Page 1

250-Watt Gold Line Power Amplifier Issue 1, Rev. C: 10/21/96

Gold Line GL-T8500

250-Watt, 900-MHz Power Amplifier

USER MANUAL

PN 9110.0 0160 (old part number = 916-8500-000)

REV C

RELEASED

Specifications subject to change without notice

Copyright © 1996 Glenayre

All rights reserved. No part of this work may be reproduced or copied in any form or by

any means—graphic, electronic, or mechanical, including photocopying, recording,

taping, or information-ret rieva l system— without writte n perm issio n of Glenayre.

Print Date: 12/17/96 Copyright © 1996 Glenayre

Page 2

250-Watt Gold Line Power Amplifier Glenayre Do cument Number : 9110.00160

Document Change Record Issue 1, Rev. C: 10/21/96

Document Change Record

Revision: 0, Preliminary

Date: 05/04/95

Changes: none, original

Issue: Rev B

Date: 02/02/96

Changes: new format

Issue: Rev C

Date: 10/21/96

Changes: made released

Copyright © 1996 Glenayre Print Date: 12/17/96

Page 3

Glenayre Document Number: 9110.00160 250-Watt Gold Line Power Amplifier

Issue 1, Rev. C: 10/21/96 Table of Contents

Table of Contents

1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 Manual Scope . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Applicable Doc u ment s . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 Manual Sections . . . . . . . . . . . . . . . . . . . . . . . 1-1

2 SPECIFICAT ION S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

3 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3- 1

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Physical Description. . . . . . . . . . . . . . . . . . . . . . 3 -1

3.2.1 Mounting Provisions . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2.2 PA Front. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2.2.1 Driv e r Board . . . . . . . . . . . . . . . . . . . . . .3-1

3.2.2.2 PA Boards. . . . . . . . . . . . . . . . . . . . . . . .3-4

3.2.2.3 Combiner B oard . . . . . . . . . . . . . . . . . . . . . 3- 4

3.2.2.4 Metering Board . . . . . . . . . . . . . . . . . . . . .3 -4

3.2.3 PA Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3.2.3.1 Isolator . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3.2.3.2 Fan . . . . . . . . . . . . . . . . . . . . . . . . . . .3 -4

3.3 Functional Description . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.1 RF Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

3.3.2 Isolator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -5

3.3.3 Metering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3- 6

4 INSTALL ATI ON AND SET UP . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3 Ultimate Disposition . . . . . . . . . . . . . . . . . . . . . 4-1

5 OPERATIO N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 Controls and Indicators . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2.1 Turn PA On and Off . . . . . . . . . . . . . . . . . . . . . . . .5 -1

3.2.3.3 Equipm ent Connectors . . . . . . . . . . . . . . . . . 3- 4

5.2.2 Turn Fan On and Off . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2.3 Key and Unkey PA . . . . . . . . . . . . . . . . . . . . . . . . .5-1

6 THEORY OF OPERATI ON . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 -1

6.1 Power Distribu tio n . . . . . . . . . . . . . . . . . . . . . . 6 -1

6.1.1 Primary Power . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Print Date: 12/17/96 Copyright © 1996 Glenayre Page: -i

Page 4

250-Watt Gold Line Power Amplifier Glenayre Do cument Number : 9110.00160

Table of Contents Issue 1, Rev. C: 10/21/96

6.1.1.1 Metering Board +25V Signal Flow. . . . . . . . . . . 6-1

6.1.1.2 Power Amplifiers +25V Signal Flow . . . . . . . . . . 6-1

6.1.2 Secondary Power . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.1.2.1 Metering Board +13.5V Signal Flow . . . . . . . . . . 6-2

6.1.2.2 Preamplifier Module +13.5V Signal Flow . . . . . . .6-2

6.1.3 Fan Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.2 RF Distribution . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.2.1 Driver Board RF Flow . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.2.2 PA Board RF Flow . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.2.3 Combiner Board RF Flow . . . . . . . . . . . . . . . . . . . . .6-4

6.2.4 Isolator RF Flow . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.3 Control Di stri but i on . . . . . . . . . . . . . . . . . . . . . 6-5

6.3.1 AGC Signal Flow. . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.3.2 Multiplexer Control Signal Flow . . . . . . . . . . . . . . . . . . 6-6

6.4 Status Distribut ion . . . . . . . . . . . . . . . . . . . . . . 6-6

6.4.1 Mux Analog Status Signal Flow . . . . . . . . . . . . . . . . . . 6-6

6.4.2 PA Fault Signal Flow. . . . . . . . . . . . . . . . . . . . . . . . 6-6

7 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

8 CHEC KOUT AND TROUBL ES HOOTI NG . . . . . . . . . . . . . . . . . . 8-1

9 REMOVAL AND REINST AL LAT ION . . . . . . . . . . . . . . . . . . . . 9-1

9.1 PA Chassis Removal and Reinstallation . . . . . . . . . . . . . 9-1

9.2 PA RF Module Removal and Reinstallation . . . . . . . . . . . . 9-1

9.3 Metering Board Removal and Reinstallation. . . . . . . . . . . . 9-1

Page: -ii Copyright © 1996 Glenayre Print Date: 12/17/96

Page 5

Glenayre Document Number: 9110.00160 250-Watt Gold Line Power Amplifier

Issue 1, Rev. C: 10/21/96 List of Figures

List of Figures

Figure 3-1 250-Watt, 900-MHz Power Amplif ier

Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Figure 3-2 250-Watt, 900-MHz Power Amplif ier

Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3- 3

Figure 3-3 PA Simplified-Block Diagram . . . . . . . . . . . . . . . . . . . . . . 3-5

Figure 5-1 Front-Panel Vie w wit h Cove r Rem o ved . . . . . . . . . . . . . . . . . 5-2

Figure 6-1 250-Watt PA Interconnection Diagram. . . . . . . . . . . . . . . . . . 6-8

Figure 6-2 250-Watt PA Functional Diagram . . . . . . . . . . . . . . . . . . . . 6-9

Figure 6-3 250-Watt PA Detailed Functional Diagram . . . . . . . . . . . . . . .6-10

Figure 6-4 Metering Board Functional Diagram . . . . . . . . . . . . . . . . . . . 6-12

Figure 9-1 PA Removal and Reinstalllation . . . . . . . . . . . . . . . . . . . . . 9-2

Figure 9-2 PA RF Module Removal and Reinstallation . . . . . . . . . . . . . . . 9-3

Figure 9-3 Metering Board Removal and Reinstallation . . . . . . . . . . . . . . . 9-5

Print Date: 12/17/96 Copyright © 1996 Glenayre Page: -iii

Page 6

250-Watt Gold Line Power Amplifier Glenayre Do cument Number : 9110.00160

List of Figures Issue 1, Rev. C: 10/21/96

Page: -iv Copyright © 1996 Glenayre Print Date: 12/17/96

Page 7

Glenayre Document Number: 9110.00160 250-Watt Gold Line Power Amplifier

Issue 1, Rev. C: 10/21/96 List of Tables

List of Tables

Table 1-1 Applicable Documents . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Table 1-2 Manual Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Table 2-1 Power Amplifier Specifications. . . . . . . . . . . . . . . . . . . . . . 2-1

Table 3-1 PA Circuit Boards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Table 6-1 Multiplexer Analog Status Inputs. . . . . . . . . . . . . . . . . . . . . 6-7

Print Date: 12/17/96 Copyright © 1996 Glenayre Page: -v

Page 8

250-Watt Gold Line Power Amplifier Glenayre Do cument Number : 9110.00160

List of Tables Issue 1, Rev. C: 10/21/96

Page: -vi Copyright © 1996 Glenayre Print Date: 12/17/96

Page 9

Glenayre Document Number: 9110.00160 250-Watt Gold Line Power Amplifier

Issue 1, Rev. C: 10/21/96 GENERAL

1 GENERAL

1.1 Manual Scope

This manual provid es informa tion for the 250-watt, 9 00-MHz Gold Line powe r ampl ifier,

part number 265-0082-013. Also included is information for the optional triple isolator,

part number 7914.00010.

