Page 1

Page 2

Our Warranty

Should you need it . . . .

Inside the paperwork which has come with this appliance,

there is a leaflet and card explaining the terms of our

extended warranty and guarantee.

In order to apply for our five year guarantee, simply fill in

the details on the card and post it off, this will register your

appliance.

Should you wish to take out extended warranty, please fill

in the details on the leaflet and post this off to:

Glen Dimplex Australia,

Unit 2, 205 Abbotts Road

Dandenong South

Victoria 3175

Australia

If your appliance is covered by the warranty and guarantee, you will not be billed for work undertaken should your

appliance be faulty, terms and conditions do apply, so

please read through the literature carefully.

Please ensure that you have available your appliances

model number and serial number, there is a space at the

back of this book for recording that information.

Page 3

1

User’s Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Be Safe - Not Sorry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Using the Grill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Using the Top Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Using the Ovens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Using the Main Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Programmer / Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Micro-computer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Fault Finding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Customer Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Please keep this handbook for future reference, or for anyone else

who may use the appliance.

CONTENTS

Page 4

Your Appliance

900GR fascia detail

Timer display

Timer buttons

Top oven

function

Grill function

Main oven

function

Temperature selectors

2

900GR oven detail

For fascia detail

- see above

Grill / Top Oven

door handle

Grill / Top Oven

glass door

Main Oven

door handle

Main Oven

glass door

Page 5

Thank you for choosing this

Stoves by Eurolec appliance.

We hope the following information

will help you to familiarise yourself

with the features of the appliance, and

to use it successfully and safely.

Our policy is one of constant

development and improvement. Strict

accuracy of illustrations and specifications

is not guaranteed. Modification to

design and materials may be necessary

subsequent to publication.

This appliance must be installed in

accordance with the regulations in

force, and only in a well ventilated

space. Read the instructions before

using or installing this appliance.

The 900GR is designed to fit into a

standard 600mm wide housing unit

with a minimum internal height of

880mm, and clear depth of 550mm.

Your first year guarantee

To fulfil the conditions of your guarantee,

this appliance must be correctly

installed and operated, in accordance

with these instructions, and only be

used for normal domestic purposes.

Before using the appliance for

the first time, remove any protective

polythene film and wash the oven

shelves and furniture in hot soapy water

to remove their protective covering of

oil. Even so, when you first switch on

the oven or grill, you may notice a

smell or some smoke.

To replace an oven light bulb

Switch off the electricity supply to the

appliance at the socket, to avoid the

risk of electric shock.

Wait until the oven is cool then remove

the oven shelves.

The lens cover on the light can be

removed by grasping the lens cover

and pulling away from the side of the

oven. Unscrew the bulb.

Please note that the oven light bulbs

are not covered by guarantee.

Replacement bulbs can be bought

from most hardware stores.

3

INTRODUCTION

Page 6

Gas & Electrical connection

Please refer to installation instructions

for the Gas & Electrical Safety Regulations

and the Ventilation Requirements.

The information below is crucial to

installing this appliance correctly and

safely.

Failure to install appliances

correctly is dangerous and could

lead to prosecution.

Disconnection of gas and electric

appliances should always be carried

out by competent persons.

Warning: This appliance must be

earthed.

In the event of a power cut

1. Switch off the electricity to the

appliance at the socket.

2. When the power returns, see the

‘Programmer / Clock’ section to

‘Set the time of day’.

Note: operating the control knobs

You may find that the control knobs on your

new appliance operate or perform

differently to those you are used to.

The controls are part of the unique electronic

operating system of the appliance and are

designed to be extremely responsive and

easy to turn.

Condensation

When hot and cold air meet,

condensation forms. The outer door is

air cooled and the inner door gets hot,

so some condensation might form; this

is normal and will disappear within

10 - 15 minutes.

During operation, a metallic click may

be heard occasionally. This is caused

by the gas valve operating and is

quite normal.

Ventilation

The use of a gas cooking appliance

results in the production of heat and

moisture in the room in which it is

installed. Ensure that the kitchen is well

ventilated; keep natural ventilation holes

open or install a mechanical ventilation

device (mechanical extractor hood).

Prolonged intensive use of the

appliance may call for additional

ventilation, for example opening of a

window, or more effective ventilation,

for example increasing the level of

mechanical ventilation where present.

This appliance is not connected to a

products evacuation device.

It should be installed and connected in

accordance with current installation

regulations. Particular attention should

be given to the relevant requirements

regarding ventilation.

4

INTRODUCTION

Gas Safety (Installation & Use)

Regulations

This appliance must by an authorised

person in accordance with the

Australian Gas Installation Standard

AS5601 the manufacturers installation

instructions, local gas fitting regulations,

and any other relevant statutory

regulations.

Particular attention should be given to

relevant requirements regarding ventilation.

Page 7

Glass door panels

To meet the relevant Standards of

Domestic cooking appliances, all the

glass panels on this appliance are

toughened to meet the fragmentation

requirements of BS3193. This ensures

that, in the unlikely event that a panel

breaks, it does so into small fragments

to minimise the risk of injury.

Please take care when handling, using

or cleaning all glass panels as any

damage to the surfaces or edges may

result in the glass breaking without

warning or apparent cause at a later

date. Should any glass panel be

damaged, we strongly recommend

that it is replaced immediately.

Ready lights

The ready lights are located in the

control knob windows, below the

indicator dial.

When the appliance is switched on,

the red lights will come on.

A steady green light indicates when

the selected oven or grill has reached

a suitable temperature.

If the lights are flashing, refer to

“Micro-computer Operation” section.

Cooling fan

When you switch on the ovens or grill

you will hear the cooling fan start.

This fan provides air for the burners

and keeps the exterior of the

appliance cool during cooking, the

appliance will not operate unless the

fan is operating.

If the fan malfunctions the appliance

will require servicing. The fan may

continue to operate to cool the

appliance for a few minutes after the

last control has been switched off.

Warning: Do not use the oven(s) if

the fan is not working.

Environmental Protection

We are committed to protecting the

environment and operate an

Environmental Management System

which complies with current regulations:

Disposal of packaging

• All our packaging materials are

recyclable and environmentally

friendly.

• Please help us to protect our

environment by disposing of all

packaging in an environmentally

friendly manner.

• Please contact your local authority

for the nearest recycling centre.

Caution: Packaging materials can

pose a risk of suffocation - keep away

from children.

