© Dimplex Boilers 2008

Dimplex 18 OV

Dimplex 32 OV

Open Vented Condensing Boilers

User’s Operating

Instructions

These instructions should be left with the user

5.0 ADDITIONAL INFORMATION

7

5.1 BOILER LOGBOOK

The logbook is included inside the Installation instructions. This

logbook should be completed by your installer to verify that

the correct installation and commissioning procedure was

followed.

Failure to complete the logbook may result in difficulties

should a problem arise with your appliance during the

guarantee period.

This logbook forms part of the industry’s Benchmark code of

practice for the installation, commissioning and servicing of

central heating systems.

All CORGI registered installers carry a CORGI identification card

and have a registration number. You can check your installer is

registered by telephoning 0870 4012300 or writing to:-

1 Elmwood

Chineham Business Park

Crockford Lane

Basingstoke

RG24 8WG

or check online at www.corgi-gas-safety.com

These appliances meet the requirements of;

Gas Appliance Directive 90/396/EEC

Efficiency of Hot Water Boilers Directive 92/42/EEC

Low Voltage Directive 92/42/EEC

Electromagnetic Compatibility Directive 92/31/EEC

Type test certified by:- Notified Body 0087 (Pin 87BT49).

Product/Production certified by:

Notified Body 0086.

For GB/IE only.

5.2 GENERAL CARE

The front panel should be cleaned with a damp cloth and mild

detergent. Do not use abrasive cleaners.

5.3 ROUTINE SERVICING

To ensure continued efficient operation of the appliance, it is

recommended that it is checked and serviced as necessary at

regular intervals. The frequency of servicing will depend upon

the particular installation conditions and usage but in general

once a year should be adequate. It is law that any service work

must be carried out by a competent person such as British Gas

or other CORGI Registered personnel.

5.5 PLUMING FROM TERMINAL

5.4 EMERGENCY

WARNING - If a gas leak is suspected or exists, turn the gas

OFF at the incoming mains (adjacent to th

e meter), Do not

operate any electrical switches. Do not operate any

electrical appliances. Open all win

dows and doors. Do not

smoke. Extinguish all naked lights. Phone the Transco 24

hour emergency

number immediately on 0800 111 999

(Do not call from a mobile phone).

For short or long periods

OFF

NOTE:

5.6 TO TURN THE BOILER OFF

5.7 BOILER OVERHEAT PROTECTION

CONTENTS

SECTION DESCRIPTION PAGE

1.0 Using the Boiler 3

2.0 Problem Solving 4

3.0 Safety 5

4.0 Error Codes 6

5.0 Additional Information 7

Natural Gas

Dimplex 18 OV - Gas Council Appliance No:

41 149 04

Dimplex 32 OV - Gas Council Appliance No:

41 149 03

2

© Dimplex Boilers 2008

GAS COUNCIL NUMBERS

Control Panel

Fig. 1

Read these instructions carefully before trying to operate the appliance.

1.0 USING THE BOILER

© Dimplex Boilers 2008

3

1.1 CONTROL PANEL

1.2 CH - CENTRAL HEATING TEMPERATURE CONTROL

Control knob shown in the OFF position.

Turn the knob clockwise to increase the temperature of the

central heating.

1.4 CH - CENTRAL HEATING TEMPERATURE CONTROL

Adjustable via the CH temperature control knob to give radiator

temperatures of between 30°C and 80°C.

During periods of no central heating requirement, the control

should be set to the STANDBY position but the permanent live

to the boiler should be left on.

1.3 TO LIGHT THE BOILER

1. Switch on the electrical supply.

2. Turn the CH temperature Control knob to the midpoint

between the minimum and maximum setting. The display

changes from ‘O’ to ‘h’.

3. Ensure Programmer and room thermostat (if fitted) are

calling for heat.

4. The display changes to ‘H’. When the boiler has lit a small

dot will also appear in the bottom right corner of the display.

5. If the burner fails to light the fan will stop. Initially this may

be due to air in the gas supply. The boiler will automatically

have five attempts at ignition.

6. After the five attempts it may be necessary to RESET the

boiler by turning the control knob to the RESET/STANDBY

position and back to ‘ON’ within TWO seconds (then repeat

step 2).

Min

Max

Central Heating

Temperature Control

7 segments

LED display

Fig. 2

Fig. 3

Fig. 4

Min

Max

Fig. 5

Digital Display

Burner On Light

3.0 SAFETY

3.1 GENERAL SAFETY

DO NOT interfere with any sealed components and use the

appliance only in accordance

with these instructions.

