gledhill StainlessLite D300, StainlessLite D90, StainlessLite D180, StainlessLite D400, StainlessLite D210 Design, Installation & Servicing Instructions

...

Design, Installation & Servicing Instructions

Models covered in this manual

Stainless Lite Direct 90-400 litres

Stainless Lite Indirect 90-400 litres

Stainless Lite Solar Direct 180-400 litres

Stainless Lite Solar Indirect 180-400 litres

Stainless Lite Slimline Direct 60-210 litres

Stainless Lite Slimline Indirect 60-210 litres

StainlessLite

Unvented mains pressure water storage in Duplex stainless steel

Page 2

Section Page

DESIGN

Description 3

Technical Information 6

System Design 10

INSTALLATION

Installation 12

Commissioning 22

USER INSTRUCTIONS 23

SERVICING AND MAINTENANCE

Servicing and Maintenance 24

Fault Finding 25

Short Parts List 28

APPENDIX

Appendix A 29

Appendix B 30

Notes 31

Terms & Conditions 32

Benchmark Checklist 34

Benchmark Service Record 35

ISSUE 23: MARCH 2016

These instructions should be read in conjunction with the installation/servicing

instructions issued by the manufacturer of the heat source being used.

Any installation must be in accordance with the relevant requirements of the Gas

Safety Regulations, Building Regulations, I.E.E. Wiring Regulations and the Water Fitting

Regulations (England and Wales) or Water Byelaws (Scotland). It should be read in

accordance with the relevant recommendations of the following:

BS 6798; BS EN 12828, BS EN 12831, BS EN 14336; BS 5546;

BS 5440:1; BS 5440:2; CP 331:3

BS EN 806-1 to 5, BS EN 8558:2011: BS EN 1458-1:2011 and BS 7593:2006

Stainless Lite is covered by Section G3 of the Building Regulations (England and Wales)

Technical Standard P3 (Scotland) and Building Regulation P5 (Northern Ireland).

Compliance can be achieved via a Competent Person Self Certication Scheme or

noticaton of installation to the Local Authority Building Control Department.

It must be installed by a competent person as dened by the relevant regulations.

Manufacturers notes must NOT be taken as over-riding statutory obligations.

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge unless

they have been given supervision or instruction concerning use of the appliance by

a person responsible for their safety. Children should be supervised at all times to

ensure they do not play with the appliance.

This information is provided to assist generally in the selection of equipment.

Responsibility for selection and specication of our equipment must however remain

that of our customer and any experts or consultants concerned with the installation(s).

Please note: that we do not therefore accept any responsibility for matters of

design selection or specication, for the eectiveness of an installation or system

containing one of our products unless specically requested to do so in writing.

All goods are sold subject to our Conditions of Sale which are set out at the rear of this

specication. In the interest of continuously improving the Stainless Lite range, Gledhill

Building Products Limited reserve the right to modify the product without notice, and

in these circumstances this booklet, which is accurate at the time of printing, should

be disregarded. An updated set of Instructions will be produced and supplied with

new appliances and will be made available for other appliances on request.

Stainless Lite is produced under an ISO 9001:2008 Quality Management System

approved by BSI.

Benchmark places responsibilities on both manufacturers and installers. The purpose is to

ensure that customers are provided with the correct equipment for their needs, that it is

installed, commissioned and serviced in accordance with the manufacturers instructions

by competent persons and that it meets the requirements of the appropriate Building

Regulations. The Benchmark Checklist can be used to demonstrate compliance with

Building Regulations and should be provided to the customer for future reference.

Installers are required to carry out installation, commissioning and servicing work

in accordance with the Benchmark Code of Practice which is available from the

Heating and Hot Water Industry Council who manage and promote the Scheme.

Visit www.centralheating.co.uk for more information.

For further information on the HWA Charter Statement, please refer to the HWA website

hotwater.org.uk.

Page 3

Maintenance

Modifications should not be made to this

product. Replacement parts, including

immersion heaters, should be purchased from

Gledhill Building Products Limited, or agents

approved by them. Unvented hot water storage

vessels need regular routine checks, and these

are detailed below. It is for this reason that this

manual must always be left with the Stainless

Lite.

It is essential that these checks be carried out

at the time of boiler maintenance by a qualied

installer:

1. Manually open the relief valves in turn, and

check that water is discharged from the

valves and runs freely through the tundish

and out at the discharge point. Ensure that

the valves re-seat satisfactorily. (Note - the

water may be very hot).

2. It is important to check that the discharge

pipework is carrying the water away

adequately. Check for blockages etc. if it is

not.

3. Turn the mains water o and remove and

clean the strainer element in the Pressure

Reducing Valve.

4. Check the charge pressure in the expansion

vessel and repressurise if required

5. Re-ll the system and ensure that all relief

valves have re-seated.

6. The Benchmark Service Record should be

updated at each service.

7. Check the water pressure downstream of the

combination valve is 3 bar in static condition.

8. Check and if necessary, descale the heat

exchanger in hard water areas ie. above

200ppm (mg/l).

Note:

The cylinder is factory fitted with a lift up

temperature & pressure relief valve that must

not be used for any other purpose or removed.

The cylinder is factory tted with immersion

heaters with thermal cut outs. Immersions

without thermal cut outs must not be tted.

Manufacturer: Gledhill Building Products Ltd

Maximum inlet pressure to

Pressure reducing valve 12 bar

Operating pressure (PRV setting) 3 bar

Expansion vessel charge pressure 3 bar

Expansion relief valve setting 4.5 bar

Opening pressure of P & T Relief Valve 6 bar

Opening temperature of P & T Relief Valve 92-95°C

Energy cut-out thermostat setting 85°C

Max. working pressure - Primary heat exchanger (Indirect models) 6 bar

Max. working pressure - Solar heat exchanger (Solar models) 10 bar

Immersion heater rating 3kW, 240V AC

All cylinders are manufactured in accordance with the requirements of BS EN 12897

The tundish must be positioned so that it is visible to the occupant and is away from

electrical devices.

Components supplied with Stainless Lite:

• Cold water inlet PRV combination valve/expansion relief

• Lift up pressure and temperature relief valve

• Control thermostat

• Energy cut-out thermostat

• Energy cut-out motorised valve (indirects only)

• Tundish

• 3kW Immersion heater including control and cut out thermostats

• Expansion vessel/mounting bracket/exible hose

• Technical/user product literature

(Note: Please refer to tables 1 and 2 on pages 6-9 to conrm the quantity of immersion

heaters supplied with the unit)

In any situation where the volume of heated pipework (eg. secondary circulation

pipes or manifold pipework for multiple units) exceeds 10 litres, then an

additional expansion vessel must be tted to accommodate the extra expansion

volume.

Handling Before Installation

Stainless Lite must be handled with care and stored the correct way up in a dry place.

Any manual handling/lifting operations will need to comply with the requirements

of the Manual Handling Operations Regulations issued by the H.S.E. The appliance

can be moved using a sack truck on the rear face although care should be taken and

the route should be even. In apartment buildings containing a number of storeys we

would recommend that the appliances are moved vertically in a mechanical lift. If it is

proposed to use a crane, expert advice should be obtained regarding the need for

slings, lifting beams etc.

A specic manual handling assessment is shown in Appendix B at the rear of this

manual.

The Environment

This product has been manufactured using many recyclable materials, including the

approved HCFC/CFC free polyurethane foam insulation. At the end of its useful life, it

should be disposed of at a Local Authority Recycling Centre, to maximise the products

full environmental benets.

DESIGN

DESCRIPTION

Page 4

Stainless Lite is a range of unvented hot water

storage cylinders, manufactured in the latest

high quality duplex stainless steel. They are

designed to provide mains pressure hot water

and are supplied as a package which complies

with Section G3 of the Building Regulations.

The appliance is extremely well insulated using

high density HCFC free foam insulation with an

ozone depleting potential (ODP) of zero and a

global warming potential (GWP) of 1. It is tted

with all necessary safety devices and supplied

with all the necessary control devices to make

installation on site as easy as possible.

