Page 1

GT 755 - GT 756

Slot-in Natural Gas Double Cavity Cooker

INSTALLATION AND USER INSTRUCTIONS

Note:

These appliances are supplied for use with the category of gas specified

(Natural Gas I2H) and cannot be converted to any other gas.

Page 2

Contents

Introduction

Installing Your Cooker

For your own safety - Never

Know your Cooker / Specification

............................................................................................................................................

....................................................................................................................

...............................................................................................................

-Always

....................................................................................................

...............................................................

Using the Timer (GT 756)

3 Button LED Clock/Minute Minder

Minute Minder Operation

Know your Control Panel

...................................................................................................................

...................................................................................................................

..................................................................................................

Using the Hob

General Notes on Safety

.......................................................................................................................

The Hob Glass Lid / Burner operation / Advice on pan suitability

Energy Saving Tips

Safety Requirements for Deep Fat Frying (IMPORTANT)

............................................................................................................................

.............................................................

Safety advice in case of a chip pan fire / Choosing your utensils

Using the Grill

GT 755 & GT 756 Grill Operation

Grilling Guidelines / Use of the Grill Pan Handle

Using the Ovens

.......................................................................................................

............................................................................

..............................................................

Shelf Positions/Use of the Ovens/Oven Lamp Operation (GT 756)

Temperature Conversion

Main Conventional Oven Cooking Guide

Top Conventional Oven Cooking Guide (GT 756)

Care and Cleaning/Replacing the Oven Lamp

Something Wrong With Your Cooker

Customer Care

.....................................................................................................................

.................................................................................................................

..........................................................................................

...........................................................................

..........................................................................

..............................................................................................

.....

..............................................

...............................................

..............................................

21-22

Back Cover

4-8

10

11

12

12

13

14

14

15

15

1

16

17

18

18

19

20

20

20

23

3

9

6

This appliance conforms to the following EEC Directives:

Gas Appliance Directive:EN 30

Low Voltage Directive:73/23/EEC

93/68/EEC

Electromagnetic Compatibility:-

89/336/EEC

92/31/EEC

93/68/EEC

2

Page 3

Introduction

0844 815 3746

Your Belling

Cooker

Getting Help

Thank you for purchasing a new Belling GT 755 & GT 756 Gas Cooker.

It's stylish and practical design will enhance your kitchen and make cooking a

pleasure.

The GT 755 model features a conventional main oven, a grill and a hob with 4

gas burners.

The GT 756 model features a conventional main oven with light, a top conventional

oven/grill, a hob with 4 gas burners and a clock/minute minder.

Even if you have used an electric or gas cooker before, it is important that you

read these instructions thoroughly before starting to cook, paying particular

attention to the installation and safety instructions.

If you have any problems with installing, operating, or cooking with your

Belling Cooker, please check through these instructions thoroughly to make

sure that you have not missed anything. If you still need help, then please

contact (including a daytime telephone number if possible):

Belling Customer Care Centre

Stoney Lane

Prescot

Merseyside

L35 2XW

Tel: 0871 22 22 503

Please quote the cooker model and serial number with all enquiries.

This can be found on the rating plate on the plinth below the main conventional

oven.

WARNING! For your own safety, make sure that these instructions on

installation, use and maintenance are followed.

We advise you to keep these instructions in a safe place for future reference.

If you sell or transfer ownership of this product, please pass on these instructions

to the new owner.

3

Page 4

Installing your cooker

Unpacking

After unpacking your cooker, make sure that you remove all the

packing from the ovens and grill, and any stickers from the oven

doors and hob.

Examine your cooker. Make sure there is no damage or missing items.

If there is anything damaged or missing, please contact your supplier for advice.

Sitting/Moving

the Cooker

Prior to installation, ensure that the local distribution conditions (nature of the

the Cooker gas and gas pressure) and the adjustment conditions are compatible.

The adjustment conditions for this appliance are stated on the rating label, which

is fitted on the plinth.

This appliance is not designed to be connected to a combustion products

evacuation device. It must be installed and connected in accordance with current

installation regulations. Particular attention should be given to the relevant

requirements regarding ventilation.

Gas

installation

The appliance is factory set for use with Natural Gas ONLY G20 at 20mbar.

It

is not convertible to any other gas.

Gas Safety (Installation and Use) Regulations

It is the law that all gas appliances are installed by competent persons in

accordance with the current edition of the above regulations. It is in your interest and

that of safety to ensure compliance with the law.

In the UK, CORGI registered installers work to safe standards of practice.

This appliance must be installed and connected in accordance with current installation

regulations. Failure to install the cooker correctly could invalidate the warranty liability

claims and could lead to prosecution.

Location

Levelling

Provision for

Ventilation

The cooker may be located in a kitchen, kitchen/diner or a bed-sitting room, but not in a

room containing a bath or shower. The cooker must not be installed in a bed-sitting room

of less than 20m

2

.

The appliance should be located on a level surface. The front/rear feet can be

adjusted to a maximum height of 910mm as required. To ensure that your appliance

is standing level, adjust the rear feet by turning clockwise or anticlockwise until

the rear of the product is set to the required height. Position the cooker in the

correct location and adjust the front feet by turning clockwise or anticlockwise to

ensure firm contact with the floor. Check the cooker is level using a spirit level

(Not provided). Adjust if necessary.

The room containing the cooker should have an air supply in accordance with

current regulations in force.

The room must have an opening window or equivalent; some rooms may also

require a permanent vent. If the room has a volume between 5 and 10m3, it will

require an air vent of 50 cm

2

effective area unless it has a door which opens

directly to outside. If the room has a volume of less than 5m3, it will require an air

vent of 100 cm2 effective area. If there are other fuel burning appliances in the

same room, current regulations should be consulted to determine air vent

requirements.

4

Page 5

Space for

Fixing

THIS APPLIANCE MUST NOT BE INSTALLED ON A NON-FIXED RAISED

BASE.

To ensure that critical air gaps are maintained under the product, we recommend

that this product is mounted on a solid base and that the feet do not sink into any

carpet or soft flooring.

