Glenmac Harley T6 Operator's Manual

Glenmac, Inc.

1805 2nd Avenue SW

Jamestown, ND 58401

701-252-9300 tel

701-252-1978 fax

701-952-9307 parts fax

by

SN: T65F201

(06/2005)

INTRODUCTION

GLENMAC, INC., based in Jamestown, North Dakota, along with your authorized harley dealer, are proud that

you chose to purchase a Harley Power Box Rake. Equipment under the Harley name has been built and sold

worldwide for over 35 years. Glenmac, Inc. specializes in the manufacturing of construction and landscape attachments

designed to make your job more efficient, cleaner, and easier regardless of the complexity of the job. The Harley

Power Box Rake® brings state-of-the-art design, ruggedness, and maneuverability to jobs such as: landscaping,

seedbed preparation, site development, rock raking and picking, golf course construction, ball field renovation and

maintenance, liner installation, horse track screening, sod farm ground work, beach cleaning - and the job for

which you purchased your Harley.

This manual will provide you, the operator, with instructions for proper safety, assembly, and operation procedures

so you can benefit from the equipment’s optimum level of performance. Successful operation and long-life of your

Harley Power Box Rake® depends on you. As owner and operator of your new Harley, it is your responsibility to

become familiar with the proper operation and care required to operate it safely and efficiently and to maintain the

equipment in top condition.

To keep your Harley equipment at peak performance, please read this manual carefully several times and follow

the directions as specified for each operation. Correct operation and maintenance will save you time and expense.

REMINDER: Fill in the warranty card and mail within 10 days of your purchase date. While filling in the card with

the correct information, put the date purchased and serial number on the front cover of this manual. Should you

need to call your dealer or GLENMAC, INC., this information will help them to more quickly provide accurate

service for you.

Thank you for purchasing a Harley Power Box Rake®.

For more information, contact your local Harley dealer or call:

Dealer Name:

___________________________

___________________________

___________________________

___________________________

___________________________

This Safety-Alert Symbol indicates a hazard and means

ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED!

DANGER Indicates an imminently hazardous situation that, if not avoided,

will result in death or serious injury.

WARNING Indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury, and includes hazards that

are exposed when guards are removed.

GLENMAC, INC.

PO Box 2135

Jamestown, North Dakota 58402-2135 U.S.A.

800/437-9779

701/252-9300

FAX 701/252-1978

Email: sales@glenmac.com

CAUTION Indicates a potentially hazardous situation that, if not avoided,

may result in minor or moderate injury.

1PN-P970612 (06/2005)

TABLE OF CONTENTS

Introduction ........................................................................... 1

Specifications ........................................................................ 3

Owner Assistance .................................................................. 3

General Information...............................................................4

Bolt Size Chart ...................................................................... 4

Bolt Torque Chart ..............................................................5-6

After 10 Hours of Operation ............................................ 5

Safety Rules .......................................................................6-9

Safety Decals.................................................................. 10-11

Operation ........................................................................ 12-17

Pre-operation Check List ............................................... 13

Start-up .......................................................................... 14

Operating Tips...........................................................14-15

Shut Down and Storage ............................................ 16-17

General Maintenance ......................................................18-24

Chain Maintenance ......................................................... 19

Gearbox ......................................................................... 19

Clutch Run In ................................................................. 22

Clutch Repair ................................................................. 23

Top Bearing Housing ..................................................... 23

Bearing and Roller Repair .............................................. 24

Trouble Shooting................................................................. 21

Assembly, Parts Identification, and Drawings................ 25-37

Frame Assembly........................................................ 28-29

Roller Assembly ........................................................ 30-31

Clutch Assembly ....................................................... 32-33

Clutch and PTO Drive Line ...................................... 34-35

Gauge Wheel Assembly ............................................36-37

Warranty .............................................................................. 38

2 PN-P970612 (06/2005)

SPECIFICATIONS

Raking Width ............................................................................................................... 72 Inches

Roller Type .......................................................................... Tooth Roller Standard 9" Diameter

Roller Angle .................................................................................... 15 Degrees Both Directions

