gledhill PulsaCoil PCBP 120, PulsaCoil PCBP 180, PulsaCoil PCBP 220, PulsaCoil PCBP 150 Design, Installation & Servicing Instructions

Design, Installation & Servicing Instructions

Models covered in this manual

PulsaCoil PCBP 120

PulsaCoil PCBP 150

PulsaCoil PCBP 180

PulsaCoil PCBP 220

PulsaCoil BP

Hot water cylinder utilising off-peak electric with an optional solar version

Page 2

CONTENTS

Section Page

DESIGN

Introduction 3

Technical Data 5

System Details 9

INSTALLATION

Site Requirements 12

Installation 13

Commissioning 16

SERVICING

Annual Service 17

Changing Components 17

Short Parts List 18

APPENDIX

Appendix A 19

Appendix B 20

Appendix C 21

Notes 22

Terms & Conditions 24

BENCHMARK

Commissioning Checklist 26

Service Record 27

ISSUE 5: JANUARY 2014

The Gledhill PulsaCoil range is a WBS

listed product and complies with the

HWA Specification for hot water only

thermal storage products. The principle was

developed in conjunction with British Gas.

This product is manufactured under an ISO

9001:2008 Quality System audited by BSI.

Gledhill’s rst priority is to give a high quality

service to our customers.

Quality is built into every Gledhill product

and we hope you get satisfactory service

from Gledhill.

If not please let us know.

Benchmark places responsibilities on both manufacturers and installers. The purpose is to

ensure that customers are provided with the correct equipment for their needs, that it is

installed, commissioned and serviced in accordance with the manufacturers instructions

by competent persons and that it meets the requirements of the appropriate Building

Regulations. The Benchmark Checklist can be used to demonstrate compliance with

Building Regulations and should be provided to the customer for future reference.

Installers are required to carry out installation, commissioning and servicing work in

accordance with the Benchmark Code of Practice which is available from the Heating

and Hot Water Industry Council who manage and promote the Scheme. Visit www.

centralheating.co.uk for more information.

For further information on the HWA Charter Membership, please refer to the HWA website

hotwater.org.uk.

Page 3

Any water distribution system/installation must comply with the relevant

recommendations of the current version of the Regulations and British Standards

listed below:-

Building Regulations

Requirements for Electrical Installations

Water Regulations

Manual Handling Operations Regulations

British Standards

BS6700 and BS7671.

The Building Regulations (England & Wales) require that the installation of a heating

appliance be noti ed to the relevant Local Authority Building Control Department.

From 1st April 2005 this can be achieved via a Competent Person Self Certi cation

Scheme as an option to notifying the Local Authority directly. Similar arrangements

will follow for Scotland and will apply in Northern Ireland from 1st January 06.

A suitably competent trades person must install the PulsaCoil and carry out any

subsequent maintenance/repairs. In fact the appliance front cover is secured by

2 screws and this should only be removed by a competent trades person. The

manufacturer’s notes must not be taken as overriding statutory obligations.

The PulsaCoil BP is not covered by section G3 of the current Building Regulations and is

therefore only noti able to Building Control as part of the domestic water installations.

The PulsaCoil BP is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience or knowledge, unless

they have been given supervision or instruction concerning use of the appliance by

a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

The information in this manual is provided to assist generally in the selection of

equipment. The responsibility for the selection and speci cation of the equipment

must however remain that of the customer and any Designers or Consultants

concerned with the design and installation.

Please Note: We do not therefore accept any responsibility for matters of design,

selection or speci cation or for the e ectiveness of an installation containing one of

our products unless we have been speci cally requested to do so.

All goods are sold subject to our Conditions of Sale, which are set out at the rear of

this manual.

In the interest of continuously improving the PulsaCoil range, Gledhill Building

Products Ltd reserve the right to modify the product without notice, and in these

circumstances this document, which is accurate at the time of printing, should be

disregarded. It will however be updated as soon as possible after the change has

occurred.

