Glenko Senator ZS100T, Senator ZS150T, Senator ZS200T, MAM-870 Instruction Manual

INSTRUCTION MANUAL

ZS100T, ZS150T & ZS200T SERIES II

AIR COMPRESSOR SETS

(MAM-870 CONTROLLER)

Thank-you and congratulations for purchasing a high quality

Senator air compressor set. It has been designed and

manufactured to provide many years of safe and reliable service if

installed, operated and maintained in accordance with these

instructions. Please read and understand this manual before

operating the compressor. Failure to do so could result in death,

severe injury and/or substantial property damage.

This manual should be considered a permanent part of the

compressor and should remain with it if resold.

Instruction Manual ZS100T, ZS150T & ZS200T Series II (MAM-870) Senator Industrial Air Compressors

Contents

Precautions .................................................................................................................... 1

List of Technical Parameters ......................................................................................... 2

Chapter 1 General Instructions .................................................................................. 3

1.1 Overview ......................................................................................................... 3

1.2 System Flow ................................................................................................... 3

1.2.1 Air System ................................................................................................... 5

1.2.2 Lubrication System ..................................................................................... 6

1.3 Cooling System ............................................................................................... 6

1.4 Control Protection System .............................................................................. 7

1.5 Electrical System ............................................................................................ 7

1.6 Compressor Controller and Operation Panel .................................................. 8

Chapter 2 Installation ............................................................................................... 11

2.1 Outline Dimensions .................................................................................... 11

2.2 Installation Site of Compressor ................................................................... 11

2.3 Electrical Safety Requirements ................................................................... 12

Chapter 3 Operation.................................................................................................. 13

3.1 Initial Start-Up ............................................................................................ 13

3.2 Daily Operation ........................................................................................... 14

3.2.1 Start-Up ................................................................................................... 14

3.2.2 Operation Status of Compressor ............................................................. 15

3.2.3 Shutdown ................................................................................................. 16

3.2.4 Monitoring During Operation ................................................................. 16

3.3 Long-Term Shutdown ................................................................................. 17

3.3.1 Preparation .............................................................................................. 17

3.3.2 Restarting ................................................................................................ 17

Chapter 4 Maintenance .............................................................................................. 18

4.1 Lubricating Oil .............................................................................................. 18

4.1.1 Oil Change Interval ................................................................................... 18

4.1.2 Replacing Oil and Oil Filter .................................................................... 18

4.2 V-Belts .......................................................................................................... 19

4.3 Air Filter ....................................................................................................... 20

4.4 Oil Filter ........................................................................................................ 21

4.5 Oil-Air Separator .......................................................................................... 21

4.6 Oil Cooler ..................................................................................................... 22

4.7 Safety Valves ................................................................................................. 22

Instruction Manual ZS100T, ZS150T & ZS200T Series II (MAM-870) Senator Industrial Air Compressors

4.8 Preventative Maintenance Program ................................................................ 23

Chapter 5 Fault Diagnosis and Repair ....................................................................... 24

5.1 Compressor Fault Analysis ......................................................................... 24

5.2 Troubleshooting Chart ................................................................................ 25

Chapter 6 Warranty ................................................................................................... 27

6.1 Proof of Purchase ........................................................................................ 27

6.2 Warranty Conditions ................................................................................... 27

Maintenance and Repair Log ....................................................................................... 29

Instruction Manual ZS100T, ZS150T & ZS200T Series II (MAM-870) Senator Industrial Air Compressors

1

Precautions

a. The compressor should only be operated by authorized persons. The operators

should thoroughly read and understand the manual and strictly follow the

procedures and safety notes in the manual.

b. The compressor should be far away from inflammable materials. It is not

permitted to place the compressor in the site with the dust and air containing salt

mist and other harmful gases. It should be far away from heat sources.

c. The proper power supply cable should be selected. It is necessary to install the

breaker switch and fuse matching the power of the compressor ahead of the lead-in

power supply cable. To ensure the safe operation of electrical equipment, a

grounding wire should be securely connected.

d. Ensure the correct phase of power supply to prevent reverse rotation of the screw

air end.

e. The compressor should not be operated above the discharge pressure specified on

the nameplate. Otherwise, it will result in shutdown due to motor overload.

f. For service and maintenance, the power supply should be switched off and the

compressed air should be released. In addition, warning signs should be placed to

prevent accidents due to unexpected compressor operation.

g. When the compressor is normally operating, the cabinet doors must be closed.

During maintenance service, take care to prevent any body part, clothing or tools

from touching the hot or moving components in the machine in order to avoid

injury.

h. It is prohibited to modify the compressor’s structure or control mode without the

written permission of the manufacturer.

i. Compressed air can contain carbon monoxide, hydrocarbons and/or other poisonous

contaminants that can cause death or serious injury. The air compressor is not

designed, intended or approved for breathing air. Do not use compressed air for

breathing air applications without proper treatment.

j. Do not use the compressor for any gas other than air.

k. All electrical installation or repair work must be carried out by a licensed

electrician.

Instruction Manual ZS100T, ZS150T & ZS200T Series II (MAM-870) Senator Industrial Air Compressors