Gap (Tube to Barrier) ................................................................................. 5/16" - 3" Adjustable

Tires ..........................................................................................................................16.5 x 6.5-8

Tire Pressure ...................................................................................................................... 60 psi

Weight ...............................................................................................................................840 lbs

Oil Capacity of Chain Case .................................................................. Approximately 1.5 Pints

Tractor Three-Point Attachment ....................................................................................... Cat. 1

3-Point Lift Requirement at 24" 903 lbs

PTO Drive ................................................................................................................... 540 RPM

Tractor Hydraulic System ..................................................... 3-Pt Hitch and One Remote Valve

Tractor PTO HP ........................................................................................................ 22 - 35 HP

OWNER ASSISTANCE

1. We at Glenmac, Inc. and your authorized Harley dealer want you to be completely satisfied with your investment.

Sometimes, however, misunderstandings can occur. To resolve any problems that may occur please follow the

instructions below. If you did not purchase your Power Box Rake® from an authorized Harley dealer, go to

number (2) below.

A. Contact the Service Manager of the dealership, explain the problem, and request assistance. If

additional assistance is needed, your dealer had direct access to our home office.

B. If your problem has not been handled to your satisfaction contact:

Customer Service (8:00 am – 5:00 pm Central Time)

Glenmac, Inc.

P.O. Box 2135

Jamestown, ND 58402-2135

(701) 252-9300

C. Please be prepared to provide the following information:

• Your name, address, and telephone number,

• Machine model and SERIAL NUMBER,

• Dealership name and address,

• Machine purchase date,

• Nature of problem.

Your problem will likely be resolved in the dealership using the dealer’s facilities, equipment, and personnel.

Therefore, it is important that your initial contact be with the dealer.

2. If you did not purchase your equipment from an authorized dealer, call Glenmac, Inc. (see B above); there may

be a new dealer in your area since you purchased your

Customer Service Department can and will help you obtain the parts and information you may need. Please be

prepared to provide the information requested under C above.

Power Box Rake

®

. If there is no dealer in your area, our

3PN-P970612 (06/2005)

GENERAL INFORMATION

The purpose of this manual is to assist you in operating

and maintaining your Power Box Rake

carefully. It furnishes information and instructions that

will help you achieve years of dependable

performance. These instructions have been compiled

from extensive field experience and engineering data.

Some information may be general in nature due to

unknown and varying operating conditions. However,

through experience and these instructions, you should

be able to develop procedures suitable to your

particular situation.

®

. Read it

The illustrations and data used in this manual were

current at the time of printing, but due to possible

inline production changes, your machine may vary

slightly in detail. We reserve the right to redesign

and change the machines as may be necessary without

notification.

Throughout this manual, references are made to front,

back, right and left directions. These are determined

by sitting in the operator’s seat of the tractor.