1.2 Applicable Documents

This manual is incomplete wi thout a dd iti on al Gol d Line ma nu als. R efer to Table 1-1 fo r a

listing and function of these manuals.

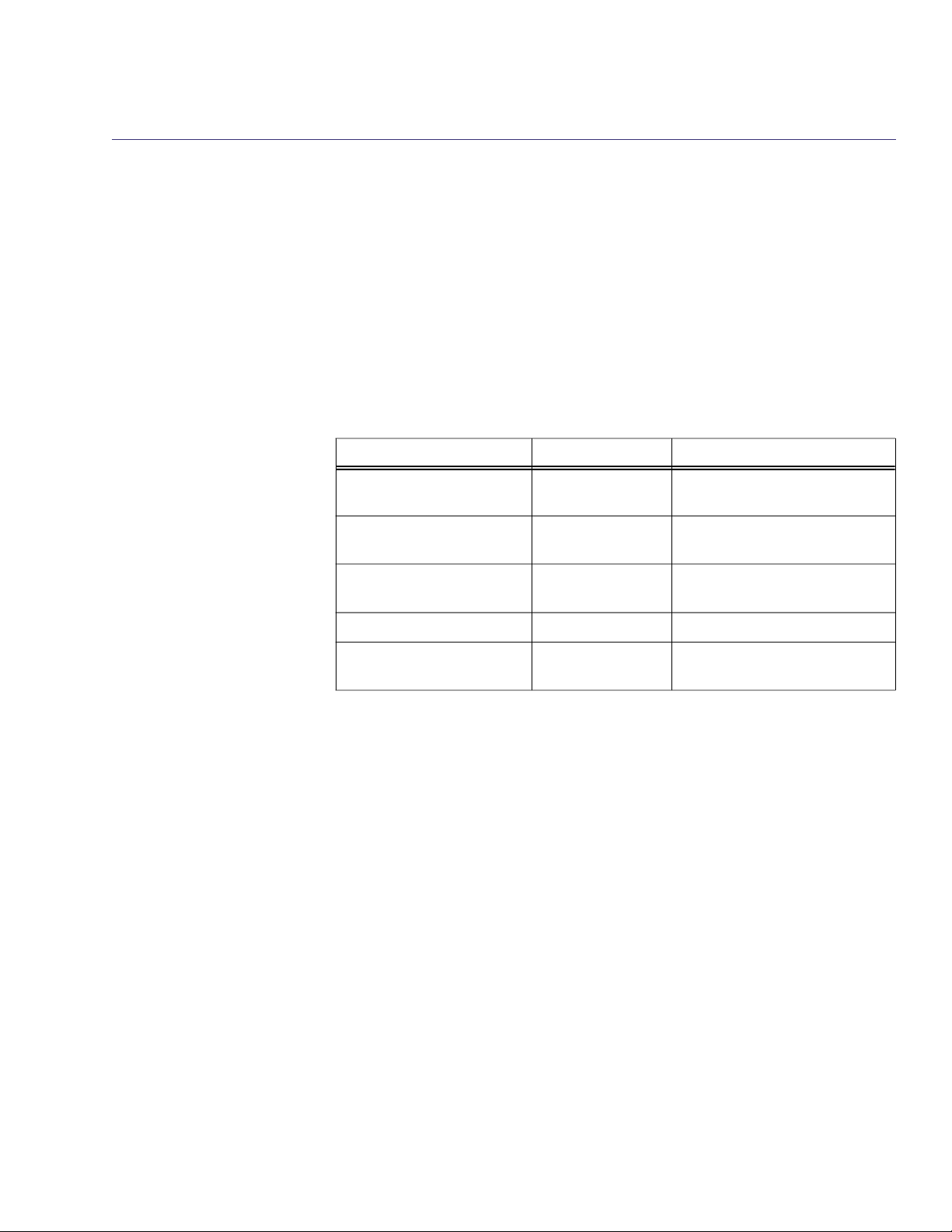

Table 1-1 Applicable Documents

document part number function

1.3 Manual Sections

GL-T8500/8600 system manual

VDT manual 9110.00164 describes PA contro l so ftwa re

exciter manual 9110.00172 describes exci ter/ PA cont ro l

250-watt PA 9110.00160 this manual

power supply manual 9110.00159 describes 50A/ 90A pow er suppl y

Table 1-2 lists the section s of thi s man u a l wit h a summary of thei r cont en t s.