5

INTRODUCTION

Page 8

When you are cooking, keep

children away from the vicinity

of the appliance.

This product is designed as a domestic

cooking appliance for the preparation

and cooking of domestic food

products, and should not be used for

any other purpose.

• Remove all packaging, protective

films and oils from the appliance

before using for the first time.

• Make sure you read and understand the instructions before using

the appliance.

• Keep electrical leads short so they

do not drape over the appliance

or the edge of the worktop.

• Keep all flammable materials (such

as curtains, furnishings & clothing)

away from the appliance.

• Parts of the appliance may be hot

during or immediately after use.

Allow sufficient time for the appliance to cool after switching off.

• Never use the appliance for

heating a room.

• Do not drape tea towels over the flue

vents as this creates a fire hazard.

• When opening the appliance

door, take care to avoid skin

contact with any steam which may

escape from the cooking.

• Do not use spray aerosols in thevicinity of the appliance while it’s

in operation.

• Do not use aluminium foil to cover

the grill pan, or put items wrapped

in foil under the grill as this creates

a fire hazard.

• Do not use foil on oven shelves, or

allow it to block the oven flue, as

this creates a fire hazard, and

prevents heat circulation.

•

Drop-down doors: Do not place

items on the door when open.

• Do not use the oven with the door

inner glass panel removed.

• Use oven gloves when removing

hot food / dishes from the oven or

grill. The oven / grill and utensils

will be very hot when in use.

• When cooking heavy items, eg;

turkeys, do not pull the oven shelf

out with the item still on the shelf.

• Switch off the electricity supply

before replacing the oven light bulb,

to avoid the risk of electric shock.

Warning: This appliance must be

earthed.

All installation, servicing and

maintenance work should be carried

out by a competent person who will

comply with current Regulations,

Standards and Requirements.

When you have finished

cooking check that all controls

are in the off position.

As with all gas appliances, it is

recommended that your appliance is

serviced annually.

6

BE SAFE - NOT SORRY

Page 9

Caution: Accessible parts may

be hot when the grill is used.

Young children should be kept

away.

Grill ignition

Open the grill door. Turn the Top

Oven / Grill control knob clockwise to

the grill setting.

The grill door must be fully open when

the grill is used. If the door is closed

the grill burner will go out. The grill

will re-light when the door is opened

again.

There is a short delay before ignition

whilst the cooling fan speeds up - this

may be for several seconds.

To switch off, return the control knob to

the “off” position.

Note that the grill will not function

when the appliance is set for

automatic cooking.

Position the grill pan centrally on the

oven shelf.

Caution:

Never

cover the grill pan or trivet

with cooking foil or allow fat to build

up in the grill pan, as this creates a

fire hazard.

Preheating

For best cooked results, the grill should

be preheated until the green ready

light appears (about 3 minutes).

Using the Grill

Push the grill pan towards the back

and centre of the shelf to position it

under the grill. Variation in grilling

performance can be achieved by

selecting a higher or lower shelf position.

Always use the top shelf position for

fast cooking, toasting and grilling

foods such as bacon, sausages or

steaks.

For thicker foods such as chops or

chicken joint pieces use a middle to

low shelf position.

The grill trivet, inside the grill pan, can

also be inverted to give a high or low

position, or it may be removed.

When you have finished

grilling, check that the control

knob is in the off position.

7

USING THE GRILL

Page 10

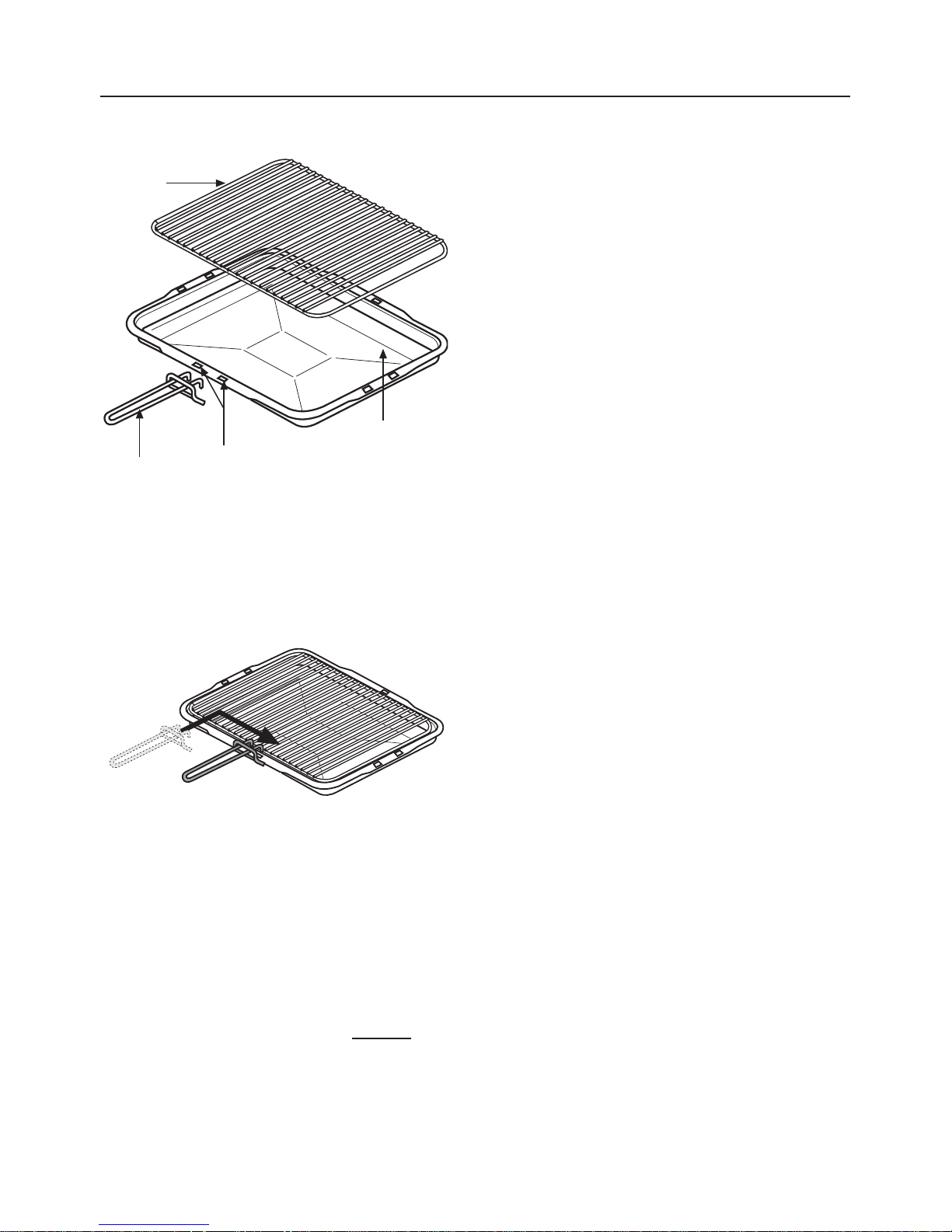

Detachable grill pan handle

Place the handle over the edge of the

grill pan, at the narrow side edges.

