Gledhill Response BoilerMate OVR Series, BMAS 180 OVR, BMAS 220 OVR, BMAS 150 OVR Design, Installation & Servicing Instructions

Design, Installation

& Servicing Instructions

Model Numbers

BMAS 150 OVR

BMAS 180 OVR

BMAS 220 OVR

All models comply with the Hot Water Association

specication for integrated thermal stores

An open vented central heating

and mains pressure hot water

supply system incorporating a

thermal store

ISSUE 1: 0715

Section Page

DESIGN

Introduction 3

Technical Data 5

System Details 11

INSTALLATION

Site Requirements 19

Installation 20

Commissioning 30

SERVICING

Annual Servicing 34

Changing Components 34

Short Parts List 35

Fault Finding 36

APPENDIX

Appendix A 37

Appendix B 38

Appendix C 39

Terms & Conditions 42

Building Regulations and Benchmark Commissioning

The Building Regulations (England & Wales) require that the installation of a heating

appliance be notied to the relevant Local Authority Building Control Department.

From 1st April 2005 this can be achieved via a Competent Person Self Certication

Scheme as an option to notifying the Local Authority directly. Similar arrangements

will follow for Scotland and will apply in Northern Ireland from 1st January 06.

CORGI operates a Self Certication Scheme for gas heating appliances.

These arrangements represent a change from the situation whereby compliance with

the Building Regulations was accepted if the Benchmark Logbook was completed and

this was then left on site with the customer).

With the introduction of a self certication scheme, the Benchmark Logbook is being

replaced by a similar document in the form of a commissioning check list and a service

interval record is included with all gas appliance manuals. However, the relevant

Benchmark Logbook is still being included with all Thermal Storage products and

unvented cylinders.

Gledhill fully supports the Benchmark aims to improve the standards of installation

and commissioning of central heating systems in the UK and to encourage the regular

servicing of all central heating systems to ensure safety and eciency.

Building Regulations require that the heating installation should comply with the

manufacturer’s instructions. It is therefore important that the commissioning check

list is completed by the competent installer. This check list only applies to installations

in dwellings or some related structures.

The Gledhill BoilerMate range is a WBS

listed product and complies with the HWA

Specication for integrated thermal storage

products. The principle was developed in

conjunction with British Gas. This product

is manufactured under an ISO 9001:2008

Quality System audited by BSI.

Patents Pending

The Gledhill’s rst priority is to give a high

quality service to our customers.

Quality is built into every Gledhill product

and we hope you get satisfactory service

from Gledhill.

If not please let us know.

Page 2

These instructions should be read in conjunction with the Installation and Servicing

Instructions issued by the manufacturers of the heat source e.g. the boiler used.

Any water distribution and central heating installation must comply with the relevant

recommendations of the current version of the Regulations and British Standards

listed below:-

Gas Safety Regulations

Building Regulations

I.E.E. Requirements for Electrical Installations

Water Regulations

British Standards

BS6798, BS5449, BS5546, BS5440:1, BS5440:2, CP331:3, BS6700, BS5258, BS7593 and

BS7671.

A suitably competent person as stated in the Gas Safety Regulations must install the

BoilerMate and carry out any subsequent maintenance/repairs. In fact the front panel

is secured by 2 screws and should only be removed by a competent trades person. The

manufacturer’s notes must not be taken as overriding statutory obligations.

DESIGN

The BoilerMate A-Class is only suitable for use with an open vented central heating

system.

The BoilerMate A-Class is not covered by section G3 of the current Building Regulations

and is therefore not notiable to Building Control.

The BoilerMate A-Class OVR is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience or knowledge,

unless they have been given supervision or instruction concerning use of the appliance

by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

The information in this manual is provided to assist generally in the selection of

equipment. The responsibility for the selection and specication of the equipment

must however remain that of the customer and any Designers or Consultants

concerned with the design and installation.

Please Note: We do not therefore accept any responsibility for matters of design,

selection or specication or for the eectiveness of an installation containing one of

our products unless we have been specically requested to do so.

All goods are sold subject to our Conditions of Sale, which are set out at the rear

of this manual.

In the interest of continuously improving the BoilerMate range, Gledhill Response Ltd

reserve the right to modify the product without notice, and in these circumstances

this document, which is accurate at the time of printing, should be disregarded. It will

however be updated as soon as possible after the change has occurred.

Page 3

INTRODUCTION

DESIGN

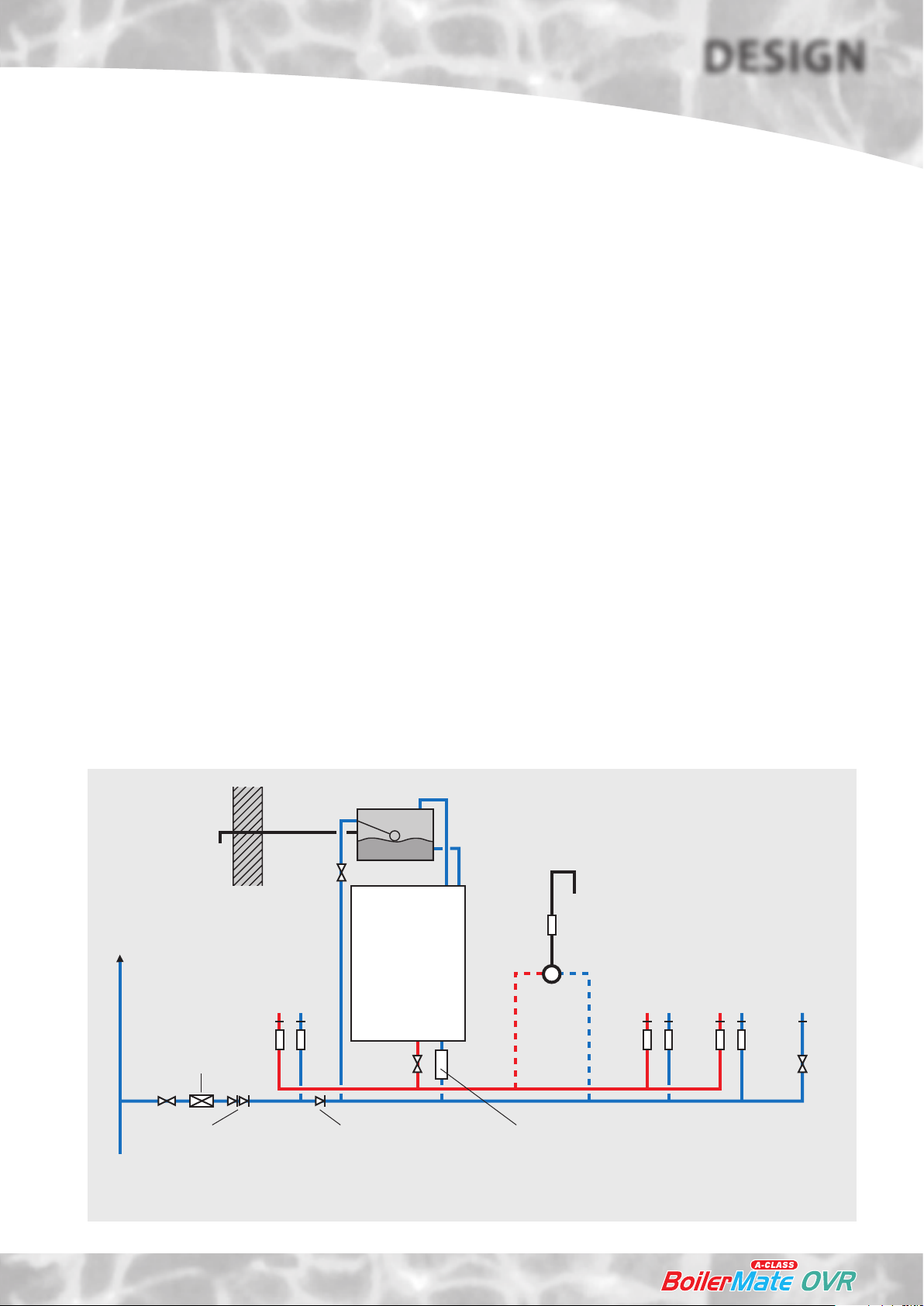

Mains cold

water

Remote

F&E tank

Open Vent

Warning/overflow

pipe

Cold feed

If scale should ever become a problem the plate

heat exchanger is easily isolated and quickly

replaced with a service exchange unit which

can be obtained at a nominal cost from Gledhill.