DESIGN

INTRODUCTION

Page 4

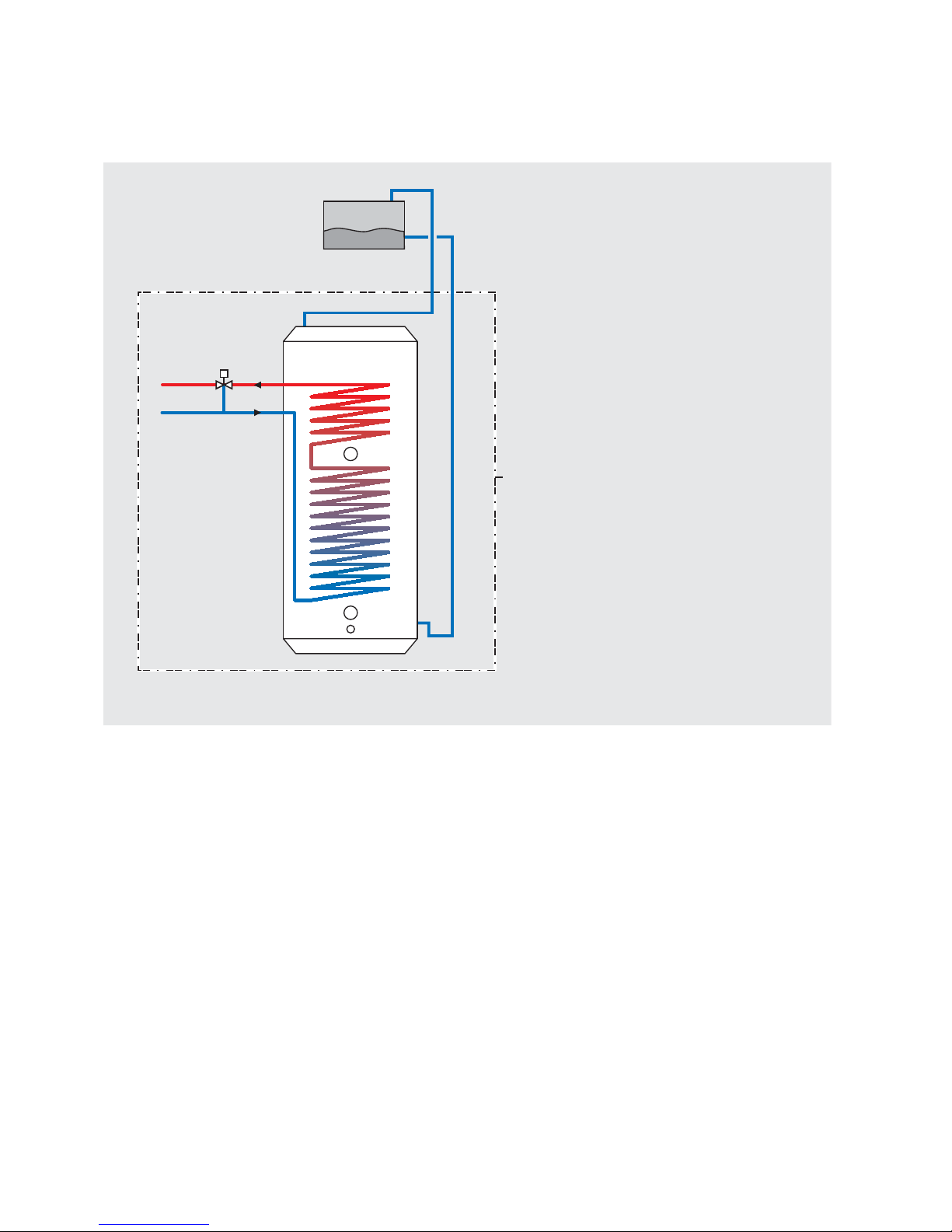

The PulsaCoil BP shown schematically above is a very highly insulated appliance. As

such, the products will allow a pass to be achieved in SAP2005 even in small apartment

situations, which is to provide an improved method of supplying mains pressure hot

water when using a suitable o peak electric supply/tari .

The heat losses from thermal stores should not be directly compared with heat losses

from unvented or vented cylinders because they are treated di erently in SAP. The

SAP calculator takes account of the type of store and various correction factors are

included to re ect the di erent ways that the hot water and heating operates.

The main feature of the concept is that hot water can be supplied directly from the

mains at conventional ow rates without the need for temperature and pressure

relief safety valves or expansion vessels. This is achieved by passing the mains water

through heat exchangers inside the thermal store. The outlet temperature of the

domestic hot water is maintained by a thermostatic blending valve.

