gledhill Stainless Lite Direct 90-300 litres, Stainless Lite Solar Direct 180-300 litres Design, Installation & Servicing Instructions

Design, Installation

& Servicing Instructions

Models

Stainless Lite Direct 90-300 litres

Stainless Lite Indirect 90-300 litres

Stainless Lite Solar Direct 180-300 litres

Stainless Lite Solar Indirect 180-300 litres

An unvented hot water storage unit complying

with the requirements of Building Regulations

Approved Document G3 and manufactured in

accordance with BS EN 12897, the specifi cation

for the unvented water storage vessels.

Page 2

Section Page

DESIGN

Description 3

Technical Information 6

System Design 8

INSTALLATION

Installation 10

Commissioning 19

USER INSTRUCTIONS 20

SERVICING AND MAINTENANCE

Servicing and Maintenance 21

Fault Finding 22

Short Parts List 25

ADDENDIX

Addendix A 26

Addendix B 27

Service Record 28

Notes 29

Terms & Conditions 30

ISSUE 9: 05-09

These instructions should be read in conjunction with the installation/servicing

instructions issued by the manufacturer of the heat source being used.

Any installation must be in accordance with the relevant requirements of the Gas

Safety Regulations, Building Regulations, I.E.E. Wiring Regulations and the W ater F itting

Regulations (England and Wales) or Water Byelaws (Scotland). It should be read in

accordance with the relevant recommendations of the following:

BS 6798; BS 5549; BS 5546;

BS 5440:1; BS 5440:2; CP 331:3

BS 6700: BS 5258 and BS 7593: 1992

Stainless Lite is covered by Section G3 of the Building Regulations (England and

Wales) Technical Standard P3 (Scotland) and Building Regulation P5 (Northern Ireland.

Compliance can be achieved via a Competent Person Self Certifi cation Scheme or

notifi caton of installation to the Local Authority Building Control Department.

It must be installed by a competent person as defi ned by the relevant regulations.

Manufacturers notes must NOT be taken as over-riding statutory obligations.

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge unless

they have been given supervision or instruction concerning use of the appliance by

a person responsible for their safety. Children should be supervised at all times to

ensure they do not play with the appliance.

This information is provided to assist generally in the selection of equipment.

Responsibility for selection and specifi cation of our equipment must however remain that

of our customer and any experts or consultants concerned with the installation(s).

PLEASE NOTE: THAT WE DO NOT THEREFORE ACCEPT ANY RESPONSIBILITY FOR

MATTERS OF DESIGN SELECTION OR SPECIFICATION, FOR THE EFFECTIVENESS

OF AN INSTALLATION OR SYSTEM CONTAINING ONE OF OUR PRODUCTS UNLESS

SPECIFICALLY REQUESTED TO DO SO IN WRITING.

All goods are sold subject to our Conditions of Sale which are set out at the rear of this

specifi cation. In the interest of continuously improving the Stainless Lite range , Gledhill

Building Products Limited reserve the right to modify the product without notice, and

in these circumstances this booklet, which is accurate at the time of printing, should

be disregarded. An updated set of Instructions will be produced and supplied with

new appliances and will be made available for other appliances on request.

A KIWA PRODUCT APPROVED TO C OMPL Y WITH ALL RELEV ANT PART S OF THE BUILDING

REGULATIONS AND WATER SUPPLY (WATER FITTINGS) REGULATIONS.

Stainless Lite IS PRODUCED UNDER AN ISO 9001:2008 QUALITY MANAGEMENT SYSTEM

APPROVED BY BSI.

As part of the industry wide “benchmark” initiative all Gledhill Stainless Lite appliances no w

include a Benchmark Installation, C ommissioning and Service Record Log Book. Please r ead

carefully and complete all sections relevant to the appliance installation. Carrying out the

work required and completing the Log Book will satisfy the requirements of the Building

Regulations for commissioning as set out in the Domestic Heating Compliance Guide. The

details of the Log Book will be required in the event of any warranty work being required .

There is also a section to be completed after each regular service visit. The completed

Log Book and these instructions should be left with the cylinder.

Page 3

DESCRIPTION

DESIGN

Maintenance

Modifications should not be made to this

product. Replacement parts, including

immersion heaters, should be purchased from

Gledhill Building Products Limited, or agents

approved by them. Unvent ed hot water storage

vessels need regular routine checks, and these

are detailed below. It is for this reason that this

manual must always be left with the Stainless

Lite.

It is essential that these checks be carried out

at the time of boiler maintenance by a qualifi ed

installer:

1. Manually open the relief valves in turn, and

check that water is discharged from the

valves and runs freely through the tundish

and out at the discharge point. Ensure that

the valves re-seat satisfactorily. (Note - the

water may be very hot).

2. It is important to check that the discharge

pipework is carrying the water away

adequately. Check for blockages etc. if it is

not.

3. Turn the mains water off and remove and

clean the strainer element in the Pressure

Reducing Valve.

4. Check the charge pr essure in the expansion

vessel and repressurise if required

5. Re-fi ll the system and ensure that all relief

valves have re-seated.

6. The Benchmark log book supplied should

be updated at each service.

7. Check the water pressure downstream of

the combination valve is 2.25 bar in static

condition.

8. Check and if necessar y, descale the heat

exchanger in hard water areas ie. above

200ppm (mg/l).

Note:

The cylinder is factory fi tted with a temperature

& pressure relief valve that must not be used for

any other purpose or removed.

The cylinder is factory fi tted with immersion

heaters with thermal cut outs. Immersions

without thermal cut outs must not be fi tted.

Manufacturer: Gledhill Building Products Ltd

Maximum inlet pressure to

Pressure Reducing Valve 12 bar

Operating pressure (PRV setting) 2.2 bar

Expansion Relief Valve setting 4.5 bar

Maximum primary working pressure 3.5 bar

Opening pressure of T & P Relief Valve 6 bar

Opening temperature of T & P Relief Valve 95°C

Energy cut-out thermostat setting 80°C

Immersion heater: Rating: 3kW, 240V AC

All cylinders are manufactured in accordance with the requirements of BS EN 12897

The tundish must be positioned so that it is visible to the occupant and is away from

electrical devices.

Components supplied with Stainless Lite:

• Cold water inlet combination valve

• Expansion relief/PRV combination valve

• Temperature and pressure relief valve

• Control thermostat

• Energy cut-out thermostat

• Energy cut-out motorised valve (indirects only)

• Tundish

• 3Kw Immersion heater

• Expansion vessel/mounting bracket/fl exible hose

• Technical/user product literature

(Note: Two immersion heaters are supplied with the direct Stainless Lite)

In any situation where the volume of heated pipew ork (eg. secondary circulation

pipes or manifold pipework for multiple units) exceeds 10 litres, then an

additional expansion vessel must be fi tted to accommodate the extra expansion

volume.

Handling Before Installation

Stainless Lite must be handled with care and stored the correct way up in a dry place.

Any manual handling/lifting operations will need to comply with the requirements of

the Manual Handling Operations Regulations issued by the H.S.E. The appliance can

be moved using a sack truck on the rear face although care should be taken and the

route should be even. In apartment buildings containing a number of storeys we would

recommend that the appliances are moved vertically in a mechanical lift. If it is proposed

to use a crane, expert advice should be obtained regarding the need for slings , lifting

beams etc.

A specifi c manual handling assessment is shown in Appendix B at the rear of this

manual.

Page 4

DESIGN

DESCRIPTION

Stainless Lite is a range of unvented hot water

storage cylinders, manufactured in the latest

high quality duplex stainless steel. They are

designed to provide mains pressure hot water

and are supplied as a package which complies

with Section G3 of the Building Regulations.

The appliance is extremely well insulated using

high density HCFC free foam insulation with an

ozone depleting potential (ODP) of zero and a

global warming potential (GWP) of 1. It is fi tted

with all necessary safety devices and supplied

with all the necessary control devices to make

installation on site as easy as possible.

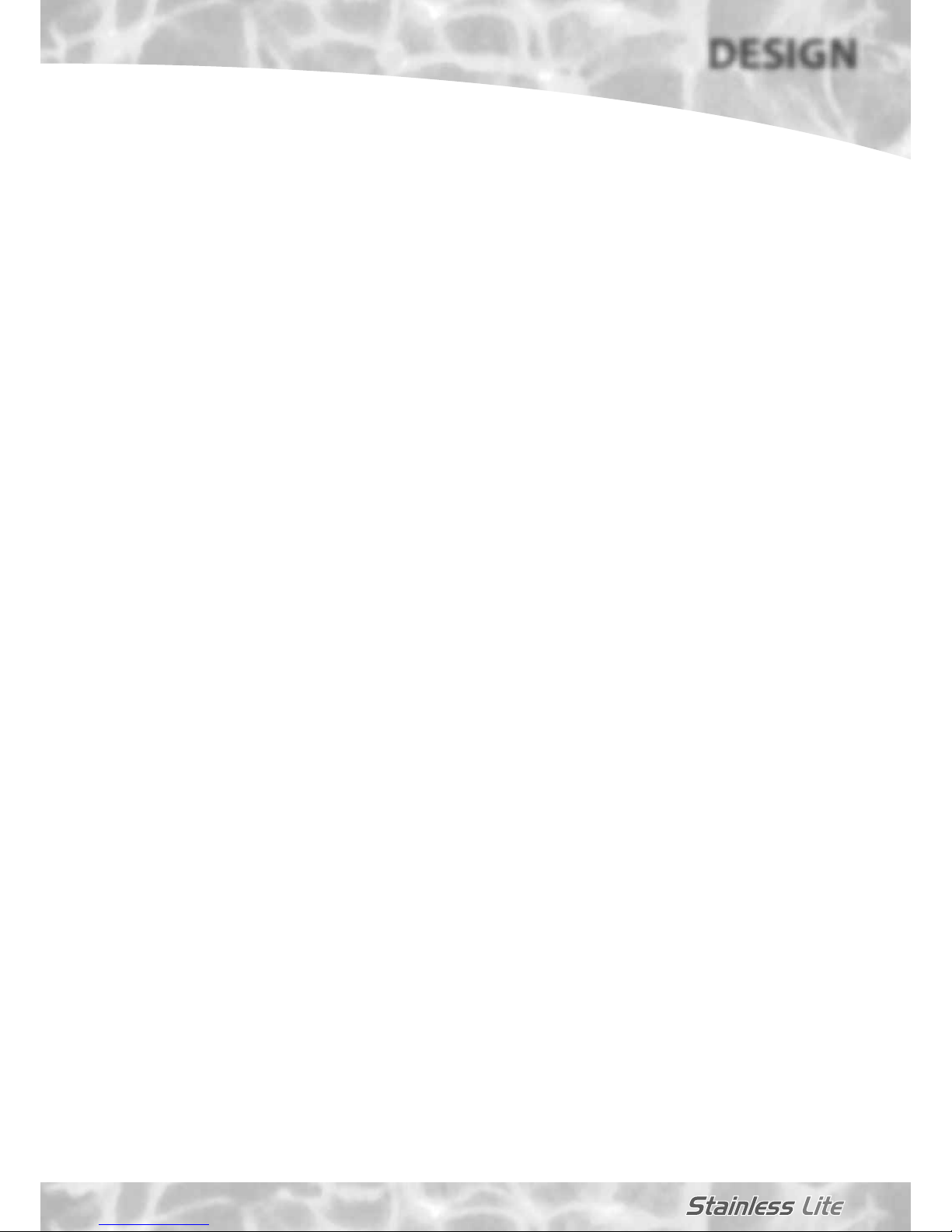

Stainless Lite is available in four basic

variants:

1. Stainless Lite Direct - For providing hot

water heated by electricity (Figure 1).