Slide the handle to the centre, and

locate between the handle position

indicators.

The handle should be removed from

the pan during grilling, to prevent

overheating.

The handle is designed for removing /

inserting the grill pan under the grill

when grilling.

If cleaning the grill pan when it is hot,

use oven gloves to move it.

Do not

use

the handle to pour hot fats from the

grill pan.

Food for grilling should be positioned

centrally on the trivet.

USING THE GRILL

handle

grill pan

grid

handle position

indicators

8

Page 11

When you are cooking keep

children away from the vicinity

of the oven.

The top oven can be used generally,

in the same way as the main oven,

to cook the full range of dishes, but it

is a

SECONDARY oven and there are

some differences.

Top oven ignition

Turn the Top Oven / Grill control knob

anticlockwise to the required gas

mark.

There is a short delay before ignition

(up to 10 seconds) as the cooling fan

builds up pressure.

The top oven burner will not come on

unless the oven door is closed.

To turn off, return the control knob to

the “off” position. Please ensure that

the oven is fully switched off when not

in use.

Notes:

As part of the cooking process, hot air

is expelled through a vent at the top of

the oven(s). When opening the oven

door, care should be taken to avoid

any possible contact with potentially hot

air, since this may cause discomfort to

people with sensitive skin. We recommend

that you hold the underneath of the

oven door handle.

Warning: Do not use the oven(s) if

the fan is not working.

9

USING THE TOP OVEN

Page 12

When you are cooking keep

children away from the vicinity

of the oven.

Manual operation

The oven cannot be used manually

when the programmer is set for

automatic cooking. If auto is showing

on the programmer display, press the

cook time and ready time buttons

simultaneously to cancel the automatic

setting and return to manual operation.

Turn the control knob anticlockwise to

the required gas mark setting.

There is a short delay before ignition

whilst the cooling fan starts and runs

up to speed. The ignition unit will

spark for approximately four seconds

to light the burner; if ignition does not

occur, the computer will close the gas

valve for 12 seconds to allow any

unburnt gas to disperse, before

attempting ignition again. This

sequence will occur automatically a

further 4 times only. The green lamp

will flash if ignition does not occur

within 4 attempts. The computer may

be reset if ignition has not occurred,

by turning the control off then on

again to the required setting.

The oven cannot be used manually

when the programmer is set for

automatic cooking; if

A (AUTO) is

showing on the programmer display,

press the cook time and ready

time buttons simultaneously to cancel

the automatic setting.

Main oven ignition

Turn the control knob anticlockwise to

the required gas mark.

To turn off, return the control knob to

the “off” position. Please ensure that

the oven is fully switched off when not

in use.

Automatic operation

See ‘Programmer / Clock’ section.

We recommend that 15 minutes is

added to the cooking time when using

the automatic cooking facility, to allow

for preheating.

Oven light

All oven lamps will light when an oven

is in use.

Notes:

As part of the cooking process, hot air

is expelled through a vent at the top of

the oven(s). When opening the oven

door, care should be taken to avoid

any possible contact with potentially hot

air, since this may cause discomfort to

people with sensitive skin. We recommend

that you hold the underneath of the

oven door handle.

Warning: Do not use the oven(s) if

the fan is not working.

10

USING THE MAIN OVEN

Page 13

Oven furniture

Oven shelves

The oven shelf must be positioned with

the upstand at the rear of the oven and

facing upwards.

Position baking trays and roasting tins

on the middle of the shelves, and leave

one clear shelf position between

shelves, to allow for circulation of heat.

Baking tray and roasting tins

For best cooked results and even

browning, the maximum size baking

trays and roasting tins that should be

used are as follows;

Baking tray 350mm x 280mm

This size of baking tray will hold up to

16 small cakes.

Roasting tin 370mm x 320mm

We recommend that you use good

quality cookware. Poor quality trays

and tins may warp when heated,

leading to uneven baking results.

11

USING THE OVENS

Page 14

Programmer / Clock

12

The Programmer Buttons

minute minder

cook time

ready time

minus

plus

To set the “Time of Day”

Press the cook time and ready time

buttons simultaneously

, and keep the

buttons depressed. Use the plus and

minus buttons to set the time of day,

eg; 12.00.

A (Auto) symbol goes out, cookpot

symbol comes on.

To select an alarm tone

Press the minus button to listen to the

first tone.

Release the minus button and press it

again to listen to the second tone, etc.

Releasing the

minus button after the

tone has sounded will automatically

select that tone.

Manual operation

To set the programmer to manual

operation at any time (cancelling any

automatic setting), press the cook time and

ready time buttons simultaneously. The

programmer must be set to manual before

the appliance can be used manually.

Setting the minute minder

Press the minute minder button, then

use the plus and minus buttons to set

the required time.

The minute minder (bell) symbol will

appear on the display.

You can cancel the minute minder at

any time by pressing the

minute

minder button and the minus button

until the display returns to 0.00.

After setting, the display will revert to

show the time of day, but you can press

the minute minder button, and the

display will show the minutes remaining.

The tone will sound at the end of the

time set - to cancel the tone, press the

minute minder button.

Page 15

Programmer / Clock

13

1. A (Auto) symbol appears.

2.

3. A (Auto) symbol will flash.

4. A (Auto) symbol goes out.

Semi-automatic cooking

(example)

You have started cooking a meal or

dish in the oven, and want to set the

time for the oven to switch off

.

Press the cook time button, then use the

plus and minus buttons to set the

display to show the length of cooking

time required, eg; 2 hours as shown (1).

After setting, the display will revert to

show the time of day, but you can

press the cook time button and the

display will show how much cooking

time still remains on the clock.