The cooker is designed to slot between standard kitchen units spaced a

minimum 500mm apart. The clearance either side need only be sufficient to

allow the cooker to be withdrawn for servicing.

It can be used with cabinets on either side but for a minimum distance of 400mm

above hotplate level allow a side clearance of 60mm between the appliance

and any wall, partition or tall cupboard. It can also be used in a free standing

position.

Allow a minimum distance of 750mm from the hob surface to the underside of

any overhead combustible surface such as overhanging cabinets.

Your cooker is heavy, so be careful when moving or positioning it. Do not try

to move the cooker by pulling on the doors or handles.

To avoid damage to surrounding units a 10mm gap should be left between

the appliance and the units. If this is not possible, a kit (part number 01 25552 00)

may be ordered from Customer Care which will protect the units.

For models with side opening doors, we recommend a side clearance of 60mm

between the cooker and any side wall to allow the door to be opened fully.

WARNING

Connecting to

Whatever the position, remember to leave enough room for the cooker to be

pulled out for cleaning and service.

Movement of your cooker is most easily achieved by lifting the front as follows

and pulling forwards. Open the Grill door and the Conventional Oven door

sufficiently to allow a comfortable grip on the underside front edge of the oven

roofs, avoiding any grill elements or oven interior furniture. Take care not to

damage any floor coverings.

If a cooker hood is to be fitted, refer to the manufacturer's instructions regarding

fixing height.

r

=

65 mm Min

o.

The use of a gas cooker results in the production of heat and moisture in the room in which

it is installed. Ensure that the kitchen is well ventilated; keep natural ventilation holes or install

a mechanical ventilation device (mechanical cooker hood)

Prolonged intensive use of the appliance may call for additional ventilation, for example

opening of a window, or more effective ventilation, for example increasing the level of mechanical

ventilation where present.

This appliance is designed not to project in front of standard 600mm

750 mm Min

_ 500 mm Mm

_ 65 mm Min

5

Page 6

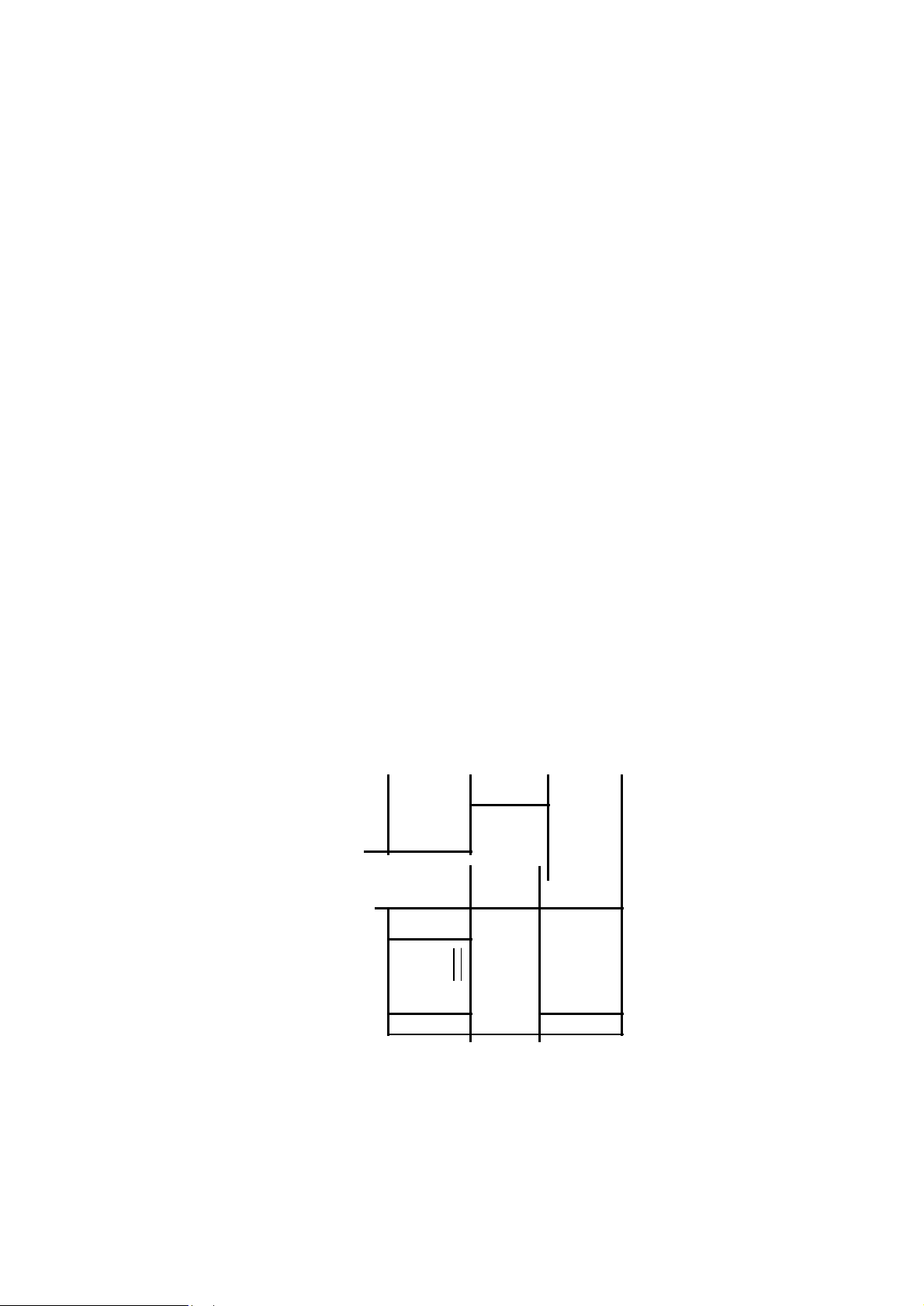

Gas Supply

worktops (excluding handles). To achieve the best fit the cooker must be pushed against the

wall. If the wall mounted adapter backplate (Fig.1) is to be fitted behind the appliance then

the suitable area for this fitting is shown as the area in (Fig.2).