9110.00163 describes fully racke d-up G old

Line tr an smitt er

installed in exciter

equipment in transmitter

equipment in transmitter

Print Date: 12/17/96 Copyright © 1996 Glenayre Page: 1-1

Page 10

250-Watt Gold Line Power Amplifier Glenayre Do cument Number : 9110.00160

GENERAL Issue 1, Rev. C: 10/21/96

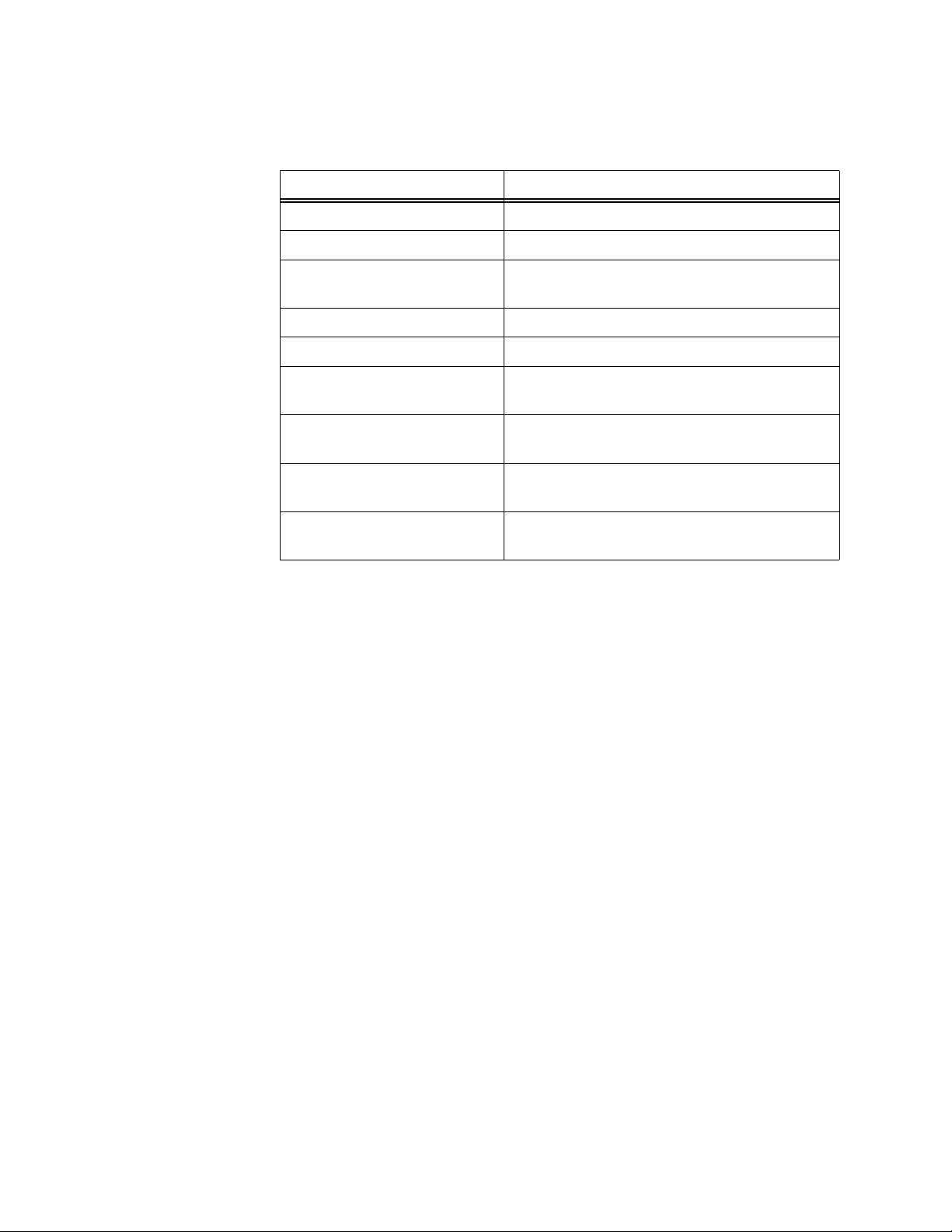

Table 1-2 Manual Sections

section contents

1. General introduct ion and purpose of manu al

2. Specificatio ns significa nt measu rem ent s of power am plifie r

3. Descripti on introdu ction and princi pal charac teristics of power

amplifier

4. Installation and Setup initial installation and activation of power amplifier

5. Operation operation of power amplifier

6. Theory of Operati on detailed func tiona l d esc ript ion of circ u itry wi thi n

power amplifier

7. Mainten ance proced ure s to be performe d on specifi c int erv al s to

maintain optimum performance of power amplifier

8. Checkout and Troubleshooting verification of proper operation, correction to proper

operation of power amplifier

9. Removal and Reinst alla tio n replacemen t proce dure s for power am pli fie r and

selected subassemblies

Page: 1-2 Copyright © 1996 Glenayre Print Date: 12/17/96

Page 11

Glenayre Document Number: 9110.00160 250-Watt Gold Line Power Amplifier

Issue 1, Rev. C: 10/21/96 SPECIFICATIONS

2 SPECIFICATIONS

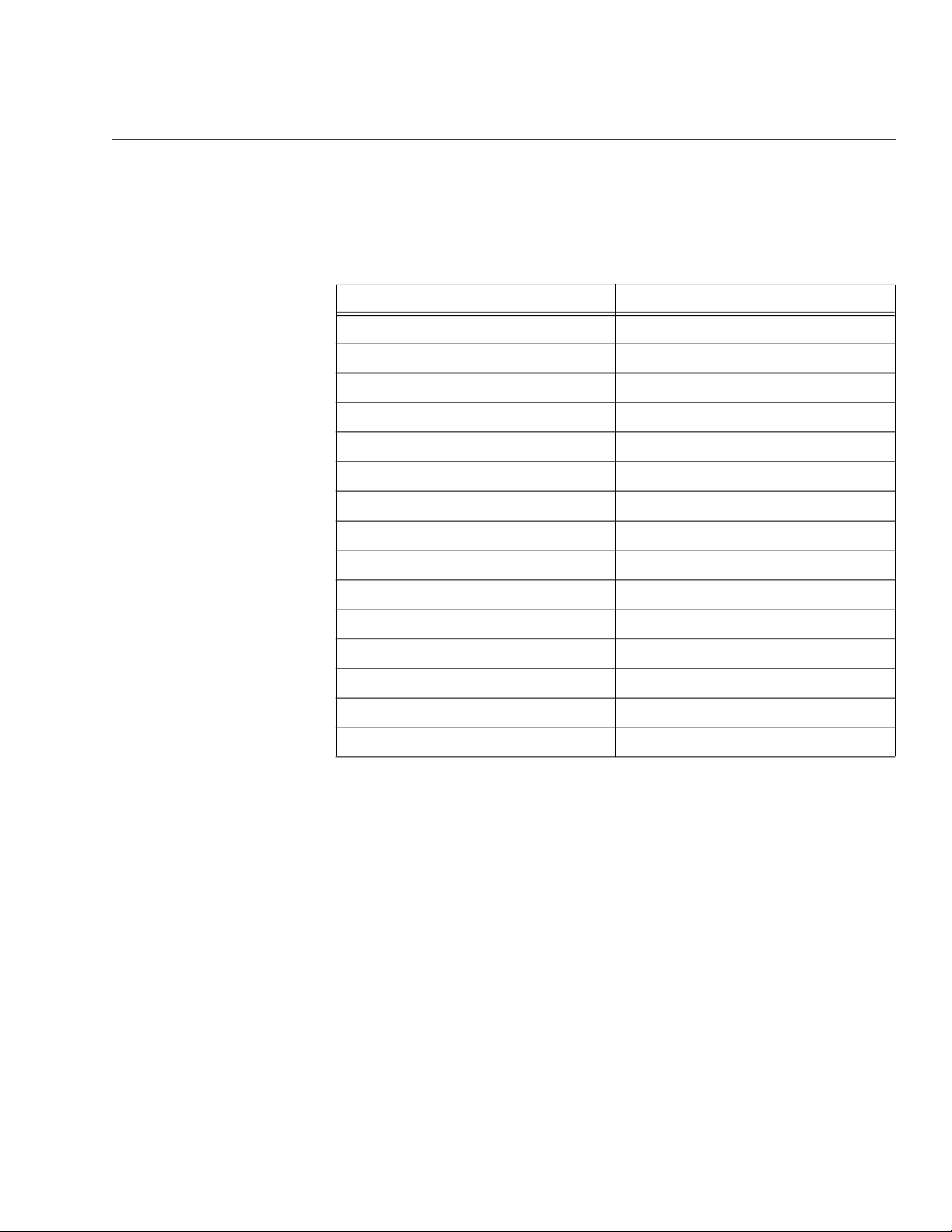

Table 2-1 lists the significant equipment-level specifications for the Gold Line power

amplifier.