Press the ready time button, and the

display will show the actual time the

oven is going to switch off, eg; 18.00

as shown (2).

At the end of the cooking time, the

alarm will sound, and the oven will

automatically switch off.

To switch off the alarm, press the

minute minder button (3).

When the oven has switched off,

return the oven control knob to

the “off” position, and press the

cook time and ready time buttons to

return to manual operation (4).

If you wish to cancel the automatic

setting, or to cancel any remaining

cooking time left on the clock before

the alarm sounds, press the

cook time

and ready time buttons simultaneously.

(

4).

A

U

T

O

A

U

T

O

A

U

T

O

Page 16

Programmer / Clock

14

5. A (Auto) symbol appears.

6. The cookpot symbol will

disappear from display.

7. The cookpot symbol will appear

on display.

8.

Fully automatic cooking

(example)

For use when a delayed start time is

required.

You want to set the length of cooking

time, and the time for the oven to switch

off. The programmer will automatically

calculate the cooking start time

.

Turn the oven control to the

required temperature.

(Oven will begin normal cooking

mode.)

Press the cook time button, then use the

plus and minus buttons to set the

display to show the length of cooking

time required, eg; 2 hours as shown (5).

Press the ready time button, and the

present ready time will be displayed.

Using the plus and minus buttons you

can set the display to show the actual

time you want the oven to switch off,

eg; 18.00 hours (6.00 pm) (6).

The display will revert to show time of day.

The oven will automatically switch on

at the calculated start time of 16.00

hours (4.00 pm) (

7).

A single press of the cook time button

shows the cooking time remaining

before the oven automatically switches

off (8).

A

U

T

O

A

U

T

O

A

U

T

O

A

U

T

O

Page 17

Programmer / Clock

15

9. A (Auto) symbol will flash.

10.

11. A (Auto) symbol goes out.

The oven will automatically switch off

at 18.00 hours (6.00 pm) and the

alarm will sound (9).

To switch off the alarm press the

minute minder button (10).

When the oven has switched off,

return the oven control knob to the

“off” position, and press the cook time

and ready time buttons simultaneously

(11).

If you wish to cancel the automatic

setting before cooking has started,

and return to manual operation, press

the cook time and ready time buttons

simultaneously (11).

To cancel any remaining cooking time

left on the clock before the alarm

sounds, press the cook time and ready

time buttons simultaneously (11).

A

U

T

O

A

U

T

O

Page 18

Automatic cooking

These notes below are to help you with

using the automatic cooking facility.

Please make sure that you read them

carefully before you start using the

automatic functions.

Do

• Familiarise yourself with the use of

the programmer.

• Select foods which are as fresh as

possible, and as cold as possible ie; preferably straight from the

refrigerator.

• Choose foods which are suitable

for cooking from a cold start, as

some dishes will be affected by

being left uncooked, at room temperature, perhaps for several

hours, especially when the weather is hot.

• Make sure that meat, poultry and

uncooked food are thoroughly

thawed before placing them in the

oven.

• Cover dishes with lids or foil, as

they may be left standing in the

oven for some time before cooking.

Do not

• Never place warm food in the

oven for delayed cooking - eg;

stews prepared by frying meat first

must be thoroughly cooled before

placing in the oven.

• Do not cook dishes containing left

over cooked meat or poultry, or

pastry dishes with wet fillings,

as they are not suitable for automatic cooking.

• Do not put food items intended for

delayed cooking into a warm oven

- allow the oven to cool before setting for delayed cooking.

• Do not over-fill dishes containing

liquids, as they might boil over.

• Never leave food in the oven to

cool slowly after cooking, serve

immediately or refrigerate.

Automatic cooking - hints

16

Page 19

Caution: Any cleaning agent

used incorrectly may damage

the appliance.

Always let the oven cool before

cleaning.

Some cooking operations generate a

considerable amount of grease. This,

combined with spillage, can become a

hazard if allowed to accumulate on

the appliance through lack of cleaning.

In extreme cases this may amount to

misuse of the appliance and could

invalidate your guarantee.

It is recommended that the appliance

is cleaned after open roasting.

Do not use caustic, corrosive or

abrasive cleaning products, products

containing bleach, coarse wire wool

or any hard implements, as they will

damage the surfaces.

All parts of the appliance can be

safely cleaned with a cloth wrung out

in hot soapy water.

Painted, plastic & metal finish parts

DOOR HANDLE, CONTROL KNOBS

Only use a clean cloth wrung out in

hot soapy water.

Chrome plated parts

OVEN SHELVES & OVEN SHELF RUNNERS,

GRILL PAN TRIVET

Do not use abrasives or polishes. Use a

moist soap pad. These items may also

be cleaned in a dishwasher.

Note: Oven shelf runners can be

removed for cleaning. Grasp the

runners, and slide out of the hanging

holes as shown.

Enamel surfaces

OVEN CAVITIES, GRILL PAN & ROASTING TINS

We recommend that the appliance is

cleaned after open roasting, and also

after roasting at temperatures higher

than gas mark 5. Use of a trivet in a

roasting tin when roasting will help

reduce fat splashing.

Caution: Most types of cleaning

agent will damage these surfaces.

Only use a few drops of washing up

liquid in hot water. Wipe the surfaces

with a clean cloth wrung out in hot soapy

water - if larger splashes of fat do not

readily disappear, scrub the area with

a nylon brush or nylon pan scourer

and hot soapy water. Rinse well and

heat the oven to dry the surfaces.

17

CLEANING

Page 20

Glass parts

FACIA PANEL & DOOR PANELS

Use a mild cream cleaner. Rinse thoroughly and dry with a soft cloth. Do

not use abrasive cleaners or polishes.

To remove the glass panel for cleaning,

open the door to the door stop position

(about 30˚ open), hold the top and

bottom edges of the panel and slide

out. Note that if the door is opened

fully when removing the inner door

glass panel, the door may spring shut.

Important: if the inner door glass

panel is removed for cleaning, it must

be replaced the right way up as

shown, and pushed fully in to the

stop position.

18

CLEANING

30˚

Door stop position

Approx.

slide in

this way up

Page 21

Stainless Steel surfaces (stainless

steel finish models only)

FACIA PANEL, HANDLES, DOOR PANELS

Only use a clean cloth wrung out in hot

soapy water, and dry with a soft cloth.

