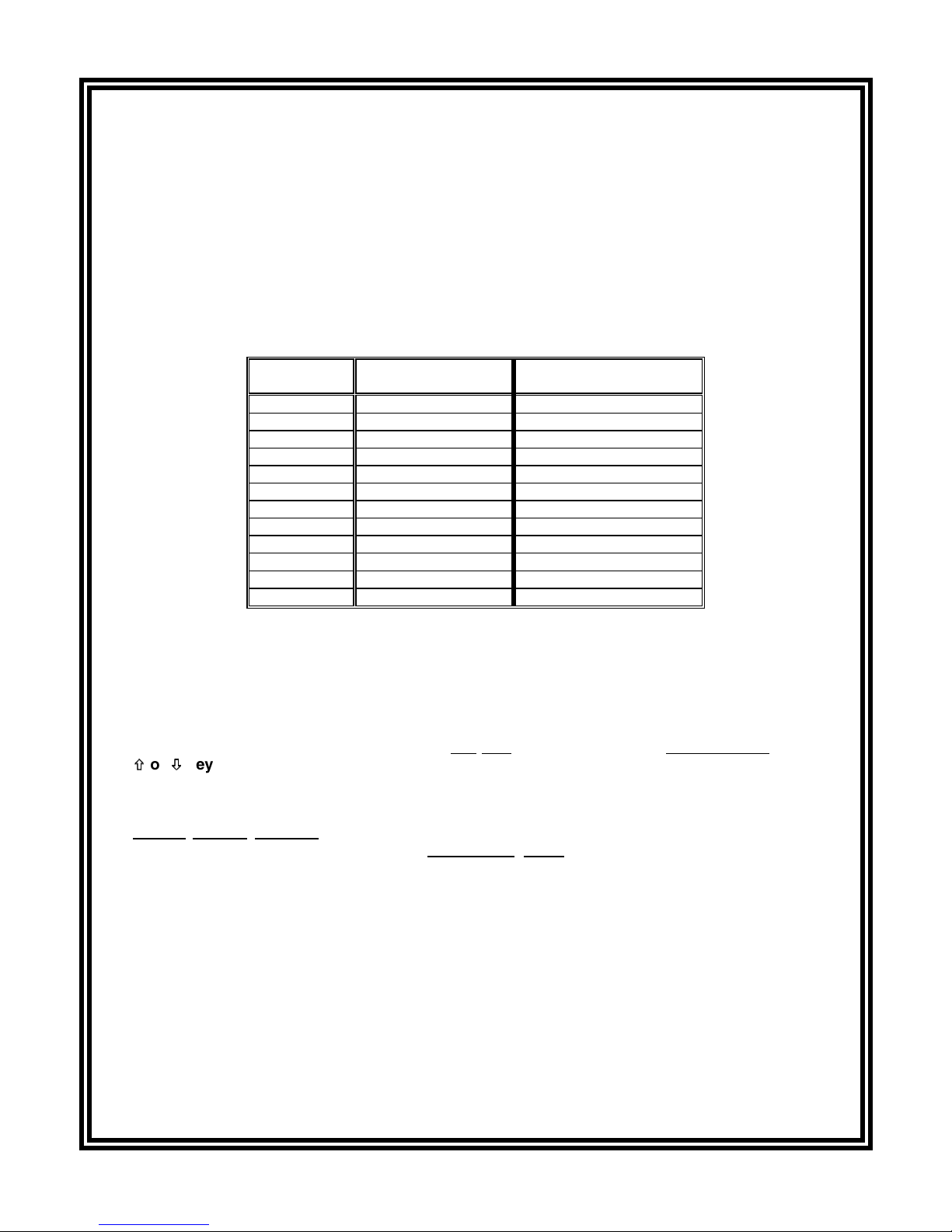

1. CONNECTING SENSOR

After the T53 analyzer is properly mounted (Part Two, Section 2.5), connect the GLI Model 8320 lowrange turbidity sensor, matching wire colors to terminals as indicated:

These condensed instructions only pertain to basic turbidity

Sensor Wire

Colors

Inner Shield Grounding strip lug Terminal #11 on TB1

Red Terminal #12 on TB1 Terminal #12 on TB1

Violet Terminal #13 on TB1 Terminal #13 on TB1

Green Terminal #14 on TB1 Terminal #14 on TB1

White Terminal #15 on TB1 Terminal #15 on TB1

Yellow Terminal #16 on TB1 Terminal #16 on TB1

Inner Shield Grounding strip lug Terminal #17 on TB1

Brown Terminal #18 on TB1 Terminal #18 on TB1

Gray Terminal #19 on TB1 Terminal #19 on TB1

Blue Terminal #20 on TB1 Terminal #20 on TB1

Black Terminal #21 on TB1 Terminal #21 on TB1

Orange Terminal #22 on TB1 Terminal #22 on TB1

Analyzers with

“B” Prefix Serial No.

Analyzers with

No Letter Prefix Serial No.

2. CONNECTING LINE POWER

Important:

Follow the instructions in Part Two, Section 3.5 to connect line power to the analyzer.

3. ADJUSTING DISPLAY CONTRAST

Ambient lighting conditions may make it necessary to adjust display contrast to improve visibility.

With the MEASURE screen displayed, press and hold

×

Ø

×

or

until attaining the desired contrast.

key

Ø

ENTER key

the

and simultaneously press the

4. CALIBRATING SYSTEM

Always initially

calibrate

the Accu4™ Low-range Turbidimeter System to ensure accurate measurement. Any time thereafter, you can conveniently check system calibration using an optional

accessory Cal-CubeTM assembly.

•

When you need to calibrate with a

method. GLI only guarantees measurement accuracy when a 40 NTU formazin suspension is used

as the primary standard.

•

When calibration need not conform to USEPA requirements

method (requires optional GLI CAL-CUBE™ assembly) or the “SAMPLE CAL” method.

Refer to Part Three, Section 5 for instructions on all calibration methods.

5. COMPLETING ANALYZER CONFIGURATION

To further configure the analyzer to your application requirements, use the appropriate CONFIGURE

screens to make selections and “key in” values. Refer to Part Three, Section 4 for complete configuration details.

Rev. 2-300 Accu4™ Low-range Turbidimeter System

primary standard

5

, use the “PRIMARY CAL” calibration

, use the “CUBE CAL” calibration

Accu4™ Low-range Turbidimeter System Rev. 2-300

6

TABLE OF CONTENTS

PART ONE - INTRODUCTION

SECTION 1 GENERAL INFORMATION

1.1 Capability Highlights ........................................................................13-15

1.2 Modular Construction ............................................................................15

1.3 Retained Configuration Values .............................................................15

1.4 Analyzer and Sensor Serial Numbers ...................................................15

1.5 EMI/RFI Immunity.................................................................................. 16

SECTION 2 SPECIFICATIONS

....................................................................................17-18

PART TWO - INSTALLATION

SECTION 1 UNPACKING

SECTION 2 MECHANICAL REQUIREMENTS

2.1 Sensor Location ...............................................................................19-20

2.2 Sensor Mounting ..............................................................................20-21

2.3 Sensor Plumbing Connections ..............................................................22

2.4 Analyzer Location..................................................................................23

2.5 Analyzer Mounting............................................................................23-24

2.6 Sensor and Analyzer Conduit Hole Requirements................................ 24

SECTION 3 ELECTRICAL CONNECTIONS

3.1 GLI Model 8320 Low-range Turbidity Sensor...................................25-27

3.2 Analog Outputs......................................................................................28

3.3 Relay Outputs...................................................................................28-29

3.4 Closed Contact TTL Input .....................................................................29

3.5 Line Power .......................................................................................30-31

.................................................................................................19

PART THREE - OPERATION

SECTION 1 USER INTERFACE

1.1 Display ..................................................................................................32

1.2 Keypad .............................................................................................32-33

1.3 MEASURE Screen (normal display mode)............................................ 34

SECTION 2 MENU STRUCTURE

2.1 Displaying Main Branch Selection Screen ............................................35

2.2 Displaying Top-level Menu Screens.................................................35-36

2.3 Displaying Submenu Screens ...............................................................36

2.4 Adjusting Edit/Selection Screen Values ...........................................36-37

2.5 Entering (Storing) Edit/Selection Screen Values/Choices.....................37

Rev. 2-300 Accu4™ Low-range Turbidimeter System

7

TABLE OF CONTENTS (continued)

SECTION 3 ADJUSTING DISPLAY CONTRAST

SECTION 4 CONFIGURING THE ANALYZER

4.1 Selecting LANGUAGE to Operate Analyzer.......................................... 38

4.2 Configuring Sensor Characteristics:

SELECT UNITS ..........................................................................38-39

SET FILTER Time............................................................................ 39

Select PULSE SUPPRESS (on/off)..................................................40

ENTER NOTE (top line of MEASURE screen).................................40

4.3 Configuring Analog Outputs (1 and 2):

SET 0/4 and 20 mA VALUES......................................................41-42

SET TRANSFER Value (mA)........................................................... 42

SET FILTER Time............................................................................ 43

Select SCALE 0 mA/4 mA (low endpoint) ........................................43

4.4 Configuring Relays (A, B, C, and D):

SET FUNCTION Mode (alarm, control, or status).......................44-45

SET TRANSFER Mode (relay on or off) ..........................................46

SET ACTIVATION (configuration values) ...................................46-48

4.5 SET PASSCODE (feature enabled or disabled) ...................................48

4.6 Configuration Settings Summary (ranges/choices and defaults) ..........49

.............................................................37

SECTION 5 CALIBRATING THE ANALYZER

5.1 Things to Know About Calibration ....................................................50-51

5.2 PRIMARY CAL Method (requires formazin suspension):

Preparing Formazin Solution ......................................................51-52

Filling Sensor..............................................................................52-54

Entering Value .................................................................................54

Resuming Operation ...................................................................54-55

5.3 CUBE CAL Method (requires optional Cal-CubeTM assembly):

TM

Inserting Cal-Cube

Assembly ..................................................55-56

Entering Value ............................................................................56-57

Resuming Operation ........................................................................57

5.4 SAMPLE CAL Method (requires sample with value

determined by laboratory analysis or portable meter)......................57-59

5.5 Analog Outputs (1 and 2) Calibration...............................................59-60

SECTION 6 TEST/MAINTENANCE

6.1 STATUS Checking (analyzer, sensor, and relays)...........................61-63

6.2 CHECK CAL/HOLD Outputs ............................................................63-64

6.3 OVERFEED RESET (relay timers)........................................................ 65

6.4 OUTPUT (1 and 2) Analog Test Signals ..........................................65-66

6.5 RELAY (A, B, C, and D) Operating Test................................................66

6.6 SENSOR TYPE Checking................................................................66-67

6.7 EPROM VERSION Checking ................................................................67

Accu4™ Low-range Turbidimeter System Rev. 2-300

8

TABLE OF CONTENTS (continued)

6.8 SIM SENSOR Setting.......................................................................67-68

6.9 RESET DEFAULTS............................................................................... 68

SECTION 7 RELAY OVERFEED TIMER FEATURE

7.1 Why Use an Overfeed Timer................................................................. 69

7.2 Configuring Relay Overfeed Timers......................................................69

7.3 Overfeed Timer “Timeout” Operation .................................................... 69

7.4 Resetting Overfeed Timers ...................................................................69

7.5 Interactions with Other Analyzer Functions......................................69-70

SECTION 8 HART OPTION

8.1 Introduction ...........................................................................................71

8.2 Analyzer Operating Modes for HART Network.................................72-73

8.3 SINGLE MODE (Point-to-Point) Wiring Arrangement ...........................73

8.4 MULTI-DROP Wiring Arrangement.......................................................74

8.5 HART Preferences Setup:

Changing Polling Address ...............................................................75

Viewing Number of Required Preambles ....................................75-76

8.6 Device Preferences Setup:

Viewing Final Assembly Number ..................................................... 76

Viewing Model Number...............................................................76-77

Viewing Manufacturer ......................................................................77

