Glendinning HOSEMASTER MODEL-S, HOSEMASTER MODEL-D Installation & Operation Instructions

HOSEMASTER MODEL-S™&MODEL-D™

INSTALLATION&OPERATION INSTRUCTIONS

∆ NOTE: Hosemater Model-S™ or Model-D™ not a pproved for potable water applications ∆

BEFORE INSTALLING THE HOSEMASTER MODEL-S™ OR MODEL-D™:

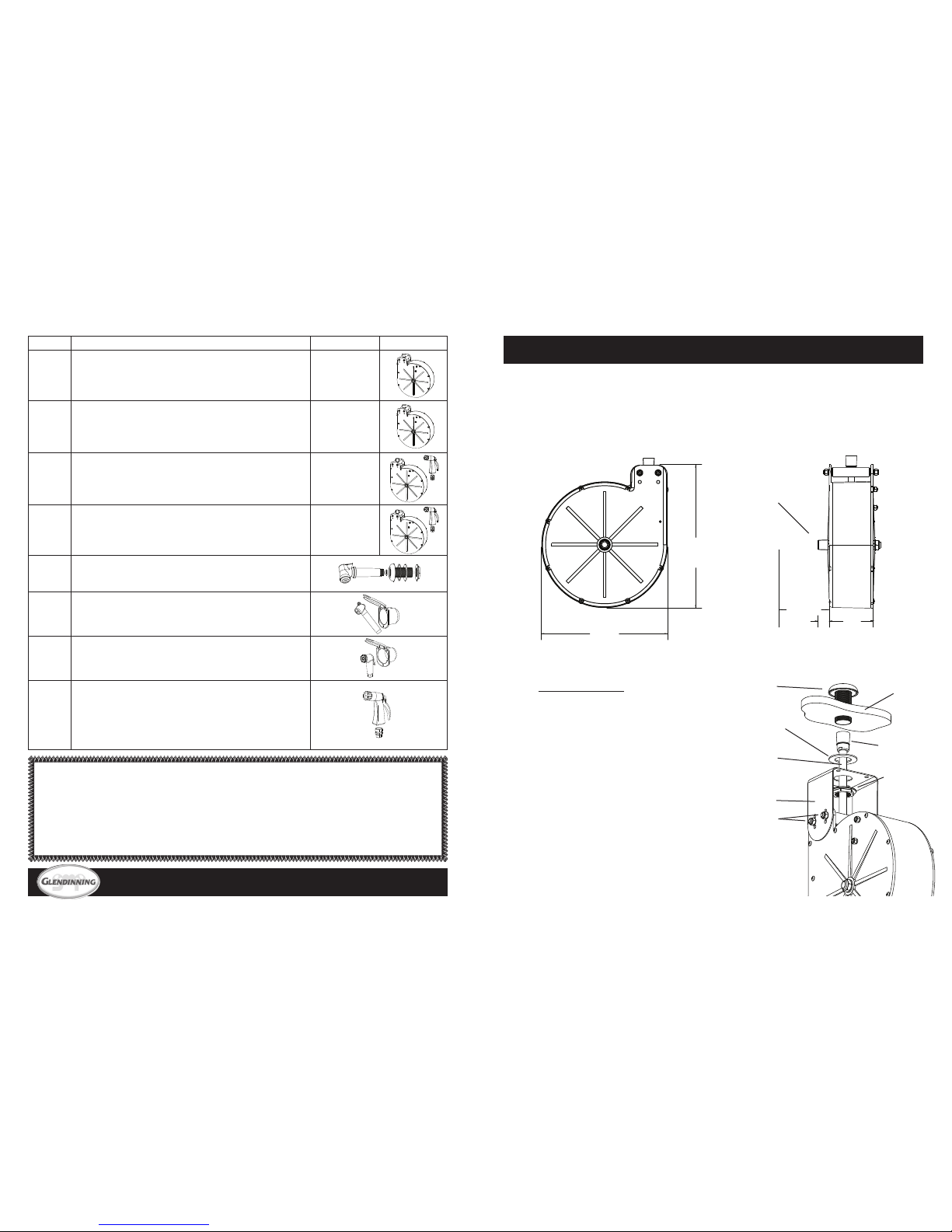

Careful consideration should be given to where the sprayer nozzle will be installed. Determine if sufficient space isavailable below the sprayer nozzle

where the base unit will beinstalled. MAKE SURE to allow a minimum of 1.60” space on the 1/2” NPToutlet side of the unit for the installation of water

connection hardware to the Hosemaster Model-S™ or Model-D™.

THERE ARE 4 DIFFERENT WAYS TO MOUNT YOURHOSEMASTER MODEL-S OR MODEL-D:

1. U-BRACKET INSTALLATION

(Fig. 1)

The U-Bracket is to be used with the thru-hull deck fitting (PN 99582-DK).