Table 2-1 Power Amplifie r Specificatio n s

measurem ent specification

height 8.75 in (22.23 cm)

width 19 in (48.3 cm)

depth 8 in (20.3 cm)

weight 26 lb (12 kg)

RF output power 100 - 250 watts

RF bandwidth 900 - 960 MHz

RF input power 200 - 400 mW

RF impedance 50 ohms

operating voltages 25 vdc, 25 Vdc, 13.5 Vdc

PA 25 Vdc current 72 mA - 33 A

fan 25 Vdc current 750 m A

13.5 Vdc current 3.3 A

ambient temperature -30° - +70° C

humidity 0 - 95% noncondensing

altitude to 10,000 ft (3050 m)

Print Date: 12/17/96 Copyright © 1996 Glenayre Page: 2-1

Page 12

250-Watt Gold Line Power Amplifier Glenayre Do cument Number : 9110.00160

SPECIFICATIONS Issue 1, Rev. C: 10/21/96

Page: 2-2 Copyright © 1996 Glenayre Print Date: 12/17/96

Page 13

Glenayre Document Number: 9110.00160 250-Watt Gold Line Power Amplifier

Issue 1, Rev. C: 10/21/96 DESCRIPTION

3 DESCRIPTION

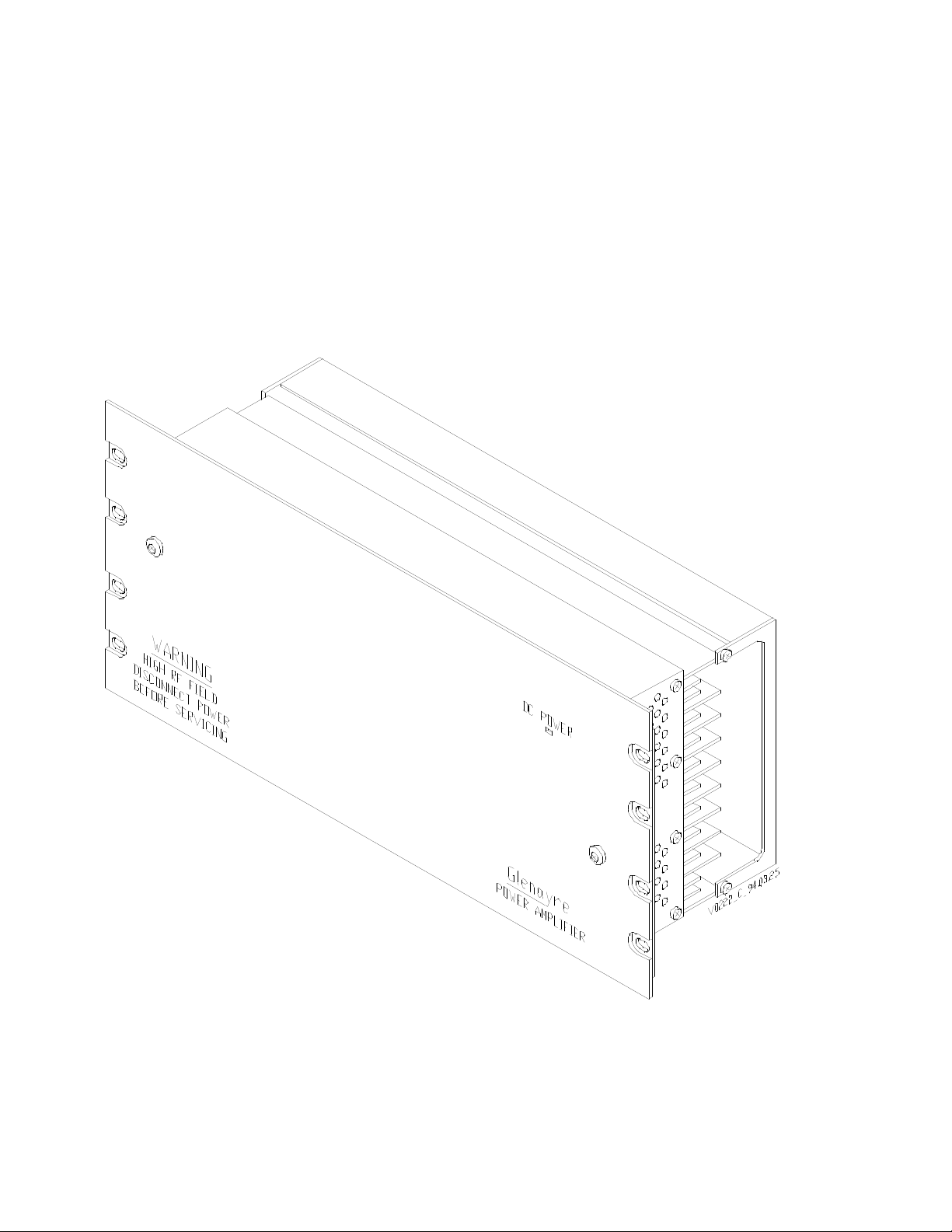

3.1 Introduction

Figure 3-1, 250-Watt, 900-MHz Power Amplifier Front View, and Figure 3-2, 250-Watt,

900-MHz Power Amplifier Rear View,show th e Gold Line power amplifi er (PA). This is a

250-watt PA intended for use in a GL-T8500 paging transmitter with an RF of 900 MHz

nominal. Th is PA is characteri zed by int egrated mon itoring dev ices that suppl y critical

status informat ion to a Gold Li ne exciter/ PA control (exciter). This exci ter contains d iagnostic softw a re that can dete ct and report a fault y PA circuit board.

3.2 Physical Description

3.2.1 Mounting Provisions

The P A is mounted to the front of most standar d 19-inch equipment racks by means of eight

screws. The fron t panel of the PA may by removed wh ile the PA is mounted in the rack.

T wo quarter-turn fasteners secure the front panel to the PA. Most PA circuit boards may be

replaced while the PA is mounted in the rack.

3.2.2 PA Front

Figure 5-1 shows the front view of the PA with the front pa nel removed. This expos es the

RF and shielded compartments, which contain the PA circuit boards. Table 3-1 lists the PA

circuit boards.

Table 3-1 PA Circuit Boards

nomencla ture part number location

driver board A1 263-0082-022 RF compartment

PA1 board A2 263-0082-007 RF compartment

PA2 board A3 263-0082-007 RF compartment

combiner board A4 263-0082-021 RF compartment

metering board A5 263-0082-018 shielded compartment

3.2.2.1 Driver Board

The driver board (A1) contain s the preamp module, the intermediate PA (IPA), and the PA

drivers (driver-1 and driver-2). These device s, in addition to on e resistor, are mounted

directly o n th e PA heat sink. T he dr i v er board co nta i ns three co n n ec to rs: t w o o n t h e f ron t

(J1 and J2) and one on the back (J3). Two RG316-type cables (not shown) are attached to

the front of the board.

Print Date: 12/17/96 Copyright © 1996 Glenayre Page: 3-1

Page 14

250-Watt Gold Line Power Amplifier Glenayre Do cument Number : 9110.00160

DESCRIPTION Issue 1, Rev. C: 10/21/96

v0222.hgl

Figure 3-1 250-Watt, 900-MHz Power Amplifier

Front View

Page: 3-2 Copyright © 1996 Glenayre Print Date: 12/17/96

Page 15

Glenayre Document Number: 9110.00160 250-Watt Gold Line Power Amplifier

Issue 1, Rev. C: 10/21/96 DESCRIPTION

v0221.hgl

Figure 3-2 250-Watt, 900-MHz Power Amplifier

Rear View

Print Date: 12/17/96 Copyright © 1996 Glenayre Page: 3-3

Page 16

250-Watt Gold Line Power Amplifier Glenayre Do cument Number : 9110.00160

DESCRIPTION Issue 1, Rev. C: 10/21/96

3.2.2.2 PA Boards

Two PA boards, PA1 (A2) and PA2 (A3), contain the power amplifiers. The PA boards are

identical but are mounte d with different orientations. Each PA board conta ins an A and a B

pair of power amplifiers. These amplifiers and six resistors are mounted directly on the PA

heat sink. Conn ect ors J1 and J3 and an RG142-type ca ble (not sh own) are attached to the

front of each board.