Assigning a Tag ...............................................................................77

Assigning a Descriptor ..................................................................... 78

Assigning a Message....................................................................... 78

Assigning User-defined Date ......................................................78-79

Viewing Identification (ID) ................................................................79

Viewing Revisions............................................................................ 79

8.7 “Master Reset” Function........................................................................ 80

8.8 “Refresh” Function ................................................................................80

8.9 Protocol Command Set for PC Programming........................................ 80

PART FOUR - SERVICE AND MAINTENANCE

SECTION 1 GENERAL INFORMATION

1.1 Cleaning Sensor Flow Chamber ......................................................81-82

1.2 Cleaning Optional Cal-CubeTM Assembly.............................................. 82

1.3 Replacing Sensor Light Source or Detector:

Removing Inoperative Part ..............................................................83

Installing New Part ......................................................................83-84

Re-calibrating Measurement System............................................... 84

1.4 Replacing Fuse(s) .................................................................................85

1.5 Replacing Relays ..................................................................................85

1.6 Inspecting Sensor Cable .......................................................................85

Rev. 2-300 Accu4™ Low-range Turbidimeter System

9

TABLE OF CONTENTS (continued)

SECTION 2 PRESERVING MEASUREMENT ACCURACY

2.1 Eliminating Bubbles in Sensor Flow Chamber:

Restricting Sensor Outlet .................................................................86

Using an External Bubble Trap ........................................................86

2.2 Keeping Sensor Flow Chamber Clean ..................................................87

2.3 Keeping System Calibrated...................................................................87

2.4 Avoiding Electrical Interference.............................................................87

SECTION 3 TROUBLESHOOTING

3.1 System Diagnostic Condition Messages ............................................... 88

3.2 Isolating the Problem:

Checking Electrical Connections ..................................................... 89

Checking Operation Using System Diagnostics ..............................89

SECTION 4 ANALYZER REPAIR/RETURN

4.1 Customer Assistance.............................................................................90

4.2 Repair/Return Policy .............................................................................90

PART FIVE - SPARE PARTS AND ACCESSORIES

.................................................................................................................91

Accu4™ Low-range Turbidimeter System Rev. 2-300

10

TABLE OF CONTENTS (continued)

ILLUSTRATIONS

Figure 1-1

Figure 2-1

Figure 2-2

Figure 2-3

Figure 2-4

Figure 2-5

Figure 2-6

Figure 2-7

Figure 2-8

Figure 2-9

Figure 2-10

Figure 2-11

Figure 2-12

Figure 2-13

Figure 2-14

Figure 2-15

Figure 2-16

Figure 2-17

Figure 2-18

Figure 3-1

Figure 3-2

Figure 3-3

Figure 3-4

Figure 4-1

Figure 4-2

Figure 4-3

EMI/RFI Immunity Diagram ..................................................................................................16

Recommended Closed-loop Sensor Piping Arrangement...................................................... 19

Recommended Sample Bypass Line Sensor Piping Arrangement ........................................ 20

Standard Design Model 8320 Sensor -- Installation Dimension Details..................................21

High Pressure Design Model 8320 Sensor -- Installation Dimension Details.......................... 21

Sampling Point Guidelines for Process Pipe Plumbing Connection.......................................22

Analyzer Mounting Arrangements ......................................................................................... 23

Analyzer Installation Dimension Details ................................................................................ 24

Terminal Block Designations for Analyzers with “B” Prefix Serial Number.............................26

Terminal Block Designations for Analyzers with No Letter Prefix Serial Number ................... 26

Connecting Model 8320 Low-range Turbidity Sensor to

Analyzers with “B” Prefix Serial Number...............................................................................27

Connecting Model 8320 Low-range Turbidity Sensor to

Analyzers with No Letter Prefix Serial Number .....................................................................27

Connecting Control/Alarm Device(s) to Electromechanical Relay(s) .....................................29

Connecting 115 V Single Phase to Analyzers with “B” Prefix Serial Number.........................30

Connecting 115 V Single Phase to Analyzers with No Letter Prefix Serial Number ...............30

Connecting 230 V Single Phase to Analyzers with “B” Prefix Serial Number.........................31

Connecting 230 V Single Phase to Analyzers with No Letter Prefix Serial Number ...............31

Connecting 230 V Split Phase to Analyzers with “B” Prefix Serial Number............................ 31

Connecting 230 V Split Phase to Analyzers with No Letter Prefix Serial Number .................. 31

Analyzer Keypad ..................................................................................................................33

Location of SINGLE MODE/MULTI-DROP Switch (HART-equipped analyzers only).............73

HART SINGLE MODE (Point-to-Point) Wiring Arrangement (for single analyzer) .................73

HART MULTI-DROP Wiring Arrangement (for multiple analyzer network) ............................ 74

Standard Design Sensor -- Component Details ..................................................................... 81

High Pressure Design Sensor -- Component Details .............................................................82

Turbidity Sensor Terminal Block Designations...................................................................... 84

Table A

Table B

Table C

Table D

Rev. 2-300 Accu4™ Low-range Turbidimeter System

Relay Configuration Settings ...........................................................................................46-47

Analyzer Configuration Settings (Ranges/Choices and Defaults) ..........................................49

Relay Overfeed Timer Interactions with Other Analyzer Functions........................................70

System Diagnostic Condition Status Screens/Meanings........................................................88

TABLES

11

Accu4™ Low-range Turbidimeter System Rev. 2-300

12

PART ONE - INTRODUCTION SECTION 1 - GENERAL INFORMATION

PART ONE - INTRODUCTION

ECTION

1.1 Capability Highlights

High Accuracy with

Minimal Maintenance

S

GENERAL INFORMATION

The Accu4™ Low-range Turbidimeter System employs a

technologically-advanced sensor to provide high measurement accuracy and stability, while reducing maintenance

requirements. It is designed to meet the International Standards For Measurement of Turbidity [ISO 7027-1984(E)]

and USEPA-approved GLI Method 2. This system has an

auto-ranging measuring scale, enabling continuous monitoring over a 0.000-100.0 NTU range with automatic

decimal point positioning.

dimeter System automatically provides increasing

display resolution as measured turbidity decreases.

further ensure high measuring accuracy, the Model 8320

sensor eliminates air or gas bubbles in the sample with its

built-in bubble trap. The system is ideal for critical monitoring and controlling applications including potable water,

filtered water, and final product clarity.

1

The Accu4™ Low-range Turbi-

To

MEASURE Screen

Passcode-protected

Access

Calibration Methods

With the display in the normal MEASURE screen mode, the

measured turbidity is always shown on the main middle line.

The bottom auxiliary display line, shown in reverse video,

can be changed by pressing the

these measurements:

• Analog Output 1 value (mA)

• Analog Output 2 value (mA)

For security, you can enable a passcode feature to restrict

access to configuration and calibration settings to authorized personnel only. See Part Three, Section 4.5 for details.

Three methods are available to calibrate the system. See

Part Three, Section 5.1 for details. With the optional Cal-

Cube™ assembly, you can conveniently check calibration any time (Section 6.2). The mA value for each analog

output can also be calibrated (Section 5.5).

ØØ and

×× keys to show

Rev. 2-300 Accu4™ Low-range Turbidimeter System

13

PART ONE - INTRODUCTION SECTION 1 - GENERAL INFORMATION

Analog Outputs

Relays

The analyzer provides two isolated analog outputs (1 and

2). Each output represents the measured turbidity, and can

be set to be 0-20 mA or 4-20 mA.

Turbidity values can be entered to define endpoints at which

the minimum and maximum analog output values are desired.

During calibration, both analog outputs can be selected to:

•

Hold their present values (HOLD OUTPUTS).

•

Transfer to preset values to operate control elements by an

amount corresponding to those values (XFER OUTPUTS).

•

Remain active to respond to the measured turbidity

(ACTIVE OUTPUTS).

For complete analog output setup details, including transfer

setup, refer to Part Three, Section 4.3.

The analyzer has four electromechanical relays with SPDT

contacts. Each relay can be set to function as a CONTROL,

ALARM (dual-alarm), or STATUS relay. CONTROL and

ALARM relays operate in response to the measured turbidity. STATUS relays operate only in response to selected

system diagnostic conditions.

☞

NOTE: Relay D is factory-set to function as a STATUS re-

lay but can be configured as a CONTROL or

ALARM relay.

When a relay is set to function as a STATUS relay, it becomes a dedicated system diagnostic-only alarm relay. A

STATUS relay can be configured for:

•

FAIL mode -- sets STATUS relay to activate when there

is a FAIL condition (analyzer, light source or detector) or

a sensor CHAMBER UNKNOWN condition.

•

WARN mode -- sets STATUS relay to activate only when

there is a sensor flow CHAMBER DIRTY condition.

•

ALL mode -- sets STATUS relay to activate when there

is any abnormal system condition (any FAIL condition,

or sensor CHAMBER DIRTY or UNKNOWN condition).

A “WARNING CHECK STATUS” message automatically

flashes on the MEASURE screen whenever the analyzer

detects any of these system diagnostic conditions:

Accu4™ Low-range Turbidimeter System Rev. 2-300

14

PART ONE - INTRODUCTION SECTION 1 - GENERAL INFORMATION

1.2 Modular Construction

•

ANALYZER FAIL

•

CHAMBER DIRTY

•

CHAMBER UNKNOWN

•

SOURCE 1 FAIL

•

SOURCE 2 FAIL

•

DETECT 1 FAIL

•

DETECT 2 FAIL

To determine the condition causing the warning message,

display the “STATUS screens” in the TEST/MAINT menu

branch. For more details, refer to Part Three, Section 6.1.

During calibration, CONTROL and ALARM relay on/off

states are affected in the same way as the analog outputs

by the “(HOLD/XFER/ACTIVE) OUTPUTS” screen selection. These relays are also held at their present on/off

states, transferred to desired preset on/off states, or remain

active to respond to measured turbidity. For complete relay

setup details, including transfer setup, see Part Three, Section 4.4.

The modular construction of the analyzer simplifies field

servicing and provides electrical safety. The front door/

keypad assembly and the sensor use voltages no greater

than 24 VDC, and are completely safe to handle.

1.3 Retained

Configuration Values

1.4 Analyzer and Sensor

Serial Numbers

Opening the analyzer door accesses terminals inside the

enclosure for electrical connections. Line power must be

connected to specifically designated terminals on TB3.

WARNING:

REMOVE LINE POWER BEFORE NEARING THIS AREA

TO AVOID ELECTRICAL SHOCK.

All user-entered configuration values are retained indefinitely, even if power is lost or turned off. The non-volatile

analyzer memory does not require battery backup.

A label with the analyzer model number, serial number,

build date, and other items is affixed to the top of the analyzer enclosure. A similar label is affixed to the sensor.