1)Attach the U-Bracket to theHosemaster base unit by placing over the studs

of the roller guide assembly. Attach the lock nuts and washers and tighten.

2) Usinga1.25” bit, drill a hole where you have determined sufficient space is

available for the installation of the Hosemaster.

2) Remove the nut and gasket from the thru-hull fitting and insert thru-hull fitting

into the hole.

3) Pull outalengthof hose and insert the hose throughthe nut, mounting bracket

and the gasket(in that order) onto thehose before inserting hose into thethru-hull

fitting. Thread nut onto thru-hull fitting shaft and tighten.

4) Connect thesprayer attachment onto the sprayer adapterand pull and release

hose to retract length of hose so that sprayer attachment fits into thru-hull fitting.

5) Connecta length of hose fromthe water source tothe 1/2” NPT inlet connector

located on the side of the reel. Hold nut on opposite side when tightening

inlet fitting.

Ø 10.25

[260mm]

11.50

[292mm]

.864

[22mm]

Allow

6.00 [152mm]

for water supply

connection

3.625

[92mm]

Water Connection

hardware

(not included)

Thru-hull

deck fitting

Hose

Fig. 1

U-Bracket

Installation with

thru-hull deck

fitting

Gasket

U-bracket

Nut

Sprayer

Adapter

Deck

lock nuts

740 Centur y Circle • Conway, SC 29526 • P: 843-399-6146 • F: 843-399-5005

www.glendinningprods.com

SML-HMS-INSTAL

LIMITED WARRANTY

PRODUCT(S) COVEREDBY THIS LIMITEDWARRANTY: HOSEMASTER—MODEL-S, MODEL-D

1. GLENDINNINGMARINE PRODUCTS,INC. warrantsto the originalconsumer purchaserthat the Hosemasterwill befree from defectsin materialand workmanship undernormal useand service for aperiod ofone (1) yearfrom

the dateof purchase.

2.This LIMITED WARRANTYapplies todefects inmaterial andworkmanship. Itdoes notapply to chromeplatedor anodizedfinish orto powercable damagecaused by inadequatecable storagearea orinstallation notin accordance

with GLENDINNINGMARINE PRODUCTS,INC. specifications.

3. ThisLIMITED WARRANTYis voidif the producthas beendamaged byaccident or unreasonableuse, neglect,improper installation, orother causesnot arisingout of defectsin materialor workmanship.

4. To obtainperformance of thisLIMITED WARRANTYobligation theoriginal purchasershould contactGLENDINNING MARINE PRODUCTS,INC. forinstructions concerningremoval and shippin g of thedefective component.Upon

compliance ofthe foregoingprocedure allwarranted defects willbe repaired,or at GLENDINNINGMARINE PRODUCTS,INC. option,the complete unitreplaced andreturned tothe consumer, shippingcharges prepaid.

5. GLENDINNINGMARINE PRODUCTS,INC. doesnot assume thecosts ofremoval and/orinstallation of theproduct orany other incidentalcosts whichmay ariseasaresult of anydefect inmaterials or workmanship.

THIS WARRANTYIS INLIEU OF ALLOTHER EXPRESSWARRANTIES. ANYWARRANTY IMPLIED BYLAW INCLUDINGWARRANTIES OF MERCHANTABILITYOR FITNESS,IS IN EFFECTONLY FORTHE DURATIONOF

THE EXPRESSWARRANTIES SET FORTHIN THE FIRST PARAGRAPHABOVE. NO REPRESENTATIVEOR PERSON IS AUTHORIZEDTO GIVE ANY OTHERWARRANTY OR TOASSUME FOR GLENDINNING MARINE

PRODUCTS,INC. ANYOTHER LIABILITYIN CONNECTIONWITH THESALE OFIT’S PRODUCTS.GLENDINNING MARINEPRODUCTS,INC. WILLNOT BELIABLE FORANY CONSEQUENTIALDAMAGESRESULTING FROM

THE USEOR INSTALLATION OFIT’S PRODUCTS.

P/N DESCRIPTION HOSE LENGTH

05550-08-X Hosemaster Model-S™ (Base unit/sprayer optional)

NOTE: must specify type of mounting bracket (U=u-bracket, S=sidebracket,

E=edge bracket)

8 ft.

[2.4 meters]

05550-16-X Hosemaster Model-S™ (Base unit/sprayer optional)

NOTE: must specify type of mounting bracket (U=u-bracket, S=sidebracket,

E=edge bracket)

16 ft.

[4.9 meters]

05551-16-X Hosemaster Model-D™ (Base unit w/ deck wash sprayer&hose adapter fitting)

NOTE: must specify type of mounting bracket (U=u-bracket, S=sidebracket,

E=edge bracket)

16 ft.