2. Stainless Lite Indirect - For use with gas

or oil boilers (Figure 2). Unvented cylinders

must not be used with solid fuel boilers or

steam as the energy source.

3. Stainless Lite Direct Solar - For providing

hot water by solar gains and electricity.

(Figure 3).

4. Stainless Lite Indirect Solar - For providing

hot water by solar gains and gas or oil boilers

(Figure 4). Unvented cylinders must not be

used with solid fuel boilers or steam as the

energy source.

Stainless Lite Direct

Stainless Lite direct is an electrically heated,

unvented hot water storage cylinder designed

primarily for use with off peak electrical

supplies.

It is supplied fi tted with two 3kW immersion

heaters which are BEAB approved for safety as

recommended by the Electricity Council.

Stainless Lite direct models are listed in

Table 1 on Page 6 & 7.

Stainless Lite Indirect

Stainless Lite indirect is an unvented hot

water storage cylinder and is provided with a

high effi ciency internal primary coil which is

designed for use with a gas or oil boiler and

is suitable for both open vented and sealed

pumped primary systems.

When used with a sealed heating system the

boiler must incorporate its own energy cut-out

overheat thermostat.

Stainless Lite indirect models are listed in

Table 1 on Page 6 & 7.

Stainless Lite

DIRECT

Stainless Lite

INDIRECT

Figure 1 Figure 2

Pipework is not supplied by manufacturer,

but to be supplied and fi tted by installer.

Page 5

DESCRIPTION

DESIGN

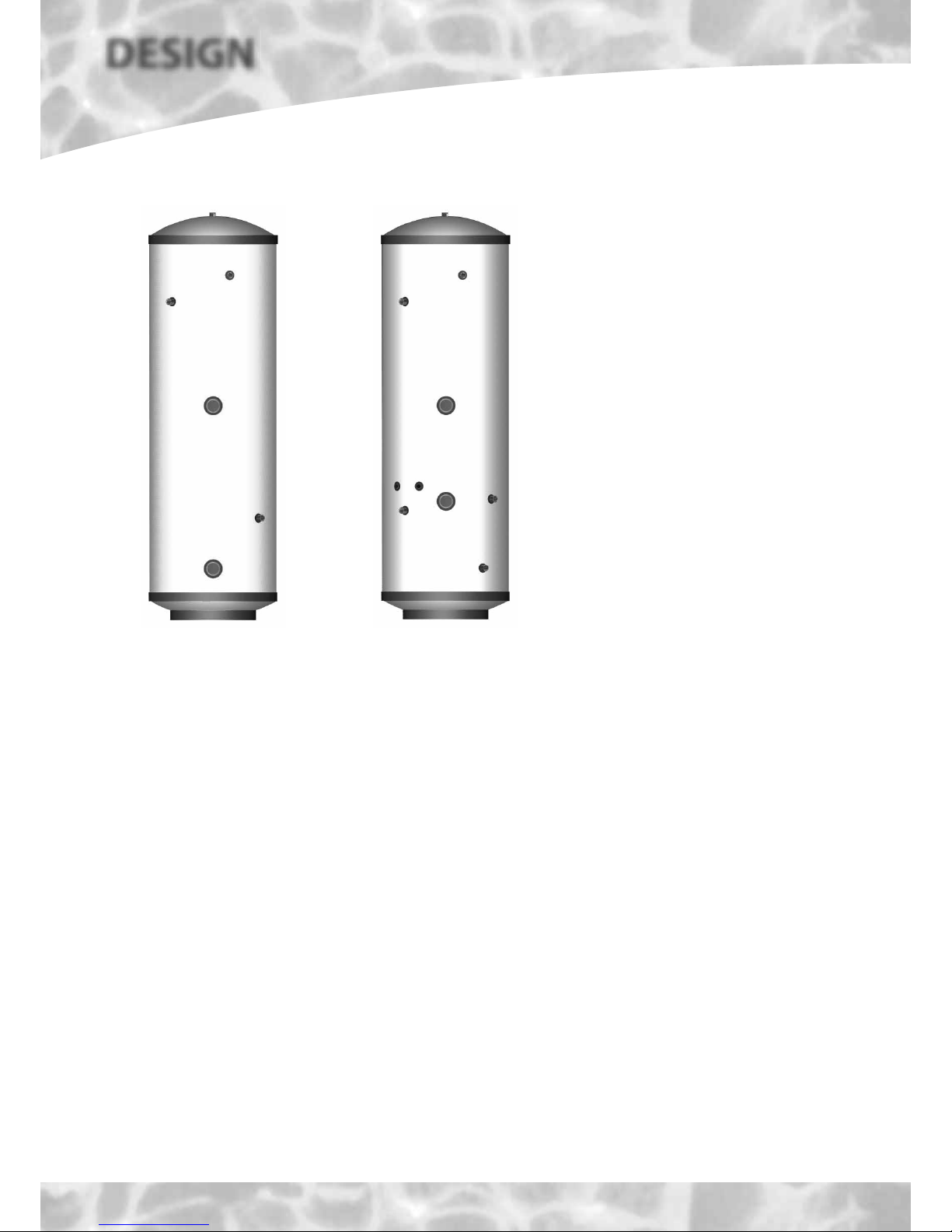

Stainless Lite

DIRECT SOLAR

Stainless Lite

INDIRECT SOLAR

Figure 3 Figure 4

Pipework is not supplied by manufacturer,

but to be supplied and fi tted by installer.

Stainless Lite Direct Solar

Stainless Lite direct is an electrically heated,

unvented hot water storage cylinder designed

primarily for use with off peak electrical

supplies.

It is supplied fi tted with two 3kW immersion

heaters which are BEAB approved for safety as

recommended by the Electricity Council.

A high effi ciency coil is positioned in the lower

part of the Stainless Lite vessel to ensure

maximum benefi t of solar gain energy.

Stainless Lite direct models are listed in

Table 1 on Page 6 & 7.

Stainless Lite Indirect Solar

Stainless Lite indirect is an unvented hot

water storage cylinder and is provided with a

high effi ciency internal primary coil which is

designed for use with a gas or oil boiler and

is suitable for both open vented and sealed

pumped primary systems.

When used with a sealed heating system the

boiler must incorporate its own energy cut-out

overheat thermostat.

A high effi ciency second solar coil is positioned

below the primary coil to ensure maximum

benefi t of solar gain energy.

Stainless Lite indirect models are listed in

Table 1 on Page 6 & 7.

Note:

The cold supply elbow c/w drain tapping

must be fi tted as shown in fi gs 1, 2, 3 and 4.

A fl exible hose can then be connected to the

drain tapping and, providing the hose runs

below the lowest level of the cylinder, then

all the water contents can be drained out by

syphonic action.

Page 6

DESIGN

TECHNICAL INFORMATION

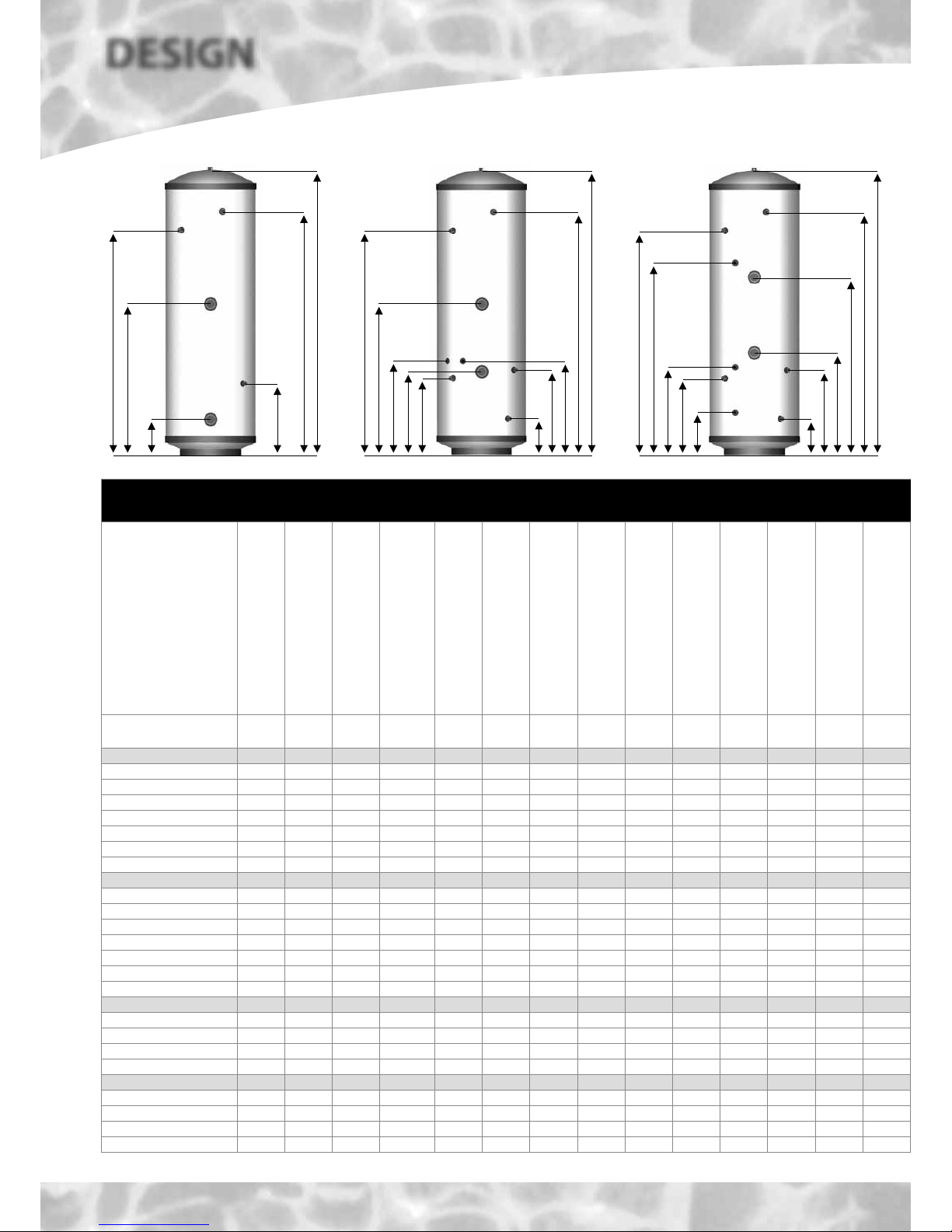

Table 1

Model

Weight - Empty

Weight - Full

Capacity (Total Volume)

Pressure Regulator 2.25bar inlet

group c/w balance cold supply,

expansion vessel connection and

expansion valve set at 4.5 bar

Exp

ansion Vessel size.

