gledhill Torrent Stainless OV, Torrent Stainless OV SOL, Torrent Stainless SP SOL Instruction Manual

WWW.GLEDHILL.NET

ONE NAME. EVERY SOLUTION.

TORRENT STAINLESS

OPEN VENTED STAINLESS STEEL

THERMAL STORE PROVIDING HEATING

AND MAINS PRESSURE HOT WATER

INSTRUCTION MANUAL

DESIGN, INSTALLATION & SERVICING

Page 2 Page 3

Section Page

DESIGN

Description 3

Technical Information 4

System Design 6

INSTALLATION

Installation 8

Wiring Diagrams 21

Commissioning 28

Installation Review 30

SERVICING AND MAINTENANCE

Servicing and Maintenance 31

Fault Finding 32

Short Parts List 39

APPENDIX

Appendix A 40

Appendix B 41

Notes 42

Terms & Conditions 44

BENCHMARK

Commissioning Check List 46

Service Record 47

ISSUE 4: APRIL 2018

These instructions should be read in conjunction with the installation/servicing

instructions issued by the manufacturer of the heat source being used.

Any installation must be in accordance with the relevant requirements of the Gas

Safety Regulations, Building Regulations, I.E.E. Wiring Regulations and the Water

Fitting Regulations (England and Wales) or Water Byelaws (Scotland). It should be

read in accordance with the relevant recommendations of the following:

BS 6798; BS 5549; BS 5546;

BS 5440:1; BS 5440:2; CP 331:3

BS 6700: BS 5258 and BS 7593: 1993 and BS7671

It must be installed by a competent person as dened by the relevant regulations.

Manufacturers notes must NOT be taken as over-riding statutory obligations.

This product overcomes Part G Building Regulation discharge requirements for

unvented cylinders but the installation is notiable to building control unless it is

carried out under an approved competent person self-certication scheme.

Although the secondary supply (domestic) is at mains pressure, it is not necessary to

t an expansion chamber, pressure or temperature relief valve, the plumbing should

allow any unusual build up of pressure to be relieved at the ball valve.

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge unless

they have been given supervision or instruction concerning use of the appliance by

a person responsible for their safety. Children should be supervised at all times to

ensure they do not play with the appliance.

This information is provided to assist generally in the selection of equipment.

Responsibility for selection and specication of our equipment must however remain

that of our customer and any experts or consultants concerned with the installation(s).

PLEASE NOTE: THAT WE DO NOT THEREFORE ACCEPT ANY RESPONSIBILITY FOR

MATTERS OF DESIGN SELECTION OR SPECIFICATION, FOR THE EFFECTIVENESS

OF AN INSTALLATION OR SYSTEM CONTAINING ONE OF OUR PRODUCTS UNLESS

SPECIFICALLY REQUESTED TO DO SO IN WRITING.

All goods are sold subject to our Conditions of Sale which are set out at the rear of this

specication. In the interest of continuously improving the Torrent Stainless range,

Gledhill Building Products Limited reserve the right to modify the product without notice,

and in these circumstances this booklet, which is accurate at the time of printing, should

be disregarded. An updated set of Instructions will be produced and supplied with new

appliances and will be made available for other appliances on request.

Benchmark places responsibilities on both manufacturers and installers. The

purpose is to ensure that customers are provided with the correct equipment for

their needs, that it is installed, commissioned and serviced in accordance with the

manufacturers instructions by competent persons and that it meets the requirements

of the appropriate Building Regulations. The Benchmark Checklist can be used to

demonstrate compliance with Building Regulations and should be provided to the

customer for future reference.

Installers are required to carry out installation, commissioning and servicing work

in accordance with the Benchmark Code of Practice which is available from the

Heating and Hot Water Industry Council who manage and promote the Scheme. Visit

www.centralheating.co.uk for more information.

For information on the HWA Charter Statement, go to the HWA website hotwater.org.uk.

Manufacturer: Gledhill Building Products Ltd

Max. mains inlet water pressure 5.0bar

Max. working pressure - Primary heat exchanger (Indirect models) 3.0bar

Max. working pressure - Solar heat exchanger (Solar models) 6.0bar

Max. working pressure - Open vented thermal store (All models) 10.0m (1.0bar)

Max. working pressure - Open vented central heating system 10.0m (1.0bar)

Max. working pressure - Sealed heating system 3.0bar

Max. ow rate - Measured by ow sensor 32 l/min

Min. ow rate - Measured by ow sensor 1.8 l/min

Immersion heater rating

3kW @ 230V ac, 50Hz

The Torrent Stainless comes complete with plate heat exchanger. This has a very

small volume of water held within it, therefore any minimal expansion will be

accomodated in the supply pipe.

Handling Before Installation

The Torrent Stainless must be handled with care and stored the correct way up in

a dry place. Any manual handling/lifting operations will need to comply with the

requirements of the Manual Handling Operations Regulations issued by the H.S.E. The

appliance can be moved using a sack truck on the rear face although care should be

taken and the route should be even. In apartment buildings containing a number of

storeys we would recommend that the appliances are moved vertically in a mechanical

lift. If it is proposed to use a crane, expert advice should be obtained regarding the

need for slings, lifting beams etc. A specic manual handling assessment is shown in

Appendix B at the rear of this manual.

Maintenance

Modications should not be made to this product. Replacement parts, including

immersion heaters, should be purchased from Gledhill Building Products Limited, or

agents approved by them. The manual must always be left with the Torrent Stainless.

The Environment

This product has been manufactured using many recyclable materials, including the

approved HCFC/CFC free polyurethane foam insulation. At the end of its useful life, it

should be disposed of at a Local Authority Recycling Centre, to maximise the products

full environmental benets.

Note:

The thermal store is supplied with either one or two immersion heaters. These

incorporate a thermostat (XB081) which cuts the electricity supply to the immersion

heater if the control thermostat fails - a thermal cut out. Under no circumstances t

an immersion heater which does not incorporate a thermal cut out.

Why use a thermal store?

a) Alternative energy fuel sources are typically low grade, inherently unpredictable

and are often available in plentiful supply but not when the heat energy is

needed! A thermal store provides the means to harness the energy when it is

available for later conversion into both hot water AND heating.

Being open vented, they provide a simple and inherently safe way to produce

high-performance mains pressure hot water.

Multiple heat sources feed into the thermal store. This means that the energy

available from solar panels or a wood burning stove, for example, can be used

to provide energy into the heating circuit to decrease the use of fossil fuel based

boilers, and hence reduce household running costs.