[4.9 meters]

05551-18-X Hosemaster Model-D™ (Base unit w/ deck wash sprayer&hose adapter fitting)

NOTE: must specify type of mounting bracket (U=u-bracket, S=sidebracket,

E=edge bracket)

18 ft.

[5.5 meters]

99582-DK Deck sprayer attachment with thru-hull fitting

NOTE: used with U-bracket mounting assembly only.

99582-REC Long sprayer attachment with hatch assembly

99582-SN Short sprayer attachment with hatch assembly

99593 Deck wash sprayer attachment with hose adapter fitting

NOTE 1: The deck wash sprayer attachment isincluded when you purchase the

Hosemaster Model-D™ (PN-05551-XX-X).

NOTE 2: The deck wash sprayer attachment canalso be used with any Hosemaster Model-S™ (PN-05550-XX-X) when purchased separately.

PROBLEMS DURING INSTALLATION

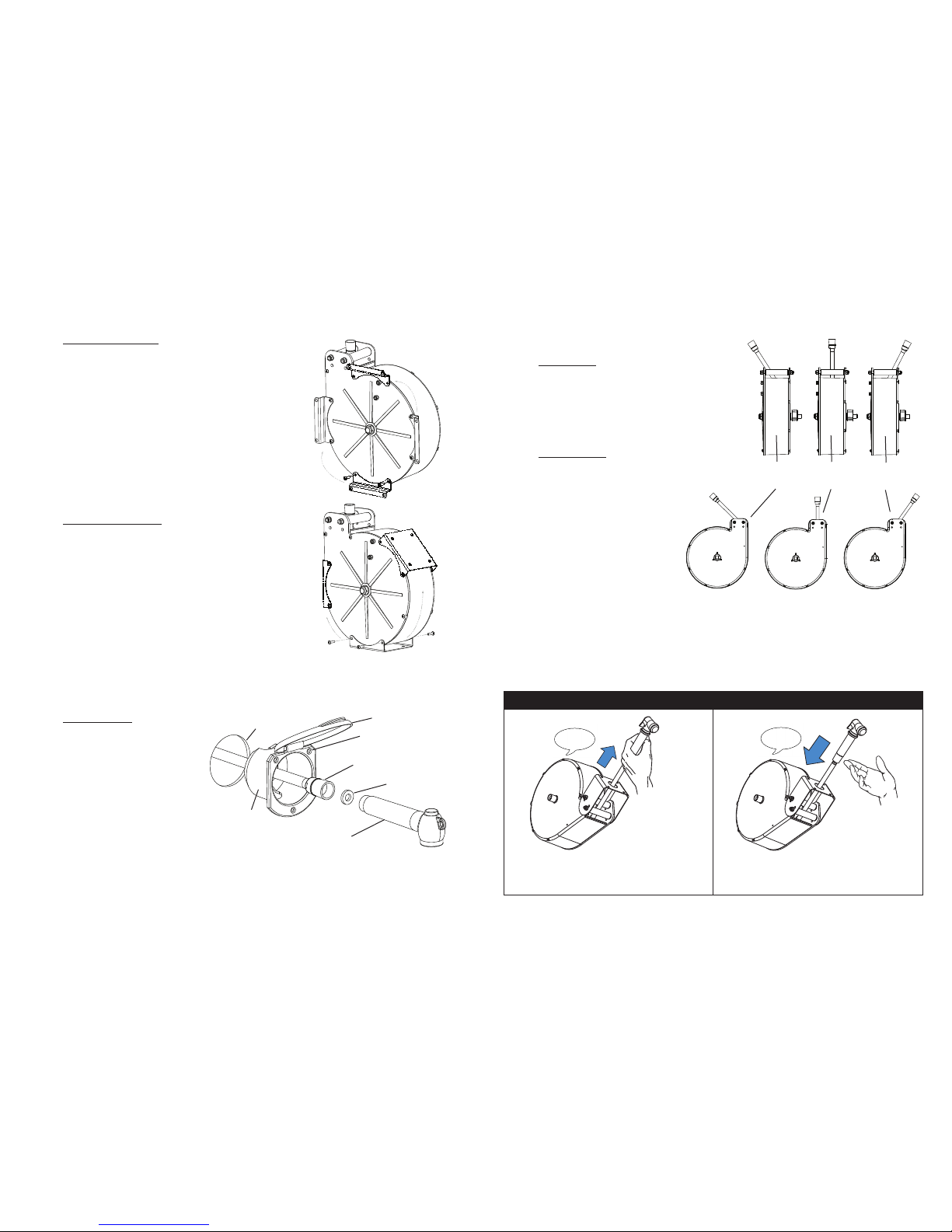

1. HOSE ALIGNMENT

(Fig. 5)

The alignment ofthe hose to the roller guideassembly is crucial

to the pr oper operation of the Hosemaster™. W hen installed

correctly the hoseshould NOT pull to oneside of the roller guide

assembly as shown in the illustrations (right). Installation Aand

C show POOR alignment and should be avoided. Installation B

shows GOOD alignment and is recommended for the best operation of the unit.