Rev. 2-300 Accu4™ Low-range Turbidimeter System

15

PART ONE - INTRODUCTION SECTION 1 - GENERAL INFORMATION

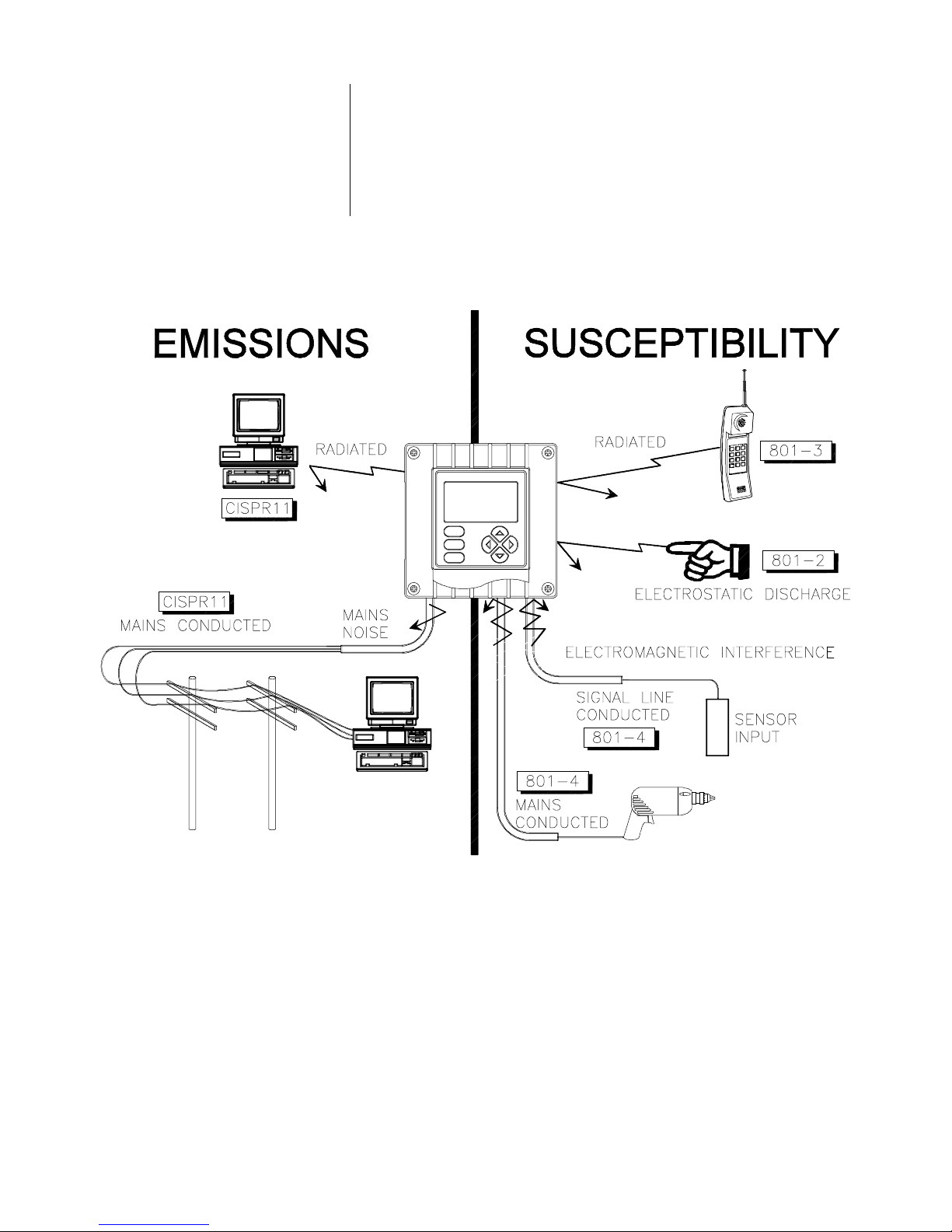

1.5 EMI/RFI Immunity

The analyzer is designed to provide protection from most

normally encountered electromagnetic interference. This

protection exceeds U.S. standards and meets European

IEC 801-series testing for electromagnetic and radio frequency emissions and susceptibility. Refer to Figure 1-1

and the specifications in Section 2.2 for more information.

Accu4™ Low-range Turbidimeter System Rev. 2-300

FIGURE 1-1 EMI/RFI Immunity Diagram

16

PART ONE - INTRODUCTION SECTION 2 - SPECIFICATIONS

ECTION

S

2

SPECIFICATIONS

2.1 Model 8320 Low-range

Turbidity Sensor

Operational

Mechanical

2.2 Model T53 Analyzer

Operational

Flow Rate................................... 0.05 to 7 GPM (0.19 to 26.5 LPM)

Ambient Conditions .................... 32-140°F (0-60°C)

Sample Temperature Range....... 32-140°F (0-60°C)

Pressure Range:

Standard Sensor Design........ 0-50 psig at 68°F (0-3.4 bar at 20°C)

High Pressure Design............ 0-150 psig at 68°F (0-10.2 bar at 20°C)

Pressure Drop:

Standard Sensor Design........ 0.0017 psig at 0.1 GPM (0.0001 bar at 0.36 LPM)

High Pressure Design............ 0.165 psig at 1.0 GPM (0.012 bar at 3.8 LPM)

Residence Time ......................... 9.5 seconds at 1 GPM (3.8 LPM)

Air Venting ................................. Integral bubble trap for 0.05 to 0.5 GPM (0.19 to

1.8 LPM) flows. Installation of restrictor valve on

the sensor outlet is recommended for flows

above 0.5 GPM (1.8 LPM) with air in sample.

Light Sources............................. Two near-infrared (860 nM wavelength) LEDs

Sensor Flow Configuration ......... Flow-through design

Process Connections.................. 1/2 inch NPT female standard; adaptable to

3/8 inch or 1/4 inch NPT, barb or tube fittings

Wetted Materials........................ PVC, polycarbonate, polystyrene, PPO,

nitrile, and Buna-N

Cleaning Method ........................ Water rinse, wipe surfaces

Enclosure:

Standard Sensor Design ....... NEMA 4X (≅ CSA type 4; ≅ IP65), molded and

fiberglass-reinforced polyester (flame retardant)

with four integral tabs for surface mounting

High Pressure Design............ NEMA 4X (≅ CSA type 4; ≅ IP65), PPO struc-

tural foam (V-0 flammability rating per U.L. 94

test) with four integral tabs for surface mounting

Mounting Configurations............. Surface or pipe mount

Net Weight................................. 10 lbs. (4.5 kg) approximately

Display....................................... Graphic dot matrix LCD, 128 x 64 pixels with

LED backlighting; 1/2 inch (13 mm) main

character height; 1/8 inch (3mm) auxiliary

information character height; menu screens

contain up to six text lines

Measurement Auto-ranging Scale

Turbidity................................ 0.000-100.0 NTU with auto-ranging and decimal

point shift above 1.000 NTU and 10.00 NTU

(same for other measurement units)

mA Outputs (1 and 2)............ 0.00-20.00 mA or 4.00-20.00 mA

Rev. 2-300 Accu4™ Low-range Turbidimeter System

Ambient Conditions:

Operation.............................. -4 to +140°F (-20 to +60°C); 0-95% relative

humidity, non-condensing

Storage................................. -22 to +158°F (-30 to +70°C); 0-95% relative

humidity, non-condensing

Relays: Types/Outputs ...................Four electromechanical relays; SPDT (Form C)

contacts; U.L. rated 5A 115/230 VAC, 5A @ 30

VDC resistive

Operational Mode ..............Each relay (A, B, C, and D) can be assigned to be

driven by the measured turbidity or diagnostics

Function Modes:

Control...................... Settings for high/low phasing, setpoint, dead-

band, overfeed timer, off delay, and on delay

17

PART ONE - INTRODUCTION SECTION 2 - SPECIFICATIONS

Alarm ...........................Settings for low alarm point, low alarm point

deadband, high alarm point, high alarm point

deadband, off delay, and on delay

Status....................... Setting for FAIL, WARN or ALL system diag-

nostic conditions to activate relay when

specific conditions exist (analyzer, light source

1/2 or detector 1/2 failure, sensor chamber

dirty or sensor chamber unknown)

Indicators...........................Relay annunciators (A, B, C, and D) indicate

respective relay on/off status

Sensor-to-Analyzer Distance ...... 30 ft. (9 m) maximum (consult factory if

longer distances are required)

Power Requirements .................. 90-130 VAC, 50/60 Hz. (10 VA max.) or

180-260 VAC, 50/60 Hz. (10 VA max.)

Calibration Methods:

PRIMARY............................... Enter one primary standard value (formazin

suspension is recommended).

CUBE CAL ............................. Temporarily insert an optional Cal-Cube

TM

assembly into the sensor and enter its factory-

certified standard value.

SAMPLE................................. Enter one sample value determined by labo-

ratory analysis or calibrated portable meter.

Analog Outputs .......................... Two isolated 0/4-20 mA outputs; each with

0.004 mA (12-bit) resolution and capability to

drive up to 600 ohm loads

NOTE:

Each output represents the measured turbidity. Turbidity values can

be entered to define the endpoints at which the minimum and maximum mA output values are desired. During calibration, both outputs

can be selected to hold their present values, transfer to preset values to operate control elements by an amount corresponding to

those values, or remain active to respond to the measured turbidity.

Communication: RS-232 ........... Enables configuration and retrieval of measured

data for one analyzer using an IBM-compatible

PC and optional GLI software tool kit

HART.............. Enables configuration and retrieval of measured

data for up to 15 analyzers over communication

link using appropriate hand-held terminal or data

system with HART software

Memory Backup (non-volatile) .... All user settings are retained indefinitely in

memory (EEPROM)

EMI/RFI Conformance................ Meets European standards for conducted and

radiated emissions and immunity; certified CE

compliant for applications as specified by EN 50081-1

for emissions and EN 50082-2 for immunity

Electrical Certifications:

General Purpose (pending) ..... UL, C-UL, FM, and CENELEC

Division 2 (pending)................ UL, C-UL, and FM: Groups A, B, C, D, F, and G

Zone 2 (pending) .................... CENELEC: Group IIC

Mechanical

2.3 Accu4™ Turbidimeter

System Performance

(electrical, analog outputs)

Accu4™ Low-range Turbidimeter System Rev. 2-300

Enclosure................................... NEMA 4X; polycarbonate face panel, epoxy-

coated cast aluminum door and case with

four 1/2 inch (13 mm) conduit holes, nylon

mounting bracket, and stainless hardware

Mounting Configurations............. Panel, surface, and pipe mounting

Net Weight................................. 5 lbs. (2.3 kg) approximately

System Accuracy ....................... ± 2% of reading, all ranges

Sensitivity .................................. 0.001 NTU

Repeatability .............................. 0.1% of span or better

Temperature Drift....................... Zero and Span: 0.01% of span per °C

18

PART TW O - INSTALLATION SECTION 1 - UNPACKING

PART TWO - INSTALLATION

ECTION

S

UNPACKING

After unpacking, it is recommended to save the shipping

carton and packing materials in case the instrument must be

stored or re-shipped. Inspect the equipment and packing

materials for signs of shipping damage. If there is any evidence of damage, notify the transit carrier immediately.