The temperature rise of areas at the reara of the cooker that are likely to come into contact

with the flexible hose do not exceed 70°C. However, do not allow contact of the hose in the

top 150mm/6 inches (the shaded area shown in Fig.3).

A Rp 1/2 union is fitted to the cooker. Connection to the appliance should be made with an

approved appliance flexible connection to BS669. The length of the hose should be such that

when the cooker is in situ, it does not touch the floor.

Stability Chain

Flame Failure

Device

Flame

failure

device

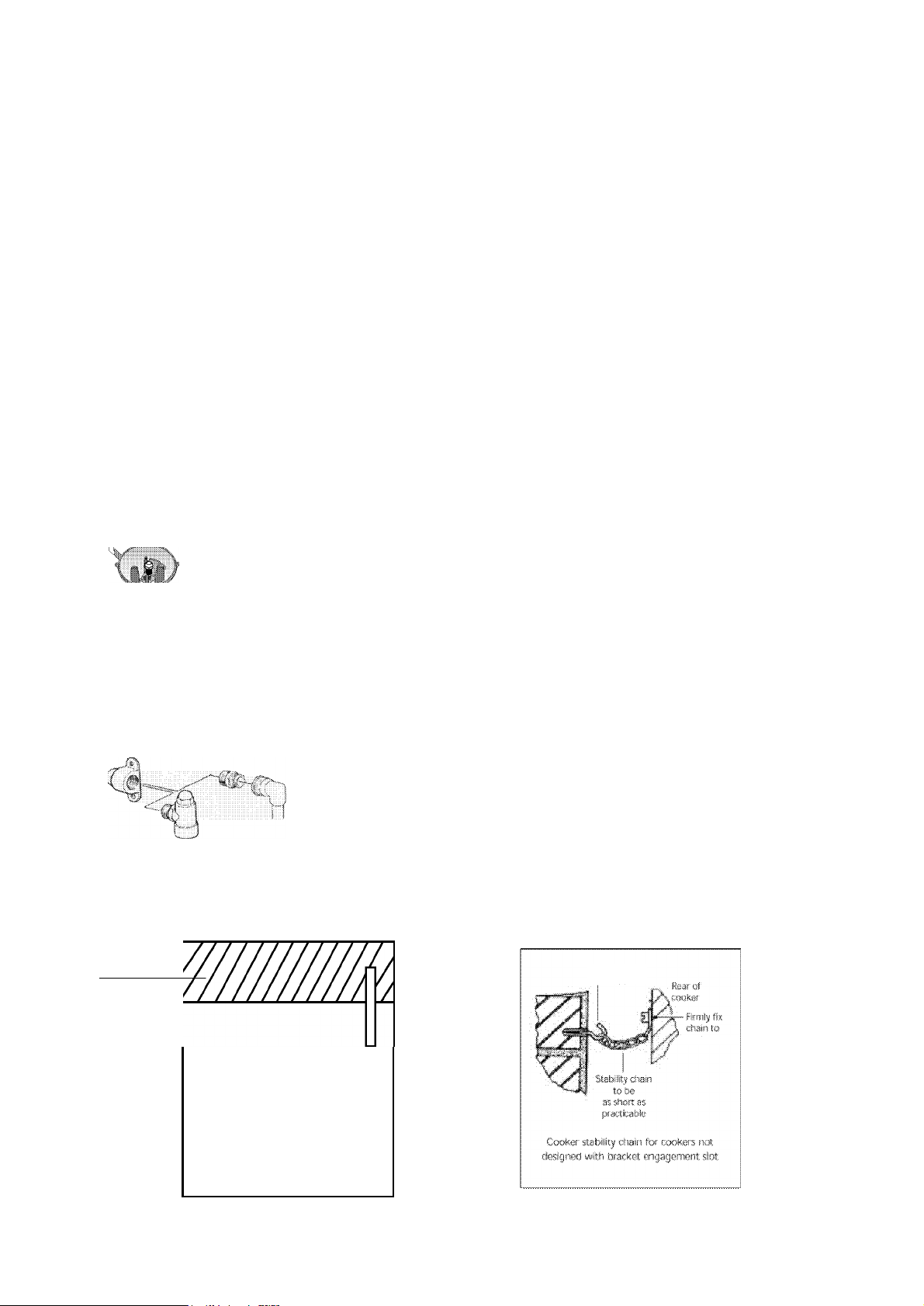

Fig.1

The cooker must be secured by a security chain to the wall or partition behind the cooker.

(Fig.4)

All burners are protected by flame failure devices, if the flames are extinguished for any reason

the gas will automatically be cut off.

The burner control knobs have a safety feature.

1

Push the appropriate knob in slightly and turn anti-clockwise to the required setting.

2

While keeping the knob depressed press the ignition button. /4;

3 Keep the knob depressed for 15 seconds after the burner has lit to override the safety

device.

If still no ignition occurs, wait for 1 minute and repeat again.

Warning: Do not keep the knob in pressed position more than 15 seconds.

4

To switch a burner off turn the corresponding knob to I.

• Turning the control knob fully anti-clockwise to the small flame symbol enables you to

simmer without accidently switching off.

Fig.2

A=150

B=175

C=700

D=500

E=150

Fig.3

The hose must

not come into

contact with

the shaded

area

Fig.4

6

%NMI hook

;rot

'4'ppl:c:d

.

)

coc.kef rear

Page 7

Electrical Connection

Legal Requirements

Connection to the electricity supply should be made via a properly earthed,

readily accessible wall socket which is adjacent to and not more than 1.25m

away from the appliance. The socket must be capable of electrical isolation.

The mains lead should be routed such that it cannot touch hot parts of the

cooker i.e. the back panel above a height of 650mm from the floor.

Should this plug not fit the socket outlet in your home it should be cut off

and replaced with a suitable plug as outlined below.

I

MPORTANT NOTE:

The severed plug cannot be used for any other appliance

and should therefore be properly disposed of in a safe manner. DO NOT

LEAVE where children might find it and plug into a supply socket - This is

an obvious hazard and extremely dangerous.