Stubborn marks can be removed using

a stainless steel cleaner. We recommend that you clean the whole of the

stainless steel area to maintain a uniform finish. Supplies can be purchased

from the Customer Care Centre.

Do not use undiluted bleach or any

products containing chlorides as they

can permanently damage the steel.

Extra care should be taken when cooking

food in salted water. Some foods are

corrosive - eg; vinegar, fruit juices and

especially

salt

- they can mark or

damage stainless steel if they are left

on the surface. Turn off and wipe any

spillage immediately, taking care to

avoid skin contact with any hot surface

or spillage.

Sharp objects can mark the surface of

stainless steel, but marks will become

less noticeable with time.

To maintain the finish of the stainless

steel, or to remove any greasy marks,

wipe the stainless steel surface sparingly with a minimum

amount of Baby

Oil and kitchen paper.

Do not use cooking oils, as these may

contain salt, which can damage the

stainless steel surface.

19

CLEANING

Page 22

If in doubt, isolate the appliance from the

gas and electrical supplies & contact

Customer Care.

The 900GR double oven & grill unit uses a

built in micro-computer to control the oven

temperature. The computer also indicates

when the ovens are ready for use, and

oversees the gas supply, fan operation and

ignition sequence ensuring that these are

operating safely.

Should the micro-computer find any fault in

the systems under its control, it will either;

- stop the ignition and gas valve

operation or;

- if the cooker is already in use it will

shut down the operation until the fault

is rectified.

The cooling fan will, however, continue to

run on for a while, and the oven lights

remain on.

Electrical interference either from the mains

or other electrical equipment may cause

the micro-computer to indicate a fault when

non exists, chiefly when first turning on.

It may be necessary to reset the microcomputer (by turning the electricity supply

off at the mains plug) when first bringing

the appliance into operation.

Opening oven doors whilst the microcomputer is running through it’s checks

may cause it to lock out.

In the event of a power cut

1. Switch off the appliance at the socket.

2. When the power returns, see the

‘Programmer / Clock section to ‘Set the

time of day’.

In the event of the gas supply being

disconnected it may be necessary to

make several lighting attempts before gas

reaches the appliance.

20

Lamp signal Cause Action

Steady green Selected oven / grill None - normal operation.

has reached required

temperature.

Green lamp & red indicator Soft lockout. Reset - turn control knob off / on.

dial of main oven cavity

flash.

Green lamp & red indicator Hard lockout. Reset - turn off / on at mains. If

dial for both ovens flash (possible interference) recurring, a service visit may be

alternately left / right. required.

Green lamp & red indicator Fault on micro-computer Service visit required.

dial for both ovens flash

together.

MICRO-COMPUTER OPERATION

Page 23

Before you start: Please read the

instructions. Planning your installation will

save you time and effort.

Prior to installation, ensure that the local

distribution conditions (nature of the gas and

gas pressure) and the adjustment of the

appliance are compatible. The adjustment

conditions are stated on the data badge.

This appliance is not connected to a combustion

evacuation device. It shall be installed and

connected in accordance with current

installation regulation. Particular attention

shall be given to the relevant requirements

regarding ventilation.

The information below is crucial to

installing this appliance correctly and

safely.

Failure to install appliances

correctly is dangerous and could

lead to prosecution.

Ventilation Requirements

Ventilation must be as specified by AS

5601 Installation code. The room conatining the appliance should have an air supply.

An appliance should be installed in a location for complete combustion of gas, proper flueing and to maintain ambient temperature of the immediate surrounding at safe

limits, under normal conditions.

Failure to install appliances correctly

is

dangerous and could lead to prosecution.

21

INSTALLATION INSTRUCTIONS

Gas Safety (Installation & Use)

Regulations

This appliance must by an authorised

person in accordance with the

Australian Gas Installation Standard

AS5601 the manufacturers installation

instructions, local gas fitting regulations,

and any other relevant statutory

regulations.

Particular attention should be given to

relevant requirements regarding ventilation.

Page 24

Step 1: Prepare installation

Do not lift the appliance by the

door handle.

Remove the fixing screws from the

polythene bag on the top of the

appliance, but leave the appliance in

the base tray packaging until you are

ready to install it.

Whilst every care is taken to eliminate

burrs and raw edges from this appliance,

please take care when handling - we

recommend the use of protective

gloves during installation.

Please note that the weight of this

appliance is approximately 48kg

(unpacked). Take care when lifting it

into the housing unit - always use an

appropriate method of lifting.

Note: When removing the appliance

from the base tray packaging care

should be taken to ensure the appliance

is not damaged.

Sitting the appliance

If this appliance is to be installed near

to a corner where the adjacent

cabinets run at right angles forward of

the appliance, there must be a gap of

at least 90mm between the appliance

and the cabinets, to prevent overheating of the cabinets.

When installed in a typical 600mm

deep built in housing unit, the false

back should be removed from the

housing unit, to provide the necessary

depth for installation.

When the false back is removed, it is

normally the case that the support shelf

for the appliance leaves a gap

between the back edge of the support

shelf and the rear wall of approximately 80mm.

If no gap occurs between the back

edge of the shelf and the wall behind

the unit, you must create a gap of at

least 30mm by shortening the shelf

and any other shelf below the appliance.

Cut 12mm from the top of any plinth

that may be fitted (see diagram).

Important: Do not modify the outer

panels of this appliance in any way.

22

Rear wall

12 mm

air gap

30 mm

air gap

INSTALLATION INSTRUCTIONS

Page 25

INSTALLATION INSTRUCTIONS

23

The appliance is designed to fit into a standard 600 mm wide housing unit, with

minimum internal dimensions as shown.

Page 26

Dimensions

The appliance is designed to fit into a

standard 600mm wide housing unit,

with minimum internal dimensions as

shown.

Note: All sizes are nominal, some

variation is to be expected.

24

888

mm

min

560mm

20mm

min

880

mm

min

890

mm

min

6mm

550mm

min

595mm

550mm

885

mm

547mm

30 - 80mm

869

mm

INSTALLATION INSTRUCTIONS

Page 27

23

INSTALLATION INSTRUCTIONS

Step 2: Connect to the electricity

supply

Warning: This appliance must be

earthed.

The flexible mains lead is supplied

connected to a fused plug, having a

fuse of 3 amp capacity, and should be

connected to a 10amp GPO (General

Purpose Outlet).

If this plug does not fit the socket in

your home, it should be replaced with

a suitable plug as outlined below.