The Building Regulations L1A: New dwellings/L1B: Existing dwellings and the

requirements set out in the Domestic Heating Compliance Guide specify that “where

the mains water hardness exceeds 200ppm provision should be made to treat the

feed water to water heaters and the hot water circuit of combination boilers to reduce

the rate of accumulation of lime scale”.

To comply with this requirement the hardness of the mains water should be checked

by the installer and if necessary the optional factory tted in-line scale inhibitor should

be speci ed at the time of order for hardness levels between 200 and 300 ppm (mg/l).

Where the water is very hard ie 300ppm (mg/l)

and above the optional polyphosphate type,

scale inhibitor should be speci ed at the time

of order. However, this will need to be tted by

the installer at a suitable point in the cold water

supply to the appliance.

Because this product does not require a safety

discharge from a temperature and pressure

relief valve, any installations will be easy to

incorporate into the building and will not su er

from the problems associated with using PVCu

soil stacks to take the discharge from unvented

cylinders.

Figure 1.1

Schematic Hydraulic Arrangement

1. Bottom (Off-Peak) immersion heater

(1H_1)

2. Top (On-Peak) immersion heater (IH_2)

3. CW inlet

4. HW outlet

5. Drain

6. Open vent

7. Cold feed

8. Top up cistern - provided separately

from the appliance

9. Thermostatic blending valve

Cistern can be provided with a

visual sight glass or ballvalve

and overflow connector as

optional extras if required.

Appliance

case

Top up cistern

PULSACOIL BP

9

5

4

3

6

8

7

2

1

DESIGN

INTRODUCTION

Page 5

Notes:-

1. The heat losses from thermal stores should not be directly compared with heat

losses from unvented or vented cylinders because they are treated di erently in

SAP. The SAP calculator takes account of the type of store and various correction

factors are included to re ect the di erent ways that the hot water and heating

operates.

2. The ow rates are based on a 35°C temperature rise and assume that recommended

pressures and adequate ow are available at the appliance. The ow rate will be

reduced if the available water pressure is below that recommended.