Pre-charged to 2.25bar

Overall Height

Overall Diameter

Pressure & Temperature

Relief Valve 6bar 90°C

22mm Secondary

Return Tapping

On Peak 1¾” Incalloy

Immersion 3kW

Cold Feed 22mm

Compression Connection

Lower 1¾” Incalloy

Immersion 3kW

Volume of On Peak Water

Heated

Dual Control & Overheat Stat

kg kg Litres bar Litres A=mm mm B=mm C=mm D=mm E=mm F=mm Litres G=mm

Direct

D90 13 103 90 2.25 12 732 550 490 n/a n/a 367 223 n/a n/a

D120 18 138 120 2.25 12 920 550 678 n/a 487 367 223 55 n/a

D150 22 172 150 2.25 18 1107 550 865 n/a 587 442 223 70 n/a

D180 24 204 180 2.25 18 1295 550 1053 n/a 686 442 223 85 n/a

D210 28 238 210 2.25 24 1483 550 1241 1127 786 442 223 90 n/a

D250 32 282 250 2.25 24 1733 550 1491 1377 927 522 223 125 n/a

D300 37 337 300 2.25 35 2020 550 1777 1577 1077 522 223 155 n/a

Indirect

IND90 19 109 90 2.25 12 732 550 490 n/a n/a 367 352 n/a 367

IND120 22 142 120 2.25 12 920 550 678 n/a n/a 367 352 n/a 367

IND150 26 176 150 2.25 18 1107 550 865 n/a n/a 442 392 n/a 407

IND180 28 208 180 2.25 18 1295 550 1053 n/a n/a 442 432 n/a 447

IND210 33 243 210 2.25 24 1483 550 1241 1127 n/a 442 432 n/a 482

IND250 38 278 250 2.25 24 1733 550 1491 1377 927 522 512 125 577

IND300 44 344 300 2.25 35 2020 550 1777 1577 1077 522 512 155 677

Solar Direct

SOL180d 26 206 180 2.25 18 1295 550 1053 n/a 746 437 482 75 n/a

SOL210d 30 240 210 2.25 24 1483 550 1241 1127 908 437 544 80 n/a

SOL250d 34 284 250 2.25 24 1733 550 1491 1377 1092 522 629 100 n/a

SOL300d 39 339 300 2.25 35 2020 550 1777 1577 1287 522 724 115 n/a

Solar Indirect

SOL180i 30 210 180 2.25 18 1295 550 1053 n/a n/a 437 717 80 732

SOL210i 35 245 210 2.25 24 1483 550 1241 1127 n/a 437 822 95 837

SOL250i 40 290 250 2.25 24 1733 550 1491 1377 n/a 522 947 115 962

SOL300i 46 346 300 2.25 35 2020 550 1777 1577 n/a 522 1042 140 1092

A

C

Direct

D

F

E

B

A

Solar Direct

C

N

M

L

P

E

K

B

D

F

A

C

Indirect

D

H

F

E

I

J

B

G

Page 7

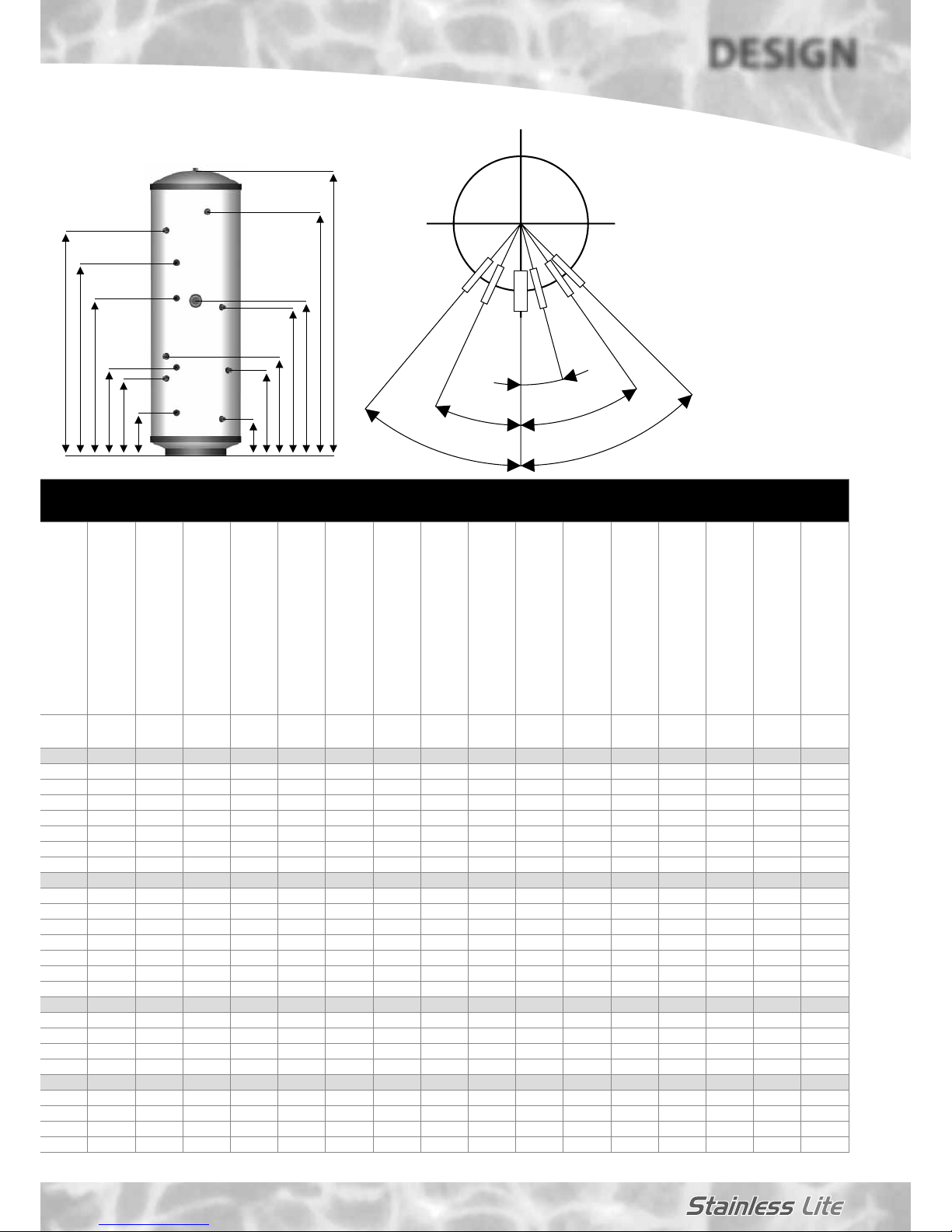

TECHNICAL INFORMATION

DESIGN

Extra Stat Pocket

For Boiler Use If Required

22mm Primary Return

Compression Connection

22mm Primary Flow

Compression Connection

22mm Solar Return

Compression Connection

22mm Solar Flow

Compression Connection

Dual Control/Overheat Stat

& Solar Control

Thermostat Pocket

Solar Pocket

Solar Pocket

kW Rating of Primary Coil

Surface Area of

Primary Heater Coil

Pressure Loss Across

Primary Heater Coil

Surface Area of

Solar Heater Coil

Pressure Loss Across Solar

Heater Coil

Heat Up Time from 15°C to 60°C

(applies to Primary Heat Source only)

Recovery Time after 70% Draw Off

(applies to Primary Heat Source only)

Standing Losses kWhr/24hr

Dedicated Solar Volume

H=mm I=mm J=mm K=mm L=mm M=mm N=mm P=mm kW m

2

bar m

2

bar min min kWh Litres

n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a 90 58 0.80 n/a

n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a 119 90 1.00 n/a

n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a 150 121 1.20 n/a

n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a 179 157 1.40 n/a

n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a 209 192 1.60 n/a

n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a 249 224 1.75 n/a

n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a 299 263 1.93 n/a

367 223 312 n/a n/a n/a n/a n/a 16.5 0.59 0.165 n/a n/a 21 16 0.80 n/a

367 223 312 n/a n/a n/a n/a n/a 18 0.59 0.165 n/a n/a 27 19 1.00 n/a

407 223 352 n/a n/a n/a n/a n/a 18.5 0.68 0.191 n/a n/a 28 19 1.20 n/a

447 223 392 n/a n/a n/a n/a n/a 19 0.78 0.216 n/a n/a 33 21 1.40 n/a

482 223 392 n/a n/a n/a n/a n/a 20.5 0.78 0.216 n/a n/a 41 26 1.60 n/a

577 223 472 n/a n/a n/a n/a n/a 21.5 0.97 0.241 n/a n/a 44 30 1.75 n/a

677 223 472 n/a n/a n/a n/a n/a 25 0.97 0.241 n/a n/a 48 32 1.93 n/a

n/a n/a n/a 223 352 419 882 203 n/a n/a n/a 0.680 0.191 n/a 90 1.40 60

n/a n/a n/a 223 352 419 1000 203 n/a n/a n/a 0.680 0.191 n/a 115 1.60 70

n/a n/a n/a 223 472 539 1180 262 n/a n/a n/a 0.968 0.241 n/a 139 1.75 84

n/a n/a n/a 223 472 539 1367 262 n/a n/a n/a 0.968 0.241 n/a 187 1.93 100

n/a 457 677 223 352 419 882 203 18 0.59 0.165 0.680 0.191 28 16 1.40 60

n/a 522 782 223 352 419 1000 203 18.5 0.68 0.191 0.680 0.191 35 16 1.60 70

n/a 607 907 223 472 539 1180 262 19 0.78 0.216 0.968 0.241 38 19 1.75 84

n/a 702 1002 223 472 539 1367 262 20.5 0.78 0.216 0.968 0.241 41 20 1.93 100

F

Solar Indirect

N

G

P

I

E

K

J

A

B

M

L

C

4

0

,0

0

º

4

5

,

00º

3

5

,

0

0º

2

5,

0

0

º

1

5

,

0

0

º

NOTES

1. Not all models - see table 1.

2. Recovery times based on Primary

Coil/I.H. duty (ie. assumes the boiler

output is adequate).

3. All connections are supplied with

compression fittings for direct

connection to copper pipework.