The wires in the mains lead are

coloured in accordance with the

following code:

Green and yellow = Earth,

Blue = Neutral,

Brown = Live.

As the colours of the wires in the

mains lead for the appliance may

not correspond with the coloured

markings identifying the terminals in

your plug, proceed as follows:

1. The wire which is coloured green

and yellow must be connected to

the terminal marked

E (Earth)

or coloured Green.

2. The wire which is coloured blue

must be connected to the terminal

marked N (Neutral), or coloured

Black.

3. The wire which is coloured brown

must be connected to the terminal

marked L (Live), or coloured Red.

The plug and socket must be

accessible after installation.

Should the mains lead of the

appliance ever require replacing, we

recommend that this is carried out by

a qualified electrician who will

replace it with a lead of the same size

and temperature rating.

Important: - ensure that you route

all mains and electrical cables and

flexible tubing well clear of any

adjacent heat source.

E (Earth)

GREEN / YELLOW

L (Live)

BROWN

N (Neutral)

BLUE

Page 28

26

INSTALLATION INSTRUCTIONS

Step 3: Connect to the gas supply

1. The inlet to the appliance is pipe

thread ISO RP

1

⁄2” internal situated

at the rear top right corner.

2. Fit the bayonet connection to the

wall in the shaded area as shown.

3. Fit the strainer (supplied with the

appliance) to the flexible hose inlet

as shown, making sure that it is

pushed fully into place.

4. Use a 900mm - 1125mm length of

flexible connector and make sure it

does not block the fan inlet and

cannot come into contact with

moving parts of the cabinetry - eg;

drawers and doors.

5. Flexible connections should be

A.S. 1869, to at least class B.

Parts of the appliance likely to

come into contact with a flexible

connector have a temperature rise

less than 70˙C.

6. Make sure all connections are gas

sound.

Important: - ensure that you route all

mains and electrical cables and

flexible tubing well clear of any

adjacent heat source, such as an oven

grill or hob.

Ensure that all pipe work is of the

correct rating for both size and

temperature.

Means of isolation shall be provided

at the shut off point by either an

approved quick connect device or a

Type 1 manual shut off valve. The

outlet of the quick connect device

shall be at, or below, the horizontal

position.

Connection to the gas supply should

be made using the Aquaknect

AS/NZS 1869 class B hose assembly with an internal diameter of not

less than 10mm and regulator (regulator for use with natural gas)

NOTE: Maximum length of hose

900mm. The temperature rise of the

areas at the rear of the cooker that

are likely to come into contact with

the flexible hose do not exceed

70˙C.

Rear

Wall

60 mm

100

mm

150 mm

square

Page 29

Step 4: Check edging strip

The edging strip is factory fitted to

the front side edges of the appliance

front frame. This strip provides the

cabinetry with extra protection from

any escape of heat.

When installing the product, ensure

that the edging strip is correctly located

on the outer edges of the front frame,

before positioning and securing the

appliance to the cabinet.

When securing the appliance, the

fixing screws provided are driven

through the edging strips into the

cabinet - the seal will straighten up

and sit flush to the cabinet when the

screws are fully home.

Step 5:

Secure appliance into

housing unit

Insert appliance into cabinet. Note:

The unit housing the appliance must be

appropriately fixed.

To secure the appliance to the housing

unit, open the grill / top oven door and

screw 2 screws through the top corner

holes in the front frame, ensuring that the

appliance is centrally located. Take care

not to damage the appliance or cabinet.

27

INSTALLATION INSTRUCTIONS

seal

front frame

door

handle

Page 30

Step 6: Commissioning

Burner aeration

All burners have fixed aeration and no

adjustment is possible.

Pressure setting

Natural Gas - 1 kPa

The pressure test point is on the

manifold inlet block.

After setting gas pressure, re-tighten

the test point screw, taking care not to

over tighten. Ensure that test point

screw is gas sound, using a non-corrosive gas leak detecting fluid.

Programmer

The programmer must be set to

manual operation before the oven can

be used manually - see the

‘Programmer / Clock’ section.

Electrical Systems Check

In the event of an electrical fault, the

preliminary electrical system check

(earth continuity, short circuit, polarity

and resistance to earth) must be

carried out. There is also a Fault

Finding Section in this book.

Ignition

The automatic ignition will continue to

spark for a short time after the burner

flame has lit, until the flame is established.

Grill

1. The door must be open for the grill

burner to ignite.

2. Turn the Top Oven / Grill control

knob clockwise to the grill setting.

Do not push in.

3. Close the door and check that the

burner goes out. The grill burner will

re-ignite when the door is opened.

Top Oven

1. Close the oven door and turn the

control knob to the required setting,

the burner will ignite.

Do not push in.

Main Oven

1. Close the oven door and turn the

control knob to the required setting,

the burner will ignite.

Do not push in.

Note: At new installations, it may be

necessary to make several attempts at

lighting before gas reaches the oven,

as only a small amount of gas is

allowed through at each lighting attempt.

Before leaving the installation

Show the customer how to ignite the

ovens and grill and give them this

book. Thank you.

28

INSTALLATION INSTRUCTIONS

Page 31

Method of operation

When the control knob is rotated from

the ‘OFF’ position, a microswitch

closes and allows the gas control

solenoids to be energised; the same

movement of the control rotates an

electrical potentiometer and lights a

red LED.

The micro-computer on the main

control board uses the resistance set

at the potentiometer to determine the

user’s requirements - ie; oven or grill

and oven temperature asked for.

The oven temperature is sensed by a

thermistor at the rear of the oven - the

computer compares the electrical

resistance of this with that set on the

potentiometer, and controls burner

accordingly.

Other inputs to the micro-computer are

signalled by door switches, the timer /

programmer unit and an air flow

checking pressure switch.

The oven fan, cooling fan, and lamps

are operated at mains voltage, the

solenoid valves, and controls at 25V.

The igniter high voltage coils are

mounted on the main PCB.

Upon applying mains voltage, the

micro-computer makes a series of checks

of the air flow and flame detector

before allowing start up.

Electrical faults

These may be either component failure

or wiring / connector faults. Should

any disconnections be made, it is

important that they be re-connected

exactly as before or the computer will

lock out; poor connections are the most

common fault. It is most important that

earth wires (green) are all connected

and earth screws tight.

