Page 1

GL-T8200 1- to 25-Watt 900-MHz Power Amplifier Rev. A: 03/23/99

GL-T8200

1- to 25-Watt, 900-MHz Power Amplifier

USER MANUAL

PN 9110.01306

REV A

Specifications subject to change without notice

Copyright © 1999 Glenayre

All rights reserved. No part of this work may be reproduced or copied in any form or by

any means—graphic, electronic, or mechanical, including photocopying, recording,

taping, or information-retrieval system—without written permission of Glenayre.

Print Date: 03/23/99 Copyright © 1999 Glenayre

Page 2

GL-T8200 1- to 25-Watt 900-MHz Power Amplifier Glenayre Document Number: 9110.01306

Document Change Record Rev. A: 03/23/99

Document Change Record

Revision: Revision A

Date: 03/23/99

Changes: none, original

Copyright © 1999 Glenayre Print Date: 03/23/99

Page 3

Glenayre Document Number: 9110.01306 GL-T8200 1- to 25-Watt 900-MHz Power Amplifier

Rev. A: 03/23/99 Table of Contents

Table of Contents

1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 Manual Scope . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Applicable Documents. . . . . . . . . . . . . . . . . . . . . 1-1

1.3 Manual Sections . . . . . . . . . . . . . . . . . . . . . . . 1-1

2 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

25w82001.toc

3 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 Physical Description. . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1 Mounting Provisions . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.1.2 PA Chassis Rear Connector Panel . . . . . . . . . . . . . . . . .3-1

3.2 Functional Description. . . . . . . . . . . . . . . . . . . . . 3-3

3.2.1 RF Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3.2.2 Signal and Power Connections . . . . . . . . . . . . . . . . . . .3-3

3.2.3 Isolator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

4 INSTALLATION AND SETUP . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Cabinet Installation and External Cabling . . . . . . . . . . . . . 4-1

4.1.1 Tools and Equipment Required. . . . . . . . . . . . . . . . . . .4-1

4.1.2 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.1.3 Rack Positioning . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.1.4 External Cabinet Equipment Cabling. . . . . . . . . . . . . . . .4-1

4.1.5 PA I/O Connections. . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.2 Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.2.1 Expected Exciter . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.2.2 Setup Using VDT . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

5 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 Controls and Indicators . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2.1 Turn PA On and Off . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2.2 Turn Fan On and Off . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2.3 Key and Unkey PA . . . . . . . . . . . . . . . . . . . . . . . . .5-1

6 THEORY OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 Power Distribution . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1.1 Fan Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.1.2 High-Current Power to PA Board. . . . . . . . . . . . . . . . . .6-1

6.1.3 Metering Circuit Regulators . . . . . . . . . . . . . . . . . . . .6-1

6.2 RF Flow . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Print Date: 04/14/99 Copyright © 1999 Glenayre Page: -i

Page 4

GL-T8200 1- to 25-Watt 900-MHz Power Amplifier Glenayre Document Number: 9110.01306

Table of Contents Rev. A: 03/23/99

6.3 PA Board . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.3.1 Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6.3.2 Internally Generated Voltages . . . . . . . . . . . . . . . . . . 6-3

6.4 Exciter Interface . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.4.1 Exciter Interface Connector Pinout. . . . . . . . . . . . . . . . . 6-5

6.5 Analog Readings Thresholds . . . . . . . . . . . . . . . . . . 6-5

6.5.1 PA Board Currents . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.5.2 PA Forward Power . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.5.3 PA Reflected Power . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.5.4 PA Board RF Input Power . . . . . . . . . . . . . . . . . . . . . 6-6

6.5.5 +28-Volt External Supply . . . . . . . . . . . . . . . . . . . . .6-6

6.5.6 +36-Volt Internal Supply . . . . . . . . . . . . . . . . . . . . . . 6-6

6.5.7 +5-Volt Internal Supplies. . . . . . . . . . . . . . . . . . . . . . 6-7

6.5.8 Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

7 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 Power Calibration . . . . . . . . . . . . . . . . . . . . . . 7-1

8 CHECKOUT AND TROUBLESHOOTING . . . . . . . . . . . . . . . . . . 8-1

8.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.2 Checkout Procedures . . . . . . . . . . . . . . . . . . . . . 8-1

8.2.1 VDT Power-Up Verification . . . . . . . . . . . . . . . . . . . . 8-1

8.2.2 Dc Voltage Verification . . . . . . . . . . . . . . . . . . . . . . 8-1

8.3 Troubleshooting Procedures . . . . . . . . . . . . . . . . . . 8-1

8.3.1 Parameter Readings at Time of Fault. . . . . . . . . . . . . . . . 8-1

8.3.2 GL-C2000 Transmitter Controller Alarms . . . . . . . . . . . . . 8-2

8.3.3 Operational Checks. . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.3.4 Power Amplifier Current Measurement . . . . . . . . . . . . . . 8-2

9 REMOVAL AND REINSTALLATION . . . . . . . . . . . . . . . . . . . . 9-1

9.1 PA . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.1.1 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

9.1.2 Reinstallation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Page: -ii Copyright © 1999 Glenayre Print Date: 04/14/99

Page 5

25w82001.lof

Glenayre Document Number: 9110.01306 GL-T8200 1- to 25-Watt 900-MHz Power Amplifier

Rev. A: 03/23/99 List of Figures

List of Figures

Figure 3-1 PA Front Isometric View . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Figure 3-2 Top View of PA RF Compartments, Showing Internal Assemblies . . . 3-3

Figure 4-1 PA Rear View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Figure 6-1 Simplified Power Amplifier Block Diagram . . . . . . . . . . . . . . . 6-2

Figure 6-2 PA Board Functional Diagram . . . . . . . . . . . . . . . . . . . . . . 6-4

Print Date: 04/14/99 Copyright © 1999 Glenayre Page: -iii

Page 6

GL-T8200 1- to 25-Watt 900-MHz Power Amplifier Glenayre Document Number: 9110.01306

List of Figures Rev. A: 03/23/99

Page: -iv Copyright © 1999 Glenayre Print Date: 04/14/99

Page 7

Glenayre Document Number: 9110.01306 GL-T8200 1- to 25-Watt 900-MHz Power Amplifier

Rev. A: 03/23/99 List of Tables

List of Tables

Table 1-1 Applicable Documents . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Table 1-2 Manual Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Table 2-1 Power Amplifier Specifications. . . . . . . . . . . . . . . . . . . . . . 2-1

Table 4-1 Required Tools and Equipment. . . . . . . . . . . . . . . . . . . . . . 4-1

Table 4-2 PA I/O Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

25w82001.lot

Table 4-3 Exciter/PA Connector Pinout (For DSP Exciter). . . . . . . . . . . . . 4-3

Table 4-4 PA Board Fuses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Table 6-1 PA Board Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Table 6-2 Metered Parameter Thresholds . . . . . . . . . . . . . . . . . . . . . . 6-7

Table 8-1 PA Board Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Print Date: 04/14/99 Copyright © 1999 Glenayre Page: -v

Page 8

GL-T8200 1- to 25-Watt 900-MHz Power Amplifier Glenayre Document Number: 9110.01306

List of Tables Rev. A: 03/23/99

Page: -vi Copyright © 1999 Glenayre Print Date: 04/14/99

Page 9

Glenayre Document Number: 9110.01306 GL-T8200 1- to 25-Watt 900-MHz Power Amplifier

Rev. A: 03/23/99 GENERAL

1

GENERAL

1.1 Manual Scope

This manual provides information for th e 1 to 25-watt, 900-MHz power amplifier, part

number 1000.02186.

25w82001

1.2 Applicable Documents

This manual is incomplete without additional manuals. Refer to Table 1-1 for a listing and

function of these manuals.