Page 8

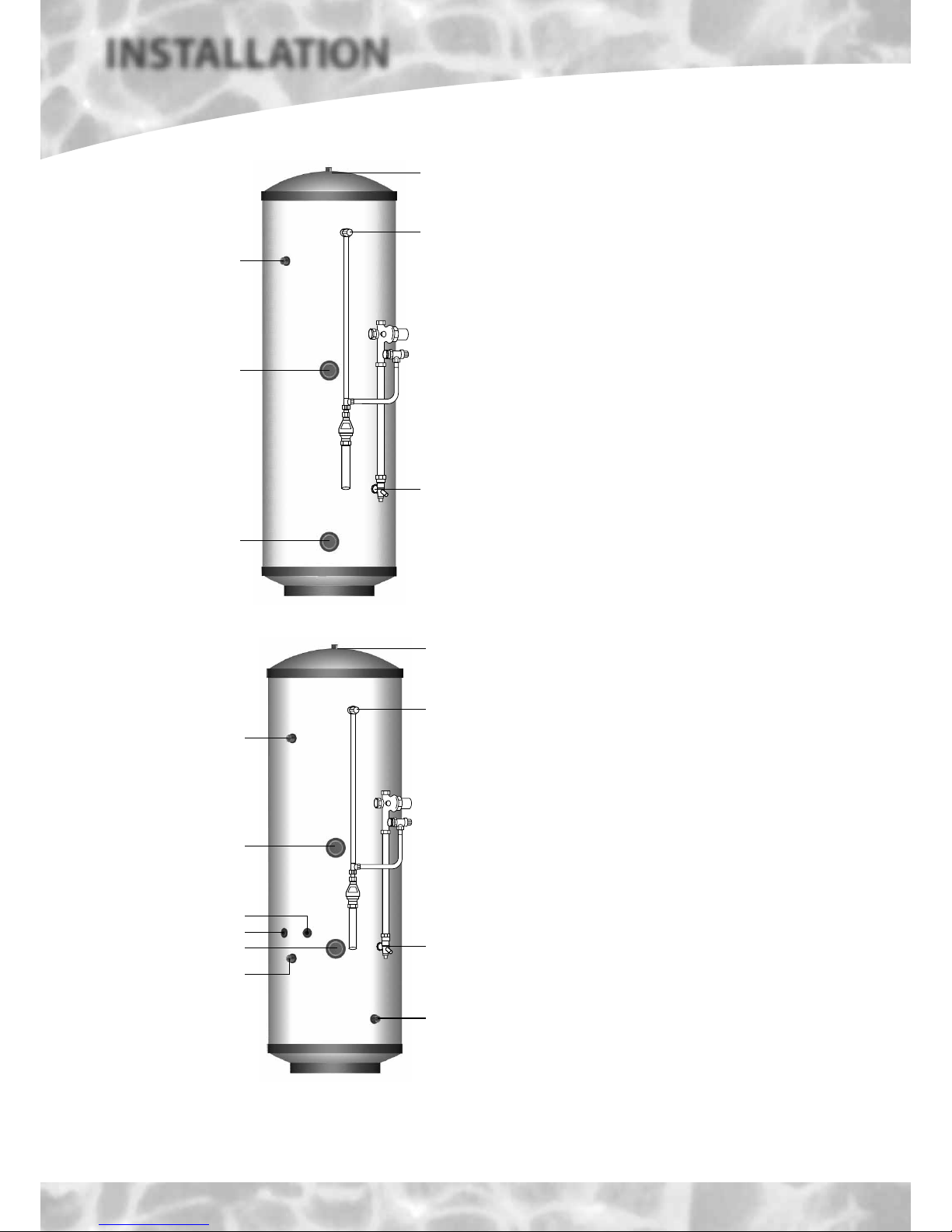

INSTALLATION

INSTALLATION

Stainless Lite Direct

Basic Appliance

1. Hot water draw off (22mm) compression

2. Temperature & pressure relief v alve 90°/6 bar

3. Hot water secondary return 22mm capped

(not fi tted to smaller sizes, see table 1)

4. Immersion heater 1¾” BSP 3kW

(normally on-peak)

5. 22mm cold supply compression

6. Immersion heater 1¾” BSP 3kW

(normally off-peak)

Component kit supplied separately

A. Combination inlet group incorporating

pressure reducing valve, strainer, check

valve, balance cold take off point, expansion

relief valve and expansion vessel connection

points.

B. Portable expansion vessels c/w fl exible hose

and wall bracket

C. Tundish

Stainless Lite Indirect

Basic Appliance

1. Hot water draw off (22mm) compression

2. Temperature & pressure relief v alve 90°/6 bar

3. Hot water secondary return 22mm capped

(not fi tted to smaller sizes, see table 1)

4. Immersion heater 1¾” BSP 3kW

5. 22mm cold supply compression

6. Immersion heater 1¾” BSP 3kW

7. Dual control/overheat stat pocket (22mm)

8. Boiler control sensor pocket (spare)

9. Primary return (22mm)

10. Primary fl ow (22mm))

Component kit supplied separately

A. Combination inlet group incorporating

pressure reducing valve, strainer, check

valve, balance cold take off point, expansion

relief valve and expansion vessel connection

points.

B. Potable expansion vessels c/w fl exible hose

and wall bracket

C. Tundish

D. Dual control thermostat and combined

overheat thermostat

E. Two port (22mm) zone valve for

primary circuit

F. Wiring junction box for primary system

1

2

5

3

4

6

1

2

3

4

7

5

6

9

8

10

Typical arrangement of component kit shown fi tted to the appliance for clarity

Pipework to be supplied and fi tted by installer.

Page 9

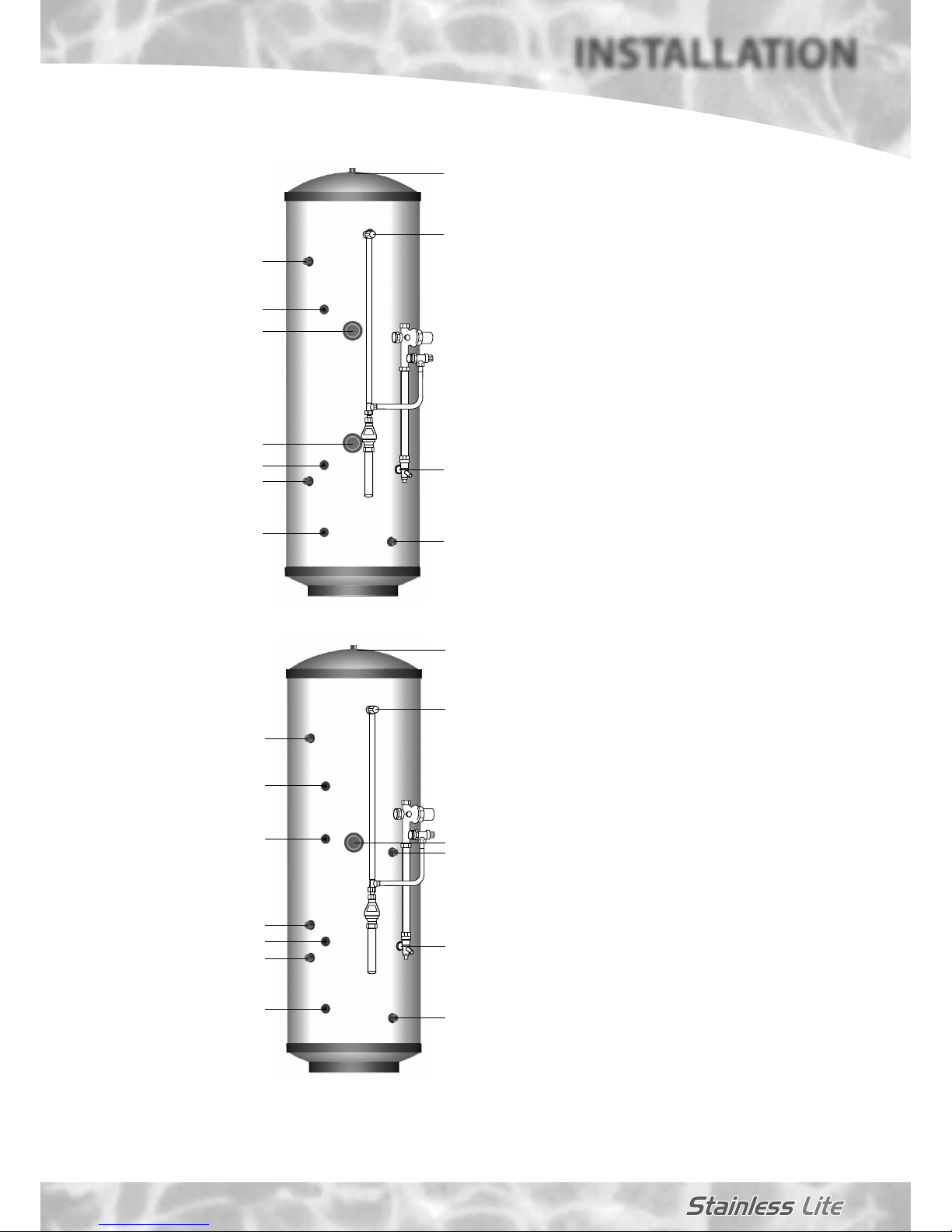

INSTALLATION

INSTALLATION

7

9

3

11

6

12

12

1

2

8

4

5

10

Stainless Lite Direct Solar

Basic Appliance

1. Hot water draw off (22mm) compression

2. Temperature & pressure relief v alve 90°/6 bar

3. Hot water secondary return 22mm capped

(not fi tted to smaller sizes, see table 1)

4. Immersion heater 1¾” BSP 3kW

(normally on-peak)

5. 22mm cold supply

6. Immersion heater 1¾” BSP 3kW

(normally off-peak)

7. Dual control/Overheat stat & solar

thermostat pocket

8. Solar coil return to panel collector (22mm)

compression

9.

Solar coil fl ow from panel (22mm) compression

10. Solar thermostat pocket

Component kit supplied separately

A.

Combination inlet group incorporating pressure

reducing valve, strainer, check valve, balance

cold take off point, expansion relief valve and

expansion vessel connection points.

B. Portable expansion vessels c/w fl exible hose

and wall bracket

C. Tundish

D. Dual control thermostat and combined

overheat thermostat

Stainless Lite Indirect Solar

Basic Appliance

1. Hot water draw off (22mm) compression

2. Temperature & pressure relief v alve 90°/6 bar

3. Hot water secondary return 22mm capped

(not fi tted to smaller sizes, see table 1)

4. Immersion heater 1¾” BSP 3kW

5. 22mm cold supply

6. Thermostat pocket (22mm)

7. Primary return (22mm)

8. Primary fl ow (22mm)

9. Dual control/Overheat stat & solar

thermostat pocket

10. Solar coil return to panel collector (22mm)

compression

11.

Solar coil fl ow from panel (22mm) compression

12. Solar thermostat pocket

Component kit supplied separately

A.

Combination inlet group incorporating pressure

reducing valve, strainer, check valve, balance

cold take off point, expansion relief valve and

expansion vessel connection points.

B. Potable expansion vessels c/w fl exible hose

and wall bracket

C. Tundish

D. Dual control thermostat and combined

overheat thermostat (x2)

E. Two port (22mm) zone valve for

primary circuit

F. Wiring junction box for primary system

1

2

5

8

7

6

4

3

9

10

10

Typical arrangement of component kit shown fi tted to the appliance for clarity

Pipework to be supplied and fi tted by installer.

Page 10

INSTALLATION

INSTALLATION

General Design Considerations

The cupboard footprint needs to be at least

650mm square.

The base chosen for the cylinder should be level

and capable of supporting the weight of the unit

when full of water as shown in General Data. The

discharge pipework for the safety valves must hav e

a minimum fall of 1 : 200 from the unit to a safe

discharge point. All exposed pipework should be

insulated and the unit should NOT be fi xed in a

location where the contents could freeze.

The pipe connecting the boiler fl ow to the

appliance must not be less than 22mm copper

or equivalent.

Mains Water Supply

Existing properties with a 15mm supply will be

satisfactory provided the local mains pressure

is good, but should be confined to single

bathroom properties. F or new properties where

simultaneous demand is required to more than

one bathroom or a bathroom and one or more

en-suites, the communication and service pipe

into the dwelling should be a minimum of 22mm

(usually in the form of a 25mm MDPE supply).

The minimum recommended static pressure

to operate a Stainless Lite domestic system is 3

bar. There should be a fl ow of at least 30 litres

per minute or above available into the property .

Normally Stainless Lite provides well in excess

of 40 litres/min in most conditions. Flow rates

for ALL mains pressure systems are subject

to district pressures and system dynamic loss.

Particularly on larger properties with more

than one bathroom, the pipe sizes should be

calculated in accordance with BS6700.

Model Selection

The suggested Direct model sizes, shown

opposite, are based on a typical days hot water

use assuming an Economy 7 tariff is provided.

A reduction of one model size can normally be

made with an Economy 10 tariff.

When using the Direct models for high

specifi cation developments an increase of one

model size should be considered.

Where selecting a solar model, it is important to

check the dedicated solar volume (shown in table

1 on page 7) is suitable for the total fl oor area of

the dwelling to ensure compliance with Building

Regulations. The maximum fl oor area of the dwelling

permitted for the models is shown opposite.

