Page 1

FFrroonntt && SSiiddee CCoonnttrrooll GGaass HHoobbss

BELLING 60T/70T

For Natural Gas Models & LP Gas Models

User & Installation Instructions

Page 2

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety and Ignition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5/6

Using your hob. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Care and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Clearance and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Gas & Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Customer Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Please keep this handbook for future reference, or for anyone else

who may use the appliance.

Page 3

Our Warranty

Should you need it . . . .

Inside the paperwork which has come with this appliance, there is a leaflet and card

explaining the terms of our extended warranty and guarantee.

In order to apply for a one year guarantee, simply fill in the details on the card and post

it off, this will register your appliance.

Should you wish to take out extended warranty, please fill in the details on the leaflet

and post this off.

Alternatively, you can register, and apply for extended warranty on line at:

www.belling.co.uk

If your appliance is covered by the warranty and guarantee, you will not be billed for

work undertaken should your appliance be faulty, terms and conditions do apply, so

please read through the literature carefully.

Our Customer Care Centre can be called on:

0844 815 3746

We aim to answer calls as quickly as possible, and in strict rotation as soon as one of our

Customer Care team becomes free.

Please ensure that you have available your appliance model number and serial number,

there is a space at the back of this book for recording that information.

Alternatively visit the web site.

Outside the UK and Northern Ireland, please contact your local supplier.

Page 4

Introduction

Thank you for buying this British built

appliance from Belling, this book is

intended to assist you with the

installing and use of your hob and we

recommend that you read it fully

before installation and use.

We hope that the following information will help you to quickly familiarise

yourself with the features of the following appliance, and use it successfully

and safely.

Our policy is one of constant development and improvement. Strict accuracy of illustrations and specifications is

not guaranteed. Modification to

design and materials may be necessary subsequent to publication.

This hob is intended to be built into a

domestic kitchen, caravan or boat

intended for use on inland waterways.

This product is designed as an appliance for the preparation and cooking

of domestic food products, and should

not be used for any other purpose.

This appliance must be installed in

accordance with the regulations in

force, and only in a well ventilated

space. Read the instructions before

using or installing this appliance.

Your 1st Year Guarantee

To fulfil the conditions of your guarantee, this appliance must be correctly

installed and operated, in accordance

with these instructions, and only be

used for normal domestic purposes.

Please note that the guarantee, and

Service availability, only apply to the

UK and Republic of Ireland.

4

Page 5

Gas & Electrical connection

Please refer to installation instructions

for the Gas & Electrical Safety

Regulations and the Ventilation

Requirements.

In your own interest, and that of safety, it is the law that all gas appliances

be installed by a competent person,

who will ensure that the installation is

in accordance with “The Gas Safety

(Installation & Use) Regulations”, & the

“The Gas Safety (Installation & Use)

(Amendment) Regulations”. Failure to

comply with these Regulations is a

criminal offence.

As with all gas appliances, it is recommended that your hob is serviced

regularly.

Disconnection of gas and electric appliances should always be carried out by

competent persons.

Warning: This appliance must be

earthed.

Ventilation

The use of a gas cooking appliance

results in the production of heat and

moisture in the room in which it is

installed. Ensure that the kitchen is

well ventilated; keep natural ventilation holes open or install a mechanical

ventilation device (mechanical extractor hood).

Prolonged intensive use of the appliance may call for additional ventilation, for example opening of a window, or more effective ventilation, for

example increasing the level of

mechanical ventilation where present.

Before installing and using the

hob for the first time, remove any

packaging or protective polythene

film.

Environmental Protection

We are committed to protecting the

environment and operate an

Environmental Management System

which complies with BS EN ISO

14001.

Disposal of packaging

• All our packaging materials are

recyclable and environmentally

friendly.

• Please help us to protect our

environment by disposing of all

packaging in an environmentally

friendly manner.

• Please contact your local authority

for the nearest recycling centre.

Caution: Packaging materials can

pose a risk of suffocation - keep away

from children.

5

Page 6

Be safe - not sorry

Caution: When you are cook-

ing, keep children away from the

vicinity of the hob.

• Parts of the appliance may be hot

during or immediately after use.