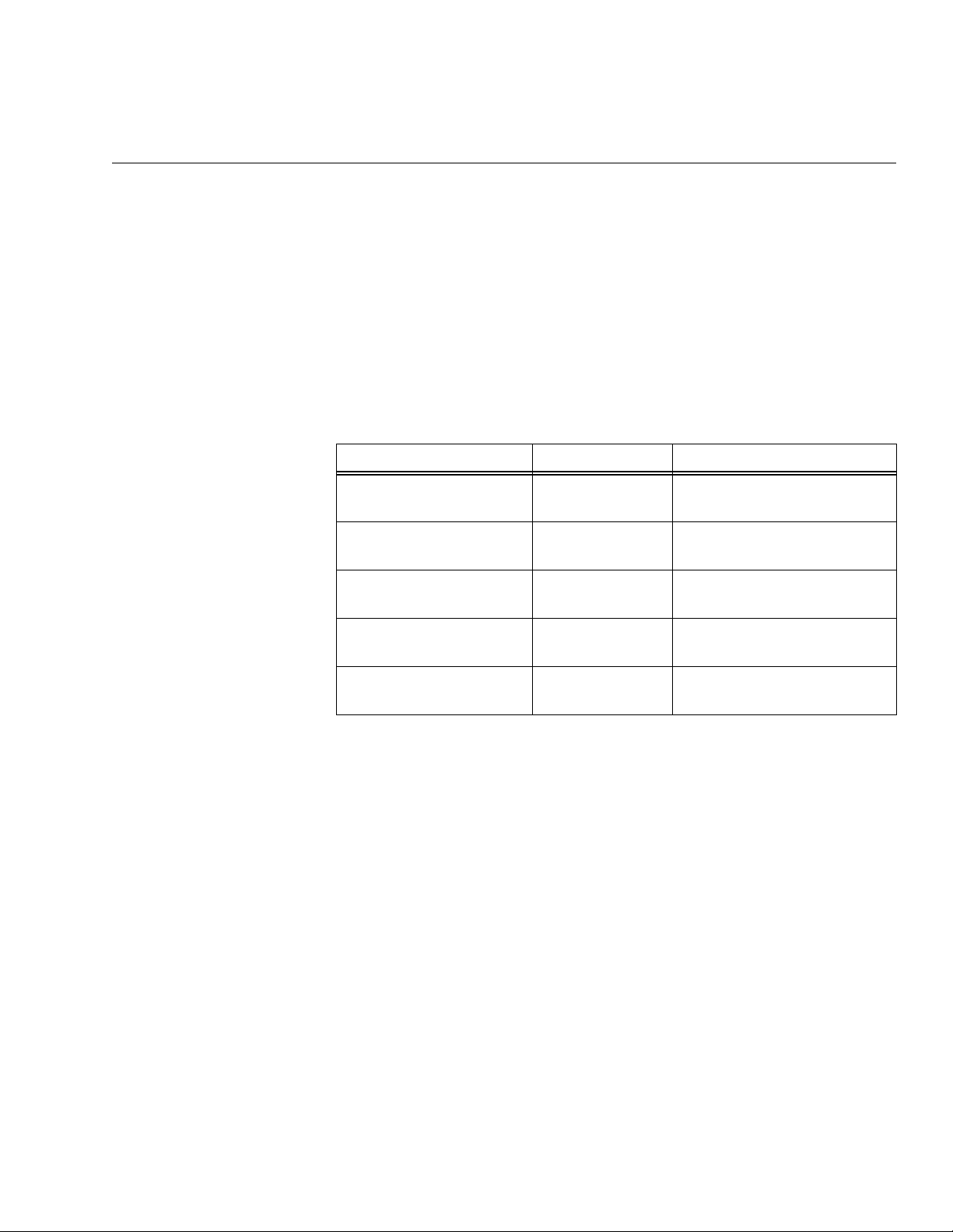

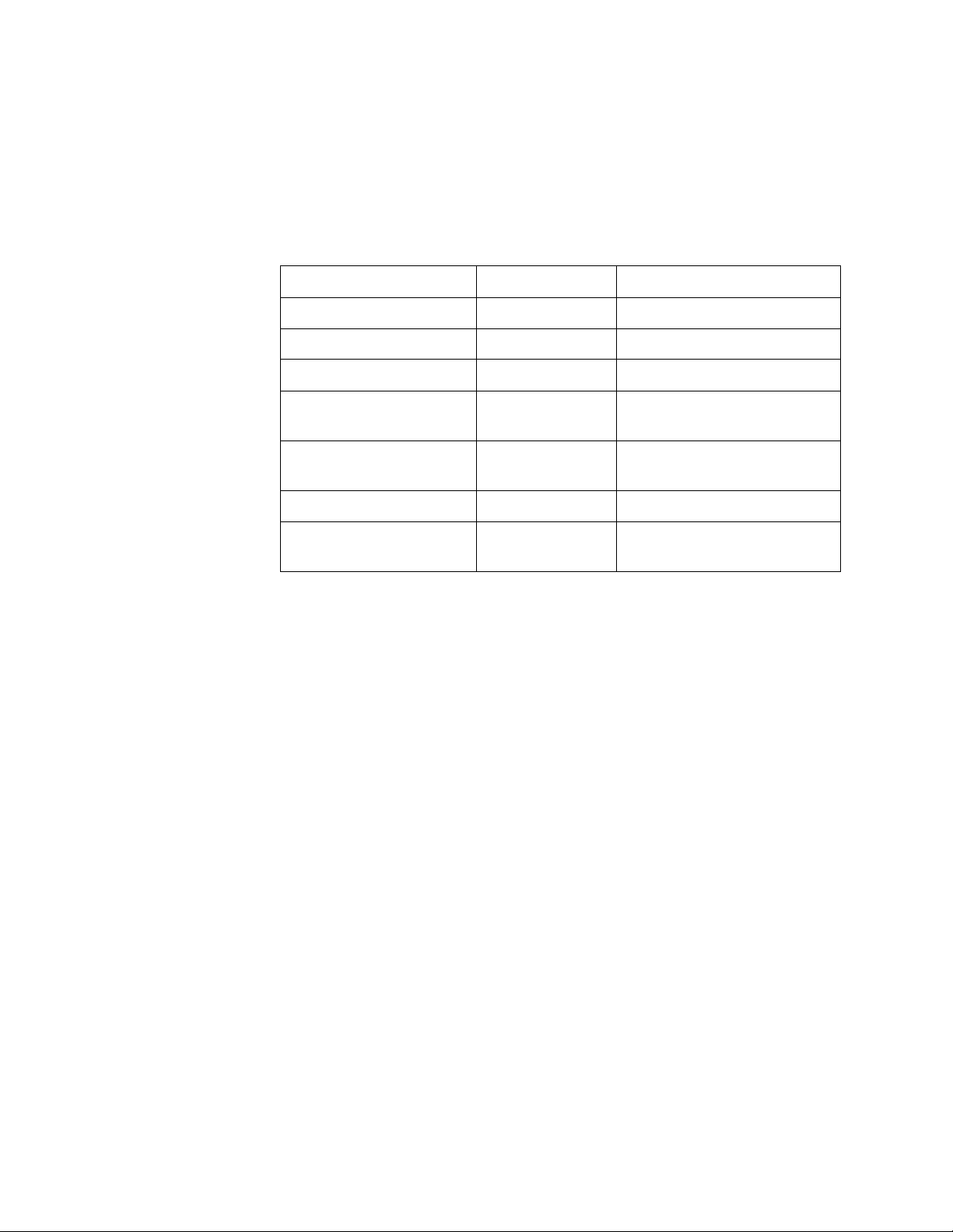

Table 1-1 Appl icable Documents

document part number function

GL-T8200 system manual 9110.01305 describes fully racked-up GL-

T8200 transmitter

1.3 Manual Sections

DSP VDT manual 9110.00259 describes DSP excit er software in-

stalled in exciter

DSP exciter user manual 9110.01021 describes DSP exciter hardware

equipment in transmitter

GL-T8200 1 to 25-watt PA

manual

power supply manual 9110.00622 describes GL2728 power supply

Table 1-2 lists the sections of this manual with a summary of their contents.

9110.01306 this manual

equipment

Print Date: 05/10/99 Copyright © 1999 Glenayre Page: 1-1

Page 10

GL-T8200 1- to 25-Watt 900-MHz Power Amplifier Glenayre Document Number: 9110.01306

GENERAL Rev. A: 03/23/99

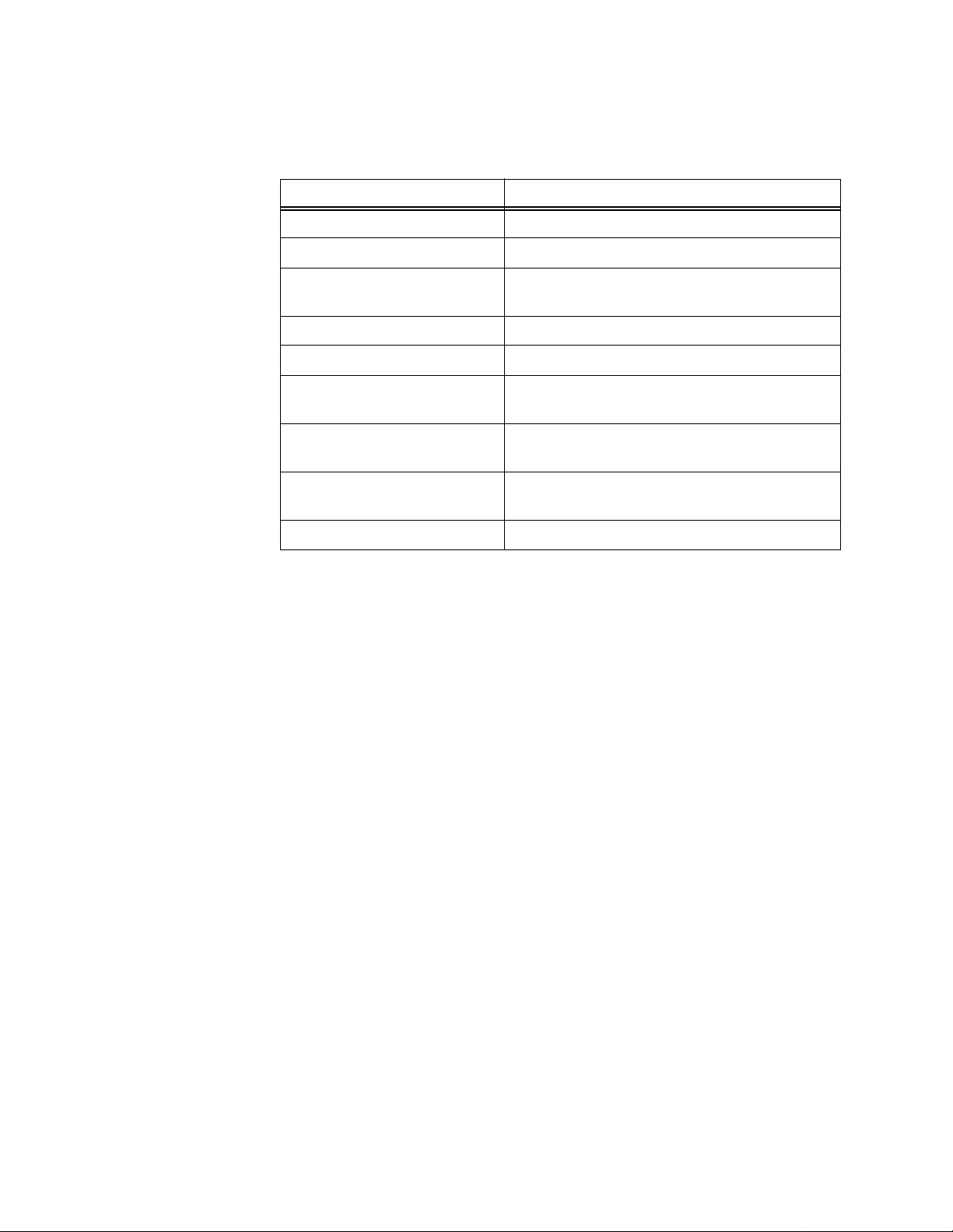

Table 1-2 Manual Sections

section contents

1. General introduction and purpose of manual

2. Specifications significant measurements of power amplifier

3. Description introduction and principal characteristics of power

amplifier

4. Installation and Setup initial installation and activation of po wer amplifier

5. Operation operation of power amplifier

6. Theory of Operation detailed functional description of circuitry within

power amplifier

7. Maintenance procedures to be performed on specific intervals to

maintain optimum performance of power amplifier

8. Checkout and Troubleshooting verification of p roper operati on, correct ion to p roper

operation of power amplifier

9. Removal and Reinstallation removal and reinstallation procedures for the PA

Page: 1-2 Copyright © 1999 Glenayre Print Date: 05/10/99

Page 11

Glenayre Document Number: 9110.01306 GL-T8200 1- to 25-Watt 900-MHz Power Amplifier

Rev. A: 03/23/99 SPECIFICATIONS

2 SPECIFICATIONS

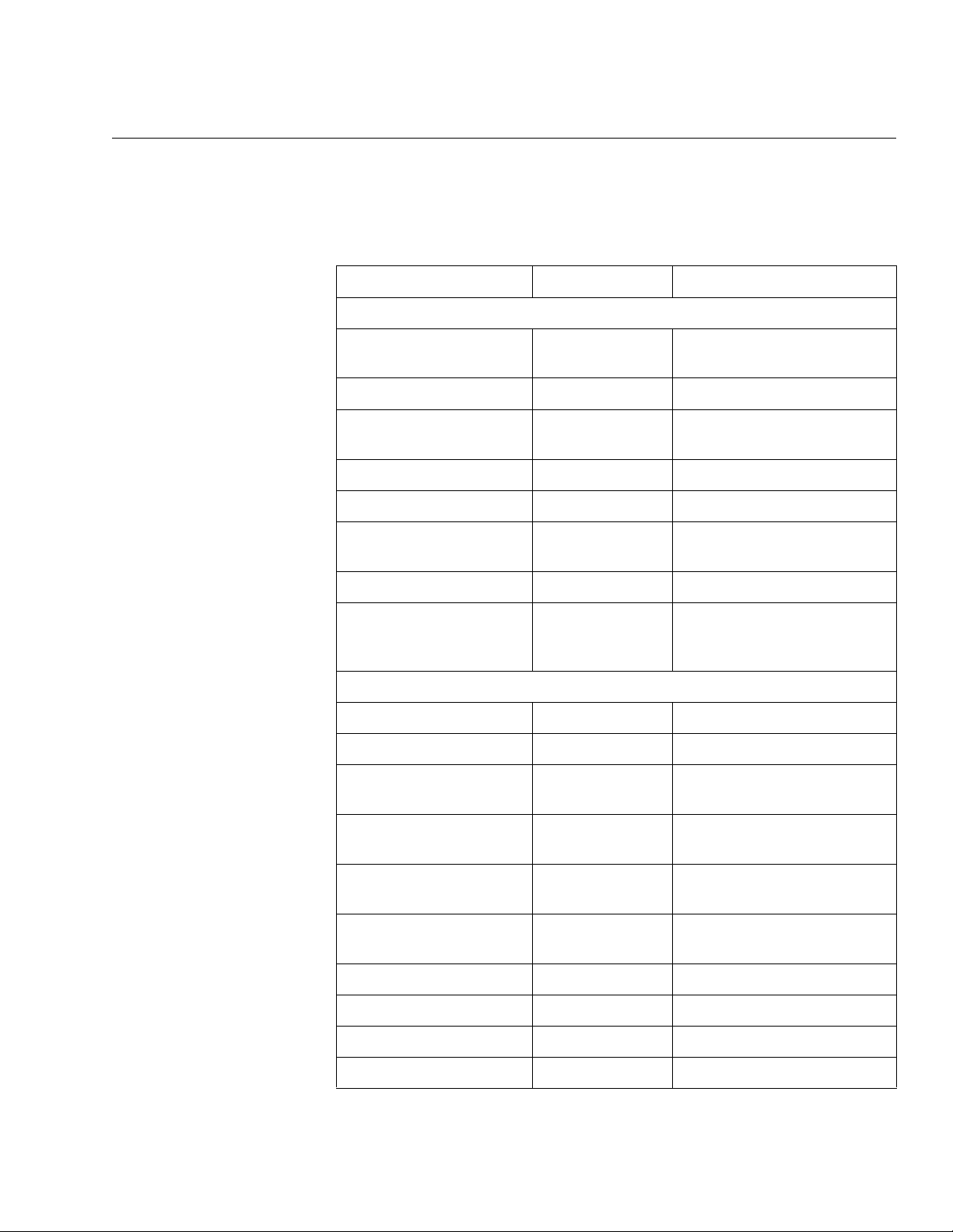

Table 2-1 lists the significant equipment-level specifications for the power amp lifier.