There are two forms of microcomputer lockout

Hard lockout (

HLO); for instance, air

flow failure. This is indicated by the

green lamps and red indicator dials of

both ovens flashing alternately left /

right. The cooling fan may continue to

run for a while. Hard lockout can only

be cancelled by turning off the mains

electricity supply.

Soft lockout (

SLO), for instance, re-

ignition failure, will cause the green

lamp and red indicator dial of the

main oven cavity to flash - the cooling

fan may run on, the oven fan will not

run on. To cancel soft lockout, turn off

the control knob.

Should the oven temperature not

reach 40˚C within approximately

four minutes, the micro-computer will

consider that a fault has occurred and

go to lockout.

29

FAULT FINDING

Page 32

30

Typical faults assuming all wiring is correct

(ensure programmer is set to manual):

Symptom Fault

HLO on switching On mains Component fault on main PCB, incorrect wiring

HLO on turning On oven/grill Fault on control board / potentiometer,

incorrect wiring, open circuit solenoid.

Oven start up, burner lights and Short circuit thermistor assembly.

immediately goes out, ready light on Note: at room temperature, thermistor

resistance is approximately 100 kΩ.

Oven fails to ignite (check that 1. Incorrectly positioned or open circuit spark

electrode sparks correctly) electrode (note both grill and oven

electrodes must be connected).

2. Faulty solenoid valve.

3. Gas not at appliance.

4. Blocked injector jet.

Oven goes out before set 1. Incorrectly adjusted spark electrode (low

temperature is reached flame current).

2. Low gas pressure.

3. Incorrectly positioned potentiometer.

4. If oven goes out after approximately 4

mins, this is due to a disconnected or open

circuit thermistor.

Oven fails to re-ignite after set 1. Incorrectly set spark electrode.

temperature is reached 2. Low Gas Pressure.

Oven fan fails to start 1. Open circuit in programmer.

burner does not light 2. Component failure on main board

3. Component failure at control board.

FAULT FINDING

Page 33

31

Grill faults are generally similar to

those listed for the oven.

If the cooling fan starts and runs, the

electrodes should spark and the

solenoid valves can be heard to open.

If the spark electrodes are correctly

positioned and no spark occurs, there

may be an air detector pressure switch

fault, one faulty solenoid valve or no

gas supply.

Symptom Fault

Oven fan does not start Faulty fan or connections.

burner lights, oven lamp lights

Oven fan does not start Component failure on main board.

lamps do not light

Cooling fan fails to start 1. Faulty fan.

‘ON’ LED fails to light 2. Faulty programmer.

cooling fan fails to start 3. Faulty component on either board.

4. Faulty mains transformer.

5. Miss set or faulty potentiometer on control

board.

6. Faulty transformer or mains supply.

7. Faulty microswitch on control board.

Temperature exceeds set level Damaged or disconnected thermistor probe.

Oven goes to HLO after four / five minutes.

Appliance will not work, green lamp Faulty micro-computer.

& red indicator dial for both ovens

flash together

FAULT FINDING

Page 34

STOVES 900 GR - AU

Wiring colour code: Bk - Black, Bn - Brown, Bu - Blue, Gn - Green, Or - Orange, R - Red, W

J11

J8

J12J16

J9J21

J13

J1

HT

HT

A1

A2

N

1 2 3 4

M.O.

T.O. / Gr.

T.O. / Gr.

M.O.

E2

K

A3

G3 (J17)

D

D

B

C3C2C1

F2

E1

M.O. T.O.Gr.

con

5

con 3

con 1

con 4

con 2

PIN2PIN10PIN

11

PIN

1

PIN5PIN3PIN4PIN

12

C

NO

K

K

08 24382 00 Fan Speed Board

B

Or

P

W

W

W

Bk

Bk

Bk

Bk

Bk

Gn

Gn

Gn

Gn

K

Y

Y

Y

Y

R

R

R

W

Bu

Bu

Bu

Bu

Bu

Bu

Bu

Bn

Bn

Bn

Bn

Bn

Bn

Bu

Bu

FIT LINK WIRE

HERE

A1 - Main oven fan

A2 - Top oven fan

A3 - Cooling fan

B - Transformer

C1 - Solenoids - grill

C2 - Solenoids - main oven

C3 - Solenoids - top oven

D - Earth screw

E1 - Thermistor - main oven

E2 - Thermistor - top oven

P

ISSUE A

F1 - Door Switch

F2 - Pressure Switch

G1 - HT Main oven

G2 - HT Grill

G3 - HT Top oven

H1 - Main Oven Microswitch

H2 - Top Oven/Grill Microswitch

K - Lamps

N - Programmer

P - Speed Control

Q - Resistor (Nat Gas 68 Ohms / LPG 100

O

G1 (J19)

G2 (J18)

Bu

Or

Or

Or

Or

1 3

2

1 3

2

Or

Bn

Or

Bn

F1

J3

J2J5

J4

J7

J10

06.07.2006

Bu

PCB Fascia

H 1

H 2

32

Page 35

Before servicing - disconnect the gas

and electric supplies.

After servicing - Check for gas soundness.

Note: The control system only allows gas

to flow when back panel is in place and

fully screwed home. Oven or grill should

only be operated with all panels in place.

1. Facia glass panel

a. Remove appliance from housing (2)

and remove the top & RH side panel.

b. Unplug the programmer connection.

c. Support the facia, remove the 2

securing screws (one each side).

2. Remove appliance from housing

a. Unscrew securing screws in the front

frame & slide the appliance forward

on to a table.

b. Disconnect the gas and electricity

supplies is necessary.

3. Door glass panel

a. Open the door and insert 2 screws

through the inner holes in the door

hinge arms (to stop the door from

springing up when you remove the

outer glass panel).

b. Slide out the inner glass panel.

c. Remove 2 plastic inner glass stops at

bottom of door extrusion.

d. The door foot can be withdrawn

completely from door extrusion.

Important: The inner glass panel

must be replaced the right way up as

shown (the reflective side faces

inwards) and also pushed fully into the

stop position.

4. Oven Light bulb

a. Remove the oven shelves.

b. Grasp the back edge of the light cover

and pull forward.

c. Unscrew the bulb.

5. Top and rear compartment

access

a. Remove the appliance from housing

unit (2).

b. Unscrew and remove top plate screws.

c. For rear compartment access, remove

top panel first.

6. Oven igniter electrode

a. Inside the oven - remove the fan cover.

b. It may be necessary to remove the

burner (7) to remove the screws

holding the igniter bracket.