The A.C.B. also incorporates the facility to

operate the heating pump for a few seconds

every few days when the heating is not being

used (to reduce the likelihood of the pumps

sticking) as well as providing a boiler pump

overrun facility.

Primary flow

BM

Primary

return

Boiler

Description

The BoilerMate A-Class OVR shown schematically above is designed to provide

improved space heating and mains pressure hot water when coupled to any remotely

sited condensing boiler.

The principle of a BoilerMate A-Class is to separate the heat generator e.g. a boiler

from heat emitters (radiators) by a thermal store, which evens out the uctuating

demands for heating and hot water.

Because this product does not require a safety discharge from a temperature and

pressure relief valve, any installations will be easy to incorporate into the building

and will not suer from the problems associated with using PVCu soil stacks to take

the discharge from unvented cylinders.

An important feature of this concept is that hot water can be supplied directly from

the mains at conventional ow rates without the need for temperature and pressure

relief safety valves or expansion vessels. This is achieved by passing the mains water

through a plate heat exchanger. The outlet temperature of the domestic hot water

is maintained by a printed circuit board (A.C.B.), which controls the speed of the

pump circulating the primary water from the store through the plate heat exchanger.

A-Class

OVR

Full bore automatic bypass valve NOT REQUIRED

unless the heating system incorporates

mechanical thermostatic control valves e.g.

T.R.V's to all radiators or 2 port zone valves.

Any automatic boiler designed to operate on an

82°C ow and a 71°C return up to a maximum

of 35kW can be linked to any suitable model of

BoilerMate A-Class and the deciding factor is the

space heating and the hot water requirements

of a dwelling. See the Technical Data section

for further details.

The heat losses from thermal stores should not

be directly compared with heat losses from

unvented or vented cylinders because they are

treated dierently in SAP. The SAP calculator

takes account of the type of store and various

correction factors are included to reect the

dierent ways that the hot water and heating

operates.

Gledhill are part of the ‘Benchmark’ scheme and

a separate commissioning/service log book is

included with the product.

A 13mm connection is required on the primary

return on all units to allow for the provision

of a pumped summer use towel rail circuit if

required (see page 16 for further details)

Note: The BoilerMate OVR is a SYSTEM

appliance and only requires a basic boiler. If a

system boiler is chosen this will present wiring/

operational difficulties as well as incurring

extra costs.

The Building Regulations L1A: New dwellings/L1B: Existing dwellings and the

requirements set out in the Domestic Heating Compliance Guide specify that “where

the mains water hardness exceeds 200ppm provision should be made to treat the

feed water to water heaters and the hot water circuit of combination boilers to reduce

the rate of accumulation of lime scale”.

To comply with this requirement the hardness of the mains water should be checked

by the installer and if necessary the optional factory tted electronic in-line scale

inhibitor should be specied at the time of order for hardness levels between 200

and 300 ppm (mg/l).

Where the water is very hard ie 300ppm (mg/l) and above the optional polyphosphate

type, inhibitor should be specied at the time of order. However, this will need to

be tted by the installer at a suitable point in the cold water supply to the appliance.

INTRODUCTION

Page 4

DESIGN

Model BMAS 150 OVR BMAS 180 OVR BMAS220 OVR

Energy eciency class C C

Heat loss (watts) 66 72

Heat loss (kWh/24hr) 1.58 1.73

Weight (empty) 51.5 54.5 61.5

Weight (full) 192 213 265

C

88

2.11

DHW Pump

Heating Pump

Boiler Pump

Primary/heating pipe connections 22mm 22mm 28mm

MCW & DHW pipe connections 22mm 22mm 22mm

Cold feed/expansion connection 22mm 22mm 22mm

Safety open vent connection 22mm 22mm 22mm

Maximum summer towel rail load 0.75kW 1.00kW 1.25 kW

Drain connection R ½” R ½” R ½”

Maximum Head 6 meters 6 meters 6 meters

Hot water ow rate (l/m) up to 35 35 35

Max heating system size 17 kW 20 kW 25 kW

Typical Dwelling Types

Bedrooms 2-3 2-4 3-5

Bathrooms 1 2 1 2

En-suite shower 2 1 4 2

Grundfos UPR 15/50 Grundfos UPR 15/50 Grundfos UPR 15/50

Grundfos ErP Ready 15/50 Grundfos ErP Ready 15/50 Grundfos ErP Ready 15/50

Grundfos ErP Ready 15/50 Grundfos ErP Ready 15/50 Grundfos ErP Ready 15/50

Notes:-

1. In many cases, large properties will benet from having 2 smaller appliances located

adjacent to the areas of peak hot water use. This will allow 2 heating zones to be

provided and remove the need to provide trace heating on the hot water system.

2. A plastic feed and expansion cistern will be supplied separately including ballvalve,

oat and overow tting.

3. The ow rates are based on a 35°C temperature rise and assume normal pressure

and adequate ow to the appliance. The actual ow rate from the appliance is

automatically regulated to a maximum of 28 litres/min.