This ap

children) with reduced physical, sensory or mental capabilities,

or lack experience and knowledge, unless they have been given

supervision or instructions concerning use of the appliance by

a person responsible for their safety. Children should be

supervised to ensure that they do not play with the appliance.

5

It is the law that all gas appliances are installed by a competant

person in accordance with the above regulations. Failure to

install appliances correctly could lead to prosecution. It is in

your own interest, and that of safety, to ensure that the law is

complied with. If the appliance is damaged, turn off the

appliance and consult a CORGI registered installer. If it is known

or suspected that a fault exists on the appliance it

MUST NOT

be used until the fault has been rectified by a competant

person.

3.2 CURRENT GAS SAFETY (INSTALLATION & USE) REGULATIONS

This appliance must be earthed.

Supply: 230V - 50Hz fused at 3A.

The method of connection to the mains supply must facilitate

complete isolation of the appliance. Either a 3A fused three pin

plug and unswitched shuttered socket outlet, or a 3A fused

double pole switch having a 3mm contact separation in both

poles, serving only the boiler (and its external controls), may

be used.

3.3 ELECTRICAL SUPPLY

3.4 CLEARANCES AND VENTILATION

Fig. 11

1. A flat vertical area is required for the installation of the

boiler.

2. Where an open flued (B23) system is used then an air vent

must be provided in the same room or internal space of the

flue duct air inlet, with a minimum free area of:

3. These dimensions include the necessary clearance around

the boiler for case removal, spanner access and air movement.

Additional clearances may be required for the passage of pipes

around local obstructions such as joists running parallel to the

front face of the boiler.

4. When installed in a cupboard or compartment it is not

permissible to store other objects in the cupboard. Additionally

no flammable objects/items must be allowed to come into

contact with the boiler.

5. The boiler does not require additional ventilation when it is

installed in a cupboard or compartment. The exception to this

is where an open flue system has been installed - See note 2.