ECTION

S

MECHANICAL REQUIREMENTS

1

2

2.1 Sensor Location

Locate the Model 8320 turbidity sensor indoors or outdoors

within 30 ft. (9 m) of where the Model T53 analyzer is to be

installed. The sensor may be installed in an “in line” process

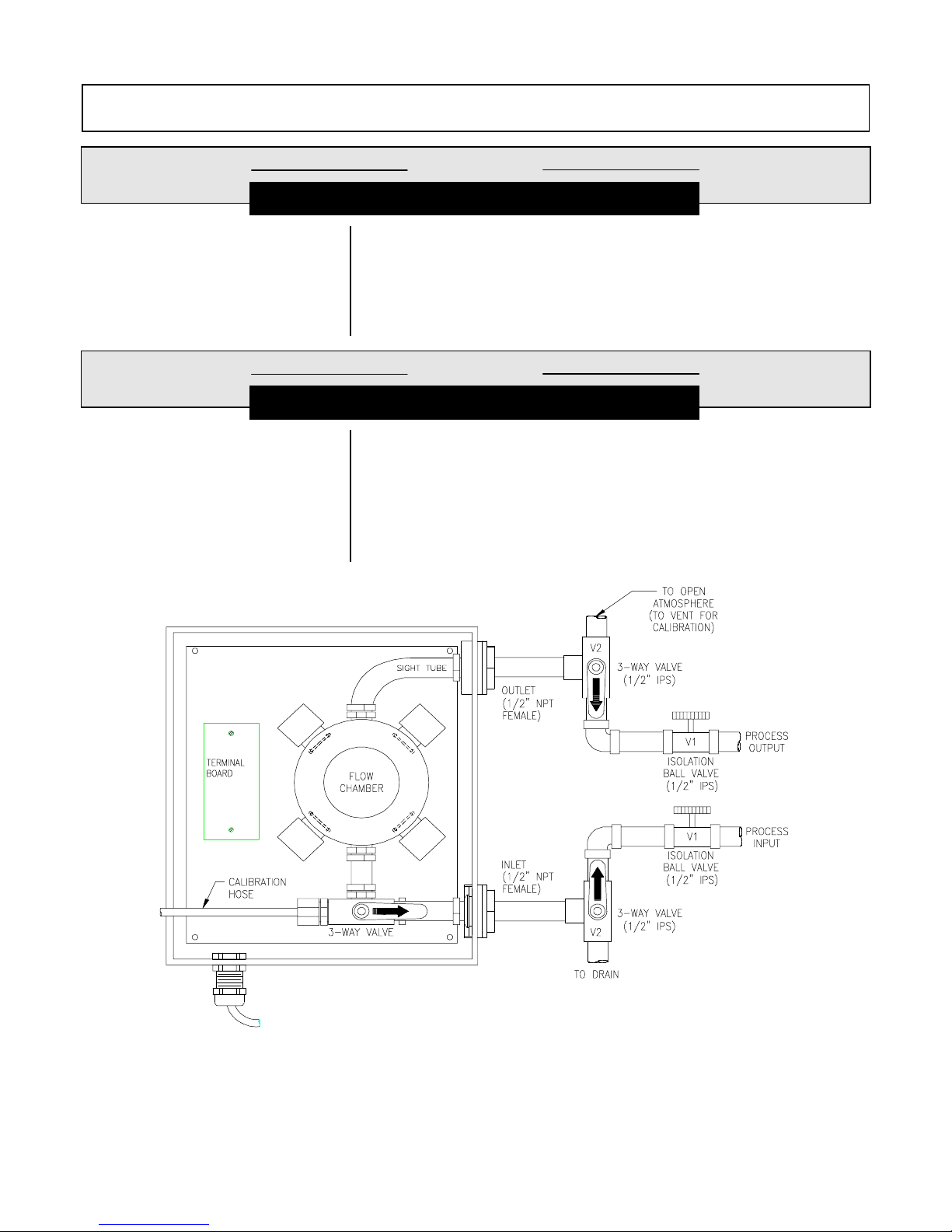

configuration using a closed loop piping arrangement (Figure 2-1) or in a sample bypass line configuration using an

open drain piping arrangement (Figure 2-2).

FIGURE 2-1 Recommended Closed-loop Sensor Piping Arrangement

Rev. 2-300 Accu4™ Low-range Turbidimeter System

19

PART TW O - INSTALLATION SECTION 2 - MECHANICAL REQUIREMENTS

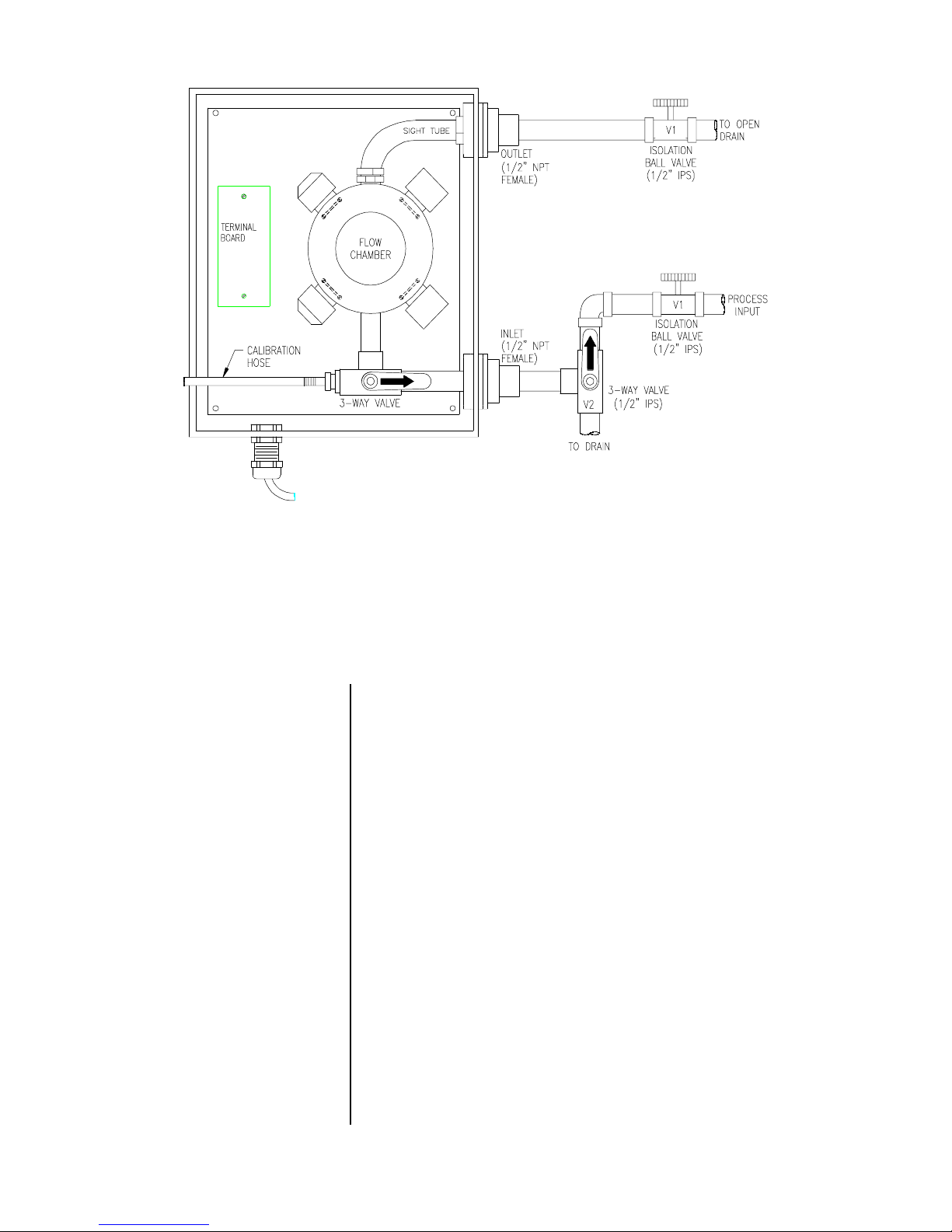

FIGURE 2-2 Recommended Sample Bypass Line Sensor Piping Arrangement

2.2 Sensor Mounting

☞

The Model 8320 low-range turbidity sensor may the standard design sensor (Figure 2-3) or the high pressure design

sensor which is housed in a different enclosure (Figure

2-4). In either case, vertically orient the sensor (inlet fitting

at bottom) and surface mount it where there is little or no

mechanical vibration. Use 1/4 inch screws to fasten the enclosure onto a flat surface. (The sensor may be mounted

onto a vertical or horizontal 1-1/2 inch or 2 inch diameter

pipe using an optional GLI pipe mount kit. Refer to Part Five

-- Spare Parts -- for the GLI part number.

NOTE:

Avoid locations where Model 8320 ambient temperature limits (32-140°F; 0-60°C) may be exceeded.

Accu4™ Low-range Turbidimeter System Rev. 2-300

20

PART TW O - INSTALLATION SECTION 2 - MECHANICAL REQUIREMENTS

Note:

Dimensions shown in inches (mm).

FIGURE 2-3 Standard Design Model 8320 Sensor -- Installation Dimension Details

Note:

Dimensions shown in inches (mm).

FIGURE 2-4 High Pressure Design Model 8320 Sensor -- Installation Dimension Details

Rev. 2-300 Accu4™ Low-range Turbidimeter System

21

PART TW O - INSTALLATION SECTION 2 - MECHANICAL REQUIREMENTS

2.3 Sensor Plumbing

Connections

☞

Plumb the process into the Model 8320 sensor inlet fitting.

Plumb the sensor outlet fitting back into the process line

(Figure 2-1) or to an open drain (Figure 2-2). Bushings may

be used to reduce to a smaller pipe size. Barb or tube fittings may be installed.

sample tubing for applications in which sediment buildup

commonly occurs. The resultant faster flow rate helps flush

sediment through the sensor.

NOTE: Use Teflon tape to seal the inlet and outlet connec-

tions. Do not use pipe dope or other liquid sealants.

Recommendation: Use ball valves (V1 designations in Figure 2-1 and 2-2) to conveniently isolate

the sensor when calibrating or removing the sensor.

In a closed-loop piping arrangement (Figure 2-1),

3-way valves (V2 designations) are required to conveniently drain the flow chamber during calibration.

A bypass line piping arrangement (Figure 2-2) only

requires one 3-way valve.

CAUTION: WHEN USING METAL FITTINGS, DO NOT

EXCESSIVELY TIGHTEN THEM ONTO THE SENSOR’S

PLASTIC INLET AND OUTLET -- THEY MAY CRACK.

Recommendation:

Use larger

☞

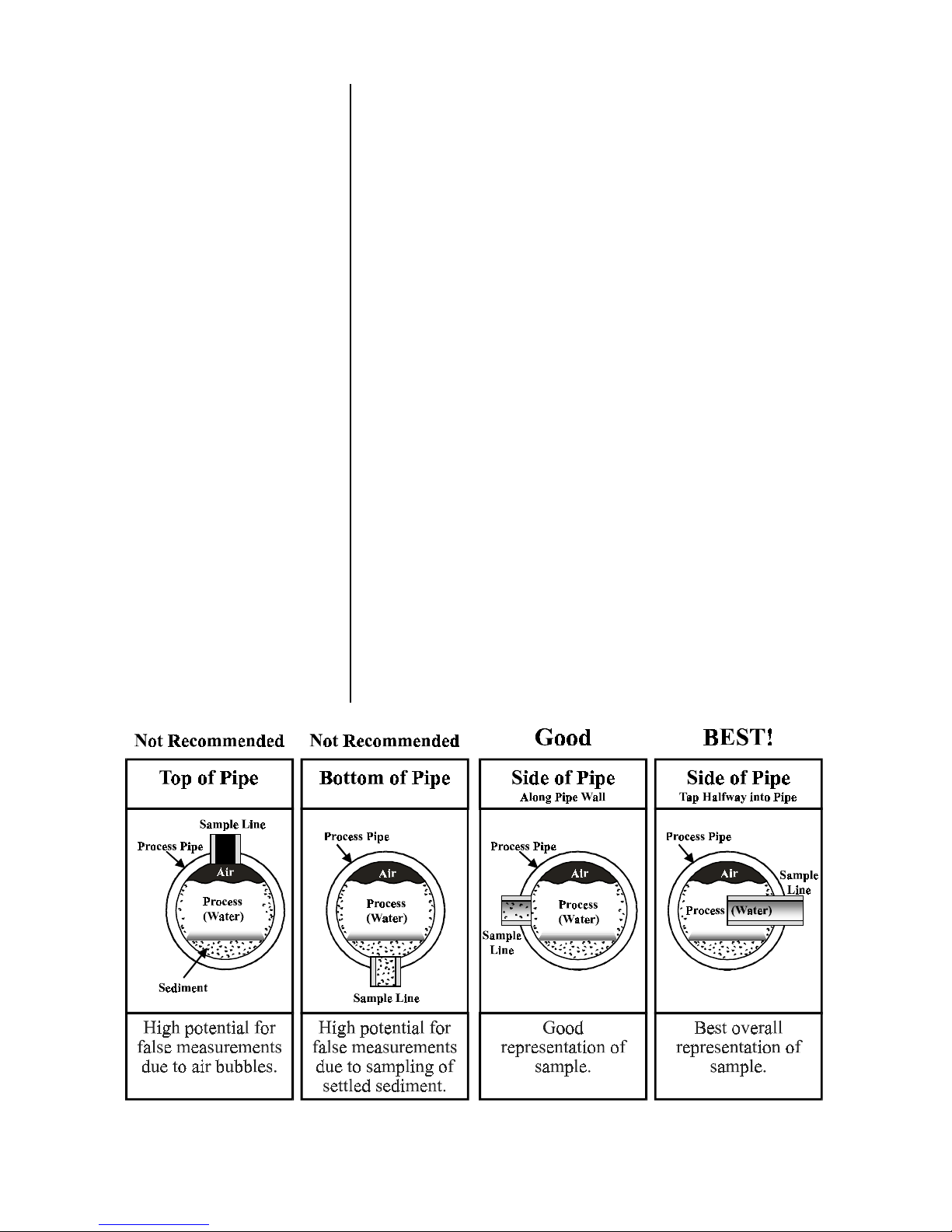

NOTE: When choosing the sampling point for the process

pipe plumbing connection, avoid a top-of-pipe or

bottom-of-pipe location. Figure 2-5 illustrates the

best sampling point location: side-of-pipe with sample line inserted to the process pipe centerline.