4. Unit is supplied on a 100mm high installation base.

5. The domestic hot water outlet temperature is automatically regulated to

approximately 52°C at the bath ow rate of 18 litres/min recommended by BS

6700. The temperature is not user adjustable.

Page 5

TECHNICAL DATA

DESIGN

10

4

3

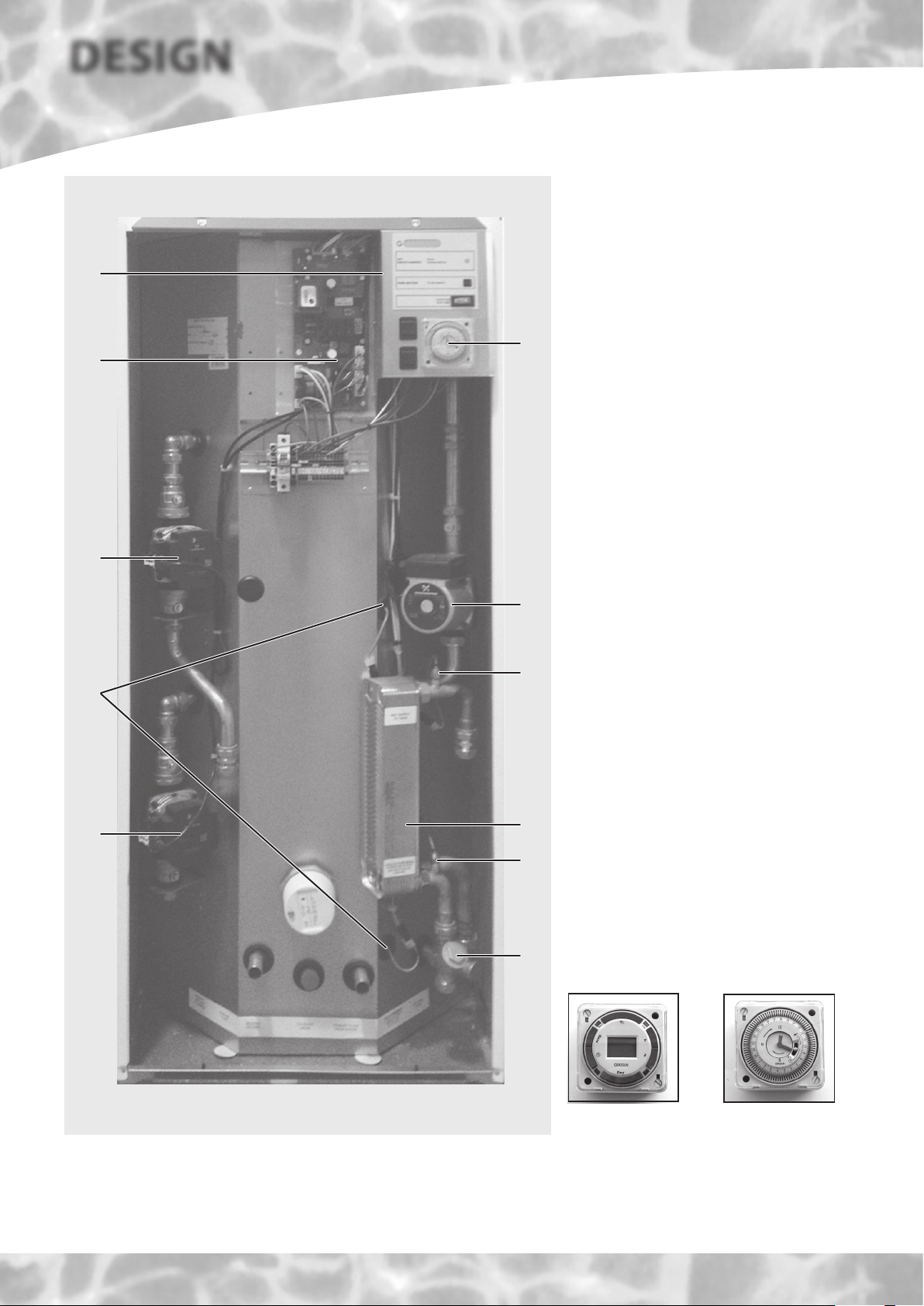

Standard Equipment

The standard conguration of the BoilerMate

A-Class OVR is shown opposite. The Appliance

Control Board (A.C.B.), mounted inside the

appliance, controls the operation of the

complete system. The A.C.B. is pre-wired to a

terminal strip where all electrical connections

terminate. It is supplied with the following

factory tted equipment:-

5

1. Boiler pump

2. Domestic hot water primary (plate

heat exchanger) pump - modulating

3. Space heating pump

4. Appliance control board (A.C.B.)

5. Electro-mechanical clock for hot water

and space heating time control.

6. Plate heat exchanger

7. DHW temperature sensor

8. Cold water inlet sensor

9. Store temperature sensors

10. Overheat sensor

11. Y type strainer/ow regulator

12. A feed and expansion cistern complete

2

with ballvalve, overow tting and cold

feed/open vent pipework assembly is

supplied separately.

Optional Equipment

7

9

1

Figure 2

• A seven day digital clock/programmer to

control the space heating (in conjunction

with a room thermostat)

• A no clock/multi-zone option.

• Hot and cold water manifolds for use

with plastic pipework.

• Electronic scale inhibitor for mains water

6

8

11

services

200ppm(mg/l) - tted in the appliance.

• Polyphosphate scale and corrosion

inhibitor for mains water services with

hardness levels above 300 ppm (mg/l)

for tting on site by the installer.

Digital clock

programmer

with hardness levels above

Electro-mechanical

clock

programmer

TECHNICAL DATA

Page 6

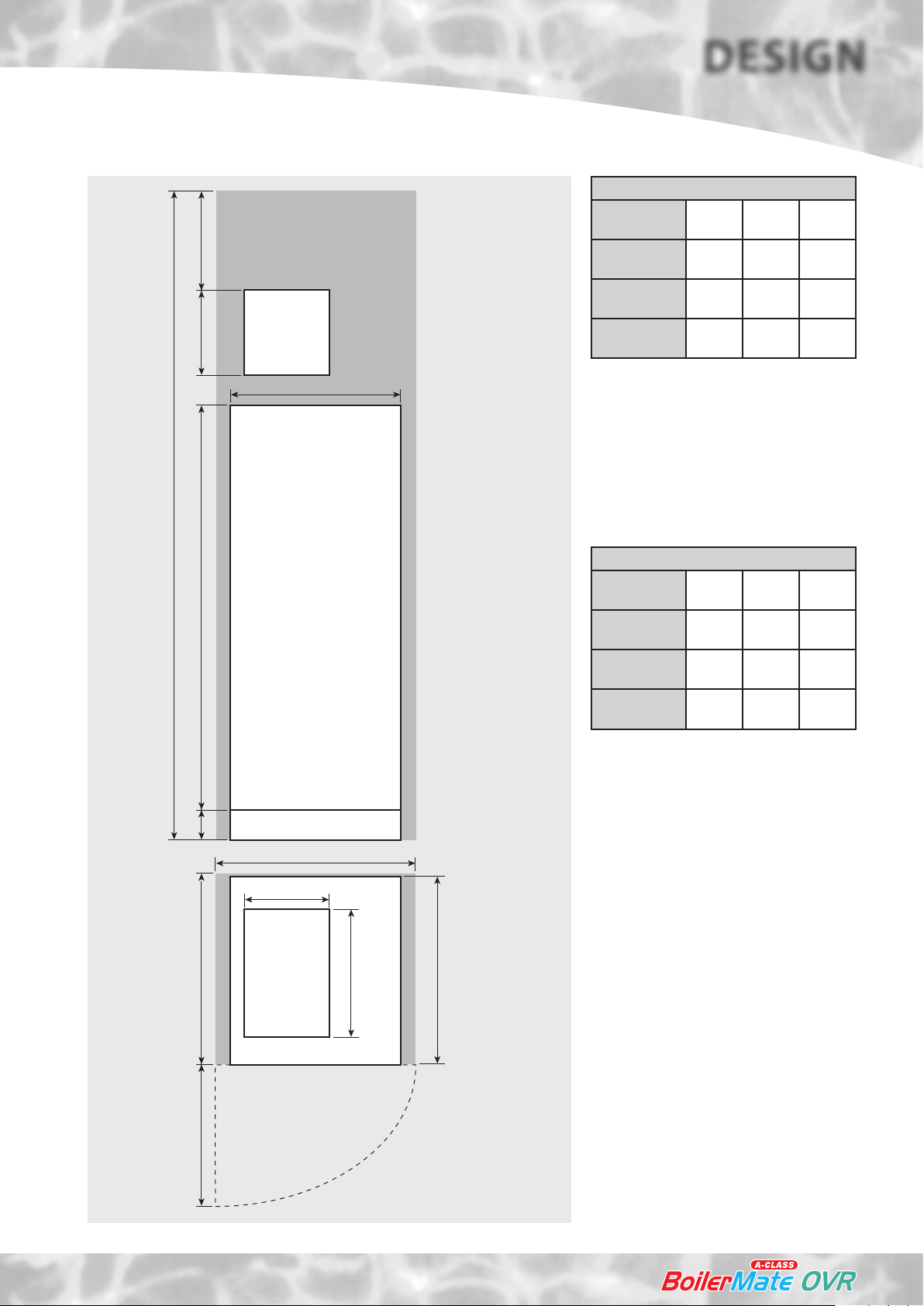

300 *350A100

F & E

cistern

*Min maintenance

access to comply with

the Water Regulations

(ballvalve model only)

Appliance Dimensions

Model

BMAS 150

OVR

BMAS 180

OVR

BMAS220

OVR

DESIGN

Height

(A)

1145 560 630

1275 560 630

1575 560 630

Width

(B)

Depth

(C)

B

D

BoilerMate A-Class

E

280

Note: The Appliance dimensions above do not

allow for the100mm high installation base.

The following table of minimum cupboard

dimensions only allow the minimum space

required for the appliance (including the F

& E cistern) and any extra space required for

shelving etc in the case of airing cupboards etc

must be added.

Minimum Cupboard Dimensions

Model

BMAS 150

OVR

BMAS 180

OVR

BMAS220

OVR

Note: The above dimensions are based on the

Appliance and the F & E cistern being in the

same cupboard.

If a Multi-Zone appliance is used an

additional 150mm must be added to the

above heights to accomodate the space

required for the zone equipment.

Height

(D)

1895 600 645

2025 600 645

2325 600 645

Width

(E)

Depth

(F)

The minimum

clear opening in

front of the

appliance to be

at least the

same depth as

the appliance.

F

F & E

cistern

Maintenance

access

420

C

The cupboard door

opening will need

to take into

account the various

sizes of appliances.