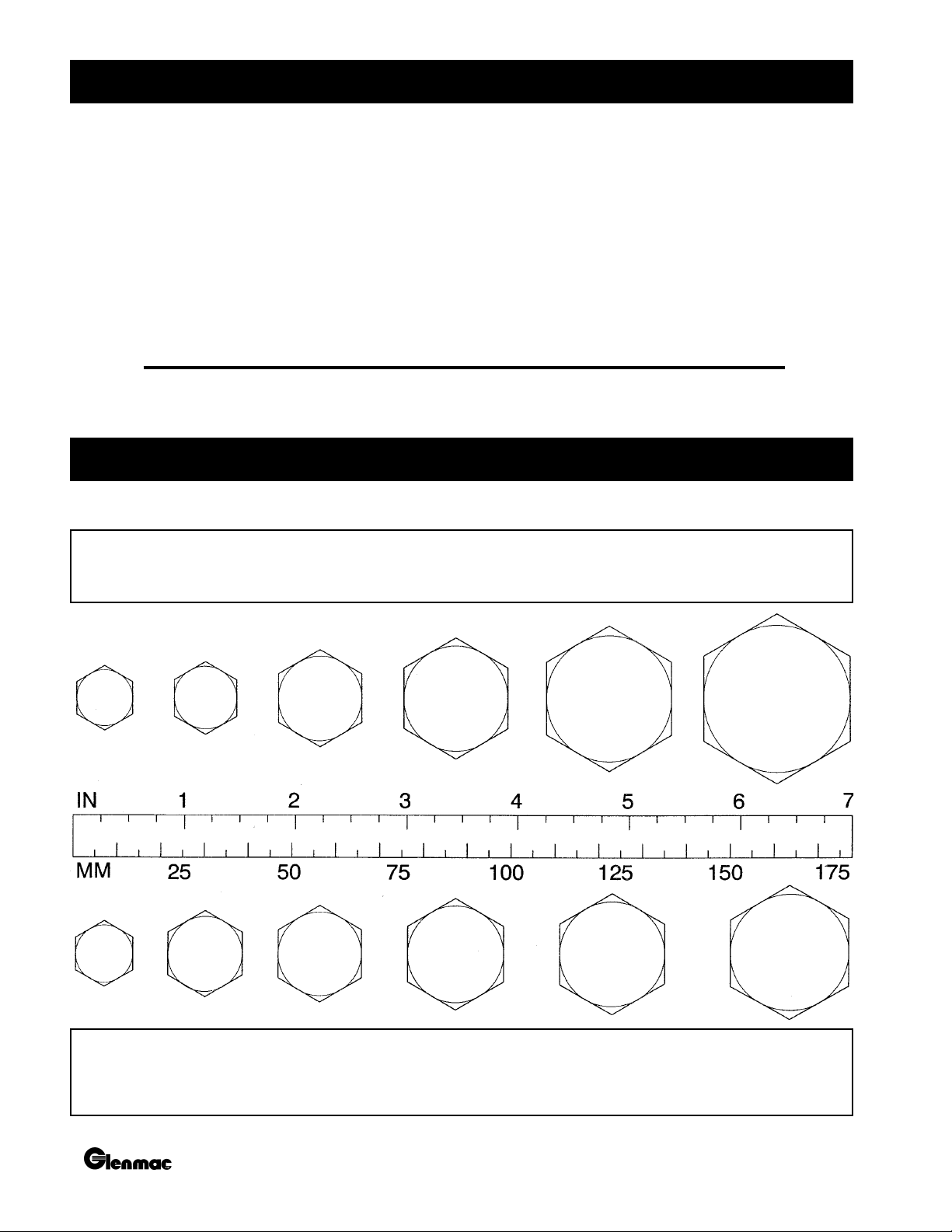

BOLT SIZE CHART

NOTE: Chart shows bolt thread sizes and corresponding head (wrench) sizes for standard SAE and Metric Bolts.