3.2.2.3 Combiner Board

The combin e r bo ard comb i nes th e outpu t s of the PA boards. The comb i ner bo a rd con t ain s

a resistor, mounted directly on the PA heat sink. Connectors J1, J2, and J3 are on the front

of the board. An RG 393-t ype cable is atta ched to the ba ck of the board . This cable terminates with a type-N connector and extends through t he rear of the PA.

3.2.2.4 Metering Board

The metering boar d contai ns the monitori ng circui ts for the PA. A bank of nine aut omoti ve

spade-ty pe fu se s prot ec t the PA. A transist o r is mounted di rec tl y on th e PA heat sink . The

metering board contains connectors J1, J2, J4, J5, and P1 on the front and J3 on the back.

The board contains one LED (DC POWER).

3.2.3 PA Rear

Figure 3-2 sh ow s the back view of the PA. The PA back pan el c onc eals the fan c ompart-

ment. The isolator and fan are mounted on the back panel. The PA equipment connectors

terminate on cables that are routed through grommeted holes in the back panel.

3.2.3.1 Isolator

The s ta n da rd iso l at o r (s how n ) i mp ro ves the i nt ermodu l at io n perform a nc e o f th e PA by 25

dB. This isolat or is mounted on its own heat si nk , wh ich extends i nto t he fan compartment .

The optional triple isola tor (not shown ) improves the interm odulation performance of the

P A by 75 dB, and is mounted on the PA. Both isolators contains three connectors: two typeN and one BNC.

3.2.3.2 Fan

A si ngle fa n pr ovides cool ing for the PA and sta nda r d is olat or. T he f an i s lo c at ed w i th i n the

fan compartment and is covered by a finger guard. The fan runs co ntinuously whenever

power is applied by the power supply equipment.

3.2.3.3 Equipment Connectors

There are five equipment connectors in addition to those on the isolator. Two 1/4-inch ring

lugs are desi g nat ed a s plus (red) a n d mi n us (black). A 9-pin plug-an d-socket con nect or i s

designated as P2. A DB15-type connector is designated as PA CONTROL. A BNC

connector is designated as P3.

Page: 3-4 Copyright © 1996 Glenayre Print Date: 12/17/96

Page 17

Glenayre Document Number: 9110.00160 250-Watt Gold Line Power Amplifier

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

Issue 1, Rev. C: 10/21/96 DESCRIPTION

3.3 Functional Description

Figure 3-3 shows a si mplifi ed, func ti onal diagr am of t he PA. The driver, comb iner , and PA

boards constitute the RF amplifier circuitry of the PA. Monitoring and controlling this RF

amplifier is the metering board. Figure 3-1 shows the RF amplifier, is olator, and meteri ng

circuit ry within the PA.

BNC

RF

IN

1/4 LUGS

DC

IN

25V

13.5V

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

P2

METERED

POWER

RF

AMPLIFIER

STATUS

VOLTAGES

METERING

POWER

AMPLIFIER

TYPE N TYPE N

AA

AA

AA

AA

AA

AA

AA

AAA

AAA

ISOLATOR

AAAA

AAAA

BNC

AA

AA

AA

AA

AA

AA

AA

VSWR

SAMPLE

AA

AA

STATU S/

AA

AA

AA

AA

CONTROL

AA

DB-15

RF

OUT

3.3.1 RF Amplifie r

3.3.2 Isolator

Figure 3-3 PA Simplified-Block Diagram

The RF amplifie r receives its RF i nput thro ugh the BNC co nnector P3. A detecto r circuit

in the RF amplifier monitors this RF input. The RF input is amplified by means of four

amplifier stages. Each amplifier stage receives its dc input power through the metering

circuit. Power detectors at critical locations throughout the RF amplifier provide sample

voltages to th e me terin g circ u it. Th e amplified output of the RF amplifier is appli ed to the

input type-N con nector on the isolator.

The isolator prevents intermodulation of the RF signal that may occur from nearby transmissions. The RF signal is routed through input and output type N connectors. A detector

circuit in the isolator moni tors the reflected power (VSW R) present at the ou tput type-N

connector. A sample voltage representing the VSWR level is output through the BNC

connector. The opt ion al t ripl e iso lat o r fu nctio n s id ent ical ly t o t he s ta nda rd is olato r e xcept

with a higher level of intermodulat ion prevention.

Print Date: 12/17/96 Copyright © 1996 Glenayre Page: 3-5

Page 18

250-Watt Gold Line Power Amplifier Glenayre Do cument Number : 9110.00160

DESCRIPTION Issue 1, Rev. C: 10/21/96

3.3.3 Metering

The me terin g boa rd perf o rms co ntro l and st atu s repo rtin g for the PA. The meteri ng bo ard

accepts a 25-Vdc power input through the 1/4-inch lugs and a 13.5-Vdc power input

through connector P2. These voltages are regulated and distributed.

Page: 3-6 Copyright © 1996 Glenayre Print Date: 12/17/96

Page 19

Glenayre Document Number: 9110.00160 250-Watt Gold Line Power Amplifier

Issue 1, Rev. C: 10/21/96 INSTALLATION AND SETUP

4 INSTALLATION AND SETUP

4.1 Installation

The PA is shipped alre ady insta lled in a cabin et. To remove or rei nstall t he PA, refer to

Section 9.

4.2 Setup

Setup of the PA is performed at the system level using an exciter/PA control unit. Refer to

the GL-T8500 system manual. The system manual includes instructions for these

applicable setup procedures:

• adjust forward power

• set low power alarm

• calibrate reflected power

4.3 Ultimate Disposition

Caution

This equipment may contain hazardous materials.

Check with the local EPA or other environmental

authority before disposing of this equipment.

Print Date: 12/17/96 Copyright © 1996 Glenayre Page: 4-1

Page 20

250-Watt Gold Line Power Amplifier Glenayre Do cument Number : 9110.00160

INSTALLATION AND SETUP Issue 1, Rev. C: 10/21/96

Page: 4-2 Copyright © 1996 Glenayre Print Date: 12/17/96

Page 21

Glenayre Document Number: 9110.00160 250-Watt Gold Line Power Amplifier

Issue 1, Rev. C: 10/21/96 OPERATION

5 OPERATION

5.1 Controls and Indicators

The PA has one indicator and no controls. Figure 5-1, Front-Panel View with Cover

Remo ved shows the location of the PA indicator LED1.

5.2 Operation

5.2.1 Turn PA On and Off

The PA does not contain an on/of f switch, but turns on and off whenever the power supply

equipment is turned on and off. When the PA is on, it remains in a standby condition until

keyed. Refe r to the pow er su ppl y man u al for turn -o n and turn-off procedu res.

5.2.2 Turn Fan On and Off

The fan doe s not contain an on/off swi tch, bu t turns on an d off whenever the p ow er supply

equipment is turned on and off. The fan runs continuously whenever the power supply

equipmen t is on. Re f e r to the po w e r su pply manual fo r tu rn-on an d tu rn - o ff pr o cedures.

5.2.3 Key and Unkey PA

The PA does not contain a key switch, but is keyed and unkeye d by the exciter/PA control

equipment. This exciter must be keyed and unkeyed remotely through transmitter

controller, or locally through a video display terminal (VDT). Refer to the controller

manual for remote key and unkey instru ctions, or to the VDT manual for local key and

unkey instruc ti ons.