Allow sufficient time for the hob to

cool after switching off.

• Never use the appliance for

heating a room.

• Turn pan handles to a safe position, so they are out of reach of children, not overhanging the appliance, and cannot be caught

accidentally.

• Position pans over the centre of the

burners / hotplates. If positioned

off centre, smaller pans may be

unstable.

• Keep all flammable materials (such

as curtains, clothing & furnishings)

away from the hob.

• Do not let pans overhang the control knobs, as this may overheat

and damage them.

• Never leave fat or oil unattended on

a lit hob.

Caution: Where this appliance

is installed in a boat or caravan, it shall not be used as a

space heater.

Check that all controls are in

the off position when you have

finished cooking.

Ignition

Auto ignition (if fitted):

Push in and hold down the control

knob, and turn to the full on position

(large flame symbol). Keep the knob

depressed after the burner has lit for

up to 15 seconds to allow the flame to

establish. Turn the control knob to the

desired setting.

Manual ignition (if fitted):

Push in & hold down the control knob

turning to the full on position (large

flame symbol) & press the ignition button until the gas lights. Keep the control knob depressed after the burner

has lit for up to 15 seconds to allow

the flame to establish. Turn the control

knob to the desired setting.

In the event of the burner flames being

accidentally extinguished, turn off the

burner control and do not attempt to

re-ignite the burner for at least 1

minute.

Reduced rate

Turn the control knob to the small

flame symbol.

To switch off

To switch off a hob burner, turn the

control knob clockwise to the “off”

position.

If the ignition fails

1.Make sure all the controls are in the

“off” position, and check there is a

spark at the back of the burner when

you depress the control knob or press

the ignition button.

2.Gas check - check there is gas to the

appliance by lighting a burner with a

lighted match.

3.Electrical check-if no spark renew

the 3 ampfuse in the fused spur.

4.Check burner caps are fitted cor-

6

rectly

Page 7

Using the hob

Adjust the burner flame so that it does

not extend over the pan base.

Pans

Use pans with a flat base of mini-

mum 120mm / 4 ins diameter and

maximum 250mm / 10 ins diameter which are stable in use.

Do not use double pans, rim based

pans, old misshapen pans or any

pan which is unstable when placed

on a flat surface.

Position pans over the centre of the

burners, resting on the pan supports. If positioned off centre, smaller pans may be unstable.

Do not use griddle plates on this

appliance, as this may be hazardous.

Material and size of pan, as well as

quantity and type of food to be

cooked, can affect cooking times.

Commercial simmering aids should

not be used as they create excessive

temperatures that can damage the

surface and may cause a hazard.

Do not let pans overhang the con-

trol knobs, as this may overheat and

damage them.

Always use pans which are large

enough to prevent spillage, especially for deep frying.

Turn pan handles to a safe position,

so they are out of reach of children,

not overhanging the appliance, and

cannot be caught accidentally.

7

Page 8

Pan supports

Always make sure the pan supports

are replaced correctly, located in the

hob spillage well, and that all rubber

feet are in place, to prevent instability.

The hob must only be operated when

both pan supports are correctly positioned.

To save gas

• Always position pans centrally

over the burner.

• Use the size of pan most suited to

the size of the burner - ie; larger

pans on the rear burners, smaller

pans on the front burners.

• Adjust the flames so that they do

not lick up the sides of the pan.

• Put lids on saucepans and only

heat the amount of liquid you

need.

• When liquids boil, reduce the control setting to maintain a simmer.

• Consider the use of a pressure

cooker for the cooking of a complete meal.

• Potatoes and vegetables will cook

quicker if chopped into smaller

pieces.

Note

Extra care should be taken when cooking food in salted water. Some foods

are corrosive - eg; vinegar, fruit juices

and especially salt

damage stainless steel if they are left

on the surface. Turn off and wipe any

spillage immediately, taking care to

avoid skin contact with any hot surface

or spillage.