Table 2-1 Power Amplifier Specifications

measurement condition specification

25w82002

Electrical

RF output power (W) continuous, at

1 to 25

output of PA

RF bandwidth (MHz) exceeds exciter bandwidth

RF input power (mW) factory-set

200-400

attenuation

RF input connector type-N female

RF output connector output of PA type-N female

input and output RF

50

impedance (ohms)

VSWR max 1.5

dc input power

voltage (Vdc)

28

current, idle/operating (A)

Mechanical and Environmental

humidity 5 to 95%, noncondensing

-30

o

to 70oC

o

to 60oC

ambient storage temperature -30

ambient operating

temperature

temperature derating factor

o

0.5

C per 100 m

above 5000 feet (1500 m)

vibration Mil-Std 810E, Method 514.4

Category 1

maximum operating

to 10,000 ft (3050 m)

elevation

height 3 RU (5.25 in, 13.4 cm)

width 19 in (48 cm)

depth 12 in (30.5 cm)

weight 25 lb (11.3 kg)

Print Date: 03/29/99 Copyright © 1999 Glenayre Page: 2-1

Page 12

GL-T8200 1- to 25-Watt 900-MHz Power Amplifier Glenayre Document Number: 9110.01306

SPECIFICATIONS Rev. A: 03/23/99

Page: 2-2 Copyright © 1999 Glenayre Print Date: 03/29/99

Page 13

Glenayre Document Number: 9110.01306 GL-T8200 1- to 25-Watt 900-MHz Power Amplifier

Rev. A: 03/23/99 DESCRIPTION

3 DESCRIPTION

This is a 1- to 25-wa tt PA intended for use on th e 900 -MHz band. This PA is characterized

by integrated monitoring devices that supply critical status information to the DSP exciter.

This exciter contains diagnostic software that can detect and report a faulty PA.

3.1 Physical Description

25w82003

Refer to Figure 3-1 and Figure 3-2. The PA consis ts of a 3 RU high chassis, including

convection fins and one fan.

The chassis contains a PA board which contains metering circuitry, power distribution

circuitry, and RF amplification circuitry.

3.1.1 Mounting Provisions

The P A i s mounted to the front of most standard 19-inch equipm ent racks by m eans of eight

screws. The front panel o f the PA may by removed while the PA is mounted in the rack for

access to fuses. Thumbscrews secure the front panel to the PA.

3.1.2 PA Chassis Rear Connector Panel

Refer to Figure 4-2 for a list of connections for th e P A . The PA chassis rear connector panel

has an RF input connector , an RF output co nnector , a dc power inpu t connector, a dc power

output connector, a fan, and a 15-pin connector for connection to the DSP exciter.

Print Date: 05/10/99 Copyright © 1999 Glenayre Page: 3-1

Page 14

GL-T8200 1- to 25-Watt 900-MHz Power Amplifier Glenayre Document Number: 9110.01306

DESCRIPTION Rev. A: 03/23/99

v0222.hgl

Figure 3-1 PA Front Isometric View

Page: 3-2 Copyright © 1999 Glenayre Print Date: 05/10/99

Page 15

Glenayre Document Number: 9110.01306 GL-T8200 1- to 25-Watt 900-MHz Power Amplifier

Rev. A: 03/23/99 DESCRIPTION

v0221.hgl

25w82003

Figure 3-2 Top View of PA Board, Showing I/O

3.2 Functional Description

The RF amplifier circuitry of the power amplifier is contained within the PA chassis. The

monitoring of the RF amplifier system is accomplished by the digital exciter through the

PA board located in the PA chassis.

3.2.1 RF Path

The PA chassis receives the exciter output at a rear-mounted type-N connector on the PA

board. The RF output power leaves the PA board through a type-N RF output connector . A

jumper delivers the signal to the lightning protector output on the cabinet.

3.2.2 Signal and Power Connections

All PA dc, signal monitoring, and control signals are routed through the PA board.

Print Date: 05/10/99 Copyright © 1999 Glenayre Page: 3-3

Page 16

GL-T8200 1- to 25-Watt 900-MHz Power Amplifier Glenayre Document Number: 9110.01306

DESCRIPTION Rev. A: 03/23/99

3.2.3 Isolator

intermodulation prevention An isolator receives the RF output of the PA chassis. It prevents intermodulation of th e RF

signal that may occ ur from nearby transmissi ons and red uces radiated ha rmonics. A sampl e

detector circuit in the isolator reject load input monitors the reflected power (VSWR)

present at the cabinet’ s RF output connector . The VSWR RF sample is rectified an d filtered,

providing a dc voltage proportional to the VSWR connector on the third isolator, w hich

voltage is supplied to the DSP exciter for transmitter control and monitoring. The VSWRdetection circuit of the third isolator is the only means of detecting whet her there is an

antenna fault, which can then be detected and reported.

reject load The triple isolator provides the power amplifier module with a stable 50-ohm load. This is

accomplished by directing any reflections from the output line to a reject load. Hence, the

load presented to the PA final transistor is always acceptable.

power control An RF sample of the f orward output signal is obtained from the for ward-power coupler and

directed to the exciter, along with the reflected-power indication from the reflected-power

coupler. Control circuits within the DSP exciter evaluate the forward power and the

reflected power and control the output power according to conditions. Additionally, if the

DSP exciter detects an RF fault, it passes the report to the GL-C2000 and VDT for system

control.

Page: 3-4 Copyright © 1999 Glenayre Print Date: 05/10/99

Page 17

Glenayre Document Number: 9110.01306 GL-T8200 1- to 25-Watt 900-MHz Power Amplifier

Rev. A: 03/23/99 INSTALLATION AND SETUP

4 INSTALLATION AND SETUP

4.1 Cabinet Installation and External Cabling

4.1.1 Tools and Equipment Required

Refer to Table 4-1. Equipment listed by brand name may be substituted with equivalent.

25w82004

For installation, only common hand tools are necessary if at all, since equipment integration

is usually completed at the factory.

Table 4-1 Required Tools and Equipment

nut driver - 5/16 in (7.9 mm)

screwdriver - #2 flat blade and #3 flat blade

screwdriver - #2 Phillips and #3 Phillips

Bird 4421 RF power meter

Bird 8327 dummy load

spectrum analyzer

barrel connector - type-N female

cable - 1 M long (max) with 7/16 Din to type-N male ends

Fluke 77 DVM

7/16 DIN male-to-type-N female adapter

4.1.2 Inspection

Refer to the system manual.

4.1.3 Rack Positioning

Refer to the system manual also. Rackup variation s are generall y not pos sible. Co oling and

cabling restraints require that equipment pieces remain racked according to standard

configurations.

4.1.4 External Cabinet Equipment Cabling

The equipment items that comprise the paging transmitter are usually contained in one

cabinet. This section describes the various input and output connection s required to bring

power and signals into and out of the cabinet.

Print Date: 05/11/99 Copyright © 1999 Glenayre Page: 4-1

Page 18

GL-T8200 1- to 25-Watt 900-MHz Power Amplifier Glenayre Document Number: 9110.01306

INSTALLATION AND SETUP Rev. A: 03/23/99

4.1.5 PA I/O Connections

Refer to Figure 4-1 and the appropriate rear views in the transmitter system manual. Most

connections are made to the rear of the PA chassis. Table 4-2 lists PA connections.

Table 4-2 PA I/O Connections

connector name function note

RF input 200 mW type-N female

RF out 25 W type-N female

TO EXCITER J6 control See Table 4-3.

+TB1-1 positive 28-Vdc

input

GROUND TB1-2 power supply

negative return

auxiliary dc outputs auxiliary power See Table 4-4.

fan supplies voltage to

PA fan

Anderson power pole (+) red

Anderson po wer pole (-) black

4.1.5.1 RF Output

Connect the antenna network to the lightning protector output. T he connector is typically a

7/16-inch DIN mounted on top of the transmitter cabinet. It should be securely tightened to

a torque specification of 250 inch-pounds (2900 g-m).

4.1.5.2 The RF Output Forward and Reflected Dc Samples

The RF output forward and reflected dc sample from the isolator are digitized and routed

to the DSP exciter. High reflected power from either the antenna network or the output of

the PA causes reduced output and eventual shutdown.

4.1.5.3 Signal and Dc Connections

Be certain that the connection between the exciter and the rear of the PA chassis is secure.

Wiring details of the exciter/PA connector are shown in Table 4-3.