Print Date: 12/17/96 Copyright © 1996 Glenayre Page: 5-1

Page 22

250-Watt Gold Line Power Amplifier Glenayre Do cument Number : 9110.00160

OPERATION Issue 1, Rev. C: 10/21/96

v0224.hgl

Figure 5-1 Front-Pane l View with Cover Rem oved

Page: 5-2 Copyright © 1996 Glenayre Print Date: 12/17/96

Page 23

Glenayre Document Number: 9110.00160 250-Watt Gold Line Power Amplifier

Issue 1, Rev. C: 10/21/96 THEORY OF OPERATIO N

6 THEORY OF OPERATION

6.1 Power Distribution

The PA requires three separate power inputs: primary 25-volt dc power, secondary 13.5volt dc pow er, and fan 25-volt d c power. All power i nputs are n ormally provided by the

Gold Line power supply.

6.1.1 Primary Power

Refer to Figure 6-2. Primary 25-volt dc operati ng power is receive d through the powe r

cables termin ating wi th 1/4-inch ring lugs . The ( - ) inpu t (bla ck c abl e) is bolted directl y to

PA chassis ground. The (+) input (red cable) is bolted to P1 on the metering board . P1

powers the +25V power bus on the me terin g board. Thi s bus distri bu tes p rimary powe r to

the metering board an d to eac h common-b a se co l lect o r (C BC ) po we r am pli f ie r in the PA.

6.1.1.1 Metering Board +25V Signal Flow

Refer to Figure 6-4. +25 volts from the power bus is supplied through fuse F13 to these

places on the meterin g board : LED 1, +25V components, divider circuitry, +5V regulator

and di v ider circuitry, and +1.2V regulator circuitry.

• LED1 activates to illuminate the DC POWER indicator on the front of the PA.

• +25V components receive operating power. These components include the current

detector amp l ifie rs.

• Divider circuit reduces the input to a sample voltage, which determines the PA 25V

meteri ng.

• +5V regulator/divider circui try generates +5V operating power for the metering board

+5V components. A portion of this +5V is reduced to a sample voltage, which determines the PA 5V metering.

• +1.2V regul ator circuitry generates the compensa tion voltage for the curren t detector

amplifiers.

6.1.1.2 Power Amplifiers +25V Signal Flow

Refer to Figure 6-1. +25 volts operating power from the power bus is paralleled through

seven resistors. Th es e resi stors are a compon ent of a current detec tio n circu it.

Current-Detection Theo ry

Current-det ecti on monitorin g occurs on the me tering boa rd. The moni tore d current is

routed through a sma ll res ist or, resu lt i ng in a slig ht vol ta ge dro p across the resist o r.

This voltage drop is amplified by a current detector amplifier, which generates an output voltage proportional to the current flowing through the resistor. This output voltage

is the current sample for the monito re d current .

Print Date: 12/17/96 Copyright © 1996 Glenayre Page: 6-1

Page 24

250-Watt Gold Line Power Amplifier Glenayre Do cument Number : 9110.00160

THEORY OF OPERATION Issue 1, Rev. C: 10/21/96

The seven mon itored +25-vol t signals are indi vidually fused before leavin g the metering

board. The signals provide operating power for power amplifiers located on the driver and

PA boards. Each signal is routed through a dc bias network.

Dc-Bias Network Theory

Dc bias networks are locat ed on the driver boa rd and PA board s. +25-v olt operat ing

power from the metering board is applied to the power amplifiers through a dc bias network . T he n etwor k is t une d and f iltere d t o cause a hi gh im p eda nc e to si gnals fr om dc to

above operating frequency. This prevents RF from transmitting backwards into the metering board.

6.1.2 Secondary Power

Seco nda ry 13 .5-v ol t dc pow er f or t he PA is ex ter nal ly fu se d, at the pow er su pply e qui pment. Refer to Figure 6-1. Secondary power is received through connector P2, which

mates w i th J 2 o n the system interco n n ect harne ss. Secon da ry power is connected to J 5 o n

the metering boa rd. The +13.5 input from J5 is distributed to the met ering board and the

preamp module.

6.1.2.1 Metering Board +13.5V Signal Flow

Refer to Figure 6-2. +13.5-volt power from J5 is paralleled to these places on the metering

board: +13.5V components, divider circuitry, and heat sink temperature trans duc er U17.

• +13.5V component s receive operat ing power. Th ese compon ents include those wit hin

the AGC integrator circuit.

• Divider circuit reduces the input to a sample voltage, which determines the system PA

13.5V metering.

• Heat-sink-temperature transducer U17 generates a vol tage proportional to the tempe ra-

ture of the PA heat sink, which determines the temperature metering.

6.1.2.2 Preamplifier Module +13.5V Signal Flow

Refer to Figure 6-2. +13.5-volt power fr om J5 is r ou ted thr o ugh a resi st or , a component of

a current-detection circuit. The sample provided by this circuit determines the preamplifier

current metering. The +13.5-volt power through the resistor is fused by F4 before distribution to the meterin g boa rd an d preampl ifi er mo dul e, on the dri ver boa rd.

6.1.3 Fan Power

25-volt dc fan power is fused externally at the power supply equipment. Refer to Figure 6-

1. Fan power is received through connector P2, which mates with J2 on the system inter-

connect harness. Fan powe r is applied directly to the fan via a qu ick-release jack (not

shown).

Page: 6-2 Copyright © 1996 Glenayre Print Date: 12/17/96

Page 25

Glenayre Document Number: 9110.00160 250-Watt Gold Line Power Amplifier

Issue 1, Rev. C: 10/21/96 THEORY OF OPERATION

6.2 RF Distribution

Refer to Figure 6-1. The PA RF input is received through a BNC connector, which mates

with J3 on the exciter/PA control. This RF input signal (at a nominal 350 mW) is split and

amplified into two RF signals (at a nominal 40 watts) by the driver board. Each RF signal

is amplifie d (to a nom inal 150 watts ) by a PA board. These RF signals are c ombin ed i nto

one RF signal (at a nominal 275 watts) by the combiner board. This is the PA RF output,

and is applie d to an isolator. The isolator R F output (at a n omin al 250 wa tts for st andard)

is sup p li ed t o an ante nna fo r trans mis s ion. A ll p ower l ev el s give n her e and in t he f ol lo wing

paragraphs are typica l; actual powe r level s wil l vary from tho se given .

6.2.1 Driver Board RF Flow

The driver bo ard splits and amplifies a 350-mW RF inpu t into two 40-watt RF outputs.

Refer to Figure 6-3. The RF i nput to the dr iver board i s ap pli ed to t he preampli fier modul e

(Q1). A portion of the RF input is appli ed to an RF-detec tion circuit on the boa rd. This

circuit rectifie s and filt er s the RF inp ut into an OK s ignal. Loss of the RF input and the OK

signal resu l ts in an exci te r output fault.

The preamplifier module is a three-stage RF power amplifier on a single IC. The first and

third stages are powered by an AGC signal. These are the variable gain stages, and control

the forward power output of the PA. The first and third stages of the preamp module are

powered by an AGC signal, generated on the metering board. AGC signal voltage is

monitored for status only. The second stage of the preamplifier module is a nonvariablegain stage, powered by +13. 5-volt power. The current draw n by the AG C and +13.5-vo lt

power signal s contribu t es to the preampli f ier curre n t meteri ng .

The amplified RF outpu t from t h e preamp module is appli e d to t he IPA (Q2). The current

drawn from the IPA’s +25-volt powe r source is mon itored to determine the IPA current

metering. The amplified RF output from the IPA is monitored for forward and reflected

power levels. The power sampl es detected at this location determine the IPA forward - and

reflected-po wer me terin g.