2

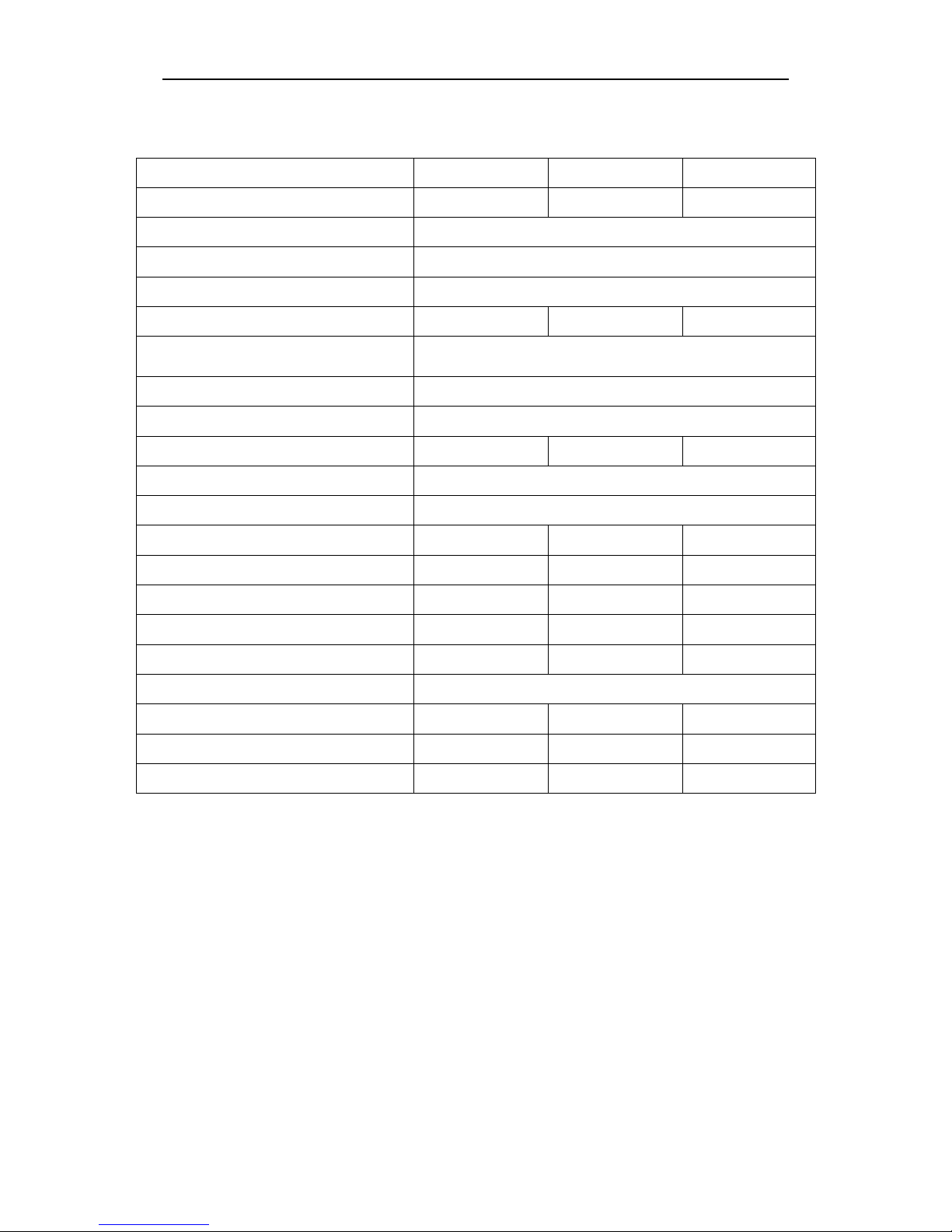

List of Technical Parameters

Machine Model

ZS100T

ZS150T

ZS200T

Air Discharge (m3/min) / Discharge Pressure

(bar)

1.13 / 8

1.70 / 8

2.27 / 8

Air Discharge Temperature (℃)

≤ 110

Shutdown Protection Temperature (℃)

110

Oil Content in Discharge Air (ppm)

≤ 3

Lubricating Oil Capacity (L)

4.5 9 9

Air Suction Conditions

Ambient temperature ≤ 45℃, at atmospheric pressure, and

relative humidity ≤ 80%

Driving Mode

Belt Drive

Cooling Mode

Air Cooling

Motor Starting Mode

Direct On Line

Y-Δ

Y-Δ

Temperature Control Mode

Control by Thermostatic Valve

Input Power Supply (V / Ph / Hz)

415 / 3 / 50

Input Power Supply (A)

15.4

23.5

28.6

Motor Power (hp) / (kW)

10 / 7.5

15 / 11

20 / 15

Motor Speed (rpm)

2,910

2,940

2,940

Fan Motor Power (kW)

0.12

0.25

0.25

Fan Motor Speed (rpm)

1,300

1,400

1,400

Discharge Air Pipe Connection

1” BSP Female

Air Tank Vol u m e ( L)

250

380

380

Overall Dimensions L × W × H (mm)

1,730 × 700 × 1,220

1,800 × 760 × 1,400

1,800 × 760 × 1,400

Wei g ht ( kg)

350

470

535

Instruction Manual ZS100T, ZS150T & ZS200T Series II (MAM-870) Senator Industrial Air Compressors