DESIGN

DESCRIPTION

It is very problematic and inherently unsafe

to connect wood burning stoves or other

uncontrolled heat sources to an unvented

cylinder, and not easily possible to combine

alternative energy heat sources to provide

energy to the heating circuit, hence the

unique advantages of a thermal store.

b) The Torrent Stainless is the ideal product

to use as the heart of an alternative energy

system as it will take energy input not only

from a conventional boiler but also from a

wide variety of alternative energy sources,

including but not limited to:

• solar panels

• wood burning stoves and other

uncontrolled heat sources

• electricity from renewable or low

carbon sources

If the system is congured appropriately

the heat from the alternative energy source

will be available for both hot water AND

heating.

c) The Torrent Stainless becomes the neutral

point in any open vented system because

the open vent and cold feed pipes are

connected to it. The benet of this is that

another device to enable dierent systems

to be joined together at a neutral point is

not required, which would be required in

other systems. In multiple fuel systems, the

Torrent Stainless acts as a low loss header.

d) Alternative energy supplies cannot be relied

upon to raise the temperature of the stored

water above 60 degrees every time they

operate. This is not a problem with a thermal

store because the store water is not the

water that comes out of the tap. The water

that comes out the hot tap is mains cold

water run through a plate heat exchanger

on the outside of the thermal store. This

water heats very quickly and the volume of

stagnent water in the heat exchanger is very

small so there is virtually no legionella risk.

e) The thermal store is open vented and

therefore does not require additional safety

devices such as temperature and pressure

relief valves or an inlet control group and

expansion vessels.

f) The running costs of this cylinder are greatly

reduced by not being required to have

an annual safety inspection where as an

unvented cylinder does.

Page 4 Page 5

Technical

Model

Energy Eciency Class

Heat Loss

Domestic Hot Water Volume

Weight - Empty

Weight - Full

Overall Height

(Excluding F&E Tank)

Overall Diameter

(Allow additional 150mm for PHE)

Cold Feed

Sealed Primary

Boiler Coil Flow

Sealed Primary

Boiler Coil Return

Solar Coil Flow

Solar Coil Return

Central Heating Flow

Central Heating Return

Cylinder Drain

Solid Fuel Flow

Solid Fuel Return

Open Vented

Boiler Flow

Open Vented

Boiler Return

Open Vent

Surface Area of

Primary Heater Coil

Surface Area of

Solar Heater Coil

Capacity (Total Volume)

Dedicated Solar Volume

Maximum Hot Water

Flow Rate

watts litres kg kg

A

mm

mm

BmmCmmDmmEmmFmmGmmHmmImmJmmKmmLmmMmmN

mm

m2m2litres litres litres/min

Torrent Stainless

OV

TST150OV B 47 141 32 180 1118 550 285 n/a n/a n/a n/a 614 220 220 614 223 651 220 1177 n/a n/a 148 n/a 26.5

TST180OV B 55 169 36 214 1306 550 285 n/a n/a n/a n/a 665 220 220 665 223 732 220 1365 n/a n/a 178 n/a 26.5

TST210OV B 62 198 39 247 1494 550 285 n/a n/a n/a n/a 710 220 220 710 223 828 220 1553 n/a n/a 208 n/a 26.5

TST250OV C 74 236 44 292 1744 550 285 n/a n/a n/a n/a 783 220 220 783 223 939 223 1803 n/a n/a 248 n/a 26.5

TST350OV C 79 328 54 399 1765 630 285 n/a n/a n/a n/a 690 218 218 690 221 896 221 1826 n/a n/a 345 n/a 26.5

Torrent Stainless

OV SOL

TST150OVSOL B 47 141 34 182 1118 550 285 n/a n/a 405 235 838 427 220 838 430 804 504 1177 n/a 0.78 148 63.9 26.5

TST180OVSOL B 55 169 38 216 1306 550 285 n/a n/a 405 235 838 427 220 838 430 804 504 1365 n/a 0.78 178 73.8 26.5

TST210OVSOL B 62 198 42 250 1494 550 285 n/a n/a 515 235 1015 537 220 1015 540 1071 611 1553 n/a 1.27 208 83.7 26.5

TST250OVSOL C 74 236 47 295 1744 550 285 n/a n/a 515 235 1040 537 220 1040 540 1441 761 1803 n/a 1.27 248 96.9 26.5

TST350OVSOL C 79 328 57 402 1765 630 285 n/a n/a 498 218 971 520 218 971 523 1446 676 1826 n/a 1.27 345 129.9 26.5

Torrent Stainless

SP SOL

TST150SPSOL B 47 141 36 184 1118 550 285 804 504 405 235 838 427 220 838 430 n/a n/a 1177 0.78 0.78 148 63.9 26.5

TST180SPSOL B 55 169 41 219 1306 550 285 804 504 405 235 838 427 220 838 430 n/a n/a 1365 1.27 0.78 178 73.8 26.5

TST210SPSOL B 62 198 45 253

1494 550 285 1071 611 515 235 1015 537 220 1015 540 n/a n/a 1553 1.27 1.27 208 83.7 26.5

TST250SPSOL C 74 236 51 299 1744 550 285 1441 761 515 235 1040 537 220 1040 540 n/a n/a 1803 1.40 1.27 248 96.9 26.5

TST350SPSOL C 79 328 63 408 1765 630 285 1446 676 498 218 971 520 218 971 523 n/a n/a 1826 2.50 1.27 345 129.9 26.5