2. WATERCONNECTION

(installer provided)

MAINTENANCE

The Hosemaster-Model S™ and Model-D™ are designed for

longevity of operation with very little maintenance required.

• Any difficulty in the extensionor retraction of the hose should

be inspected immediately.Inspect water connections onaroutine basis.

• When winterizing, caution should be taken to prevent freeze damage to Hosemaster-Model S™ or Model-D™.

2. SIDE BRACKET INSTALLATION (Fig. 2)

The side bracketsare used when mountingthe base unit to the ceilingor wall of a storage area.

1) Attachthe side brackets to the Hosemaster base unit asshown in the illustration in

Figure2using the (4) screws provided with the brackets. Tighten securely.

2) Install (4) 1/4 - 20 lock nuts and washers to roller shafts.

3) Depending on theconfiguration of the base unit for your installation,it may be necessary toattach the side brackets inone of the other locationson the side of theHosemaster.As the illustrations depicts, you may rotate the side brackets around the face

of the base unit to achieve the desired mounting location.

4) DO NOTattach the Hosemaster brackets to an exteriorwall. Attach the side brackets to the ceiling or wall of the storage area using (4) #10 screws.

3. EDGE BRACKET INSTALLATION

(Fig. 3)

The edge bracket is used when mounting the base unit to the ceiling, floor,and side

or back wall ofastorage area.

1) Unlike the side bracket installation above, you must install the edge bracket to the

storage space BEFOREattaching the bracket to the Hosemaster.Make sure that you

DO NOT attach the bracket to an exterior wall. Attach the edge bracketto the wall or

ceiling/floor using (4) #10 type screws. Tighten securely.

3) Depending on theconfiguration of the base unit for your installation,it may be nec-

2) Install (4) 1/4 - 20 locknuts and washers to roller shafts.

essary to attachthe edge bracket in oneof the other locations onthe side of the Hosemaster.As the illustrations depics, you may rotate the edge bracket around the width

of the base unit to achieve the desired mounting location.

4. HATCH INSTALLATION

(Fig. 4)

When using the Recessed Hatch Assembly, you will still be required to install the Hosemaster™ using one of the3methods

described above. Two styles of hatch assemblies are available

(PN 99582-REC shownand PN 99582-SN), each hatch assembly will be installed as indicated below.

1) Usinga2.75” bit,drillahole where you have determined sufficient spaceis available for the installationof the recessed hatch

assembly. Insert cup through hole and open cap exposing

mounting screw holes.

2) Using three (3) #10 screws NOT provided, insert into screw

holes inflange and tighten screws againstmounting cup housing

being careful not to break plastic flange with too much force.

3) Pull outalength of hose and insertit through the bottom of the hatch. Connect the sprayer attachment to the hoseinserting rubber washer between

hose adapter and sprayer attachment. Pull and release hose to retract hose so that sprayer attachment fits into the recessed hatch assembly.

4) Make sure cap closes securely.

Cap

2.75” Hole

in Deck

Hose Adapter

Rubber Washer

Sprayer Attachment

Fig. 4

Hatch Installation with sprayer

Hatch Mounting

Screw Holes (x3)

POOR

ALIGNMENT

POOR

ALIGNMENT

GOOD

ALIGNMENT

Fig. 2

Side Bracket

Installation

Fig. 3

Edge Bracket

Installation

Recessed

Hatch Assembly

TO EXTEND THE HOSE:

Pull out sufficient hose length until you hear an audible“click”.

Releasing tension when “click” is heard will lo ck hose length

into place.

TO RETRACT THE HOSE:

Pull hose until NO CLICK is heard and release. Hose will automatically retract (CAUTION—Spray attachment may scratch or

injure surface if left to retract unattended).

OPERATION INSTRUCTIONS

“CLICK!”

NO

SOUND

Fig. 5

Alignment Issues

X

X

X

X

5) Connectalength of hose from the water source to the 1/2” NPT inlet connector located on the side of the reel. HOLD nut on opposite side of inlet fitting

when tightening inlet fitting.

4) Attach the edge bracket to the Hosemaster base unit as shown inthe illustration in

Figure3using the (4) screws provided with the bracket. Tighten securely.

When determining where you will mount the Hosemaster™,

ample space must beprovided on the water connection side of

the unit. Thedimensional drawing on page1shows aminimum

of 1.60” required for the addition of the water connection hardware (not provided with unit).

HOLD nut on opposite side of inlet fitting when tightening inlet

fitting.

5) Connectalength of hose from the water source to the 1/2” NPT inlet connector located on the side of the reel. HOLD nut on opposite side of inlet fitting when

tightening inlet fitting.

Loading...

Loading...