- they can mark or

8

Page 9

Care & Cleaning

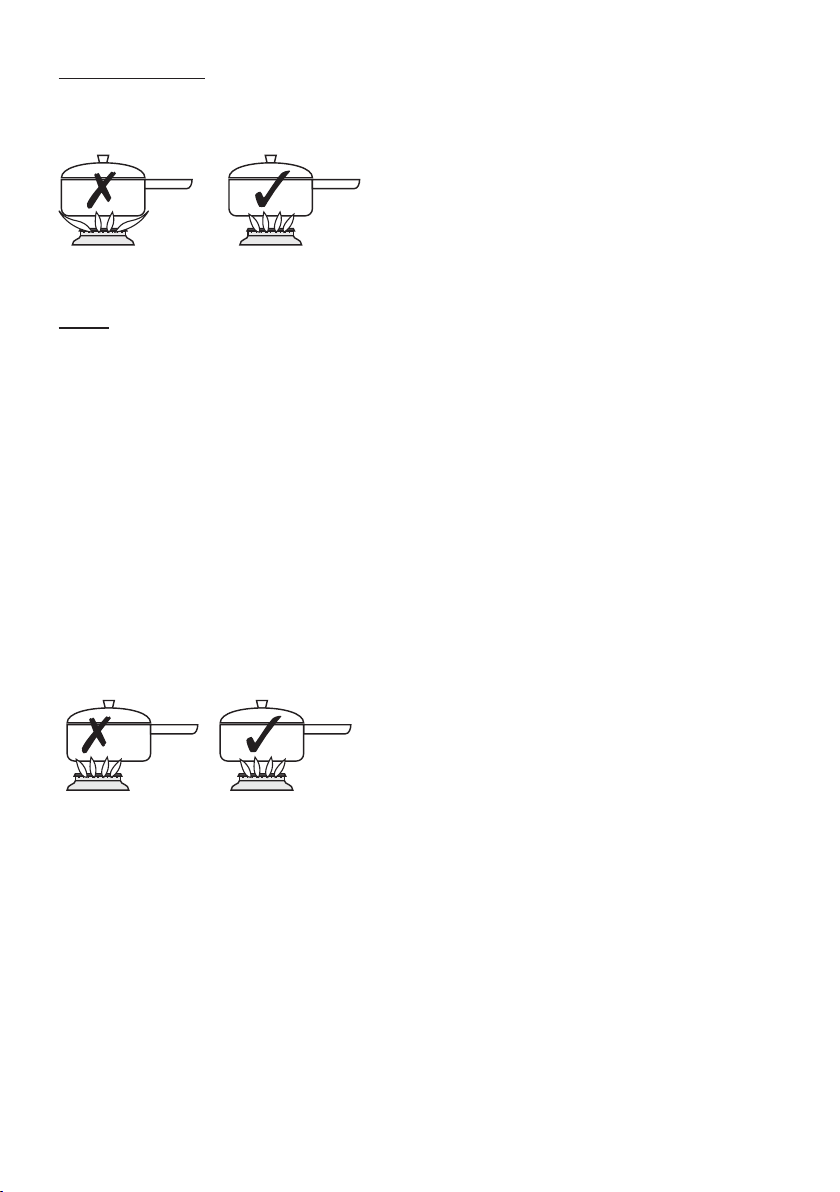

incorrect

burner cap not central

incorrect

angled

correct

parallel

burner cap

burner head

Caution: Any cleaning agent

used incorrectly may damage

the hob.

Always let the hob cool before

cleaning.

Some cooking operations generate a

considerable amount of grease. This,

combined with spillage, can become a

hazard if allowed to accumulate on

the hob through lack of cleaning. In

extreme cases this may amount to misuse of the appliance & could invalidate your guarantee.

Do not use caustic, corrosive or abrasive cleaning products, coarse wire

wool or any hard implements, as they

will damage the surfaces.

All parts of the hob can be safely

cleaned with a cloth wrung out in hot

soapy water.

Any brownish coloured marks on the

burners are carbon deposits or fat stains,

which can be removed by gently rubbing with a soapy pad.

Important: The burner caps and

heads must

be repositioned correctly

so that they sit squarely onto the hob

as shown below.

This is particularly important with stainless steel models as failure to reposition the caps correctly may result in

discolouration of the stainless steel

around the burners.

Burner caps and heads

Important: Allow burners to cool

before cleaning.