Stainless Lite is available in four basic

variants:

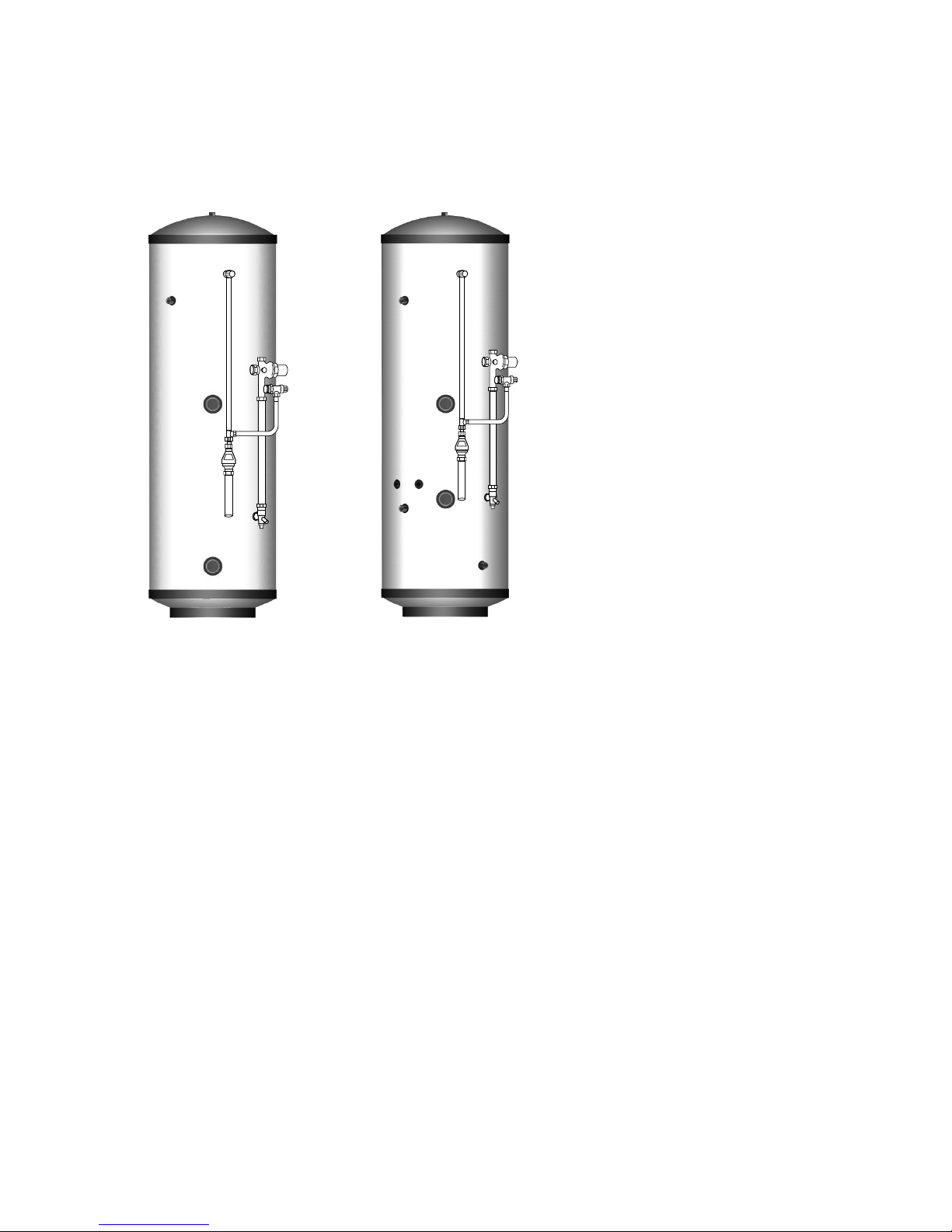

1. Stainless Lite Direct - For providing hot

water heated by electricity (Figure 1).

2. Stainless Lite Indirect - For use with gas

or oil boilers (Figure 2). Unvented cylinders

must not be used with solid fuel boilers or

steam as the energy source.

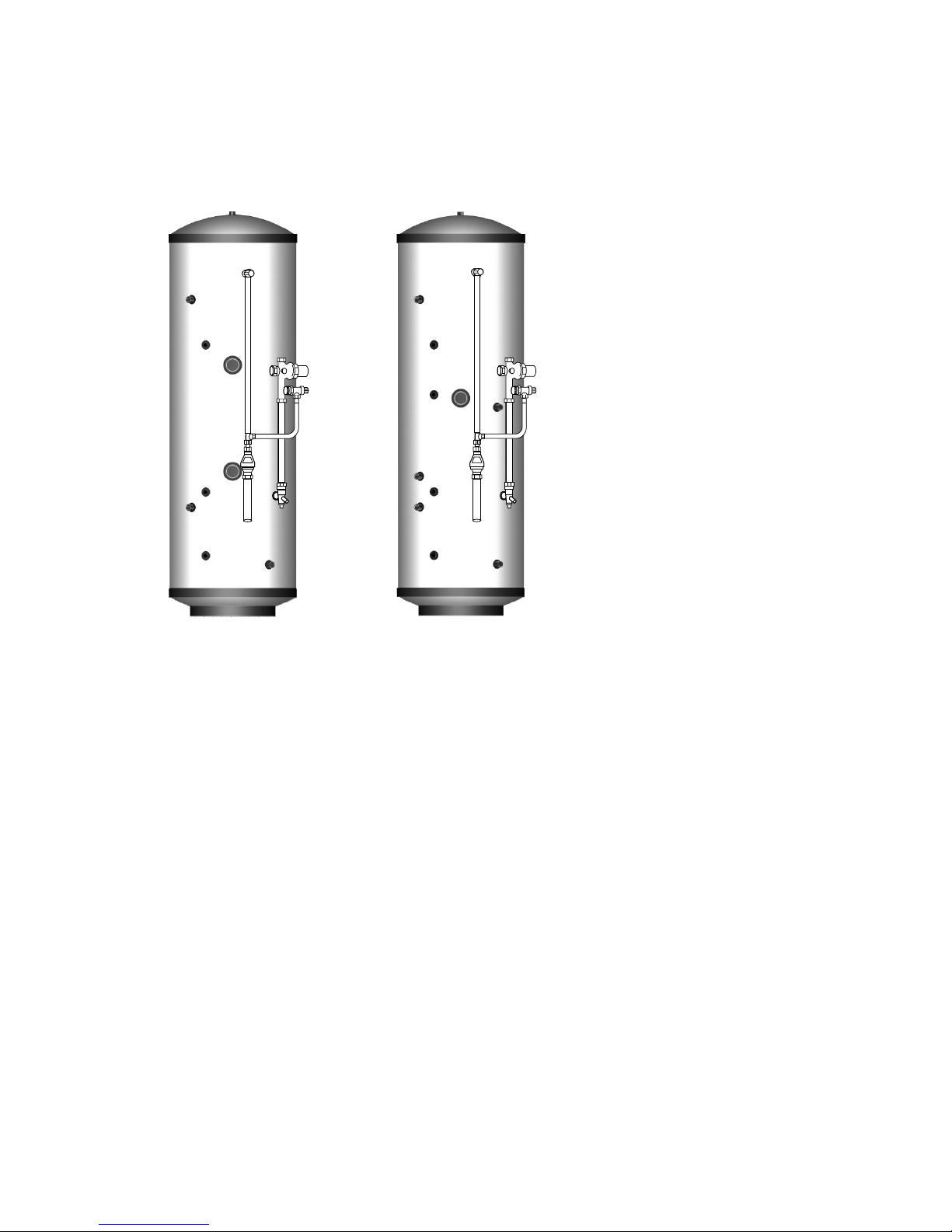

3. Stainless Lite Direct Solar - For providing

hot water by solar gains and electricity.

(Figure 3).

4. Stainless Lite Indirect Solar - For providing

hot water by solar gains and gas or oil boilers

(Figure 4). Unvented cylinders must not be

used with solid fuel boilers or steam as the

energy source.

Stainless Lite Direct

Stainless Lite direct is an electrically heated,

unvented hot water storage cylinder designed

primarily for use with off peak electrical

supplies.

It is supplied tted with two 3kW immersion

heaters which are BEAB approved for safety as

recommended by the Electricity Council.

Stainless Lite direct models are listed in

Table 1 on Page 6 & 7.

Stainless Lite Indirect

Stainless Lite indirect is an unvented hot

water storage cylinder and is provided with a

high eciency internal primary coil which is

designed for use with a gas or oil boiler and

is suitable for both open vented and sealed

pumped primary systems.