Figure 2-5 Sampling Point Guidelines for Process Pipe Plumbing Connection

Accu4™ Low-range Turbidimeter System Rev. 2-300

22

PART TW O - INSTALLATION SECTION 2 - MECHANICAL REQUIREMENTS

2.4 Analyzer Location

2.5 Analyzer Mounting

1. Locate the analyzer as close as possible to the installed

sensor. Do not exceed a maximum distance of 30 feet

(9 m) between the sensor and analyzer. (Consult factory if longer distances are required.)

2. Mount the analyzer in a location that is:

➥

Clean and dry where there is little or no vibration.

➥

Protected from corrosive fluids.

➥

Within ambient temperature limits (-4 to +140°F or

-20 to +60°C).

CAUTION:

EXPOSING THE ANALYZER TO DIRECT

SUNLIGHT MAY INCREASE THE OPERATING

TEMPERATURE ABOVE ITS SPECIFIED LIMIT.

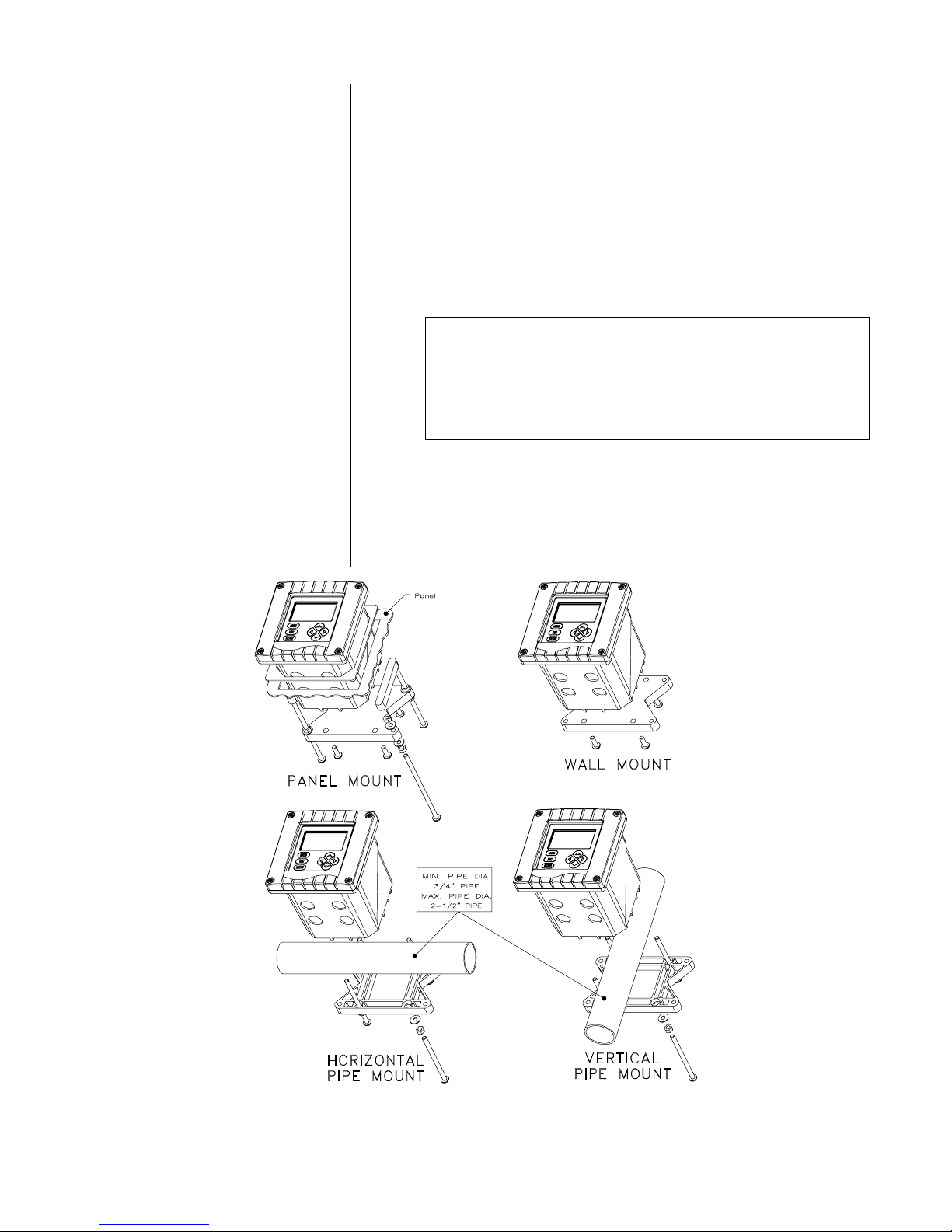

Figure 2-6 illustrates various ways to mount the analyzer

using the supplied bracket and hardware. Determine the

mounting method and attach the hardware as shown in the

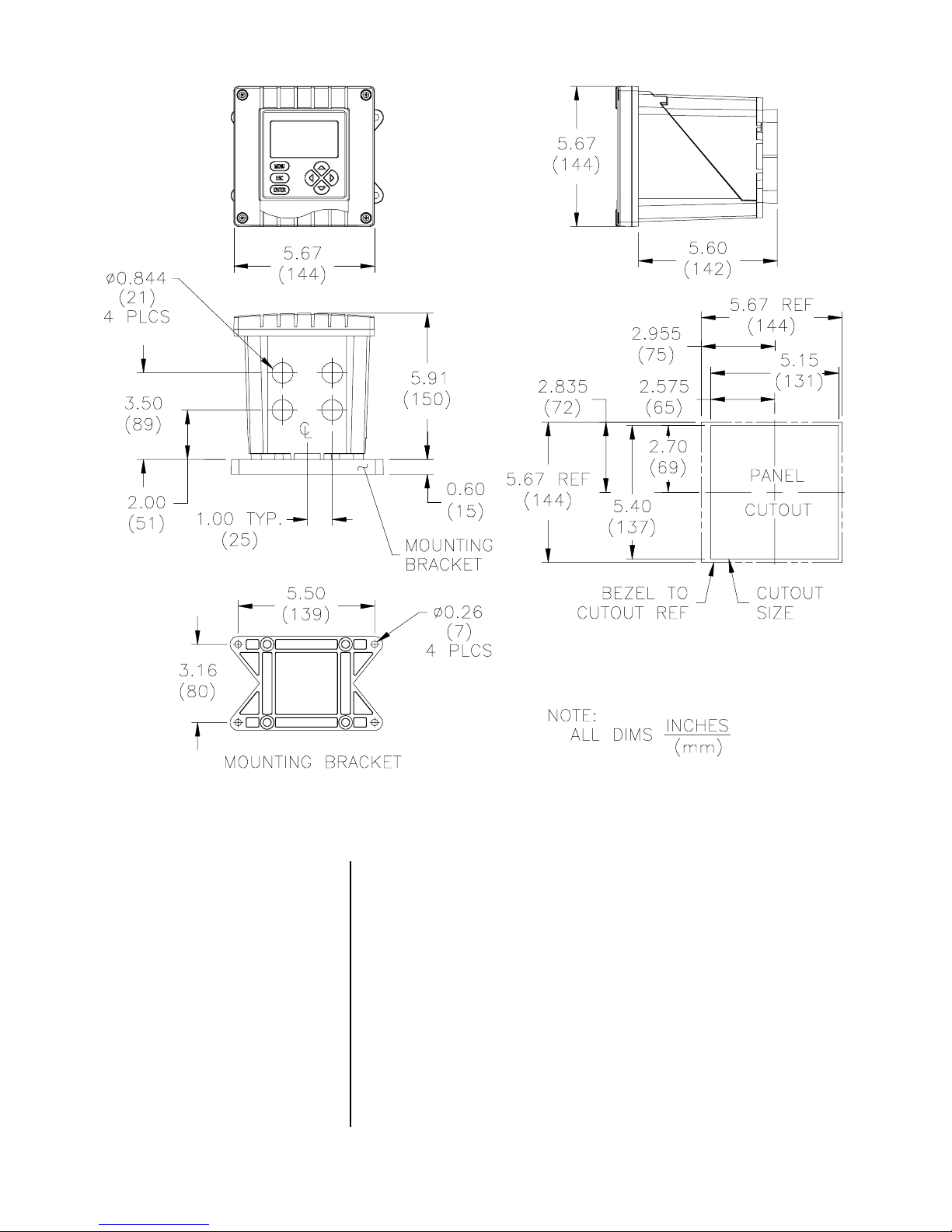

respective illustration. Refer to Figure 2-7 for analyzer installation dimension details.

FIGURE 2-6 Analyzer Mounting Arrangements

Rev. 2-300 Accu4™ Low-range Turbidimeter System

23

PART TW O - INSTALLATION SECTION 2 - MECHANICAL REQUIREMENTS

FIGURE 2-7 Analyzer Installation Dimensions Details

2.6 Sensor and Analyzer

Conduit Hole

Requirements

☞

Accu4™ Low-range Turbidimeter System Rev. 2-300

Recommendation:

lyzer in 1/2-inch, grounded metal conduits. If using only

shielded cables, appropriate strain reliefs or cable grips are

required. (GLI sells accessory cable grips, part number

3H1091, and watertight locknuts, part number 3H1230, for

cable entries.) Seal unused cable entry holes with appropriate plugs.

NOTE:

Use NEMA 4 (≅ CSA type 4; ≅ IP65) rated fittings

Run all wiring to the sensor and ana-

and plugs to maintain the watertight integrity of the

NEMA 4X sensor and analyzer enclosures, and to

comply with Div. 2 hazardous area requirements.

24

PART TW O - INSTALLATION SECTION 3 - ELECTRICAL CONNECTIONS

ECTION

S

ELECTRICAL CONNECTIONS

To access terminal blocks for electrical connections, open

the left-hinged enclosure door by unscrewing the four fasteners. Figure 2-8 or 2-9 shows the terminal block

arrangement and terminal designations inside the analyzer.

3

☞

☞

☞

NOTE: All terminals are suitable for single wires up to 14

AWG (2.5 mm2).

Wiring Tip!

electromagnetic compatibility requirements, follow these

general wiring guidelines:

1. Keep all cable shields as short as possible inside

the analyzer, and connect them to the ground terminals provided. Performance may be improved by

using cable glands that enable the shield to directly

contact the analyzer chassis.

2. Use Steward ferrite 28 B0590-000 or equivalent on

the sensor cable -- two turns required.

3. In harsh conducted RF conditions, connect the earth

ground of the analyzer to a local, known earth

ground source.

NOTE: For ease of wiring, route line power and relay out-

To comply with European Community (CE)

puts through the back conduit holes, and use the

front conduit holes for all other wiring.

3.1 GLI Model 8320

Low-range

Turbidity Sensor

☞

☞

Rev. 2-300 Accu4™ Low-range Turbidimeter System

The Model 8320 sensor is supplied with LED light source

and detector cables connected to its terminal board. Remove its protective cover to check that these cables have

not been accidentally disconnected during shipment (refer

to wiring diagram on inside of sensor enclosure door).

Wiring Tip!

grounded metal conduit to protect it from moisture,

electrical noise, and mechanical damage.

NOTE: Do not route sensor cable in any conduit containing

AC power wiring (“electrical noise” may interfere

with sensor signal). Also, always re-calibrate the

system when the cable length between sensor and

analyzer changes.