Caution: Hotplate burners can be

damaged by soaking, automatic dishwashers (or dishwasher powders / liquids), caustic pastes, hard implements,

coarse wire wool, and abrasive cleaning pastes.

Clean with a moist soapy pad.

For the burners to work safely, the slots

in the burner head where the flames

burn need to be kept clear of deposit.

Clean with a nylon brush, rinse, & dry

thoroughly.

9

Page 10

Control knobs

Only use hot soapy water.

When cleaning the fascia area, care

must be taken on symbols / markings.

Control knobs can be removed for

cleaning, but take care to ensure that

they are repositioned correctly after

cleaning.

Vitreous enamel surfaces

HOB SPILLAGE WELL (enamel hobs), PAN

SUPPORTS (if fitted)

Use a mild cream cleaner .

Stainless Steel hob

Only use a clean cloth wrung out in

hot soapy water, and dry with a soft

cloth.

Stubborn marks can be removed using

“Luneta”. We recommend that you

clean the whole of the stainless steel

area to maintain a uniform finish.

Supplies can be purchased from the

Customer Care Centre.

Do not use undiluted bleach or any

products containing chlorides as they

can permanently damage the steel.

Extra care should be taken when cooking food in salted water. Some foods

are corrosive - eg; vinegar, fruit juices

and especially salt

- they can mark or

damage stainless steel if they are left

on the surface. Turn off and wipe any

spillage immediately, taking care to

avoid skin contact with any hot surface

or spillage.

Sharp objects can mark the surface of

stainless steel, but marks will become

less noticeable with time.

To maintain the finish of stainless steel,

or to remove any greasy marks, wipe

the stainless steel surface sparingly

with a minimum amount of Baby Oil

and kitchen paper. Do not use cooking oils, as these may contain salt,

which can damage the stainless steel

surface.

Please note: Do not steam clean any

parts of the hob.

Cast iron pansupports (if fitted)

After cooking allow the pan-

supports to cool completely

before attempting to remove or

clean.

Before cleaning, remove any excess

fat with kitchen paper.

The pan supports can be cleaned with

hot soapy water and a nylon brush. If

any food residue is left on them leave

them to soak for a few minutes

in hot

soapy water before attempting to

clean it. Do not

use caustic pastes,

abrasive cleaning powders, coarse

wire wool or any hard implements, as

they will damage the surface.

Do not clean in a dishwasher.

10

Page 11

Installation

This appliance must be installed in

accordance with the regulations in

force, and only in a well ventilated

space. Read the instructions before

using or installing this appliance.

This appliance will be factory set for

use on either natural gas only, or LPG

only. If the appliance requires conversion from natural gas to LPG, then the

conversion kit, part number 0130145

00, can be ordered from the Customer

Care Centre helpline given at the back

of this book.

Regulations & Standards

Prior to installation, ensure that the local

distribution condition (nature of the gas

and gas pressure) and adjustment of

the appliance are compatible.

The adjustment conditions for this

appliance are stated on the data

badge.

This appliance is not connected to a

combustion products evacuation device.

It shall be installed and connected in

accordance with current installation

regulations. Particular attention shall

be given to the relevant requirements

regarding ventilation.

The appliance must be installed, converted to LPG (where necessary) and

serviced by a competent person to

ensure that the installation is in accordance with “The Gas Safety

(Installation & Use) Regulations”, & the

“The Gas Safety (Installation & Use)

(Amendment) Regulations ”.

Failure to comply with these

Regulations is a criminal

offence.

Where regulations or standards have

been revised since this handbook was

printed, always use the latest edition.

All gas installation, servicing and

repair work must be in accordance

with local standards and regulations.

11

Page 12

In the UK the regulations and

standards are as follows (inclusive of successive issues:

1. Gas Safety Regulations

(Installation and Use).

2. Building Regulations - Issued by

the Department of the

Environment.

3. Building Standards (Scotland)

(Consolidated) - Issued by the Scottish

Development Department.

4. The current I.E.E. Wiring

Regulations.

5. Electricity at Work Regulations.

6. BS6172 Installation of Domestic

Gas Cooking Appliances

Also, for LP Gas refer to BS5482

Part 1, Part 2 or Part 3 as relevant.