When used with a sealed heating system the

boiler must incorporate its own energy cut-out

overheat thermostat.

Stainless Lite indirect models are listed in

Table 2 on Page 8 & 9.

Stainless Lite

DIRECT

Stainless Lite

INDIRECT

Figure 1 Figure 2

Pipework is not supplied by manufacturer,

but to be supplied and tted by installer.

DESIGN

DESCRIPTION

Page 5

Stainless Lite

DIRECT SOLAR

Stainless Lite

INDIRECT SOLAR

Figure 3 Figure 4

Pipework is not supplied by manufacturer,

but to be supplied and tted by installer.

Stainless Lite Direct Solar

Stainless Lite direct is an electrically heated,

unvented hot water storage cylinder designed

primarily for use with off peak electrical

supplies.

It is supplied tted with two 3kW immersion

heaters which are BEAB approved for safety as

recommended by the Electricity Council.

A high eciency coil is positioned in the lower

part of the Stainless Lite vessel to ensure

maximum benet of solar gain energy.

Stainless Lite direct models are listed in

Table 1 on Page 6 & 7.

Stainless Lite Indirect Solar

Stainless Lite indirect is an unvented hot

water storage cylinder and is provided with a

high eciency internal primary coil which is

designed for use with a gas or oil boiler and

is suitable for both open vented and sealed

pumped primary systems.

When used with a sealed heating system the

boiler must incorporate its own energy cut-out

overheat thermostat.

A high eciency second solar coil is positioned

below the primary coil to ensure maximum

benet of solar gain energy.

Stainless Lite indirect models are listed in

Table 2 on Page 8 & 9.

Note:

The cold supply elbow c/w drain tapping

must be tted as shown in gs 1, 2, 3 and

4. A exible hose can then be connected to

the drain tapping and, providing the hose

runs below the lowest level of the cylinder,

then all the water contents can be drained

out by syphonic action. (The cold feed pipe

dips internally to the base of the cylinder.)