3

Chapter 1 General Instructions

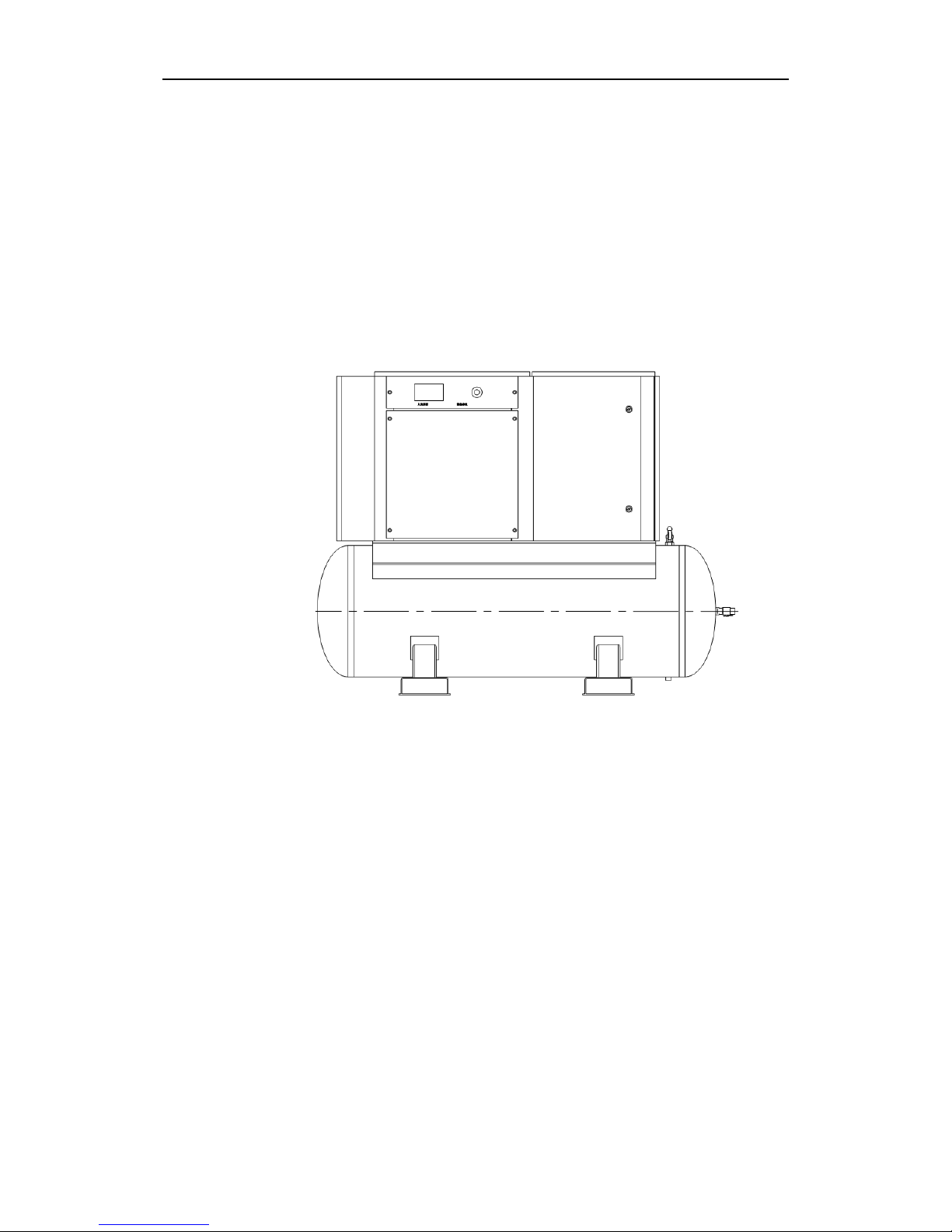

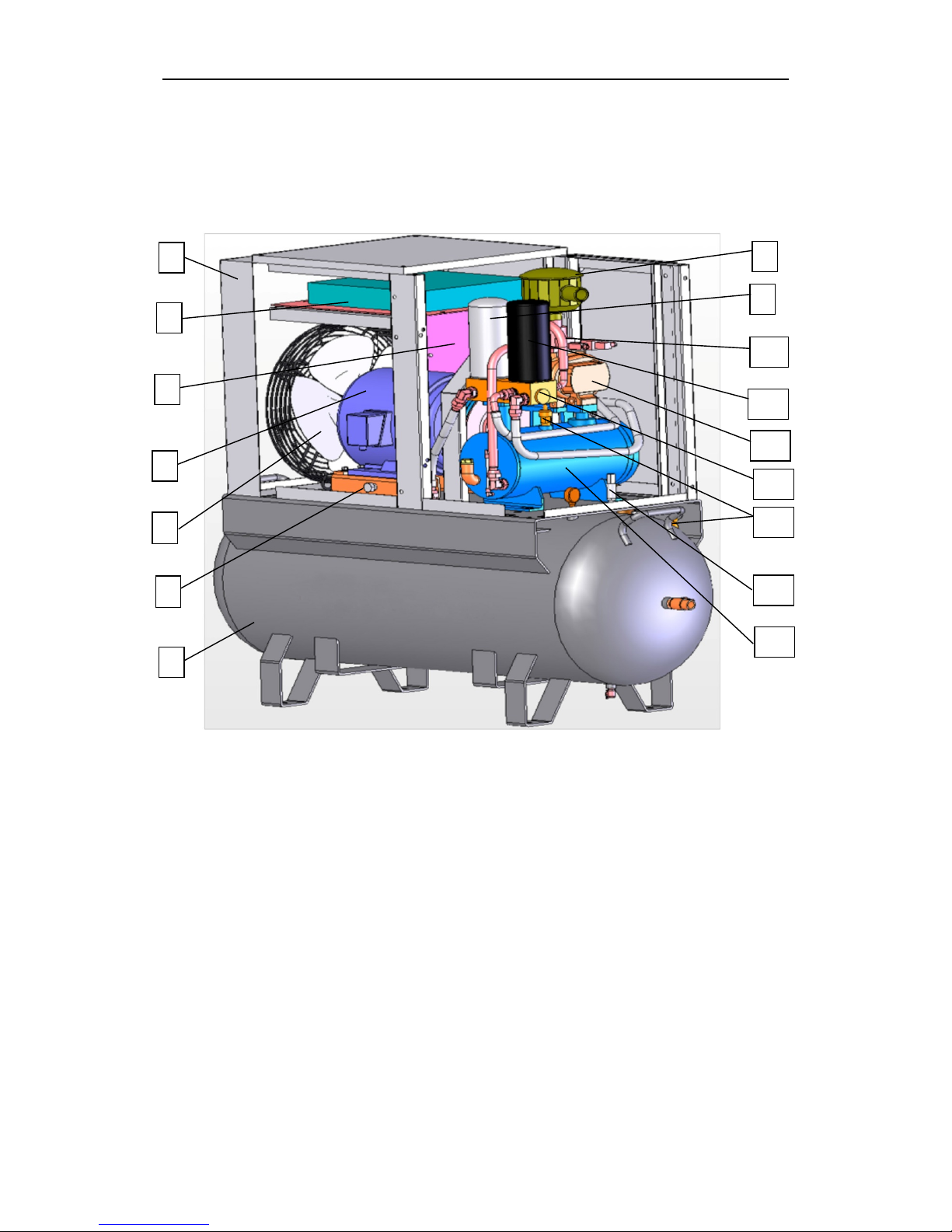

1.1 Overview

The ZST Series II compressor sets are stationary single-stage, oil-injection type screw

compressors driven by electric motors. The unit is installed above the air tank. The

compressor has an advanced micro-computer controller with an LCD display. It can

efficiently reduce the power consumption and provide the operators with convenient

operation and monitoring. The typical outside view of ZST Series II screw

compressors is shown in Fig. 1-1.