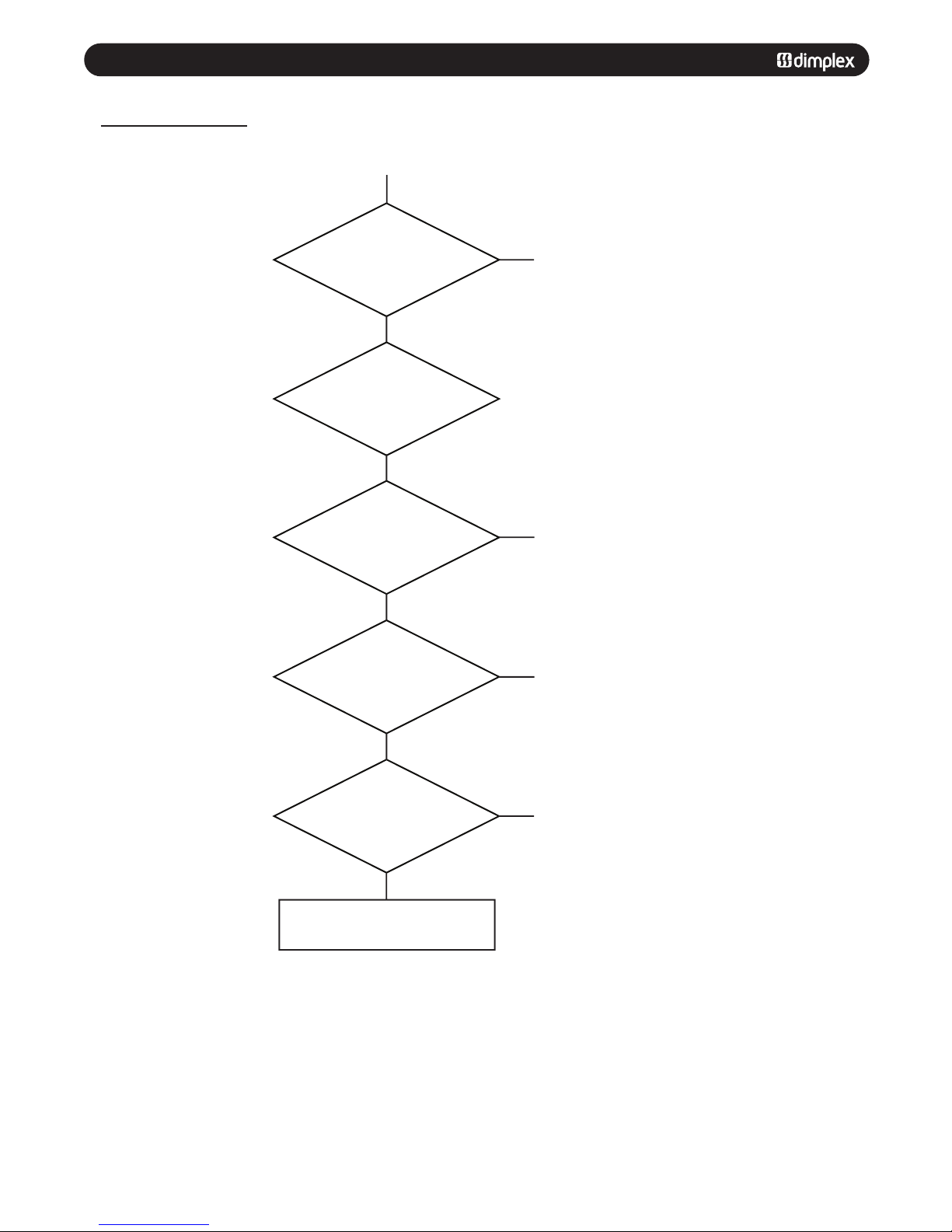

2.0 PROBLEM SOLVING

2.1 STEP BY STEP GUIDE

4

© Dimplex Boilers 2008

Boiler Not Working

Check that the gas

supply is turned on.

Are other gas appliances

working ?

Is the central heating

indicator light on ?

Is the CH

temperature control knob ON ?

Is the timer on and

calling for heat ?

Is the room thermostat

set high enough ?

Reset the boiler - see Section 5.7.

If the boiler does not reset, contact

your installer or service engineer

Yes

No

No

No

No

No

Yes

Yes

Yes

Consult gas supplier

Turn the knob clockwise

Ensure the timer is set for central heating

on (see your timerinstructions)

Turn the room thermostat to maximum

3.0 SAFETY

3.1 GENERAL SAFETY

DO NOT interfere with any sealed components and use the

appliance only in accordance

with these instructions.

This ap

pliance is not intended for use by persons (including

children) with reduced physical, sensory or mental capabilities,

or lack experience and knowledge, unless they have been given

supervision or instructions concerning use of the appliance by

a person responsible for their safety. Children should be

supervised to ensure that they do not play with the appliance.

© Dimplex Boilers 2008

5

It is the law that all gas appliances are installed by a competant

person in accordance with the above regulations. Failure to

install appliances correctly could lead to prosecution. It is in

your own interest, and that of safety, to ensure that the law is

complied with. If the appliance is damaged, turn off the

appliance and consult a CORGI registered installer. If it is known

or suspected that a fault exists on the appliance it

MUST NOT

be used until the fault has been rectified by a competant

person.

3.2 CURRENT GAS SAFETY (INSTALLATION & USE) REGULATIONS

This appliance must be earthed.

Supply: 230V - 50Hz fused at 3A.

The method of connection to the mains supply must facilitate

complete isolation of the appliance. Either a 3A fused three pin

plug and unswitched shuttered socket outlet, or a 3A fused

double pole switch having a 3mm contact separation in both

poles, serving only the boiler (and its external controls), may

be used.

3.3 ELECTRICAL SUPPLY

3.4 CLEARANCES AND VENTILATION

5mm Min

372mm

5mm Min

580mm

200mm

200mm

285mm Wall

450mm Min

For Servicing

Purposes

5mm Min

In Operation

2.5°

Fig. 11

1. A flat vertical area is required for the installation of the

boiler.

2. Where an open flued (B23) system is used then an air vent

must be provided in the same room or internal space of the

flue duct air inlet, with a minimum free area of:

Dimplex 18 = 60cm

2

Dimplex 32 = 125cm

2

3. These dimensions include the necessary clearance around

the boiler for case removal, spanner access and air movement.

Additional clearances may be required for the passage of pipes

around local obstructions such as joists running parallel to the

front face of the boiler.

4. When installed in a cupboard or compartment it is not

permissible to store other objects in the cupboard. Additionally

no flammable objects/items must be allowed to come into

contact with the boiler.