DESIGN

DESCRIPTION

Page 6

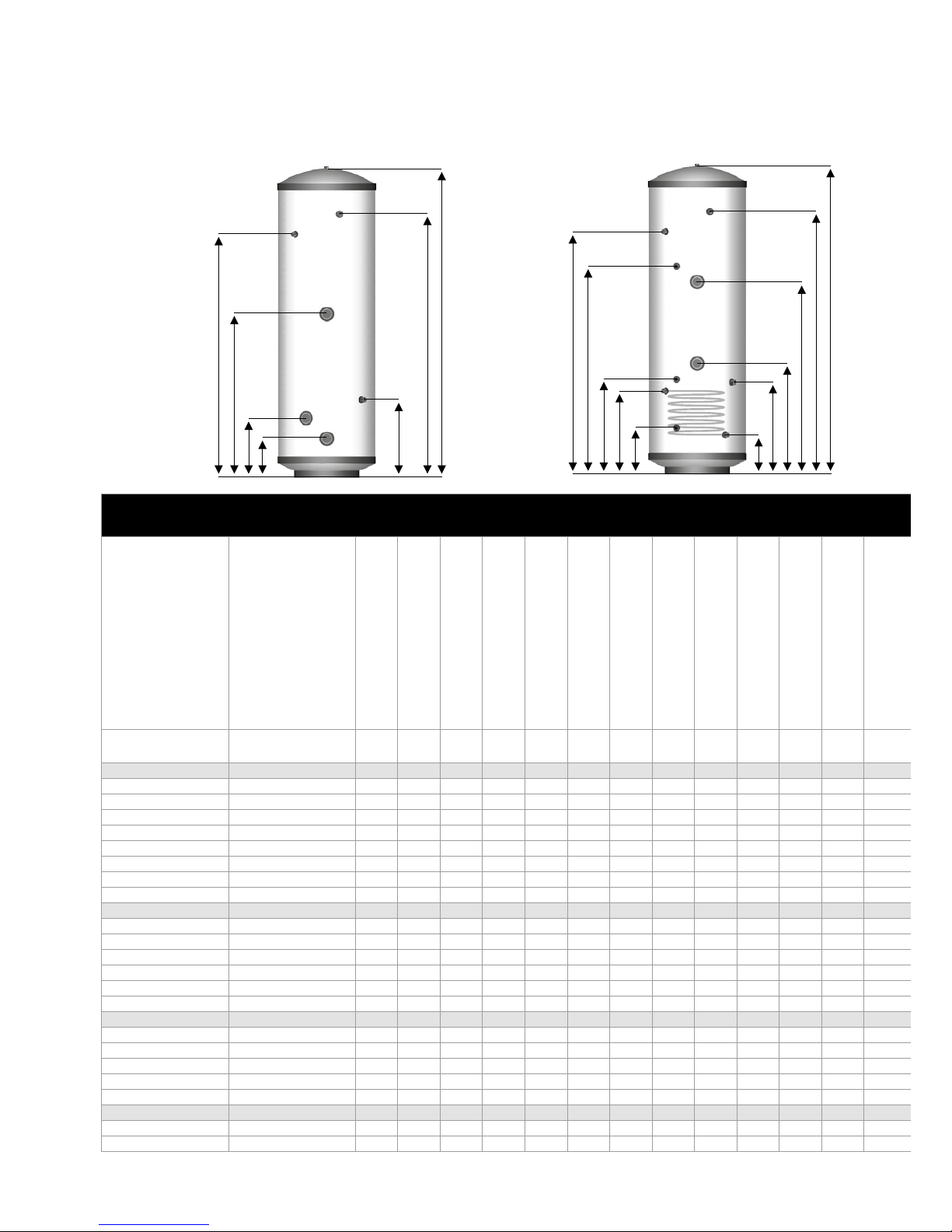

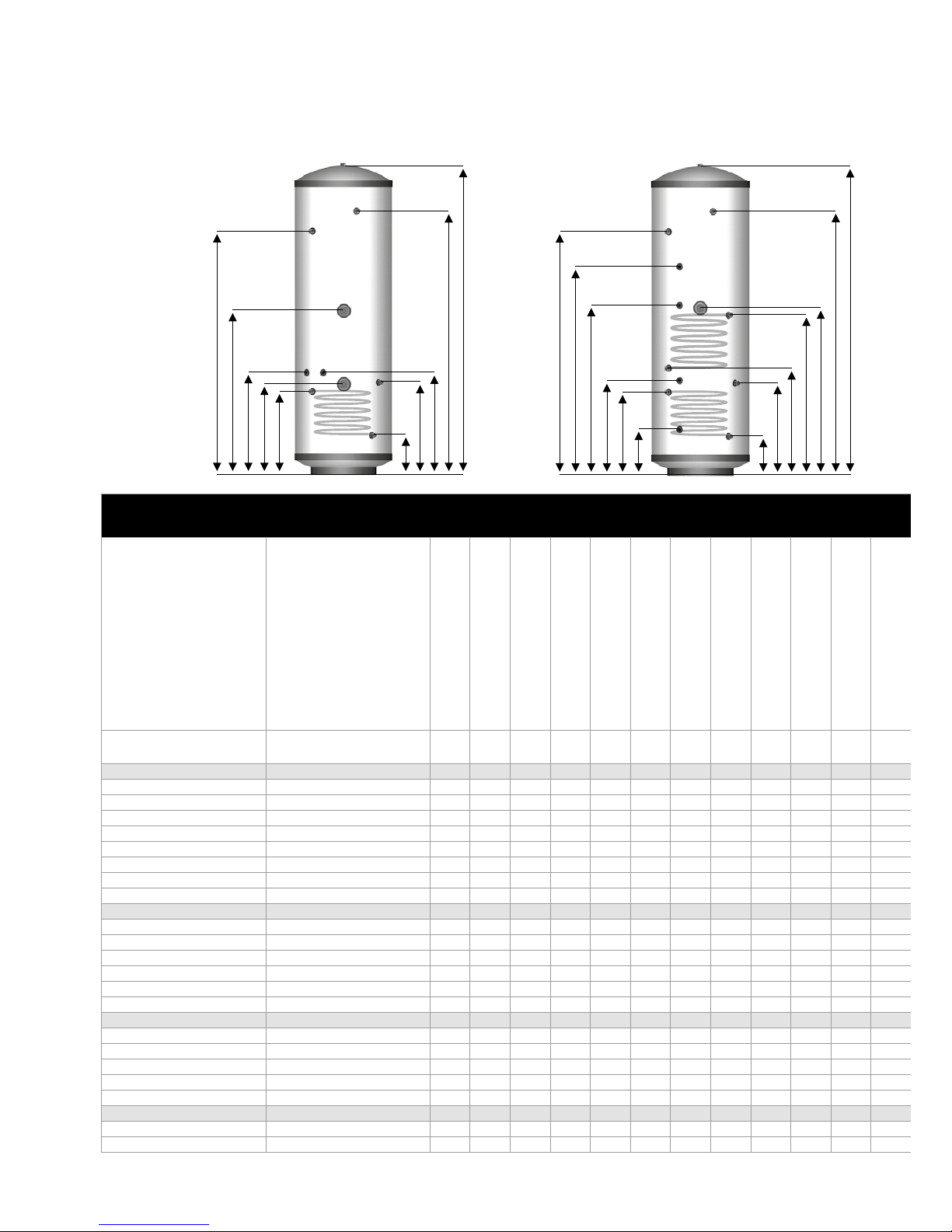

Table 1 - Direct Models

Model

Stock Code

Load Prole

Energy Eciency Class

Heat Loss

Energy Eciency %

Annual Consumption

Other Load Prole

Thermostat

Temperature Setting

Sound Power Level

O-Peak Available

Capacity (Total Volume)

Weight - Empty

Weight - Full

Pressure Regulator 3 bar inlet group c/w balance

cold supply, expansion vessel connection and

expansion valve set at 4.5 bar

Expansion Vessel size.

Pre-charged to 3 bar

Overall Height

Watts % kWh °C db Litres kg kg bar

Litres A=mm mm B=mm C=mm D=mm E=mm F=mm Litres K=mm L=mm M=mm N=mm P=mm R=mm m

Direct

D90

ASL0001 M D 35 36 2320 - 62 15 Y 90 13 103 3

12 745 550 490 n/a n/a 367 223 n/a n/a n/a n/a n/a n/a n/a n/a n/a 90 n/a

D120

ASL0005 M D 44 35 2366 - 62 15 Y 120 18 138 3

12 930 550 678 n/a 487 367 223 55 n/a n/a n/a n/a n/a n/a n/a n/a 119 n/a

D150

ASL0010 L D 51 37 4522 M 62 15 Y 150 22 172 3

18 1120 550 865 n/a 587 442 223 70 n/a n/a n/a n/a n/a n/a n/a n/a 150 n/a

D180

ASL0015 L D 54 36 4537 M 62 15 Y 180 24 204 3

18 1305 550 1053 n/a 686 442 223 85 n/a n/a n/a n/a n/a n/a n/a n/a 179 n/a

D210

ASL0020 XL D 65 37 6939 L/M 62 15 Y 210 28 238 3

24 1495 550 1241 1127 786 442 223 90 n/a n/a n/a n/a n/a n/a n/a n/a 209 n/a

D250

ASL0025 XL D 75 37 6990 L/M 62 15 Y 250 32 282 3

24 1745 550 1491 1377 927 522 223 125 n/a n/a n/a n/a n/a n/a n/a n/a 249 n/a

D300

ASL0030 XL D 85 36 7042 L/M 62 15 Y 300 37 337 3

35 1992 550 1720 1577 1077 522 223 155 n/a n/a n/a n/a n/a n/a n/a n/a 299 n/a

D400

ASL0031 XL D 118 36 7213 L/M 62 15 Y 400 48 448 3

2 x 24 2030 630 1784 1592 1181 457 238 180 n/a n/a n/a n/a n/a 338 n/a n/a

Direct Slimline

D60-SL

ASL475D60 M D 40 35 2341 - 62 15 Y 60 13 73 3

12 705 475 462 n/a n/a 348 197 n/a n/a n/a n/a n/a n/a n/a n/a n/a 60 n/a

D90-SL

ASL475D90 M D 52 34 2407 - 62 15 Y 90 16 106 3

12 978 475 734 n/a n/a 348 197 n/a n/a n/a n/a n/a n/a n/a n/a n/a 90 n/a

D120-SL

ASL475D120 L D 59 36 4561 M 62 15 Y 120 22 142 3

12 1250 475 1006 n/a 650 348 197 55 n/a n/a n/a n/a n/a n/a n/a n/a 119 n/a

D150-SL

ASL475D150 L D 68 36 4609 M 62 15 Y 150 30 180 3

18 1520 475 1278 n/a 785 423 197 70 n/a n/a n/a n/a n/a n/a n/a n/a 150 n/a

D180-SL

ASL475D180 L D 76 37 4522 M 62 15 Y 180 31 211 3

18 1790 475 1548 n/a 921 423 197 85 n/a n/a n/a n/a n/a n/a n/a n/a 179 n/a

D210-SL

ASL475D210 XL D 84 36 7036 L/M 62 15 Y 210 32 242 3

24 1970 475 1706 1540 1147 503 197 90 n/a n/a n/a n/a n/a n/a n/a n/a 209 n/a

Solar Direct

SOL180d

ASL0070 n/a B 54 n/a n/a n/a n/a n/a n/a 180 26 206 3

18 1305 550 1053 n/a 746 437 482 75 223 352 419 882 203 n/a 0.680 0.191 n/a 60

SOL210d

ASL0075 n/a C 65 n/a n/a n/a n/a n/a n/a 210 30 240 3

24 1495 550 1241 1127 908 437 544 80 223 352 419 1000 203 n/a 0.680 0.191 n/a 70

SOL250d

ASL0080 n/a C 75 n/a n/a n/a n/a n/a n/a 250 34 284 3

24 1745 550 1491 1377 1092 522 629 100 223 472 539 1180 262 n/a 0.970 0.241 n/a 84

SOL300d

ASL0085 n/a C 85 n/a n/a n/a n/a n/a n/a 300 39 339 3

35 1992 550 1720 1577 1287 522 724 115 223 472 539 1367 262 n/a 0.970 0.241 n/a 100

SOL400d

ASL0086 n/a D 118 n/a n/a n/a n/a n/a n/a 400 49 449 3

2 x 24 2030 630 1784 1592 1296 557 691 140 238 548 651 1383 334 n/a 1.270 0.310 n/a 150

Solar Direct Slimline

SOL 180d-SL

ASL475D180SOL n/a C 51 n/a n/a n/a n/a n/a n/a 180 32 212 3

18 1790 475 1548 n/a 1090 423 640 75 179 329 678 1263 243 n/a 0.680 0.191 n/a 60

SOL 210d-SL

ASL475D210SOL n/a C 84 n/a n/a n/a n/a n/a n/a 210 36 246 3

24 1970 475 1706 1540 1190 503 730 80 179 409 778 1363 273 n/a 0.680 0.191 n/a 70

A

C

Direct

D

F

E

B

R

A

Solar Direct

C

N

M

L

P

E

K

B

D

F

DESIGN

TECHNICAL INFORMATION

Page 7

Expansion Vessel size.

Pre-charged to 3 bar

Overall Height

Overall Diameter

Pressure & Temperature

Relief Valve 6bar 95°C

22mm Secondary

Return Tapping

On Peak Immersion

Heater - High Level

Cold Feed 22mm

Compression Connection

O Peak Immersion

Heater - Low Level

Volume of On Peak Water

Heated

22mm Solar Return

Compression Connection

22mm Solar Flow

Compression Connection

Dual Control & Overheat Stat

Solar Pocket

Solar Pocket

Second O Peak Immersion

Heater - Low Level

Surface Area of

Solar Heater Coil

Pressure Loss Across Solar Heater

Coil

Heat Up Time from 15°C to 60°C

(applies to Primary Heat Source only)

Dedicated Solar Volume

Litres A=mm mm B=mm C=mm D=mm E=mm F=mm Litres K=mm L=mm M=mm N=mm P=mm R=mm m2bar min Litres