We recommend that the appliance is connected by a competent electrical

installer, who is a member of a recognised "competent persons" scheme

and who will comply with the I.E.E. and local regulations.

Where a fixed connections is used, a device allowing the appliance to be

isolated on all poles from the mains supply with a contact opening width of

at least 3mm must be provided.

If the Fitted Plug is

Removed

This appliance must be earthed.

I

mportant:

Ensure that you route all mains electrical cables well clear of any

adjacent heat source, such as an oven or grill.

The flexible mains lead must be correctly connected as below to a three

pin plug of not less than 13amp capacity. If a BS 1363 plug is used, then

it must be fitted with a 3amp fuse approved to BS 1362.

Green &

Yellow to

IMPORTANT: The wires in the mains lead fitted

Earth

to this appliance are coloured

in accordance with the following code:

GREEN AND YELLOW

BLUE

BROWN

- Earth

-

Neutral

- Live

Blue to

Neutral

Mains Lead Clamp

Brown to

Live

13 Amp Fuse

As the colours of the wires in the mains lead of this appliance may not

correspond with the coloured markings identifying the terminals in your plug,

proceed as follows:- The wire which is coloured green and yellow must be

connected to the terminal in the plug marked with the letter 'E' or by the

earth symbol or coloured k green or green and yellow. When connection

is completed, close the terminal block, ensuring the cover is engaged on

the locking tabs.

7

Page 8

The wire coloured blue must be connected to the terminal marked with the

letter 'N' or coloured black. The wire coloured brown must be connected

to the terminal marked with the letter

'L'

or coloured red. When wiring the

plug, ensure that all strands of wire are securely retained in each

terminal.

Do not forget to tighten the mains lead clamp on the plug. As the appliance

must be earthed, do not use 2-pin socket outlets. If you are in doubt, consult

a qualified electrician. Should the mains lead ever require replacement, it is

essential that this operation be carried out by a suitably qualified

electrician and should only be replaced with a flexible cord of the same size

i.

e. 0.75mm2 cross sectional area and temperature rating of 85°C e.g. heat

resisting PVC.

After connection to the electicity supply please check that all electrical parts

of the appliance are working.

The maximum power rating is specified in the Technical Data of this handbook

and also on the Data Label on the appliance.

If a Moulded Plug

is Fitted

Operational Checks

In the event of replacing a fuse in the plug supplied, a 13amp ASTA

approved fuse to BS 1362 must be fitted.

NOTE:

The fuse cover must be refitted when changing the fuse. In the event

of losing the fuse cover, the plug must not be used until a replacement fuse

cover has been obtained and fitted. A new fuse cover can be obtained from

your local electrical retailer. The colour of the correct replacement fuse

cover is that of the coloured marks or inserts in the base of the plug.

After installation check for gas soundness.

Assemble burner caps and rings; fit pan supports in position.

Turn on the gas supply and check for soundness at the hotplate injector. Light two

burners and check that the pressure is correct.

Before you cook for the first time, we recommend that you light each burner in turn to

burn off any odours remaining from manufacture. Simply operate the grill on maximum

for a few minutes and the oven(s) for approximately 30 minutes. Ensure that the room

is well ventilated (e.g. open a window or use an extractor fan) and that persons who

may be sensitive to the odour avoid any fumes. It is suggested that any pets be removed

from the room until the smell has ceased.

Instruct the user on the operation of the cooker.

8

Page 9

For your safety

When used properly your Belling GT 755,GT 756 Gas cooker is completely safe, but as

with any electric or gas appliance there are some precautions you must take in its use.

Never..

•

Never allow anyone except an authorised Belling Service Agent to service or repair your cooker.

Never remove any part of the cooker other than those intended in normal use, or attempt to modify the

•

cooker in any way.

•

Never use the cooker for commercial catering. It is designed for domestic use and for cooking food only.

•

Never allow young children to operate or play with the cooker, as all surfaces get hot while in use.

•

Never allow children to sit or stand on any part of the appliance.

•

Never store items above a cooker that children may attempt to reach.

•

Never use a chip pan or deep fat fryer more than 1/3 full of oil, or use a lid while frying, and do not leave a

fryer unattended while cooking.

•

Never operate the grill with the grill/top oven door closed. This may cause overheating of your cooker.

•

Never line the shelves, floor, or sides of the oven or grill, with aluminium foil as overheating and damage may

result.

•

Never place materials which might catch fire, such as tea towels on the hob or elements, even when the

cooker is not in use.

Never allow aluminium foil or plastic to touch any hob element when it is hot.

•

Never use an asbestos mat, trivet or rack of any kind under pans on the hob.

•

Never store anything which might catch fire in the oven or grill.

•

•

Never heat unopened containers.

•

Never place flammable or plastic items on or near the hob.

•

Never dry clothes on either hob or oven doors.

•

Never store flammable liquids, aerosols, etc. in adjacent cabinetry.

•

Never use large preserving pans or fish kettles across two hotplates as this will damage the hob.

9

Page 10

For your safety

Always..

•

•

•

•

•

•

•

•

•

•

•

•

•

Always take care when touching any part of the cooker which may be hot. Use dry oven gloves when

removing or replacing food or dishes. Care should be taken to avoid touching the heating elements inside

the oven.

Always stand back when opening the oven door to allow any build-up of heat or steam to disperse.

Always keep the oven and grill doors closed when not in use to prevent accidents, but remember that

the grill door must be kept open when grilling to prevent overheating.

Always make sure that the roof, side and back panels, and shelves are fitted correctly before using the

oven or grill.

Always keep your cooker clean, as a build-up of grease or fat from cooking may be a fire hazard.

Always switch off at the mains supply and allow the cooker to cool before cleaning your cooker.

Always supervise children and pets, particularly when grilling, as exposed parts of the cooker may become

hot.

Always place pans centrally over the hotplate burners, and position them so that the handles cannot be

accidentally knocked or become heated by other burners.