Page: 4-2 Copyright © 1999 Glenayre Print Date: 05/11/99

Page 19

Glenayre Document Number: 9110.01306 GL-T8200 1- to 25-Watt 900-MHz Power Amplifier

Rev. A: 03/23/99 INSTALLATION AND SETUP

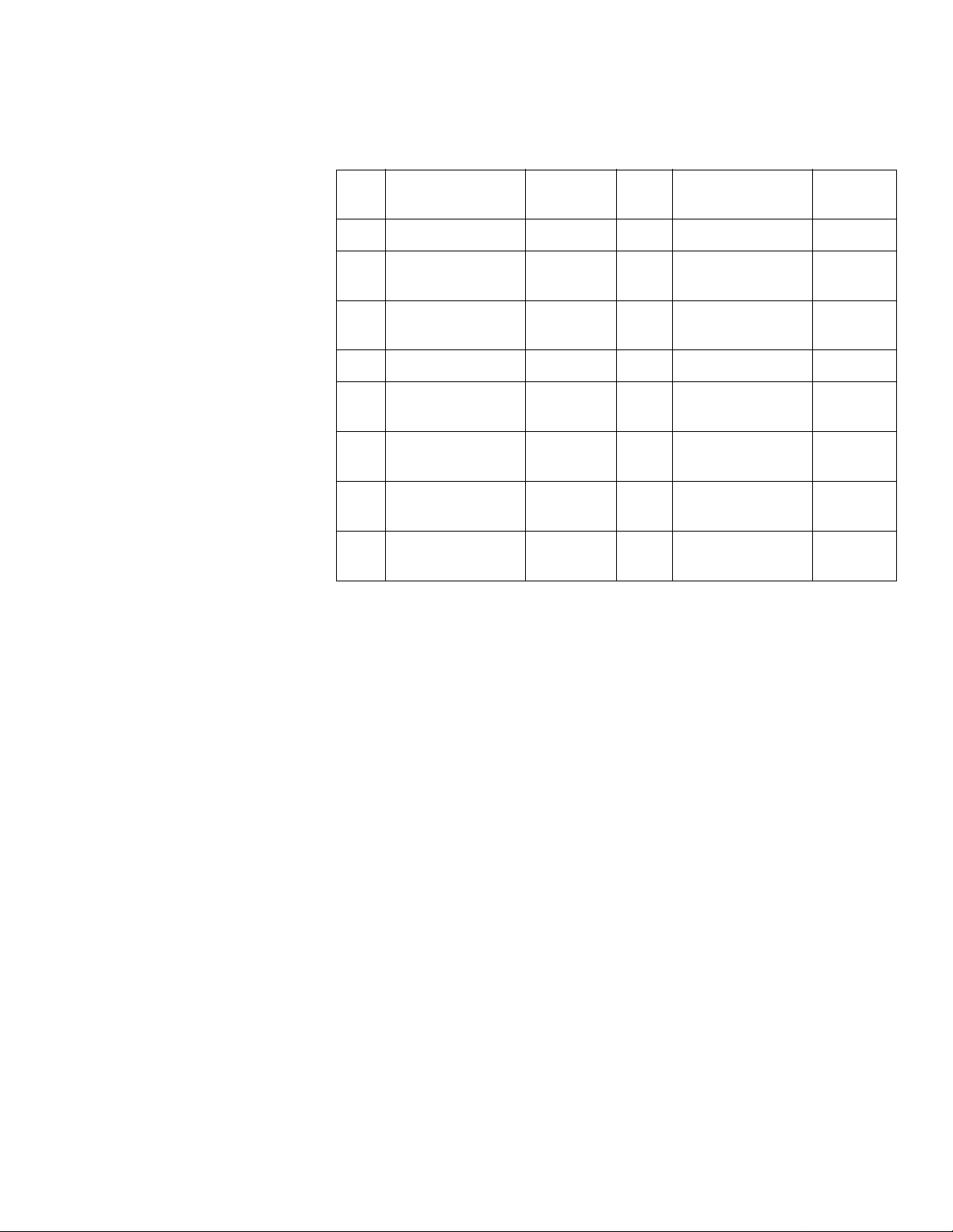

Table 4-3 Exciter/PA Connector Pinout (For DSP Exciter)

PA

J6-x description direction

1 analog 1 to exciter 9 analog 2 to exciter

2 analog 3 to exciter 10 analog 4/aux. for

25w82004

3 AGC reference from

exciter

4 PA ground 12 PA ground

5 PA ground 13 mux select 1 from

6 mux select 2 from

exciter

7 key input from

exciter

8 reflected sample

(combiner)

to exciter

PA

J6-x description direction

to exciter

C.S.

11 PA fault to exciter

exciter

14 mux select 3 from

exciter

15 nc

4.2 Setup

4.2.1 Expected Exciter

The PA chassis is interfaced to the exciter. The connection is:

• J6 to J6 for the DSP exciter.

4.2.2 Setup Using VDT

Setup of the PA is performed at the system level using a VDT. Refer to the VDT manual

and screens, which include instructions for these applicable setup procedures:

• adjust forw ard power

• set low-power alarm

Figure 3-2 shows controls, test points, and fuses on the PA board.

Print Date: 05/11/99 Copyright © 1999 Glenayre Page: 4-3

Page 20

GL-T8200 1- to 25-Watt 900-MHz Power Amplifier Glenayre Document Number: 9110.01306

INSTALLATION AND SETUP Rev. A: 03/23/99

Figure 4-1 PA Rear View

Page: 4-4 Copyright © 1999 Glenayre Print Date: 05/11/99

Page 21

Glenayre Document Number: 9110.01306 GL-T8200 1- to 25-Watt 900-MHz Power Amplifier

Rev. A: 03/23/99 INSTALLATION AND SETUP

Table 4-4 PA Board Fuses

PA board fuse label connection

F1 (3A) powers remaining circuitry of

PA board

F2 (5A) R9000 J2-2

25w82004

F3 (3A) RX J2-6

F4 (5A) C2000 J2-8

F5 (3A) DSP exciter J2-4

F6 (3A) powers transistor, first stage and

second stage of PA board

F7 (3A) powers remaining circuitry of

PA board

Print Date: 05/11/99 Copyright © 1999 Glenayre Page: 4-5

Page 22

GL-T8200 1- to 25-Watt 900-MHz Power Amplifier Glenayre Document Number: 9110.01306

INSTALLATION AND SETUP Rev. A: 03/23/99

Page: 4-6 Copyright © 1999 Glenayre Print Date: 05/11/99

Page 23

Glenayre Document Number: 9110.01306 GL-T8200 1- to 25-Watt 900-MHz Power Amplifier

Rev. A: 03/23/99 OPERATION

5OPERATION

5.1 Controls and Indicators

The PA has no indicators nor controls which are suitable for user adjustment.

5.2 Operation

25w82005

The transmitter normally operates within the paging system in an unattended manner . Local

control is not intended for operati on, but for setup, checkout, or maintenance. Refer to the

appropriate section:

• Section 7, MAINTENANCE

• Section 8, CHECKOUT AND TROUBLESHOOTING

• Section 9, REMOVAL AND REINSTALLATION

Also refer to VDT manual.

5.2.1 Turn PA On and O ff

Power is supplied to the transmitter and PA whenever the power supply is energized.

5.2.2 Turn Fan On and Off

The fan does not contain an on/off switch, but turns on and off with the power supply. The

fan is not equipped with a thermal switch, it runs continuously whenever the power supply

equipment is energized.

5.2.3 Key and Unkey PA

The PA does not contain a key switch, but is keyed and unkeyed by the presence of the RF

output signal fro m the exci ter when it is keyed. The ex cite r is nor mally key ed an d unkey ed

remotely through transmitter controller, but it can be keyed and unkeyed locally throu gh a

video display terminal (VDT). Refer to the controller manual for remote key and unkey

instructions, or to the DSP exciter VDT manual for local key and unkey instructions.

Print Date: 05/10/99 Copyright © 1999 Glenayre Page: 5-1

Page 24

GL-T8200 1- to 25-Watt 900-MHz Power Amplifier Glenayre Document Number: 9110.01306

OPERATION Rev. A: 03/23/99

Page: 5-2 Copyright © 1999 Glenayre Print Date: 05/10/99

Page 25

Glenayre Document Number: 9110.01306 GL-T8200 1- to 25-Watt 900-MHz Power Amplifier

Rev. A: 03/23/99 THEORY OF OPERATION

6 THEORY OF OPERATION

6.1 Power Distribution

The PA requires a primary 28-volt dc power input, which is typically provided by the ac

power supply.

25w82006

6.1.1 Fan Power

Fan power is received directly from the fan plug.

6.1.2 High-Current Power to PA Board

Positive dc operating power is received through the Anderson power poles. The positive

side of the 28-volt supply enters through TB1-1 on the PA board. Power to the board is

distributed through fuses. Refer to Table 4-4.

6.1.3 Metering Circuit Regulators

The PA board has three on-board regulators which supply po wer to s everal circui ts on the

PA board. Refer to Table 6-1 for the PA board voltages, test points, and functions.

Table 6-1 PA Board Voltages

function (PA board unless

voltage (Vdc) test point

+36 J1-6 supply voltage for current-

specified otherwise)

sensing op-amps

+28 TB1-1 PA board +28-Vdc supply

+5VREF J1-4 reference for measuring op-amps

+5 J1-3 supply voltage for metering and

control circuits

ground TB1-2 ground

6.2 RF Flow

Refer to Figure 6-1. The PA board receives its RF input through a type-N connector , via the

P A chassis. A coupler red uces the RF input to an acceptable level. The RF in put is amplified

by means of two amplifier stages. A detector circuit in the input to th e PA board monitors

the RF input. The PA output is connected to the output type-N connector of the P A chassis.

Print Date: 05/10/99 Copyright © 1999 Glenayre Page: 6-1

Page 26

GL-T8200 1- to 25-Watt 900-MHz Power Amplifier Glenayre Document Number: 9110.01306

THEORY OF OPERATION Rev. A: 03/23/99

6.3 PA Board

Figure 6-1 Simplified Power Amplifier Block Diagra m

The DSP exciter monitors currents, voltages, powers, and other valuable status information

from the power amplifier through the PA board. The two main functions of the PA board

are to channel information from the PA chassis to the exciter and to distribute dc power to

the exciter, R9000, receiver and C2000.

Most of the information passed to the exciter is in the form of voltages that represent

powers, currents, supply voltages and temperatur e. This information is m ultiplexed in th e

PA board onto two analog lines that feed the exciter’s analog-to-digital converter (ADC).

The P A board also detects overcurrent and high reflected power conditions in the PA. Once

this condition is detected, the PA board pulls a PA fault line hig h initiating an i nterrupt in

the exciter. This interrupt causes the exciter to reduce power or shut the transmitter d own

to protect it from damage.

Page: 6-2 Copyright © 1999 Glenayre Print Date: 05/10/99

Page 27

Glenayre Document Number: 9110.01306 GL-T8200 1- to 25-Watt 900-MHz Power Amplifier

Rev. A: 03/23/99 THEORY OF OPERATION

6.3.1 Input Voltage

dc power input Refer to Figure 6-2. The +28-volt supply voltage from the main power supply feeds the

distribution circuitry on the PA board through an Anderson power pole. The negative side

of the supply is grounded to the black (-) connection. The positive side of the supply goes

to the red (+) connection and on to the distribution circuitry on the PA board.

fuses The +28-volt supply is distributed throughout the PA board through current monitoring

circuits and fuses. The +28-vo lt s upply voltage i s also us ed in the me teri ng circuitry. Refer

25w82006

to fuse information in Table 4-4.

internal voltages The internal supply voltages described in Paragraph 6.3.2 are derived from the main

supply line. Refer to Table 6-1 for more information concerning the PA board regulators,

voltages, and test points.

6.3.2 Internally Generated Voltages

6.3.2.1 +36-Volt Internal Supply

The +36-volt supply is derived with a voltage doubling circuit. This supply has a very low

current since it only drives the current monitoring op-amps in the PA board. These op-amps

monitor the current of transistors Q1 and Q2 from the high side of the 28-volt supply, and

therefore require a supply higher voltage. The +36-volt supply can be monitored at J1-6

with reference to ground

6.3.2.2 +5-Volt Precision Reference Internal Supply

The +5-volt reference supply also supp lies very little current and is used for fault detections, where the trip point is critical. The +5-volt reference supply can be monitored at J 14 with reference to ground.

6.3.2.3 +5-Volt Internal Supply

The +5-volt supply has to supply approximately 1 ampere at 5 volts to portions of the PA

board. Filtering is required to keep RF from getting onto the PA board circuitry. The +5volt supply can be monitored at J1-3 with reference to ground.

6.3.2.4 +28-Volt Supply

The +28-volt supply is monitored by the multiplexer 0 on the PA board. The +28-volt

supply can be monitored at TB1-1.