3. The domestic hot water outlet temperature is automatically regulated to

approximately 52°C at the bath ow rate of 18 litres/min recommended by BS

6700. The temperature is user adjustable.

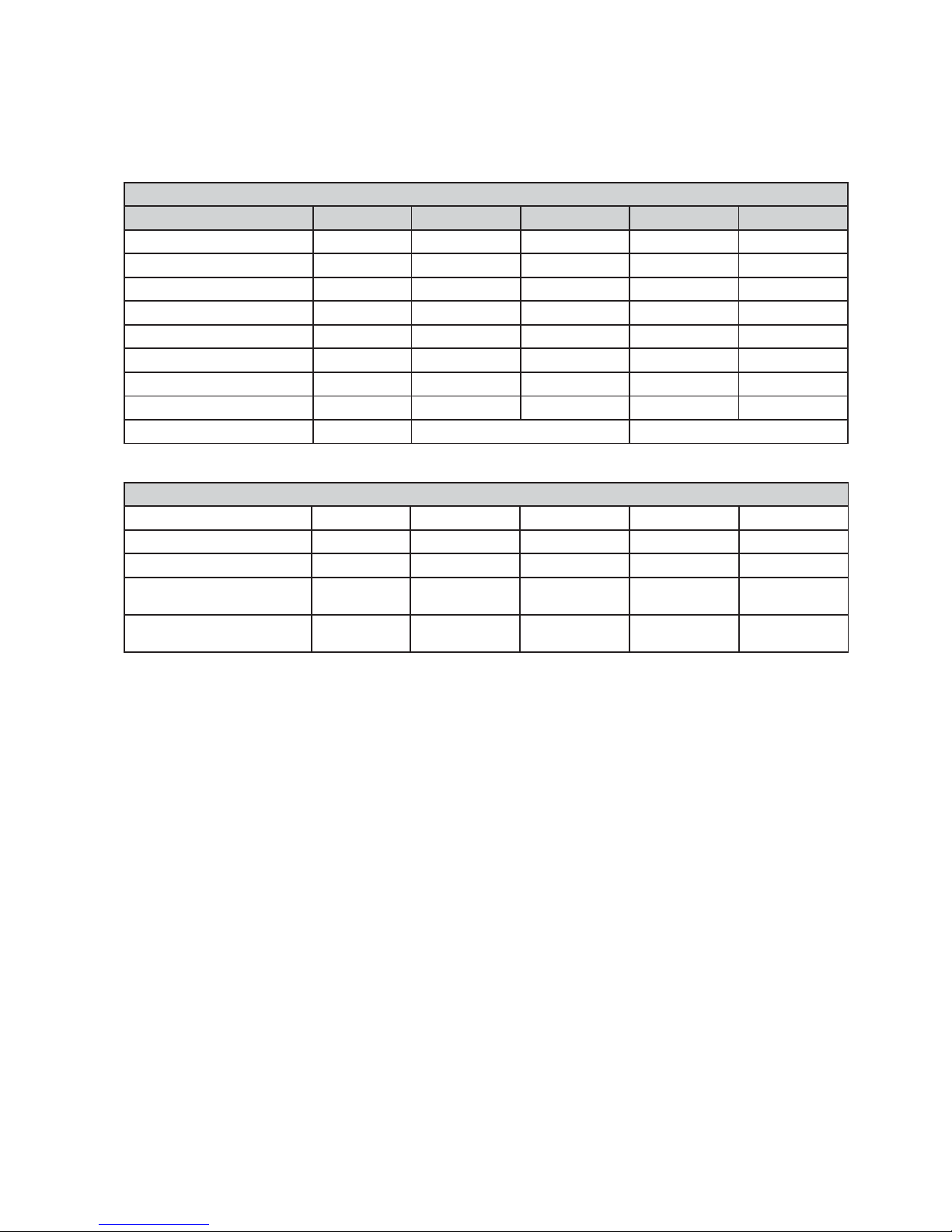

Technical Speci cation

Description PCBP 120 PCBP 150 PCBP 180 PCBP 220

Appliance height mm 1131 1332 1533 1734

Appliance width mm 560 560 560 560

Appliance depth mm 605 605 605 605

Appliance weight (empty) kg 54 63 69 78

Approx weight (full) kg 172 205 234 268

Total volume (nominal) litres 118 142 165 190

Volume heated (on peak) litres 60 60 70 80

Heat loss

1

kWh/24hr 1.12 1.31 1.50 1.60

Hot water ow rate

2

up to 18 litres/minute up to 22 litres/minute

Table 1.1

Model Selection

Bedroom 1 1-2 2-3 2-3

Bathroom 1 or 1 or 1 1

En-suite shower room 1 1 1 2

Model selection data

(7 hour o peak)

PCBP 150 PCBP 150 PCBP 180 PCBP 220

Model selection data

(10 hour o peak)

PCBP 120 PCBP 150 PCBP 150 PCBP 180

Table 1.2

DESIGN

TECHNICAL DATA

Page 6

Standard Equipment

The standard con guration of the PulsaCoil BP

is shown opposite.

1. Drain - 1/2” BSP

2. Cold water inlet (22mm)

3. Hot water outlet (22mm)

4.

Bottom (o -peak) immersion heater (3kW)

5. Top (on-peak) immersion heater (3kW)

6. Scale inhibitor PCB - (factory tted

optional extra)

7. Hot water thermostatic blending valve

8. Cold feed/expansion pipe (15mm)

9. Open vent pipe (22mm)

10. Manual ll sight glass for top up cistern (not

shown)

Note : Both immersion heaters are low watts

density type with incaloy 825 sheaths and are

specially manufactured to suit Thermal Stores.

It is recommended that any replacements

should be obtained from Gledhill Building

Products.

Optional Extra Equipment

• In line scale inhibitor for mains water

services with hardness levels between

200 and 300ppm (mg/l) tted but ready

for wiring by the installer to the suitable

230V ac supply.

• Polyphosphate scale inhibitor for tting on

site by the installer.

• Ballvalve/over ow connector for top up

cistern.