12 745 550 490 n/a n/a 367 223 n/a n/a n/a n/a n/a n/a n/a n/a n/a 90 n/a

12 930 550 678 n/a 487 367 223 55 n/a n/a n/a n/a n/a n/a n/a n/a 119 n/a

18 1120 550 865 n/a 587 442 223 70 n/a n/a n/a n/a n/a n/a n/a n/a 150 n/a

18 1305 550 1053 n/a 686 442 223 85 n/a n/a n/a n/a n/a n/a n/a n/a 179 n/a

24 1495 550 1241 1127 786 442 223 90 n/a n/a n/a n/a n/a n/a n/a n/a 209 n/a

24 1745 550 1491 1377 927 522 223 125 n/a n/a n/a n/a n/a n/a n/a n/a 249 n/a

35 1992 550 1720 1577 1077 522 223 155 n/a n/a n/a n/a n/a n/a n/a n/a 299 n/a

2 x 24 2030 630 1784 1592 1181 457 238 180 n/a n/a n/a n/a n/a 338 n/a n/a

398/198

n/a

12 705 475 462 n/a n/a 348 197 n/a n/a n/a n/a n/a n/a n/a n/a n/a 60 n/a

12 978 475 734 n/a n/a 348 197 n/a n/a n/a n/a n/a n/a n/a n/a n/a 90 n/a

12 1250 475 1006 n/a 650 348 197 55 n/a n/a n/a n/a n/a n/a n/a n/a 119 n/a

18 1520 475 1278 n/a 785 423 197 70 n/a n/a n/a n/a n/a n/a n/a n/a 150 n/a

18 1790 475 1548 n/a 921 423 197 85 n/a n/a n/a n/a n/a n/a n/a n/a 179 n/a

24 1970 475 1706 1540 1147 503 197 90 n/a n/a n/a n/a n/a n/a n/a n/a 209 n/a

18 1305 550 1053 n/a 746 437 482 75 223 352 419 882 203 n/a 0.680 0.191 n/a 60

24 1495 550 1241 1127 908 437 544 80 223 352 419 1000 203 n/a 0.680 0.191 n/a 70

24 1745 550 1491 1377 1092 522 629 100 223 472 539 1180 262 n/a 0.970 0.241 n/a 84

35 1992 550 1720 1577 1287 522 724 115 223 472 539 1367 262 n/a 0.970 0.241 n/a 100

2 x 24 2030 630 1784 1592 1296 557 691 140 238 548 651 1383 334 n/a 1.270 0.310 n/a 150

18 1790 475 1548 n/a 1090 423 640 75 179 329 678 1263 243 n/a 0.680 0.191 n/a 60

24 1970 475 1706 1540 1190 503 730 80 179 409 778 1363 273 n/a 0.680 0.191 n/a 70

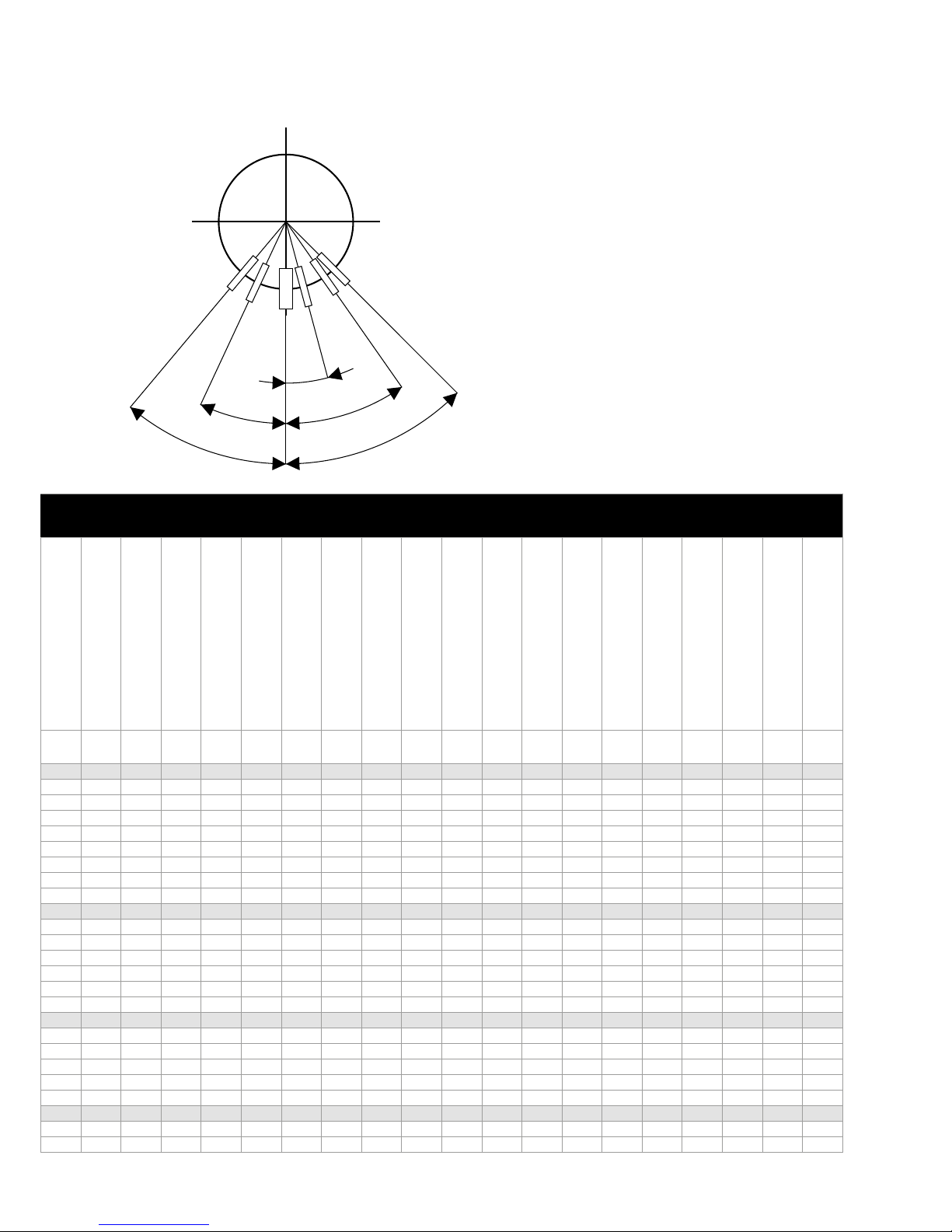

4

0

,0

0

º

4

5

,

00º

3

5

,00º

2

5,

0

0

º

1

5

,

0

0

º

NOTES

1. Not all models - see table 1.

2. Recovery times based on Primary

Coil/I.H. duty (ie. assumes the boiler

output is adequate).

3. All connections are supplied with

compression fittings for direct

connection to copper pipework.

4. The heat up times shown for

the D400 model indicate the

times when 1 or 2 immersions are

connected.

5. The diagrams shown are generic.

For exact product specification

refer to the table eg. the number

of immersion heaters varies

depending on model.

6. Heat up and recovery times based

on 0.25 l/s primary ow rate and at

82°C ow temperature.