SAE Bolt Thread Sizes

5/16 3/8 1/2 5/8 3/4 7/8

Metric Bolt Thread Sizes

8MM 10MM 12MM 14MM 16MM 18MM

4 PN-P970612 (06/2005)

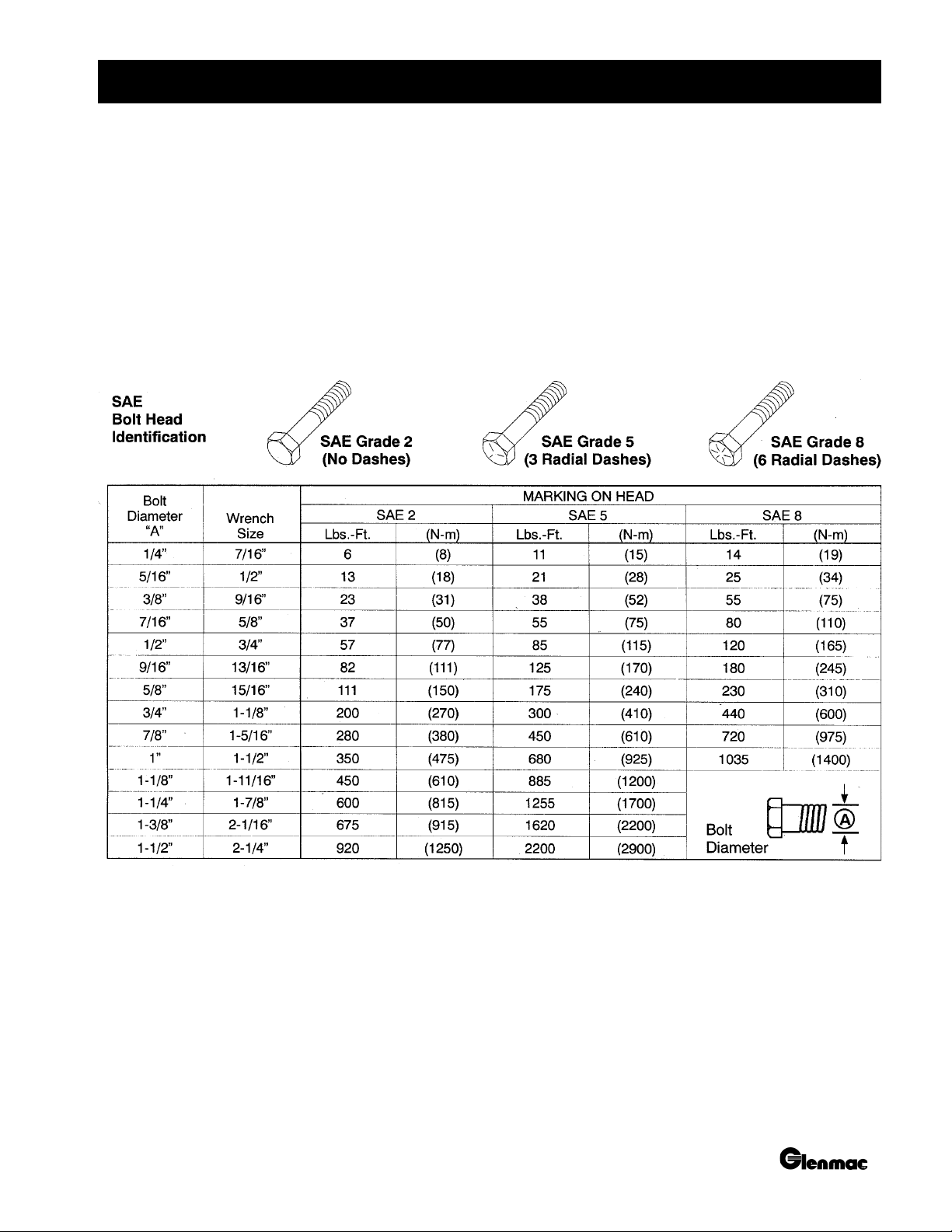

BOLT TORQUE CHART

After every ten (10) hours of operation, check all hardware and tighten where required.

SAE Series Torque Chart

DO NOT use these values if a different torque value or tightening procedure is listed for a specific application.

Torque values listed are for general use only.

Fasteners should be replaced with the same grade.

Make sure fastener threads are clean and you properly start thread engagement. This will prevent them from failing

when tightening.

5PN-P970612 (06/2005)