Figure 1.2

6

8

3

7

2

1

4

5

9

DESIGN

TECHNICAL DATA

Page 7

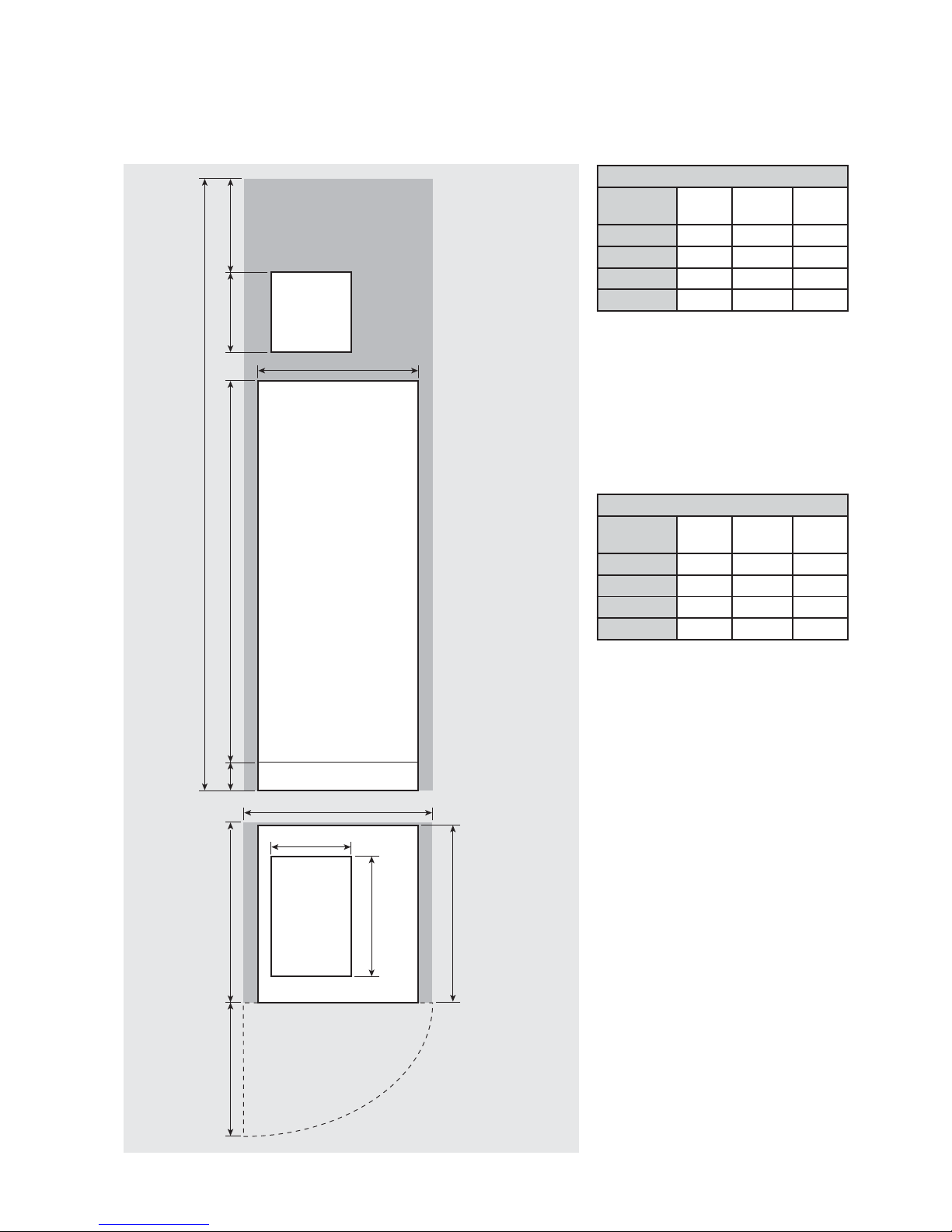

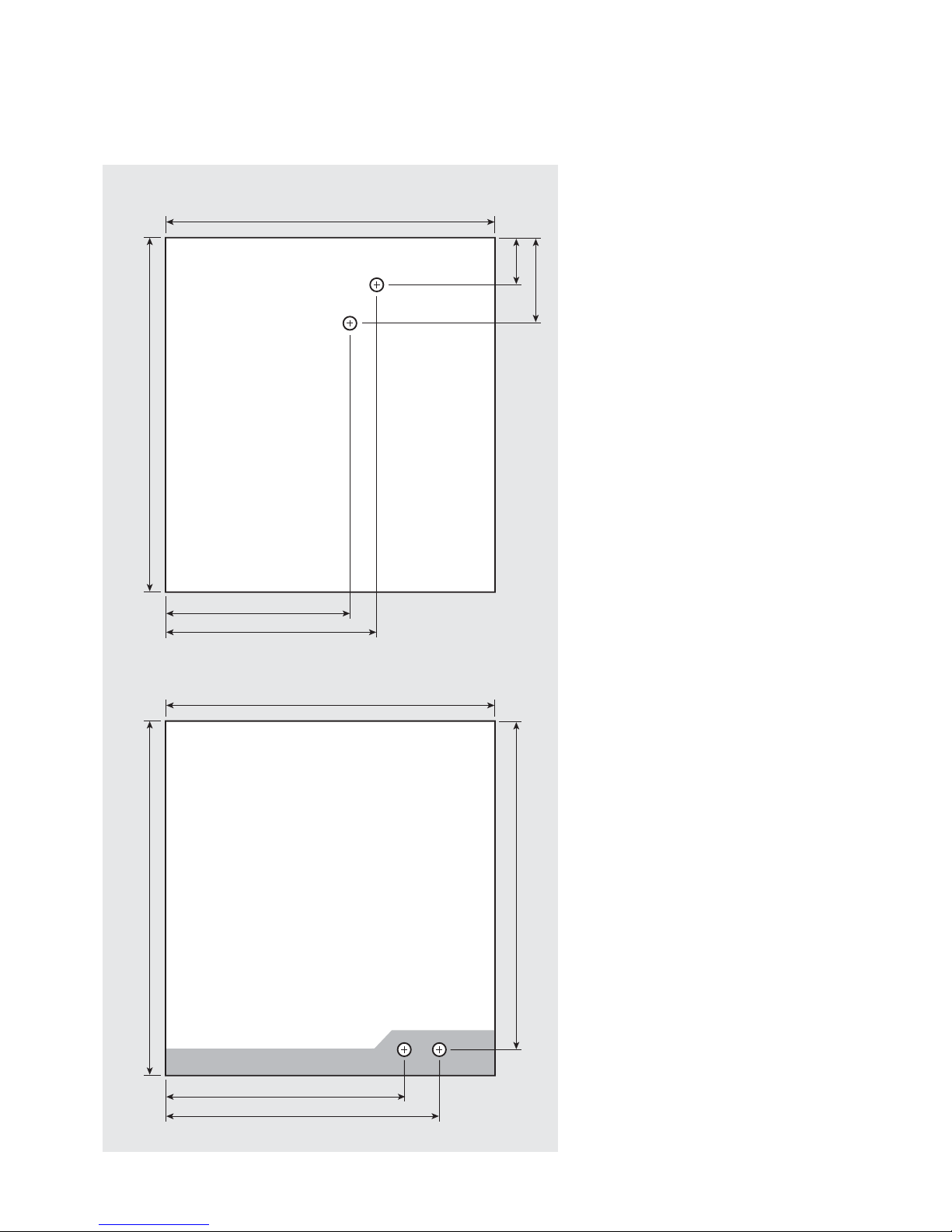

Appliance Dimensions

Model

Height

(A)

Width

(B)

Depth

(C)

PCBP 120 1131 560 605

PCBP 150 1332 560 605

PCBP 180 1533 560 605

PCBP 220 1734 560 605

B

E

C

PulsaCoil BP

Top up

cistern

Top up

cistern

300 *350A10 0

D

F

Maintenance

access

Figure 1.3

280

420

*Min maintenance

access to comply with

the Water Regulations

(ballvalve model only)

The minimum

clear opening in

front of the

appliance to be

at least the

same depth as

the appliance.

The cupboard door

opening will need

to take into

account the various

sizes of appliances.

Minimum Cupboard Dimensions

Model

Height

(D)

Width

(E)

Depth

(F)

PCBP 120 1881 600 620

PCBP 150 2082 600 620

PCBP 180 2283 600 620

PCBP 220 2484 600 620

Note: The Appliance dimensions above do not

allow for the100mm high installation base.

The following table of minimum cupboard

dimensions only allow the minimum space

required for the appliance (including the top up

cistern). Any extra space required for shelving

etc in the case of airing cupboards etc must

be added.

