Glidewell Dental TS150 Quick Start Manual

QUICK-START GUIDE

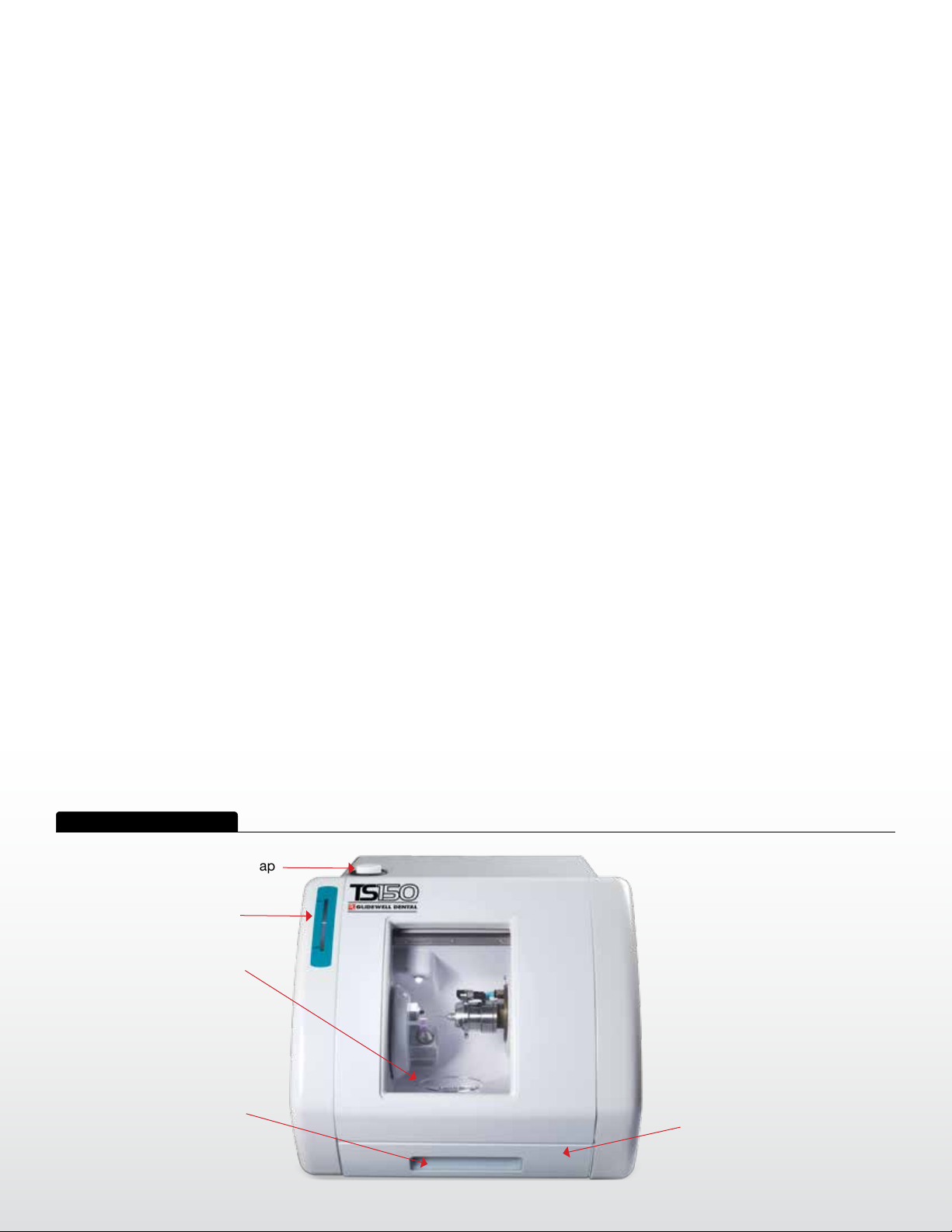

System Components

Getting to know your TS150

Oil Reservoir Cap

Oil Level Window

Machining

Chamber

Door Handle

Trough Window

and Handle

Coolant Trough

Page 2 of 22

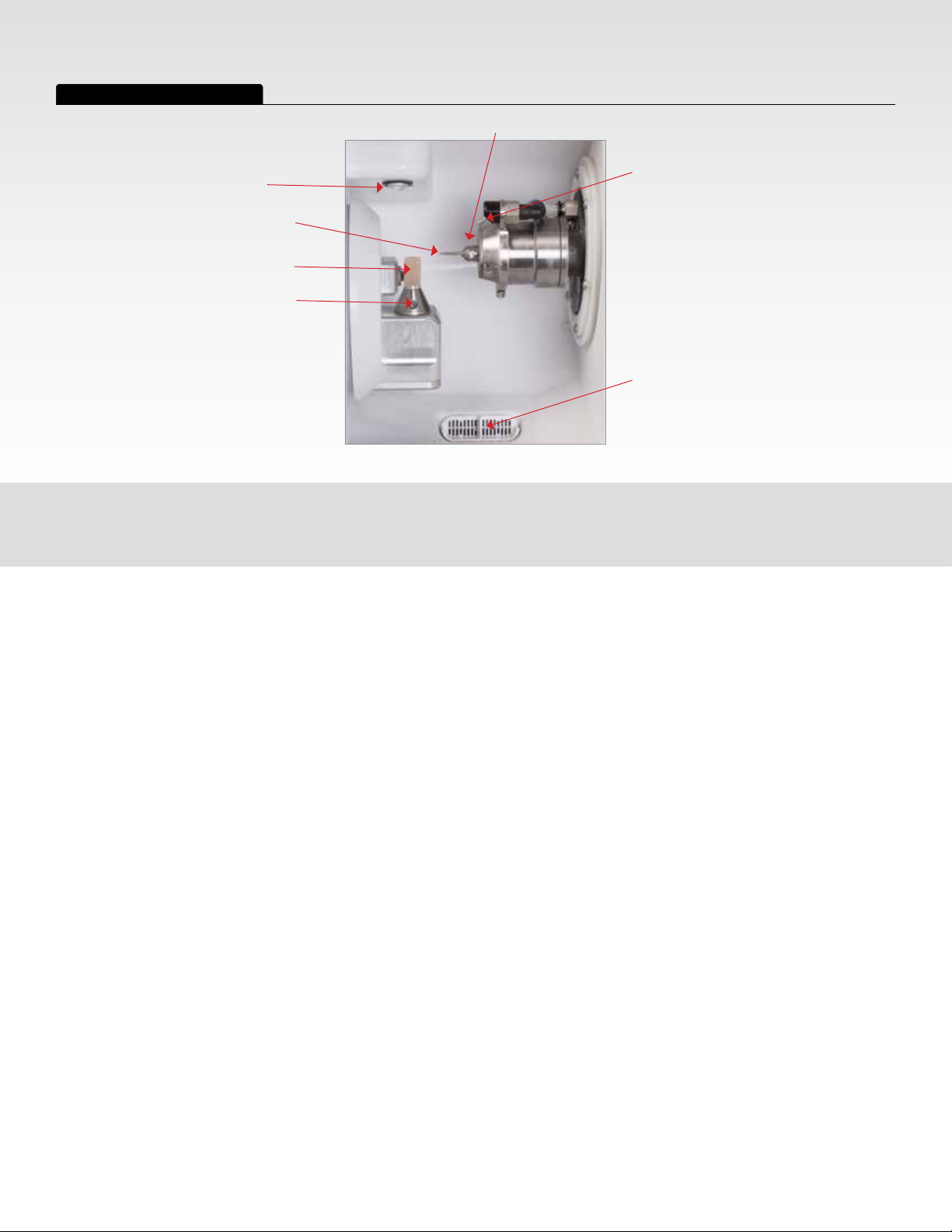

Machining Chamber Components

Spindle Collet Nut

Chamber Light

Milling Tool

Material Block

Material

Retaining

Screw

Coolant Spray Nozzle

Coolant Drain Screen

Page 3 of 22

SYSTEM COMPONENTS

Setup

Basic Setup

1

Locate the TS150 Mill in a spare

room with a sturdy support, such as

table or cabinet top surface, which

is capable of holding a weight of

150 lbs.

2

Mount the supplied air pressure

regulator on the back of the unit or

on the wall near the unit.

3

Connect the ofce air supply to the

regulator (3/8” inch OD tubing), the

output of the regulator to the air inlet

located on the rear of the unit. (Air

Consumption Requirement: 4.5CFM

@ 85–90 psig)

4

Use the power cord to connect the

system to a grounded power outlet.

5

Switch the power on at the power

inlet on the back of the unit.

6

Load the coolant trough with a

mixture of distilled or R.O. water

and TS150 coolant solution.