The suggested model sizes are based on

typical hot water usage. For high specifi cation

dwellings an increase of one model size should

be considered.

I.V.

Combination Valve

I.V.

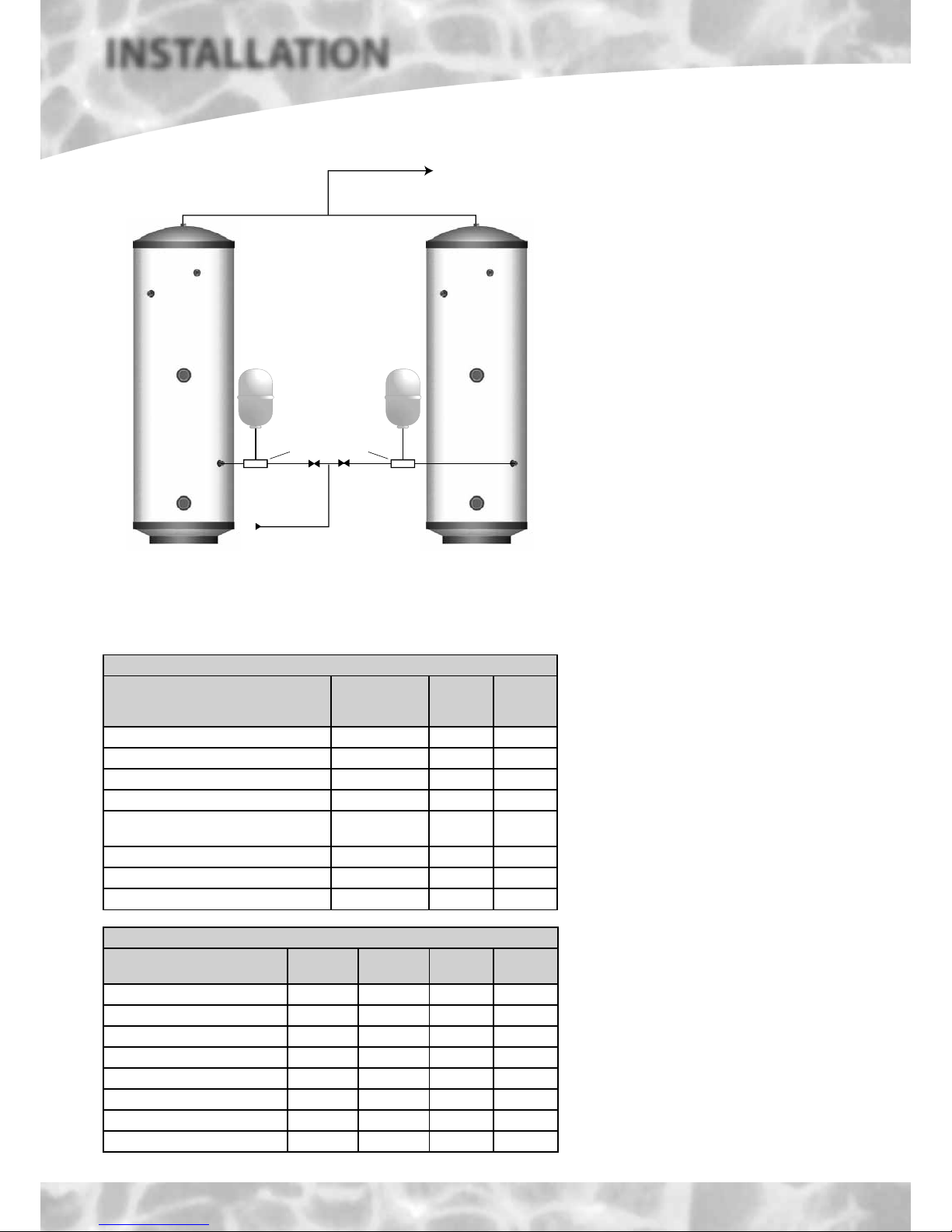

Model Selection Guide

Max hot water demand

Max number

of bed spaces

(Bedrooms)

Indirect

litres

Direct

litres

1 shower room Bedsit (0) 90 120

1 bathroom 2 (2) 120 150

1 bathroom 4 (3) 120 180

1 bathroom + separate shower room 6 (4) 150 210

1 bathroom + 2 separate shower rooms

or 2 bathrooms

7 (5) 180 210

2 bathrooms + separate shower room 7 (5) 210 250

2 bathrooms + 2 separate shower rooms 7 (5) 250 300

3 bathrooms + 2 separate showers rooms 9 (6) 300 -

If two Stainless Lites are coupled together the secondary inlet and outlet pipes must

be balanced. The units must be fi tted on the same level.

Note: No valves must be fi tted between the expansion vessel and the storage cylinder(s).

Solar Model Selection Guide

Max hot water demand

Max fl oor

area (m

2

)

Bedrooms

Indirect

litres

Direct

litres

1 shower room 44 Bedsit - 180

1 bathroom 44 1-3 180 -

1 bathroom 66 1-3 210

1 bathroom + 1 shower room 66 1-3 210 1 bathroom + 1 shower room 84 1-3 - 250

1 bathroom + 2 shower rooms 84 2-4 250 1 bathroom + 2 shower rooms 113 2-4 - 300

2 bathrooms + 1 shower room 113 3-4 300 -

Page 11

INSTALLATION

INSTALLATION

INCOMING COLD SUPPLY

M

DC

DC

DC

TO

EXTERNAL

TAP

SINK

WATER SOFTENER (IF NECESSARY)

WM or DWM

WHB

W.C.

DC

DC

SH

DHW

WHB

WC BATH

SCV

SCV

P&T

ERV/NRV

PRV

DCV

Note:

Cold supplies to single taps must be

taken from the mains cold water

system.

Cold supplies to mixer taps must be

taken from the balanced cold water

connection on the combination

valve.

General Restrictions

a. The highest hot or cold water draw off point should not exceed 10 metres above

the Pressure Reducing Valve.

b. An ascending spray type bidet or any other appliance with a Class 1 back-syphonage

risk requiring a type A air gap should not be used.

c. Stainless Lit e should not be used wher e steam is the primary heating medium, or

in a situation where maintenance is likely to be neglected.

d. Unvented cylinders are not suitable for use with solid fuel boilers.

e. If the supply to the mixer fi ttings (other than a dual outlet type) is not taken

from the balanced supply the system will become over pressuriz ed and cause

the pressure relief valve to discharge. Over time this could also cause the

premature failure of the appliance itself which will not be covered by the

warranty.

f. In larger properties with a number of bathrooms/en-suites and long pipe runs

we would recommend that the balance cold supply is provided with its own

pressure reducing valve and is not taken from the balanced cold connection on

the combination valve. In this case it will also be nec essary to fi t a small expansion

vessel on the balanced cold water system to accommodate the pressure rise caused

by the increase in temperature of the balanced cold water.

g. Check the performance requirements of the terminal fi ttings with regard to fl ow/

pressure are suitable.

Shower Fittings

Aerated taps are recommended to prevent splashing . Any type of shower mixing valv e

can be used as long as both the hot and cold supplies are mains fed. However, all

mains pressure systems are subject to dynamic changes particularly when other hot

and cold taps/showers are opened and closed, which will cause changes in the water

temperature at mixed water outlets such as showers. For this reason and because

these are now no more expensive than a manual shower we strongly recommend

the use of thermostatic showers with this appliance. These must be used in 3 storey

properties where the impact on pressure/temperature of opening another tap in the

system is greater than normal. The shower head provided must also be suitable for

mains pressure supplies.

Pipe Layout

In all mains pressure installations it is important

to remember that the incoming cold supply

must be shared between all terminal fi ttings. It

is important that a 22mm supply is brought to

the appliance and a 22mm take-off is continued

at least to the bath. If there are two baths, 28mm

pipework should be considered. One metre of

smaller diameter pipework, or fl ow restrictors,

should be provided on the fi nal connection to

all outlets so as to balance the water available.

In any event the distribution pipework should

generally be in accordance with EN806:1.

Plastic Pipework

This appliance is suitable for use with

plastic pipework as long as the material

is recommended for the purpose by the

manufacturer and is installed fully in accordance

with their recommendations.

Secondary Hot Water Circulation

Some models are fi tted with a secondary return

tapping as standard (see table 1 for details).

If fitted, an extra expansion vessel may be

necessary. A non-return v alve MUST be FITTED

near the return connection. No v alve or terminal

fi tting should be installed between the non

return valve and the cylinder. (See schematic

arrangement on page 13.)

Page 12

INSTALLATION

INSTALLATION

15 mm

discharge

pipe

Expansion

relief valve

Typical Discharge Pipe Arrangement

Dotted line showing

alternative route with

single tundish being used

500 mm max.

P & T

Relief

Valve

300 mm

min.

22 mm metal pipe with continuous

fall up to 9m equivalent length (D2).

NOTES:

The discharge will consist of scalding

waterand steam. Asphalt, roofing felt

and non-metallic rainwater goods may

be damaged by such discharges.

It is not acceptable to discharge straight

into a soil pipe.

Discharge below

fixed grating

Fixed Grating

Trapped gully

Pressure & Temperature/expansion Relief

Valve Pipework

The relief valve should be installed to discharge

in accordance with G3 of the Approved

Document of the Building Regulations and

should be piped to where it is visible, but will

not cause danger to persons or damage to

materials.

The following information is taken from

Approved Document G3 of the Building

Regulations and is provided to assist with

the design and installation of the discharge

pipework. However, the information is not

exhaustive and reference should always be

made to Approved Document G3 of the Building

Regulations. The fi nal decision regarding any

arrangements rests with Building Control and

it is recommended that their advice is sought

if you have any concerns regarding this aspect

of the installation.

The two safety valves will only discharge

water under fault conditions. When operating

normally water will not be discharged.

The tundish should be vertical, located in the

same space as the unvented hot water storage

system and be fi tted as close as possible and

within 500mm of the safety device e.g. the

temperature relief valve.

The discharge pipe (D2) from the tundish should

terminate in a safe place where there is no risk

to persons in the vicinity of the discharge, be

of metal and:

a) Be at least one pipe size larger than the

nominal outlet size of the safety device unless

its total equivalent hydraulic resistance

exceeds that of a straight pipe 9m long

i.e. discharge pipes between 9m and 18m

equivalent resistance length should be at

least two sizes larger than the nominal outlet

size of the safety device, between 18 and

27m at least 3 sizes larger, and so on. Bends

must be taken into account in calculating

the fl ow resistance. Refer to the table and

the worked example.

An alternative approach for sizing

discharge pipes would be to follow BS6700

Specifi cation for design installation, testing

and maintenance of services supplying water

for domestic use within buildings and their

curtilages.

b) Have a vertical section of pipe at least

300mm long, below the tundish before any

elbows or bends in the pipe work.

c) Be installed with a continuous fall.

Worked Example

The example below is for G1/2 temperature relief valve with a dischar ge pipe (D2)

having 4 elbows and length of 7m from the tundish to the point of discharge.

From T able 1:

Maximum resistance allowed for a straight length of 22mm copper discharge

pipe (D2) from a G1/2 temperature relief valve is: 9m subtract the resistance for

4 x 22mm elbows at 0.8m each = 3.2m.

Therefore the maximum permitted length equates to: 5.8m.

5.8m is less than the actual length of 7m therefore calculate the next largest size.