Fig. 1-1 Outside View of ZST Series II Screw Compressor

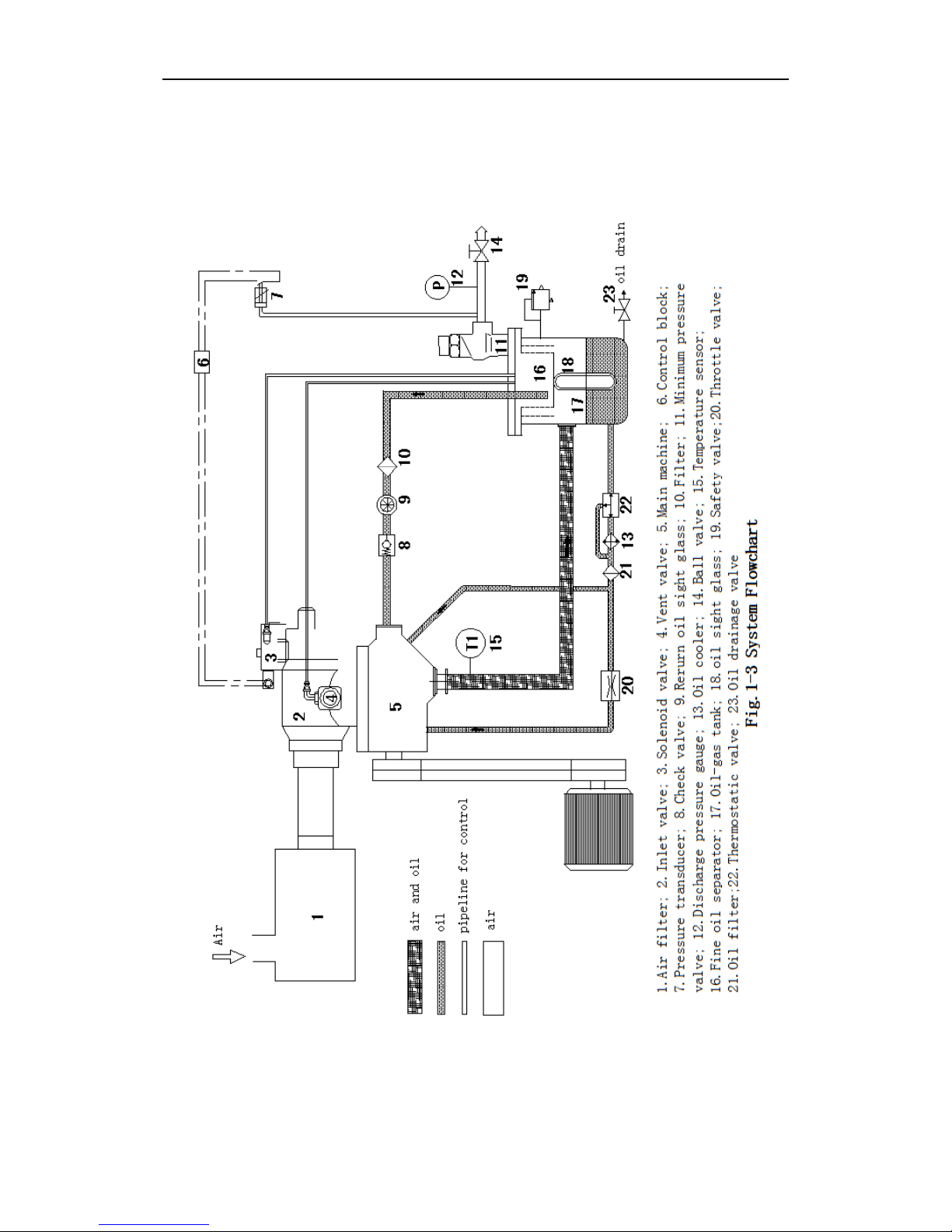

1.2 System Flow

The unit primarily consists of the screw air end, motor, oil-air separator, oil pipeline

system, cooling system, air pipeline system, electrical control system and other parts

and components.

The system flow of the unit is shown in Fig. 1-3.

Instruction Manual ZS100T, ZS150T & ZS200T Series II (MAM-870) Senator Industrial Air Compressors

4

Instruction Manual ZS100T, ZS150T & ZS200T Series II (MAM-870) Senator Industrial Air Compressors

5

1.2.1 Air System

The typical internal structure of ZST Series II screw air compressors is shown in

Fig.1-4.

Fig. 1-4 Structure of ZST Series II Low Noise Screw Compressor

The air is sucked through the air filter and flows into the main machine of compressor

through the inlet valve for compression. The compressed oil-air mixture flows into the

oil-air tank for preliminary separation, and then into the fine oil separator. After the

oil-air separation, the compressed air flows through the minimum pressure valve and air

tank, and then it will be discharged out of the compressor and into the pipeline network

of the user.

The function of the air filter is to filter the foreign matter in the air to ensure that only

clean air enters into the compressor’s screw air end. The inlet valve can adjust the air

1

2

4

5

6 7 8

9

10

11

12

13

14

15

16

1. Air tank

2. Belt tension adjusting screw

3. Fan

4. Main motor

5. Cooler

6. Electrical control system

7. Case

8. Air filter

9. Oil separator element

10.

Inlet valve

11.

Oil filter

12.

Screw air end

13. Combination valve

14. Safety valve

15. Pressure

sensor

16. Oil

-air tank

3

Instruction Manual ZS100T, ZS150T & ZS200T Series II (MAM-870) Senator Industrial Air Compressors

6

input of the compressor automatically according to the air consumption, ensuring the

balance between demand and supply and thus saving energy. In addition, the inlet

valve will be closed for start-up at reduced load when the unit is started. When the

unit is shut down, the inlet valve will be closed to prevent compressed air and

lubricating oil in the separator from flowing backwards and being ejected out of the air

inlet.

The minimum pressure valve can ensure that the pressure in oil-air tank is not below

0.35 MPa, which will enable the lubricating oil to normally flow in the system. In

addition, when the compressor is unloaded or shut down, the minimum pressure valve

can prevent the compressed air in the pipeline network of the user from flowing

backwards.

The automatic vent valve is located beside the inlet valve. When the compressor is

unloaded or shut down, the vent valve will automatically open to drain out the air and

release the pressure.

1.2.2 Lubrication System

The compressed oil-air mixture is injected into the oil-air tank and collides with its

inner wall. Most lubricating oil will be separated from the oil-air mixture in the

collision and will settle down in the lower part of the oil-air tank; the remaining oil will

be separated via the fine oil separator and led to the screw air end via the oil return pipe.

During operation of the compressor, if the temperature of the lubricating oil is below

71°C, the thermostatic valve will automatically open the bypass circuit and the

circulating oil from the oil-air tank will be directly injected under air pressure to the

screw air end and individual lubricating points via the lubricating pipe and oil filter. If

the temperature rises to 71°C, the thermostatic valve will gradually shut off the bypass

circuit and at the same time it will gradually open the circuit going to oil cooler through

which a part of lubricating oil will be cooled down. If the temperature rises to 85°C,

the bypass circuit will be completely shut off, and the lubricating oil will completely

cool down through the oil cooler and then enter into the main machine.