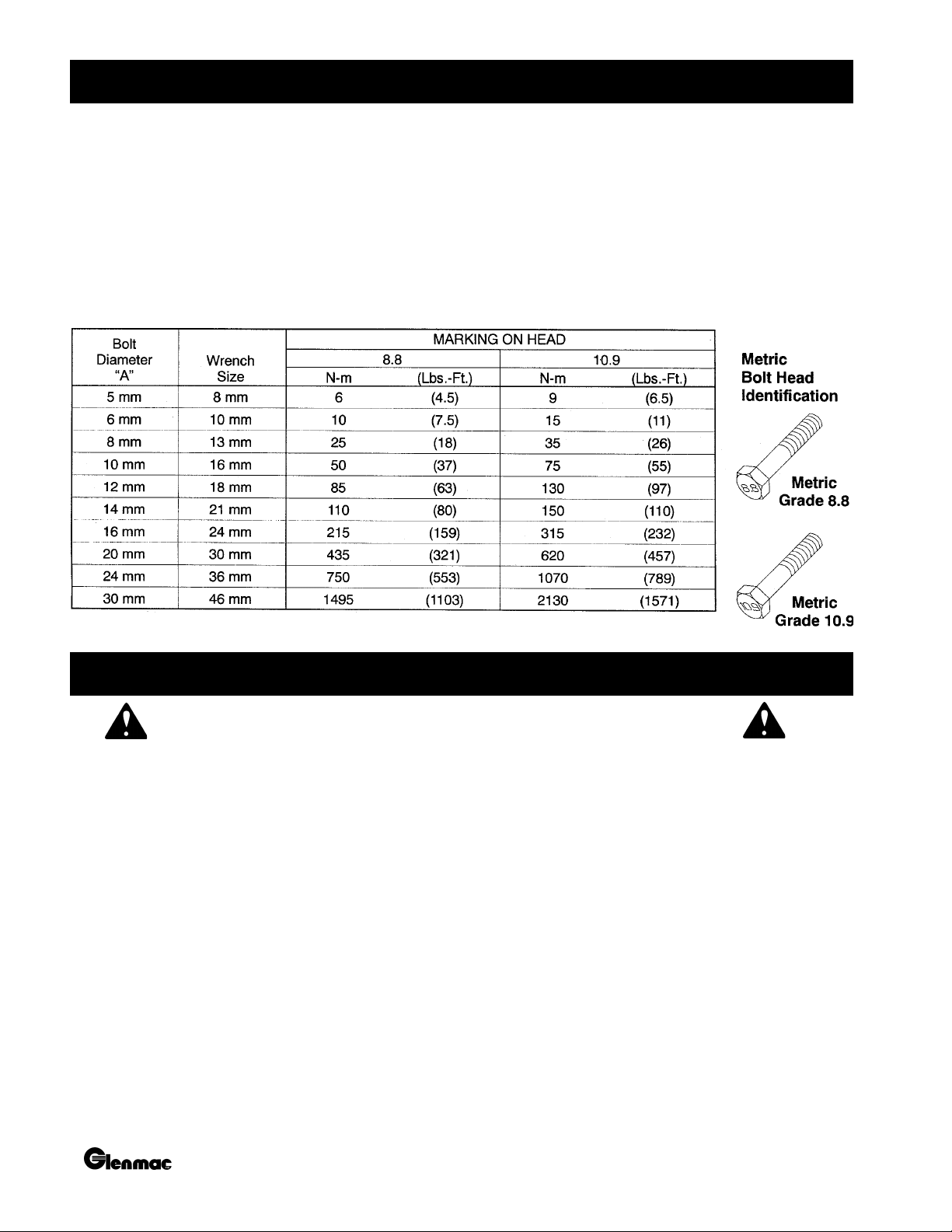

BOLT TORQUE CHART

Metric Series Torque Chart

Use only metric tools on metric hardware. Other tools may not fit properly. They may slip and cause injury.

DO NOT use these values if a different torque value or tightening procedure is listed for a specific application.

Torque values listed are for general use only.

Fasteners should be replaced with the same grade.

Make sure fastener threads are clean and you properly start thread engagement. This will prevent them from failing

when tightening.

After every ten (10) hours of operation, check all hardware and tighten where required.

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

TRAINING

Safety is a primary concern in the design and

manufacture of our products. Unfortunately, our

efforts to provide safe equipment can be wiped out by

a single careless act of an operator.

In addition to the design and configuration of

equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence, and

proper training of personnel involved in the operation,

transport, maintenance, and storage of equipment.

It has been said, “The best safety device is an informed,

careful operator.” We ask you to be that kind of an

operator.

The designed and tested safety of this equipment

depends on it being operated within the limitations as

explained in this manual.

• Safety instructions are important! Read all

attachment and power unit manuals; follow all

safety rules and safety decal information.

(Replacement manuals are available from dealer

or, in the United States and Canada, call 1-800437-9779.) Failure to follow instructions or safety

rules can result in serious injury or death.

• If you do not understand any part of this manual

and need assistance, see your dealer.

• Know your controls and how to stop engine and

attachment quickly in an emergency.

• Operators must be instructed in and be capable of

the safe operation of the equipment, its

attachments, and all controls. Do not allow anyone

to operate this equipment without proper

instructions.

6 PN-P970612 (06/2005)

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

• Keep hands and body away from pressurized lines.