Figure 3

TECHNICAL DATA

Page 7

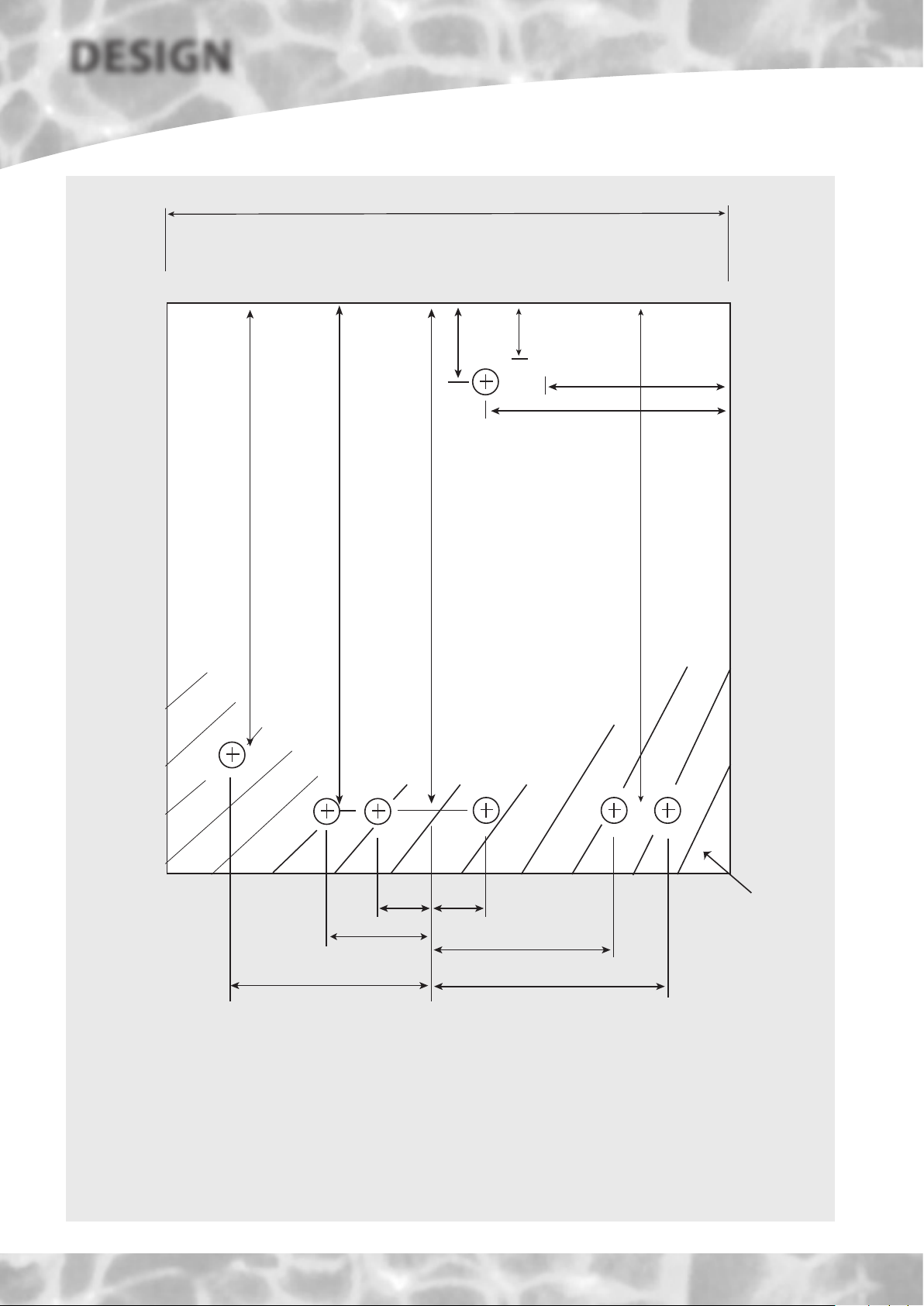

DESIGN

530

BOILER RETURN 475

CENTRAL HEATING FLOW 560

560

OPEN VENT

120

22

COLD FEED

55

22

145

205

550

DOMESTIC HOT WATER

COLD FEED

TECHNICAL DATA

CENTRAL HEATING RETURN

C

L

65

95

220

All dimensions in mm - to centre line of pipework

The BoilerMate A-Class units are supplied on an installation base to allow the pipe runs to

connect to the appliance from any direction. It is easier if all pipes protrude vertically in the

cut out area shown. Compression or push t connections can be used. All pipe positions

are approximate and subject to a tolerance of +/-20mm in any direction. A 15mm cold

water supply and a 22mm warning/overow pipe will also be required for the separate

feed and expansion tank.