Power-Moni toring Theory

Power-m on i tor circ u it s are loca t ed on th e driv er boa rd, PA boa rd s, an d com bin e r

board. A microstrip line parallel to the RF signal path couples a small portion of the ac

signal ac ross a rectifier and filtering circuit. The ac signal may be rectified to detect either the forward or reflected power. After filtering, a dc sample voltage is available that

is proportional to the power detected at the monitored location.

Print Date: 12/17/96 Copyright © 1996 Glenayre Page: 6-3

Page 26

250-Watt Gold Line Power Amplifier Glenayre Do cument Number : 9110.00160

THEORY OF OPERATION Issue 1, Rev. C: 10/21/96

After monitoring, the amplified RF output from the IPA is split in two by means of an RF

splitter, common ly known as a Wilkinson splitter. The two split RF sig nals are appl ied to

driver-1 (Q3) and driver-2 (Q4). The current draw n from each driver ’s +25-volt power

source is monitored to determine the driver-1 and driver-2 current metering. The amplified

RF outputs from the two drivers are the driver board’s 40-watt RF outputs.

Wilkinson Spl itter/ Co m biner Th eor y

Wilkinson splitter and combiner networks are located in the RF signal path on the driver board, PA boa rd s, an d combiner board . A wa ste r resi sto r is lo c ated a pre ci se dis tance from th e sig n al jun c ti o n . Th is resistor dissipate s any o ut-of-pha se im ba la n ce or

amplifier imbalance that may exist between the RF signals being split or combined, resulting in a more sta ble am plifier.

6.2.2 PA Board RF Flow

Each P A board a mplifies a 40-watt RF input into a 150-watt RF output. Refer to Figure 6-

3. The RF input to the P A board is split into four signals by means of three Wilkinson split-

ters. Each RF signal drives a power amplifier, for a total of four amplifiers (Q1, Q2, Q3,

and Q4). Q1 and Q2 receive operating power from a common +25-volt power source. The

current drawn by thi s source is monitored to det ermine the PA board’s A-pair curren t.

Likewise, the current drawn by Q3 and Q4 common +25-volt power source is monitored to

determin e the PA board’s B-pair current.

The amplified RF out puts from the four power amplifiers are c ombined into one by mean s

of three Wilkinson combiners. The RF signal from the last Wilkinson combiner is

monitored for forward and reflected power levels. The power samples detected at this

location determine the PA board’s forward and reflected power metering. The combined

and monitored RF signal is the PA board’s 150-watt RF output.

6.2.3 Combiner Board RF Flow

The combiner board combines two 150-watt RF inputs into a single 275-watt RF output.

Refer to Figure 6-3. The two RF inputs are com bined by a Wilkinson combiner. The

combined RF is monitored for forward power level. The power sample detected at this

loca ti on det er mi n es the t ota l f or war d p ow er me te r in g. Th e com b i ned an d mo ni to r e d sig na l

is the combiner board’s 275-watt RF output.

6.2.4 Isolator RF Flow

The isolator conducts its 275-watt RF input only in the forward direction, suppressing any

intermodulation or VSWR present at its RF output. Refer to Figure 6-3. The RF input is

applied throu gh a circulato r. The optional triple isolator RF inpu t is applied thro ugh three

circulators.

Circulator Th eor y

A circulator consists of several circular layers of copper, ferrite, and a magnetic material that biases th e ferrit e. The circ ula tor ha s th ree inpu t s/ou t put s. The biase d ferrit e co nducts electric ity only in one dire ction , outpu ttin g the signa l appli ed at its previou s

input. Each circulator prov id es 25 d B of isola ti on.

Page: 6-4 Copyright © 1996 Glenayre Print Date: 12/17/96

Page 27

Glenayre Document Number: 9110.00160 250-Watt Gold Line Power Amplifier

Issue 1, Rev. C: 10/21/96 THEORY OF OPERATION

The circulato r RF ou tput i s applied throu gh a notc h filt er to rem ove the seco nd harmo nic s

generated by the circulator. This filtered RF is the isolator’s RF output. This RF output is

ty pica lly 250 wa tts for a stan dard i solator o r 225 watt s for a tripl e isolat or. Any reflected

power present at the isolator RF output is conducted back through the circulator to a

rectifier and filtering circuit. This circuit generates a dc sample voltage proportional to the

VSWR present a t the isolator RF o utput. The sample vo l tage d etermines the to t al r ef l ec tedpower metering.

6.3 Control Distribution

Refer to Figure 6-1. The PA control inputs are received through a DB15 connector, which

mates with J6 on the exciter/PA control. Two ty pes of control inputs are received: AGC

referenc e and mul ti ple xer.

6.3.1 AGC Signal Flow

The metering board c ompares the AGC referenc e signal (from the exciter) wi th the total

forward power sample (from the combiner board) to create an AGC signal (to the driver

board). Refer to Figure 6-2. The AGC reference signal and the total forward power sample

are applied t o an integ rator circu it, which ge nerates the AGC signa l. An increa se in the

AGC refere nce si gn al or a decre ase in th e tota l forw ard po wer sa mple causes an in crease

in the AGC signal. This AGC signal provides operating power for the first and third

amplifie r stag e s of the pre am pli fier. Divider c ircu i try red uce s a port ion of th e AG C sig nal

to a sample voltage, which determines the AGC metering.

6.3.2 Multiplexer Control Signal Flow

6.4 Status Distribution

Analog Multiplexer Theory

Three analog multiplexers are located on the metering board. Each multiplexer receives as many as eight analog inputs, at a sample voltage which represents a PA parameter or status. Control lines from the exciter command the multiplexer to connect

one of the inputs to a common output, which is measured by the exciter. The multiplexer is switched quickly between the analog inputs, resulting in a multiplexed analog

output.

Refer to Figure 6-2. The exciter controls each multiplexer by four control lines: three

address lines and a lat ch. The addres s lines (0, 1, a nd 2) are binary signals wi th a total of

eight possible states. The address lines sequence through the eight states in about 360

microse conds. A s each s tate occurs, the la tch line i s toggled, selectin g the an alog input

corresponding to that address state. The voltag e present at the multiplexer commo n out put

is the most recently latched analog input.

Refer to Figure 6-1. The PA status outputs are supplied through the same DB15-type

connector as the PA control inputs, which mates with J6 on the exciter/PA control. Two

types of status outputs are supplied: multiplexed (mux) analog and PA fault.

Print Date: 12/17/96 Copyright © 1996 Glenayre Page: 6-5

Page 28

250-Watt Gold Line Power Amplifier Glenayre Do cument Number : 9110.00160

THEORY OF OPERATION Issue 1, Rev. C: 10/21/96

6.4.1 Mux Analo g Stat us Sig nal Flow

Mux analog status signals consist of dc voltages that repres ent a paramete r or fault within

the PA. These s ignals are ge nerated by c urrent detecto rs, power mon itors, and mete ring

dividers, which supply a status voltage propo rtional to the leve l of parameter i t is representing, or the existence of the fault it is representing. Refer to Figure 6-2. These status

voltages are applied to one of the three multiplexers located on the metering board. The

multiplexers ro u te t he a ppro pria te st at us v olt age t o the ex cit er i n the fo rm o f mu x a n alo g.

Table 6-1 lis ts a ll s tatus vo lta ge nom enc latur e, the mu lt ipl exer that rou tes t ha t vo lta ge , a nd

the control address that directs the multiplexer to route that voltage.