Note: The above dimensions are based on the

Appliance and the Top up cistern ( tted with a

ballvalve) being in the same cupboard. If the

manual fill model is chosen, the heights

shown above can be reduced by 125mm.

If pipework needs to rise vertically adjacent

to the appliance the width/depth will need

increasing to accommodate this.

DESIGN

TECHNICAL DATA

Page 8

PLAN OF APPLIANCE CONNECTIONS

The PulsaCoil BP units are supplied on an

installation base to allow the pipe runs to

connect to the appliance from any direction.

It is easier if all pipes protrude vertically in the

cut out area shown. Compression or push t

connections can be used. All pipe positions

are approximate and subject to a tolerance of

+/- 10mm in any direction. Space will also be

required for a 15mm cold water supply and a

22mm warning / over ow pipe (if the optional

extra ball valve and over ow connector have

been specified. If a warning/overflow pipe

is NOT provided the F&E Cistern should be

filled from a temporary hose connection

incorporating a double check valve. This can

be from a temporary hose connection supplied

from a cold water tap or a permanent cold

branch provided adjacent to the Top up Cistern.

The temporary connection must be removed

once the appliance is lled.

Note: All dimensions are shown in mm and

are to the centre line of pipework.

Connection Details/Dimensions For Top Of Unit

Figure 1.4

580 (605 including the door/clock)

560

67

125

353 - Cold Feed/Expansion

315 - Open Vent

Connection Details/Dimensions For Bottom Of Unit

580 (605 including the door/clock)