BOILER FLOW

65

185

220

Cut out area

in base

Figure 4

Page 8

DESIGN

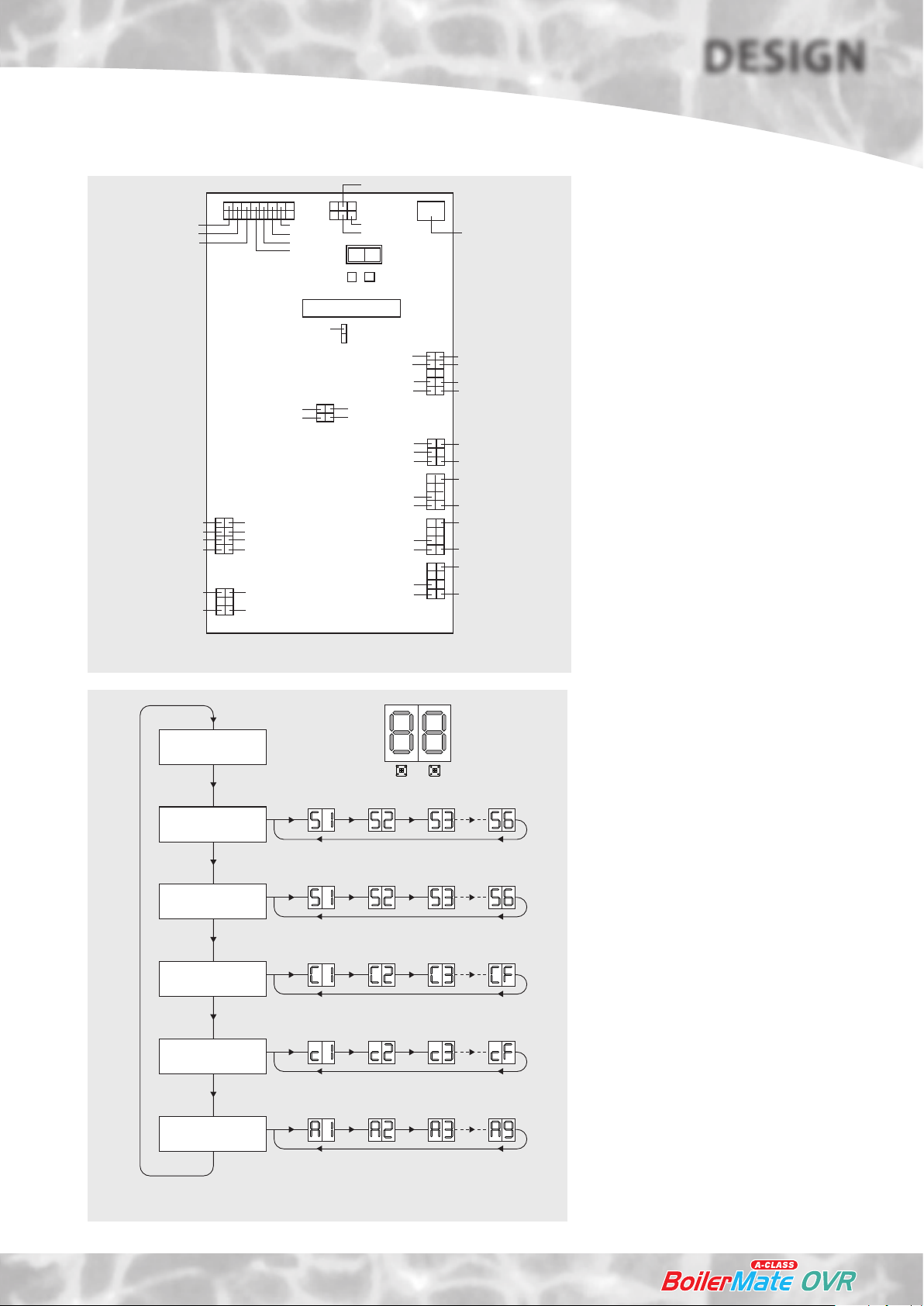

1

J9 J31

220_1

220_1

SWL_IN

220_0

220_1

220_PE

9

J28

J5

reading

Tank_middle

T_overh_2

T_dhw_in

Normal - standby state

Indicate system status

Press S2

Sensor temperature

Push button

8

DIV_OUT_1

DHW_ON_IN

CH_ON_IN

220_INPUT

220_0

220_0

220_PE

16

ID_resistor

T_overh_1

Tank_bot

T_dhw_out

FLIP jumper

220_0

Reset

button

S2 S1

Main processor

J29

DIV_OUT_2

220-0

Ext_led_k

Ext_se_1

Enter

button

WD_RECEIVE

VSS

SAFETY

220_1

OVERHEAT

220_0

BOIL_HEAT_DEM

CH_P_MOD

CH_P_L CH_P_L

BOILER_P_MOD

BOIL_P_L BOIL_P_N

DHW_P_MOD

DHW_P_L DHW_P_N

APPLIANCE CONTROL BOARD

S2 S1

Press

S1

Press

S1

Press

S1

Appliance Control Board

The appliance control board (shown opposite)

has a 2 digit display and 2 push buttons which

PC Connector

are used to check the status of the appliance,

check and set its identity and interrogate it for

the current faults and the fault history.

The 2 digit display is controlled by 2 buttons S1

and S2 The ow chart of display modes is shown

J30

SEND_TO_GAS

VSS

GASV_IN

220_0

below. Generally, each press of button S2 cycles

the display from top to bottom and each press

of button S1 cycles the display functions from

left to right.

The button S2 is also used to reset the appliance

J3

EL_HEAT_OUT

BOIL_HEAT_DEM

J33

J32

CH_P_PE

BOIL_P_PE

i.e. clear the lockout errors and reset the

appliance. (Note: Appliance resetting can also

be carried out using the push button on the

front panel)

Display in Normal (Standby) Mode

In the standard/normal mode the 2 digit display

indicates the status of the appliance inputs

J34

DHW_P_PE

and outputs by switching on the appropriate

segments of the display - see page 29 for details.

Appliance Type Selection

The BoilerMate is tted with an identity (ID)

Figure 5

resistor which is read by the controller for

comparison with the appliance type (code)

set on the controller. The two must match for

the controller/appliance to function. Therefore

if either the appliance code setting or the ID

resistor is wrong, the appliance will shut down

safely and ag the error code until the fault

is rectified. The controller codes and the ID

resistor values for the BoilerMate are 01 and 1K5

Press

S1

respectively. The procedure for checking and

setting the appliance code on the controller is

described below.

Press S2

Control set-point

reading

Press S2

Fault code indicator

lock outs

Press S2

Fault code indicator

block outs

Press S2

Appliance

type

Press

S1

Press

S1

Press

S1

Press

S1

Press

S1

Press

S1

Press

S1

Press

S1

2 DIGIT ACB BOARD DISPLAY FLOW CHART

Press

S1

Press

S1

Press

S1

Press

S1

Press

S1

Press

S1

Press

S1

Press

S1

Page 9

Figure 6

• The appliance selection menu (A0 ... A9) on the

controller is hidden. It is only possible to get to

the appliance selection using the reset button

(Left hand, S2) on the main board.

• When going from the show ‘ locking error’ to

show ‘blocking error’ menu (see opposite), do

not release the button but hold it for 10 seconds.

The display will change from ‘c’ to ‘A’. At this stage

the push button (S2) can be released.

• The appliance type can now be selected by

using right hand push button, S1, e.g. for this

appliance A01.

Press the reset button, S2, to accept the setting.

If the selected appliance code does not match

with the ID resistor tted to the appliance, then,

an error ‘33’ will be displayed.

TECHNICAL DATA

DESIGN

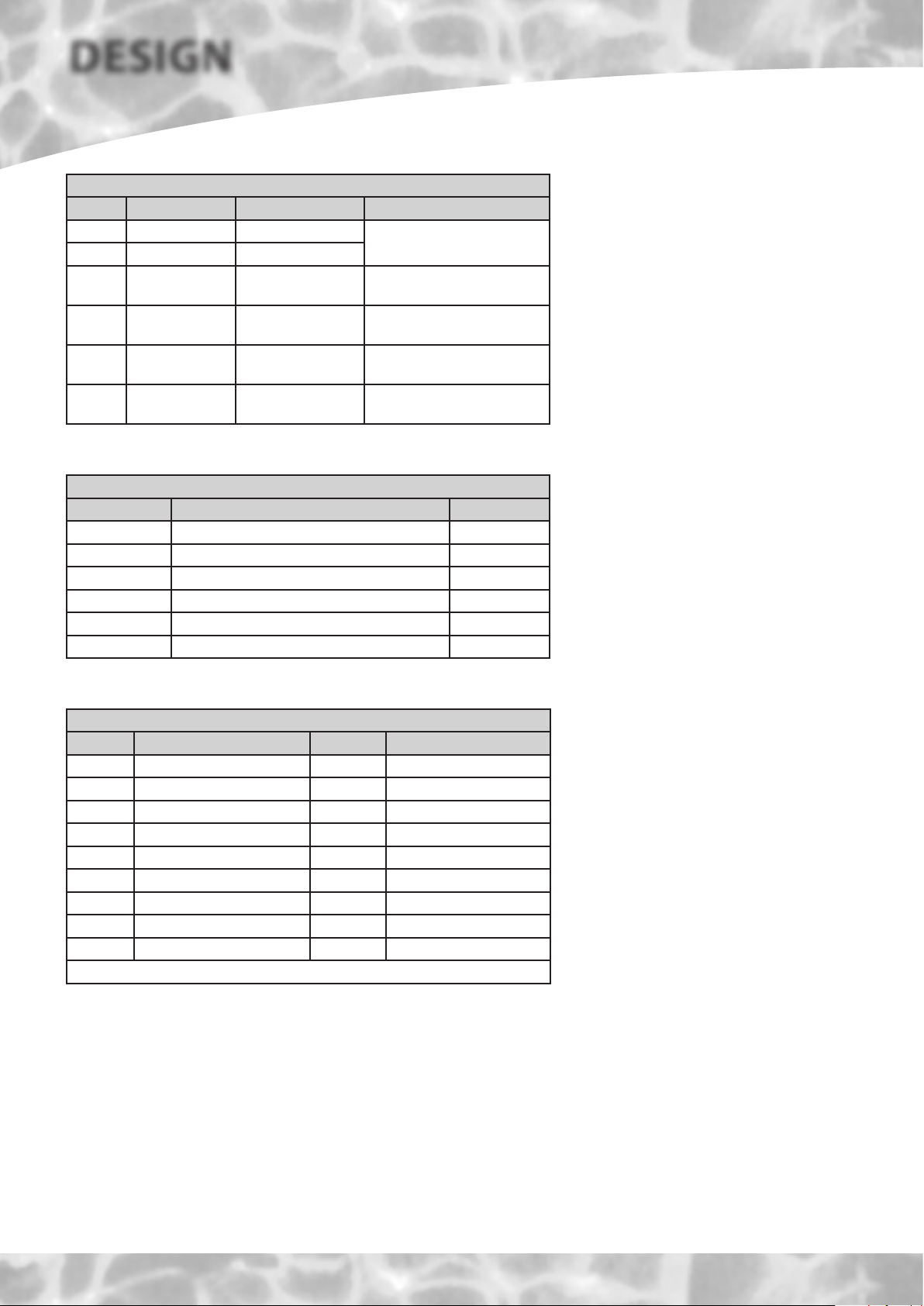

Sensors used in BoilerMate A-Class

Sensor Sensor Connector J9 pins Location

S1 T Overheat 1 6 & 14

S2 T Overheat 2 2 & 10

S3 T DHW in 3 & 11 In cold water inlet pipe (Wet

S4 T DHW out 4 & 12 In hot water outlet pipe (Wet

S5 T Tank bottom 5 & 13 Bottom of store in dry pocket

S6 T Tank middle 1 & 9 Middle of store in dry pocket

Sensor Control Set Points

Display Sensor Temp

S1 Middle store sensor on 68

S2 Middle store sensor o 77

S3 DHW in 35

S4 DHW out 55

S5 Bottom store sensor on 60

S6 Bottom store sensor o 70

Top of store in dry pocket (S1 &

S2 are in single housing)

i.e. direct)

i.e. direct)

for store charging

for store charging

Sensor Tempature Readings

Details of the various sensors S1-S6 used in

the BoilerMate A-Class are shown opposite.