DESIGN DESIGN

TECHNICAL INFORMATION TECHNICAL INFORMATION

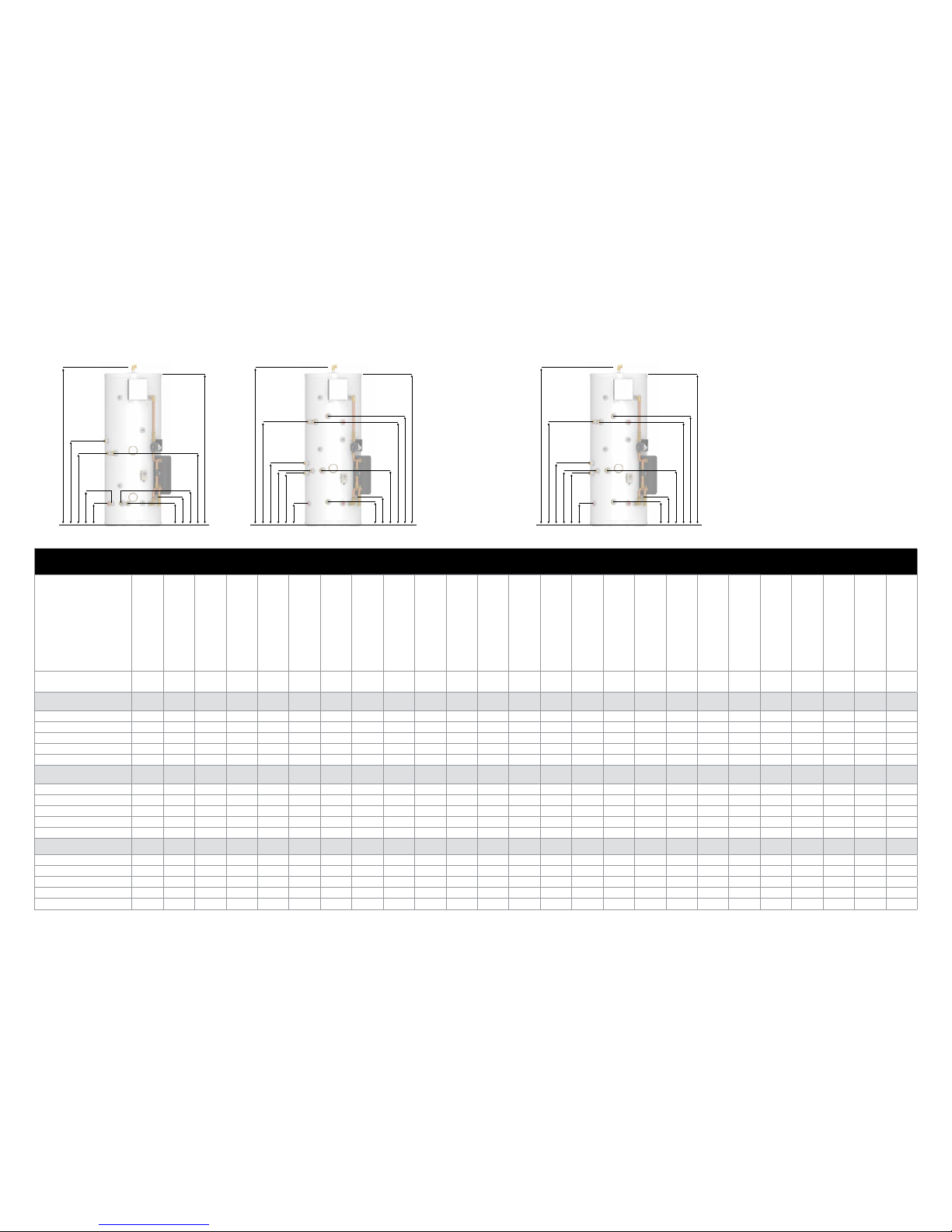

Torrent Stainless SP SOL

G

D

H

J

K

C

B

E

I

F

A

N

Torrent Stainless OV SOL

G

M

H

J

K

L

B

E

I

F

A

N

Torrent Stainless OV

L

G

J

K

B

H

I

M

A

N

NOTES

1. The diagrams shown are generic. For exact

product specication refer to the table eg.

the number of immersion heaters varies

depending on model.

2. All connections are within 120˚.

3. Thedomestichotwatervolumeshownis

basedon oneheatup, andthe storeis

fully charged to 75°C.

4.

Domestichot water volume shown in

solar cylinders will reduce where the solar

input reduced or unavailable (potentially up

to 40%).

If more detail is required, please contact our

technical desk on 01253 474584

Page 6 Page 7

Torrent Stainless OV

Available Components and Tappings

1. Open Vent - 22mm Compression

2. Cold Feed (F&E tank) - 22mm Compression

3. On-Peak Immersion Heater - 1 3/4” Female

4. O-Peak Immersion Heater - 1 3/4” Female

5. Control Thermostat Pocket - 22mm Dual

Pocket

6. Control Thermostat - 22mm Dual Pocket

7. Control Thermostat Pocket- 22mm Dual

Pocket

8. Central Heating Flow - 22mm Compression

9. Central Heating Return - 22mm Compression

10. Cylinder Drain - 1/2” Female

11. PHE Flow - 22mm Plain Pipe

12. PHE Return - 22mm Plain Pipe

13. DHW Store Sensor - 10mm Single Pocket

14. Open Vented Flow - 22mm Compression

15. Open Vented Return - 22mm Compression

16. Solid Fuel Flow - 28mm Compression

17. Solid Fuel Return - 28mm Compression

18. Solid Fuel Overheat Stat - 22mm Dual Pocket

19. Solid Fuel Control Thermostat - 22mm Dual

Pocket

20. Hot water supply - 22mm Compression

21. Mains cold water supply - 22mm Comp.

Torrent Stainless OV SOL

Available Components and Tappings

1. Open Vent - 22mm Compression

2. Cold Feed (F&E tank) - 22mm Compression

3. Immersion Heater - 1 3/4” Female

4. Solar Coil Flow - 22mm Compression

5. Solar Coil Return - 22mm Compression

6. Control Thermostat Pocket - 22mm Dual

Pocket

7. Control Thermostat - 22mm Dual Pocket

8. Solar Sensor Pocket - 22mm Dual Pocket

9. Solar Sensor Pocket - 22mm Dual Pocket

10. Central Heating Flow - 22mm Compression

11. Central Heating Return - 22mm Compression

12. Cylinder Drain - 1/2” Female

13. PHE Flow - 22mm Plain Pipe

14. PHE Return - 22mm Plain Pipe

15. DHW Store Sensor - 10mm Single Pocket

16. Open Vented Flow - 22mm Compression

17. Open Vented Return - 22mm Compression

18. Solid Fuel Flow - 28mm Compression

19. Solid Fuel Return - 28mm Compression

20. Solid Fuel Overheat Stat - 22mm Dual Pocket

21. Solid Fuel Control Thermostat - 22mm Dual

Pocket

22. Hot water supply - 22mm Compression

23. Mains cold water supply - 22mm Comp.

Torrent Stainless SP SOL

Available Components and Tappings

1. Open Vent - 22mm Compression

2. Cold Feed (F&E tank) - 22mm Compression

3. Immersion Heater - 1 3/4” Female

4. Solar Coil Flow - 22mm Compression

5. Solar Coil Return - 22mm Compression

6. Control Thermostat Pocket - 22mm Dual

Pocket

7. Control Thermostat - 22mm Dual Pocket

8. Solar Sensor Pocket - 22mm Dual Pocket

9. Solar Sensor Pocket - 22mm Dual Pocket

10. Central Heating Flow - 22mm Compression

11. Central Heating Return - 22mm Compression

12. Cylinder Drain - 1/2” Female

13. PHE Flow - 22mm Plain Pipe

14. PHE Return - 22mm Plain Pipe

15. DHW Store Sensor - 10mm Single Pocket

16. Primary Coil Flow - 22mm Compression

17. Primary Coil Return - 22mm Compression

18. Solid Fuel Flow - 28mm Compression

19. Solid Fuel Return - 28mm Compression

20. Solid Fuel Overheat Stat - 22mm Dual

Pocket

21. Solid Fuel Control Thermostat - 22mm Dual

Pocket

22. Hot water supply - 22mm Compression

23. Mains cold water supply - 22mm Comp.

10

8

16

14

18

19

4

7 1215179

1

2

3

5

11

13

6

20

21

4

12

20

21

11

10

18

19

17

9 145

1

2

3

6

8

16

13

15

7

22

23

4

12

20

21

11

10

18

19

17

9 145

1

2

3

6

8

16

13

15

7

22

23

DESIGN DESIGN

SYSTEM DESIGN SYSTEM DESIGN

The cold feed to the cylinder is taken from the F&E tank (connection 2 shown

above). The mains cold water supply is connected to the pipework leading to the

plate heat exchanger (connection 23 shown above).

The feed and expansion tank for the Torrent Stainless must be sized to take the

water expansion of the whole system (i.e. solid fuel boiler, open vented boiler and

auxiliary heating).

Specify optional components at time of order with any of the Torrent Stainless

models

A. Header tank

B. Ball valve

C. Float

D. Overheat thermostat

E. Scale inhibitor (tted to the control panel)

See page 39 for part reference codes.

2

23

Page 8 Page 9

Model Selection

The suggested model sizes shown in the tables

opposite are based on a typical daily hot water

usage and on the assumptions that the heating

system is correctly sized and that the thermal

store is fully charged to at least 75°C by the main

heat source.