560

550

358 - Mains Cold Water Inlet

474 - Hot Water Outlet

DESIGN

TECHNICAL DATA

Page 9

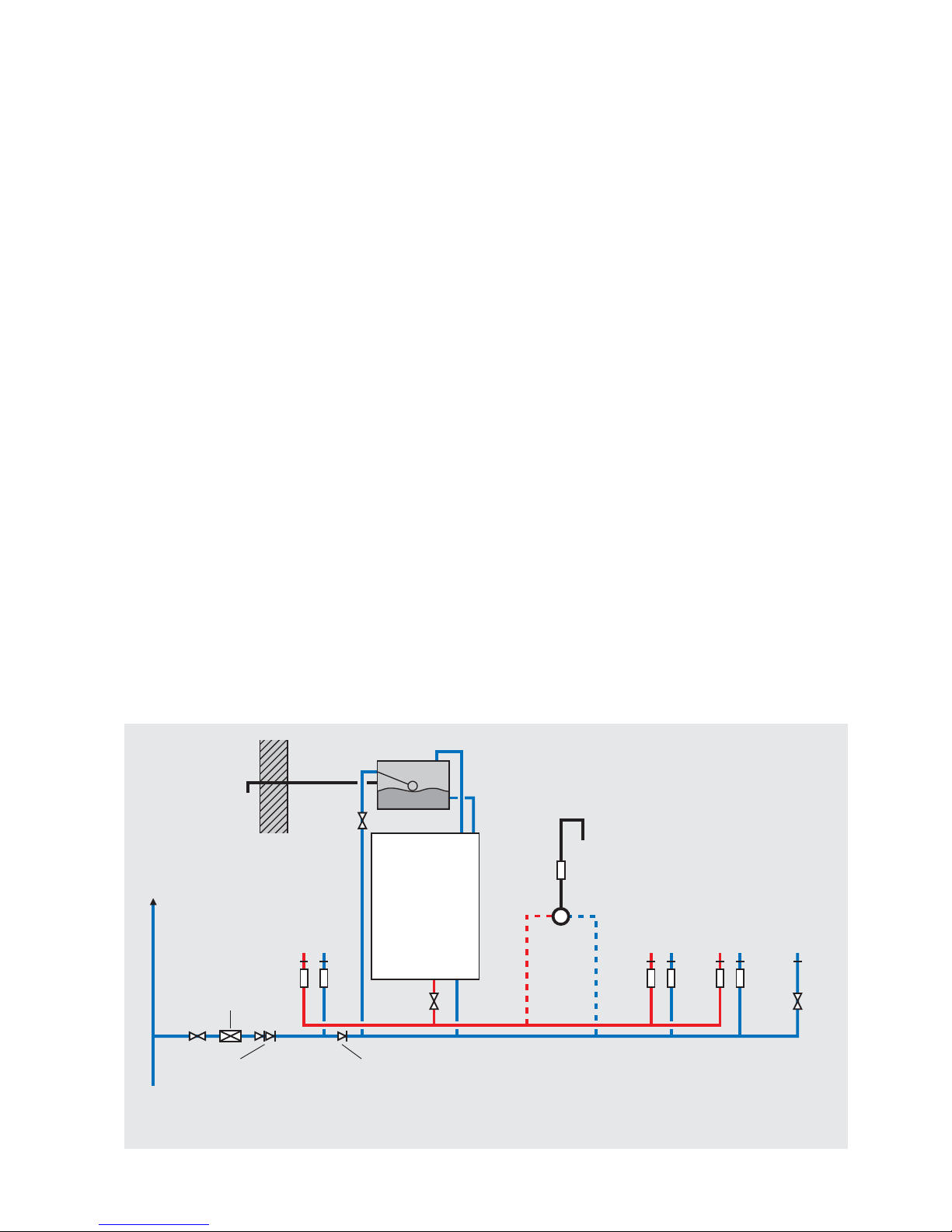

Hot and Cold Water System

General

A schematic layout of the hot and cold water services in a typical small dwelling is

shown below. PulsaCoil BP will operate at mains pressures as low as 1.5 bar and as

high as 5 bar although the recommended range is 2-3 bar dynamic at the appliance.

It is also important to check that all other equipment and components in the hot

and cold water system are capable of accepting the mains pressure available to the

property. If the mains pressure can rise above 5 bar or the maximum working pressure

of any item of equipment or component to be tted in the system, a pressure limiting

(reducing) valve set to 3 bar will be required.

If you encounter a situation where the water pressure is adequate but ow rates are

poor please contact our technical helpline for details of an e ective solution.

No check valve or similar device should be tted on the cold water supply branch to

the PulsaCoil BP.

The Building Regulations L1A: New dwellings/L1B: Existing dwellings and the

requirements set out in the Domestic Heating Compliance Guide specify that “where

the mains water hardness exceeds 200ppm provision should be made to treat the feed

water to water heaters and the hot water circuit of combination boilers to reduce the

rate of accumulation of lime scale”.

To comply with this requirement the hardness of the mains water should be checked

by the installer and if necessary the optional factory tted in-line scale inhibitor should

be speci ed at the time of order for hardness levels between 200 and 300 ppm (mg/l).

Where the water is very hard ie 300ppm (mg/l) and above the optional polyphosphate

type, inhibitor should be speci ed at the time of order. However, this will need to be

tted by the installer at a suitable point in the cold water supply to the appliance.

The hot water flow rate from the PulsaCoil

BP is directly related to the adequacy of the

cold water supply to the dwelling. This must

be capable of providing for those services,

which could be required to be supplied

simultaneously, and this maximum demand

should be calculated using procedures de ned

in BS 6700.

If a water meter is tted in the service pipe,

it should have a nominal rating to match the

maximum hot and cold water peak demands

calculated in accordance with BS 6700. This

could be up to 60ltr/min in some properties.

Note: The diagram below shows the Top up

cistern with ballvalve and warning/over ow

pipe. The ballvalve/overflow connector can

be supplied as an optional extra if required.

However, the standard preferred arrangement

is for the cistern to be manually lled from a

temporary hose connection tted with a double

check valve.

The cistern must not be fitted more than 6

metres above the PulsaCoil BP appliance itself.

Warning/

overflow

pipe

MCWS

Safety/open vent

Shower

Expansion/

cold feed

Second

dwelling

Pressure limiting valve

NOT REQUIRED at

pressures below 5 bar

unless any components

have a lower

maximum working

pressure

Double check valve

NOT REQUIRED unless

pipe supplies more

than one dwelling

‘a’ - flow regulator recommended for

better balance of hot and cold

water supplies

MCWS

supply

pipe

Sink

H C

a a

SV

a a a a

Bath

H C

Hand basin

H C

WC - fitted

with BS1212

ballvalve

C

Figure 1.5

Typical hot and cold water distribution

PULSACOIL BP

Check valve

NOT REQUIRED unless

chemical water

treatment unit is fitted

a

Top up cistern

DESIGN

SYSTEM DETAILS

Loading...

Loading...