The sensor reference i.e. S1 and the actual

temperature at that sensor ash alternately on

the display when selected.

Control Set Points

The sensor control set points are shown

opposite. Please note that the display s1 - s6

is not the same as the sensor reference.

Common Fault Codes

Code Code

10 Overheat error 45 S1 overheat 1 shorted

30 Phase error 48 I.D. resistor shorted

33 Appliance selection 49 S4 sensor shorted

37 S1 overheat 1 open 50 S5 sensor shorted

40 I.D. resistor open 51 S6 sensor shorted

41 S4 sensor open 52 S2 overheat 2 shorted

42 S5 sensor open

43 S6 sensor open

44 S2 overheat 2 open

Any other code displayed should be checked against the full chart

Fault Codes

Fault code locations are numbered C0 - CF

and c0 - cF.

CO/cO locations hold the latest fault recorded.

A code of FF indicates that the fault location

is empty.

If a sensor is faulty instead of a temperature it

will show E1 if open circuit and E2 if short circuit.

TECHNICAL DATA

Page 10

DESIGN

Hot and Cold Water System

General

A schematic layout of the hot and cold water services in a typical small dwelling is

shown below. BoilerMate A-Class will operate at mains pressures as low as 1 bar and

as high as 5 bar although the recommended range is 2-3 bar. These pressures are the

minimum dynamic pressures at the cold connection to the BoilerMate A-Class at the

time of the maximum calculated simultaneous demand. If manifolds are being used

the inlet pressure to the manifold must be a minimum of 2 bar. Particular consideration

should also be given to available pressures in the case of 3 storey properties. It is also

important to check that all other equipment and components in the hot and cold water

system are capable of accepting the mains pressure available to the property. If the

mains pressure can rise above 5 bar or the maximum working pressure of any item

of equipment or component to be tted in the system a pressure limiting (reducing)

valve set to 3 bar will be required.

If you encounter a situation where the water pressure is adequate but ow rates are

poor please contact our technical helpline for details of an eective solution.

Note: Each BoilerMate A-Class is tted with a strainer and ow regulator on the cold

mains supply connection. If the supply pressure is less than 2 bar or if the manifolds

(available as an optional extra) are being used or if all taps are provided with ow

regulators the ow regulator on the cold inlet should be removed.

No check valve or similar device should be tted on the cold water supply branch to

the BoilerMate A-Class.

To comply with this requirement the hardness

of the mains water should be checked by the

installer and if necessary the optional factory

tted in-line scale inhibitor should be specied

at the time of order for hardness levels between

200 and 300 ppm (mg/l).

Where the water is very hard ie 300ppm (mg/l)

and above the optional polyphosphate type,

inhibitor should be specied at the time of

order. However, this will need to be tted by

the installer at a suitable point in the cold water

supply to the appliance.

If scale should ever become a problem the plate

heat exchanger is easily isolated and quickly

replaced with a service exchange unit which

can be obtained at a nominal cost from Gledhill.

The hot water ow rate from the BoilerMate

A-Class is directly related to the adequacy

of the cold water supply to the dwelling.

This must be capable of providing for those

services, which could be required to be supplied

simultaneously, and this maximum demand

should be calculated using procedures dened

in BS 6700.

The Building Regulations L1A: New dwellings/L1B: Existing dwellings and the

requirements set out in the Domestic Heating Compliance Guide specify that “where

the mains water hardness exceeds 200ppm provision should be made to treat the feed

water to water heaters and the hot water circuit of combination boilers to reduce the

rate of accumulation of lime scale”.

Open vent

Warning/

overflow

pipe

MCWS

Second

dwelling

Top up cistern

BOILERMATE

Expansion/

cold feed

a

A-CLASS

Pressure limiting valve

NOT REQUIRED at

pressures below 5 bar

unless any components

have a lower

maximum working

pressure

Sink

H C

a a

OVR

If a water meter is tted in the service pipe,

it should have a nominal rating to match the

maximum hot and cold water peak demands

calculated in accordance with BS 6700. This

could be up to 80ltr/min in some properties.

‘a’ - flow regulator recommended for

better balance of hot and cold

water supplies

Shower

WC - fitted

Bath

H C

a a a a

Hand basin

H C

with BS1212

ballvalve

C

SV

MCWS

supply

pipe

Double check valve

NOT REQUIRED unless

pipe supplies more

than one dwelling

Check valve

NOT REQUIRED unless

chemical water

treatment unit is fitted

Typical hot and cold water distribution

Optional polyphosphate scale inhibitor -

NOT REQUIRED unless the hardness

level exceeds 300ppm (mg/l)

Page 11

Figure 7

SYSTEM DETAILS

DESIGN

Hot and Cold Water System

Pipe Sizing / Materials

To achieve even distribution of the available supply of hot and cold water, it is

important in any mains pressure system, that the piping in a dwelling should be sized

in accordance with BS 6700. This is particularly important in a large property with

more than one bathroom.

However, the following rule of thumb guide lines should be adequate for most smaller

property types as long as water pressures are within the recommended range of 2-3

bar.

1. A 15mm copper or equivalent external service may be sucient for a small

1bathroom dwelling (depending upon the ow rate available), but the minimum

recommended size for new dwellings is 22mm (25mm MDPE). For the BMA 225

model we recommend a 28mm (32mm MDPE) supply pipe.

2. The internal cold feed from the main incoming stop tap to the BoilerMate should

be run in 22mm pipe. The cold main and hot draw-o should also be run in 22mm

as far as the branch to the bath tap.

3. The nal branches to the hand basins and sinks should be in 10mm and to the

baths and showers in 15mm. (1 metre minimum)

4. If an external hose tap is provided this should be branched in 15mm pipework

from the cold pipework as near to the incoming mains as possible.

5. We would recommend that best results for a balanced system are

achieved by fitting appropriate flow regulators to each hot and cold

outlet. This is particularly relevant where the water pressures are above the

recommended water pressure range of 2-3 bar, or the dwelling is 3 storey.

Details of suitable ow regulators are provided in Appendix.

Note: If manifolds are being used suitable ow regulators need to be provided

at each outlet.

All the recommendations with regard to pipework systems in this manual are generally

based on the use of BS/EN Standard copper pipework and ttings.

However, we are happy that plastic pipework systems can be used in place of copper

internally as long as the chosen system is recommended for use on domestic hot

and cold water systems by the manufacturer and is installed fully in accordance with

their recommendations.

However, if it is proposed to use a ‘whole body’

or similar shower with a number of high ow/

pressure outlets please discuss with the Gledhill

technical department.

The hot water supply to a shower-mixing valve

should be fed wherever practical directly from

the BoilerMate A-Class or be the rst drawo point on the hot circuit. The cold supply

to a shower-mixing valve should wherever

practical be fed directly from the rising mains

via an independent branch. The shower must

incorporate or be fitted with the necessary

check valves to provide back-syphonage

protection in accordance with the Water

Regulations.

The supply of hot and cold mains water directly

to a bidet is permitted provided that it is of the

over-rim ushing type and that a type ‘A’ air gap

is incorporated.

Hot and Cold Water System.

If the length of the hot water draw off

pipework is excessive the delivery time may

be unacceptable before hot water is available

at the tap, you may wish to consider using trace

heating to the hot water pipework such as the

Raychem HWAT system. Please consult Gledhill

Technical Department for further details.