When selecting a solar model, it is important

to check the dedicated solar volume (shown in

table on pages 4-5) complies with the Building

Regulations ADL1 Domestic Building Services

Compliance Guide.

The suggested model sizes are based on

typical hot water usage. For high specication

dwellings an increase of one model size should

be considered.

Please see page 18 for pipework conguration

where Torrent Stainless SP SOL is selected and

both coils are to be used with a boiler.

General Design Considerations

As a general rule, the cupboard footprint needs

to be a minimum of 150mm wider, 80mm

deeper and 80mm taller than the unit selected.

to accommodate the plate heat exchanger and

associated pipework.

The base chosen for the Torrent Stainless should

be level and capable of supporting the weight of

the unit when full of water as shown in General

Data.

General Restrictions

a. Bidets incorporating an ascending spray

inlet, or using a exible hose or arranged

with a spray or jet are a uid category 5 risk.

These should not be used with the Torrent

Stainless when it is also serving other outlets.

b. Torrent Stainless should not be used where

steam is the primary heating medium.

The gures above are to be used where there is only a sealed system boiler connected,

and both boiler and solar coils are connected to the boiler.

Torrent Stainless OV Model Selection Guide

Max hot water demand Bedrooms Model

1 bathroom 1 - 2 TST150OV

1 bathroom + en-suite shower 2 - 3 TST180OV

2 bathrooms + en-suite shower 2 - 3 TST210OV

2 bathrooms + 2 en-suite showers 3 - 4 TST250OV

3 bathrooms + 2 en-suite showers 4 - 5 TST350OV

Torrent Stainless SP SOL Model Selection Guide (Boiler Only)

Max hot water demand Bedrooms Model

1 bathroom 1 - 2 TST150SPSOL

1 bathroom + en-suite shower 2 - 3 TST180SPSOL

2 bathrooms + en-suite shower 2 - 3 TST210SPSOL

2 bathrooms + 2 en-suite showers 3 - 4 TST250SPSOL

3 bathrooms + 2 en-suite showers 4 - 5 TST350SPSOL

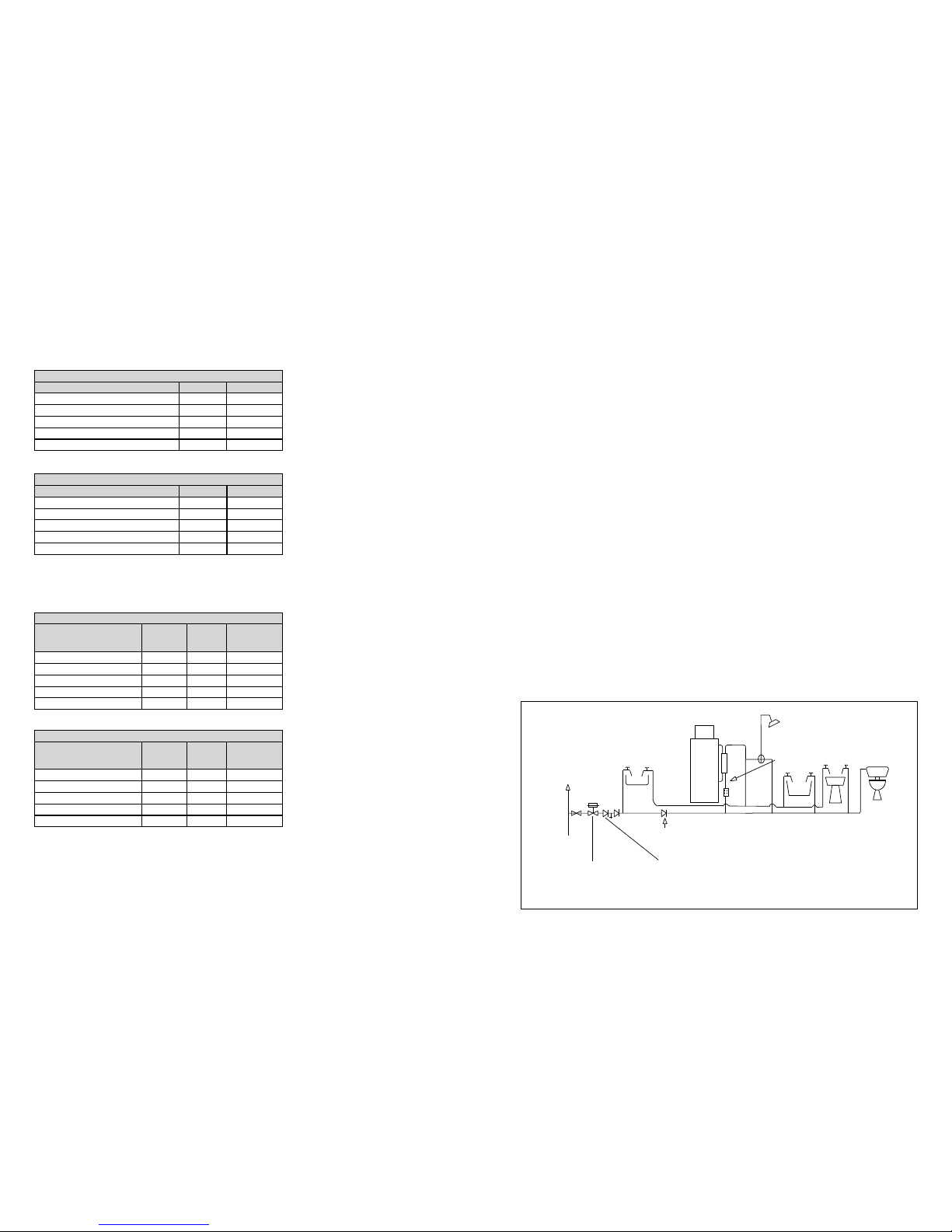

Mains Water Supply

A typical arrangement of the hot and cold water system is shown below. The PHE on all

Torrent Stainless models are designed to be fed directly from the mains water supply

and they full the requirements of WRAS Schedule 2 (paragraph 15.2), and therefore

do not require a check valve to be tted to the cold water supply pipe.

The performance of the Torrent Stainless is directly related to the cold water supply

pressure and volume to the dwelling. This must be capable of providing for all those

services which could be required simultaneously and the maximum demand should

be calculated for sizing the distribution network.

As a general guideline, although a 15mm external service may be sucient for the

smaller dwelling with one bathroom, a 22mm service is preferred (25mm MDPE) and

should be the minimum for larger dwellings.

The Torrent Stainless will operate at dynamic pressure as low as 1.5 bar (at the

appliance) which must be available when the local demand is at its maximum, but

the preferred range is between 2 and 3.0 bar.

If the incoming static mains pressure exceeds 5.0 bar at any point in the 24 hour cycle,

then a pressure limiting valve set at 3.0 bar should be tted downstream of the stop

tap where the cold supply enters the dwelling.

If a water meter is tted in the service pipe, it should have nominal rating to match

the anticipated maximum simultaneous hot and coldwater demand, calculated in

accordance with BS EN 8558:2011. This could be up to 50 l/min in some properties.