Maximum resistance allowed for a straight length of 28mm pipe (D2) from a G1/2

temperature relief valve equates to: 14m.

As the actual length is 7m, a 28mm (D2) copper pipe will be satisfactory.

Table 1: Sizing of copper discharge pipe ‘D2’ for a temperature relief

valve with a G1/2 outlet size (as supplied)

Size of discharge

pipework

Maximum length of

straight pipe

(no bends or elbows)

Deduct the fi gure

below from the

maximum length for

each bend or elbow in

the discharge pipe

22mm Up to 9m 0.8m

28mm Up to 18m 1m

35mm Up to 27m 1.4m

Page 13

INSTALLATION

INSTALLATION

d) It is preferable for the discharge to be visible at both the tundish and the fi nal point

of discharge but where this is not possible or practically diffi cult there should be

clear visibility at one or other of these locations. Examples of acceptable dischar ge

arrangements are:

1. Ideally below the fi xed grating and above the water seal in a trapped gulley.

2. Downward discharges at a low level; i.e. up to 100mm above external surfaces

such as car parks, hard standings, grassed areas etc ar e acceptable providing that

where children play or otherwise come into contact with discharges, a wire cage

or similar guard is positioned to prevent contact whilst maintaining visibility.

3. Discharges at a high level; e.g. int o metal hopper and metal down pipe with the

end of the discharge pipe clearly visible (tundish visible or not) or onto a roof

capable of withstanding high temperature discharges of water and 3m from

any plastic guttering systems that would collect such discharges.

4. Where a single pipe ser ves a number of discharges, such as in blocks of fl ats,

the number served should be limited to not more than 6 systems so that any

installation can be traced reasonably easily. The single common discharge pipe

should be at least one pipe size larger than the largest individual discharge pipe

to be connected. If unvented hot water storage systems are installed where

discharges form safety devices may not be apparent i.e. in dw ellings occupied by

blind, infi rm or disabled people, consideration should be giv en to the installation

of an electronically operated device to warn when discharge takes place.

Safety

The safety devices supplied or fi tted on an Stainless Lite are selected for their suitability

for the temperatures and pressures involv ed. They must not be changed, removed or

by-passed and it is essential that only genuine replacement parts supplied or approved

by Gledhill Building Products Limited are used. This includes the immersion heaters,

which must incorporate an energy cut-out. All parts are available to approv ed installers

from Gledhill Building Products Limited, Sycamore Estate, Squires Gate, Blackpool

(Telephone 01253 474402).

P&T Relief Valve

Tundish

Hot Outlet

To D rain

PRV

ERV

NRV

Stop

Tap

Kitchen

Cold

Tap

Combination

Valve

Balanced

Cold

Outlets

Immersion Heater

Expansion

Vessel

Boiler

Return

Boiler

Flow

2 Port Valve

Secondary

Return Circuit

Schematic Diagram

Non Return

Valve

Pump

Combination Inlet Group

Combines elements 1, 2 and 3 below.

1. Pressure Reducing Valve - This must be fi xed

near the cylinder. The cold water supply to

any mixer taps/showers must be taken from

the cold water tapping of this valve to ensure

balanced hot and cold pressures. This valve

is factory set to ensure the correct operating

pressure for the Stainless Lite.

2. Non Return Valve - This is integral with the

pressure reducing valve to prevent backfl ow

of hot water towards cold water draw off

points.

3. Cold Water Expansion Relief Valv e - T his safety

device is preset at the factory and will relieve

excess cold water pressure resulting from a

fault condition.

Page 14

INSTALLATION

INSTALLATION

Safety

Cut-out

Thermostat

Immersion Heater Wiring

E

L

N

Temperature/pressure Relief Valve

This safety device is also pre-set at the factory and relieves before the temperature

reaches 100°C. It is also a Pressure Relief Valve, and is pre-set to 6 bar.

Immersion Heaters

These are 3kW 240V AC heaters and incorporate a thermostat and a manually reset

energy cut-out which operates at 80°C. They have incalloy elements to pr olong their

life expectancy in aggressive water conditions.

Two immersion heaters are fi tted to all direct models and the indirect 250 and 300

models. All other models have one immersion heater fi tted. Where it is intended that

units are fi tted to offpeak circuits, then suitable controllers such as the Horstmann off

peak electric time controller will be required. External wiring to the immersion heaters

must be in accordance with the relevant IEE Wiring Regulations and the cir cuit must

be protected by a suitable fuse and a double pole isolating switch.

The correct method of terminating the wiring to the immersion heater is shown

opposite.

Line Strainer

This is integral within the combination inlet group to reduce the likelihood of

contaminants fouling the valve seat. Following installation this line strainer must be

cleaned and replaced. This needs to be carried out on a regular basis. as part of the

annual maintenance/service check.

Tundish

This is to allow the discharge from any Relief Valve to be seen. It must be fi tted away

from any electrical devices. See page 13 for discharge pipework details.

Safety

The immersion heaters must be earthed and they must be isolated from the mains

before the cover is removed on every occasion. Replacement immersion heaters

should be obtained from Gledhill Building Products Limited.

Control/overheat Dual Thermostats

Care must be taken to ensure that the solar probes are fully inserted into the pockets

provided.

Page 15

INSTALLATION

INSTALLATION

Heating/primary Systems

The boiler and primary/heating systems should

be sized and installed in accordance with BS

5449.

Safety

Stainless Lite is fitted with a Combined

Temperature/Pressure Relief Valve to cope

with any increase in system temperature and

pressure above the design limitations, when

used with boilers up to 45kW output, which

is the maximum allowed by section G3 of the

Building Regulations.

The primary water temperatures should be

controlled as outlined below.

Primary Circuit

It is essential that the circuit between the boiler

and the Stainless Lite is pumped. The motorised

zone valve supplied should be fi tted adjacent

to the unit and controlled by the cylinder

thermostat supplied. The thermostat and

motorised valve must be wired so that they both

switch off should an overheat situation develop.

It is important to follow the wiring diagram in

the Wiring Section of these instructions.

Sealed Primary Circuit

Any boiler used must be fi tted with an over

temperature cut-out.

Unvented primary circuits may be filled

or replenished by means of a temporary

connection between the circuit and a supply

pipe provided a ‘Listed’ double check valve

or some other no less effective backflow

prevention device is permanently connected

at the inlet to the circuit and the temporary

connection is removed after use.

Alternatively, a CA devic e can be used, which will

allow the system to be permanently connected

to the cold mains supply. The primary system

can then be topped up, when required, in the

same way as an open vented system fi tted with

an F&E Cistern.

Schematic Open Vented Primary System

Boiler

Pump

150mm max.

Warming/Overflow

Pipe

F & E Cistern

Minimum

distance as

required by

boiler

manufacturers

instructions

Motorised Valve

Motorised Valve

(Energy cut-out)

Schematic Sealed Primary System

Boiler

Motorised Valve

Motorised Valve

(Energy cut-out)

Expansion

Vessel

Gauge

Safety Valve

Pump

Page 16

INSTALLATION

INSTALLATION

Schematic Solar Direct System

Solar Pumping Station

Solar Panel

Expansion

Vessel

Solar

Controller

Motorised Valve

Energy cut-out

(Not supplied)

All components in a solar primary system must

be marked or identifi able in such a way that

their design pressure and temperature can be

readily determined.

A safety device (pressure relief valve) to control

the risk of over-pressure in system components

should be fi tted. A termination from a safety

pressure device should minimise the risk of

damage to persons or materials. Suitable

locations are a high temperature receptacle, an

internal gully or else issue externally at ground

level. High level termination from walls or on

roofs could cause injury to people or animals

below if the valve were to release scalding water

and steam.

The pipe leading to the safety device and

the collector should be of rigid and nondeformable construction, without an y possibility

of restriction or disclosure by any other fi tted

component.

A more detailed diagram of our recommended

arrangement for a typical solar system is shown

on page 17.

This provides all the necessary controls and

safety devices necessary for the solar system i.e.

the two port zone valve is wired as an energy

cut out and the pump/valve will only allow heat

transfer as required under control of the Delta

Sol controller.

The pocket provided for the Dual Thermostat

also includes the facility to accommodate an

8mm diameter sensor which, with the sensor

located in the solar collector (or in the fl ow

pipe immediately adjacent to the collector), will

provide the information required by the Delta

Sol BS controller.

Note: If the motorised valve is not used then

any factory built hydraulic station for solar

use MUST be fi tted with suitable non-return

valves in both flow and return pipes to

prevent gravity circulation when the pump

is not running.

Schematic Solar Indirect System

Solar Pumping Station

Solar Panel

Expansion

Vessel

Solar

Controller

Motorised Valve

Energy cut-out

(Not supplied)

Motorised Valve

Energy cut-out

(Not supplied)

Page 17

INSTALLATION

INSTALLATION

19876543210

12 34567 8

S1 S2 S3

201918171615141312

LNR1R2 NN

T

S1

S1

1 bar

Solar

Pumping

Station

Solar Coil

DeltaSol BS

TWO PORT

ZONE VALVE

A

B

C

12C1

+ C

o

+ C

o

LN

230 VAC 5 amp

Mains Supply

Dual Thermostat

Gledhill Stainless Lite

Unvented Cylinder

T

Anti Gravity

Check Valve

Pressure

Relief Valve

Anti Gravity

Check Valve

Standard 10 way

wiring junction box

(Not supplied)

This valve must be fitted on

the return to the solar panels

and be suitable for higher

temperatures operation

(Not

supplied)

No isolation valve

should be installed

between the solar

circuit and the safety

valve (pressure relief

valve)

Schematic Showing Solar Wiring Requirements

Page 18

INSTALLATION

INSTALLATION

19876543210

11

12

NL1234

Clock

OFF ON OFF ON

HW CHST6400

V4043A

TWO PORT

ZONE VALVE

A

B

HTG

V4043A

TWO PORT

ZONE VALVE

A

B

DHW

1234

Room Thermostat T6360

T6360B1028

GLEDHILL

HE BOILER

L

L_P

SL_B

E

N

N_P

E_P

C

1

2

C

1

Dual Aqua Stat

Control Stat Overheat Stat

L

N

E

Boiler Pump

Mains Supply

Fed Via Double

Pole Isolator

230 VAC ~ 5 Amps

Danfoss

WB12

Wiring

Centre

SL-B

L

N

E

HTG

VALV E

HW

VALV E

Typical schematic wiring diagram for an unvented installation

The electrical installation must

comply with IEE requirements.

For electrical installation

refer to BS7671

Note: Do not attempt

the electrical work unless

you are competent to carry

out to the above standard

BlueBl

BrownBr

Green

Grey

Green / Yellow

G

Gr

G/Y

WIRE COLOUR LEGEND

Black

Orange

Yellow

White

Red

BOrY

Wh

R

Br Bl G/Y B Br Br Bl G/Y Or Gr

Br Bl

G/Y

Br Bl G/Y Or Gr Br Bl G/Y Or Gr

5 Amps

Br Bl

G/Y

Br Br B B

*Br

Bl G/Y Br B

Bl Br Br Br

Br Bl

B

G/Y

G/Y Br *Br

* Blue core used

from standard 3 core

flex please ensure you

use brown sleeving at

both terminating ends

to identify core potential.

3 core flex

4 core cable

LN

Br Bl G/Y

B

Br Bl G/Y

3 core flex

4 core cable

ISSUE No : 1

APPROVED

DRN.

DATE

04-01-08

S. McGachie

Page 19

COMMISSIONING

INSTALLATION

Connections can come loose in transit, and all should be checked before

installation.