Always keep handles away from the edge of the hob. For added safety you should consider using a

suitable hob guard.

Always make sure that all the controls are switched off when you finish cooking.

Always remember that your cooker may stay hot for a time even after you have finished cooking.

Always keep ventilation slots clear of obstructions.

Always keep children away from cooker when cleaning at maximum

oven setting.

0

1

Page 11

Know Your Cooker

2.0 kW

3 Button Clock/Minute Minder

(If Fitted)

Glass Lid

Control Panel

Top Oven and/or Grill

Windowed Metal Doors

Conventional Oven

Specification

Supply Voltage

Supply Frequency

Maximum Wattage

GT 755

GT

Grill Wattage

Top Oven Wattage

Conventional Oven Wattage GT 755

Conventional Oven Wattage GT 756 inc 25W-230V Lamp

Rear Left Burner

Front Left Burner

Front Right Burner

Rear Right Burner

GT 756

230 V AC

50 Hz

Electric=0.02 kW

756

Electric=0.06 kW

Gas = 12.7 kW

2.3 kW

2.1 kW

2.5

2.5

2.0

2.0

2.9

1.0

Grill Pan with removable Handle

and Wire Food Support Grid

(1) Oven/Grill Shelf With baffle

Cookclean Side & Rear Liners

(If Fitted)

(2) Oven Shelves With baffles

Plinth Ventilation Slots

kW

kW

kW

kW

kW

kW

Ignition

Safety Device

Unpacked

External Dimensions

Packed

External Dimensions

Grill Area

Push Button Electric

Gas valves are lockable

and Flame Failure Devices

H: 900 mm

W: 500 mm

D: 600 mm

H: 985 mm

W: 560 mm

D: 700 mm

800 sq cm

I 2H AT 20 mbar

Gas

G 20

Because we continually strive to improve our products, we may change our specifications and designs without prior notice.

Supply Pressure

20 mbar

Destination Countries

GB

11

Cat I 2H

Page 12

Using the timer (G756 Only)

3 Button LED Clock/Minute Minder

To Set Time of Day

10

a

0

I

It*

*

Step 1

Step 2

Check that the electricity supply to the cooker is

turned on.

When switched on the display will shou 0.00

flashing intermittently.

o

..........

Step 3

$

Press the "1" button and then press either the

"+" or "

Note: If the electricity supply has been off, the

"+" button must be prissed once before the

"2 button, if it is required to reduce thi time of

day.

2

buttons to set the correct time of day.

THE TIME OF DAY IS NOW SET.

12

Page 13

Minute minder operation

To Set the Minute Minder

:::

:::

.:::::::

i.

::::.

.::: .:.:::,

:::::::.

:::.

:::::::

:::::::

D

:

:::

.:::::::

O

.

c

......

r

000

Step 1

It can also be adjusted by pressing the "2 button.

At the end of the set time, a bleeping sound will be

heard and the "Bell" will disappear.

Press the button until the required time is set. A

"Bell" symbol will light up. During setting the time

adjusts in 10 second intervals up to a maximum

of 99mins 50secs.

0

NOTE:

"-"buttons together until 0.00 appears in the display window.

To adjust the pitch of the bleeper, press the "2 button while the bleeper is sounding. For example:

(a)

(b)

(c)

If a temperature is selected for the main oven first the oven will switch off after the set period.

If necessary the minute minder can be cancelled before the bleeper sounds by pressing the "+" and

Press the "+" button and set 10 seconds.

When the bleeper sounds, press and release the "2 button, until preferred pitch is set.

Press and release the "+" button to cancel the bleeper.

The bleeper can be cancelled by pressing the "+"

button.

13

Page 14

Know your Control Panel

Rear left burner

Rear left burner

Clock/Minute

Minder

Front left

burner

Front left

burner

Front right Rear right Main Conventional Grill Control

burner burner

Front right

,

burner

burner

Oven Control

Rear right Main Conventional

Oven Control

Oven light Switch

Ignition Switch

Top Oven &

Grill Control

Ignition

Switch

Using the Hob

GENERAL NOTES ON SAFETY

When the hob is in use do not leave unattended and make sure there are no small children in the vicinity.

1

Check that pan handles are positioned correctly and always keep an eye on the pan whenever oils or fats are

used, as they are easily immflamable.

2

Do not use spray cans near the appliance when it is in use.

3 Even after use, surfaces retain heat for a long time so do not put your hands or other objects on them.

4 After you have used the appliance make sure that all the controls are in the OFF position.

14

Page 15

The Hob Glass Lid

The hob glass lid on the cooker is toughened for your protection and safety. Before opening it remove any food

deposits from its surface. The glass lid is purely decorative and is not intended as a work surface and should

not be used for this purpose. As with any glass surface care must be taken to avoid scratches or damage, as

this may result in the glass breaking. The glass lid incorporates a safety valve that shuts off the gas supply to

the four hob burners, when the lid is lowered.

The oven(s) and grill will still operate with the lid in its closed position. Do not

use this facility as a means

of controlling the burners. This device is fitted in the interests of safety.

WARNING: Always make sure that all the control knobs are in the

OFF

position and the burners have cooled

before the hob lid is closed. Failure to do so could result in damage to the lid and a risk of personal injury.

Please note that if the gas taps have not been turned off, the

the hob is lifted and

Burner operation

1.

Check that the electricity supply is switched on.

2.

Ensure the glass lid is in its open (Upright) position. Select the burner to be used. Push in and turn the control

will not

re-light until a spark or flame ignites them.

supply of gas

to the hob burners will

restart

when

knob anti-clockwise to the large flame symbol. Press the ignition button until the burner lights (Or manual ignition

by match, taper or other auxiliary methods may be used). Turn the control knob to the required setting. A simmer

position is achieved when the control knob is turned fully anti-clockwise.

3.

To turn off, turn the control knob fully clockwise to the '0' symbol.