7. Installation & Servicing Instructions

for this appliance.

For installation in countries other than

the UK, the appliance must be connected in accordance with all local

gas and electrical regulations.

In the Republic of Ireland, installers

should refer to IS813 Domestic Gas

Appliances.

Ventilation Requirements

The room containing the appliance

should have an air supply in accordance with BS5440: Part 2

• All rooms require an openable

window, or equivalent, and some

rooms will require a permanent

vent as well.

3

• For room volumes up to 5m

2

vent of 100cm

is required.

an air

• If the room has a door that opens

directly to the outside, or the room

exceeds 10m3NO AIR VENT is

required.

• For room volumes between 5m

and 10m3an air vent of 50cm2is

required.

• If there are other fuel burning

appliances in the same room, BS

5440: Part 2: should be consulted

to determine the air vent requirements.

• This appliance must not be

installed in a bed sitting room of

less than 20m3or in a bathroom or

shower room.

• Windows and permanent vents

should therefore not be blocked or

removed without first consulting a

compenent engineer.

LP Gas only - Do not install this

appliance in a room below ground

level. This does not preclude installation into rooms which are basements

with respect to one side of the building

but open to ground level on the opposite side.

For installation into environments other

than domestic dwellings, e.g. caravans, boats and similar - refer to the

relevant standards on ventilation and

gas supply.

Failure to install appliances correctly is dangerous & could

lead to prosecution.

12

3

Page 13

Clearances & dimensions

600 hob - 600mm

700 hob - 700mm

40mm

40mm

worktop

420

mm

wall unit wall unit

This area must

be kept clear

of combustible

materials

650mm

above level of

pan supports

53mm min

side wall

rear wall

555mm

485

mm

cutout

600 - 53mm min

700 - 103mm min

The room should have good light and

ventilation but be free from draughts.

The worktop should be at least

600mm deep, & 30mm thick to

enable the cutout to be made to the

dimensions shown below.

A minimum distance of 40mm should

be maintained between the hob and

rear wall / combustible surface.

A minimum distance of 78mm should

be maintained between the hob and

any side walls / combustible surface.

Surfaces which are non-combustible, or

are protected with suitable non-combustible material, may have reduced

clearances. Refer to New World for

guidance.

We recommend ceramic tiling for the

rear wall directly behind the hob.

No shelf or overhang of combustible

material should be closer than 650mm

above the hob.

Extractor or cooker hoods should only

be fitted above the hob in accordance

with the manufacturer’s instructions.

No combustible materials or flammable liquids should be stored below the

hob.

Sufficient length of cable should be

allowed so the hob can be removed

for servicing, but make sure it is routed

away from the underside of the hob &

does not get trapped during installation.

Important: Ensure that you route all

electrical cables and flexible tubing

well clear of any adjacent heat source

- eg; oven / grill.

13

Page 14

Base Tray

GDHA specified dimensions with batons

Existing dimension without batons

Important Information

It is important when installing front

control gas hobs, that the work top

cut out is the same as is quoted in

this installation manual. If the cut out

is too large, then batons must be fitted to the front, rear and sides - to

correct the discrepancy and ensure

the correct fit. Please ensure that if

batons are fitted they are level with

the top surface of the work top

Please ensure that the seal for the

hob has full contact with the work

top surface.

There are two ways to install

the clamps, depending on the thick-

ness of the work top, please measure

the thickness of your work top and

ensure that the correct method is

used. Both methods are detailed in

the installation manual.

Failure to follow these instructions can

lead to exessive force being applied

to the basetray, which results in the

clearence between the control knob

and the hob top pressing being

reduced. This can effect the operation of the gas control, and the ignition.

14

Page 15

Fit the hob into the cutout &

seal

hob

40mm

worktop

seal

hob

30mm

worktop

secure to worktop

Place the hob into the cutout and

secure in place using the four brackets

and screws provided.

The brackets should be orientated to

suit the worktop thickness as shown,

then inserted into the four slots (two on

the front edge and two on the rear)

and screwed into the underside of the

worktop using the woodscrews provided.

The screws should be tightened just

sufficiently to secure the hob and pull

the top pressing flush with the worktop.