Ensure that the immersion heater setting is 60°C and that the wiring is in accordance

with the diagram.

Check the pressure on the air side of the expansion vessel = 2.2bar. This must be done

when the volume in the cylinder is cold.

Check that the drain cock is closed, and open all the cold and hot water taps and other

terminal fi ttings. Allow the system to fi ll with water , and t o run until there is no air left

in the system. Close the taps and inspect the system closely for leaks.

Manually open the Relief Valves one by one and check that water is discharged and

run freely through the tundish and out at the discharge point. The pipework should

accept full bore discharge without overfl owing at the tundish, and the valve should

seat satisfactorily.

Allow the cylinder to heat to normal working temperature, then thoroughly fl ush the

domestic hot and cold water pipework through each tap.

NOTE: If this appliance is to be installed in other than a single domestic dwelling ie.

in an apartment block or student fl ats etc., the hot and cold water system will need

to be disinfected in accordance with BS6700 and the Water Regulations.

Because the Stainless Lite appliance is stainless steel, the use of chlorine as the

disinfection agent can cause damage unless the appliance is adequately fl ushed and

refi lled with the mains water immediately on completion of the disinfection procedure.

Damage caused through a failure to do this adequately will not be covered by the

warranty.

For the above reasons we recommend the use of a non chlorine dased disinfectant

such as Fernox LP Sterox as manufactured by C ookson Electronics when carrying out

disinfection of systems incorporating these appliances.

Remove the fi lter from the combination inlet group clean and replace. Refi ll the system

and open all hot taps until there is no air in the pipe work. ENSURE CYLINDER IS

DRAINED PRIOR TO CHECKING OR REMOVING FILTER FROM THE COMBINATION

INLET GROUP.

Allow the cylinder to heat to normal working temperature with whatever heat source

is to be used, and check again for leaks. T he Pressure Relief Valve should not operate

during the heating cycle.

The boiler/heating systems should be filled

and commissioned in accordance with good

practice following the guidance in BS 5449/the

boiler manufacturers instructions. This includes

adequately fl ushing the system to remove any

debris that may have been introduced during

installation/maintenance.

NOTE: This appliance is co vered by BENCHMARK

and the log book must be completed after

commissioning and after every maintenance/

service visit.

IMPORTANT - DRAIN DOWN PROCEDURE

1 Switch off both the boiler and the immersion heater

2 Open the nearest hot tap and run all hot water until cold

3 Close the incoming cold main at the stop tap

4 Hold open the pressure and temperature relief valve until water stops

discharging into the tundish

5 Open all the taps in the property

6 Open the drain cock and immediately hold open the pressure and

temperature relief valve again until the cylinder is empty

Page 20

Your Stainless Lite un vented cylinder is automatic in normal use , but requires routine

maintenance which is normally carried out at least annually along with the boiler

service. The maintenance must be carried out by a suitably competent tradesperson

who is qualifi ed to work on unvented cylinders. The checks/work needed are listed

in the maintenance part of these Instructions.

The temperature of the hot water is adjustable, but the control thermostat should

have been set to 60˚C to meet the relevant regulations/ensure safe oper ation. In the

direct pattern, the contr ol thermostat is part of the immersion heater and should only

be adjusted by a suitably competent tradesperson. A simple, manually adjustable

control thermostat is fi tted to the indirect pattern units, but it is recommended that

this is left at 60˚C as hotter water will increase the risk of scalding.

When initially opening the taps, a small surge in fl ow may be experienced, which

disappears as the pressure in the system stabilises. This is quite normal with these

types of systems and does not indicate a fault.

In some areas the water will initially appear cloudy, but will quickly clear when left to

stand. This is nothing to be concerned about and is due to aeration of the water.

WARNING - If water is seen fl owing through the tundish, this indicates a fault condition

which needs action.

If the discharge is hot and continuous, turn the boiler and/or the immersion heaters

off, but do not turn off the cold water to the appliance until the dischar ge is cold. Note:

The discharge may stop by itself as the discharge cools.

If the discharge is cold and intermittent, no immediate action is needed but this

indicates a problem with the expansion vessel.

However , in both cases you must call the r egistered installer / a suitably qualifi ed,

competent tradesperson, advise them that you have an unvented cylinder and

request a maintenance visit.

DO NOT , at any time , tamper in any way with the safety valves or o verheat thermostats/

wiring.

USER INSTRUCTIONS

USER INSTRUCTIONS

Page 21

The Registered Installer is responsible for the safe installation and operation of the

system. The installer must also make his customer aware that periodic maintenance

of the equipment is essential for safety.

Maintenance periods will vary for many reasons. Gledhill Building Products Ltd

recommend a maximum of 12 months to coincide with boiler maintenance. Experience

of local water conditions may indicate that more frequent maintenance is desirable,

eg, when water is particularly hard, scale-forming or where the wat er supply contains

a high proportion of solids, eg, sand. Maintenance must include the following:

1. Check and clean fi lter

2. Manually check the operation of the temperature relief valve.

3. Manually check the operation of the expansion relief valve.

4. Check discharge pipes fr om temperature and expansion relief valv es are free from

obstruction and blockage and are not passing any water.

5. Check the condition and if necessary descale the heat exchangers in hard water

areas.

6. Check that water pressure downstream of pressure reducing valve is within the

manufacturers limits.

7. Check operation of motorised valve.

8. Check the pressure on the air side of the expansion vessel. This must be done when

the volume in the cylinders is cold.

9. Check and advise the householder not to place any clothing or other combustible

materials against or on top of this appliance.

10. On completion of the work, fi ll in the Service Record part of the Benchmark Log

Book.

SERVICING AND MAINTENANCE

SERVICING AND MAINTENANCE

IMPORTANT NOTE

When draining down the appliance for any reason, the instructions

provided in the Commissioning Section MUST be followed to prevent

potential damage to the cylinder.

Page 22

SERVICING AND MAINTENANCE

FAULT FINDING

Scale

In hard water areas it is recommended that an in-line scale inhibitor is fi tted. Reducing

the temperature of the stored water will reduce the rate at which scale forms. If the

recovery rate is badly affected, this is an indication that scaling may have occurr ed. In

this event, follow the procedures as recommended by a reputable Water Treatment

Company.

General

No water at the tap. Check that the mains water supply is turned ON. Check the line

strainer is not blocked. Check that the combination valve has been fi tted so that water

is fl owing in the correct direction.

If the water at the tap is cold, ensure that the boiler has been switched ON and is

working correctly. Check that there are no air locks in the primary system. ISOLATE

THE UNIT AT THE MAINS ELECTRIC SUPPLY AND THEN CHECK THE FOLLOWING:

i. The cylinder thermostat

ii. The thermal cut-out, which can be re-set by pushing the red button

iii. The motorised valve

iv. The boiler thermostat

v. The boiler thermostat cut-out (if fi tted)

ANY ENERGY CUT-OUT MUST NEVER BE BY-PASSED UNDER ANY CIRCUMSTANCES.

If the units are not getting hot and the heat source is electrical, ensure that the

immersion heaters are isolated from the mains before re-setting the energy cut-out.

If the immersion heater(s) need replacing this should be done with the units supplied

from Gledhill Building Products Limited. Same day despatch to approved installers

can be arranged by telephoning 01253 474402.

Discharge From Relief Valves

If cold water is discharging from the expansion relief valve into the tundish check the

pressure on the expansion vessel when cold and recharge if necessary.

If the fault continues and the problem cannot be stopped by operating the easing

control a few times then either the Pressure Reducing Valve or the Relief Valve may

be at fault. If the cold wat er pressure is too high, this would suggest that the Pr essure

Reducing Valve is at fault and the Gledhill approved replacement should be fi tted.

If the pressure is correct then the Relief Valve will require replacing with a Gledhill

approved component.

See Commissioning for drain down procedure.

If there is an overheat fault and very hot water is being discharged, turn off the heat

source, but not the water supply.

When the supply is cool, check thermostats and energy cut-outs in the boiler and

immersion heaters and replace the faulty component with a unit supplied by Gledhill

and check that it works correctly before returning the system to full operation.

Page 23

FAULT FINDING

SERVICING AND MAINTENANCE

FAULT - No Hot Water (Direct)

Switch on

Re-set

Replace element

START

Is power on to elements?

Is control temperature

set at 55ºC - 60ºC?

Has high limit tripped?

Check wiring links

continuity and Re-set

END

YES

YES

YES

NO

NO

NO

FAULT - No Hot Water (Indirect)

Switch on

Set programmer

Re-set, check wiring &

plumbing is correct

Re-set

Is all wiring to the

controls ok?

Replace thermostat

Re-wire

START

Is boiler on?

Is hot water programmer

in ‘on’ position?

Is zone valve in

correct position?

Is control temperature

set at 55ºC - 60ºC?

Has high limit cut out?

Re-set

END

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO NO

NO

Page 24

SERVICING AND MAINTENANCE

FAULT FINDING

Water service check by

supply company required

Clean or replace strainer

as appropriate

Service /replace PRV

as appropriate

START

END

Is incoming mains supply

flow/pressure adequate?

Is in-line strainer

(in combination valve)

clean?

YES

YES

YES

YES

NO

NO

NO

Clear obstructions

Is system free from

restrictions/blockages?

YES

NO

Is pressure reducing valve

(in combination valve)

working?

FAULT - Poor Water Flow at Hot Taps

FAULT - Water Discharge Into Tundish

Clean or replace

as required

Is expansion vessel

charge pressure correct?

Replace ERV/TPRV

Replace PRV END

START

Is pressure downstream

of pressure reducing valve

correct?

Is valve seal and seat

clean & undamaged?

Is heater operating at

less than 60ºC?

Re-set temperature

NO

YES

YES

NO

NO

YES

YES

Is ERV/TPRV

discharging?

YES

Recommission

expansion

vessel pressure

NO

NO

Page 25

SHORT PARTS LIST

SERVICING AND MAINTENANCE

SPARE PARTS LIST

Description Quantity Stock Code No.

1 3kW immersion element 1 SH001

2 22mm 90° compression elbow c/w/drain 1 SF003

3 Pressure and temperature relief valve 6 bar 95°C 1 SG001

4 Inlet group set at 2.25 bar c/w expansion relief valve set at 4.5 bar 1 SG002

5¾” fl exible hose 1 SG003

6 12/18 litre wall mounting bracket for expansion vessel 1 XG010

7 12 litre expansion vessel 1 XG164

8 18 litre expansion vessel 1 XG009

9 24 litre expansion vessel 1 XG183

10 24 litre wall mounting bracket for expansion vessel 1 XG184

11 35 litre fl oor standing expansion vessel 1 XG057

12 35 litre wall mounting bracket for expansion vessel 1 XG058

13 22mm 2 port valve (indirects only) 1 XG083

14 Junction wiring box (12 way) 1 XG129

15 Control and overheat limit thermostat 1 XG168

16 15mm x 22mm tundish 1 XG173

Page 26

Vast quantities of water are needlessly run off to waste due to Taps , Mixers and Showers

discharging fl ow rates far in excess of the rates required for them to perform their

duties.

The contrasting fl ow rates shown on this leafl et clearly illustrate the savings that can

be made whilst still providing a good performance.

British made Aquafl ow Regulators provide constant fl ow rates by automatically

compensating for supply pressure changes between 1 bar & 10 bars.