Advice on

Pan Suitability

Do not use pans which are unstable when placed on a flat work top. The use of split pans,

e. those comprising two or more pans designed to fit together over a single burner, is not

i.

recommended as these can be unstable on the hotplate. In order to get best value out of

your hob, the following economy tip is recommended. Choose the correct burner for the size

of pan e.g. 18cm (for auxiliary burner), 20cm (for semi-rapid burner) and 22cm (for rapid burner).

Energy Saving Tips

1.

Do use saucepans with lids.

2.

Place pans centrally over burner.

3.

Do not allow flames to lick up the sides of the pan.

4.

Only fill kettles or pans with the amount of liquid needed.

5.

Turn down the gas as soon as the contents of the pan boil.

6.

Do not light the burner until the pan is in position and turn off before removing the pan.

7.

Cut vegetables into smaller pieces so that they cook quicker and cook more than one vegetable in the same

pan, e.g. carrots and potatoes.

8.

In hard water areas de-scale kettles regularly.

9.

Consider using a pressure cooker.

15

Page 16

Safety Requirements for Deep Fat frying

I

MPORTANT:

As there could be some fire risk attached to the heating of oil, particularly for deep fat frying, cooking utensils

containing oil must not be left unattended (e.g. to answer the telephone) or in close proximity to hotplates.

In the unfortunate event of a fire it will assist in smothering the flames if the pan lid is replaced. Turn off all the gas

taps.

1.

Use a deep pan, large enough to completely cover the appropriate heating area.

2.

Never fill the pan more than one third full of fat or oil.

3.

Never leave oil or fat unattended during the heating or cooking period.

4.

Do not try to fry too much food at a time, especially frozen food. This only lowers the temperature of the oil

or fat too much, resulting in greasy food.

5.

Always dry food thoroughly before frying, and lower it slowly into the hot oil or fat. Frozen foods, in particular,

will cause frothing and spitting, if added too quickly.

6.

Never heat fat, or fry, with a lid on the pan.

7.

Keep the outside of the pan, clean and free from streaks of oil or fat.

Safety advice in case of a chip pan fire

In the event of a chip pan fire or any other pan fire.

1.

TURN OFF ALL THE GAS TAPS.

2.

COVER THE PAN WITH A FIRE BLANKET OR DAMP CLOTH, this

will smother the flames and extinguish the fire.

3.

LEAVE THE PAN TO COOL FOR AT LEAST 60 MINUTES BEFORE

MOVING IT. Injuries are often caused by picking up a hot pan and rushing outside with it.

NEVER USE A FIRE EXTINGUISHER TO PUT OUT A PAN FIRE as the force of the extinguisher is likely

to tip the pan over.

Never use water to extinguish oil or fat fires.

Choosing your Utensils

For best results we recommend the use of good quality saucepans with smooth flat bases. Aluminium pans with

coloured vitreous enamelled bases absorb heat and are therefore more efficient in use. Almost equally as good

are saucepans with a thick machined aluminium base. If using enamelled steel or cast iron pans, ensure that they

have good smooth flat bases as otherwise the heat will not be distributed evenly and damaging heat spots may

be created.

Never use recessed or ridged base utensils. Ideally the base of saucepan should be approximately the same size

as the heating area, up to a maximum of 254mm (10").

16

Page 17

Using the grill

Parts may become hot when the grill is in use, children must be kept away.

ALWAYS ENSURE THE DOOR IS OPEN WHEN GRILLING

GT 755 Grill Operation

1

Depress and hold the control knob while at the same time pressing the spark ignition button until the spark lights

the gas. Keep the knob depressed after the burner has lit for a further 15 seconds for the flame to establish.

Allow the grill to pre-heat for around 5 mins.

Turn the grill on by depressing and turning the grill control knob anti-clockwise to the large flame position.

2

Rotate the grill control knob anti-clockwise to the required setting. Only turn the control knob between

the large flame symbol and the small flame symbol when adjusting the setting. (Refer to 'Grilling Guidelines' on

Page 18)

3

4

To turn off, turn the control knob fully clockwise to the '0' symbol.

In the event of the burner flames being accidentally extinguished, turn off the control knob and

do not attempt to re-light the grill for at least one minute.

GT 756 Grill Operation

1

Turn the grill on by depressing and turning the grill control knob clockwise to the large flame position.

Depress and hold the control knob while at the same time pressing the spark ignition button until the spark lights

the gas. Keep the knob depressed after the burner has lit for a further 15 secs for the flame to establish. Allow

the grill to pre-heat for around 5 mins.

2 The gas flame is not adjustable. (Refer to 'Grilling Guidelines' on Page 18)

3 To turn off, turn the control knob fully anti-clockwise to the '0' symbol.

4 In the event of the burner flames being accidentally extinguished, turn off the control knob and

do not attempt to re-light the grill for at least one minute.

GT 756 Grill Operation

•

Only use the bottom shelf position for grilling. Do not use any other position.

Ensure the food is correctly positioned under the grill burner.

•

Food that requires browning only should be placed under the hot grill, either in the grill pan, or on the floor

•

of the grill compartment, according to the depth of the dish. The grill pan wire grid can be removed.

•

Do not line the grill pan with aluminum foil.

•

Plates and dishes placed on the floor of the grill compartment will be heated when the main oven is in use.

•

Do not switch on the grill when using the compartment for storage.

•

During use the appliance becomes hot. Care should be taken to avoid touching heating elements

inside the oven.

17

Page 18

Grilling Guidelines

Use the following chart for guidelines.

For thicker foods requiring longer cooking, turn the control to a lower setting after the

initial sealing on both sides. The thicker the food, the lower the control should be set.

When grilling thicker food, the grill rack should be turned over to its lowest position.

Food

Toasting of Bread products

Small cuts of meat, sausages,

bacon, etc.

Chops etc.

Gammon steaks

Chicken pieces

Fish:

Fingers

Whole Fillets

Fish in breadcrumbs

Pre — Cooked potato products

Pizzas

Browning of food

Grill Setting

Full On

High to Full

Med to Full

Med to High

Med to High

Med to High

Med to High

Full On

Approximate Cooking time

3 - 10 mins.

15 - 20 mins.