(See Routine Maintenance for

instructions.)

7

Fill the oil reservoir with TS150-

approved lubricant. (See Routine

Maintenance for instructions.)

8

The TS150 requires a USB ready

“out-of-the-box” cable or Ethernet

connection to the computer running

FastDesign™ (your Technical

Support Specialist will help set up

this connection).

Page 4 of 22

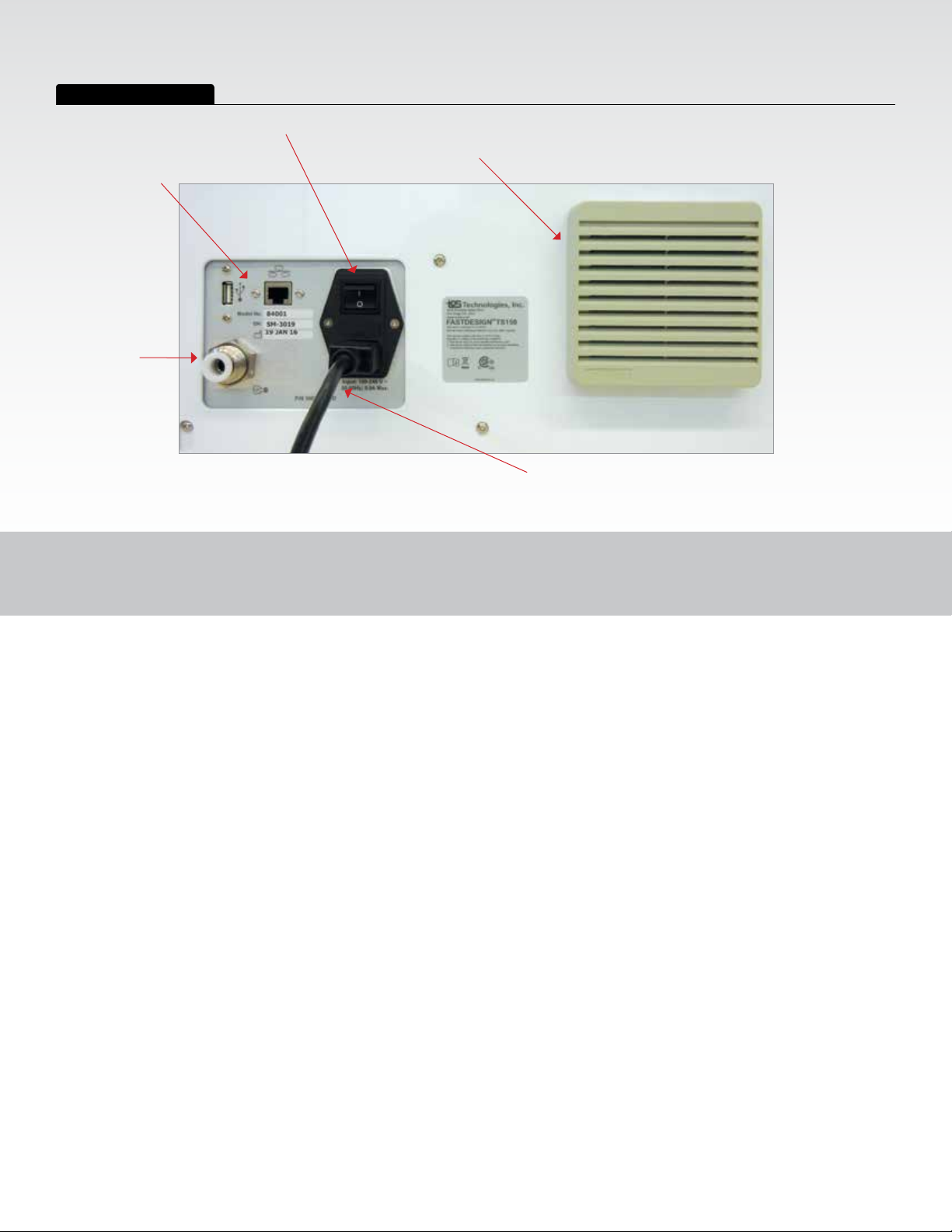

Rear Panel Components

USB/Ethernet

Cable

Air Input

AC Input

I/O Power

Switch

Fan Filter

Power Cord

Page 5 of 22

SETUP

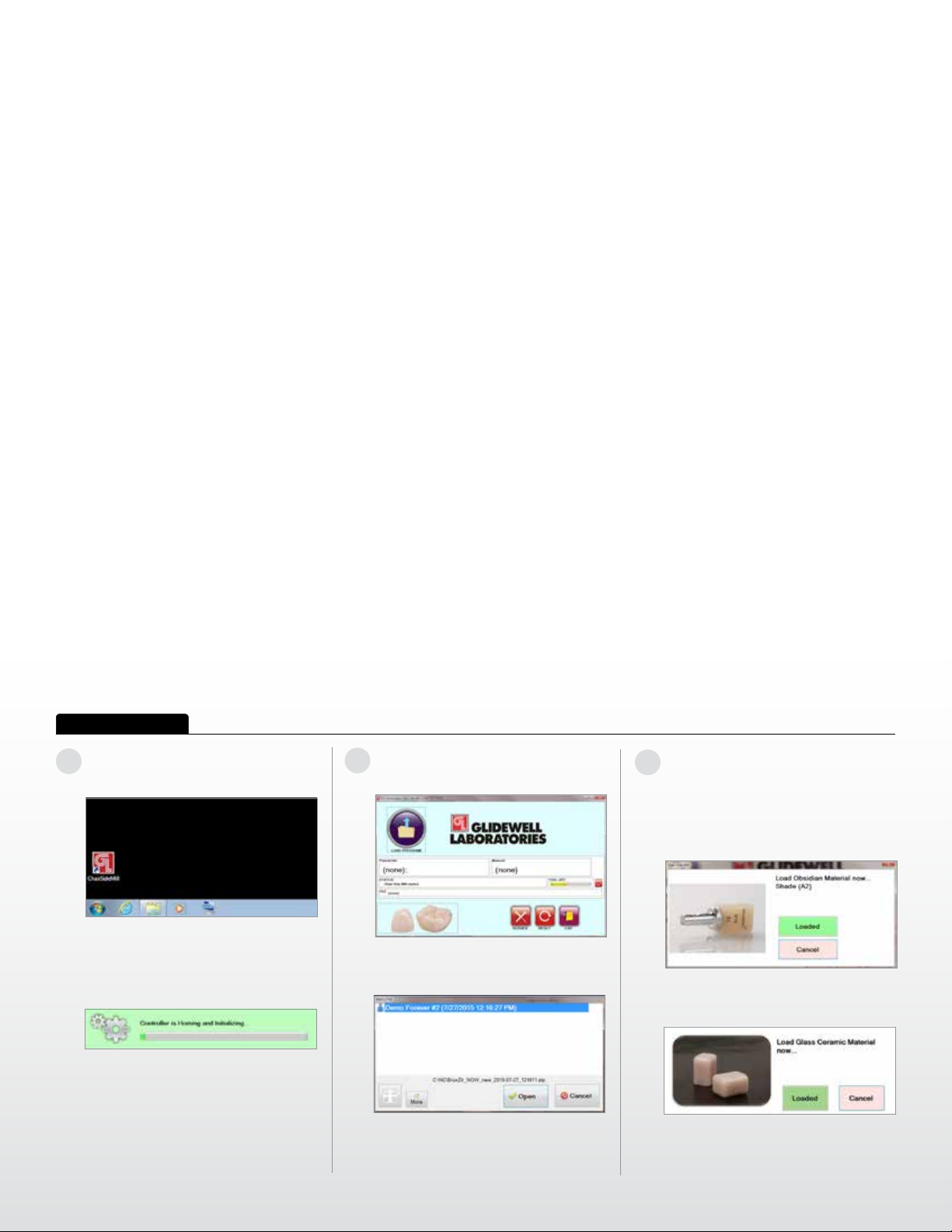

Running the TS150

Mill Preparation

1

From the TS150 start screen, select

CHAIRSIDE MILL ICON.

The TS150 will go through a selfcheck sequence which will verify that

motion control and other systems

are working correctly.

Select LOAD PROGRAM from the

2

home screen.

Select the case le to be milled

and Open.

3

OBSIDIAN, ENAMIC, LAVA

MATERIAL ONLY

Once the le is loaded, the software

will move the mechanism to the

Load Material position.

Once the material is loaded, select

Loaded.

• If the case calls for BruxZir® NOW,

skip to step 7.

• If the case is designated as Obsidian

ENAMIC® or Lava™, proceed to

following step 3.