5. The boiler does not require additional ventilation when it is

installed in a cupboard or compartment. The exception to this

is where an open flue system has been installed - See note 2.

1.0 USING THE BOILER

3

1.1 CONTROL PANEL

1.2 CH - CENTRAL HEATING TEMPERATURE CONTROL

Control knob shown in the OFF position.

Turn the knob clockwise to increase the temperature of the

central heating.

1.4 CH - CENTRAL HEATING TEMPERATURE CONTROL

Adjustable via the CH temperature control knob to give radiator

temperatures of between 30°C and 80°C.

During periods of no central heating requirement, the control

should be set to the STANDBY position but the permanent live

to the boiler should be left on.

1.3 TO LIGHT THE BOILER

1. Switch on the electrical supply.

2. Turn the CH temperature Control knob to the midpoint

between the minimum and maximum setting. The display

changes from ‘O’ to ‘h’.

3. Ensure Programmer and room thermostat (if fitted) are

calling for heat.

4. The display changes to ‘H’. When the boiler has lit a small

dot will also appear in the bottom right corner of the display.

5. If the burner fails to light the fan will stop. Initially this may

be due to air in the gas supply. The boiler will automatically

have five attempts at ignition.

6. After the five attempts it may be necessary to RESET the

boiler by turning the control knob to the RESET/STANDBY

position and back to ‘ON’ within TWO seconds (then repeat

step 2).

Fig. 2

Fig. 3

Fig. 4

Fig. 5

4.0 ERROR CODES

6

© Dimplex Boilers 2008

AFTER ENSURING THAT ALL ACTIONS HAVE BEEN CARRIED OUT RESET THE BOILER (REFER TO SECTION 5.4) IF ANYY OF

THE BELOW FAULTS OCCUR DURING INSTALLATION PLEASE REFER TO THE ACTIONS, HOWEVER IF ANY OTHER E

R

RROR

CODE IS SHOWING PLEASE CONTACT THE INSTALLER OR TECHNICAL HELP LIN

EE:

: 01926 834834

ERROR CODE DESCRIPTION REASON ACTION RESET POSSIBLE

1

Overheated CH Water temperature •Check no air is in heat exchanger / CH system

appliance greater than 105°C •Check external pump operation Yes

•Check PCB / X1C connector

•Check flow thermistor

•Check wires to sensors not crossed

2 Different check faulty / Sensor temperature • Check water pressure

Flame for 15 seconds differential incorrect • Check external pump / CH system blockage Auto Restart When Fixed

• Check no air is in heat exchanger / CH system

• Check flow, and return sensors

3 No gas or Lockout flame Low gas pressure. • Check gas supply

signal / No flame, Loss of flame signal during • Check gas service cock

Lockout after 5 ignition operation • Check gas valve and lead

attempts • Check detection electrode / lead Yes

• Check PCB / X2A & X2B connectors

• Check spark generator /spark electrode

• Check mains earth lead continuity

4 Flue gas sensor / Flue gas temperature greater • Check flue sensor

No flame than 95°C • Check flue system

• Check no air is in heat exchanger / CH system Yes

• Check external pump

• Check PCB / PCB connectors

ERROR CODE DESCRIPTION REASON ACTION RESET POSSIBLE

5 Defective sensor or Defective flow, return or flue • Check wiring to sensors

thermal fuse blown sensor or heat exchanger • Check PCB / X6 & X8 connectors

reached maximum safe • Check flow, return and flue sensors

working temperature • CHECK THERMAL FUSE IS OPEN CIRCUIT.

IF SO REPLACE HEAT EXCHANGER (SEE 10.8)

6 Defective gas valve / 5 sec flame signal after burner • Check gas valve and lead

Flame continues after is switched off • Check PCB

demand ends

7

Def

ective fan / No flame Missing or Erroneous RPM • Check fan

signal • Check mains fan lead & connector

• Check low voltage fan lead & connector

• Check PCB / X3 connector Auto Restart When Fixed

A PCB error / No flame Internal error • Check PCB

b Activate BCC / No flame New BCC • Turn CH control knob to reset twice to activate