Use paper or cardboard, not body parts to check

for leaks. Wear safety goggles. Hydraulic fluid

under pressure can easily penetrate skin and will

cause serious injury or death.

• Make sure that all operating and service personnel

know that in the event hydraulic fluid penetrates

skin, it must be surgically removed as soon as

possible by a doctor familiar with this form of

injury or gangrene, serious injury, or death will

result. CONTACT A PHYSICIAN

IMMEDIATELY IF FLUID ENTERS SKIN

OR EYES. DO NOT DELAY.

• Do not allow children or untrained persons to

operate equipment.

PREPARATION

• Air in hydraulic systems can cause erratic operation

and allows loads or equipment components to drop

unexpectedly. Before operating or allowing

anyone to approach the equipment, purge any air

in the system by operating all hydraulic functions

several times after connecting equipment,

connecting hoses, or doing any hydraulic

maintenance.

• Check that all hardware is tight and properly

installed. Always tighten to torque chart

specifications.

• Before starting tractor, check all equipment

driveline guards for damage and make sure they

rotate freely on all drivelines. Replace any

damaged guards. If guards do not rotate freely on

drivelines, repair and replace bearings before

operating.

• Make sure driveline is correct length to prevent

bottoming out or pulling apart during the full lift

range of the hitch.

• Make sure spring-activated locking pin or collar

slides freely and is seated firmly in tractor PTO

splined groove.

• After connecting hoses, check that all control lever

positions function as instructed in the Operator’s

Manual. Do not operate until control lever and

equipment movements are correct.

• Make sure all hydraulic hoses, fittings, and valves

are in good condition and not leaking before starting

power unit or using equipment. Check and route

hoses carefully to prevent damage. Hoses must

not be twisted, bent sharply, kinked, frayed,

pinched, or come into contact with any moving

parts. Operate moveable components through full

operational range to check clearances. Replace any

damaged hoses immediately.

• Always wear relatively tight and belted clothing to

avoid entanglement in moving parts. Wear sturdy,

rough-soled work shoes and protective equipment

for eyes, hair, hands, hearing, and head.

• Ensure implement is properly attached, adjusted,

and in good operating condition.

• Power unit must be equipped with ROPS (Roll

Over Protection Structure) or ROPS CAB and seat

belt. Keep seat belt securely fastened. Falling off

power unit can result in death from being run over

or crushed. Keep foldable ROPS systems in

“locked up” position at all times.

• Remove accumulated debris from this equipment,

tractor, and engine to avoid fire hazard.

• A minimum 20% of tractor and equipment weight

must be on tractor front wheels with attachments

in “transport” position. Without this weight,

tractor could tip over causing personal injury or

death. The weight may be attained with a loader,

front wheel weights, ballast in tires, or front tractor

weights. When attaining the minimum 20%

weight on the front wheels, you must not exceed

the Roll Over Protection Structure (ROPS) weight

certification. Weigh the tractor and equipment.

Do not estimate.

• Ensure all safety decals are installed. Replace if

damaged. (See “Safety Decals” section for

location.)

• Ensure shields and guards are properly installed

and in good condition. Replace if damaged.

7PN-P970612 (06/2005)

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

OPERATIONAL SAFETY

SAFETY RULES

• No riders are allowed on equipment.

• Consult local utilities before digging. Know location

and depth of, and avoid contacting, all underground

cables, pipelines, and other hazards in working area.

• Do not allow other people in the area when

operating, attaching, removing, assembling, or

servicing equipment.

• Only engage power when equipment is at ground

operating level. Always disengage power when

equipment is raised off the ground.

• Do not disconnect hydraulic lines until all system

pressure is relieved. Lower unit to ground, stop

engine, and operate all hydraulic control levers.

• Ensure implement is properly attached, adjusted,

and in good operating condition.

• Keep bystanders away from equipment while it is

in operation.

• Never go underneath equipment lowered to the

ground or raised. Never place any part of the body

underneath equipment or between moveable parts

even when the engine has been turned off.

Hydraulic system leak-down, hydraulic system

failures, mechanical failures, or movement of

control levers can cause equipment to drop or rotate

unexpectedly and cause severe injury or death.