The function of the thermostatic valve is to maintain the constant temperature and

viscosity of lubricating oil and to allow the system to reach the optimal operating

temperature as soon as possible while at the same time and subsequently maintaining

the temperature to prevent water vapour in the system from condensing. The function

of lubricating oil filter is to remove the metal particles and lubricating oil cracking

products in the lubricating oil to reduce the wear of bearing and male and female rotors

and increase their service life.

1.3 Cooling System

This is how the cooling system functions: The cooling air is sucked from the outside

of the unit by the fan and then blown through the radiator fin of cooler where it will

have the heat exchange with the lubricating oil flowing through the cooler for the

cooling effect. The maximum temperature of cooling air in the cooling system is

Instruction Manual ZS100T, ZS150T & ZS200T Series II (MAM-870) Senator Industrial Air Compressors

7

45°C. If it exceeds 45°C, excessively high air discharge temperature will be caused in

the compressor.

1.4 Control Protection System

For intelligent automatic control, the compressor has a micro-computer controller which

can adjust the operating state of the compressor according to the actual air consumption

conditions of the user’s application.

If the air consumption of the user is low or the air application is paused, the main inlet

valve will be shut off to allow the compressor to operate at light load and turn into the

unloading state, consequently realizing the energy-saving target. After the air

consumption is recommenced, the micro-computer controller will open the main inlet

valve again to enable the compressor to operate at the full load and recover the loading

operation state. At the same time, the micro-computer controller will monitor the unit.

If any abnormal condition - such as motor overload, air discharge over-temperature, etc.

- occurs to the unit, it will automatically shut down the compressor to protect it against

damage.

A safety valve is installed in the oil-air tank. If the pressure inside the oil-air tank

exceeds the setting, the safety valve will automatically open to quickly discharge the air

and release the pressure, ensuring the safety of the unit. The unit has the ideal pressure

relief function. Therefore, the safety valve will not open in normal operation.

