Glendo 004-895, GraverSmith Operation And Maintenance Manual

NOTICE

This engraving system requires clean, dry, oil-free air. An oil-free compressor is

recommended for use with this system. For any oil‑type compressors, an oil‑removal lter

(coalescing type) in the air supply line to this engraving system MUST BE INSTALLED AND

IN USE.

OIL OR WATER CONTAMINATION

IS NOT COVERED

BY WARRANTY.

For help with ordering or installing an oil‑removal lter, or for guidance with operation or

maintenance, please call GRS Technical Support at 800-835-3519 or +1-620-343-1084.

To send a request for assistance via electronic formats, e-mail support@glendo.com or visit:

http://www.grstools.com/customerservice/

Important notes are highlighted in yellow or marked in red.

GraverSmith™

OPERATION AND MAINTENANCE MANUAL

#004-895

ORIGINAL INSTRUCTIONS

READ THIS MANUAL ENTIRELY

BEFORE CONNECTING TO POWER.

Damage not covered by the warranty may result from not

following the instructions and maintenance in this manual.

Manual Contents

Important Notice For Operators ...........................1

Required Equipment & Important Notes .....................2

Introduction, Operation Note ..............................4

Setup & Connections ....................................6

Mount & Connect Air Filter, Connect Foot Throttle, Connect Handpiece(s),

Connect Electrical Power

Operation .............................................8

Strokes Per Minute (SPM), Fine Adjustments for Handpiece Operation,

Handpiece Adjustment Troubleshooting, Foot Throttle Operation,

Handpiece Operation

Maintenance .........................................12

Handpiece, Foot Throttle

Important Notices .....................................13

GRS Progressive Foot Control Owners, Air Contaminants & Water

Accumulation

Service & Repair ......................................14

Parts Lists ...........................................15

Wiring, Hose Diagrams .................................20

Warranty .....................................Back Cover

READ THIS MANUAL ENTIRELY

BEFORE CONNECTING TO POWER.

Damage not covered by the warranty may result from not

following the instructions and maintenance in this manual.

1

FOR PROPER OPERATION, THIS SYSTEM REQUIRES:

• Included 24-volt power converter connected to a properly grounded electrical

power outlet

• Clean, dry, oil-free air provided by an air compressor

• A compatible GRS pneumatic handpiece

• A graver or similar tool

• A clean, sturdy work surface with adequate lighting

• Workholding device or material

IMPORTANT NOTICE FOR OPERATORS

Read this manual thoroughly before operation. The manufacturer is

not responsible for injury resulting from improper operation or when

used by untrained operators.

Do not modify this equipment or remove warning labels. Modi cations

can increase risks to the operator. Do not use this equipment if it is

damaged. This equipment allows the use of small sharp cutting tools

that can break suddenly. Always wear eye protection appropriate for

each application, and protect hands from sharp edges.

Like other power tools, this device exposes the operator to

mechanical vibration. If any user experiences discomfort, pain,

numbness, aching, etc., in their hands, ngers, arms, or related joints,

discontinue use and consult with an appropriate health professional.

Although this equipment does not generate dust itself, the tools used

in the handpieces may do so. When sharpening tools, the user should

take appropriate steps to avoid dust inhalation. Certain tool materials

generate harmful dust while being ground or sharpened.

The proper use of this equipment does not generate signi cant or

harmful noise emissions.

2

• Included 24-volt power converter

USE ONLY THE SUPPLIED 24-VOLT POWER CONVERTER. The included power

converter may be connected to any properly grounded single-phase source of

AC power within a voltage range of 100 to 240 V, 50 or 60 Hz. If necessary, use

the supplied grounded 2-prong plug adapter or other suitable adapter. The power

converter must be used with a suitable grounded electrical system. Using it with an

ungrounded system could expose the equipment to electrical damage. Do not use

older generation power converters. If a replacement is needed, contact GRS or an

authorized GRS dealer to order #022-987.

DO NOT OPERATE THE MACHINE WITHOUT A COMPRESSED AIR SUPPLY.

Compressed air not only provides the handpiece with power, it lubricates internal

components including the rotary air valve. Do not add oil or any lubricant to the

compressed air supply.