C Safety system failure / Failure of internal self • Check PCB

No flame checking system • Check BCC is initialised

E BCC error / No flame Incorrect / missing BCC • Reset or replace BCC

h No flame Faulty connector • Check PCB / X1A connector

0 Different check faulty / Water flow rate too low • Check water pressure

Flame for 15 seconds • Check external pump / CH system blockage

• Check no air is in heat exchanger / CH system

• Check wires to sensors not crossed

• Check flow, and return sensors

P Error in power supply / Low mains voltage • Check mains voltage

No flame • Check PCB connectors

No light indication Defective power supply • Check power supply

• Check PCB / X1B connector

• Check PCB fuse

RESET LOCK-OUT CODES

BLOCKING CODES

5.0 ADDITIONAL INFORMATION

© Dimplex Boilers 2008

7

5.1 BOILER LOGBOOK

The logbook is included inside the Installation instructions. This

logbook should be completed by your installer to verify that

the correct installation and commissioning procedure was

followed.

Failure to complete the logbook may result in difficulties

should a problem arise with your appliance during the

guarantee period.

This logbook forms part of the industry’s Benchmark code of

practice for the installation, commissioning and servicing of

central heating systems.

All CORGI registered installers carry a CORGI identification card

and have a registration number. You can check your installer is

registered by telephoning 0870 4012300 or writing to:-

1 Elmwood

Chineham Business Park

Crockford Lane

Basingstoke

RG24 8WG

or check online at www.corgi-gas-safety.com

These appliances meet the requirements of;

Gas Appliance Directive 90/396/EEC

Efficiency of Hot Water Boilers Directive 92/42/EEC

Low Voltage Directive 92/42/EEC

Electromagnetic Compatibility Directive 92/31/EEC

Type test certified by:- Notified Body 0087 (Pin 87BT49).

Product/Production certified by:

Notified Body 0086.

For GB/IE only.

5.2 GENERAL CARE

The front panel should be cleaned with a damp cloth and mild

detergent. Do not use abrasive cleaners.

5.3 ROUTINE SERVICING

To ensure continued efficient operation of the appliance, it is

recommended that it is checked and serviced as necessary at

regular intervals. The frequency of servicing will depend upon

the particular installation conditions and usage but in general

once a year should be adequate. It is law that any service work

must be carried out by a competent person such as British Gas

or other CORGI Registered personnel.

5.5 PLUMING FROM TERMINAL

Like all condensing boilers this appliance will produce a plume

of condensation from the flue terminal. This is due to the high

efficiency and hence low flue gas temperature of the boiler. It

is normal and not a fault indication.

The boiler is fitted with a condensate trap.

The condensate drain point must not be modified or blocked

(see section 7.6 of the installation manual).

5.4 EMERGENCY

WARNING - If a gas leak is suspected or exists, turn the gas

OFF at the incoming mains (adjacent to th

e meter), Do not

operate any electrical switches. Do not operate any

electrical appliances. Open all win

dows and doors. Do not

smoke. Extinguish all naked lights. Phone the Transco 24

hour emergency

n

number immediately on 0800 111 999

(Do not call from a mobile phone).

For short or long periods

Switch the programmer and/or room thermostat switch to the

OFF

position.

NOTE:

The ap

pliance is fitted with a frost protection device In

the event of very cold conditions. Providing there is mains

power supply to the appliance, the frost protection mode is

integral. If the system temperature falls below 5°C then the

boiler will fire on its minimum setting until a flow temperature

of 30°C is reached. Further protection can be incorporated by

using a system frost thermostat.

The pump will automatically operate for 1 minute in every 24

hours to prevent sticking.

5.6 TO TURN THE BOILER OFF

In the event of overheating, the boiler will shut down and the

digital display will show ‘1’. Allow the boiler to cool, then

briefly turn the CH control knob fully anti-clockwise to the

RESET/STANDBY position and then back to ‘ON’ within two

seconds.

If the fault persists, consult a CORGI Registered installer.

5.7 BOILER OVERHEAT PROTECTION

Dimplex 18 OV

Dimplex 32 OV

Open Vented Condensing Boilers

Part No: 751288 - Issue 3 - 07/07/10

© Dimplex Boilers 2008

Glen Dimplex Boilers is continually improving its products and therefore

reserve the right to change product specifications without prior notice.

Errors & omissions excepted.

Glen Dimplex Boilers

Stoney Lane

Prescot

Merseyside. L35 2XW

For all telephone enquiries call:

0844 371 2222

website:

www.glendimplexboilers.com

Part of the Glen Dimplex Group

SALES AND SERVICE HELPLINE: 0844 371 1111

Loading...

Loading...