DESIGN

TECHNICAL INFORMATION

Page 8

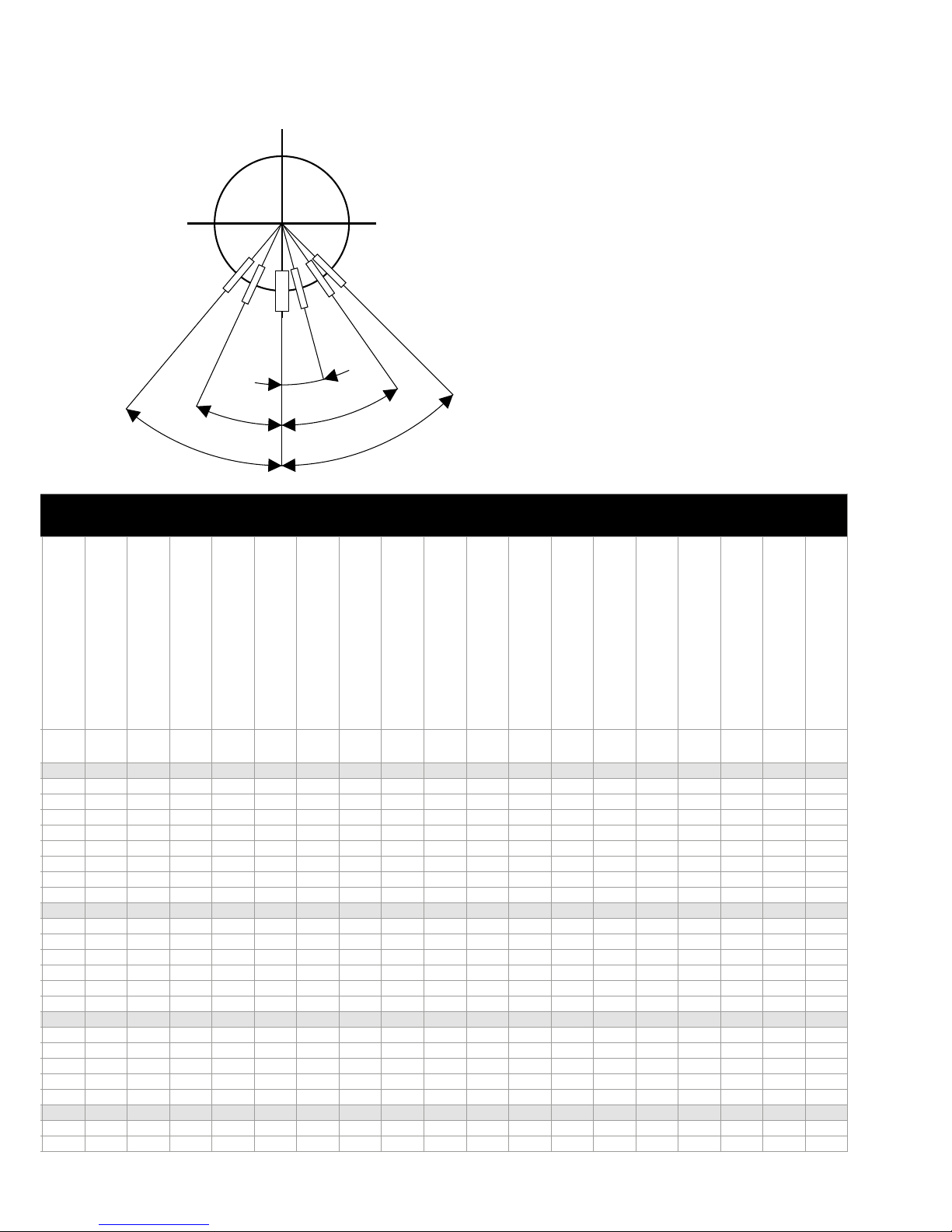

Table 2 - Indirect Models

Model

Stock Code

Energy Eciency Class

Heat Loss

Capacity (Total Volume)

Weight - Empty

Weight - Full

Pressure Regulator 3 bar inlet group c/w balance

cold supply, expansion vessel connection and

expansion valve set at 4.5 bar

Expansion Vessel size.

Pre-charged to 3 bar

Overall Height

Overall Diameter

Pressure & Temperature

Relief Valve 6bar 95°C

22mm Secondary

Return Tapping

On Peak Immersion

Heater - High Level

Cold Feed 22mm

Compression Connection

O Peak Immersion

Heater - Low Level

Watts Litres kg kg bar Litres A=mm mm B=mm C=mm D=mm

E=mm F=mm Litres G=mm H=mm I=mm J=mm K=mm L=mm M=mm N=mm P=mm R=mm kW m

Indirect

IND90

ASL0035 B 35 90 19 109 3 12 745 550 490 n/a 352

367 n/a 40 367 367 223 312 n/a n/a n/a n/a n/a n/a 16.5 0.59 0.165 n/a n/a 17 n/a

IND120

ASL0040 B 44 120 22 142 3 12 930 550 678 n/a 352

367 n/a 67 367 367 223 312 n/a n/a n/a n/a n/a n/a 18 0.59 0.165 n/a n/a 21 n/a

IND150

ASL0045 B 51 150 26 176 3 18 1120 550 865 n/a 392

442 n/a 92 407 407 223 392 n/a n/a n/a n/a n/a n/a 18.5 0.68 0.191 n/a n/a 25 n/a

IND180

ASL0050 B 54 180 28 208 3 18 1305 550 1053 n/a 432

442 n/a 116 447 447 223 392 n/a n/a n/a n/a n/a n/a 19 0.78 0.216 n/a n/a 30 n/a

IND210

ASL0055 C 65 210 33 243 3 24 1495 550 1241 1127 432

442 n/a 145 482 482 223 392 n/a n/a n/a n/a n/a n/a 20.5 0.78 0.216 n/a n/a 32 n/a

IND250

ASL0060 C 75 250 38 288 3 24 1745 550 1491 1377 927

522 512 109 577 577 223 472 n/a n/a n/a n/a n/a n/a 21.5 0.97 0.241 n/a n/a 36 n/a

IND300

ASL0065 C 85 300 44 344 3 35 1992 550 1720 1577 1077

522 512 130 677 677 223 522 n/a n/a n/a n/a n/a n/a 25 0.97 0.241 n/a n/a 38 n/a

IND400

ASL0066 D 118 400 55 455 3 2 x 24 2030 630 1784 1577 1151

542 586 180 668 668 223 533 n/a n/a n/a n/a n/a n/a 30.5 1.27 0.310 n/a n/a 41 n/a

Indirect Slimline

IND60-SL

ASL475IND60 B 40 60 14 74 3 12 705 475 462 n/a 352

348 n/a 28 242 242 179 329 n/a n/a n/a n/a n/a n/a 15 0.59 0.165 n/a n/a 13 n/a

IND90-SL

ASL475IND90 C 52 90 19 109 3 12 978 475 734 n/a 392

348 n/a 54 359 359 179 329 n/a n/a n/a n/a n/a n/a 16.5 0.59 0.165 n/a n/a 17 n/a

IND120-SL

ASL475IND120 C 59 120 23 143 3 12 1250 475 1006 n/a 432

348 n/a 75 423 423 179 329 n/a n/a n/a n/a n/a n/a 18 0.59 0.165 n/a n/a 21 n/a

IND150-SL

ASL475IND150 C 68 150 28 178 3 18 1520 475 1278 n/a 462

423 n/a 102 514 514 179 409 n/a n/a n/a n/a n/a n/a 18.5 0.68 0.191 n/a n/a 25 n/a

IND180-SL

ASL475IND180 C 76 180 31 211 3 18 1790 475 1548 n/a 512

503 n/a 125 604 604 179 449 n/a n/a n/a n/a n/a n/a 19.0 0.78 0.216 n/a n/a 30 n/a

IND210-SL

ASL475IND210 C 84 210 34 244 3 24 1970 475 1706 1540 512

503 n/a 150 695 695 179 449 n/a n/a n/a n/a n/a n/a 20.5 0.78 0.216 n/a n/a 32 n/a

Solar Indirect

SOL180i

ASL0090 B 54 180 30 210 3 18 1305 550 1053 n/a 680

437 n/a 80 825 n/a 715 935 223 352 419 882 218 n/a 18 0.59 0.165 0.680 0.191 28 96

SOL210i

ASL0095 C 65 210 35 245 3 24 1495 550 1240 1127 723

437 n/a 95 888 n/a 758 1018 223 352 419 1000 233 n/a 18.5 0.68 0.191 0.680 0.191 35 101

SOL250i

ASL0100 C 75 250 40 290 3 24 1745 550 1491 1377 785

522 n/a 115 970 n/a 820 1120 223 472 539 1180 294 n/a 19 0.78 0.216 0.970 0.241 38 107

SOL300i

ASL0105 C 85 300 46 346 3 35 1992 550 1720 1577 910

522 n/a 140 1095 n/a 945 1245 223 472 539 1367 300 n/a 20.5 0.78 0.216 0.970 0.241 41 125

SOL400i

ASL0110 D 118 400 59 459 3 2 x 24 2030 630 1784 1592 872

557 n/a 190 1060 1060 930 1190 238 548 651 1383 357 n/a 22 0.97 0.241 1.270 0.310 45 165

Solar Indirect Slimline

SOL180i-SL

ASL475IND180SOL C 76 180 33 213 3 18 1790 475 1548 n/a 1044

423 n/a 75 897 n/a 619 1004 179 320 583 1232 243 n/a 18 0.59 0.165 0.680 0.191 28 60

SOL210i-SL

ASL475IND210SOL C 84 210 37 247 3 24 1970 475 1706 1540 1130

503 n/a 85 1083 n/a 710 1095 179 409 673 1383 273 n/a 18.5 0.68 0.191 0.680 0.191 35 70