®

,

Page 6 of 22

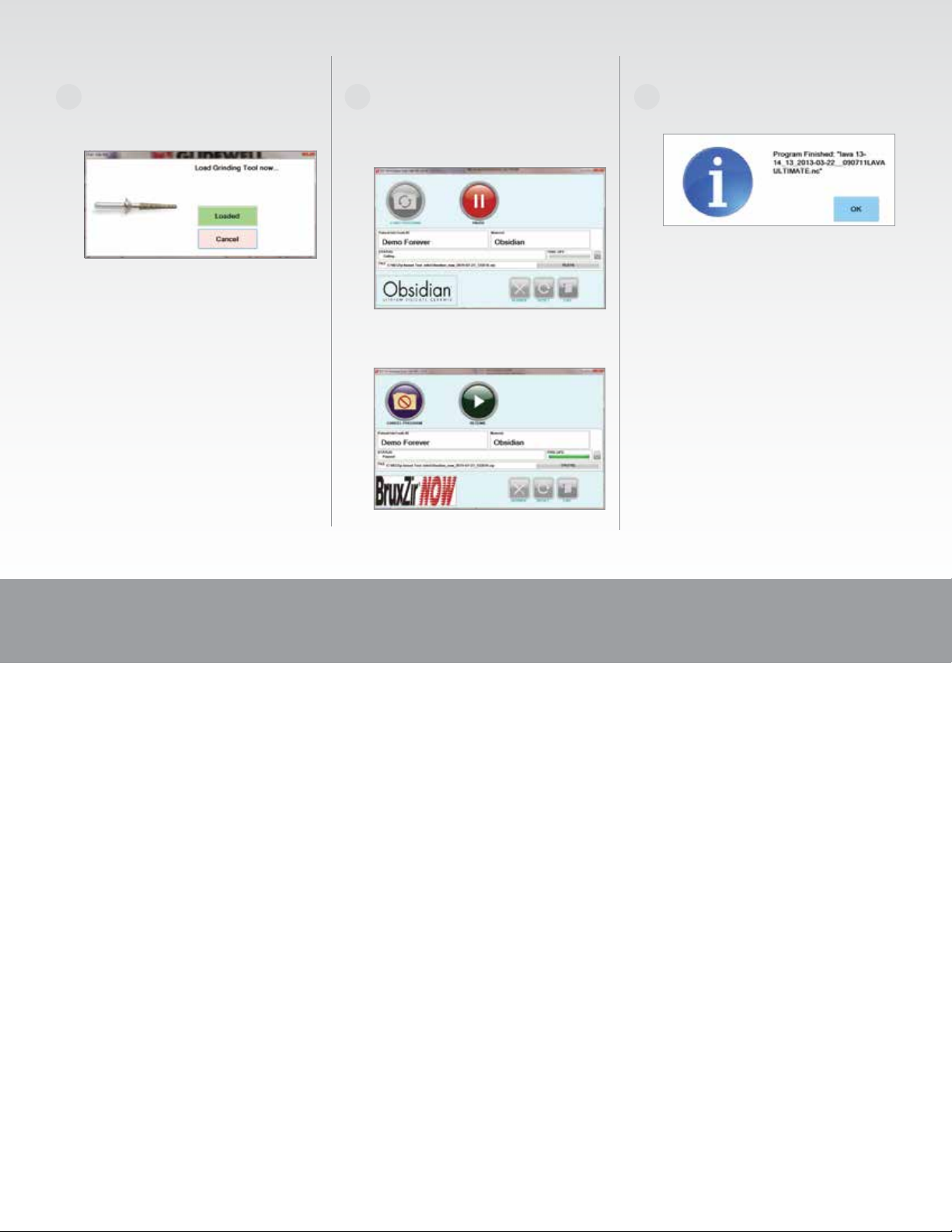

4

If the milling tool has reached the

end of its life, the mechanism will

move to the LOAD TOOL position.

If prompted, open the chamber door

to load a new tool. Close the door

and select LOADED.

5

With the door closed and LOADED

icon selected, the TS150 will

automatically begin machining. The

UI will change to the following screen.

While the TS150 is machining, the

Operator can PAUSE the job if necessary.

6

When the machining is complete,

select OK.

Select RESUME to continue machining

or select CANCEL to halt the job.

RUNNING THE TS150

Page 7 of 22

Loading...

Loading...