20 - 25 mins. Wire food support

used in upturned position for

chicken.

10 - 20 mins. Whole fish and

fillets placed in the base of the

grill pan.

15 - 20 mins.

15 - 20 mins.

12 - 15 mins. in the base of the

grill pan.

8 - 10 mins. Dish placed directly

on the base of the grill

compartment

Note:- The Grill setting on the GT 756 is Full On Only. Adjust cooking times accordingly.

Use of Grill Pan Handle

Warning! Always use an oven glove to protect your hand when using the grill

as all metal parts can become very hot.

The grill pan has a detachable handle. Make sure the handle is securely located

between the raised profiles across the front of the grill pan. See the diagrams for fitting

the handle. To remove the handle, reverse the sequence of operations.

Always take care not to touch hot surfaces when

using the grill panhandle. Ensure when using the grill

panhandle that it is centralized and secure. Please

note that the grill panhandle will get very hot during

use.

18

Page 19

Using the Ovens

Your appliance has either one or two conventional ovens. The ovens have different heat zones with the thermostat

settings referring to the temperature on the middle shelf; above the shelf it is hotter and below it is cooler. The

main oven has two shelves and five possible shelf positions (reference numbered 1 to 5 from the top down). The

top oven (GT756 Only) has one shelf and two possible shelf positions (reference numbered 1 to 2 from the top

down). The varying shelf positions allow full use of the different temperatures inside the ovens.

Shelf Positions

The shelf positions are counted from the top runner down as shown below.

1

2

Shelf

3

Levels

4

1

2

Shelf

Levels

Control holes

MAIN CONVENTIONAL OVEN

Control holes

TOP CONVENTIONAL OVEN

Use of the ovens

1 Open the door

2 Adjust the shelves to the positions required

3 Turn the oven on by depressing and turning the oven control knob anti-clockwise to setting 7.

Depress and hold the control knob while at the same time pressing the spark ignition button until the spark lights

the gas. Keep the knob depressed after the burner has lit for a further 15 seconds for the flame to establish.

The flame is visible through the control holes as shown in the diagrams above.

4 Close the door

5 Select the temperature in the oven by rotating the knob to the required setting.

6 Allow 10 minutes for pre-heating.

7

To turn off,

8 In the event of the burner flames being accidentally extinguished, turn off the control knob and

do not attempt to re-light the oven for at least one minute.

turn the control knob fully clockwise to the '0' symbol.

Ensure you stand back from the appliance when opening the oven door to allow any build up of steam

or heat to escape.

•

Check food is thoroughly cooked and is piping hot before serving.

•

When cooking, rotate the food and turn the food over (If suitable) approximately half way through the cooking

cycle. This will ensure even cooking/baking results.

Oven Lamp Operation (GT 756)

The main oven is fitted with a 25W - 230V SES (300°C) lamp and can be illuminated by depressing the lamp

switch situated on the control panel (See Know Your Control Panel Page 14).

NOTE:- The oven lamp is not covered by the guarantee. For a replacement call our Spares Department

on (tel. 08 4

4 815 3745

)

19

Page 20

Temperature Conversion

The oven temperature control markings are gas marked 0 to 9.

The equivalent degrees Celsius (sometimes called Centigrade) and degrees Fahrenheit are shown below as a

guide.

Gas Mark

1/2

1

2

3

4

5

6

7

8

9

MAIN OVEN

(Centre Oven Temperatures)

Celcius °C

110

120

150

175

195

210

220

230

235

240

Fahrenheit °F

230

250

300

350

385

410

430

445

455

465

TOP OVEN (GT 756)

(Centre Oven Temperatures)

Celcius °C

110

130

1

40

150

1

65

175

1

90

205

220

235

Fahrenheit °F

230

265

285

300

330

315

340

400

430

455

Main Conventional Oven Cooking Guide

This chart is for guidance only, follow food manufacturers recommendations whenever available.

FOOD

BEEF

LAMB

PORK

POULTRY

CASSEROLES

FRUIT CAKE

SMALL CAKES

VICTORIA SANDWICH

APPLE PIE

SCONES

COOKING

GAS MARK

4-5

4-5

4-5

4-5

3

2

5

4

6

7

TIME

25-30 mins/450g + 30 mins

25-30 mins/450g + 30 mins

35-40 mins/450g + 40 mins

25-30 mins/450g +25 mins

1.5/2 hours dependant on quantity

2 - 3.5 hours dependant on size

17-25 mins

20-30 mins

50-60 mins

12-15 mins

SHELF

POSITION

5

5

5

5

4 or 5

3

2 & 4

2 & 4

1

1 & 3

Top Conventional Oven Cooking Guide (GT 756)

This chart is for guidance only, follow food manufacturers recommendations whenever available.

FOOD

BEEF

L

AMB

PORK

POULTRY

SMALL CAKES

SCONES

Accuracy:-

COOKING

GAS MARK

5-6

5-6

5-6

5-6

5

7

25-30 mins/450g + 30 mins

25-30 mins/450g + 30 mins

35-40 mins/450g + 30 mins

25-30 mins/450g + 25 mins

TIME

17-25 mins

12-15 mins

Note that times and temperatures in this book are for guidance only.

20

SHELF

POSITION

2

2

2

2

1

1

Page 21

Care and Cleaning

TURN OFF COOKER AT MAIN WALL SWITCH BEFORE CLEANING

Before switching on again, ensure that all controls are in the OFF position.

Refer to instructions below for cleaning the 'Cookclean' removable side oven panels.

Glass Lid (Glass)

Clean with a cloth wrung out in soapy water. Stubborn stains can be removed with a cream, paste or liquid

cleaner, or by gently rubbing with liberally soaped, very fine steel wool pads. Polish with a clean dry cloth

or kitchen roll.

Glass Lid (Painted Trims)

Clean with a cloth wrung out in hot soapy water only. Polish with a clean dry cloth or kitchen roll.

DO NOT USE ABRASIVES.