Print Date: 05/10/99 Copyright © 1999 Glenayre Page: 6-3

Page 28

GL-T8200 1- to 25-Watt 900-MHz Power Amplifier Glenayre Document Number: 9110.01306

THEORY OF OPERATION Rev. A: 03/23/99

sheet1.plt

Figure 6-2 PA Board Functional Diagram

Page: 6-4 Copyright © 1999 Glenayre Print Date: 05/10/99

Page 29

Glenayre Document Number: 9110.01306 GL-T8200 1- to 25-Watt 900-MHz Power Amplifier

Rev. A: 03/23/99 THEORY OF OPERATION

sheet2.plt

25w82006

Figure 6-2, PA Board Functional Diagram (continued)

Print Date: 05/10/99 Copyright © 1999 Glenayre Page: 6-5

Page 30

GL-T8200 1- to 25-Watt 900-MHz Power Amplifier Glenayre Document Number: 9110.01306

THEORY OF OPERATION Rev. A: 03/23/99

6.4 Exciter Interface

The physical interface is a 15-pin, filtered male connector on the exciter and the PA chassis.

15-pin connector J6 is mounted on the PA board.

More information concerning the DSP exciter interface connector pinout is given in

Paragraph 6.4.1. For information on setting the PA to expect the standard DSP exciter,

refer to Paragraph 4.2.1.

6.4.1 Exciter Interface Connector Pinout

Refer to Ta ble 4-3 . The interface connector pin numbers refer to the 15-pin exciter/PA

interface connector on the rear of the PA chassis and the DSP exciter.

6.4.1.1 Analog 1 Output

Pins 1 (+) of the D-sub 15-pin interface connector is the analog 1 output from multiplexer

0 on the P A board. The output voltage range is 0-5 volts for the + pin, the - pin is referenced

to PA ground. The analog value on the multiplexer output may be one of eight different

channels and is selected by the microcontroller through the multiplexor select lines 0-2.

6.4.1.2 Analog 3 Output

Pins 2 (+) of the D-sub 15-pin interface connector is the analog 3 output which goes to J62 and is used for customer specials. The output voltage range is 0-5 volts for the (+) pin,

the (-) pin is referenced to PA ground. This analog output operation is the same as the

analog 0 output described above.

6.4.1.3 Mux Select Lines 0-2

Pins 13, 6, and 14 of the D-sub 15-pin interface connector are multiplex lines 0 through 2,

respectively. These input lines from the exciter are digital in nature and are used to select

the appropriate channel of the analog multiplexers on the PA board.

6.4.1.4 PA Fault Interrupt

Pin 11 of the D-sub 15-pin interface connector is the chassis fault-interrupt output line. This

output goes from LO to HI to indicate that a high VSWR or high-current condition has

occurred in the P A. This output is digital in nature and drives an interrupt input to the microcontroller in the exciter. This output from the PA board is ORed with the other PA board

fault outputs; therefore only one line has to be active to indicate a fault.

6.5 Analog Readings Thresholds

Refer to Table 6-2.

Page: 6-6 Copyright © 1999 Glenayre Print Date: 05/10/99

Page 31

Glenayre Document Number: 9110.01306 GL-T8200 1- to 25-Watt 900-MHz Power Amplifier

Rev. A: 03/23/99 THEORY OF OPERATION

6.5.1 PA Board Currents

The currents monitored in the PA board have various upper limits, as shown in Table 6-2.

They are read on the VDT screen. When one or more of these thresholds is met, it causes

an interrupt to the microcontroller in the exciter, which then reduces output power until the

fault condition no longer ex ists or until shutdown occurs. As of this printing, no lower

current limit has been programmed.

6.5.2 PA Forward Power

25w82006

The PA board forward and reflected samples are digitized and sent out the I20 interface.

The forward power readin g from t he PA board has a lower limit whi ch is deter mined by the

forward power setting of the transmitter. This limit is based on efficiency and losses in the

PA . The lower limit is 1 watt. The upper limit fo r the forward power reading is 25 watts.

This does not cause an interrupt to the exciter, but if a reading exceeds this level, the exciter

shuts the transmitter down.

6.5.3 PA Reflected Power

The reflected power reading in the PA has a lower limit of 0 W, and an upper limit of 5 W

average power. When this limit is achieved, it initiates an interrupt to the microcontroller

in the exciter which reduces power until the fault goes away or until a shutdown condition

occurs.

6.5.4 PA Board RF Input Power

The input power to the PA has a lower limit of 200 mW. If the threshold is not reached, the

PA shuts down.

6.5.5 +28-Volt External Supply

The upper limit of the PA’s 28 volt supply is +29 volts, and the lower limit is +22 volts.

Excursions outside these limits are a fault state. The transmitter shuts down.

6.5.6 +36-Volt Internal Supply

The +36 volt supply to the current metering op-amps has a window of +33 volts and +39

volts. When these limits have been exceeded, it results in an alarm condition only, no power

reduction.

Print Date: 05/10/99 Copyright © 1999 Glenayre Page: 6-7

Page 32

GL-T8200 1- to 25-Watt 900-MHz Power Amplifier Glenayre Document Number: 9110.01306

THEORY OF OPERATION Rev. A: 03/23/99

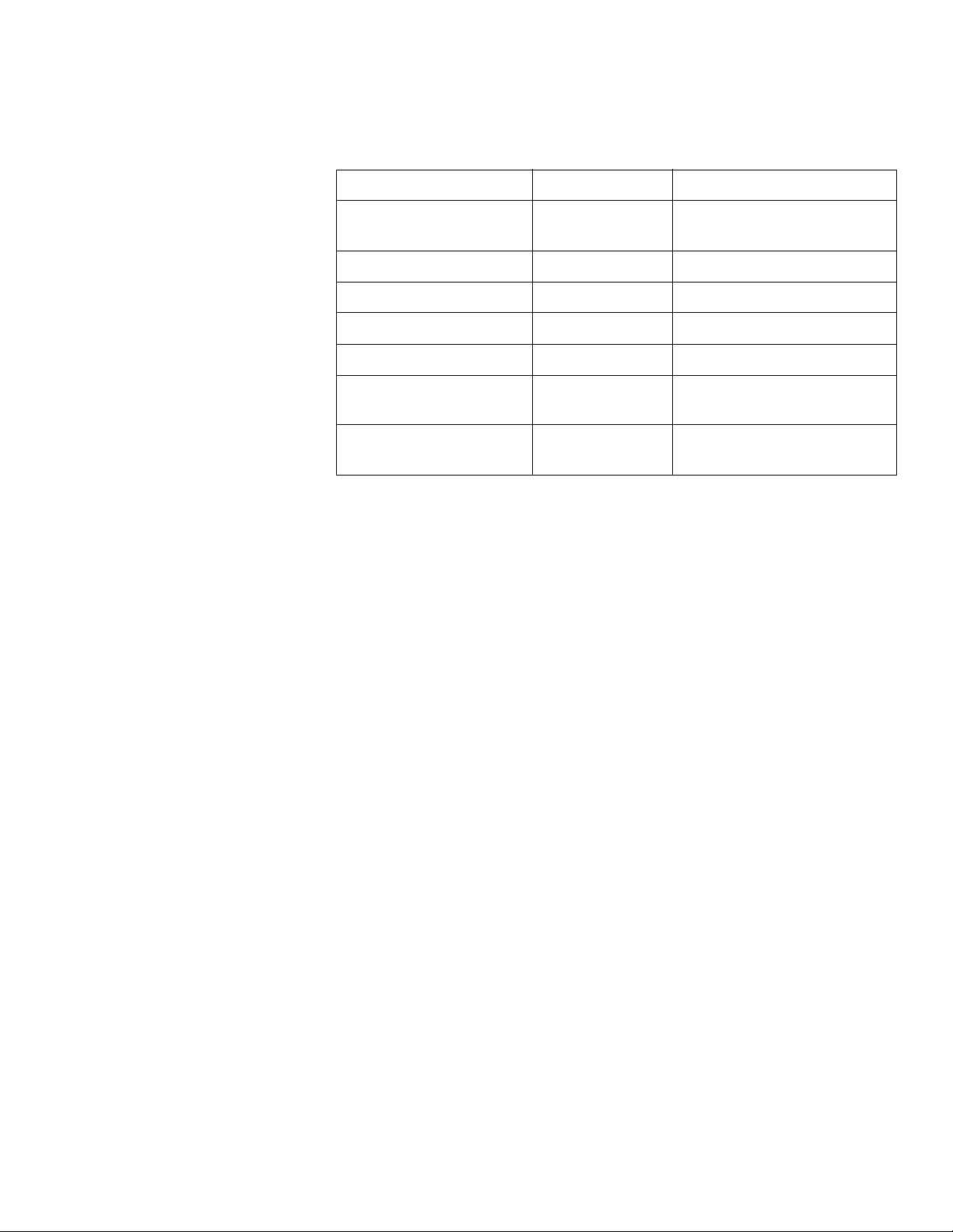

Table 6-2 Metered Parameter Thresholds

analog reading

total forward power (W) 25 1

total reflected power (W) 5 0

PA current Q1 1.6 none

PA current Q2 3.3 none

+36 Vdc 39 33

+28 Vdc 29 22

+5 Vdc 5.5 4.5

temperature 80

6.5.7 +5-Volt Internal Supplies

Both of the +5-volt supplies in the PA have an alarm window of +5.5 and +4.5 volts.

Exceeding either parameter results in an alarm condition only.

upper

threshold

lower

threshold

PA PA

o

85

(alarm)

o

(fault)

-30

o

6.5.8 Temperature

The ambient temperature in the PA has an upper limit of +85 C. If this limit is exceeded,

the transmitter shuts down.

Page: 6-8 Copyright © 1999 Glenayre Print Date: 05/10/99

Page 33

Glenayre Document Number: 9110.01306 GL-T8200 1- to 25-Watt 900-MHz Power Amplifier

Rev. A: 03/23/99 MAINTENANCE

7 MAINTENANCE

If the PA becomes faulty, get a replacement from Glenayre customer service.

7.1 Cleaning

The PA chassis should be kept clean and free of dust. Dust and dirt can reduce the cooling

efficiency of the PA which can lead to module failure. Dirt on the printed circuit b oards can

25w82007

7.2 Power Calibration

also lead to other types of failures. Most dust and dirt can be removed with a vacuum

cleaner. Do not use air pressure to blow dust and dirt from the module, because it allows

dust to resettle on other equipment which may have already been cleaned.

The complete power calibration was done with precise measuring equipment at the factory;

the accuracy exceeds that of field-quality test equipment. Refer to the DSP exciter user

manual for details. The transmitter is adjusted to the desired power via the video display

terminal.

Print Date: 03/26/99 Copyright © 1999 Glenayre Page: 7-1

Page 34

GL-T8200 1- to 25-Watt 900-MHz Power Amplifier Glenayre Document Number: 9110.01306

MAINTENANCE Rev. A: 03/23/99

Page: 7-2 Copyright © 1999 Glenayre Print Date: 03/26/99

Page 35

Glenayre Document Number: 9110.01306 GL-T8200 1- to 25-Watt 900-MHz Power Amplifier Rev. A: 03/23/99 CHECKOUT AND TROUBLESHOOTING

8 CHECKOUT AND TROUBLESHOOTING

8.1 Introduction

Checkout procedures can be performed at any time to verify that the power amplifier (and

transmitter) is functioning properly. After the checkout procedures are successfully

completed, the site can be returned to normal service. Pursue any troubleshooting

procedure provided or referenced, which is a direct result of a failed checkout procedure

25w82008

8.2 Checkout Procedures

8.2.1 VDT Power-Up Verification

before trying to complete the checkout procedure.

The following procedures presume that the ins tallation and setup procedur es in section 4 of

this manual have already been successfully completed. Refer to the DSP exciter VDT user

manual for more checkout procedures.