The sanitary water equipment used in the system should be suitable for a working

pressure of 10 bar and the units must be fitted strictly in accordance with the

requirements of the Water Supply (Water Fittings) Regulations 1999.

Torrent Stainless SP SOL Model Selection Guide

Max hot water demand

Max solar

collector

area (m

2

)

Bedrooms Mo del

1 bathroom 2.22 1 - 2 TST150SPSOL

1 bathroom 2.54 2 - 3 TST180SPSOL

1 bathroom + en-suite shower 2.91 2 - 3 TST210SPSOL

2 bathrooms + en-suite shower 3.88 3 - 4 TST250SPSOL

2 bathrooms + 2 en-suite showers 4.64 4 - 5 TST350SPSOL

Torrent Stainless OV SOL Model Selection Guide

Max hot water demand

Max solar

collector

area (m

2

)

Bedrooms Mo del

1 bathroom 2.22 1 - 2 TST150OVSOL

1 bathroom 2.54 2 - 3 TST180OVSOL

1 bathroom + en-suite shower 2.91 2 - 3 TST210OVSOL

2 bathrooms + en-suite shower 3.88 3 - 4 TST250OVSOL

2 bathrooms + 2 en-suite showers 4.64 4 - 5 TST350OVSOL

INSTALLATION INSTALLATION

INSTALLATION INSTALLATION

TYPICAL HOT AND COLD DISTRIBUTION

Check valve NOT REQUIRED unless

supply pipe services more than one dwelling

Check valve NOT REQUIRED unless scale inhibitor is a chemical type.

In any event, do not fit a check valve down stream of this point (see 5.1.9)

Pressure limiting valve

(Not required unless mains pressure is greater than 5 bar)

Supply

pipe

Second dwelling

Sink

Scale inhibitor

(where necessary)

Bath

H.B.

W.C.

BS1212

Ballvalve

Hot and Cold Distribution Pipe Arrangement - All Models

Taps and Shower Fittings

Aerated taps are recommended to prevent

splashing.

All types of shower mixing valves can be used

as long as both hot and cold supplies are mains

fed. However all mains pressure systems are

subject to dynamic changes particularly when

other hot and cold taps/showers are opened

and closed, which will cause changes in the

water temperature at the mixed water outlet

such as showers. For this reason and because

thermostatic showers are now no more

expensive than manual showers, we strongly

recommend thermostatic showers with Torrent

Stainless. The shower head provided must also

be suitable for mains pressure supplies.

The hot water supply to a shower-mixing valve

should be fed where practical directly from the

Torrent Stainless or be the rst draw-o point

on the hot circuit. The cold water supply to a

shower-mixing valve should where practical

be fed directly from the rising mains via an

independent branch.

The shower must incorporate or be tted with the

necessary check valves to prevent back-syphonage

protection in accordance with Water Regulations.

Bidets in domestic locations of the over rim

style, that have no ascending spray or spray

and/or exible hose may be supplied by the

Torrent Stainless, providing that a type AUK2

air gap is maintained between the outlet of the

water tting and the spill over level of the bidet.

Page 10 Page 11

from any heating from the hot water pipework

to ensure that the water remains cold and of

drinking water quality.

A pipe thermostat is incorporated in the circuitry

which cuts the supply to the pump when

the water in the return pipe reaches the set

temperature. Ensure the hot water temperature

is set correctly to avoid excessively hot water at

the outlets and long pump run times.

Secondary circulation pipework must be

insulated to prevent energy loss in both heated

and unheated areas.

Immersion Heaters

These are 3kW 230V AC heaters and incorporate

a thermostat. The thermostat incorporates a

manual reset. They have incalloy elements

to prolong their life expectancy in aggressive

water conditions. We recommend best practice

of connecting the wiring to the immersion heater

is using crimp connections.

Utilising O Peak Electricity

Where it is intended that units are fitted to

unrestricted offpeak circuits, then suitable

controllers such as the Horstmann o peak electric

time controller will be required. External wiring

to the immersion heaters must be in accordance

with the relevant IEE Wiring Regulations and the

circuit must be protected by a suitable 16A MCB

fuse and a 20A double pole isolating switch.

Safety

The immersion heaters must be earthed and they

must be isolated from the mains before the cover

is removed on every occasion. Replacement

immersion heaters should be obtained from

Gledhill Building Products Limited.

Important

The unit must not be powered up unless the

thermal store has been lled with water, the

pump has been bled and water is conrmed

to be present in the pipework above the pump.