SERVICING INSTRUCTIONS

33

SLIDE

IN

SLIDE

IN

THIS SIDE UP

Page 36

7. Burner

a. It is easier to lift out the fan cover if you

first remove the oven shelf runners:

(i) Pull the bottom edge away from the

oven side.

(ii) Disengage the runners from the

hanging holes.

b. From the inside of the oven, unscrew

the 4 screws which secure the fan

cover to the back of the oven.

c. Remove 2 screws from electrode

bracket.

d. Remove rear service panel (5).

e. Prevent motor from rotating whilst

unscrewing burner from within oven.

Note: Left hand thread, turn clock-

wise to unscrew.

8. Micro-computer

a. Gain access to the rear chamber (5)

and disconnect all wire connectors

from PCB.

b. Remove the PCB earthing screw found

near the spark transformer.

c. Ensure the distance tube around the

earthing screw is retained and

replaced when refitting the PCB.

d. The complete board can now be

removed by disconnecting the

insulating stand-offs.

Note: It is practically impossible to

exchange individual components from

the computer board. A complete new

board should be substituted.

9. Cooling fan

a. Remove appliance from housing unit (2).

b. Gain access to rear compartment (5).

c. Disconnect the fan leads from the

terminal block.

d. Unscrew the 4 screws which secure

the fan mounting bracket.

e. Remove the 4 screws which secure the

fan to the mounting bracket.

10. Door switch

a. Remove appliance from housing unit (2).

b. Remove top panel and RHS panel.

c. Unscrew the screws which secure the

door switch and its bracket to the oven

door frame.

11. Oven light fitting(s)

a. Remove appliance from housing unit (2).

b. Remove the top and side panels.

c. Remove the leads from the back of the

light fitting.

d. Squeeze in the metal retaining clips to

release the fitting from the oven side.

12. Grill burner

a. Remove appliance from housing unit (2).

b. Unscrew the top & rear panel securing

screws.

c. Remove the top & rear panels.

d. Unclip the grill injector holder.

e. Unscrew the grill assembly from the

side struts and lift out the complete

assembly.

13. Ceramic grill glass

a. Gain access to top compartment (5).

b. Remove the grill burner (12).

c. Lift up all the tabs which secure the

grill glass.

d. Replace the glass & bend the tabs

down.

14. Grill igniter electrode

a. Gain access to the top and rear

compartment (5).

b. Remove the grill burner assembly (12)

and unplug the connecting line at the

control board.

SERVICING INSTRUCTIONS

34

Page 37

15. Programmer / clock

a. Remove appliance from housing.

b. Remove top & facia panels (1).

c. The programmer is fixed to the facia

panel with high temperature double

sided adhesive tape.

16. Door seal(s)

a. Pull off the old seal.

b. Slacken the screws in the stainless

steel flue cover at the front of the

oven/grill roof to ease insertion of the

seal.

c. Partly open the door to obtain best

access for the seal all around the

oven/grill.

d. Locate the middle of the new seal &

start to push it into place at the middle

of the bottom edge of the oven / grill

cavity.

e. Make sure the narrow gap goes to the

inside, & locates onto the oven cavity.

f. Do not stretch the seal.

g. Make sure the seal is fitted correctly as

shown, and cut to fit.

h. Re-tighten the screws in the flue cover.

17. Solenoid Block

a. Remove appliance from housing.

b. Remove top, rear and right side panels.

c. Disconnect the olive pipe connection

at the oven fan motor and unclip the

grill injector block.

d. Disconnect electric plug/socket.

e. Remove 4 screws from side of

appliance securing the block, & lift out

solenoid valve complete with pipes.

18. Pressure Switch

a. Remove appliance from housing.

b. Remove top and rear panels.

c. The pressure switch can now be dis-

connected and the two securing

screws removed.

Note: Ensure that the pressure tubing

is pushed securely through the hole

when replacing.

SERVICING INSTRUCTIONS

35

narrow

gap

flue

cover

oven

cavity

Page 38

Data Badge

Abbreviated data badge located on

front frame. Full data badge located

on rear panel.

Gas Category

This appliance is factory set for use on

Natural Gas only.

Pressure Test Point

On pressure Regulator

Pressure Setting

Natural Gas - 1.0kPa

Ignition

Automatic re-ignition system

Oven / Grill Light(s)

4 x 25W (2 in each oven)

Electrical supply

220 - 240V ~ 50Hz, 230W

Grill

Burner: Surface combustion.

Spark gap: 3 - 4mm.

Top Oven

Burner: Rotary surface combustion.

Spark gap: 3 - 4mm.

Main Oven

Burner: Rotary surface combustion.

Appliance class

Class 3, Built-In Oven & Grill Unit

Countries of Destination

AUS - Australia

36

TECHNICAL DATA

Burner

Grill

Top Oven

Main Oven

Total Heat Input

∑

∑ Qn

Nominal Rate

Qn

10.1 MJ/h

7.2 MJ/h

9.0MJ/h

19.1 MJ/h

Injector size

Nat Gas

1.60mm

1.3mm

1.50 mm

Page 39

Service Record

Date of purchase Installer stamp / Printed name Date of installation

Place of purchase:

Date Part(s) replaced Engineers Stamp/

Printed Name

Model Number

Serial Number

Please record your model number and serial number in the space below.

Where are my model and serial numbers?

Freestanding HL appliances: base of storage drawer

Freestanding appliances: front frame near oven cavity

Built in oven: front frame near oven cavity

Hobs: base plate of the hob

Having these numbers to hand will help us to help you, quickly and more efficiently.

When contacting us, please use the Customer Care number on the back cover of this

handbook.

Page 40

Glen Dimplex Australia, Unit 2, 205 Abbotts Road, Dandenong South, Victoria 3175

Australia

08 27313 01 © 08.2007

Built In Gas Oven

Model Names: 900GR

Contact Us

Calling for a service

If you should experience any problems with your cooker please contact your retailer or

place of purchase.

Important note:

Service work is to be conducted by authorised persons only. It is also adviseable that

your cooker is checked regularly and maintained in good condition. An annual maintenance is recommended.

Always check the instruction book before calling a service agent to make sure you have

not missed anything.

Before you contact a service agent, make sure that you have the following information to

hand:

Model Number

Serial Number

Date or Purchase

Postcode

Loading...

Loading...