Once powered, verify that the VDT is powered. Check list below:

• the VDT should have a cursor displayed and blinkin g

• or the VDT should ha ve an instructional prompt displayed

• or the VDT should have an auto-loaded program running.

8.2.2 Dc Voltage Verification

Once powered, verify that the fan is operating. The fan is located on the rear of the PA. Also

insure that air flow is not obstructed inside or outside of the transmitter cabinet, around the

cabinet vents, and in the heat sink cooling fins of the PA.

8.3 Troubleshooting Procedures

Connect the VDT to the VT -100 co nnector on the front panel of the DSP exciter . Check the

power amplifier parameters using the VDT, refer to the DSP exciter VDT user manual for

assistance in using the VDT menus for troubleshooting.

8.3.1 Parameter Readings at Time of Fault

When the DSP exciter receives a fault indication from the transmitter or exciter, it records

all of the transmitter parameters at that instant. This is a valuab le source of PA troubleshooting data and should always be checked when transmitter problems occur. Connect the

VDT to the VT -100 connector on the front panel of the exciter to access the transmitter fault

information. Refer to the DSP exciter VDT user manual for assistance in read ing the transmitter faults. Check the transmitter fault parameters against the normal transmitter

operating parameters. The normal transmitter operating parameters can be obtained from

the factory transmitter test data sheets; or (if available) from the transmitter parameters log

mentioned in sections 4 and 7 of this manual.

Print Date: 05/10/99 Copyright © 1999 Glenayre Page: 8-1

Page 36

GL-T8200 1- to 25-Watt 900-MHz Power Amplifier Glenayre Document Number: 9110.01306

CHECKOUT AND TROUBLESHOOTING Rev. A: 03/23/99

8.3.2 GL-C2000 Transmitter Controller Alarms

Another valuable source of PA troubleshooting data is the GL-C2000 alarm history. It is

accessed by connecting the VDT to the VT-100 connector on the front panel of the GLC2000 transmitter controller. Consult the GL-C2000 user manual for assistance in

accessing the controller alarm history.

If the GL-C2000 has a telephone line connected to its modem output, its alarm history can

be accessed remotely through the use of the Glenayre GL-N2000 console, or with a

computer which is running a communication program with VT-100 emulation and has a

2400-baud modem.

The GL-N2000 console equipped with version 3.5 or later software can also perform an

over-the-air connection if telephone lines are not connected to the GL-C2000 controller.

8.3.3 Operational Checks

If the transmitter is operational, valuab le troubleshooting information can be ob tained by

comparing the present transmitter operating parameters, obtained through the exciter VDT

connection, to the parameters from the factory transmitter data sheets; or (if available) from

the transmitter parameters log.

8.3.4 Power Amplifier Current Measurement

Refer to Table 8-1, PA Board Current. The PA board has provisions to measure the current

flow of the first and second stage.

Table 8-1 PA Board Current

PA board function transistor current measured

first stage measure Q1 current

second stage measures Q2 current

Page: 8-2 Copyright © 1999 Glenayre Print Date: 05/10/99

Page 37

Glenayre Document Number: 9110.01306 GL-T8200 1- to 25-Watt 900-MHz Power Amplifier Rev. A: 03/23/99 REMOVAL AND REINSTALLATION

9 REMOVAL AND REINSTALLATION

Caution

When fastening dc connectors, be certain that the

plug is centered directly on its corresponding jack

and that the polarity is correct. Do not make dc

connections while power is applied to the chassis.

25w82009

The PA is secured to the rails by eight screws.

9.1 P A

9.1.1 Removal

Note

Before removing the PA as a result of fault isolation, be certain that the

fault is with it. The exciter and intercon necting wiring are essential to

proper operation of the power amplifier.

1. Loosen the eight screws on the front of the PA.

2. Disconnect I20, dc power in, dc power out, RF in, and RF out from the back of the

PA.

3. Pull PA out of rack until it is completely out.

9.1.2 Reinstallation

1. Place PA into location in rack.

2. Put in eight screws and lightly fasten.

3. Attach I20, dc power in, dc power out, RF in and RF out to the back of the PA.

4. Tighten screws.

This procedure is complete. Check out the transmitter to see that it functions properly.

Print Date: 03/26/99 Copyright © 1999 Glenayre Page: 9-1

Page 38

GL-T8200 1- to 25-Watt 900-MHz Power Amplifier Glenayre Document Number: 9110.01306

REMOVAL AND REINSTALLATION Rev. A: 03/23/99

Page: 9-2 Copyright © 1999 Glenayre Print Date: 03/26/99

Page 39

GL-T8200 1- to 25-Watt 900-MHz Transmitter System Rev. A: 03/24/99

GL-T8200

1- to 25-Watt 900-MHz Transmitter System

USER MANUAL

PN 9110.01305

REV A

Specifications subject to change without notice

Copyright © 1999 Glenayre

All rights reserved. No part of this work may be reproduced or copied in any form or by

any means—graphic, electronic, or mechanical, including photocopying, recording,

taping, or information-retrieval system—without written permission of Glenayre.

Print Date: 03/24/99 Copyright © 1999 Glenayre

Page 40

GL-T8200 1- to 25-Watt 900-MHz Transmitter System Glenayre Document Number: 9110.01305

Document Change Record Rev. A: 03/24/99

Document Change Record

Revision: A

Date: 03/24/99

Changes: none; original

Copyright © 1999 Glenayre Print Date: 03/24/99

Page 41

Glenayre Document Number: 9110.01305 GL-T8200 1- to 25-Watt 900-MHz Transmitter System

Rev. A: 03/24/99 Table of Contents

Table of Contents

1 GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 Manual Scope . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Applicable Documents. . . . . . . . . . . . . . . . . . . . . 1-1

1.3 Manual Sections . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.4 About Glenayre . . . . . . . . . . . . . . . . . . . . . . . 1-2

8200sys1.toc

2 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

3 +DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.4.1 Product Warranty Information . . . . . . . . . . . . . . . . . . .1-3

1.4.2 Service Warranty Information . . . . . . . . . . . . . . . . . . .1-3

1.5 Regulatory-Authority Compliance . . . . . . . . . . . . . . . . 1-3

1.5.1 FCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.5.2 Industry Canada . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.5.3 Other . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

3.1 Physical Description. . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1 Mounting Provisions . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.1.2 Exciter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.1.3 Power Amplifier (PA). . . . . . . . . . . . . . . . . . . . . . . .3-2

3.1.4 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.1.5 Video Display Terminal (VDT). . . . . . . . . . . . . . . . . . .3-2

3.2 Simplified Paging-Site Functional Description . . . . . . . . . . . 3-2

3.2.1 Paging Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.2.2 Link Equipment and Transmitter Controller . . . . . . . . . . . .3-2

3.2.3 Paging Transmitter . . . . . . . . . . . . . . . . . . . . . . . . .3 -4

3.2.4 Video Display Terminal. . . . . . . . . . . . . . . . . . . . . . .3-4

3.2.5 Ac Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3.3 Site Signal Flows . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3.1 Site RF-Signal Flow . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3.3.2 Site Audio/Modulation-Signal Flow . . . . . . . . . . . . . . . .3-5

3.3.3 Simplified Block-Diagram Description. . . . . . . . . . . . . . .3-6

3.3.4 Site Control-Signal Flow . . . . . . . . . . . . . . . . . . . . . .3-7

3.3.5 Status-Signal Flow . . . . . . . . . . . . . . . . . . . . . . . . .3-7

4 INSTALLATION AND SETUP . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Site Checks . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1 Transmitter Environment . . . . . . . . . . . . . . . . . . . . . .4-1

4.1.2 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Print Date: 04/14/99 Copyright © 1999 Glenayre Page: -i

Page 42

GL-T8200 1- to 25-Watt 900-MHz Transmitter System Glenayre Document Number: 9110.01305

Table of Contents Rev. A: 03/24/99

4.1.3 Primary Power Requirement . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2.1 Tools and Equipment Required. . . . . . . . . . . . . . . . . . . 4-2

4.2.2 Rack Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2.3 Rack Grounding . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.2.4 Positioning within the Rack . . . . . . . . . . . . . . . . . . . . 4-3

4.2.5 Equipment Cabling . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.3 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.4 Ultimate Disposition . . . . . . . . . . . . . . . . . . . . . 4-4

5 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 Controls and Indicators . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2.1 Turn Transmitter On and Off . . . . . . . . . . . . . . . . . . . . 5-1

5.2.2 Turn Fans On and Off . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2.3 Key and Unkey PA . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

6 THEORY OF OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 Cabinet Power Distribution . . . . . . . . . . . . . . . . . . 6-1

6.1.1 Ac Power Input . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1.2 Dc Power Distribution . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Cabinet Signal Distribution . . . . . . . . . . . . . . . . . . 6-1

6.2.1 Control, Data, and Modulation Paths. . . . . . . . . . . . . . . . 6-1

6.2.2 Alarm Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

7 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 Maintenance Procedures. . . . . . . . . . . . . . . . . . . . 7-1

7.2.1 PA Current Check . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2.2 Dc Ripple Check . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

8 CHECKOUT AND TROUBLESHOOTING . . . . . . . . . . . . . . . . . . 8-1

8.1 Preparation for Checkout Procedures. . . . . . . . . . . . . . . 8-1

8.1.1 Dc-Voltage Verification . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1.2 VDT Power-up Verification . . . . . . . . . . . . . . . . . . . . 8-1

8.1.3 Cooling-Fan Check . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.2 Operational Verification. . . . . . . . . . . . . . . . . . . . 8-1

8.2.1 RF Power and Antenna . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.2.2 Paging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.3 Field Replacement of Assemblies . . . . . . . . . . . . . . . . 8-2

Page: -ii Copyright © 1999 Glenayre Print Date: 04/14/99

Page 43

Glenayre Document Number: 9110.01305 GL-T8200 1- to 25-Watt 900-MHz Transmitter System

Rev. A: 03/24/99 Table of Contents

9 REMOVAL AND REINSTALLATION. . . . . . . . . . . . . . . . . . . . . 9-1

9.1 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.2 Exciter Removal and Reinstallation. . . . . . . . . . . . . . . . 9-1

9.3 PA Removal and Reinstallation . . . . . . . . . . . . . . . . . 9-2

8200sys1.toc

Print Date: 04/14/99 Copyright © 1999 Glenayre Page: -iii

Page 44

GL-T8200 1- to 25-Watt 900-MHz Transmitter System Glenayre Document Number: 9110.01305

Table of Contents Rev. A: 03/24/99

Page: -iv Copyright © 1999 Glenayre Print Date: 04/14/99

Page 45

8200sys1.lof

Glenayre Document Number: 9110.01305 GL-T8200 1- to 25-Watt 900-MHz Transmitter System

Rev. A: 03/24/99 List of Figures

List of Figures

Figure 3-1 Transmitter Front View. . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Figure 3-2 Transmitter Simplified Block Diagram. . . . . . . . . . . . . . . . . . 3-6

Figure 4-1 Rear View Showing Dc and Signal Connections. . . . . . . . . . . . . 4-5

Print Date: 04/14/99 Copyright © 1999 Glenayre Page: -v

Page 46

GL-T8200 1- to 25-Watt 900-MHz Transmitter System Glenayre Document Number: 9110.01305

List of Figures Rev. A: 03/24/99

Page: -vi Copyright © 1999 Glenayre Print Date: 04/14/99

Page 47

8200sys1.lot

Glenayre Document Number: 9110.01305 GL-T8200 1- to 25-Watt 900-MHz Transmitter System

Rev. A: 03/24/99 List of Tables

List of Tables

Table 1-1 Applicable Documents . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Table 1-2 Manual Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Table 2-1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Table 3-1 Site Equipment List. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Table 4-1 Required Tools and Equipment. . . . . . . . . . . . . . . . . . . . . . 4-2

Print Date: 04/14/99 Copyright © 1999 Glenayre Page: -vii

Page 48

GL-T8200 1- to 25-Watt 900-MHz Transmitter System Glenayre Document Number: 9110.01305

List of Tables Rev. A: 03/24/99

Page: -viii Copyright © 1999 Glenayre Print Date: 04/14/99

Page 49

Glenayre Document Number: 9110.01305 GL-T8200 1- to 25-Watt 900-MHz Transmitter System

Rev. A: 03/24/99 GENERAL

1GENERAL

1.1 Manual Scope

This manual provides information for the following transmitter:

• 1 to 25-watt, 900-MHz transmitter, model GL-T8200.