Route the sensor cable in 1/2-inch,

25

PART TW O - INSTALLATION SECTION 3 - ELECTRICAL CONNECTIONS

OUTPUT 2

RELAY A

NC COM

RS-232

TX RX

NO

3312 5476

4-20 mA

OUTPUT 1

-+-

+

HART

234567

TB2

TURBIDITY INTERCONN ECT

TTL

+

GND

GND

ORANGE

2189 2210 1920 1618

TURBIDITY ANA LYZER

RELAY B

RELAY C

COMNC NCNO

POWER

90-130 VAC

180-260 VAC

10VA 50/60 Hz

COM

8

BLUE

BROWN

F

80mA

T

WHITE

F

2

100mA

T

VIOLET

GREEN

131415 12

115230 N

RED

YELLOW

1

BLACK

GRAY

RELAY D

NCNO NOCOM

1091211 342

TB1

TB3

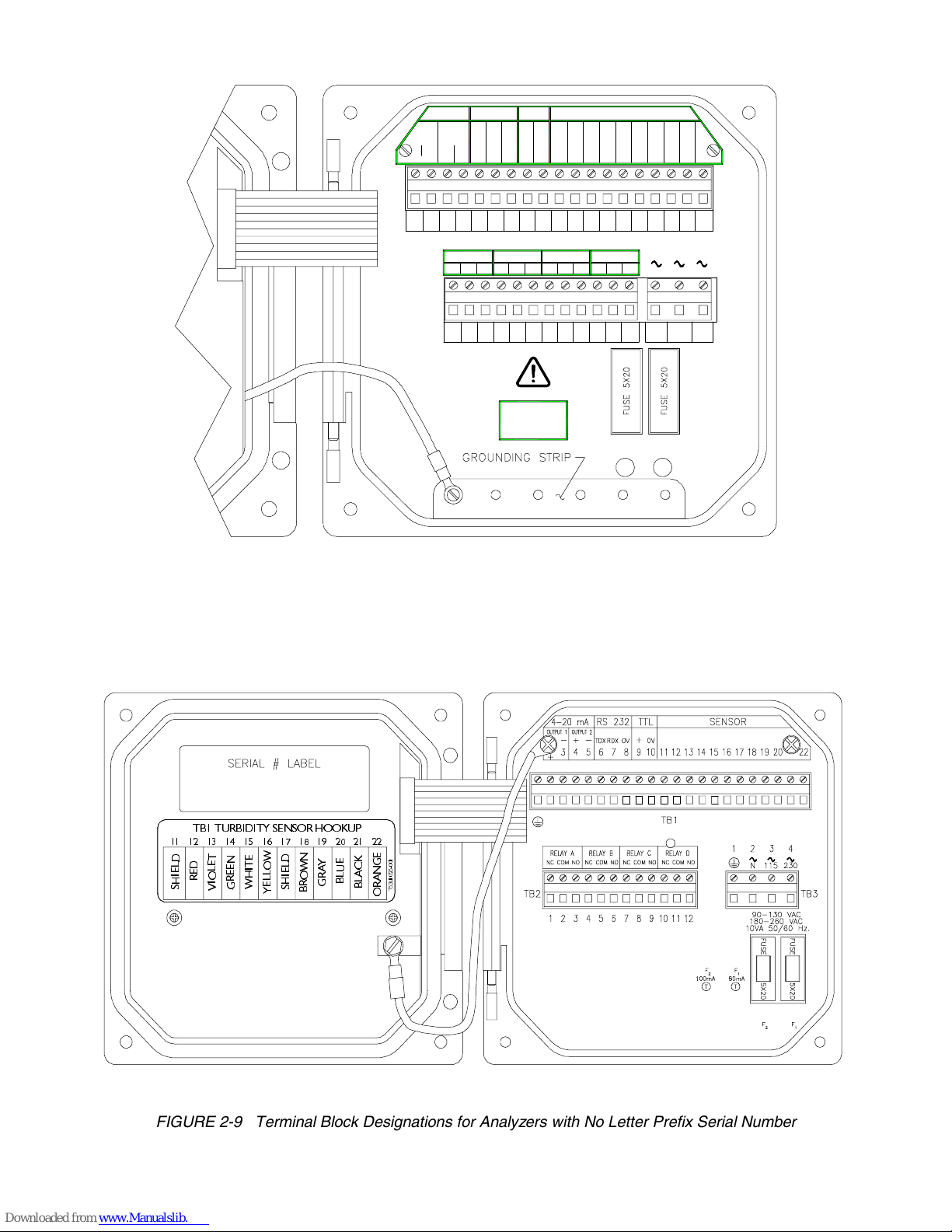

FIGURE 2-8 Terminal Block Designations for Analyzers with “B” Prefix Serial Number

7% 785%,',7< 6(1625 +22.83

5('

6+,(/'

9,2/(7

:+,7(

*5((1

6+,(/'

<(//2:

%/8(

*5$<

%/$&.

%52:1

7/

25$1*(

FIGURE 2-9 Terminal Block Designations for Analyzers with No Letter Prefix Serial Number

Accu4™ Low-range Turbidimeter System Rev. 2-300

26

PART TW O - INSTALLATION SECTION 3 - ELECTRICAL CONNECTIONS

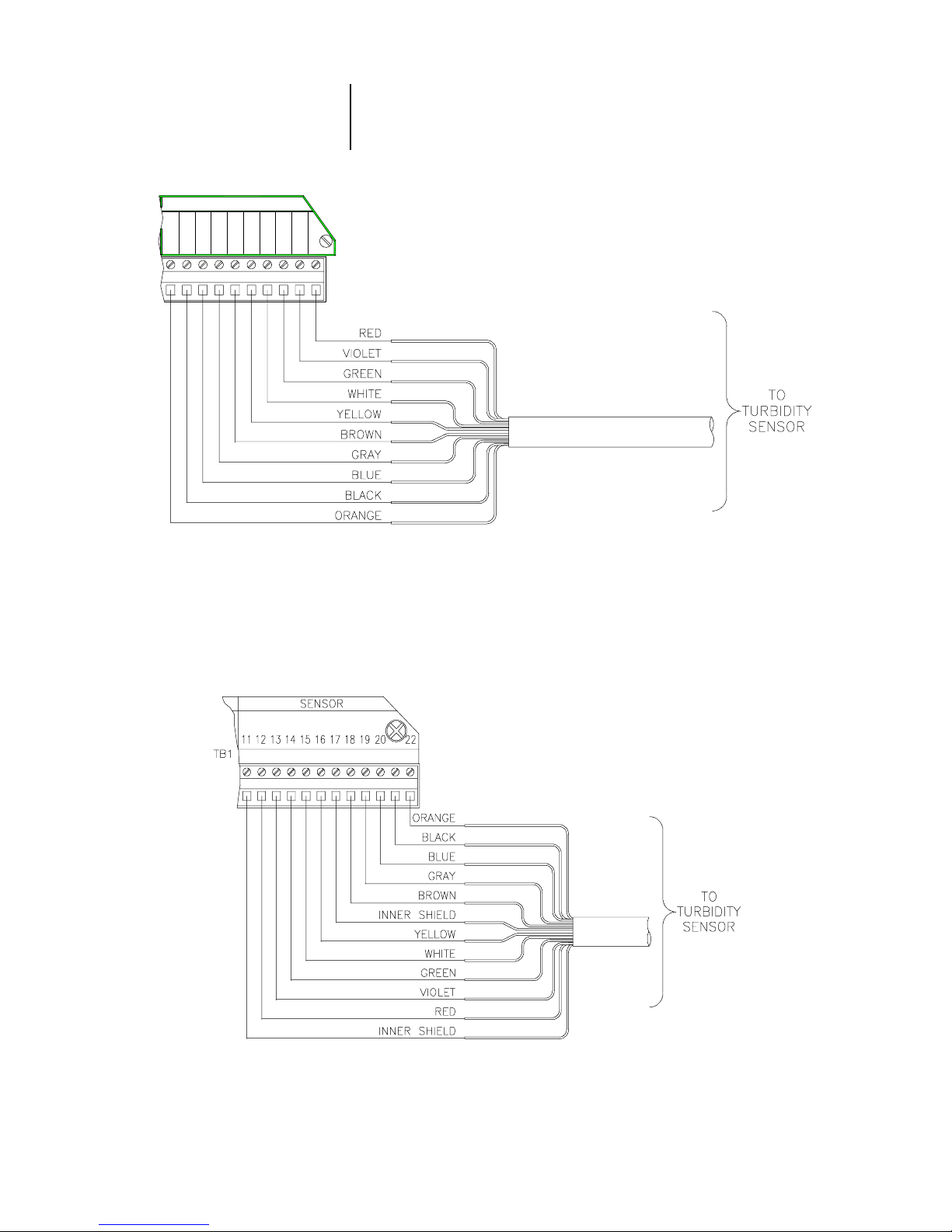

Refer to Figure 2-10 or 2-11 and connect the sensor (or interconnect) cable wires to appropriate terminals on TB1,

matching colors as indicated.

TURBIDITY INTERCONNECT

TB1

BLUE

BLACK

ORANGE

2122 1920 1618

GRAY

BROWN

YELLOW

VIOLET

WHITE

GREEN

RED

131415 12

FIGURE 2-10 Connecting Model 8320 Low-range Turbidity Sensor

to Analyzers with “B” Prefix Serial Number

FIGURE 2-11 Connecting Model 8320 Low-range Turbidity Sensor

to Analyzers with No Letter Prefix Serial Number

Rev. 2-300 Accu4™ Low-range Turbidimeter System

27

PART TW O - INSTALLATION SECTION 3 - ELECTRICAL CONNECTIONS

3.2 Analog Outputs

☞

Two isolated analog outputs (1 and 2) are provided. Each

output represents the measured turbidity, and can be set to

be 0/4-20 mA.

and earth ground, but not from each other.

configuring the outputs, refer to Part Three, Section 4.3.

Wiring Tip!

cable for connecting the analog outputs. To protect the

output signal from EMI/RFI, connect cable shields to:

The grounding strip at bottom of case (5 open holes,

Fig. 2-8) for analyzers with “B” prefix serial number.

The “ground symbol” Terminal 1 on TB1 (Figure 2-9)

for analyzers with no letter prefix serial number.

Each 0/4-20 mA output can drive a load of up to 600 ohms.

• Output 1: Connect the load to Terminals 2 and 3 on TB1,

matching polarity as indicated.

The outputs are isolated from the inputs

For details on

Use high quality, shielded instrumentation

3.3 Relay Outputs

☞

• Output 2: Connect the load to Terminals 4 and 5 on TB1,

matching polarity as indicated.

NOTE: When using the HART communication option, a

digital signal is encoded onto the 4-20 mA analog

Output 1 signal. In a HART SINGLE MODE wiring

configuration, Output 1 remains available for normal

use. However, in a HART MULTI-DROP wiring configuration, Output 1 becomes dedicated to that

function and cannot be used. See Part Three, Section 8 for more HART communication information.

The analyzer is equipped with four electromechanical relays. For relay setup details, see Part Three, Section 4.4.

CAUTION:

DO NOT EXCEED THE CONTACT RATING FOR

EACH RELAY (5A 115/230 VAC). WHEN SWITCHING

LARGER CURRENTS, USE AN AUXILIARY RELAY

SWITCHED BY THE ANALYZER RELAY TO EXTEND

ANALYZER RELAY LIFE. WHEN USING RELAY

OUTPUTS, MAKE SURE THAT LINE POWER WIRING

CAN ADEQUATELY CONDUCT THE CURRENT

DRAW OF THE SWITCHED LOAD(S).

Accu4™ Low-range Turbidimeter System Rev. 2-300

28

PART TW O - INSTALLATION SECTION 3 - ELECTRICAL CONNECTIONS

Four sets of SPDT relay outputs (Relays A, B, C, and D) are

provided at Terminals 1 through 12 on TB2.

puts are not powered.

The line power used to power the

The relay out-

analyzer may also be used to power the control or alarm

devices with these relay contacts. Refer to Figure 2-12 for a

general wiring arrangement. Always check control wiring to

insure that line power will not be shorted by the relay

switching action, and that wiring conforms to local codes.