• Service work does not require going underneath

equipment.

• Read Operator’s Manual for service instructions

or have done by a qualified dealer.

• Never direct discharge toward people, animals, or

property.

• Do not operate equipment while under the

influence of alcohol or drugs.

• Operate only in daylight or good artificial light.

• Keep hands, feet, hair, and clothing away from

equipment while engine is running. Stay clear of

all moving parts.

• Always comply with all state and local lighting and

marking requirements.

• Always sit in tractor seat when operating controls

or starting engine. Securely fasten seat belt, place

transmission in neutral, engage brake, and ensure

all other controls are disengaged before starting

tractor engine.

• Operate tractor PTO at RPM speed stated in

“Specifications” section.

• Do not operate tractor PTO during transport.

• Stop tractor and implement immediately upon

striking an obstruction. Turn off engine, remove

key, inspect, and repair any damage before

resuming operation.

• Before dismounting tractor or performing any

service or maintenance, disengage power to

implement, lower the 3-point hitch and all raised

components to the ground, operate valve levers to

release any hydraulic pressure, stop engine, set

parking brake, remove key, and unfasten seat belt.

• Lower implement to ground or block securely, turn

tractor engine off, remove key, and disconnect

driveline from tractor PTO before performing any

service or maintenance.

• Power unit must be equipped with ROPS or ROPS

CAB and seat belt. Keep seat belt securely fastened.

Falling off power unit can result n death from being

run over or crushed. Keep foldable ROPS systems

in “locked up” position at all times.

• Look down and to the rear and make sure area is

clear before operating in reverse.

• Use extreme care when working close to fences,

ditches, other obstructions, or on hillsides.

• Do no operate on steep slopes.

• Do not stop, start, or change directions suddenly

on slopes.

• Use extreme care and reduce ground speed on

slopes and rough terrain.

• Watch for hidden hazards on the terrain during

operation.

8 PN-P970612 (06/2005)

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

MAINTENANCE SAFETY

• Your dealer can supply original equipment,

hydraulic accessories and repair parts. Substitute

parts may not meet original equipment

specifications and may be dangerous.

• Always wear relatively tight and belted clothing to

avoid entanglement in moving parts. Wear sturdy,

rough-soled work shoes, and protective equipment

for eyes, hair, hand, hearing, and head.

• Before dismounting tractor or performing any

service or maintenance, disengage power to

implement, lower the 3-point hitch and all raised

components to the ground, operate valve levers to

release any hydraulic pressure, stop engine, set

parking brake, remove key, and unfasten seat belt.

• Lower implement to ground or block securely, turn

tractor engine off, remove key, and disconnect

driveline from tractor PTO before performing any

service or maintenance.

• Do not allow other people in the area when

operating, attaching, removing, assembling, or

servicing equipment.

• Keep all persons away from operator control area

while performing adjustments, service, or

maintenance.

• Tighten all bolts, nuts, and screws to torque chart

specifications. Check that all cotter pins are

installed securely to ensure equipment is in a safe

condition before operating.

• Ensure all safety decals are installed. Replace if

damaged. (See “Safety Decals” section for

location.)

• Ensure shields and guards are properly installed

and in good condition. Replace if damaged.

• Do not disconnect hydraulic lines until all system

pressure is relieved. Lower unit to ground, stop

engine, and operate all hydraulic control levers.

STORAGE

• Follow manual instructions for storage.

• Keep children and bystanders away from storage

area.

• Do not modify or alter, or permit anyone else to

modify or alter, the equipment or any of its

components in any way.

• Never go underneath equipment lowered to the

ground or raised. Never place any part of the body

underneath equipment or between moveable parts

even when the engine has been turned off.

Hydraulic system leak-down, hydraulic system

failures, mechanical failures, or movement of

control levers can cause equipment to drop or rotate

unexpectedly and cause severe injury or death.

• Service work does not require going underneath

equipment.

• Read Operator’s Manual for service instructions

or have done by a qualified dealer.

• Ensure implement is properly attached, adjusted,

and in good operating condition.