It is important that the cold water pipework

is adequately separated/protected from any

heating/hot water pipework to ensure that

the water remains cold and of drinking water

quality.

It is also essential that if an alternative pipework material/system is chosen the

manufacturer conrms that the design criteria of the new system is at least equivalent

to the use of BS/EN Standard copper pipework and ttings.

Taps/Shower Fittings

Aerated taps are recommended to prevent splashing.

Any type of shower mixing valve can be used as long as both the hot and cold

supplies are mains fed. However, all mains pressure systems are subject to

dynamic changes particularly when other hot and cold taps/showers are opened

and closed, which will cause changes in the water temperature at mixed water

outlets such as showers. For this reason and because these are now no more

expensive than a manual shower we strongly recommend the use of thermostatic

showers with this appliance. These must be used in 3 storey properties where

the impact on pressure/temperature of opening another tap in the system is

greater than normal.

The shower head provided must also be suitable for mains pressure supplies.

SYSTEM DETAILS

Page 12

Heating System

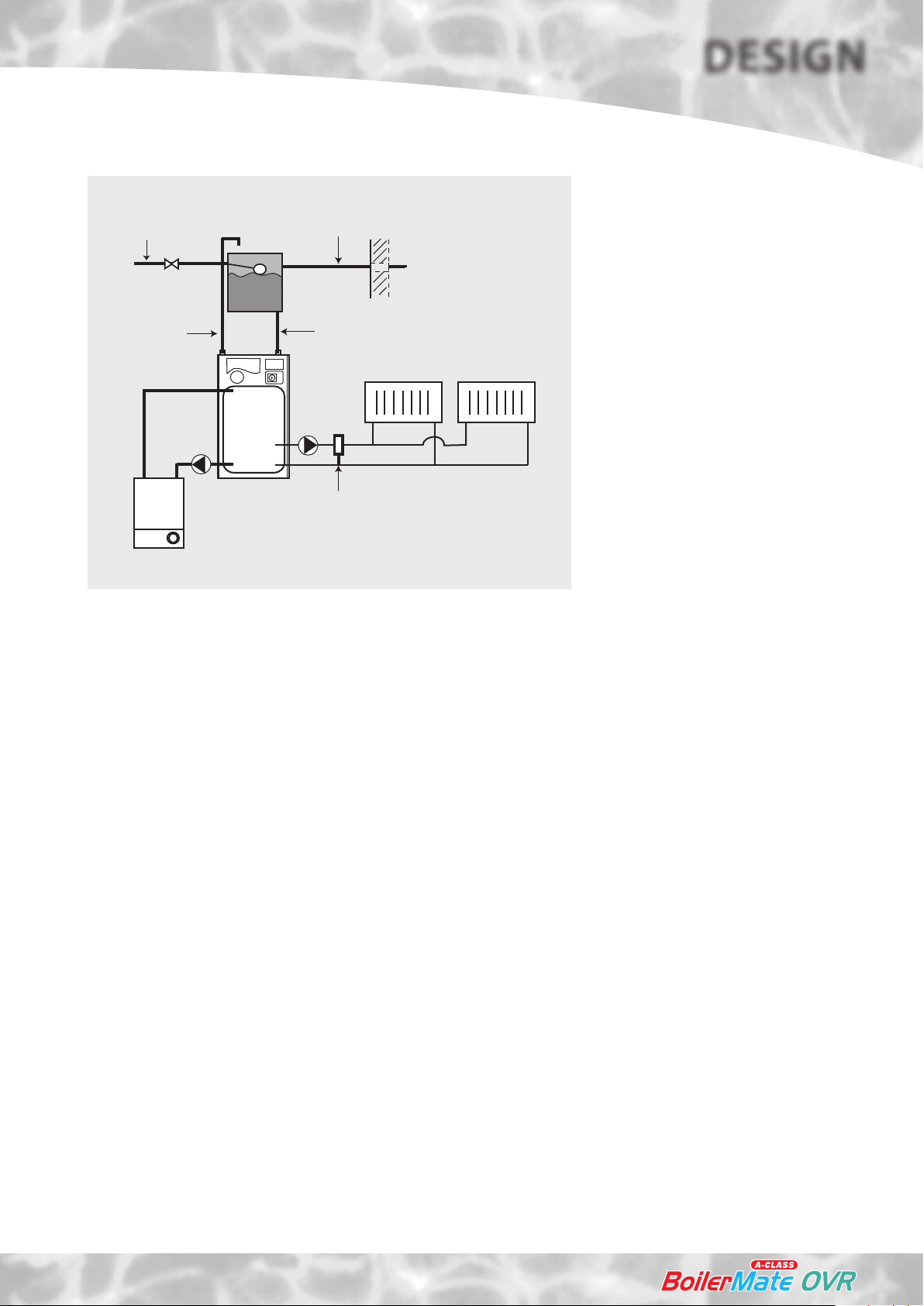

DESIGN

Mains cold

water

Open Vent

Primary flow

Primary

return

Boiler

Warning/overflow

pipe

Remote

F&E tank

Cold feed

BM

A-Class

OVR

Full bore automatic bypass valve NOT REQUIRED

unless the heating system incorporates

mechanical thermostatic control valves e.g.

T.R.V's to all radiators or 2 port zone valves.

Figure 8

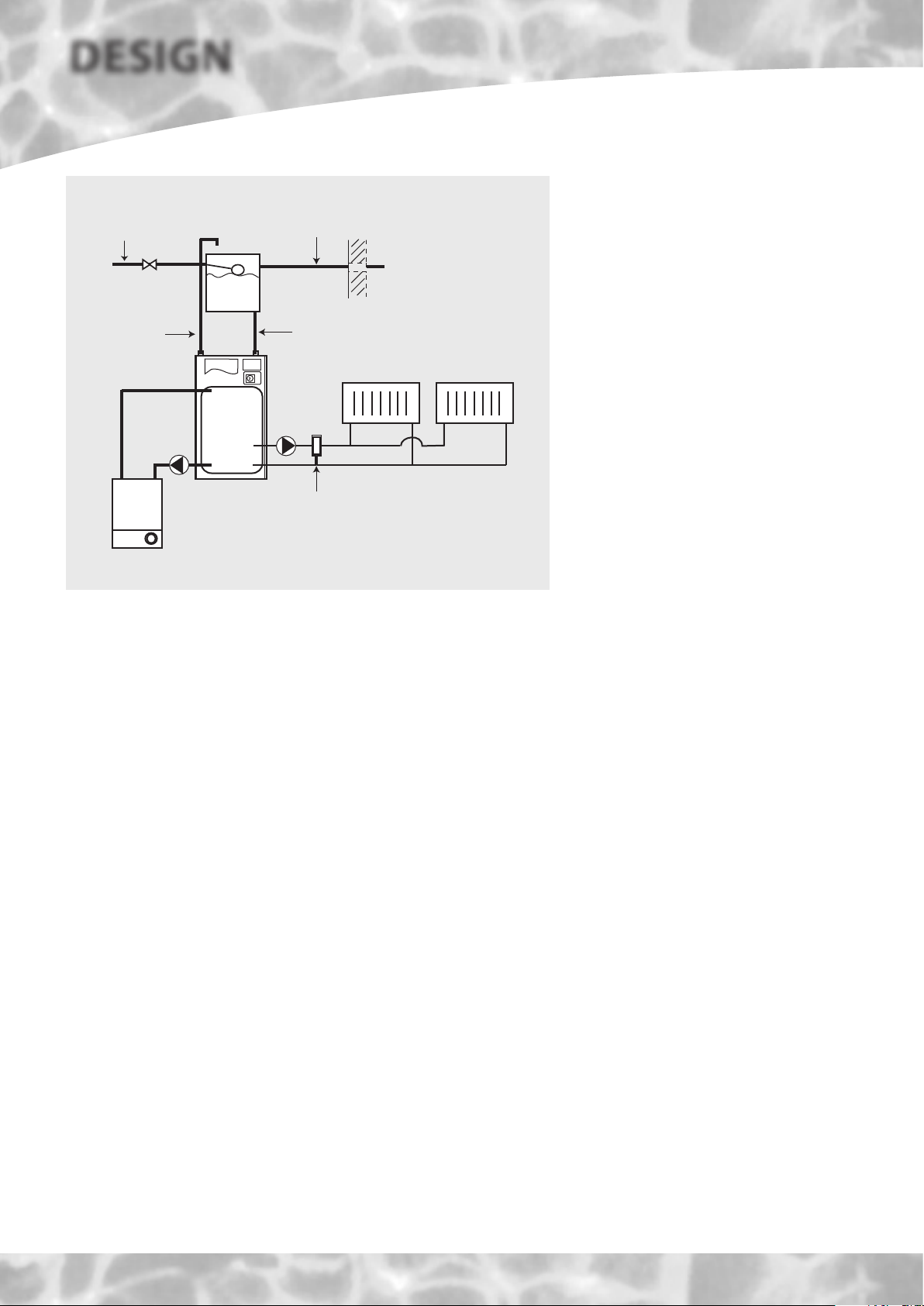

General

A schematic layout of the heating system in a

typical small dwelling is shown opposite.