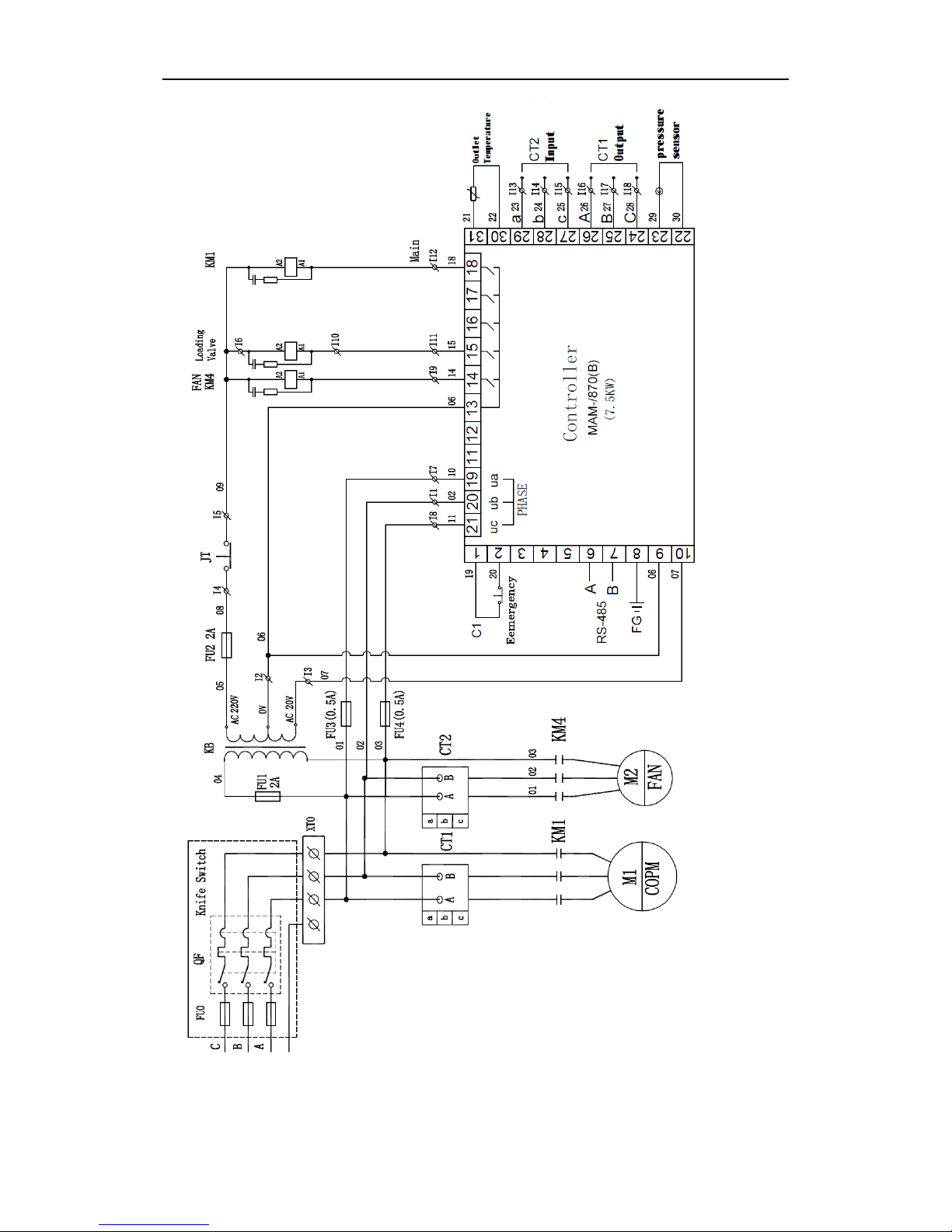

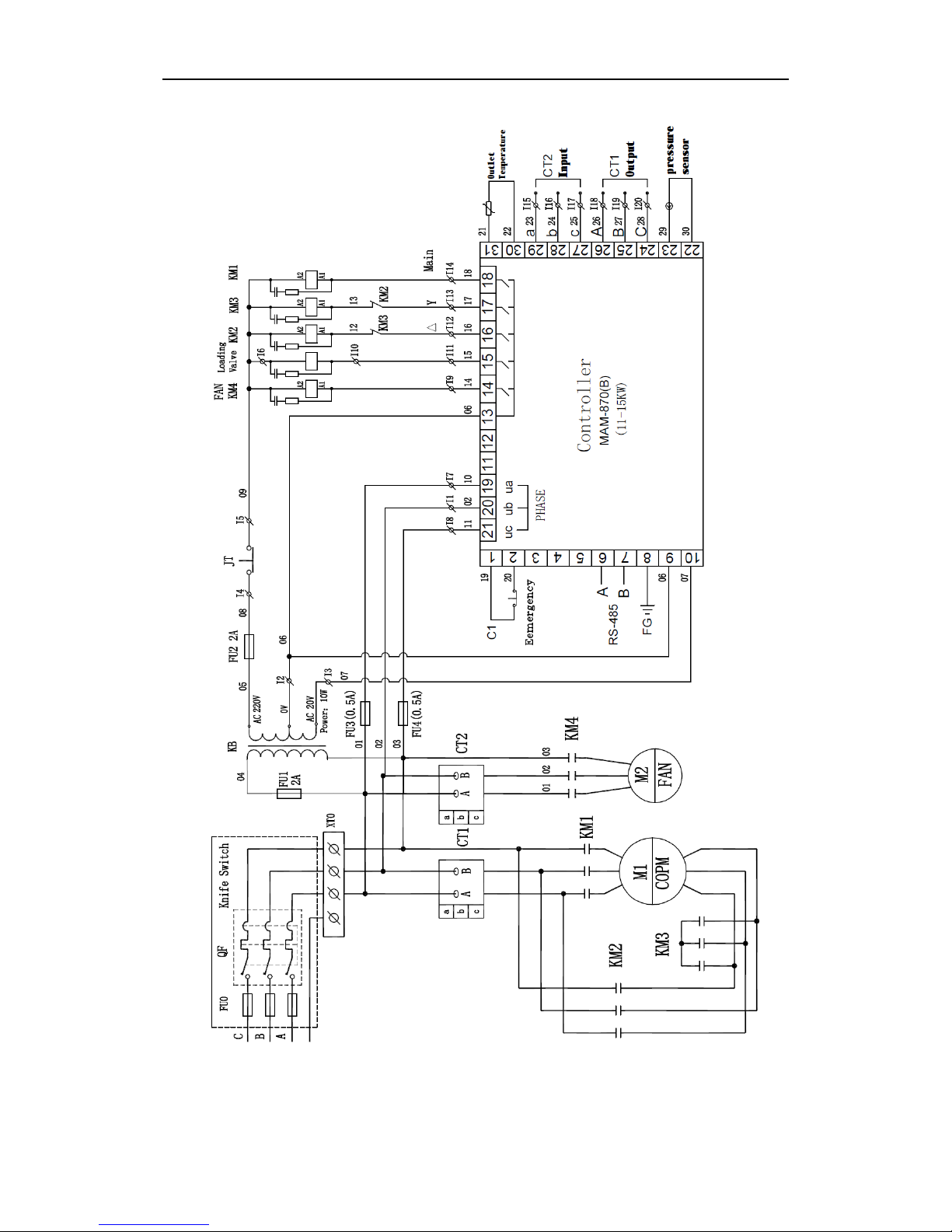

1.5 Electrical System

The electrical system consists of the main motor, electrical control cabinet assembly,

solenoid valve, temperature sensor, pressure sensor, and operation panel.

To further protect the main motor against overheating damage due to abnormal

conditions, the operating current of main motor will be monitored by the controller. If

the motor current exceeds the allowable current, the compressor controller will perform

immediate shutdown protection, and the motor overload will be shown on the operation

panel at the same time.

The electrical schematic diagrams are shown in Fig’s 1-5 and 1-6.

Caution: The user should provide the necessary short circuit protection and

other safety devices ahead of the lead-in power supply cable of the compressor, and

the secure grounding wire should be present.

Warning: It is prohibited to remove and install the connecting lines inside the

electrical control cabinet and from it to individual motors without permission!

Instruction Manual ZS100T, ZS150T & ZS200T Series II (MAM-870) Senator Industrial Air Compressors

8

1.6 Compressor Controller and Operation Panel

The compressor micro-computer controller configured in the unit as well as its

supporting operation panel is the integrated controller covering the operation control

and protection, temperature indication and protection, phase-sequence protection, motor

protection, pressure control, operation record and so on.

To ensure normal operation of the unit, the user should be familiar with the functions

and meanings of individual buttons, display windows and indicating lights on the

controller and operation panel, and have the proper decision on the indicated parameters

and signals.

Please refer to the separate MAM-870 Compressor Controller Operation Manual.

Instruction Manual ZS100T, ZS150T & ZS200T Series II (MAM-870) Senator Industrial Air Compressors

9

Fig. 1-5 Electrical Schematic Diagram of ZS100T Series II

Instruction Manual ZS100T, ZS150T & ZS200T Series II (MAM-870) Senator Industrial Air Compressors

10

Fig. 1-6 Electrical Schematic Diagram of ZS150T and ZS200T Series II

Instruction Manual ZS100T, ZS150T & ZS200T Series II (MAM-870) Senator Industrial Air Compressors