• Never perform service or maintenance with engine

running.

Review the video

included with

your Rake for

safety tips!

9PN-P970612 (06/2005)

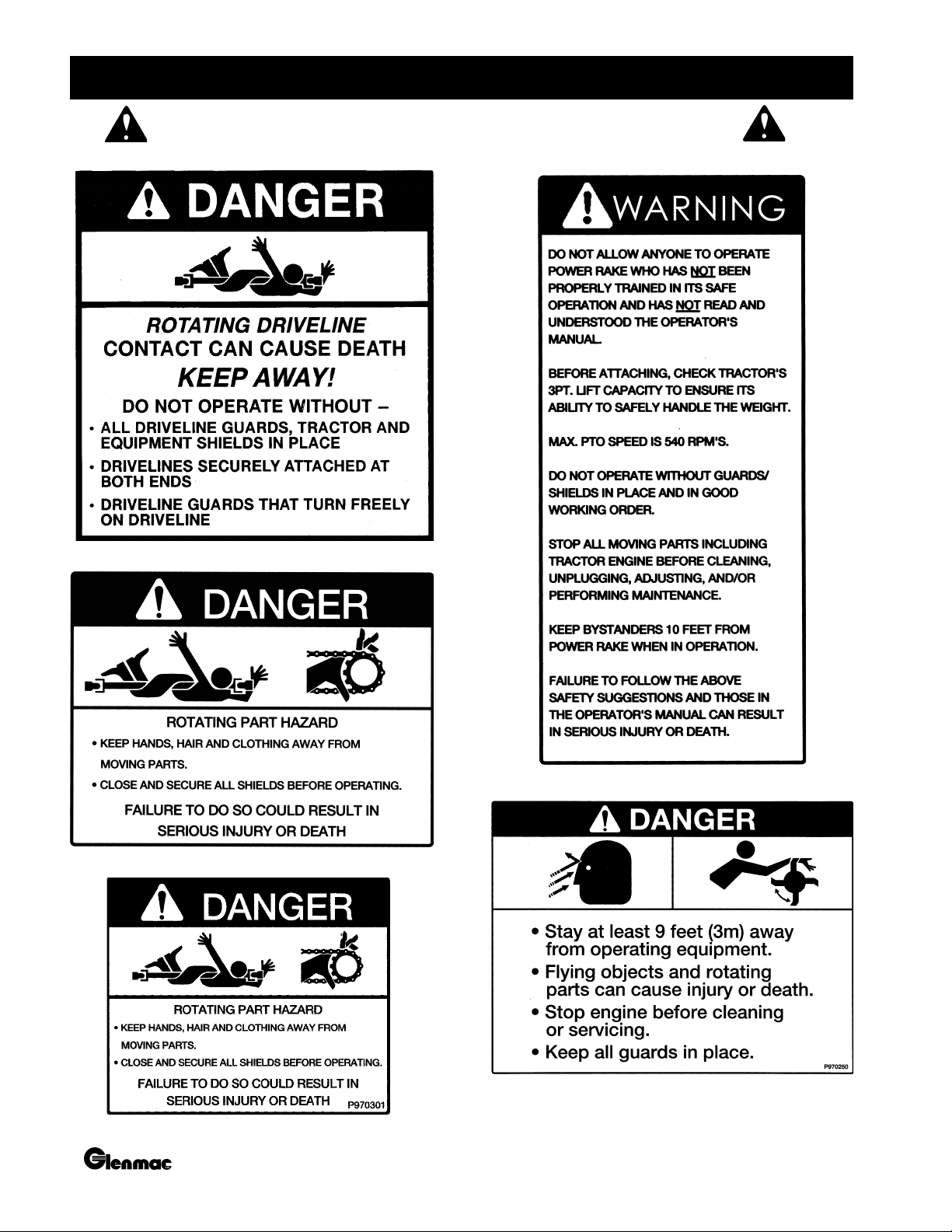

SAFETY DECALS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

#1 - PN: P970400

#2 - PN: P970300

#4 - PN: P970100

#3 - PN: P970301

#5 - PN: P970250

10 PN-P970612 (06/2005)

Loading...

Loading...