Burners

The pan supports can be removed and the top burner plate can be cleaned with soapy water and rinsed

with a dry cloth. Wash and rinse the gas burner caps and the pan supports with soapy water. Never wash

them in a dishwasher. For the dirt and stains on the burner heads that does not wash off, use a proprietary

metal surface cleaner

Vitreous Enamel Hob Surround

Clean with a cloth wrung out in soapy water. Stubborn stains can be removed with a cream, paste or liquid

cleaner, or by gently rubbing with liberally soaped, very fine steel wool pads.

Control Panel

Wipe over the control panel with a damp cloth and polish with a dry cloth. Do not use oven cleaners or

aerosols scouring pads or abrasive powder for cleaning the plastic knobs, as damage will occur.

How 'Cookclean' Oven Liners Work (If fitted)

The surfaces of the 'Cookclean' oven liners are treated on the mottled face with a special vitreous enamel

which absorbs cooking soils at temperatures of 220°C (Gas Mk 6) or above, the special

surface enables these soils to be slowly destroyed. The higher the temperature the more effective it is. In

most cases normal cooking operation at this temperature will permit this cleaning operation to proceed

during cooking. However if higher cooking temperatures are not used regularly it may be necessary, to

prevent heavy soiling, to run the oven at a higher temperature setting of 230°C (Gas Mk 9) for a couple of

hours. This may be necessary once a month or once every two or three months, depending on the type

and amount of oven cooking.

'Cookclean Panels' (If fitted)

It should not normally be necessary to clean the 'Cookclean' panels in water. If the user feels it is desirable

to do so, remove the rod shelf and the side panels and wash them in warm soapy water, followed by rinsing

in clear water.

Do not use enzyme/biological washing powder, harsh abrasives or oven chemical cleaners of

any kind.

Do not rub the surface dry as it can damage the 'Cookclean' finish. After cleaning, replace the

panels immediately and run the oven at maximum setting for about 30 minutes to prevent

deterioration of the enamel.

21

Page 22

Oven & Grill compartments

0844 815 3745

Remove the grill/meat pan and grid. It is best to wash these items immediately after use to prevent stains

from being burnt on when used again.

Wipe around the oven or grill compartment, removing stubborn stains with a fine soap impregnated steel

wool pad. Harsh abrasives should be avoided.

Remove the rod shelf for washing at the sink. Use a fine steel wool soap pad for removing stubborn stains

from the rod shelf and floor of the oven. Take care during cleaning not to damage, bend or dislodge from

the supporting clips the thermostat phial which is across the back of the oven just below the roof in the

oven compartment.

Doors and Handles

Wipe over with a cloth wrung out in hot soapy water and rinse with a cloth wrung out in clear water. Dry

with a soft clean cloth.

Do not use scouring pads or abrasive powder which may scratch the surface.

Take care during cleaning not to damage or distort the Door Seal. Do not lift the Door Seal from the Oven

Front Frame, if necessary remove the seal by carefully unhooking the corner clips.

Care must be taken that Rating Label edges are not lifted during cleaning and furthermore that the

N.B.

lettering is not blurred or removed . Only use oven cleaners which carry the Vitreous Enamel Development

Council's Approvals symbol, and always follow the manufacturers instructions for use.

Models with removeable inner glass panels

When you wish to clean the interior glass of the oven door, use a screwdriver to remove the top and bottom

washers that secures the interior glass to the door, remove the glass with care.Clean as above, but do not

use house hold detergent, bleach,scouring pads or rust removers. After drying, position the gasket back

into its place. Reinstall the glass panels carefully preventing sudden shocks.

* If low emissive glass is fitted, ensure the printed side is facing outwards.

Replacing the Oven Lamp (GT 756)

If the oven lamp fails you can replace it yourself by following these few instructions:-

WARNING!

Switch off the cooker at the mains supply before attempting to replace the oven lamp.

Remove the oven shelves. Unscrew and remove the lamp cover glass. Unscrew the lamp and replace it

with a new 25W - 230V SES (300°C) lamp. These are the only lamps suitable for use in your cooker.

Replace the lamp cover glass before switching on.

NOTE:- The oven lamp is not covered by the guarantee. For a replacement call our Spares

Department on (tel. 0870 458 9695)

22

Page 23

Something Wrong with your Cooker?

Before contacting your Belling approved Service Centre/Installer, check the problem guide

below; there may be nothing wrong with your cooker.

Problem

Slight odour or small amount of smoke

when using the cooker for the first time.

Sinking of cakes

Over/Under cooking

Fast/Slow cooking

Nothing works

Check

This is normal and should cease after

a short period.

The following may cause cakes to

sink:

1.

Cooking at too high a temperature.

2.

Using normal creaming method with

soft margarine.

Refer to the cooking times and

temperatures given in the oven

temperature charts, however, it may be

necessary to increase or decrease

temperatures by 1/2 gas mark (10°C) to

suit personal taste.

Do not use oven/meat pans greater than

56mm (2 1/4 ") in height.

Rotate/Turn the food.

Is the main cooker electric wall switch

turned on?

Is the gas supply turned on?

Hob Burners do not work

Ignition does not work

Is the glass lid in its fully opened (Upright)

position?

If all hotplate burners fail to ignite, check

that there are sparks at the burners, a

clicking noise should be heard.

Check that the burner parts are seated

correctly and that the slots in the burner

body are not blocked.

All burners can be lit with a match in case

of ignition failure.

23

Page 24

Customer Care Centre

0844 815 3746

0844 815 3746

0844 815 3745

In case of difficulty within the UK please call,

having the model number and serial number to hand:

Opening Hours for Customer Care Centre

Monday to Friday

Saturday

Sunday

For Belling Customer Helpline please call

0871 22 22 503

For Belling Service please call

0871 22 22 503

For Belling Spares please call

0870 458 9695

8am - 8pm

8:30am - 6pm

lOarn - 4 pm

Model No

Serial No

Glen Dimplex Home Appliances, Stones Lane,

Prescot, Merseyside L35 2XW

Part no. FS 756001 June 2005

c

6 i Tlii"

.

485.9209.38/R.0/23.07.2008

24

Loading...

Loading...