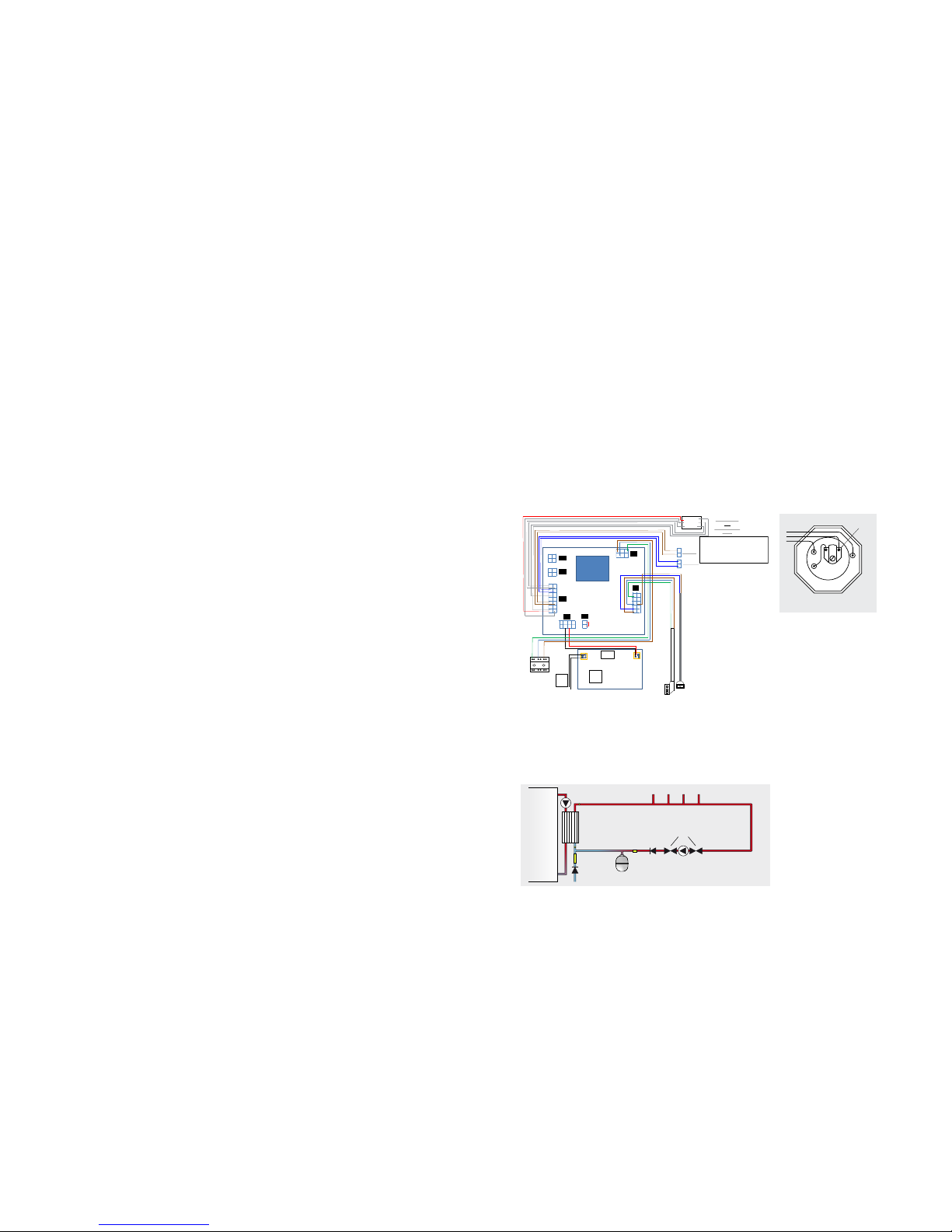

Wiring The Control Panel

The control panel requires a separate 3 amp fuse spur double pole to ensure safe

isolation. The cable/ex from the fuse spur to the control panel must be a minimum

of 0.75mm2 C.S.A. and be heat resistant. The cable should be clipped to prevent

accidental snagging.

The control panel front cover is secured by 4 screws. Remove these and lift o the

front cover to expose the power terminals. These are found at the bottom left of the

control panel. Prepare the cable end and feed it through the cable gland.

Use a screwdriver to press the neutral cross down on the WAGO connector. This opens

the clamp and the neutral wire can be fed into the connector. Remove the screwdriver

and test the wire is securely t. Repeat with the PE and live cables. Tighten the cable

gland and check for security. Perform the necessary safety checks and ret the front

panel.

Secondary Hot Water Circulation

If the length of the hot water draw-o pipework is excessive and the delivery time

will be more than 60 seconds before hot water is available at the tap, you may wish to

consider using trace heating to the hot water pipework such as the Raychem HWAT

system. Also a conventional pumped secondary circulation system (shown below)

can be used with any model of the Torrent Stainless.

It is important that the cold water pipework is adequately separated and protected

Pipe Layout

In all mains pressure installations it is important to remember that the incoming cold

supply must be shared between all terminal ttings. It is important that a 22mm supply

is brought to the appliance and a 22mm take-o is continued at least to the bath.

If there are two baths, 28mm pipework should be considered. One metre of smaller

diameter pipework, or ow restrictors, should be provided on the nal connection to

all outlets so as to balance the water available. In any event the distribution pipework

should generally be in accordance with BS EN 806:3.

Plastic Pipework

All the recommendations with regard to the heating systems in this manual are

generally based on BS/EN Standards copper pipework and ttings. However plastic

pipework system can be used in place of copper as long as:-

a. The chosen system is recommended for use in domestic heating systems by the

manufacturers and it is installed fully in accordance with their recommendations.

b. The design criterion of the plastic system is at least equivalent to the use of BS/EN

Standards copper pipework and ttings.

c. Barrier pipework for these systems is recommended.

Ball Valve and Overow

The feed and expansion tank can be lled manually if required e.g. using a hose pipe

tted with a double check valve.

In this situation an overow pipe can still be tted if required to ensure that if a leak occurs

on the plate heat exchanger it can be discharged safely to the outside of the building.

Note: If a ball valve is tted, then a warning/overow pipe must always be tted.

The feed and expansion tank (provided by the installer) must be sized correctly to

enable the expansion of the entire system volume. This will include the central heating,

store, solid fuel and boiler circuit volumes.

See page 12 for guidance sizing the feed and expansion tank.

Water Treatment

In all Torrent Stainless models, the primary (i.e. non-potable) water is stored and the

domestic hot water is heated instantaneously by means of heat exchangers. Therefore

treating the primary water will not contaminate the domestic hot water supply.

Although the Torrent Stainless primary store has no special water treatment

requirements, the radiators and other parts of the circuit will require the application of

a scale and corrosion inhibitor. The only Fernox products that arent compatible are the

Flux and to a lesser extent some of our Acidic Cleaning products, namely DS40. This is

because the Chloride in Flux can cause pitting in even Duplex Steel. The volumes and

concentration should be calculated in accordance with the manufacturers instructions

and when calculating the system volume (i.e. the water content), the volume of the

Torrent Stainless should be taken into account.

Use In Hard Water Areas And Scale Protection

The patented design of the domestic hot water plate heat exchanger is such that

the turbulence through the plates slows down the formation of scale in moderate

hard water conditions. However, the requirements set out in the ‘Domestic Building

Services Compliance Guide’ and the Building Regulations approved documents L1A

and L1B regarding scale protection should be complied with.

INSTALLATION INSTALLATION

INSTALLATION INSTALLATION

Thermostat

Immersion Heater Wiring

E

L

N

These requirements state that; “where the mains

water hardness exceeds 200ppm provision should

be made to treat the feed water to the water

heaters and the hot water circuit of combination

boilers to reduce the rate of accumulation of

scale”. To comply with this requirement: -

a. The hardness of the mains water should be

checked by the installer and if necessary a

suitable in-line scale inhibitor device should

specied for hardness levels between 200

and 300ppm (mg/l).

b. Where the hardness level is 300ppm (mg/l) and

above, the optional phosphate type inhibitor

should be specied and tted at a suitable

point in the cold water supply to the appliance.

It is important that where the supply to the

Torrent Stainless is in 22mm the in-line scale

inhibitor is also 22mm. In practice servicing is not

normally required but in hard water areas, the

requirements can be considered similar to those

needed for instantaneous or ‘combi’ appliances.

The installation of scale inhibitor should be in

accordance with the manufacturers instructions

and Water Byelaws.

London Loop

As the thermal store gets hot the water will

expand and the water level in the F&E tank will

rise, as will the level of water in the vent pipe.

Hot water will also rise to the top of the cylinder.

When the water at the base of the cylinder

becomes hotter it may run out the cold feed

connection pipe. If the cold feed pipe then runs

vertically it works like a chimney with the hot

water rising to the top in the same way hot air

does from a re. If this section is not insulated

then it will lose heat and waste energy.

If, however, the cold feed is formed into a sheppard’s

crook or london loop it will form a thermal trap. A

thermal trap works by ensuring that cold water is

held below hot water. Because hot water always

rises it will not be able to move down and around

the loop/crook and therefore will not rise up the

cold feed pipe work. This will reduce heat loss and

thereby prevent energy waste.

The minimum depth of the U trap is calculated by

multiplying the pipe diameter by 8. For example;

• Using 22mm pipework will require a

minimum of 176mm

22mm pipework is highly recommended to

ensure that the London loop does not air lock

during the commissioning process. It also

enables a faster installation of the product due

to the increased lling rate.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1 2 3

4

1 2 3

4

1

2 3 4

5 6 7 8

1

2

1

2

3

4

5

6

7

8

9

1

10

2

3

4

5

6

J18

J20

J19

J3

J7

J8

J1

TS sensor

GND GND

IN OUT

T1 T2

1

2

CW sensor

1

2

Combined flow

and

HW temperature

sensor

L - Brown

PR61

E – G/Y

N - Blue

PWM -

PWM

+

SPARE

Fuse

Dip

Switch

1 2 3 4

To

DHW

pipe

All the these sensor inputs carry a

Voltage of 5V.