8200sys1

1.2 Applicable Documents

This manual is incomplete without additional manuals. Refer to Table 1-1 for a list of

applicable documents, their part numbers, and a brief description of each.

document part number description

9100.XXXXX 9100.XXXXX assembled GL-T8200 manual. Requestors

GL-T8200 system manu-al9110.001305 this document

DSP VDT manual 9110.00259 describes DSP exciter software installed in

DSP exciter User Manual 9110.01021 describes DSP exciter hardware equipment

GL-C2000 User Manual 9110.01248 describes GL-C2000 controller hardware

GL-T8200 power amplifier manual

Table 1-1 Appl icable Documents

should ask for option manuals which match

their configuration.

exciter

in transmitter

and software

9110.001306 describes 1 to 25 watt, 900-MHz power

amplifier

power supply manual 9110.00622 describes GL2728 power supply equipment

1.3 Manual Sections

Refer to Table 1-2. This table lists the sections in this manual, and provides a brief description of the content of each section.

Print Date: 05/10/99 Copyright © 1999 Glenayre Page: 1-1

Page 50

GL-T8200 1- to 25-Watt 900-MHz Transmitter System Glenayre Document Number: 9110.01305

GENERAL Rev. A: 03/24/99

Table 1-2 Manual Sections

section contents

1. General introduction and purpose of manual

2. Specifications significant system measurements; also see individual equipment manuals

3. Description introduction and principle characteristics of the equipment

4. Installation & Setup initial installation and activation of the equipment

5. Operation operation of equipment

6. Theory of Operation detailed functional description of transmitter

7. Maintenance procedu r es to be performed on specific intervals to maintain

optimum performance of the equipment

1.4 About Glenayre

8. Checkout and Troubl e-

shooting

9. Removal and Reinstal-

lation

Questions regarding the equipment or this manual should be directed to:

verification of proper operation, correction to proper operation

replacement procedures for assemblies which do not have

their own, separate equipment manuals

U.S.A. CANADA

Glenayre Customer Service - RF Glenayre Customer Service - RF

One Glenayre Way 1450 Kootenay Street

Quincy, Illinois 62305-3726 Vancouver, B.C.V5K 4R1

Phone: (217) 223-3211 Phone: (604) 293-1611

Fax: (217) 221-6259 Fax: (604) 293-4301

UNITED KINGDOM SINGAPORE

Glenayre Electronics (UK) Ltd. Glenayre Electronics Pte Ltd.

Unit 22, Challenge House No. 8 Ang Mo Kio

Sherwood Drive Industrial Park 2

Bletchley, Milton Keynes, MK3 6JD 569500 Singapore

Phone: 44 (1908) 484800 Phone: 65 483-8787

Fax: 44 1908 484801 Fax: 65 483-9663

For additional Glenayre contacts, refer to

www.glenayre.com/corporate/contacts/default.asp .

Page: 1-2 Copyright © 1999 Glenayre Print Date: 05/10/99

Page 51

Glenayre Document Number: 9110.01305 GL-T8200 1- to 25-Watt 900-MHz Transmitter System

Rev. A: 03/24/99 GENERAL

1.4.1 Product Warranty Information

Glenayre warrants to the original purchaser that Glenayre products are free from defects in

material and workmanship for a period of twenty-four months from the original invoice

date, subject to the provisions herein. Glenayre will repair or replace at its option, FOB our

factory , free of char ge within one year f rom the date of ship ment, any component , assembly

or subassembly of our manufacture found to be defective under conditions of normal use.

The unit, if repaired, will be returned to its original specifications. Failures caused by unauthorized modifications, force majeure, lightning, physical, environmental, or electrical

8200sys1

damage including use with incompatible equipment are specifically excluded from this

warranty. Glenayre disclaims any and all liability for loss or other damage whether direct,

consequential or of any nature whatsoever, resulting from product failure.

This warranty is in lieu of all other warranties expressed or implied and co vers only th ose

items manufactured by Glenayre. Equipment supplied by, but not manufactured by

Glenayre, is subject only to any warranty offered by the manufacturer of said equipment.

1.4.2 Service Warranty Information

Return of a defective item must be authorized by Glenayre prior to shipment. A Return

Authorization number can be ob tained fro m Glen ayre Customer Service. When requesting

a Return Authorization number , give the serial numb er of the unit. A description of the faul t

should accompany the unit on its return and the RA number must be shown on labels

attached to the item(s). The cost of shipping to Glenayre is to be paid by the customer.

Shipping from Glenayre will be prepaid by the customer, and shipped via surface mail. If

express shipping is required, the unit will be shipped collect.

Any repair service performed by Glenayre under this lim ited warranty is warranted to be

free from defects in material or workmanship for ninety days from the date of repair. All

other terms of this limited warranty apply to the service warranty.

1.5 Regulatory-Authority Compliance

1.5.1 FCC

Refer to Table 2-1 for authorizations.

1.5.2 Industr y Canada

Refer to Table 2-1 for authorizations.

1.5.3 Other

Refer to Table 2-1 for authorizations. Type approvals have been applied for in all major

markets. Refer to Paragraph for more information.

Print Date: 05/10/99 Copyright © 1999 Glenayre Page: 1-3

Page 52

GL-T8200 1- to 25-Watt 900-MHz Transmitter System Glenayre Document Number: 9110.01305

GENERAL Rev. A: 03/24/99

Page: 1-4 Copyright © 1999 Glenayre Print Date: 05/10/99

Page 53

Glenayre Document Number: 9110.01305 GL-T8200 1- to 25-Watt 900-MHz Transmitter System

Rev. A: 03/24/99 SPECIFICATIONS

2 SPECIFICATIONS

Table 2-1 contains transmitter and power supply specifications . The ac power supp ly is a

purchased item. Refer to the power supply manual, PN 9110.00622, for more specifications. Refer also to the exciter and PA manuals for detailed specifications. Test and

measurement equipment is, where possible, calibrated in accordance with standards established by the National Institute of Standards and Technology (NIST).

Table 2-1 Specifications

8200sys2

characteristic

(unit of

measurement) condition, model specification

Electrical

RF output power

(W)

dimensions 16 RU in standard EIA

weight 50 lb (23 kg)

elevation continuous operation

temperature operating -30 to +60 degrees C

temperature derating factor

humidity operating, noncon-

country model identifier

continuous duty, at PA

RF output connector

Physical and Environmental

cabinet (can be reduced to 14 RU in nonstandard configurations)

at rated power

storage -30 to +70 degrees C

above 5000 ft

(1525 m)

densing

Certification

1-25

28 x 19 x 9 in (71 x 48 x 22 cm)

to 10,000 ft (3050 m) (see temperature derating factor)

0.5 degrees C per 100 m

5 to 95%

USA GL-T8200 BFL-GL-T8200

Canada GL-T8200

Print Date: 05/10/99 Copyright © 1999 Glenayre Page: 2-1

Page 54

GL-T8200 1- to 25-Watt 900-MHz Transmitter System Glenayre Document Number: 9110.01305

SPECIFICATIONS Rev. A: 03/24/99

Table 2-1 Specifications (continued)

characteristic

(unit of

measurement) condition, model specification

other Contact Glenayre Sales for country-by-country type-approval infor-

mation

Electrical (power supply)

ac input voltage

195 to 265

(Vac)

ac input frequency

47 to 440

(Hz)

ac input current (A) 4 max at 195 Vac to 265 Vac

Page: 2-2 Copyright © 1999 Glenayre Print Date: 05/10/99

Page 55

Glenayre Document Number: 9110.01305 GL-T8200 1- to 25-Watt 900-MHz Transmitter System

Rev. A: 03/24/99 +DESCRIPTION

3 +DESCRIPTION

The purpose of the paging transmitter is to provide a modulated, high-level RF signal,

which sets off pagers within the coverage area of its associated antenna. The paging transmitter receives modulation and control information fro m the transmitter controller, which

receives information from a control site. In a simulcasting environment, the control site

may feed several paging sites at once.

8200sys3

3.1 Physical Description

Figure 3-1 shows a front view of the PA chassis. Refer to the transmitter ID label on the

rear of the unit for identification purposes.

3.1.1 Mounting Provisions

3.1.1.1 Transmitter Controller

The transmitter controller, normally a GL-C2000, is mounted above the exciter and may be

packaged with blank panels.

Table 3-1 Site Equipment List

equipment part number function

power amplifier

GL-T8200

digital DSP

exciter with I20 option

GL-S2164 Receiver See receiver manual for

1000.02186 amplifies 900 MHz RF for broadcast

DSP EX/I20 OPT generates then modulates RF; controls PA

I/O activities, receives fault signals and

takes action based on status

receives data and commands from the

configurations and part

No.

system controller

GL-C2000 (typical)

transmitter controller

power supply module ac switching power supply which converts

GL-C2000 controls paging transmitter activities;

performs I/O functions for paging site

main power to dc voltage for the transmit-

ter

3.1.2 Exciter

The exciter is one rack unit high. It is racked where shown and is held in place with four

machine screws. The top cover is removable for access to subassemblies, jumpers, and

adjustments contained in the unit. All but one of its connectors are on the back of the unit.

The front of this unit has a connector which allows the VDT to be connected to it.

Print Date: 05/10/99 Copyright © 1999 Glenayre Page: 3-1

Page 56

GL-T8200 1- to 25-Watt 900-MHz Transmitter System Glenayre Document Number: 9110.01305

+DESCRIPTION Rev. A: 03/24/99

3.1.3 Power Amplifier (PA)

The transmitter PA is mounted in the rack by screws which are inserted into the angle

brackets on either side of the chassis. Access to PA fuses is gained from the front; access to

the fan and I/O connections is from the rear.

A chassis-mounted fan draws air across the PA heat sink and out the back.

Most exciter and PA fault isolations can be performed with the units mounted in the rack.

It is not recommended to troubleshoot the PA if is is defective. A defective PA should be

sent back to Glenayre.

3.1.4 Power Supply

The power supply is contained in a separate chassis which is mounted separately from the

transmitter, normally as the lowest assembly in the rack. The power supply used is an ac

switching power supp ly whi ch converts mai n power to dc voltag e for the tran smitter. Refer

to power supply manuals for deta ils .

3.1.5 Video Display Terminal (VDT)

A video display terminal (VDT) is not part of the racked-up equipment; instead, it is a piece

of test equipment which the user brings to the site wh en setup, maintenance, or troubleshooting is necessary; or it is used as a monitoring device. Refer to the VDT manual for

details, including cable requirements.

3.2 Simplified Paging-Site Functional Description

3.2.1 Paging Site

The following paragraphs provide a block di agram-level fu nctional d escription of a t ypical

paging site.