A

C

Indirect

D

H

F

E

I

J

B

G

D

Solar Indirect

N

G

P

I

E

K

J

A

B

M

L

C

DESIGN

TECHNICAL INFORMATION

Page 9

Cold Feed 22mm

Compression Connection

O Peak Immersion

Heater - Low Level

Volume of On Peak Water

Heated

Dual Control & Overheat Stat

Extra Stat Pocket

For Boiler Use If Required

22mm Primary Return Compression

Connection

(28mm tails for 400 litre model)

22mm Primary Flow Compression

Connection

(28mm tails for 400 litre model)

22mm Solar Return

Compression Connection

22mm Solar Flow

Compression Connection

Dual Control & Overheat Stat

Solar Pocket

Solar Pocket

Second O Peak Immersion

Heater - Low Level

kW Rating of Primary Coil

Surface Area of

Primary Heater Coil

Pressure Loss Across

Primary Heater Coil

Surface Area of

Solar Heater Coil

Pressure Loss Across Solar Heater

Coil

Heat Up Time from 15°C to 60°C

(applies to Primary Heat Source only)

Dedicated Solar Volume

E=mm F=mm Litres G=mm H=mm I=mm J=mm K=mm L=mm M=mm N=mm P=mm R=mm kW m2bar m2bar min Litres

367 n/a 40 367 367 223 312 n/a n/a n/a n/a n/a n/a 16.5 0.59 0.165 n/a n/a 17 n/a

367 n/a 67 367 367 223 312 n/a n/a n/a n/a n/a n/a 18 0.59 0.165 n/a n/a 21 n/a

442 n/a 92 407 407 223 392 n/a n/a n/a n/a n/a n/a 18.5 0.68 0.191 n/a n/a 25 n/a

442 n/a 116 447 447 223 392 n/a n/a n/a n/a n/a n/a 19 0.78 0.216 n/a n/a 30 n/a

442 n/a 145 482 482 223 392 n/a n/a n/a n/a n/a n/a 20.5 0.78 0.216 n/a n/a 32 n/a

522 512 109 577 577 223 472 n/a n/a n/a n/a n/a n/a 21.5 0.97 0.241 n/a n/a 36 n/a

522 512 130 677 677 223 522 n/a n/a n/a n/a n/a n/a 25 0.97 0.241 n/a n/a 38 n/a

542 586 180 668 668 223 533 n/a n/a n/a n/a n/a n/a 30.5 1.27 0.310 n/a n/a 41 n/a

348 n/a 28 242 242 179 329 n/a n/a n/a n/a n/a n/a 15 0.59 0.165 n/a n/a 13 n/a

348 n/a 54 359 359 179 329 n/a n/a n/a n/a n/a n/a 16.5 0.59 0.165 n/a n/a 17 n/a

348 n/a 75 423 423 179 329 n/a n/a n/a n/a n/a n/a 18 0.59 0.165 n/a n/a 21 n/a

423 n/a 102 514 514 179 409 n/a n/a n/a n/a n/a n/a 18.5 0.68 0.191 n/a n/a 25 n/a

503 n/a 125 604 604 179 449 n/a n/a n/a n/a n/a n/a 19.0 0.78 0.216 n/a n/a 30 n/a

503 n/a 150 695 695 179 449 n/a n/a n/a n/a n/a n/a 20.5 0.78 0.216 n/a n/a 32 n/a

437 n/a 80 825 n/a 715 935 223 352 419 882 218 n/a 18 0.59 0.165 0.680 0.191 28 96

437 n/a 95 888 n/a 758 1018 223 352 419 1000 233 n/a 18.5 0.68 0.191 0.680 0.191 35 101

522 n/a 115 970 n/a 820 1120 223 472 539 1180 294 n/a 19 0.78 0.216 0.970 0.241 38 107

522 n/a 140 1095 n/a 945 1245 223 472 539 1367 300 n/a 20.5 0.78 0.216 0.970 0.241 41 125

557 n/a 190 1060 1060 930 1190 238 548 651 1383 357 n/a 22 0.97 0.241 1.270 0.310 45 165

423 n/a 75 897 n/a 619 1004 179 320 583 1232 243 n/a 18 0.59 0.165 0.680 0.191 28 60

503 n/a 85 1083 n/a 710 1095 179 409 673 1383 273 n/a 18.5 0.68 0.191 0.680 0.191 35 70

4

0

,0

0

º

4

5

,

00º

3

5

,00º

2

5,

0

0

º

1

5

,

0

0

º

NOTES

1. Not all models - see table 2.

2. Recovery times based on Primary

Coil/I.H. duty (ie. assumes the boiler

output is adequate).

3. All connections are supplied with

compression fittings for direct

connection to copper pipework.

4. The diagrams shown are generic.

For exact product specification

refer to the table eg. the number

of immersion heaters varies

depending on model.

5. Heat up and recovery times based

on 0.25 l/s primary ow rate and at

82°C ow temperature.

DESIGN

TECHNICAL INFORMATION

Page 10

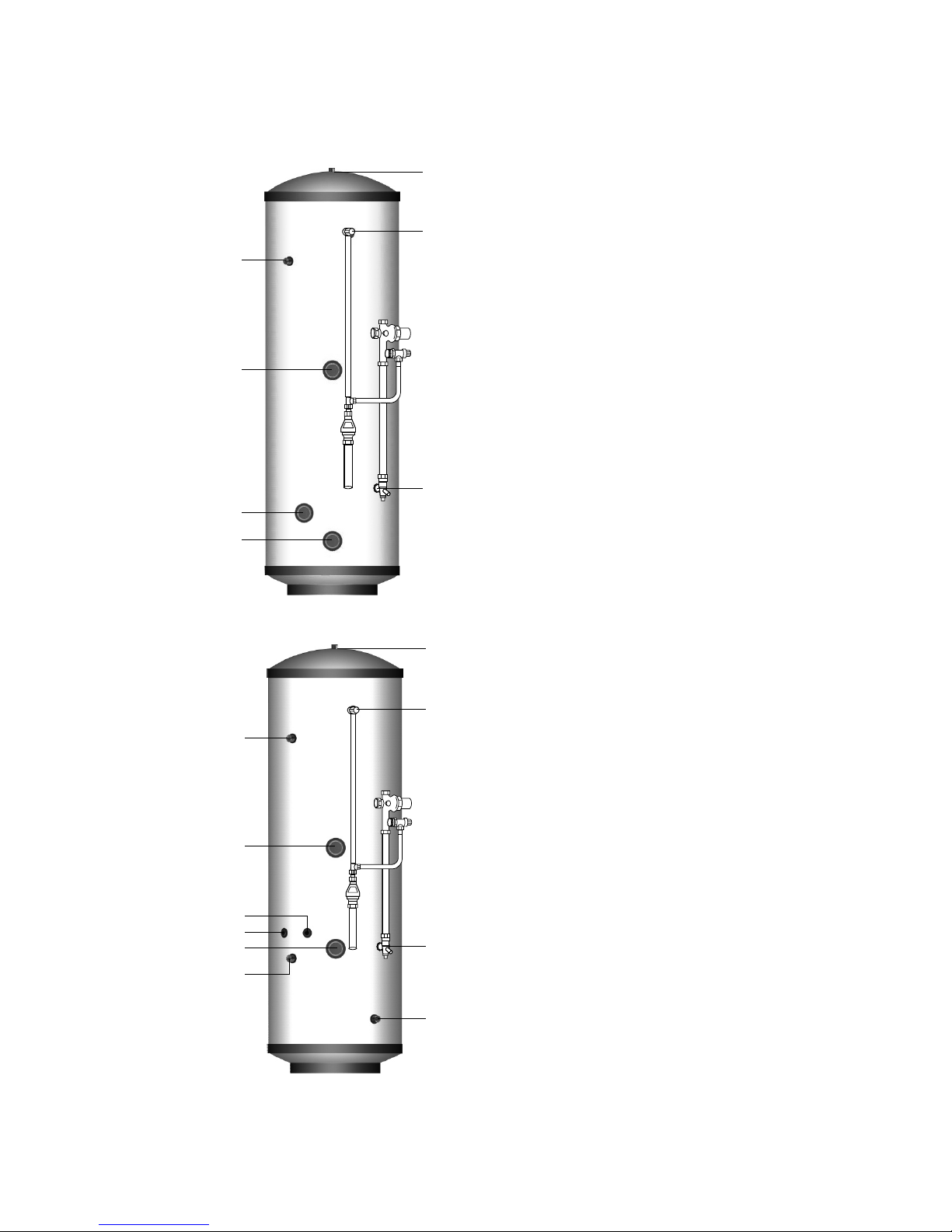

Stainless Lite Direct

Basic Appliance

1. Hot water draw o (22mm) compression

2. Lift up temperature & pressure relief valve

92-95°/6 bar

3. Hot water secondary return 22mm

(not tted to smaller sizes, see table 1)

4. Immersion heater 1¾” BSP 3kW

(normally on-peak)

5. 22mm cold supply compression

6. Immersion heater 1¾” BSP 3kW

(normally o-peak)

7. Immersion heater 1¾” BSP 3kW

(normally o-peak - 400 litre model only)

Part G3 loose components supplied in a

separate box

A. Combination inlet group incorporating

pressure reducing valve, strainer, check

valve, balance cold take o point, expansion

relief valve and expansion vessel connection

points.