6.4.2 PA Fault Signal Flow

A PA fault signal is activated when a reflected power threshold is exceeded by the PA1 or

P A2 board. Refer to Figure 6-2. A port ion o f the P A 1 boa rd an d PA2 board re flect ed p ower

status voltages are applied to a comparator and switching circuit. When either status

exceeds a voltage repre senting a bout 20 watts, the switch is activa ted. Th e switch appl ies

a PA fault to the exciter, which shuts down the transmitter.

Table 6-1 Multiplexer Analog Status Inputs

addr multiplexer 1 multiplexer 2 multiplexer 3

000 PA1-A current preamp current total forward power

001 PA1-B current IPA current (no input)

010 PA2-A current driver-1 current IPA forward power

011 PA2-B current driver-2 current IPA reflected powe r

100 PA1 forward power (no input) +25V voltage level

101 reflected power (no input) +13.5V voltage level

110 PA2 forw ard power exciter output fault +5V voltage level

111 PA2 reflected power AGC voltage level PA heat sink temp

Page: 6-6 Copyright © 1996 Glenayre Print Date: 12/17/96

Page 29

Glenayre Document Number: 9110.00160 250-Watt Gold Line Power Amplifier

Issue 1, Rev. C: 10/21/96 THEORY OF OPERATION

v0229.hgl

Figure 6-1 250-Watt PA Interconnection Diagr am

Print Date: 12/17/96 Copyright © 1996 Glenayre Page: 6-7

Page 30

250-Watt Gold Line Power Amplifier Glenayre Do cument Number : 9110.00160

THEORY OF OPERATION Issue 1, Rev. C: 10/21/96

v0203.hgl

Figure 6-2 250-W att PA Functional Diagram

Page: 6-8 Copyright © 1996 Glenayre Print Date: 12/17/96

Page 31

Glenayre Document Number: 9110.00160 250-Watt Gold Line Power Amplifier

Issue 1, Rev. C: 10/21/96 THEORY OF OPERATION

v0202l.hgl

Figure 6-3 2 50-Watt PA Detailed Functional Diagram

Print Date: 12/17/96 Copyright © 1996 Glenayre Page: 6-9

Page 32

250-Watt Gold Line Power Amplifier Glenayre Do cument Number : 9110.00160

THEORY OF OPERATION Issue 1, Rev. C: 10/21/96

v0202r.hgl

250-Watt PA Detailed Functional Diagram

Page: 6-10 Copyright © 1996 Glenayre Print Date: 12/17/96

Page 33

Glenayre Document Number: 9110.00160 250-Watt Gold Line Power Amplifier

Issue 1, Rev. C: 10/21/96 THEORY OF OPERATION

v0204l.hgl

Figure 6-4 Metering Bo ard Functi onal Diagr am

Print Date: 12/17/96 Copyright © 1996 Glenayre Page: 6-11

Page 34

250-Watt Gold Line Power Amplifier Glenayre Do cument Number : 9110.00160

THEORY OF OPERATION Issue 1, Rev. C: 10/21/96

0204r.hgl

Metering Board Functional Diagram

Page: 6-12 Copyright © 1996 Glenayre Print Date: 12/17/96

Page 35

Glenayre Document Number: 9110.00160 250-Watt Gold Line Power Amplifier

Issue 1, Rev. C: 10/21/96 MAINTENANCE

7 MAINTENANCE

Refer to the system and VDT manuals.

Print Date: 12/17/96 Copyright © 1996 Glenayre Page: 7-1

Page 36

250-Watt Gold Line Power Amplifier Glenayre Do cument Number : 9110.00160

MAINTENANCE Issue 1, Rev. C: 10/21/96

Page: 7-2 Copyright © 1996 Glenayre Print Date: 12/17/96

Page 37

Glenayre Document Number: 9110.00160 250-Watt Gold Line Power Amplifier

Issue 1, Rev. C: 10/21/96 CHECKOUT AND TROUBLESHOOTING

8 CHECKOUT AND TROUBLESHOOTING

Refer to the system and VDT manuals.

Print Date: 12/17/96 Copyright © 1996 Glenayre Page: 8-1

Page 38

250-Watt Gold Line Power Amplifier Glenayre Do cument Number : 9110.00160

CHECKOUT AND TROUBLESHOOTING Issue 1, Rev. C: 10/21/96

Page: 8-2 Copyright © 1996 Glenayre Print Date: 12/17/96

Page 39

Glenayre Document Number: 9110.00160 250-Watt Gold Line Power Amplifier

Issue 1, Rev. C: 10/21/96 REMOVAL AND REINSTALLATION

9 REMOVAL AND REINSTALLATION

9.1 PA Chassis Removal and Reinstallation

Figure 9-1 sh o w s d etails of removin g an d reinstall i ng t h e c h assis. Cal ibration of fo rward

and reflected power is required after reinstallation.

9.2 PA RF Module Removal and Reinstallation

Figure 9-2 shows details of removing and reinst al ling P A RF modules.

9.3 Metering Board Removal and Reinstallation

Figure 9-3 shows details of removing and reinstalling the metering board.

Print Date: 12/17/96 Copyright © 1996 Glenayre Page: 9-1

Page 40

250-Watt Gold Line Power Amplifier Glenayre Do cument Number : 9110.00160

REMOVAL AND REINSTALLATION Issue 1, Rev. C: 10/21/96

v0223.hgl

Figure 9-1 PA Removal and Reinstalllation

Page: 9-2 Copyright © 1996 Glenayre Print Date: 12/17/96

Page 41

Glenayre Document Number: 9110.00160 250-Watt Gold Line Power Amplifier

Issue 1, Rev. C: 10/21/96 REMOVAL AND REINSTALLATION

Print Date: 12/17/96 Copyright © 1996 Glenayre Page: 9-3

Page 42

250-Watt Gold Line Power Amplifier Glenayre Do cument Number : 9110.00160

REMOVAL AND REINSTALLATION Issue 1, Rev. C: 10/21/96

v0225.hgl

Figure 9-2 PA RF Module Removal a nd Reinst all ati on

Page: 9-4 Copyright © 1996 Glenayre Print Date: 12/17/96

Page 43

Glenayre Document Number: 9110.00160 250-Watt Gold Line Power Amplifier

Issue 1, Rev. C: 10/21/96 REMOVAL AND REINSTALLATION

Figure 9-2 PA R F Module Removal and Reinstallation (continue d)

Print Date: 12/17/96 Copyright © 1996 Glenayre Page: 9-5

Page 44

250-Watt Gold Line Power Amplifier Glenayre Do cument Number : 9110.00160

REMOVAL AND REINSTALLATION Issue 1, Rev. C: 10/21/96

v0228.hgl

Figure 9-3 Metering Board Removal and Reinstallation

Page: 9-6 Copyright © 1996 Glenayre Print Date: 12/17/96

Page 45

Glenayre Document Number: 9110.00160 250-Watt Gold Line Power Amplifier

Issue 1, Rev. C: 10/21/96 REMOVAL AND REINSTALLATION

v0227.hgl

Figure 9-3 Metering Board Removal and Reinstallation (continued)

Print Date: 12/17/96 Copyright © 1996 Glenayre Page: 9-7

Page 46

250-Watt Gold Line Power Amplifier Glenayre Do cument Number : 9110.00160

REMOVAL AND REINSTALLATION Issue 1, Rev. C: 10/21/96

Page: 9-8 Copyright © 1996 Glenayre Print Date: 12/17/96

Loading...

Loading...