•

A compatible GRS pneumatic handpiece

All GRS Standard Handpieces (and GRS Airtact Handpieces with an attached

Airtact Control System) are compatible with this system. DO NOT USE SYSTEM 3

OR GRAVERMEISTER HANDPIECES. Please contact GRS or an authorized GRS

dealer for a complete list of compatible handpieces.

•

A graver or similar tool

A properly sharpened graver or similar tool is required to cut through the surface of

metal and other materials; use with care. The dust created while sharpening some

tool materials may present a health risk. Please contact GRS or an authorized GRS

dealer for a list of available gravers and tools.

READ THIS MANUAL ENTIRELY

BEFORE CONNECTING TO POWER.

Damage not covered by the warranty may result from not

following the instructions and maintenance in this manual.

REQUIRED EQUIPMENT & IMPORTANT NOTES

3

• Clean, dry, oil-free air from an air compressor

Oil-free compressors are ALWAYS RECOMMENDED. When using an oil-lubricated

compressor, install an oil‑removal lter (coalescing type – GRS #004‑579 or

equivalent) in the air supply line to this engraving system. Damage due to oil or

water contamination IS NOT COVERED BY WARRANTY. Even slight amounts of

oil can damage internal parts and cause erratic handpiece operation. The supplied

nal lter is not capable of removing large amounts of water, oil, or contaminants.

See Setup & Connections for mounting the supplied air lter to engraving system.

If compressed air supply has excessive water, oil, or contaminants, an additional

lter/water trap and oil‑removal lter (coalescing type) must be installed ahead of

the engraving system.

GraverSmith™ requires a compressed air supply with minimum pressure 45 psi (3

bar) and maximum pressure 120 psi (8 bar). The compressed air supply must have

a minimum fl ow capacity of 1.4 CFM [ft³/min] or 40 LPM [L/min]. To ensure a stable

compressed air supply, the user should consider an additional air regulator to

adjust the air pressure to 45-60 psi (3-4 bar) before it enters the GraverSmith™.

•

A sturdy surface with adequate lighting

Make use of a heavy workbench or suitable solid furniture to support this

equipment, workpiece, and any additional equipment and supplies. Adequate

lighting allows clear sight, and may help prevent accidents and reduce fatigue.

Placement of this engraving system on the bench is solely user preference and

may be determined by left or right hand use during operation.

•

Workholding device or material

For best results, using a workholding device or material is highly recommended.

Properly secure the workpiece to ensure user safety and to guard the piece from

damage while working. GRS manufactures several sizes and types of workholding

devices, such as the MagnaBlock, Positioning Vise, MicroBlock vise, Thermo-Loc

material, and the BenchMate™.

REQUIRED EQUIPMENT & IMPORTANT NOTES (continued)

DO NOT OPERATE ENGRAVING SYSTEM

WITHOUT AN ACTIVE AIR SUPPLY CONNECTED.

The air supply lubricates the rotary valve as the air passes through the

system. No additional lubrication is required.

4

FIG. 1 • GraverSmith™ Overview

Front View

Back View

A

B

C

D

I

G

G

H

H

F

E

J K

5

INTRODUCTION

The GraverSmith™ is an engraving system engineered and manufactured under the

GRS Tools line of products by Glendo Corporation in the United States of America. This

system is designed for assistance in creating unique works in metal, stone, wood, ivory,

and many other materials.

OPERATION NOTE

IMPORTANT

NEVER OPERATE WHILE ON SIDE. Always use the system in a vertical

position (FIG. 1).