If the base of the hob is accessible

after installation then a partition must

be fitted 20mm below the base to prevent access.

15

Page 16

Installation advice - cabinetry

Dealing with sides, cross-rails

and back-panels in cabinetry

Depending on the cabinets, the worktop thickness and the hob positioning,

it is possible for the hob base, the

clamp brackets and/or the gas connection to interfere with parts of the

cabinet. These can be dealt with as

follows:

Cabinet sides

If the hob is to be installed across the

top of two cabinet housing units, then

the base of the hob may interfere with

the sides of these units. It will be necessary to cut away the top of the unit

sides locally to clear the hob, clamp

brackets and/or gas connection.

Cross-Rails

1. Interference with hob base

If there are any cross-rails which

obstruct the hob base by running

across the worktop cutout, they can

simply be removed or locally cutaway to allow the hob to be

installed, depending on the particular installation. Any modifications

must ensure that the strength of the

cabinet is maintained.

2. Interference with clamp brackets

If there are any cross-rails which

prevent the clamps from being

positioned on the front or rear

edges of the hob, then they can be

removed or locally cut-away

around the brackets to allow the

brackets to be installed.

Any modifications must ensure that

the strength of the cabinet is maintained.

Back-panel

1. Interference with clamp brackets

If the cabinet has a back-panel

which prevents the clamps from

being positioned on the rear edge

of the hob, then this panel can be

completely removed or locally cutaway to allow the brackets to be

installed.

2. Interference or restriction of gas

connection

If the cabinet has a back-panel

which interferes with the position

of the gas supply to the hob, then

the panel can be completely

removed or locally cut-away to

allow connection to the gas supply.

16

Page 17

Alternative clamp positions

If the front and rear clamp positions

are problematic, alternative positions

can be used on the sides of the hob,

dependant on the particular installation.

These positions will require clearance

from any cabinet sides and may effect

how tightly the hob will meet the worktop.

Stone (Granite or equivalent)

worktops

Depending on the type of worktop

being used, there may or may not be

any backing material to screw the

clamp screws into.

1. If the worktop is a composite type

(backed with MDF or similar) there

may be enough backing to screw

directly into. This will depend on

the worktop thickness and backing

thickness and will have to be

assessed at the installation. In this

case, install the hob as for a standard worktop.

2. If there is insufficient backing material to screw into, or if the worktop

is completely solid in construction,

then it will be necessary to glue a

strip of wood, MDF, fibreboard or

similar to the underside of the worktop, along the front and rear edges

of the cutout. Use a strong, proprietary adhesive to bond these strips

and allow to cure before attempting to clamp the hob into position.

17

Page 18

Connect gas hob to gas supply

The inlet is at the rear RHS of the hob.

The hob may be connected to the gas

supply either by rigid pipework or flexible connection.

Flexible connections

Use a 900mm - 1125mm length of

flexible connector. Ensure that the

hose is installed hanging freely downwards, is not trapped, is not subjected

to undue forces and is not supported

at the bottom by a horizontal surface.

Natural Gas - Flexible connections

should comply with BS669, latest edition.

LP Gas - For flexible connections use

a bayonet type hose, suitable for use

on LP gas up to 50 mbar pressure rise

and 70˚C temperature rise. The flexible hose should be coloured black

with a red stripe, band or label. If in

doubt, contact your supplier.

The installation must ensure that the

flexible tube cannot come into contact

with movable parts of the housing unit

(eg; a drawer) and does not pass

through any space susceptible to becoming

congested.

Make sure the appliance is gas

sound & all components are

operating correctly.

Connect to the electricity supply

Unless this appliance is supplied with a

fitted plug, it must be connected by a

competent person, using fixed wiring

via a double pole switched fused spur

outlet, with a contact separation of 3mm

at all poles.

Connect the mains lead wires to the

terminals:

The blue wire must be connected to the

OAD

L

terminal marked N (Neutral)

or

coloured black. The brown wire must

be connected to the terminal marked L

(Live) LOAD or coloured red.

The green/yellow coloured wire must

be connected to the terminal marked

E (Earth) or coloured green.