11

Chapter 2 Installation

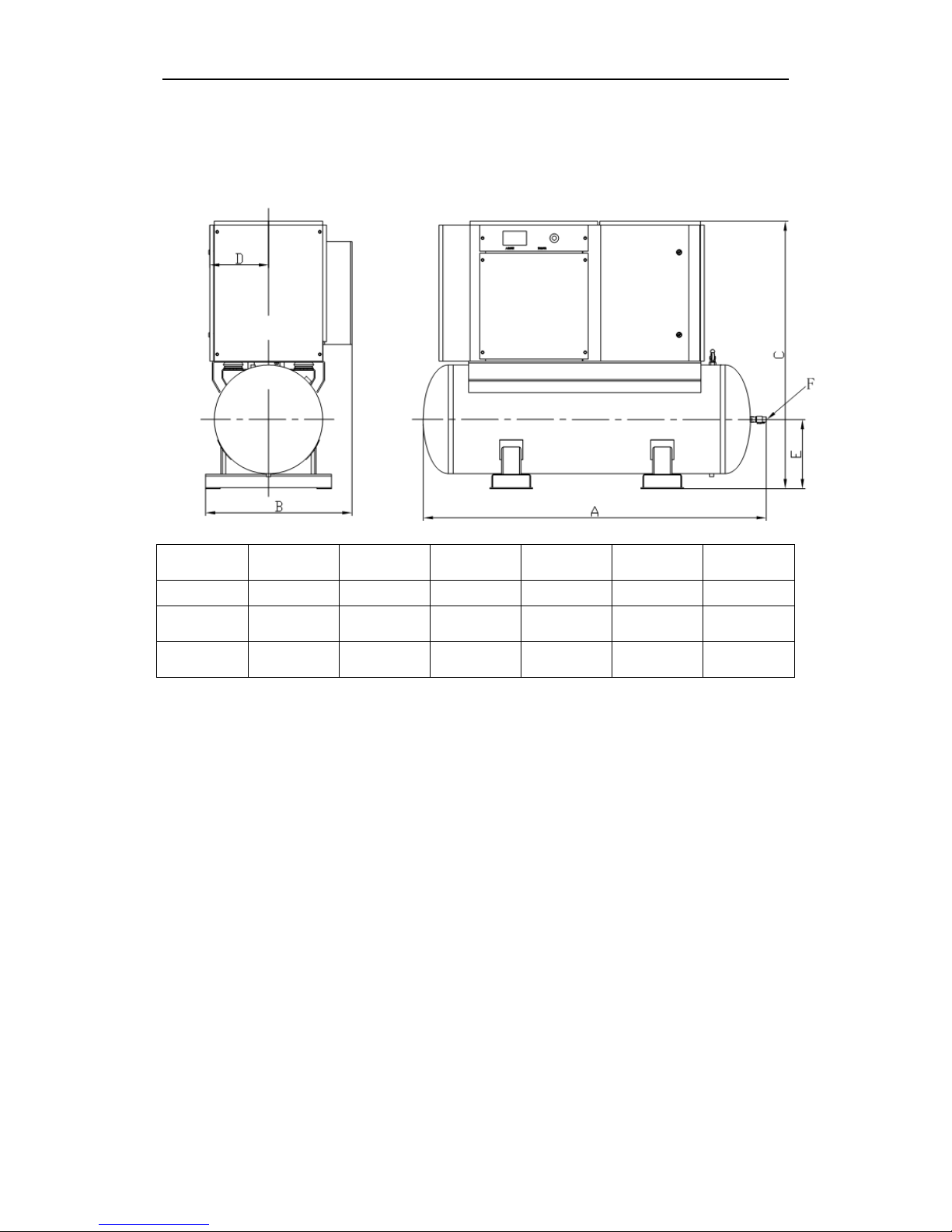

2.1 Outline Dimensions

Model A B C D E F

ZS100T

1,730

700

1,220

280

305

1″ BSP

ZS150T

1,800 760 1,400 310 357 1″ BSP

ZS200T

1,800 760 1,400 310 357 1″ BSP

Fig. 2.1 Outline Dimensions of ZS100T/ZS150T/ZS200T Series II

2.2 Installation Site of Compressor

A proper installation site should be selected for the compressor. It is recommended to use

a dedicated compressor room. The installation site should meet the following

requirements:

a. It is essential to install the compressor in an area with good lighting and sufficient

free space for unhindered operation and maintenance. The compressor should have

a distance no less than 1 m away from its surrounding walls and ceiling.

b. Good ventilation should be provided and proper heat radiation facility should be set

to ensure that the indoor ambient temperature is not above 40°C. It is

recommended to fit the hot air duct for heat radiation. The air draft volume of fan

should be higher than the air discharge flow of the cooling fan of the compressor.

c. The ambient air should have low relative humidity, low dust content and no acid or

alkali corrosive gas content. If the air quality fails to reach the requirement, then it

Instruction Manual ZS100T, ZS150T & ZS200T Series II (MAM-870) Senator Industrial Air Compressors

12

will be necessary to guide the air entry of compressor to a place with clean air or to

install pre-filtration equipment.

d. The compressor should be placed in a horizontal position on solid and flat ground to

avoid vibration occurring to the compressor due to poor ground condition. The use

of flexible vibration isolators underneath the mounting feet is highly recommended

and will reduce noise emissions.

2.3 Electrical Safety Requirements

a. The 3-phase mains power supply voltage should be stabilized to 415 V. A separate

supply circuit is recommended for the compressor to avoid motor current overload

due to excessive voltage drop or unbalanced 3-phase caused by other electrical

equipment operating in parallel.

b. The power supply cable diameter should be properly selected in accordance with

local regulations. Do not use an undersized cable.

c. Make sure that the connected power supply is consistent with the rated voltage of

the motor of compressor.

d. According to the power of the compressor, the necessary short circuit protection and

other safety devices such as breaker switch, etc. should be installed in front of the

lead-in power supply cable of the compressor.

e. It is essential to connect the compressor to a secure grounding (earthing) line,

preventing the hazards due to electricity leakage. Do not connect the compressor ’s

earth wire to the compressed air pipeline.

Instruction Manual ZS100T, ZS150T & ZS200T Series II (MAM-870) Senator Industrial Air Compressors

13

Chapter 3 Operation

Before compressor start-up, the operator should thoroughly read this manual. They should

strictly follow all related safety regulations including the related contents specified in the

manual and expertly master the related characteristics of the unit and its operation methods.

3.1 Initial Start-Up

a. Loosen the transport supports or bolts connected to air tank on the mounting plate of the

unit.

b. Connect the power supply cord and the grounding line. Check whether the voltage is

correct and the 3-phase voltage is balanced.

c. Check whether the electrical wiring is safe, secure and reliable.

d. Check whether the oil level in the oil-air tank is in a proper position.

e. Check whether the V-belt tension is correct.

f. Before initial start-up or restarting after 3-6 months long-term shutdown, add 0.5-1.5 L

of compressor lubricating oil into the compressor through the air inlet valve and rotate

the screw air end for several turns by hand. This is to prevent friction/heat damage to

the screw air end due to insufficient lubrication upon start-up.

g. At the first power-on, the power supply light will be lit and the current temperature will

be shown on the panel. Caution: If the phase of power supply is inconsistent, the

LCD window will indicate ‘wrong phase sequence’. At this point, any two phases of

power supply cable should be interchanged to correct the phase sequence.