Refer to Figure 3-2. This figure shows basic signal flows between the various paging site

equipment pieces. The communications device which the transmitter uses in order to

communicate with the control site is not shown and may vary from application to

application.

3.2.2 Link Equipment and Transmitter Controller

A link receiver, satellite receiver, microwave drop, telephone link, or other similar device

is used for communication between the transmitter controller and the control site. Th e

particular device depends on the application.

The transmitter controller is typically a model GL-C2000. There are various ways of interfacing the transmitter controller to the I/O portions of the exciter. Refer to the transmitter

controller manual and the exciter manual for details.

Page: 3-2 Copyright © 1999 Glenayre Print Date: 05/10/99

Page 57

Glenayre Document Number: 9110.01305 GL-T8200 1- to 25-Watt 900-MHz Transmitter System

Rev. A: 03/24/99 +DESCRIPTION

8200sys3

Figure 3-1 Transmitter Front View

Print Date: 05/10/99 Copyright © 1999 Glenayre Page: 3-3

Page 58

GL-T8200 1- to 25-Watt 900-MHz Transmitter System Glenayre Document Number: 9110.01305

+DESCRIPTION Rev. A: 03/24/99

3.2.3 Paging Transmitter

The paging transmitter converts the digital signal from the transmitter controller into

modulated and amplified RF power.

Operation is in response to commands from the transmitter controller via the DSP exciter.

The transmitter monitors its functions and reports its status to the VDT and the GL-C2000

via the exciter. The transmitter controller permits the transmitter to be controlled and

monitored from a remote location. Local control and monitoring are performed through a

VT-100 video depl ay terminal (VDT) .

The DSP exciter combines functions of an RF exciter and a PA controller. The exciter

generates modulation using digital signal processing (DSP) to achieve accurate, stable

modulation that does not vary with time or temperature. The PA-co ntrol section monitors

transmitter status signals in the form of fault logic and voltage samples. The microprocessor

in the exciter reports PA status to the transmitter controller, VDT, and the exciter front

panel. If a malfunction occurs, the transmitter enters a reduced operating condition,

depending on the seriousness of the fault. PA control and status monitoring are performed

by the microprocessor, which consolidates control logic from the transmitter controller or

the locally operated VDT. Both the exciter and transmitter controller receive continuous

status reports from the microprocessor. The exciter is the control and status-monitoring

interface between the transmitter and the user.

3.2.4 Video Display Terminal

3.2.5 Ac Power Supply

3.3 Site Signal Flows

3.3.1 Site RF-Signal Flow

The DSP exciter provides up to 400 milliwatts of RF drive.

A power-reference signal from the PA is fed back to the exciter, via the PA board, to allow

control and monitoring of output power. The exciter-supplied control voltage functions as

AGC control for the PA.

The VDT, though not part of the transmitter, is required for setup, local control, and local

monitoring of the transmitter. The VDT can be any laptop or desk top terminal with a VT100 type program. The VDT interfaces the transmitter through the connector on the front

of the exciter. The VDT software is menu-driven.

Refer to Figure 3-1. The switching power supply is mounted below th e PA. The power

supply is two rack units high. The front panel contains a dc power on indicator.

The on-frequency carrier is created by the VCO circuitry in the DSP exciter. It is then

modulated with paging information, amplified, and sent to the PA via connector J3 on the

back of the DSP exciter. Through coaxial cable, the carrier goes to the back of the PA,

where it is further amplified to a preset level under control of a microprocessor within the

exciter. The amplified carrier is cabled from the PA outpu t to a low-pass filt er and a triple

Page: 3-4 Copyright © 1999 Glenayre Print Date: 05/10/99

Page 59

Glenayre Document Number: 9110.01305 GL-T8200 1- to 25-Watt 900-MHz Transmitter System

Rev. A: 03/24/99 +DESCRIPTION

isolator and then to a cabinet-mounted lightning protector/connector for connection to the

antenna system. Note that some installations have a ten-MHz reference signal cabled from

the transmitter controller to connector J8 on the back of the DSP exciter.

3.3.2 Site Audio/Modulation-Signal Flow

Modulation information arrives at the site either through a link receiver or by wire line. The

digital signal is first routed through the transmitter controller, which checks for and

responds to appropriate embedded commands. Paging information is supplied to the

8200sys3

exciter. The exciter modulates this signal using digital signal processing, then up-converts

this modulated signal to final o utput frequency. This modulated RF from the exciter is

supplied to the PA, which amplifies the signal to the RF output lev el. This modulated,

amplified RF from the PA is supplied to an antenna network for transmission.

Print Date: 05/10/99 Copyright © 1999 Glenayre Page: 3-5

Page 60

GL-T8200 1- to 25-Watt 900-MHz Transmitter System Glenayre Document Number: 9110.01305

+DESCRIPTION Rev. A: 03/24/99

3.3.3 Simplified Block-Diagram Description

Refer to Figure 3-2. The interface between the transmitter and the transmitter controller is

the I20 interface. Refer to the exciter manual for details.

Figure 3-2 Transmitter Simplified Block Diagram

Page: 3-6 Copyright © 1999 Glenayre Print Date: 05/10/99

Page 61

Glenayre Document Number: 9110.01305 GL-T8200 1- to 25-Watt 900-MHz Transmitter System

Rev. A: 03/24/99 +DESCRIPTION

3.3.4 Site Control-Signal Flow

Transmit te r paging-site control is done two ways:

• remotely (normally operation), and

• locally.

In either case, the paging transmitter is keyed when the transmitter controller commands it,

via the DSP exciter, to key.

8200sys3

Control functions are shared by the transmitter controller and the DSP exciter, which

controls the power amplifier. The DSP exciter also controls the power amplifier locally by

responding to co mmands from the VDT.

Control signals enter and exit the paging site via the transmitter controller, which has

overall control of the paging site. The transmitter controller is part of the larger paging

control system even though it is racked with paging-site equipment. The transmitter

controller has control functi ons which i nclude these:

• transmitter alarm-gathering

• transmitter-alarm dispatching

• simulcast-parameter implementation

• remote control.

Remote control of the paging site is do ne through comm ands b ein g sent to th e transm itter

controller from the external paging control system.

Control commands originating from a remo te site are supplied to the exciter through the

controlling device. Control and setup commands may be applied to the exciter locally

through the VDT. A microprocessor within the exciter interprets each command and

responds by performing the appropriate function.

3.3.5 Status-Signal Flow

The exciter monitors transmitter status signal in the form of fault logic and voltage samples.

The microprocessor within the exciter reports transmitter status to the controlling device,

VDT, and the exciter front panel. If a transmitter malfunction occurs, a reduced operating

condition is entered, depending on the seriousness of the fault.

Print Date: 05/10/99 Copyright © 1999 Glenayre Page: 3-7

Page 62

GL-T8200 1- to 25-Watt 900-MHz Transmitter System Glenayre Document Number: 9110.01305

+DESCRIPTION Rev. A: 03/24/99

Page: 3-8 Copyright © 1999 Glenayre Print Date: 05/10/99

Page 63

Glenayre Document Number: 9110.01305 GL-T8200 1- to 25-Watt 900-MHz Transmitter System

Rev. A: 03/24/99 INSTALLATION AND SETUP

4 INSTALLATION AND SETUP

4.1 Site Checks

4.1.1 Transmitter Envi ronment

The transmitter environment should be clean and well ventilated. Additionally, the temper-

8200sys4

4.1.2 Inspection

ature inside the transmitter room should be maintained within the equipment specifications.

Refer to Table 4-2. The lower temperature limit is generally less of a problem due to the

heat produced by the equipment during operation, but it can become a problem in the colder

months of the year. The upper temperature limit is often a problem, especially in the

summer months. In accordance with local building codes an d the permission of the building

owners, the advice of local heating and air conditioning professionals is recommended

prior to installation.

Inspect the equipment to be certain that the shipmen t is complete. Compar e items receiv ed

to the packing list. The packing list shows two portions of the equipment and options

specified on the sales order: t he portion presently be ing shipped, and the p ortion still on

back order. It does not report the portio n of the sales or der that has already bee n shipped.

Report shipping loss or damage to carrier within 15 days of receipt. Remove any packing

material from the rack and check each assembly. Pay particular attention to the power

amplifier modules and power supply; check them closely an d rem ove any foreign material

in the chassis or air cooling passages. Be certain to disconnect primary power from the

power supply before removing any equipment covers

4.1.3 Primary Power Requirement

The primary power source must be capable of delivering adequate power to the equipment.

Refer to the power supply manual. Electrical connections made to this equipment must be

made in accordance with local electrical codes.

• A switching power su pply whic h operate s in 11 5-Vac range and 230-Vac ran ge. Refer to

power supply manual for specifications.

• Dc-to-dc converters may be used in some configurations.

The wire used to deliver the primary power must be large enough to safely carry the

required current. If the run of wire is too long, a larger size wire must be used to prevent

excessive voltage drop.

Print Date: 05/10/99 Copyright © 1999 Glenayre Page: 4-1

Page 64

GL-T8200 1- to 25-Watt 900-MHz Transmitter System Glenayre Document Number: 9110.01305

INSTALLATION AND SETUP Rev. A: 03/24/99

4.2 Installation

Refer to Figure 4-1, for general information.

4.2.1 Tools and Equipment Required

Refer to Table 4-1. Equipment listed by brand name may be substituted with equivalent.

For installation, only common hand tools are necessary if at all, since installation is usually

completed at the factory.

Table 4-1 Required Tools and Equipment

nut driver - 5/16 in (7.9 mm)

screw driver - #2 flat blade and # 3 flat blade

screw driver - #2 Phillips and #3 Phillips

Bird 4421 RF power meter

Bird 8327 dummy load

barrel connector - type-N

cable - 1 M long (max) with type-N ends

Fluke 77 DVM

4.2.2 Rack Positioning

Cooling and cabling restraints require that equipment pieces be racked so that there is

adequate ventilation for exhaust air. The front and back of the rack should have at least ten

inches of free space. The cabinet should be placed as close as possible to the transmitting

antenna, and to the primary power source as a secondar y consideration . To gain reasonable

access to the back, 30 inches (75 cm) of free space should be allowed..

Never place the rack where moisture, steam,

condensation, or standing water, can come in

contact with it. The host room may need to be air

conditioned or additionally ventilated to remove

excess heat generated by this equipment.

4.2.3 Rack Grounding

Caution

The rack cabinet must be connected to a reliable earth ground. Connect the earth ground

point to the ground stud provided in the bottom of the cabinet; use four gauge or larger

copper conductor.

Page: 4-2 Copyright © 1999 Glenayre Print Date: 05/10/99

Page 65

Glenayre Document Number: 9110.01305 GL-T8200 1- to 25-Watt 900-MHz Transmitter System

Rev. A: 03/24/99 INSTALLATION AND SETUP

4.2.4 Positioning within the Rack

When it is used in a no rmal, o ne-transmitter-per-cabinet rackup, the transm itter should be

placed just above the power supply.

The transmitter is normally shipped already installed in a cabinet. To remove or reinstall

the transmitter, refer to Section 9.

8200sys4

Rotating fan blades are a hazard to maintenance

personnel who access equipment from the rear.

4.2.5 Equipment Cabling

4.2.5.1 Ac and Dc Connections

DANGER

Refer to Figure 4-1. Be certain that the site-environmental requirement for available ac

power has been met. A grommeted hole in the cabinet is recommended for ac power input

cable. The ac input is fused at the back of the power supply. Generally, all ac connections