GraverSmith™ FIG. 1 Diagram

A. Rugged plastic carrying handle

B. Power on/off button

C. Strokes Per Minute (SPM) dial

D. Primary air pressure gauge

E. Standard Handpiece push-to-connect fitting

F. Air supply input push-to-connect fitting

G. Air filter

H. Air filter bowl drain knob

I. Air filter output push-to-connect fitting

J. Air filter input push-to-connect fitting

K. Foot Throttle push-to-connect fitting

6

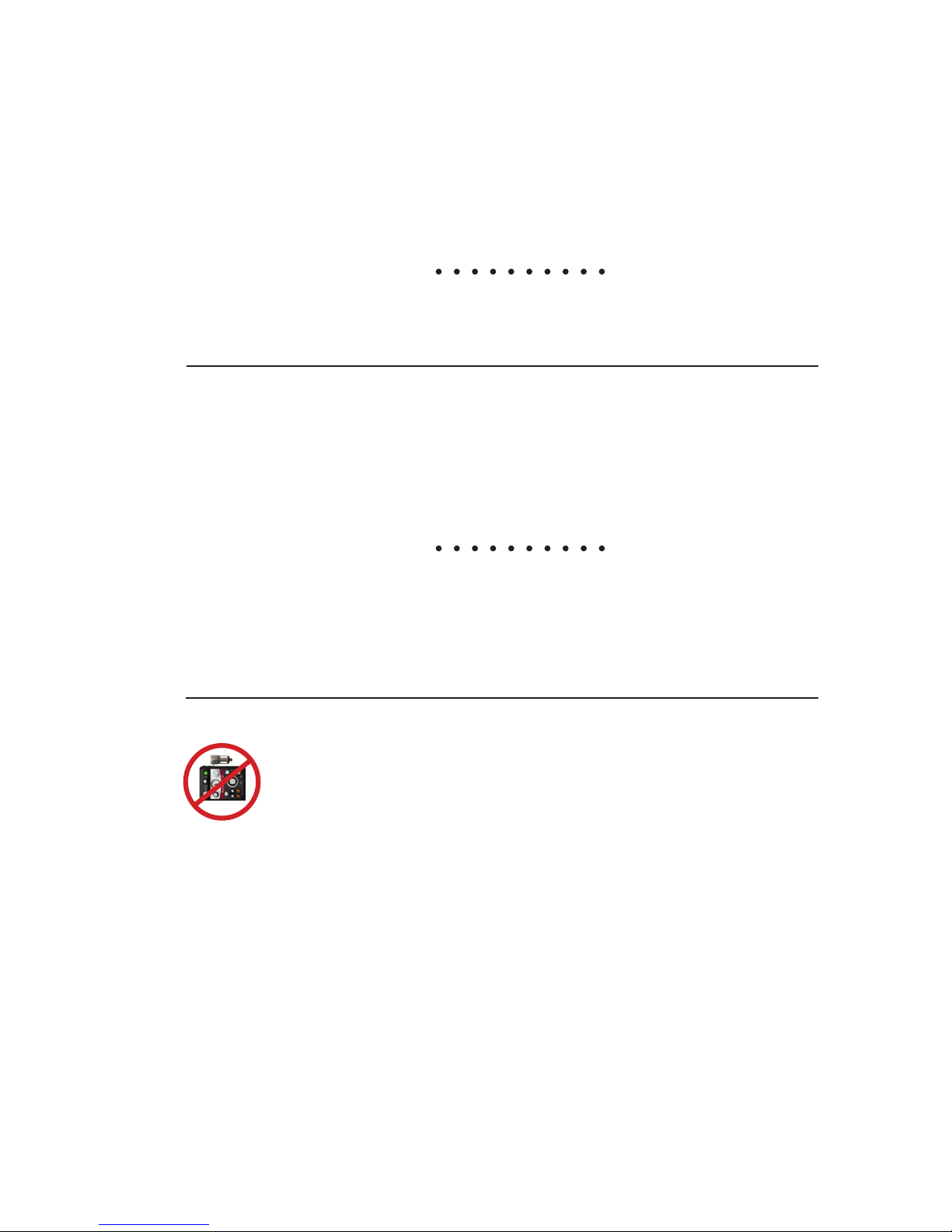

A

C

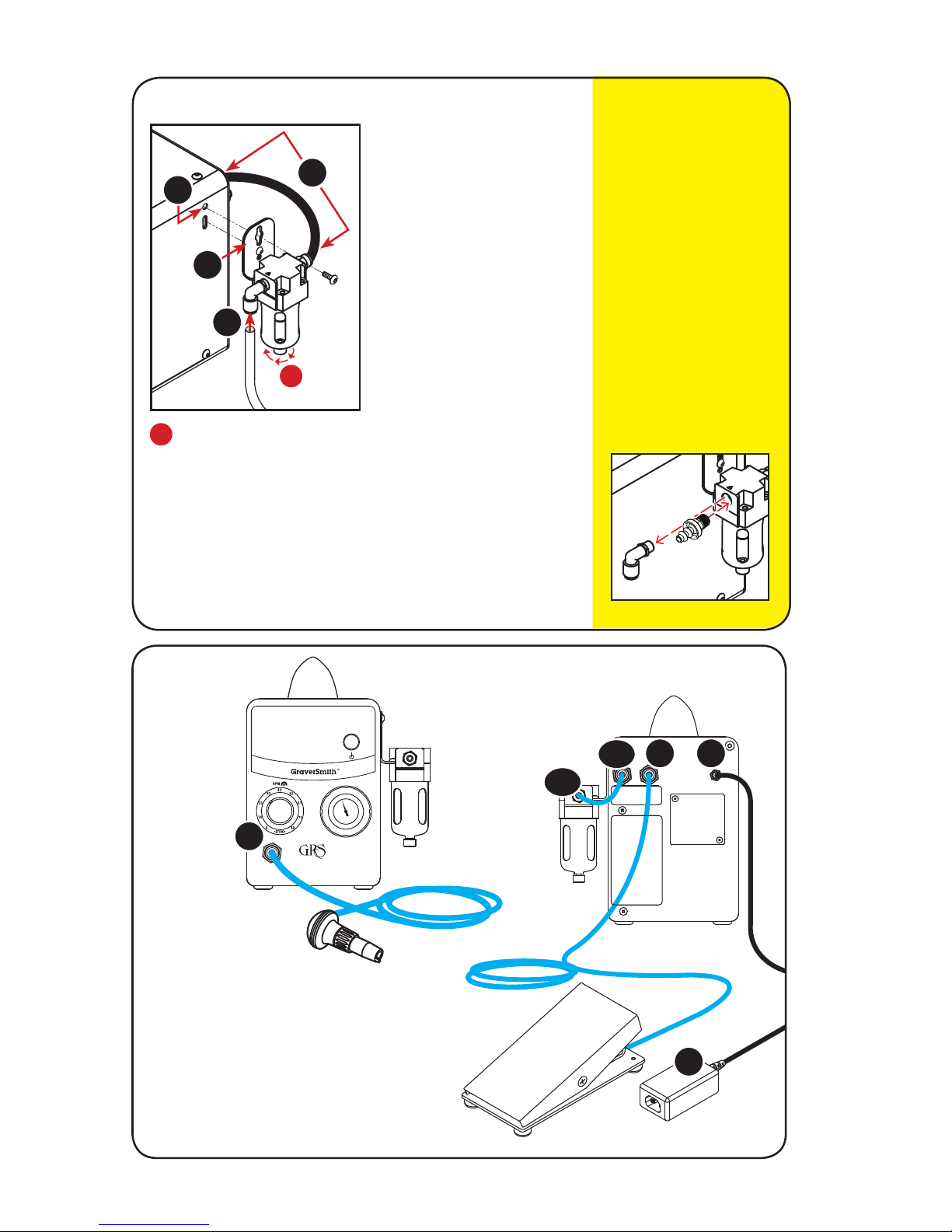

FIG. 3 • Hose

Connections

D

E

1. Remove top screw from hole.

2. Place screw through top hole

on air fi lter bracket. Tighten

screw. Lower screw keeps

fi lter from swinging freely; do

not tighten or remove.

3. Power off system and air

supply. Connect supplied

short black hose (#044-229)

to straight fi tting on fi lter.

Connect other end to “Air

Input” fi tting.

To mount elsewhere, use

supplied longer black hose

(#044-069) — see page 18.

4. Connect hose from air supply

to fi lter fi tting marked “N”.

FIG. 2 • Mounting Air Filter to Side

7

9

6

10

1

3

4

Air Filter

Knob

Drain water from fi lter

daily. Turn knob clockwise

(from top view) to open.

Drain. Turn knob counterclockwise to close valve.

A

A

Turn Clockwise

2

NOTE: If air supply

hose is larger than

1/4" (6.35 mm) OD,

either replace the

push-to-connect

tting with the

included barbed

tting and attach the

air supply hose or

purchase a reducer

to decrease the OD

to 1/4" (6.35 mm).

A. Standard Handpiece fi tting

B. Air fi lter fi ttings

C. Foot Throttle fi tting

D. 24-V power converter receptacle

E. 24-V power converter (#022-987)

B.2

B.1

Loading...

Loading...