h. Open the air tank discharge valve.

i. Rotation direction test: Although the unit has reverse phase protection measure, the

rotation direction test is still an important step in the initial start-up. It should be

repeated additionally after the motor is repaired or replaced.

j. Press ‘ON’ to start the compressor to rotate, and immediately press the ‘Emergency

Stop’ button. Make sure that the rotation direction of the compressor is consistent with

the arrow direction on the air end. If it is incorrect, just interchange any two phases of

power supply cables. The rotation direction of fan motor should be checked as well;

the cooling air should discharge upwards from the exhaust duct at the rear of the unit.

k. Restart the compressor. The unit will automatically turn to the star-delta starting

process. Close the valve at the air tank discharge to allow the discharge pressure to

rise, until the unit starts unloading. Check whether the unloading pressure is consistent

with the setting, and observe whether the indicating meters and lights are normal at the

same time. If any abnormal sound, vibration or leakage occurs, immediately press the

‘Emergency Stop’ button to shut down the machine for maintenance.

Instruction Manual ZS100T, ZS150T & ZS200T Series II (MAM-870) Senator Industrial Air Compressors

14

l. Shutdown: Press ‘OFF’ shutdown key, and the unit will turn to the shutdown

procedure. At first, the light/heavy-load solenoid valve will reduce the power, the

compressor vent valve will discharge the air, and the inlet valve will be shut off for

unloading. After several seconds, the motor will stop.

Caution: During normal operation, do not use the ‘Emergency Stop’ button for

shutdown.

3.2 Daily Operation

3.2.1 Start-Up

a. Open the screw-plug and ball valve at the oil discharge outlet of oil separation tank to

drain out the condensate settling down on the lowest part of oil-air tank after shutdown.

Immediately close them when the lubricating oil flows out.

Caution: Before opening the water drainage and oil discharge outlet in the oil

separation tank, always check that there is no air pressure inside it.

b. Open the ball valve underneath the air receiver tank to drain out all water condensate

and then close the valve afterwards.

c. Open the discharge valve on the air tank.

d. Turn on the power supply and operate the compressor’s peripheral equipment such as a

compressed air dryer.

e. Press the ‘ON’ button to start the compressor. Please note whether the compressor

operates normally with the direct on line or Y-Δ switching time, operating noise, etc.

Check the discharge pressure, lubricating oil pressure, air discharge temperature, and

complete the related records.

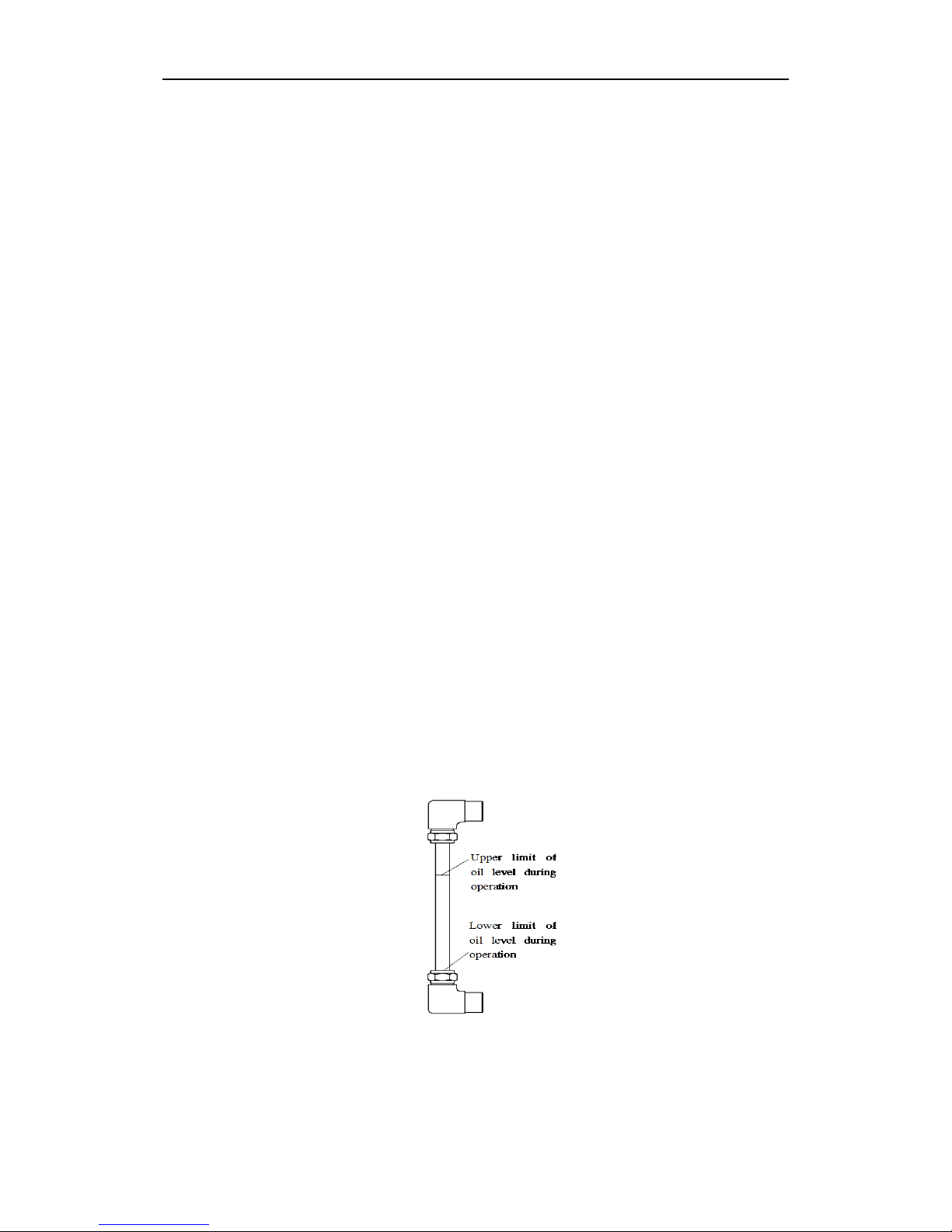

Fig. 3-1 Oil Level Indications

f. After the operation becomes stable, check the oil level. If the oil level is lower than or

close to the ‘lower limit of oil level during operation’ in Fig. 3-1, then shutdown the

Loading...

Loading...