To facilitate installation into the wide range of plumbing equipment which is

encountered in the U.K, Four Fixing Options are available:-

Options For Showers

1. MXF “DW” Range - F or fi tting behind Fixed Shower Heads or onto Flexible Hoses for

Handshowers (preferably onto the inlet end when lightweight hoses are used).

2. Compression Fitting Range. “In Line” regulators as in Option 4 for Taps & Mixers.

Information by courtesy of

AQUAFLOW REGULATORS LTD

Haywood House, 40 New Road, Stourbridge, West Midlands DY8 1PA

TELEPHONE (01384) 442611 FAX: (01384) 442612

Water Savings

Water Related Costs Can Be Reduced By Good Plumbing Practice

TAPS & MIXERS

SHOWERS

Unregulated

25 - 30 l/m

Regulated

10 - 12 l/m

Over

20 l/m

5, 6 or

8 l/m

2 tap

half open

Fitted with regulator

Unregulated

4 Fixing Options For Taps & Mixers

1. MK Range - Combined Regulators & Aerator

for screwing onto T aps & Mixers with internal

or external threads on their noses. Anti Vandal

models also available.

2. MR05-T Range - Internal Regulators. Pushfit into Tap or Mixer seats. Produced in

three sizes - 12.5mm (BS1010), 12mm &

10mm, Flangeless models also available for

Taps with Low Lift washers.

3. MXF Standard Range - Screw on tail

models for Taps & Mixers. Fix onto the tails

before fi tting the tap connectors. Available

in 3/8", 1/2", 3/4" and 1" BSP.

4. Compression Fitting Range - “In Line”

regulators housed in 15mm & 22mm CXC

Couplers & Isolating V alves. “ ”UK WFBS listed

by the Wa ter Research Centre. Isolation valves

available for slotted screwdriver operation or

with coloured plastic handles. Now available

also in plastic bodied push-fi t couplers &

valves.

2

1

1

2

1

2

3

3

1

4

APPENDIX

APPENDIX A

Page 27

Description

Manual handling means any transporting or supporting of a load (including lifting,

putting down, pushing, pulling, carrying or moving) by hand or bodily force.

Scope

This assessment will cover the largest appliance within each product range

manufactured by Gledhill.

The maximum weight of thelargest product in any range can be up to98kg and the

size is 595 x 595 x 2020 mm high.

Main Hazards

Vision may not be clear due to the size of the products.

Adopting an incorrect method of lifting may cause injury, attempting to lift these

products will require help from others. (Team lifts)

ControlMeasures

Manual lifting procedure

The lift, key factors in safe lifting are:

a. Balance

b. Positionof back

c. Positioning of the arms and body

d. Thehold

e. Takingthe lead for team lifts

a. Balance- Since balance depends essentially upon the position of the feet,

they should be apart about hip breadth with one foot advanced giving full

balance sideways and forward without tension. In taking up this position,

lifting is done by bending at the knees instead of the hips and the muscles

that are brought into use are those of the thigh and not the back.

b. Position of back - Straight - not necessary vertical. The spine must be

kept rigid, this coupled with a bent knee position, allows the centre line of

gravity of the body to be over the weight so reducing strain.

c. Positioning of arms and body - The further arms are away from the side,

the greater the strain on the shoulders, chest and back.Keep elbows close

to the body arms should be straight.

d. The hold - Before lifting ensure you have a good hold. Two handles are

provided on Appliance products at the top rear side, these allow one or

two persons to have a purposely-designed hold at the topof the appliance

to ensure easy lifting at the top of the product. Each appliance is supplied

with a pallet, which has been attached to the unit via the packaging. The

pallet will also allow for one or two persons to get a good hold.

e. Taking the lead for team lifts-As

more than one person is required

for these products ensure that one

person is taking the lead. This may

be you so ensure that each person

that is helping is made aware of the

weight and of the items listed within

this assessment. Make sure you and

any others helping know the route

you intend to take that it is clear of

any obstructions. Never jerk the load

as this will add a little extra force and

can cause severe strain to the arms,

back and shoulders. If there are steps

involved decide on where you will

stop and take a rest period. Move

smoothly andin unison taking care to

look and listen to others helping with

the lift. Where possible use a sack

truck to move the product over long

flat distances, only lift the products

when necessary. If in doubt stop and

get more help. The unit handles and

packaging with the pallet have been

designed to ensure that two-four

people can assist when lifting up

stairs or over longer distance.

Individual capability

Individual capability plays an important

part in handling these products. Persons

above average build and strength will

find it easier and should be in good

health. Persons below average build and

strength may require more rest periods

during the handling process.

Pregnant women should not carry out

this operation.

Persons who are not in good health

should seek medical advice prior to

commencing any lifting or manual

handling operation.

Residual risk

Following the guidelines givenabove will

reduce any risk to injury.

All persons carrying out this operation

must be fully trained and copies of the

specific risk assessment made available

for inspection and use in their training

process.

Further guidance on Manual Handling

can be obtained from the Health and

Safety Executive. Manual Handling

Operations Regulations 1992.

MANUALHANDLING OFAPPLIANCE PRODUCTS

APPENDIX B

APPENDIX

Page 28

SERVICE RECORD

SERVICE INTERVAL RECORD

It is recommended that your heating system is serviced regularly

and that you complete the appropriate Service Interval Record Below.

Service Provider. Before completing the appropriate Service Interval Record below, please ensure you have carried out the service

as described in the boiler manufacturer’s instructions. Always use the manufacturer’s specified spare part when replacing all controls

SERVICE 1

DATE

ENGINEER NAME

COMPANY NAME

TEL No.

CORGI ID CARD SERIAL

No.

COMMENTS

SIGNATURE

SERVICE 2

DATE

ENGINEER NAME

COMPANY NAME

TEL No.

CORGI ID CARD SERIAL No.

COMMENTS

SIGNATURE

SERVICE 3

DATE

ENGINEER NAME

COMPANY NAME

TEL No.

CORGI ID CARD SERIAL No.

COMMENTS

SIGNATURE

SERVICE 4

DATE

ENGINEER NAME

COMPANY NAME

TEL No.

CORGI ID CARD SERIAL No.

COMMENTS

SIGNATURE

SERVICE 5

DATE

ENGINEER NAME

COMPANY NAME

TEL No.

CORGI ID CARD SERIAL No.

COMMENTS

SIGNATURE

SERVICE 6

DATE

ENGINEER NAME

COMPANY NAME

TEL No.

CORGI ID CARD SERIAL No.

COMMENTS

SIGNATURE

SERVICE 7

DATE

ENGINEER NAME

COMPANY NAME

TEL No.

CORGI ID CARD SERIAL No.

COMMENTS

SIGNATURE

SERVICE 8

DATE

ENGINEER NAME

COMPANY NAME

TEL No.

CORGI ID CARD SERIAL

No.

COMMENTS

SIGNA

TURE

SERVICE 9

DATE

ENGINEER NAME

COMPANY NAME

TEL No.

CORGI ID CARD SERIAL No.

COMMENTS

SIGNATURE

SERVICE 10

DATE

ENGINEER NAME

COMPANY NAME

TEL No.

CORGI ID CARD SERIAL No.

COMMENTS

SIGNATURE

Page 29

NOTES

Page 30

TERMS AND CONDITIONS

Gledhill (Building Products) Ltd

AMD. JUNE 2008

CONDITIONS OF SALE & GUARANTEE TERMS

1. Gledhill (Building Products) Ltd (“We” or “Gledhills”) only do business upon the Conditions which appear

below and no other. Unless we so agree in writing these Conditions shall apply in full to any supply of goods by us

to the exclusion of any Conditions or terms sought to be imposed by any purchaser. These Conditions of Sale and

Warranty Terms override those which are contained on the Invoice Forms and all Sales are now subject to these

Conditions of Sale and Warranty terms only.

2. PRICE

Once an order or call off has been accepted the price will be held for three months but if delivery is extended

beyond that period at the customer’s request, then we reserve the right to amend the price when necessary.

The company reviews its pricing annually to adjust for changes in our cost base. We reserve the right to alter prices

at any time for severe movements in raw materials (mainly copper and steel). If there is to be a change we will give

customers at least four weeks notice but anything delivered after that date will be at the revised price. An order

may not be cancelled or varied after acceptance without the written consent of the company. Such cancellation or

variation shall be subject to such reasonable charges as may be appropriate.

3. SPECIFICATION

The goods are supplied in accordance with the Specifications (if any) submitted to the Purchaser and any additions

and alterations shall be the subject of an extra charge. Any goods not so specified shall be in accordance with our

printed literature or the literature of any of our component suppliers (subject to any modifications made since

publication). If we adopt any changes in construction or design of the goods, or in the specification printed in our

literature, the Purchaser shall accept the goods so changed in fulfilment of the order.

4. PAYMENT

The invoice price of goods shall be payable within 30 days of despatch by us of our invoice for the goods or such

longer time as may be stated by our quotation or invoice. If we receive payment in full on or before the due date we

will allow an appropriate settlement discount except where we have quoted a special net price. If payment is not

received in full on or before the due date we shall be entitled in addition to the invoice price to:

(i) payment of a sum equal to any increase in the copper price supplement applicable to the particular goods

sold between the date of receipt of order and the date of receipt of payment in full; and

(ii) interest on any part of the invoice price unpaid after the due date at the rate of 3% per annum over the base

rate for the time being of HSBC Bank plc.

5. TIME

We give estimates of delivery dates in good faith and time of delivery is not nor shall be made of the essence of any

contract nor shall we be liable for any loss or damage occasioned by delay in delivery.

6. DELIVERY

We deliver free normally by our own vehicles within 25 miles of any of our manufacturing depots. Delivery to any

place more than 25 miles from one of our manufacturing depots may be subject to our quoted delivery charges. We

reserve the right to make delivery of goods contained in one order by more than one consignment and at different

times. Where a period is agreed for delivery and such period is not extended by our Agreement, the Purchaser shall

take delivery within that period. If the Purchaser fails to take delivery, we shall be entitled at the Purchaser’s risk and

expense to store the goods at the Purchaser’s premises or elsewhere and to demand payment as if they had been

despatched. Off loading at point of delivery shall be the responsibility of and be undertaken by the Purchaser.

7. SHORTAGES OR DAMAGE

Goods must be inspected before signature of delivery note and any damage, shortage or discrepancy noted on the

delivery note and the goods returned on the same vehicle. The buyer must also give us immediate written notice of

the damage, shortage or discrepancy so that we may prompt investigation.

8. RETURN OF GOODS

Goods may not be returned to the Company except by prior written permission of an authorised officer of the

Company and such return shall be subject to payment by the Purchaser of handling and re-stocking charges,

transport and all other costs incurred by the Company.

9. COMPANY LIABILITY AND GUARANTEE

9.1. Subject to the terms of these Conditions of Sale and Guarantee Terms Gledhills provide Guarantees in respect

of specific products as set out in this clause.

9.2. Each Guarantee is strictly conditional upon the following:-

9.2.1. Complaints must be given to us immediately, before any action is taken, as responsibility cannot be accepted

if repairs or renewals are attempted on site without our written approval.

9.2.2. The unit has been installed in accordance with our installation and service instructions and all relevant codes

of practice and regulations in force at the time of installation.

9.2.3. All necessary inlet controls and safety valves have been fitted correctly.

9.2.4. The unit has only been used for the storage of potable water supplied from the public mains.

9.2.5 Where appropriate the unit has been regularly maintained as detailed in the installation and service

instructions

9.2.6. Defects caused by corrosion or scale deposits are not covered by any Guarantee.