Warning: this appliance must be

earthed.

The fused spur must be accessible after

installation.

If the supply cord is damaged, obtain

a special cord from the Customer Care

Helpline, which must be fitted by a

qualified person.

18

Page 19

Troubleshooting

Before you call Customer Care, please

check the following points:

Burner fails to ignite:

• Check the electricity supply is on.

• Check the fuse.

There is a spark to the burner

but it fails to ignite:

• Check that the flame holes in the

flame spreader are clear of water

or deposits.

• Check that the gas supply is turned

on.

Smell of gas:

• Check that none of the controls

have inadvertently been turned

on. If all the controls are in the off

position, turn off the gas supply &

call Customer Care.

The burner flame appears

uneven:

• Check the burner is fitted correctly.

• Check the flame holes in the flame

spreader are clear of water or

deposits.

19

Page 20

Technical DataThis information is

for the following appliances:

Belling 60T side control & Belling

60T/70T front control NG & LPG

Data badgeUnderside of the hob

base

Electrical supply

220-240V ~ 50Hz 1W

Ignition

Mains repetitive ignition.

Gas connectionThe inlet connection

is at the rear right-hand side -

ISO7 - Rp1/2” (1/2” BSP)

Appliance class

Class 3 Built-In Hotplate

Gas category

Natural Gas II2H3+

LPG only I3+

The adjustment conditions for this

appliance are stated on the data

badge.

This appliance is factory set for either

natural gas only or LPG only. If you

wish to convert this hob from natural

gas to LPG, a conversion kit -part no

013014500 - can be ordered from the

Customer Care helpline.

Gas pressure settings

G20 Natural gas @ 20 mbar

G31 Propane gas @ 37 mbar

G30 Butane gas @ 28 - 30 mbar

Countries of destination

(GB) Great Britain, (IE) Ireland

The Gas Consumer Council (GCC) is

an independent organisation which

protects the interests of gas users. If

you need advice, you will find the telephone number in your local telephone

directory under gas.

Burner Natural Gas LP Gas Bypass

kW Injector kW Injector Grammes per hour screw

60T side control- marking marking Butane Propane sizes

Back LH 2.0kW 104 2.0kW 70 145g/h 143g/h 32

Back RH 2.0kW 104 2.0kW 70 145g/h 143g/h 32

Front LH 3.0kW 129 3.0kW 87 218g/h 215g/h 40

Front RH 1.0kW 77 1.0kW 50 73g/h 72g/h 27

60T/70T front control-

Back LH 2.0kW 104 2.0kW 70 145g/h 143g/h 32

Back RH 3.0kW 129 3.0kW 87 218g/h 215g/h 40

Wok 3.5kW 121 & 63 3.5kW 87 & 35 254g/h 250g/h 68

Front RH 2.0kW 104 2.0kW 70 145g/h 143g/h 32

Front LH 1.0kW 77 1.0kW 50 73g/h 72g/h 27

Total Heat Input ∑Qn

60T 8.0kW 8.0kW 582g/h 572g/h

70T 11.5kW - 11.5kW - 836g/h 822g/h -

20

Page 21

Customer Care & Service

Please keep this handbook in a safe place as the information inside may be of

use should you sell, or pass on the appliance. Please fill in the model number

and serial number in the spaces provided below as they will assist us should you

need to call.

0844 815 3746

When you dial this number you will hear a recorded message and be given a

number of options. This indicates that your call has been accepted and is being

held in a queue. Calls are answered in strict rotation as our Customer Care

Representatives become available.

Enter appliance numbers here for future reference:

Model No

Serial No

Please ensure you have the above details (Model No and Serial No) to hand

when calling Belling Customer Care. They are essential to booking your call.

Outside the UK and Northern Ireland, refer to your local supplier.

If you smell gas:

Do not try to light any appliance. Do not touch any electrical switch.

Call the Gas Emergency Helpline at TRANSCO on: 0800 111999

In the Republic of Ireland, call the Bord Gaìs emergency line on 1850 205050 or contact your local gas supplier.

21

Page 22

08 2742103 © 11.2009

Stoney Lane, Prescot, Merseyside, L35 2XW

Belling

Loading...

Loading...