WARNING:

MAKE SURE THAT LINE POWER IS NOT PRESENT

WHILE CONNECTING WIRES TO TB2 RELAY

TERMINALS.

3.4 Closed Contact

TTL Input

Rev. 2-300 Accu4™ Low-range Turbidimeter System

FIGURE 2-12 Connecting Control/Alarm Device(s) to

Electromechanical Relay(s)

The closed contact TTL input feature of the analyzer enables you to conveniently:

•

Hold the analog outputs at their present values.

•

Hold all CONTROL or ALARM relays at their present

on/off states.

To activate holding the analog outputs and relays, remotely

or locally jumper Terminals 9 and 10 on TB1.

29

PART TW O - INSTALLATION SECTION 3 - ELECTRICAL CONNECTIONS

3.5 Line Power

☞

Refer to appropriate figures and connect line power to TB3

terminals using the standard three-wire connection arrangement.

codes

U.S.A.).

REMOVE LINE POWER WHILE CONNECTING LINE

POWER WIRES TO THE TB3 TERMINALS. ALSO,

USE ONLY THE STANDARD THREE-WIRE CONNECTION ARRANGEMENT FOR SINGLE-PHASE LINE

POWER TO PREVENT AN UNSAFE CONDITION, AND

TO ENSURE PROPER ANALYZER OPERATION.

Use wiring practices which conform to local

(example: National Electric Code Handbook in the

WARNING:

NOTE: In all cases, connect the line power cable ground

wire (usually green) to:

The grounding strip at bottom of case (5 open

holes -- Figures 2-13, 2-15, or 2-17) for analyzers with “B” prefix serial number.

☞

115230 N

342

The “ground symbol” Terminal 1 on TB3 (Figures

2-14, 2-16, or 2-18) for analyzers with no letter

prefix serial number.

The “115” and “230” voltage circuits are protected with internal, board-mounted slow-blow fuses.

NOTE: For 230 volt split phase line power, be sure to con-

form to local codes with regard to fusing the 115

volt line connected to the “N” terminal.

FIGURE 2-13

Connecting 115 V Single Phase

to Analyzers with “B” Prefix Serial Number

Accu4™ Low-range Turbidimeter System Rev. 2-300

FIGURE 2-14

Connecting 115 V Single Phase

to Analyzers with No Letter Prefix Serial Number

30

PART TW O - INSTALLATION SECTION 3 - ELECTRICAL CONNECTIONS

230 115 N

234

FIGURE 2-15

Connecting 230 V Single Phase

to Analyzers with “B” Prefix Serial Number

N115230

234

FIGURE 2-17

Connecting 230 V Split Phase

to Analyzers with “B” Prefix Serial Number

FIGURE 2-16

Connecting 230 V Single Phase

to Analyzers with No Letter Prefix Serial Number

FIGURE 2-18

Connecting 230 V Split Phase

to Analyzers with No Letter Prefix Serial Number

Rev. 2-300 Accu4™ Low-range Turbidimeter System

31

PART THREE - OPERATION SECTION 1 - USER INTERFACE

PART THREE - OPERATION

ECTION

S

USER INTERFACE

The user interface consists of an LCD display and a keypad

MENU, ENTER, ESC

with

1

,

ÕÕ,

ÖÖ,

××, and

ØØ keys.

1.1 Display

By using the keypad, you can display three basic types of

screens:

• MEASURE screen to show measured values. The meas-

ured turbidity is always shown on the display’s main

middle line. Pressing the

play’s bottom auxiliary line (in reverse video) to show the

Analog Output 1 or 2 value in mA.

An example of a typical MEASURE screen is:

On the MEASURE screen’s top line, Relay A, B, C, and D

annunciators will appear when their relay operational

state changes. When a relay overfeed timer is used and it

has “timed out,” the respective relay annunciator continuously blinks until the overfeed condition is resolved.

• MENU screens to move within the three main branches of

the analyzer menu tree, enabling access to edit/selection

screens. (EXIT screens indicate the end of a menu

branch and enable you, by pressing the ENTER key, to

move up one level in the menu tree. This is functionally

the same as pressing the ESC key.)

ØØ and

×× keys changes the dis-

1.2 Keypad

Accu4™ Low-range Turbidimeter System Rev. 2-300

• Edit/Selection screens to enter values/choices to cali-

brate, configure, and test the analyzer.

The keypad enables you to move throughout the analyzer

menu tree. The keys and their related functions are:

1. MENU key: Pressing this key always displays the top of

the menu tree (“MAIN MENU” selection screen). To

display the top-level menu screen for a desired main

branch (CALIBRATE, CONFIGURE, or TEST/MAINT),

use

ØØ and

×× keys to select the corresponding line, and

32

PART THREE - OPERATION SECTION 1 - USER INTERFACE

press

ENTER key

. The

MENU key

can also be used to

“abort” the procedure to change values or selections.

ENTER key:

2.

Pressing this key displays an available

menu or edit/selection screen, or enters (saves) values

or selections.

ESC key:

3.

Pressing this key always takes the display up

one level in the menu tree. (Example: With the “MAIN

MENU” branch selection screen displayed, pressing the

ESC key

once takes the display up one level to the

MEASURE screen.) This key can also “abort” the procedure to change a value or selection.

4.

and

Õ

Õ

keys:

Ö

Ö

Depending on the type of displayed

screen, these keys do the following:

•

MEASURE Screen: These keys are non-functional.

•

Menu Screens: These keys are non-functional.

•

Edit/Selection Screens: “Coarse” adjusts the

displayed numerical value.

5.

and

×

×

keys:

Ø

Ø

Depending on the type of displayed

screen, these keys do the following:

•

MEASURE Screen: Changes the bottom auxiliary

display line, shown in reverse video, between Output

1 mA value and Output 2 mA value.

•

Menu Screens: Moves reverse video cursor up or

down respectively to select a displayed line item.

•

Edit/Selection Screens: “Fine” adjusts the displayed

numerical value (holding key down changes value

faster), or moves up or down between choices.

Rev. 2-300 Accu4™ Low-range Turbidimeter System

FIGURE 3-1 Analyzer Keypad

33

PART THREE - OPERATION SECTION 1 - USER INTERFACE

1.3 MEASURE Screen

(normal display mode)

The MEASURE screen is normally displayed. Pressing the

MENU key

screens to calibrate, configure, or test the analyzer. If the

keypad is not used within 30 minutes, except during calibration and while using specific analyzer test/maintenance

functions, the display automatically returns to the MEASURE screen. To display the MEASURE screen at any time,

press the

When viewing the MEASURE screen, you can press the

or

keys

×

×

the bottom auxiliary display line. These MEASURE screen

examples illustrate this feature:

temporarily replaces this screen with various

MENU key

to select between other measurements shown on

once and then the

ESC key

once.

Ø

Ø

☞

NOTE: When the analyzer returns to its normal MEASURE

screen mode, the appearing MEASURE screen is

always the version last selected. Note that these

MEASURE screen examples show “BASIN 1” nota-

tions on their top lines, illustrating the analyzer

notation feature. To create your own notation, refer

to Part Three, Section 4.2, under the subheading

“ENTER NOTE (top line of MEASURE screen).”

When a measured value is beyond the analyzer measuring

range, a series of “ + ” or “ - ” screen symbols appear, respectively indicating that the value is above or below range.

Accu4™ Low-range Turbidimeter System Rev. 2-300

34

PART THREE - OPERATION SECTION 2 - MENU STRUCTURE

ECTION

S

MENU STRUCTURE

The analyzer menu tree is divided into three main branches:

CALIBRATE, CONFIGURE, and TEST/MAINT. Each main

branch is structured similarly in layers with top-level menu

screens, related lower-level submenu screens and, in many

cases, sub-submenu screens.

Each layer contains an EXIT line or screen to return the

display up one level to the previous layer of screens. For

convenience, the layers within each main branch are organized with the most frequently used functions at their

beginning, rather than the functions used for initial startup.

2

2.1 Displaying

Main Branch

Selection Screen

2.2 Displaying

Top-level

Menu Screens

Press the

selection screen:

1. After displaying the main branch selection screen, use

the

the desired branch (shown in reverse video).

2. Press the ENTER key to display the top-level menu

screen for that branch.

The top-level menu screens for each main branch are:

MENU key

ØØ and

to always display this main branch

&21),*85(

7(670$,17

(;,7

×× keys to select the line corresponding to

☞

Rev. 2-300 Accu4™ Low-range Turbidimeter System

Menu Structure Tip! The symbol pointing at each listed

item indicates there is a related lower-level submenu

screen, sub-submenu screen or edit/selection screen.

Some menu lists are too long to completely fit on the

screen. A

ÈÈ symbol at the bottom right of the list indicates

35

PART THREE - OPERATION SECTION 2 - MENU STRUCTURE

2.3 Displaying

Submenu Screens

☞

or

Ø

Ø

Ø

Ø

that you can display hidden items by pressing the

key

. As you display these items a ↕ symbol appears, indicating that items now hidden above and below the list

can be displayed by respectively pressing the

key

. When a

reached the end of the menu list. You can move back up

the list using the

ÇÇ symbol appears, it indicates you have

×× key.

×

×

NOTE: The symbol pointing at a listed menu item indi-

cates that this item is not relevant to, nor required

for, the previously entered setup choices and,

therefore, is not available.

1. After displaying the top-level menu screen, use the

ØØ and

desired lower-level submenu screen.

2. Press the ENTER key to display the submenu screen.

×× keys to select the line corresponding to the

2.4 Adjusting

Edit/Selection

Screen Values

When a submenu or sub-submenu screen contains a first

line ending with a “?,” it is an edit/selection screen. Pressing

the

ØØ or

×× key changes the value/choice enclosed by pa-

renthesis (second line on screen).

Example: With this submenu edit screen displayed:

pressing the

Edit/selection screens always contain a second line enclosed by parenthesis -- see examples shown above and

below. The enclosed value/choice can be edited/changed

by using the

saves the change.

×× and

ØØ key displays this related choice:

ØØ keys. Pressing the ENTER key

Accu4™ Low-range Turbidimeter System Rev. 2-300

Use the

The

×× and

ÕÕ and

ÖÖ keys to “coarse” adjust numerical values.

ØØ keys “fine” adjust numerical values up or

36

PART THREE - OPERATION SECTION 3 - ADJUSTING DISPLAY CONTRAST

down respectively. The longer the key is pressed, the faster

the number changes.

2.5 Entering (Storing)

Edit/Selection Screen

Values/Choices

After the desired value/choice is displayed, press the

ENTER key

memory. The previous screen will then re-appear.

NOTE: You can always press the ESC key to abort saving

☞

S

ADJUSTING DISPLAY CONTRAST

Ambient lighting conditions may make it necessary to adjust

the analyzer display contrast to improve visibility. With the

MEASURE screen displayed, press and hold the

key

and simultaneously press the

the desired contrast.

to enter (store) it into the non-volatile analyzer

a new setting. The original setting will be retained.

ECTION

3

×

×

or

Ø

Ø

key

until attaining

ENTER

Rev. 2-300 Accu4™ Low-range Turbidimeter System

37

PART THREE - OPERATION SECTION 4 - CONFIGURING THE ANALYZER

ECTION

S

CONFIGURING THE ANALYZER

4

☞

4.1 Selecting LANGUAGE

to Operate Analyzer

NOTE: When the passcode feature is enabled (Section

4.5), you must successfully enter the passcode

before attempting to enter a configuration setting.

The analyzer can display screens in various languages including English, French (Français), German (Deutsche),

Spanish (Español), and others. The analyzer is factory-set

for English. To change languages:

&21),*85(

7(670$,17

(;,7

1. Press

key to select the “CONFIGURE” line.

2. Press ENTER key to display . Use

ØØ key to select the “LANGUAGE” line.

MENU key

to display

. Use

Ø

Ø

4.2 Configuring

Sensor Characteristics

SELECT UNITS

☞

3. Press ENTER key to display a screen like

. Use

guage choices.