The max cable length is 1 meter.

The sensors connected to the control

Should be free from the appliance earth

Torrent Stainless

Inline lter &

ow regulator

Single check

valve

Single

check

valve

Pump isolation

valves

Cold water inlet

Plate heat exchanger

Hot water outlets

Pipework length and

diameter to suit

property demands

Pipework length and

diameter to suit

recirculation ow rate

approx 1-2 l/min

Cold water sensor

Control

stat

Flow sensor

Potable water

expansion vessel

Secondary

circulation

pump

Page 12 Page 13

INSTALLATION INSTALLATION

INSTALLATION TORRENT STAINLESS OV

Boiler Size

The minimum total boiler power required is the

sum of the power required for space heating

which should be calculated in accordance with

BS EN 12831 and/or the CIBSE guide and the

power required for producing hot water which

can be read from the table to the left.

The coil performance gures are based on a

boiler ow temperature of 82°C and ow rate

of 0.25 litres per second. The boiler needs to be

able to modulate down to the 7°C temperature

dierence setting to maximise eciency.

Please see page 18 for pipework conguration

where Torrent Stainless SP SOL is selected and

both coils are to be used with a boiler.

Expansion Vessel For Sealed Heating System

The table opposite can be used for sizing the

heating system expansion vessel. The water

content of the Torrent Stainless primary heat

exchanger is listed in specication tables on

pages 4 and 5 and a gure of 4.5 l/kW of installed

radiator capacity can be used for a preliminary

assessment of the water content of the heating

system.

The expansion vessel requirements shown in

the table are based on a maximum boiler ow

temperature of 93°C. The expansion vessel

must be suitable to accommodate the change

in volume of water in the heating system when

heated from 10°C to 100°C, with a maximum

operating temperature of 99°C.

Feed And Expansion Tank For Open Vented

Heating System

The table opposite shows the recommended

size and number of F & E tanks required for an

open vented hot water only system, which can

be supplied as an optional extra.

Expansion for the open vented heating systems

connected to the store must be added to this

gure. So, as a preliminary assessment of the

water content of the attached open vented

systems, a gure of 4.5 l/kW of radiator output

can be used. For example, 20 kW radiator output

would have a system volume of 90 litres, and

potential expansion of this would be 3.6 litres,

and 10 kW would be 45 litres total volume and

1.8 litres for expansion.

Please refer to page 19 for further information

regarding F&E tanks when using solid fuel input.

Allowance for domestic hot water for sizing the boiler

Torrent Stainless model

Allowance for domestic hot water heating (kW)

Full divert mode Flow share mode

150 0 2

180 0 3

210 0 4

250 0 5

350 0 7

Open vented heating systems

The open vented primary system is lled via the

feed and expansion (F&E) tank tted with the

Torrent Stainless OV model and therefore it is

important that the F&E tank is positioned at least

250mm above the highest point in the system.

Please check the F&E tank is big enough for the

whole system expansion. Also ensure that the

height of the F&E tank is sucient to meet the

manufacturer’s requirements for the minimum

head required for the boiler and the system

pump(s).

The Torrent Stainless OV models can be installed

using both ‘Y’ Plan and ‘S’ Plan heating system

controls. These models can also be installed

without either 3-port or 2-port valves using

a separate central heating pump as shown in

diagrams on this page. In this case no bypass valve

is required unless TRV’s are used on all radiators.

If the ow and return pipes between the boiler

and the Torrent Stainless OV thermal store are

dipped as illustrated in the schematic shown

opposite, then the boiler selected must be

suitable for a sealed heating system i.e. it must be

tted with an overheat thermostat. Automatic

air vents should be tted at appropriate places

to vent the system and a pressure relief valve

should also be tted close to the boiler.

Any boiler can be used with the Torrent Stainless

OV and the Torrent Stainless SOL provided the

ow pipe from the boiler to the Torrent Stainless

is continuously rising. The ow pipe between

the boiler and the Torrent Stainless thermal

store is part of the open vent and therefore it

must not be tted with any isolating valve, nonreturn valve or any other component which can

obstruct the ow.

The minimum size of flow and return pipe

between the boiler and the Torrent Stainless

should be 22mm copper or equivalent. In any

case it should be sized to suit the installed boiler

capacity, available pump head and the circuit

resistance.

The water level must be set correctly by adjusting

the ball valve in the F&E tank. The overow/

warning pipe, should be no less than the 20mm

internal diameter and have a continuous fall.

The overow/warning pipe should be tted to

discharge clear of the building and be sited so

that any overow can be easily observed. The

warning pipe should be installed in either high

temperature uPVC or copper and should not

have any other connections to it.

If the boiler does not incorporate an overheat

thermostat, then one should be tted to the store.

Sealed Heating System Expansion Vessel Requirements

Safety valve setting 3.0

Vessel charge

pressure (bar)

0.5 1.0 1.5

Initial system charge

pressure (bar)

0.5 1.0 1.5 2.0 1.0 1.5 2.0 1.5 2.0

Total System

Volume (litres)

Expansion Vessel Volume (litres)

25 2.1 3.5 6.5 13.7 2.7 4.7 10.3 3.9 8.3

50 4.2 7.0 12.9 27.5 5.4 9.5 20.6 7.8 16.5

75 6.3 10.5 19.4 41.3 8.2 14.2 30.9 11.7 24.8

100 8.4 14.0 25.9 55.1 10.9 19.0 41.2 15.6 33.1

125 10.4 17.5 32.4 68.3 13.6 23.7 51.5 19.5 41.3

150 12.5 21.0 38.8 82.6 16.3 28.5 61.8 23.4 49.6

Thermal Store

Minimum Number of Feed and Expansion Tanks

(16 litre model inc. 10 litre expansion)

TST150, TST180, TST210 1

TST250, TST350 2

Expansion of all connected open vented systems must be added to the store

expansion when choosing the size of the feed and expansion tank.

The weight of each tank when full is 27kg (not including pipework and valves).

2 Pump System

Max.

height

10m

Min. 250mm

2 Pump System With Dipped Boiler Flow and Return Pipe

Must comply

with boiler

manufacturer

instructions

Min. 250mm

Coil Performance

Nominal volume litres 150 180 210 250 350

(SP SOL) Primary coil only

Coil power at 7°C temp.

dierence

kW 3 4 6 6 7

Average power kW 9 13 15 16 18

Coil power at 47°C temp.

dierence

kW 23 26 33 32 36

Volume of water heated litres 84 102 130 144 230

Recovery time min 22 18 22 20 28

(SP SOL) Combined coils coil

Coil power at 7°C temp.

dierence

[kW] 4 4 6 4 3

Average power [kW] 12 16 18 16 15

Coil power at 47°C temp.

dierence

[kW] 25 36 39 36 41

Volume of water heated litres 150 180 210 250 350

Recovery time [min] 25 28 30 34 42

coil coguration series parallel parallel parallel parallel

Page 14 Page 15

INSTALLATION INSTALLATION

TORRENT STAINLESS OV TORRENT STAINLESS SP SOL

Sealed heating system

All Torrent Stainless SP models are suitable for

sealed heating systems up to 3.5 bar maximum

operating pressure, however the normal

pressure relief valve setting is 3.0 bar. The typical

layout of the open vented ‘Y Plan’ and ‘S Plan’ for

the indirect Torrent Stainless models is shown

in the diagrams on this page.