The flow and return from the boiler must

always run directly to the BoilerMate A-Class

and the flow should rise continuously to

facilitate venting. The heating circuit is taken

from the BoilerMate A-Class and is piped in the

conventional manner.

The BoilerMate A-Class is only suitable for an

open vented system.

The F & E cistern can be tted remotely up to 6

m above the base of the BoilerMate A-Class i.e.

the maximum static pressure in the store must

not exceed 0.6 bar.

If any radiators are located above the level

of the BoilerMate A-Class the system should

be designed so that gravity circulation does

not occur when the heating pump is not

running. To be certain of preventing this it is

recommended that a check valve, or valves, are

tted on the vertical ow pipes.

The water level in the F & E cistern should be

at least 250mm above the highest point on

the system including the radiators and must

be high enough to provide the minimum

head required by the boiler being used.

The boiler manufacturer’s instructions with

regard to minimum head must always be

followed. This is particularly important in

situations where the headroom is restricted

(e.g. in a at).

Range rated boilers can be used but should

always be set at the highest output. The

system eciency will not be impaired while

the recovery rate will be improved.

It is not necessary to provide a boiler bypass on

the primary circuit (i.e. between the boiler and

the thermal store.)

Page 13

SYSTEM DETAILS

DESIGN

Heating System

Pipe Sizing/Materials

The primary pipework connecting the boiler and the thermal store should be sized

to achieve a maximum of 8°C rise across the boiler or the maximum temperature

rise specied by the boiler manufacturer, whichever is smaller, but in any instance it

should not be less than 22mm copper tube.

Note: There should be no valves in the pipework connecting the boiler to the

BoilerMate A-Class.

The heating circuit operates on the normal primary boiler temperatures i.e. 82°C ow

and 71°C return. Therefore any traditional hot water radiators or convectors can be

used with this system and no special over-sizing of the heat emitters is necessary.

All the recommendations with regard to pipework systems in this manual are generally

based on the use of BS/EN Standard copper pipework and ttings.

However, we are happy that plastic pipework systems can be used in place of

copper internally as long as the chosen system is recommended for use on domestic

heating systems by the manufacturer and is installed fully in accordance with their

recommendations. We always recommend the use of barrier pipe for these systems.

It is also essential that if an alternative pipework material/system is chosen the

manufacturer conrms that the design criteria of the new system is at least equivalent

to the use of BS/EN Standard copper pipework and ttings.

Boiler Size

It is only necessary to calculate the heating

requirements in accordance with BS 5449. The

allowances shown below should be added

for domestic hot water. The control system

automatically gives priority to hot water when

necessary.

Allowance for domestic hot water

Model (kw)

BMA 150 OVR 3

BMA 180 OVR 4

BMA 220 OVR 5

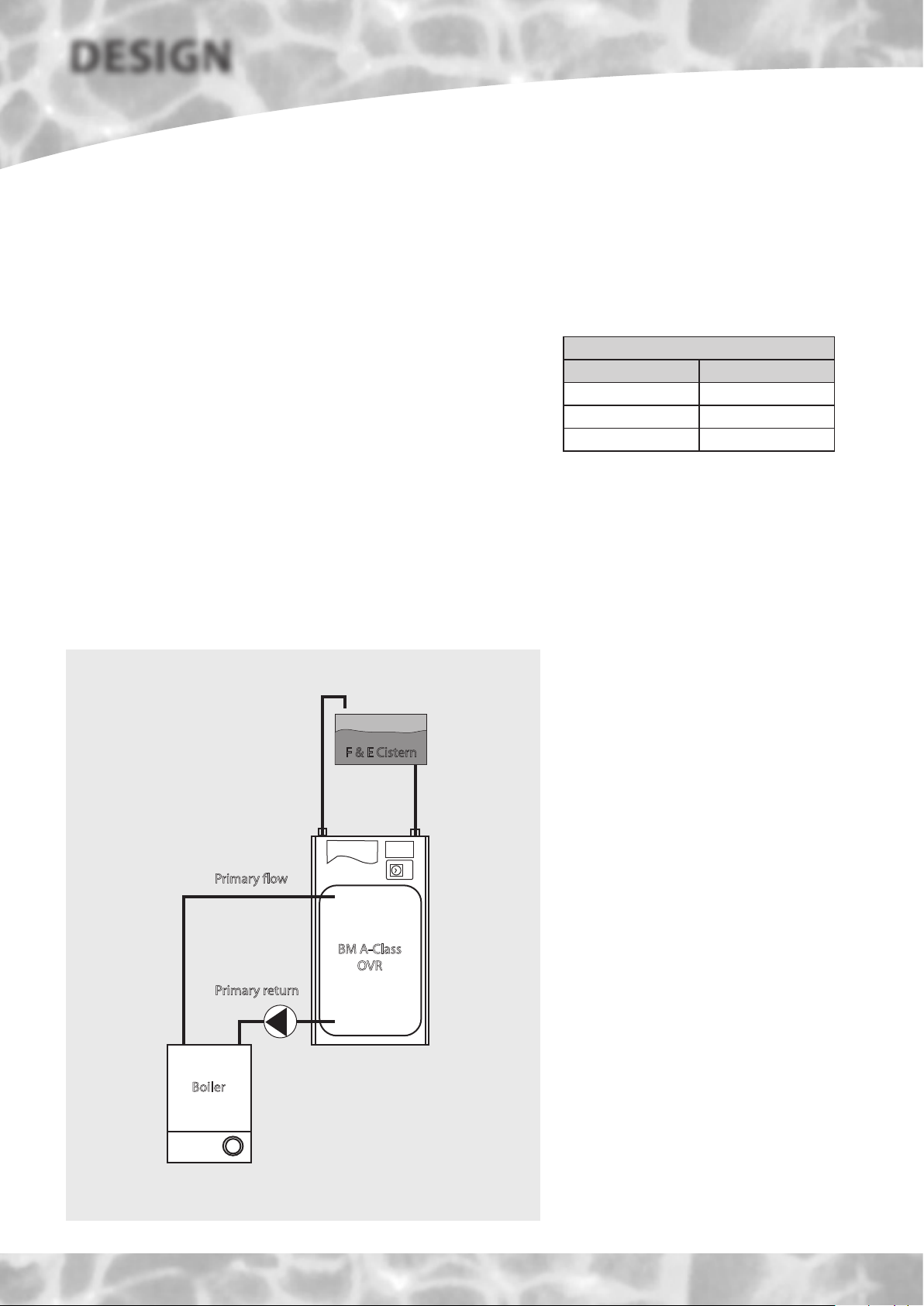

Boiler Sited Below BoilerMate A-Class

Any temperature controlled boiler can be used

when the flow pipe from the boiler to the

BoilerMate A-Class rises continuously. No valve

shall be tted in the primary ow or open vent.

Primary flow

Primary return

Boiler

F & E Cistern

BM A-Class

OVR

SYSTEM DETAILS

Figure 9

Page 14

Loading...

Loading...