B. Portable expansion vessels c/w exible hose

and wall bracket

C. Tundish

Stainless Lite Indirect

Basic Appliance

1. Hot water draw o (22mm) compression

2. Lift up temperature & pressure relief valve

92-95°/6 bar

3. Hot water secondary return 22mm

(not tted to smaller sizes, see table 2)

4. Immersion heater 1¾” BSP 3kW

5. 22mm cold supply compression

6. Immersion heater 1¾” BSP 3kW

7. Dual control/overheat stat pocket (22mm)

8. Boiler control sensor pocket (spare)

9. Primary return (22mm)

- (28mm tails for 400 litre models)

10. Primary ow (22mm)

- (28mm tails for 400 litre models)

Part G3 loose components supplied in a

separate box

A. Combination inlet group incorporating

pressure reducing valve, strainer, check

valve, balance cold take o point, expansion

relief valve and expansion vessel connection

points.

B. Potable expansion vessels c/w exible hose

and wall bracket

C. Tundish

D. Dual control thermostat and combined

overheat thermostat

E. Two port (22mm) zone valve for

primary circuit

F. Wiring junction box for primary system

1

2

5

3

4

6

7

1

2

3

4

7

5

6

9

8

10

Typical arrangement of component kit shown tted to the appliance for clarity

Pipework to be supplied and tted by installer.

DESIGN

SYSTEM DESIGN

Page 11

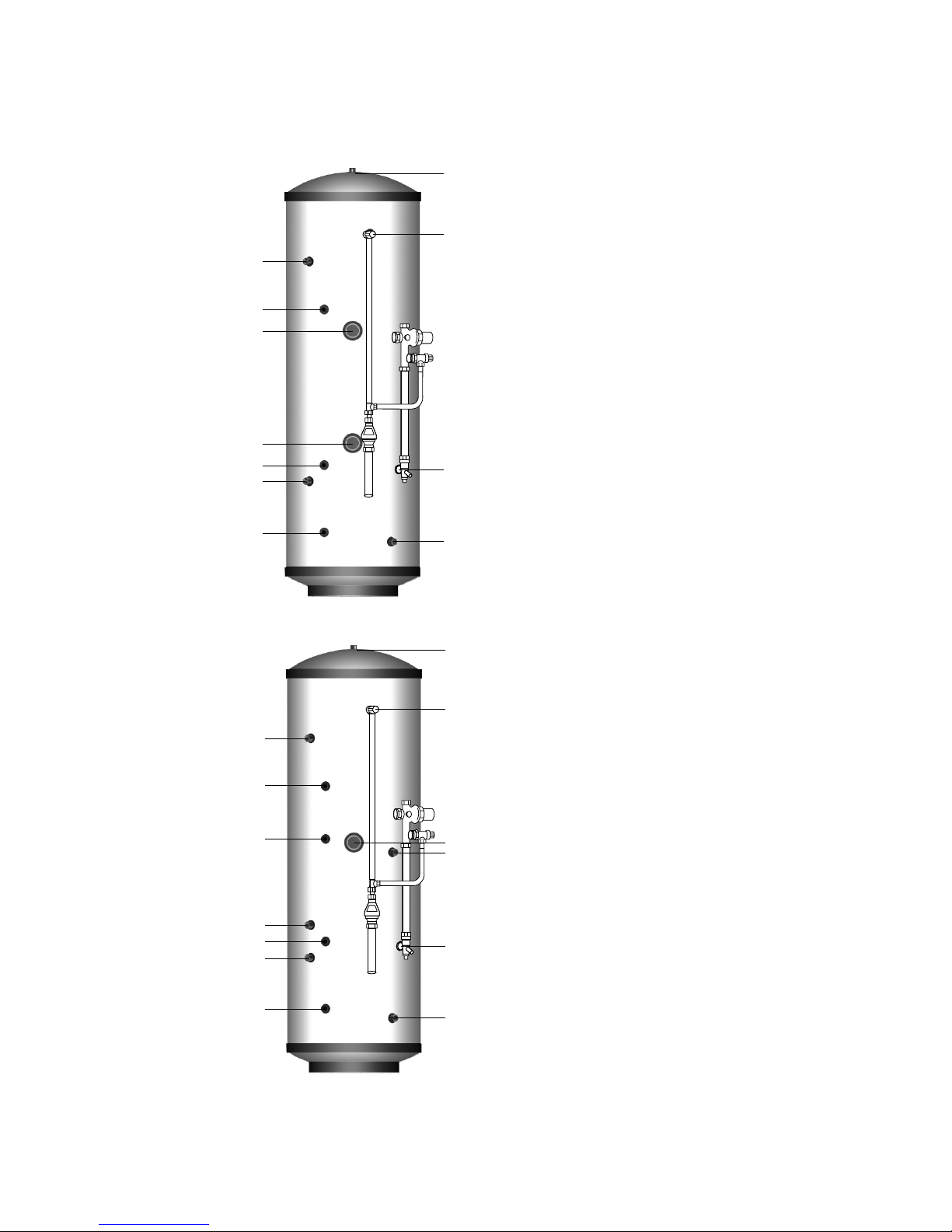

7

9

3

11

6

12

12

1

2

8

4

5

10

Stainless Lite Direct Solar

Basic Appliance

1. Hot water draw o (22mm) compression

2. Lift up temperature & pressure relief valve

92-95°/6 bar

3. Hot water secondary return 22mm

(not tted to smaller sizes, see table 1)

4. Immersion heater 1¾” BSP 3kW

(normally on-peak)

5. 22mm cold supply

6. Immersion heater 1¾” BSP 3kW

(normally o-peak)

7. Dual control/Overheat stat pocket (solar)

8. Solar coil return to panel collector (22mm)

compression

9.

Solar coil ow from panel (22mm) compression

10. Solar thermostat pocket

Part G3 loose components supplied in a

separate box

A.

Combination inlet group incorporating

pressure reducing valve, strainer, check valve,

balance cold take o point, expansion relief

valve and expansion vessel connection points.

B. Portable expansion vessels c/w exible hose

and wall bracket

C. Tundish

D. Dual control thermostat and combined

overheat thermostat

Stainless Lite Indirect Solar

Basic Appliance

1. Hot water draw o (22mm) compression

2. Lift up temperature & pressure relief valve

92-95°/6 bar

3. Hot water secondary return 22mm

(not tted to smaller sizes, see table 2)

4. Immersion heater 1¾” BSP 3kW

5. 22mm cold supply

6. Dual control/Overheat stat pocket (solar)

7. Primary return (22mm)

- (28mm tails for 400 litre models)

8. Primary ow (22mm)

- (28mm tails for 400 litre models)

9. Dual control/Overheat stat pocket (boiler)

10. Solar coil return to panel collector (22mm)

compression

11.

Solar coil ow from panel (22mm) compression

12. Solar thermostat pocket

Part G3 loose components supplied in a

separate box

A.

Combination inlet group incorporating

pressure reducing valve, strainer, check valve,

balance cold take o point, expansion relief

valve and expansion vessel connection points.

B. Potable expansion vessels c/w exible hose

and wall bracket

C. Tundish

D. Dual control thermostat and combined

overheat thermostat (x2)

E. Two port (22mm) zone valve for

primary circuit

F. Wiring junction box for primary system

1

2

5

8

7

6

4

3

9

10

10

Typical arrangement of component kit shown tted to the appliance for clarity

Pipework to be supplied and tted by installer.

DESIGN

SYSTEM DESIGN

Loading...

Loading...