A boiler used in a sealed heating system must

be suitable for this application i.e. it must be

fitted with an overheat cut-out thermostat

and can be located above the thermal store

F&E tank, as can the central heating system

connected to the boiler.

It is recommended that the F&E tank (for the

thermal store) is tted at a high level in the same

cupboard as the Torrent Stainless. However

it can be fitted remotely up to 10m above

the base of the Torrent Stainless, and sized to

accomodate the expansion of the cylinder and

any attached central heating and solid fuel

volumes.

The F&E tank overow/warning pipe should

be installed in a material suitable for a heating

system feed and expansion tank.

There shall be no permanent connection to

the mains water supply for lling the heating

system even through a non-return valve

without the approval of the Local Water

Authority. An approved lling loop is required

for lling the heating system, which should be

disconnected after commissioning the system.

The filling loop should be located adjacent

to the boiler along with a suitable expansion

vessel, pressure gauge, pressure relief valve and

discharge arrangement.

The minimum system pressure should not be

less than the static head plus 0.5 bar i.e. the

height of the highest point in the system above

the expansion vessel plus a margin of 0.5 bar.

A solid fuel boiler is also able to be connected

to the Torrent Stainless SP, please refer to page

19 for further information.

Where a sealed primary coil is used, the thermal

store is a hot water only thermal store. If too

much heat is taken out of store, then hot water

performance will be limited. The hot water priority

should be protected by use of an appropriate

thermostat. Heating can be taken from the SP

thermal store to provide auxilliary heating to

towel radiators, which are low output. It is not

suitable for full central heating systems, this

should be taken directly from the boiler.

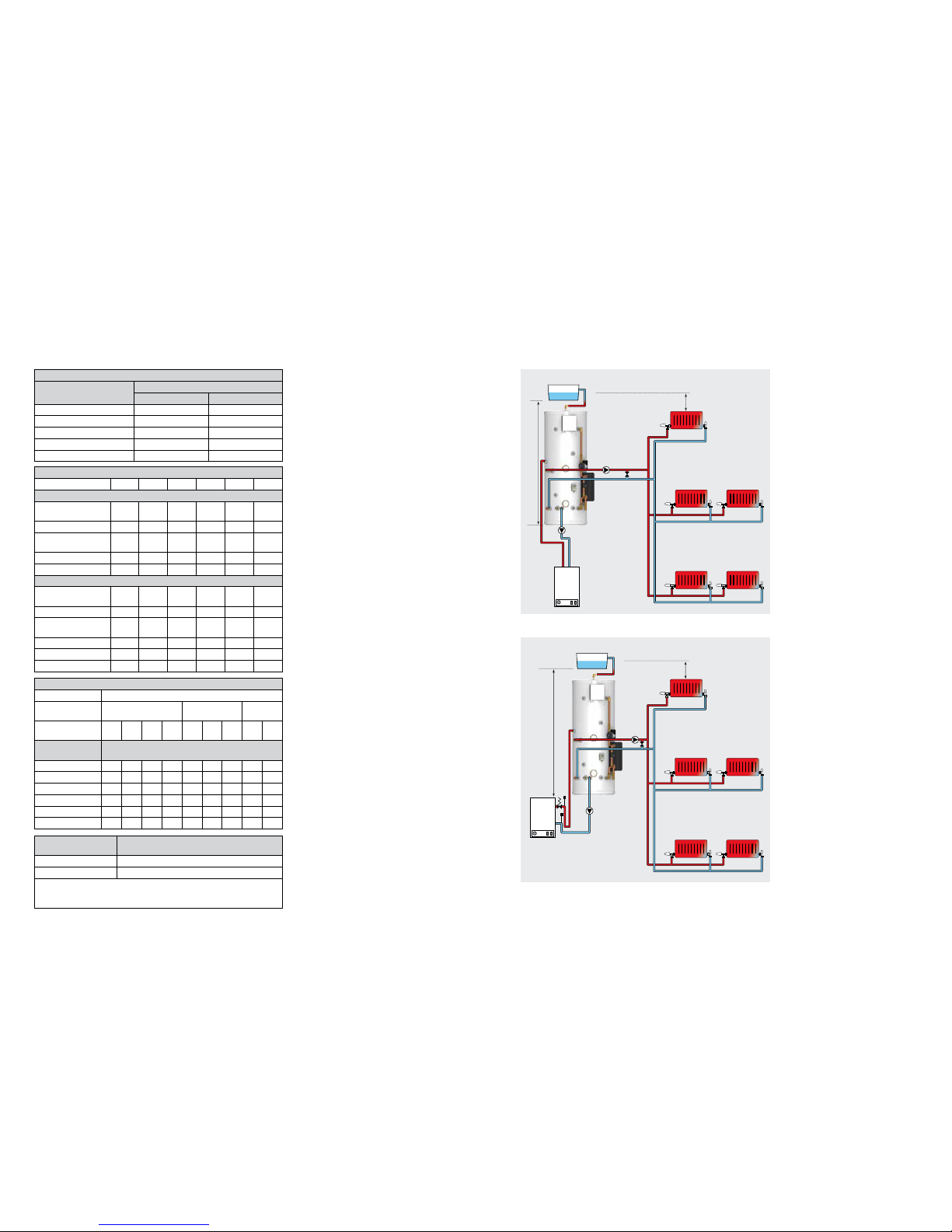

The two diagrams shown on this page show

how an ‘S’ plan and ‘Y’ plan may be used in

conjunction with the Torrent Stainless OV, with

another space heating supply being taken

direct from the store. The type of space heating

used is the installer’s choice and the diagrams

only show possible layouts.

The auto bypass is positioned here to allow

minimum flow rates through the boiler as

TRVs close; and to allow for boilers with pump

overrun.

Off delay timers may be considered for use

in situations where the boiler pump overrun

is controlled by sensing a temperature drop

before shutting off. This type of boiler may

cause the pump to run on for some minutes

while the temperature slowly drops, but the

store temperature may also drop causing the

boiler to re again; the boiler then short cycles.

If an o delay timer is used it allows the pump

to overrun for about a minute to remove any

excess heat; then shuts o the pump, but it does

not remove so much of the heat from the store

that it causes the boiler to re again.

A solid fuel boiler is also able to be connected

to the Torrent Stainless OV, please refer to page

19 for further information.

S Plan Sealed Main Heating System

Max.

height

10m

Sealed

system kit

Auxiliary

heating

Min.

250mm

S Plan Open Vented Heating System

Max.

height

10m

Min. 250mm

Auxiliary

central heating

Y Plan Open Vented Heating System

Max.

height

10m

Min. 250mm

Auxiliary

central heating

Y Plan Sealed Main Heating System

Max.

height

10m

Sealed

system kit

Auxiliary

heating

Min.

250mm

Loading...

Loading...