4. With the desired language displayed, press ENTER

key to enter this selection.

NOTE: After a language is selected and entered, all

screens will be displayed in that language.

You may want to configure the analyzer to define related

sensor characteristics such as units of measure, input signal filtering, pulse suppression, and a MEASURE screen

top line notation to specifically tailor the instrument to your

application.

The Accu4™ Low-range Turbidimeter System is factory

set to display turbidity in NTUs. However, you may want

to select different measurement units:

ØØ and

×× keys to view the lan-

Accu4™ Low-range Turbidimeter System Rev. 2-300

38

PART THREE - OPERATION SECTION 4 - CONFIGURING THE ANALYZER

key

1. With the screen displayed, use

Ø

Ø

to select the “SENSOR” line.

SET FILTER Time

2. Press

3. With the “SELECT UNITS” line selected, press

key

and

4. With the desired choice displayed value, press

key

ENTER key

to display .

ENTER

to display a screen like . Use

keys

×

×

•

NTU (Nephelometric Turbidity Units)

•

FTU (Formazin Turbidity Units

•

FNU (Formazin Nephelometric Units)

•

TEF (TruebungsEinhelt Formazin -- a German unit)

to view all choices which are all equivalent:

ENTER

to enter this selection.

Ø

Ø

A time constant (in seconds) can be set to filter or “smooth

out” the sensor signal. A minimum value of “0 seconds” has

no smoothing effect. A maximum value of “60 seconds” provides maximum smoothing. Deciding what sensor signal

filter time to use is a compromise. The higher the filter time,

the longer the sensor signal response time will be to a

change in the actual turbidity value.

Rev. 2-300 Accu4™ Low-range Turbidimeter System

key

1. With the screen displayed, use

Ø

Ø

to select the “SET FILTER” line.

2. Press

ENTER key

to display a screen like

.

3. Adjust the displayed value to the desired filter time, and

press

keys

ENTER key

for coarse adjust;

39

to enter the value. (Use

and

×

×

keys

Ø

Ø

for fine adjust.)

and

Ö

Ö

Õ

Õ

PART THREE - OPERATION SECTION 4 - CONFIGURING THE ANALYZER

Select

PULSE SUPPRESS

(on/off)

Sometimes an external interference may occasionally cause

the measurement system to provide unstable readings.

Common causes include entrained gas bubbles in the sample, and electromagnetic interference (EMI or “electrical

noise” pulses). The analyzer has a pulse suppression feature to counteract this condition and stabilize readings.

Example: Suppose the analyzer reading is steadily showing

0.284 NTU, then suddenly jumps to 0.396 NTU for a few

seconds, and returns to 0.284 NTU. By turning on this feature, the analyzer will perceive this as a temporary upset,

“suppressing” most of this pulse change and providing a

smoother measurement reading.

key

1. With the screen displayed, use

Ø

Ø

to select the “PULSE SUPPRESS” line.

2. Press

ENTER key

. Use

to display a screen like

and

Ø

Ø

keys

×

×

to view both

choices (OFF or ON).

ENTER NOTE (top line

of MEASURE screen)

3. With the desired choice displayed, press

ENTER key

to

enter this selection.

The MEASURE screen top line is factory set to read “ACCU4.”

This notation can be changed, for example, to “BASIN 1” to

tailor the MEASURE screen to the application. The notation is

limited to eight characters which can be a combination of

capital letters A through Z, numbers 0 through 9, and spaces.

key

1. With the screen displayed, use

Ø

Ø

to select the “ENTER NOTE” line.

2. Press

ENTER key

to display . Create

the desired notation within second line’s parenthesis:

A. Starting with extreme left character position, use

and

keys

Ø

Ø

to select the desired first character.

×

×

Accu4™ Low-range Turbidimeter System Rev. 2-300

key

B. Press

use

Ö

and

×

×

Ö

once to select the next character, and

keys

Ø

Ø

to select desired character.

C. Repeat procedure until desired notation is displayed.

3. Press

ENTER key

40

to enter the displayed notation.

PART THREE - OPERATION SECTION 4 - CONFIGURING THE ANALYZER

4.3 Configuring Analog

Outputs (1 and 2)

☞

The analyzer provides two isolated analog outputs (1 and

2), each representing the measured turbidity. During calibration, both analog outputs can be held at their present

values, transferred to a preset value, or remain active. During normal measurement operation, both outputs can be:

•

Held for up to 30 minutes by using the “CHECK CAL/

HOLD” function in the TEST/MAINT menu.

•

Held indefinitely by locally or remotely connecting both

TTL input terminals on TB1.

If a TEST/MAINT hold is applied in addition to a TTL hold,

both “holds” must be removed before the outputs return to

active status. If the outputs are set to “XFER” or “ACTIVE”

during a calibration, they remain in that state until after calibration regardless of the TTL input status.

NOTE: When using the HART communication option, a

digital signal is encoded onto the 4-20 mA analog

Output 1 signal. In a HART SINGLE MODE wiring

configuration, Output 1 remains available for normal

use. However, in a HART MULTI-DROP wiring configuration, Output 1 becomes dedicated to that

function and cannot be used. See Part Three, Section 8 for more HART communication information.

SET 0/4 and

20 mA VALUES

These instructions configure Output 1. Configure Output 2 in the same way using its respective menu

screens.

You can set the turbidity values to define the endpoints at

which the minimum and maximum output values are desired.

1. With the top-level menu screen displayed and the “SET OUTPUT 1” line selected, press

ENTER key

to display

.

Rev. 2-300 Accu4™ Low-range Turbidimeter System

41

PART THREE - OPERATION SECTION 4 - CONFIGURING THE ANALYZER

2. With the “SET 4 mA VALUE” line selected, press

☞

ENTER key

3. Set the displayed value at which 0/4 mA is desired, and

press

keys

for coarse adjust;

4. After the screen re-appears, use

to select the “SET 20 mA VALUE” line.

5. Press

6. Set the displayed value at which 20 mA is desired, and

press

ENTER key

to display a screen like .

ENTER key

ENTER key

to enter the value. (Use

and

×

×

to display a screen like

.

to enter the value.

keys

Ø

Ø

for fine adjust.)

and

Ö

Ö

Ø

Ø

Õ

Õ

key

NOTE: If the same values are set for 0/4 mA and 20 mA, the

output automatically goes to, and remains at, 20 mA.

SET TRANSFER

Value (mA)

Normally, each analog output is active, responding to the

measured turbidity value. During calibration, however, you

can transfer (XFER) each output to a preset value to operate a control element by an amount corresponding to that

value.

If you desire to set a milliamp transfer value for an analog

output to suit your application, follow these steps:

key

1. With the screen displayed, use

to select the “SET TRANSFER” line.

2. Press

3. Set the displayed value to the desired transfer value,

and press

for coarse adjust;

ENTER key

.

ENTER key

and

×

×

to display a screen like

and

to enter it. (Use

keys

Ø

Ø

for fine adjust.)

Ö

Ö

Ø

Ø

keys

Õ

Õ

Accu4™ Low-range Turbidimeter System Rev. 2-300

42

PART THREE - OPERATION SECTION 4 - CONFIGURING THE ANALYZER

SET FILTER Time

☞

A time constant (in seconds) can be set to filter or “smooth

out” the output signal. A minimum value of “0 seconds” has

no smoothing effect. A maximum value of “60 seconds” provides maximum smoothing. Deciding what output filter time

to use is a compromise. The higher the filter time, the longer

the output signal response time will be to a change in the

measured turbidity.

NOTE: The output filter time setting combines with the sen-

sor signal filter time setting, providing an additive

delay in output response to the actual reading.

key

1. With the screen displayed, use

to select the “SET FILTER” line.

2. Press

ENTER key

.

to display a screen like

Ø

Ø

Select SCALE 0 mA/

4 mA (low endpoint)

3. Adjust the displayed value to the desired filter time, and

press

coarse adjust;

Select each output to be 0-20 mA or 4-20 mA.

1. With the screen displayed, use

to select the “SCALE 0mA/4mA” line.

2. Press

Ø

Ø

3. With the desired choice displayed, press

enter this selection.

ENTER key

ENTER key

and

×

×

to enter it. (Use

and

×

×

keys

to view both choices (0 mA or 4 mA).

keys

Ø

Ø

to display . Use

for fine adjust.)

and

Ö

Ö

ENTER key

keys

Õ

Õ

Ø

Ø

for

key

to

Rev. 2-300 Accu4™ Low-range Turbidimeter System

43

PART THREE - OPERATION SECTION 4 - CONFIGURING THE ANALYZER

4.4 Configuring Relays

(A, B, C, and D)

The analyzer is equipped with four electromechanical relays

(A, B, C, and D). Each relay can be set to function as a

CONTROL, ALARM, or STATUS relay. For details on each

relay function, see subsection “SET FUNCTION Mode.”

During calibration, CONTROL and ALARM (not STATUS)

relays can be held at their present on/off states, transferred

to preset on/off states, or remain active. During normal

measurement operation, CONTROL and ALARM relays can

be:

•

Held at their present on/off states for up to 30 minutes

by using the “CHECK CAL/HOLD” function in the TEST/

MAINT menu.

•

Held at their present on/off states indefinitely by locally

or remotely connecting both TTL input terminals on

TB1.

If a TEST/MAINT hold is applied in addition to a TTL hold,

both “holds” must be removed before CONTROL and

ALARM relays return to active status. If the relays are set to

“XFER” or “ACTIVE” during a calibration, they remain in that

state until after calibration regardless of the TTL input

status.

SET FUNCTION Mode

(alarm, control, or status)

These instructions configure Relay A. Configure other

relays in the same way using their respective menu

screens.

Each relay can be selected to function as a:

ALARM

•

relay (with separate high and low alarm points

and deadbands) that operates in response to the

measured turbidity.

CONTROL

•

relay (with phasing, setpoint, deadband,

and overfeed timer) that operates in response to the

measured turbidity.

STATUS

•

relay that operates only in response to

selected system diagnostic conditions. It can be

configured for:

FAIL mode -- sets STATUS relay to activate when

there is a FAIL condition (analyzer, light source or

detector) or a sensor CHAMBER UNKNOWN

condition.

Accu4™ Low-range Turbidimeter System Rev. 2-300

44

PART THREE - OPERATION SECTION 4 - CONFIGURING THE ANALYZER

WARN mode -- sets STATUS relay to activate only when

there is a sensor flow CHAMBER DIRTY condition.

ALL mode -- sets STATUS relay to activate when

there is any abnormal system condition (any FAIL

condition, or sensor CHAMBER DIRTY or

UNKNOWN condition).

A “WARNING CHECK STATUS” message automatically

flashes on the MEASURE screen whenever the analyzer

detects any of these system diagnostic conditions:

•

ANALYZER FAIL

•

CHAMBER DIRTY

•

CHAMBER UNKNOWN• DETECT 2 FAIL

•

SOURCE 1 FAIL

•

SOURCE 2 FAIL

•

DETECT 1 FAIL

To determine the condition causing the warning message,

display the “STATUS” screens in the TEST/MAINT menu

branch. For more details, see Part Three, Section 6.1.

Relay D is factory-set to function as a STATUS relay but

can be configured as a CONTROL or ALARM relay.

1. With the screen displayed, press

key

once to display .

ESC

Rev. 2-300 Accu4™ Low-range Turbidimeter System

key

2. Use

Ø

Ø

ENTER key

to select the “SET RELAY A” line, and press

to display .

3. With the “SET FUNCTION” line selected, press

key

to display a screen like

and

keys

×

×

to view the choices (ALARM, CONTROL or

. Use

STATUS).

4. With the desired choice displayed, press

ENTER key

enter this selection.

45

ENTER

Ø

Ø

to

PART THREE - OPERATION SECTION 4 - CONFIGURING THE ANALYZER

SET TRANSFER Mode

(relay on or off)

Normally, each CONTROL or ALARM relay is ACTIVE, responding to the measured turbidity. During calibration,